- Release form

- Advantages and disadvantages

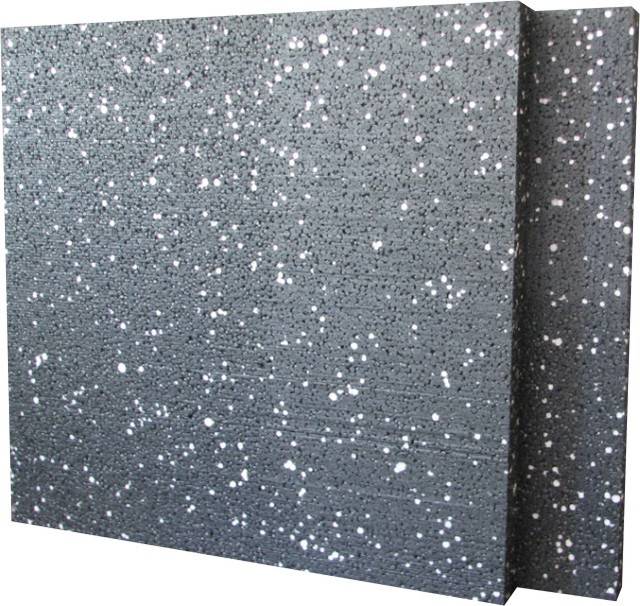

- Description

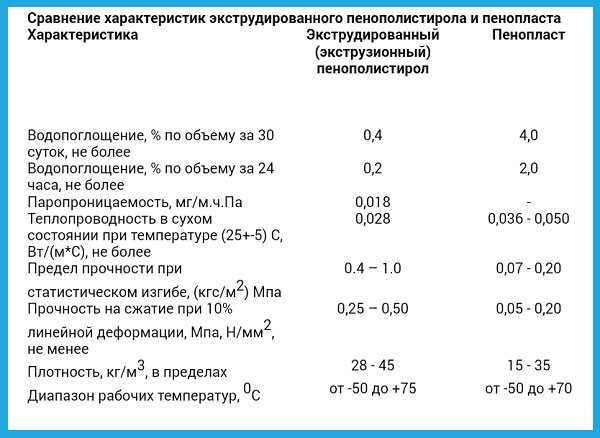

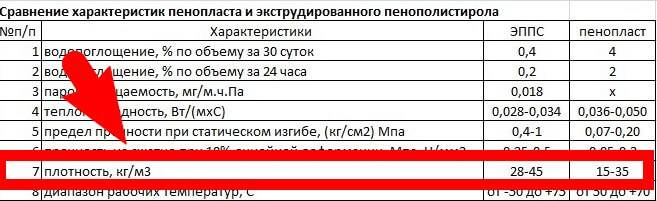

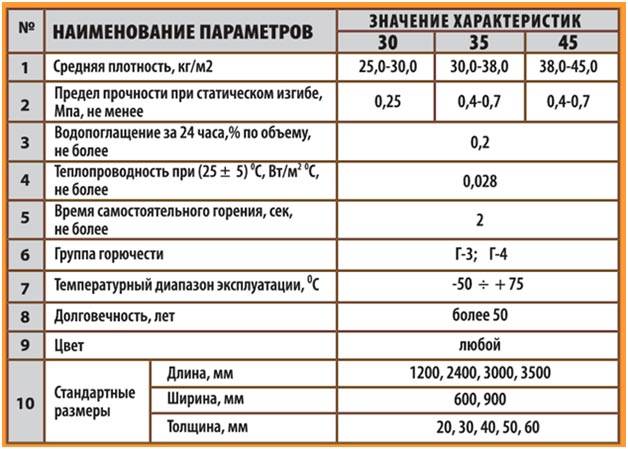

- Density

- Installation work

- moisture absorption

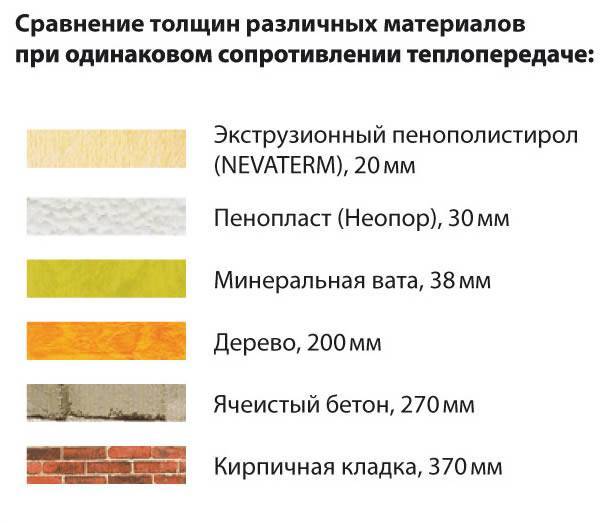

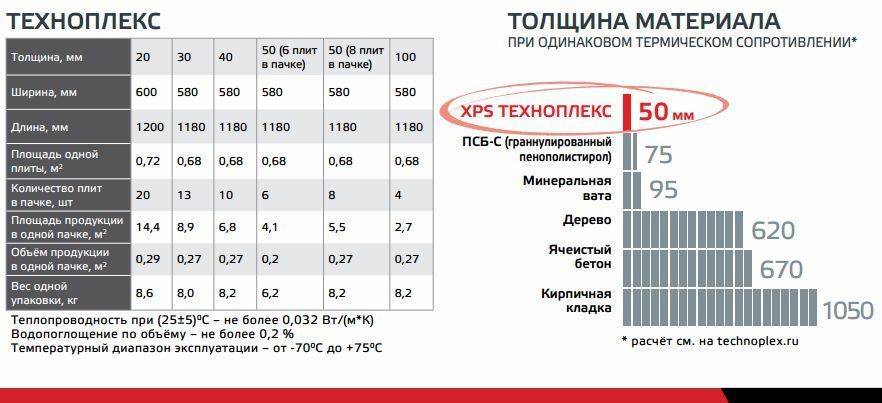

- Thermal conductivity

- Chemical resistance

- Other properties

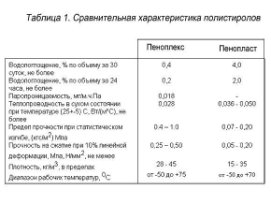

- What is the best polystyrene foam? Foamed or extruded?

- Complete information about extruded polystyrene foam

- Advantages and disadvantages

- Application area

- How to choose the right polystyrene foam

- Description

- Density

- Installation work

- moisture absorption

- Thermal conductivity

- Chemical resistance

- Other properties

- About the properties of expanded polystyrene - in detail and accessible

- About thermal conductivity

- About vapor permeability and moisture absorption

- About strength

- What is polystyrene foam afraid of

- About the ability to absorb sounds

- About biological sustainability

- Disadvantages of foam

- Easy flammability

- brittleness

- Hygroscopicity

- High sensitivity to solvents

- Great housing for mice

- fragility

- Toxicity

- Vapor barrier

- Difficulty in installation due to the large number of joints

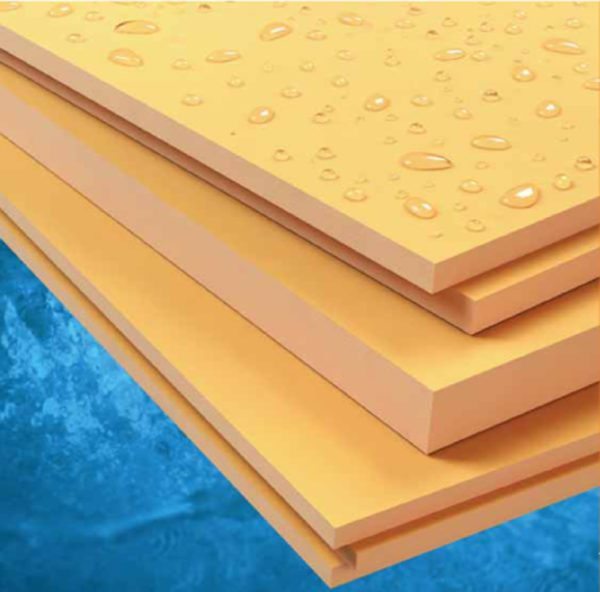

Release form

Plasticizers are added to the EPP insulation, due to which the material acquires various properties. They are in demand in various sectors of construction activity, allowing you to solve the most complex engineering problems.

The consumer can purchase material in this form:

- Plates are expanded polystyrene extrusive.Products are produced in square and rectangular format. The thickness of the sheets is 25-150 mm. Standard sizes of plates are 600x1200 mm, 600x1250 mm, 600x2400 mm. In the insulation of the walls of private buildings, the most popular layers are 50x100x100 cm in size with a selected edge. Plates are used for thermal insulation of objects with a smooth and durable outer surface. The scope of use extends to interior and exterior decoration.

- Substrates. The material plays an important role in the insulation of the flooring, in the sound insulation of rooms and in protecting them from moisture. The substrate is produced in the form of plates and rolls with a width of 50 cm to 100 cm. Some brands have an accordion configuration, which, when unfolded, forms a monolithic surface without slots and joints. The density of the flooring is high enough not to sag under vertical loads. At the same time, the material has elasticity and flexibility, which helps to compensate for small defects in the base. The corrugated top provides free air circulation, prevents the accumulation of moisture, the formation of mold and fungus.

- Decorative elements. The dense and lightweight material has found application in the manufacture of products used for finishing and decorative finishing of the facades of houses, residential and office premises; baguettes, platbands, ceiling and corner skirting boards are made from PPS. After mounting on the surface, the polystyrene is covered with oil, acrylic or water-based paint.

Such widespread use of the material is justified by its unique properties.

Advantages and disadvantages

Due to its corrosion resistance, XPS is used for thermal insulation of foundations.

Consider the pros and cons of XPS Styrofoam.

Let's start with the positives:

- Low thermal conductivity makes EPS one of the most effective means for thermal insulation of building structures, as well as many other components;

- The material is durable, as it is not afraid of electrochemical and biological corrosion;

- Extruded polystyrene foam during operation does not lose its properties, it does not cake, does not decompose and does not change its structure;

- The service life of EPS is comparable to the service life of the building itself, and is at least 60 years old;

- The material is not afraid of moisture, mold fungi, bacteria and other factors of biological corrosion;

- The installation instructions for the sheets are so simple that even an amateur can handle the work;

- The heat-insulating layer weighs little and does not load the walls of the building;

- It is possible to produce curved, cylindrical parts for processing curved surfaces and pipes.

Installation of XPS under siding.

EPS for pipes.

As can be seen from the above list, XPS is one of the most effective heat-insulating materials. This explains its high popularity among consumers.

Use inside the wall.

Extrusion PPS in the underfloor heating system.

EPS also has disadvantages:

- Low permeability to water vapor and air. This leads to the fact that it is necessary to build a forced ventilation system in the room;

- The price of the material is still quite high compared to the usual foam. This is often the deciding factor;

- PPP is afraid of high temperatures and is able to release harmful and toxic substances. An unscrupulous manufacturer can save on flame retardants, which can lead to a fire and even tragedy.

- When installed indoors, the PPS coating creates an unpleasant microclimate in the room.

Expanded polystyrene extruded does not breathe.

Use under floor screed.

Description

Density

High-quality EPS has a homogeneous structure and closed pores much smaller than conventional polystyrene foam (no more than 0.2 mm). Due to the increased compressive density, XPS can be used where the foam turned out to be too soft. Extruded polystyrene foam is able to withstand a load of 35 tons per 1 m2!

Installation work

Another advantage that such a structure of the material gives is the ability to handle it comfortably. Many people know how not easy it was to cut foam. The balls crumbled, flew apart and were magnetized to hands, tools and surfaces. And even with careful handling, the plate could crack and break in the wrong place.

Insulation of the house with Penoplex

Extruded polystyrene foam is deprived of all these shortcomings. It is easy to cut with a regular hacksaw. The cut is precise and even. And the laying of the plates is carried out directly on the base - it does not require additional layers of vapor - waterproofing. Joints are sealed with mounting foam. XPS does not emit toxic substances, unpleasant odors. Work with it does not require special equipment for installers.

moisture absorption

The dense structure increased the moisture resistance of the material (against the background of vulnerable mineral wool, water absorption of 0.2 looks like an error). In the first 10 days, the side cells on the cut gain a minimum amount of moisture. Then water absorption stops, water does not pass inside.

Thermal conductivity

In the battle for heat retention, even the slightest difference in thermal conductivity counts. For different grades of expanded polystyrene, this figure ranges from 0.037 to 0.052 W / (m * ° C).Extruded polystyrene foam, on the other hand, has an indicator of 0.028 - 0.03 W / (m * ° C)!

Chemical resistance

EPPS has shown itself to be resistant to:

- various acids (organic and not);

- salt solutions;

- ammonia;

- cement and concrete;

- lime;

- alkalis;

- alcohol dyes, alcohol;

- carbon dioxide, oxygen, acetylene;

- freons (fluorinated hydrocarbons);

- paraffin;

- water and water-based paints;

- bacteria and fungi.

Other properties

The thickness of the produced plates can be from 2 to 12 cm.

For ease of installation, three types of edges are available:

- Straight.

- With the selected quarter (letter S on the marking).

- Spike - groove (letter N on the marking).

The outer surface can be smooth or corrugated (indicated by the letter G on the marking).

The color range of extruded polystyrene foam is diverse. Uniform standards do not yet exist, so each manufacturer molds plates of different sizes, thicknesses and in different colors indicates XPS of different quality.

The properties of XPS do not change even after 1000 cycles of freezing - thawing, after prolonged immersion in water. Extruded polystyrene foam remains unchanged, being in conditions of -60 +85 ° C!

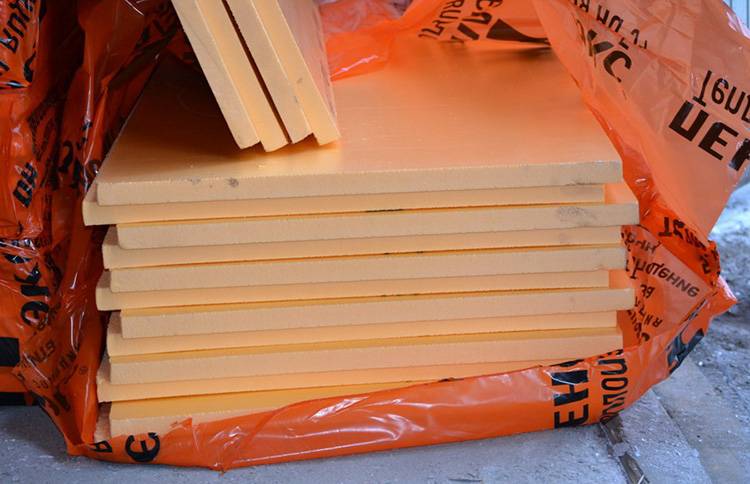

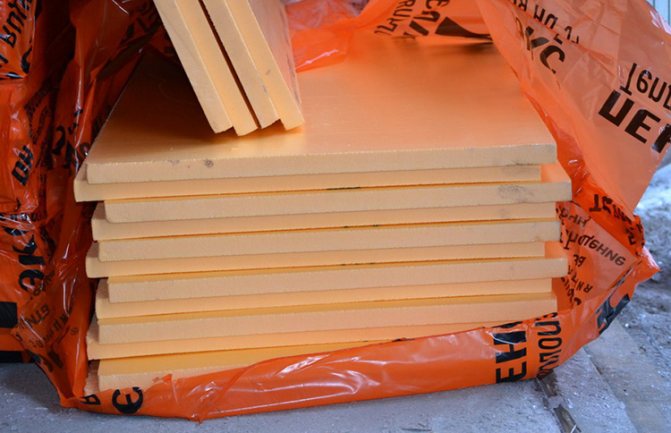

Orange tiles

Cons and weaknesses:

- Penoplex is vulnerable to solvents, some gases (methane), petroleum jelly, tar, gasoline, oil and fuel oil.

- Subject to destruction upon contact with polyvinyl chloride (siding).

- Flammability. It corresponds to the level of combustibility of wood, but all foams release toxic substances when melted, which suffocate a person faster than carbon monoxide.

- The material must be protected from direct exposure to ultraviolet radiation (not used in open form).

- There are temperature restrictions for warming baths, saunas and stokers. The surface must not be heated above +75 °C.

- Just like Styrofoam, extruded polystyrene foam can be damaged by rodents. They do not eat it, but grind it up and build nests in it.

There are no ideal materials, therefore, knowing about its shortcomings, you need to be able to adjust technologies for them. For example, in order to protect residents in case of fire, EPS is not recommended for internal insulation of ceilings, and plastering must be done on top of the insulation layer.

To protect the wall from rodents, Penoplex plates can be covered with a fine mesh.

What is the best polystyrene foam? Foamed or extruded?

Part 1

Is styrofoam insulation the best solution?

I will not consider here the question of whether it is good to insulate buildings with polystyrene foam or polystyrene foam, or, more precisely, with expanded polystyrene foam? This is often written about. And both for and against. Manufacturers and dealers sing with one voice about the benefits. Those who have taken advantage of these benefits timidly share their impressions. Often also contradictory. Understanding why different results are obtained is a separate topic.

My attitude to the insulation of buildings with polystyrene foam is negative. I will focus on just one question. Before insulation, at the usual temperature of the coolant supplied to the building (which depends on the outside temperature and is specified in the instructions), the dew point was outside the wall. When insulated with expanded polystyrene, the dew point moves to the outer surface of the wall. Which leads to wetting.This is not entirely good, especially in cold weather. If you add plastic windows, poor ventilation, and high humidity (kitchen or bathroom), then moisture may appear on the inner surface of the walls.

So let's stop this discussion. We will proceed from the fact that buildings are insulated with expanded polystyrene foam. They fix it to the wall - with glue + plastic dowels (parachutes). Then fiberglass + glue is applied and the exterior finish is performed. Most often it is structural plaster, but it can also be ceramic tiles.

Foamed polystyrene foam does not cause any special problems in further operation.

The only condition is that it should have maximum density. Polystyrene granules - foam balls should fit snugly and not crumble at the slightest touch.

There are examples when ordinary C / P plaster was applied to dense foam plastic along the lighthouses and then ceramic tiles were glued. And all this on the plinth. And in the most unfavorable, lower part.

The positive aspects of using expanded polystyrene foam on the facade of the building:

- The surface of the sheets is rough, with a large number of depressions. Fiberglass adheres well to such a surface. The separation goes along the foam layer;

- Expanded polystyrene assumes all temperature and sedimentary deformations of the building. All these deformations do not reach ceramic tiles. And she holds up relatively well;

- Small price.

This is where the pros end, the problems begin:

- The adhesion strength of the granules is still weak. Often foam is produced without following the technology. Advertised brand and durability are overpriced;

- There are fears that on the southern wall, in the summer there is an intensive destruction. Especially if the wall is painted dark.Put your palm on such a wall in the heat. The temperature is 50-60 degrees. At this temperature, the foam begins to flow;

- For the above reasons, it is impossible to carry out finishing work on polystyrene foam boards on the south side of the building in summer.

Part 2

The use of extruded polystyrene foam for other purposes.

Based on the weak strength of expanded polystyrene foam and incomprehensible durability, they began to use extruded polystyrene foam on the facade. Although its direct purpose is laying under warm floors and lining a part of the basement going under the backfill. It is much stronger, does not crumble. But here, as always, there are pitfalls. Fiberglass on extruded polystyrene foam does not hold!!! Be it with pimples or with notches. It just doesn't hold up. Pull the fiberglass around the corner - you don’t need to apply much effort, the mesh will come off.

Therefore, if the technology of durable fastening of fiberglass is developed, then the issue of wall insulation with extruded polystyrene foam will be resolved.

Complete information about extruded polystyrene foam

What is extruded polystyrene foam? Extruded (extruded) expanded polystyrene is a synthetic material for thermal insulation developed by an American construction company in the 1950s. It is made using foaming technology, polymer compositions are used in the composition. The material is pressed through a special mold and combined into a single piece.

Produced in the form of plates, substrates. It is found on the market as a decorative element. The standard plate size is 600x1200 or 600x2400 mm. Standard dimensions are set by GOSTs, but many companies change the dimensions by making plates of a different width.A common size is 580 mm. The thickness of the elements varies from 20 mm to 10 cm, depending on the manufacturer.

The material is delivered to retail outlets in packages of several elements. The number of units in one package depends on the thickness of the products. For example, if the thickness of the boards is 5 cm, the package usually contains 8 items. With a thickness of 10 cm, 4 plates are packed.

Advantages and disadvantages

Like any other material, extruded polystyrene foam has advantages and some disadvantages. Before purchasing and using it is worth familiarizing yourself with them.

Advantages of extruded polystyrene foam:

- Moisture absorption within 0.2%. This indicator means almost complete water resistance.

- Minimum thermal conductivity. At a standard temperature of 25 ° C, it is about 0.032 W / m * K. If we compare the conductivity of heat, the following results in terms of indicators: 55 cm of brick is equal to 3 cm of polystyrene foam.

- Good resistance to deformation. It can be used for laying under the blind area, laying after the foundation.

- Does not react with inorganic chemicals.

- Withstands significant temperature fluctuations, the performance does not change at air temperatures from -50 to +75 ° C.

- According to the documentation, the material can be used for at least half a century. During this time, the characteristics will not change.

- Environmentally friendly substance. It is used not only as a heater, but, for example, for the production of light disposable plates or other types of cheap dishes. Children's toys are made from it.

- Has a minimum weight. A small thickness is enough for good insulation.

In addition to numerous positive characteristics, there are some disadvantages:

- comparison with other types of heaters shows that the price of the material is high;

- strong flammability. In the process of combustion, harmful substances, black smoke are released;

- under the influence of infrared rays is destroyed. To maintain performance, it must be hidden from direct sunlight;

- manufacturers assure that rodents do not start inside the insulation. Indeed, they do not live inside, but often make channels for movement;

- solvents destroy the structure.

In addition to the above disadvantages, low vapor permeability can be added to them. Sometimes this is a plus, but if you insulate a wooden house, fungi and mold may occur. As a result, an unpleasant smell appears in the dwelling, dampness is constantly felt.

Application area

Extruded gray polystyrene foam has a wide range of applications. Mainly used for insulation work. The scope of use is limited only by temperature indicators (not higher than 75 ° C). The material can be laid in damp places, in the ground.

Usually the scope of use is limited only by financial possibilities. The high cost makes it impractical to use in many places. In places where there is no need for high technical characteristics, ordinary foam is used instead of PPS, reviews of which are also positive in order to save money.

Used for insulation:

- concrete or wooden floors;

- walls inside or outside the building. Compatible with any material;

- wells. It is not uncommon for concrete rings to be coated with a material for additional protection;

- blind area;

- the surface of the earth.To prevent destruction of the structure, paint is applied. Even a thin layer will not allow damage to the composition.

In addition to these areas, the material is used in road construction. Included in many refrigeration units as an extrusion heater. Used in agriculture. Expanded polystyrene insulates roofs, underground floors. One of the promising areas is the production of sandwich panels.

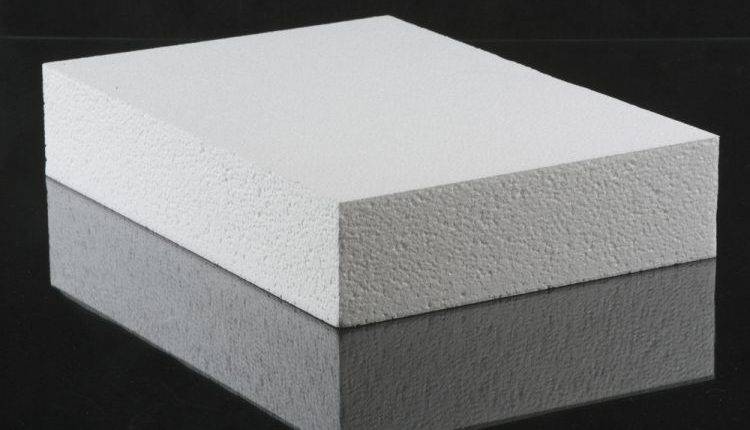

How to choose the right polystyrene foam

Expanded polystyrene is one of the most popular building materials. It is light, warm and cheap, and it is very easy to work with it. Since the demand is high, there are more and more offers from manufacturers. And each of them assures that it is his expanded polystyrene that is the best, and the quality is beyond praise.

1. Getting lost from countless offers, do not rush to buy material. First, carefully study its parameters. If you need to insulate the facade, take PSB-S expanded polystyrene, which is positioned as self-extinguishing. Its brand must be no lower than the fortieth. And if the brand has a number of 25 or less, then do not look in the direction of such material - it is only suitable for packaging, but not for construction work.

2. When buying a material, check to what standards it is made. If the manufacturer manufactures products not according to GOST, but according to its own specifications, then the characteristics of the material may differ. For example, expanded polystyrene PBS-S-40 (fortieth grade) can have a different density - from 28 to 40 kilograms per cubic meter.

It is beneficial for the manufacturer to mislead the buyer in this way - less money is spent on the production of polystyrene foam of lower density.Therefore, you cannot focus only on the number in the brand name, but you must ask to show documents confirming the technical characteristics of expanded polystyrene.

3. Before buying, try to break off a piece of material from the very edge. If it turns out to be low-grade packaging foam, then it will break with a jagged edge, on the sides of which round small balls will be visible. The material obtained by extrusion, in place of a neat fracture, has regular polyhedra. The fault line will pass through some of them.

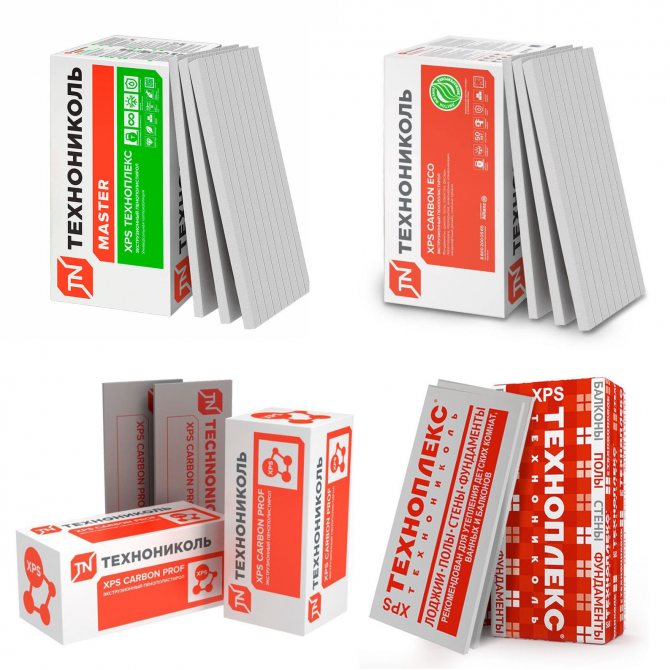

4. As for the producers of expanded polystyrene, the best of them are the European companies Polimeri Europa, Nova Chemicals, Styrochem, BASF. Russian manufacturing companies, such as Penoplex and Technonikol, do not lag behind them. They have a production capacity that is quite enough for the manufacture of very high quality polystyrene foam.

Description

Density

High-quality EPS has a homogeneous structure and closed pores much smaller than conventional polystyrene foam (no more than 0.2 mm). Due to the increased compressive density, XPS can be used where the foam turned out to be too soft. Extruded polystyrene foam is able to withstand a load of 35 tons per 1 m2!

Installation work

Another advantage that such a structure of the material gives is the ability to handle it comfortably. Many people know how not easy it was to cut foam. The balls crumbled, flew apart and were magnetized to hands, tools and surfaces. And even with careful handling, the plate could crack and break in the wrong place.

Insulation of the house with Penoplex

Extruded polystyrene foam is deprived of all these shortcomings.It is easy to cut with a regular hacksaw. The cut is precise and even. And the laying of the plates is carried out directly on the base - it does not require additional layers of vapor - waterproofing. Joints are sealed with mounting foam. XPS does not emit toxic substances, unpleasant odors. Work with it does not require special equipment for installers.

moisture absorption

The dense structure increased the moisture resistance of the material (against the background of vulnerable mineral wool, water absorption of 0.2 looks like an error). In the first 10 days, the side cells on the cut gain a minimum amount of moisture. Then water absorption stops, water does not pass inside.

Usually houses are insulated from the outside, but in some cases, internal thermal insulation is necessary. How to insulate the walls from the inside of the house: see the review of thermal insulation materials.

You can find a DIY siding guide for your home here.

And in this article you can find tips on choosing a material for ceiling insulation in a private house. Mineral wool, foam plastic, bulk materials - which is better to choose?

Thermal conductivity

In the battle for heat retention, even the slightest difference in thermal conductivity counts. For different grades of expanded polystyrene, this figure ranges from 0.037 to 0.052 W / (m * ° C). Extruded polystyrene foam, on the other hand, has an indicator of 0.028 - 0.03 W / (m * ° C)!

Chemical resistance

EPPS has shown itself to be resistant to:

- various acids (organic and not);

- salt solutions;

- ammonia;

- cement and concrete;

- lime;

- alkalis;

- alcohol dyes, alcohol;

- carbon dioxide, oxygen, acetylene;

- freons (fluorinated hydrocarbons);

- paraffin;

- water and water-based paints;

- bacteria and fungi.

Other properties

The thickness of the produced plates can be from 2 to 12 cm.

For ease of installation, three types of edges are available:

- Straight.

- With the selected quarter (letter S on the marking).

- Spike - groove (letter N on the marking).

The outer surface can be smooth or corrugated (indicated by the letter G on the marking).

The color range of extruded polystyrene foam is diverse. Uniform standards do not yet exist, so each manufacturer molds plates of different sizes, thicknesses and in different colors indicates XPS of different quality.

The properties of XPS do not change even after 1000 cycles of freezing - thawing, after prolonged immersion in water. Extruded polystyrene foam remains unchanged, being in conditions of -60 +85 ° C!

Orange tiles

Cons and weaknesses:

- Penoplex is vulnerable to solvents, some gases (methane), petroleum jelly, tar, gasoline, oil and fuel oil.

- Subject to destruction upon contact with polyvinyl chloride (siding).

- Flammability. It corresponds to the level of combustibility of wood, but all foams release toxic substances when melted, which suffocate a person faster than carbon monoxide.

- The material must be protected from direct exposure to ultraviolet radiation (not used in open form).

- There are temperature restrictions for warming baths, saunas and stokers. The surface must not be heated above +75 °C.

- Just like Styrofoam, extruded polystyrene foam can be damaged by rodents. They do not eat it, but grind it up and build nests in it.

There are no ideal materials, therefore, knowing about its shortcomings, you need to be able to adjust technologies for them.For example, in order to protect residents in case of fire, EPS is not recommended for internal insulation of ceilings, and plastering must be done on top of the insulation layer.

To protect the wall from rodents, Penoplex plates can be covered with a fine mesh.

About the properties of expanded polystyrene - in detail and accessible

About thermal conductivity

Expanded polystyrene is nothing more than a lot of air bubbles enclosed in thin shells of polystyrene. In this case, the ratio is as follows: two percent polystyrene, the remaining ninety-eight is air.

The result is a kind of hard foam, hence the name - polystyrene foam. The air is hermetically sealed inside the bubbles, thanks to which the material perfectly retains heat. After all, it is known that the air gap, which is motionless, is an excellent heat insulator.

Compared to mineral wool, the thermal conductivity of this material is lower. It can have a value from 0.028 to 0.034 watts per meter per Kelvin. The denser the expanded polystyrene, the greater the value of its thermal conductivity coefficient. So, for extruded polystyrene foam, having a density of 45 kilograms per cubic meter, this parameter is 0.03 watts per meter per Kelvin. This means that the ambient temperature is not higher than + 75% C and not lower than -50 C.

About vapor permeability and moisture absorption

Extruded polystyrene foam has zero vapor permeability. And the characteristics of expanded polystyrene foam, which is manufactured in a special way, are different. Its vapor permeability varies from 0.019 to 0.015 kilograms per meter-hour Pascal.This seems strange, since, in theory, such a material with a foam structure is not capable of passing steam.

The answer is simple - the molding of expanded polystyrene foam is carried out by cutting a large block into slabs of the required thickness. So steam penetrates through the cut foam balls, climbing inside the air cells. Extruded polystyrene foam, as a rule, is not cut, the plates exit the extruder already with a given thickness and a smooth surface. Therefore, this material is not available for steam penetration.

As for moisture absorption, if you immerse a sheet of expanded polystyrene foam in water, it will absorb up to 4 percent of it. Dense expanded polystyrene, made by extrusion, will remain almost dry. It will absorb ten times less water - only 0.4 percent.

About strength

Here the palm belongs to extruded polystyrene foam, in which the bond between the molecules is very strong. In terms of static bending strength (from 0.4 to 1 kilogram per square centimeter), it significantly exceeds ordinary expanded polystyrene foam (its strength ranges from 0.02 to 0.2 kilograms per square centimeter). Therefore, in recent years, expanded polystyrene foam has been produced less and less, since it is less in demand. The extrusion method allows you to get a more modern material for insulation, durable and moisture resistant.

What is polystyrene foam afraid of

Expanded polystyrene does not react in any way to substances such as soda, soap and mineral fertilizers. It does not interact with bitumen, cement and gypsum, lime and asphalt emulsions. Nor does he care about groundwater.But turpentine with acetone, some brands of varnishes, as well as drying oil can not only damage, but also completely dissolve this material. Expanded polystyrene is also soluble in most products obtained by distillation of oil, as well as in some alcohols.

It just does not like polystyrene foam (neither foamed nor extruded) in direct sunlight. They destroy it - with constant ultraviolet irradiation, the material first becomes less elastic, losing strength. After that, snow, rain and wind complete the destruction.

About the ability to absorb sounds

If you need to escape from excessive noise, polystyrene foam will absolutely not help. It is able to muffle impact noise somewhat, but only on condition that it is laid in a sufficiently thick layer. But airborne noise, the waves of which propagate through the air, is too tough for polystyrene foam. These are the design features and properties of expanded polystyrene - rigidly located cells with air inside are completely isolated. So for sound waves flying through the air, it is necessary to put barriers from other materials.

About biological sustainability

As it turned out, mold on polystyrene foam is not able to live. This is confirmed by American scientists who conducted a series of laboratory studies in 2004. These works were ordered by the manufacturers of expanded polystyrene from the United States. The result completely satisfied them.

Disadvantages of foam

This material is very popular and is used almost everywhere, it occupies a leading position in the demand for thermal insulation materials. It can be used both for domestic purposes and in mass construction.For all its popularity, many simply do not know all the disadvantages that this product has.

Easy flammability

Despite the many different types of foam, none of them can withstand fire for a long time; with prolonged exposure to high temperatures, it lights up and turns into a liquid mass. The smoke emitted during combustion can paralyze the human respiratory system.

It is because of this minus that the material is not suitable for finishing ventilation. There will be a constant supply of oxygen and empty space. In this case, extinguishing the fire will be very problematic.

brittleness

Correctly mounting this material is quite difficult, it crumbles and breaks a lot. It is very fragile: for example, if the ceiling is insulated with foam, then walking in the attic can damage the insulation.

Hygroscopicity

Hygroscopicity is the property of a material to absorb moisture. It is not recommended to use foam in damp, damp rooms. It will not be the best choice for decorating a basement or bathroom, but extruded polystyrene foam will stand up to such a test.

High sensitivity to solvents

When gluing foam boards, it is imperative to make sure that the materials are compatible. Some adhesives can corrode foam.

Great housing for mice

This building material has all the properties that mice want to settle there: it retains heat well, is easy to “gnaw through” and provides reliable protection.

To avoid this, it is required to cover the material with mineral wool, which will scare away rodents with its pungent odor.You can beat the foam plastic with metal inserts - this is labor-intensive, but they will become an insurmountable obstacle for mice.

fragility

Approximately every ten years, the material will have to be changed, and when exposed to destructive factors, even earlier.

Toxicity

Styrofoam is dangerous not only when burning. Due to the long exposure to time and the lack of timely replacement, it begins to produce a harmful substance - styrene monomer.

When it is installed in an unventilated room, there will be a specific smell that has a negative impact on human health.

Vapor barrier

During installation, it should be borne in mind that the foam "does not breathe", therefore, if you install it in a room without artificial ventilation, this will give increased humidity and constant condensation on the glass.

Difficulty in installation due to the large number of joints

It is very difficult to thermally insulate surfaces of complex shape. The foam sheets are small enough and it will not work to cover the ceiling or floor with one monolithic layer.

You will have to spend a lot of effort to fit the insulation closely and seal all the joints.

In conclusion, we can say that the foam has a number of qualities that are not characteristic of other materials, therefore, it is indispensable for some construction work: thermal insulation, design.

Its popularity is widespread, despite some shortcomings. It's easy to use and cheap enough to be a great choice.