- Features and benefits of boilers "Svetlobor"

- Main advantages

- Design features

- Pellet boilers

- The principle of operation of the pellet boiler

- Advantages

- Disadvantages of pellet boilers

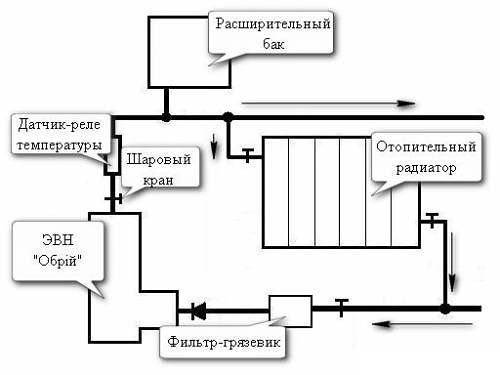

- The main requirements for the installation of a Svetlobor brand boiler

- What are the pros and cons of Svetlobor equipment

- Boilers from Wirbel - versatility and ease of installation

- What is a pellet boiler

- Selection Tips

- 2 Kostrzewa Pellets Fuzzy Logic 2 25 kW

- Boilers from Grandeg with increased fire safety

- 2 Froling P4 Pellet 25

- What is a pellet boiler

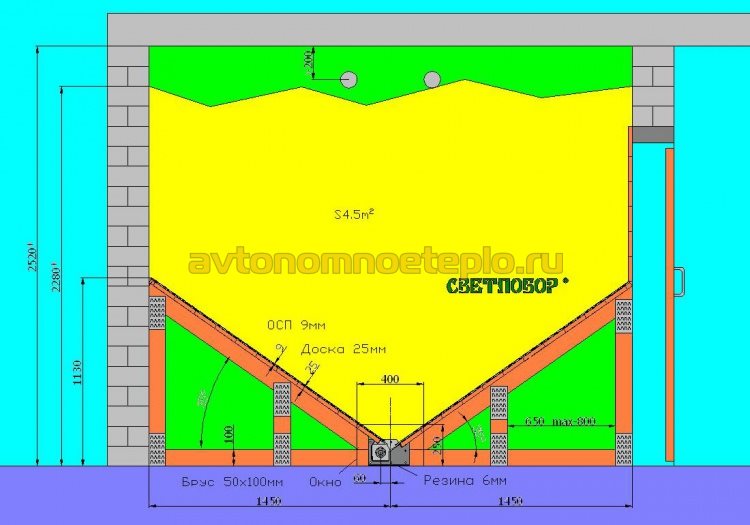

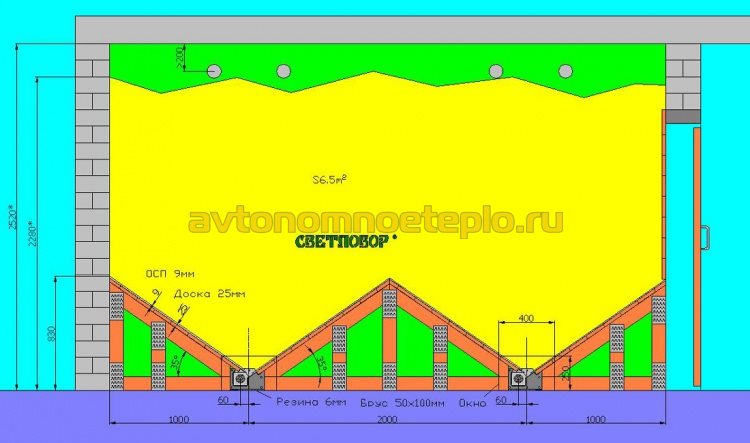

Features and benefits of boilers "Svetlobor"

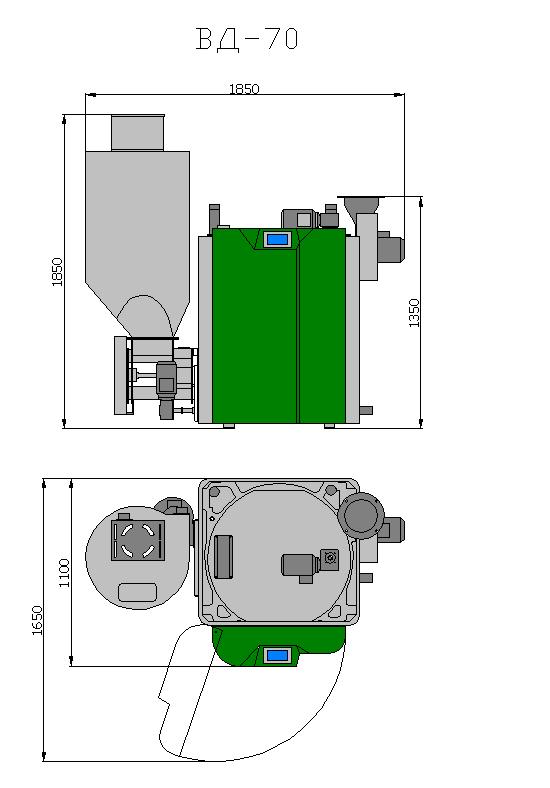

A distinctive feature of these devices is that all models are based on three main models: 20, 40 and 80 kW. Based on them, six boilers of different capacities are produced: from 20 to 90 kW. So, for example, the VD-35 and VD-45 devices are designed on the same base and differ only in height.

All models use a cylindrical vertical combustion chamber with chimneys arranged radially around it.

As you can see, all models of Svetbor boilers have a cylindrical combustion chamber installed vertically.

Thanks to the correct arrangement of structural elements (vertical water supply, chimney and horizontally located smoke exhauster), it was possible to significantly reduce the dimensions of the equipment.Also, one wall of the boiler is not involved, therefore, it can be placed close to the wall.

Main advantages

"Svetlobor" pellet boiler has a number of advantages over its counterparts, namely:

- Price. Perhaps the main and most significant advantage of these devices. Their cost is two or even three times lower than their foreign analogues, although, in terms of “stuffing” and characteristics, domestic models are in no way inferior.

- Consumption of any fuel. Design features (adaptive control, complete cleaning of the grate and others) ensure the complete unpretentiousness of the Svetlobor boilers to the quality of combustible materials. You can fill the device with both expensive European fuel (white) and cheap - gray, which is used in industry. Moreover, it does not matter whether it is wet, with a high or low ash and dust content. European counterparts, on the contrary, are very picky.

- Complete autonomy. You do not need to control the operation of the device even for a month. The warehouse allows you to load fuel automatically, without the presence and participation of a person. Such a module exists only on the best foreign models. You can also control the boiler using your mobile phone via SMS messages.

- Automation at a high level. The boiler is equipped with various automation systems: burner cleaning system, heat exchanger, ash unloading mechanism and others. Thanks to these modules, you do not need to clean the device manually, the automation will do everything for you. In turn, the automatic fuel supply module will greatly simplify your life.It will no longer require any intervention in the loading of combustible materials, it is enough to load the fuel into a special storage once for a long time, the boiler itself will do the rest for you.

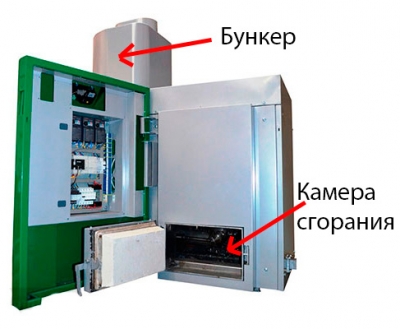

Design features

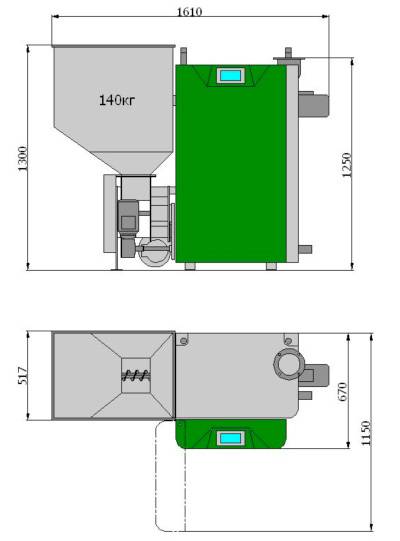

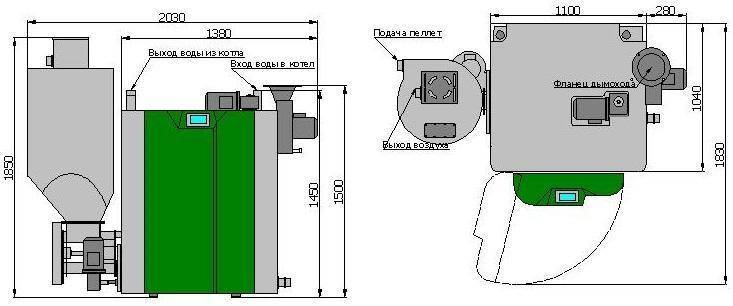

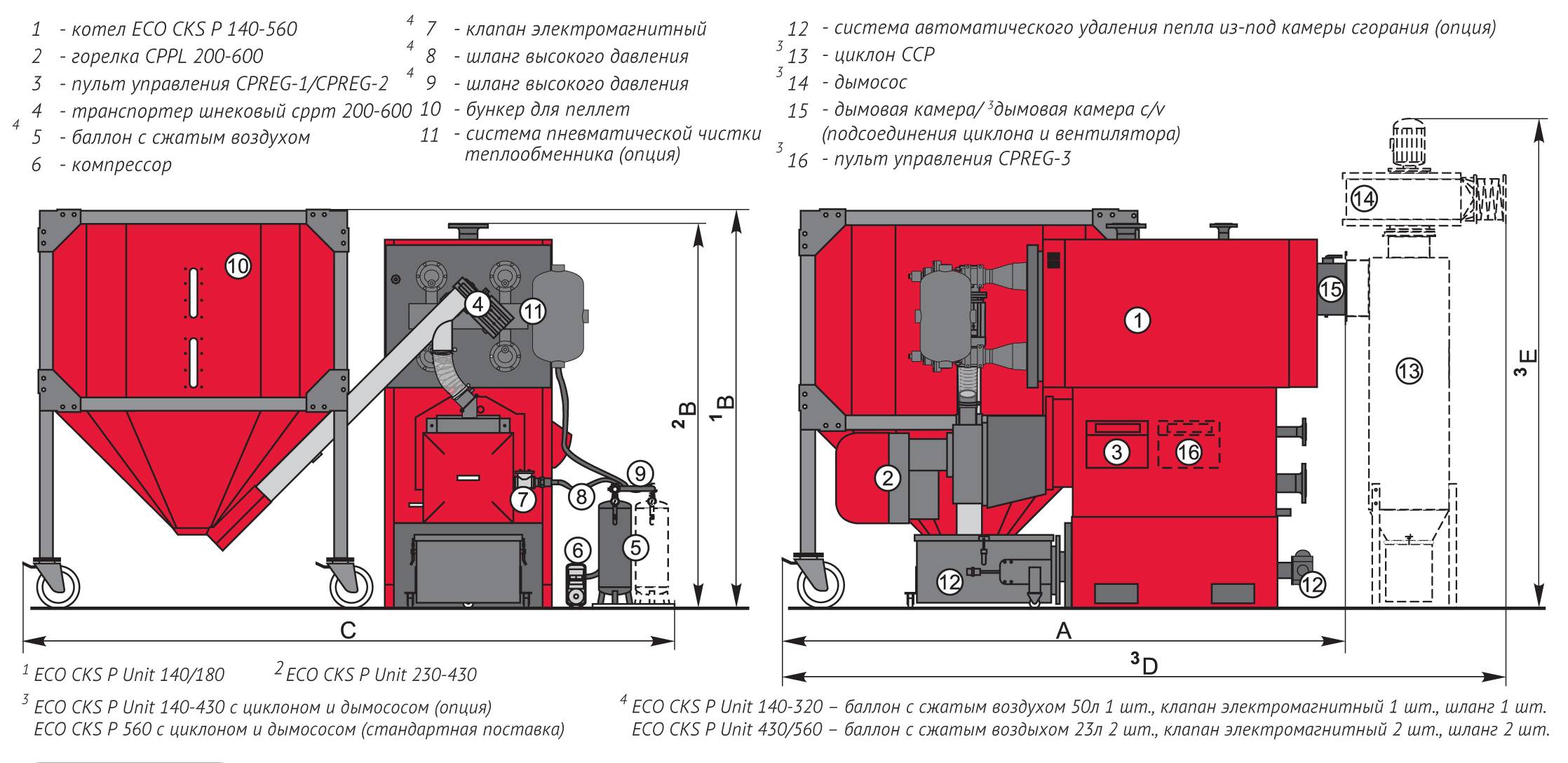

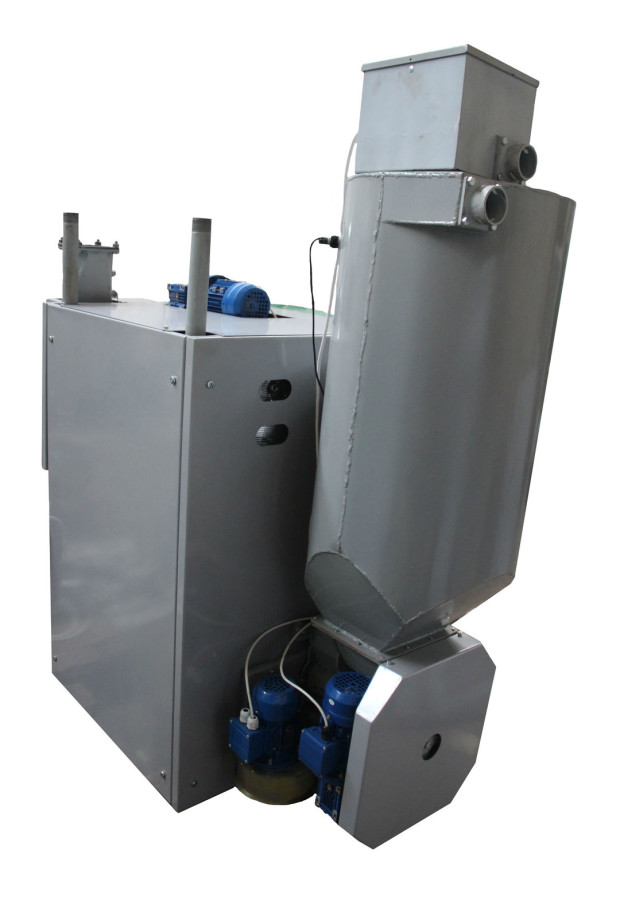

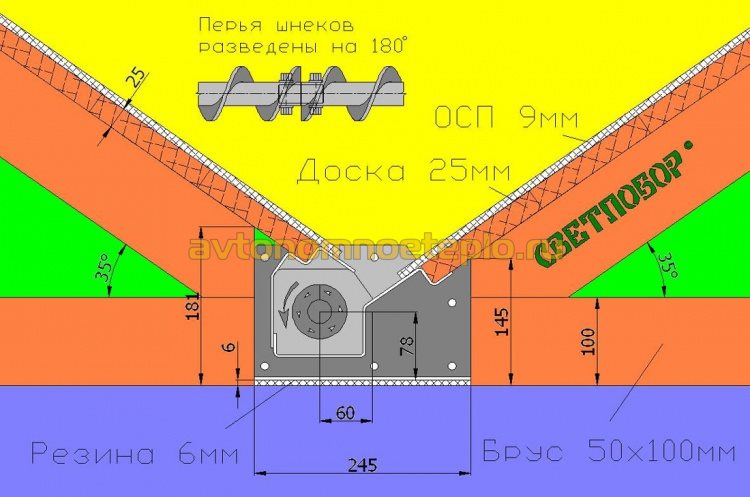

Bunker and combustion chamber of the Svetlobor pellet boiler.

"Svetlobor" pellet boiler differs significantly from its counterparts in its appearance. It is more like a refrigerator or a washing machine. The device consists of two blocks: a bunker where pellets are stored and a combustion chamber. The latter is a cylindrical vertical furnace, at the bottom of which there is a steel bowl - a burner. Above it is an afterburner and a secondary air supply system. Thanks to this arrangement of the boiler, the temperature in the combustion zone reaches 1000 degrees.

The ash accumulated after the combustion of the fuel is removed using a special cleaning system. This mechanism cleans the smoke tubes and the burner every half an hour with special brushes. Waste is sent to the ash pan, and then to the box.

Pellets are fed into the furnace using a screw system. And the last two in the bunker. The first prevents the fuel from caking, and the second feeds it into the furnace. The performance of all systems is monitored by a special controller made by the Japanese company Mitsubishi.

Pellet boilers

serve for heating private houses

Wood pellets, as needed, are fed from the bunker into the furnace using a special auger, which is controlled by automation. When the set temperature is reached, the auger stops and the pellets are not fed into the furnace. Usually the volume of the bunker allows you to keep a supply of pellets for several days.If it is possible to organize a warehouse for storing pellets, from which they are immediately fed into the bunker, then the process becomes more convenient. Experts recommend using a pellet boiler in combination with a backup device on another heat source, most often electricity. But today there are models on the market that can, if necessary, work both on wood and on briquettes.

According to the reviews of consumers who have something to compare with, according to the requirements for location, installation and safe operation, pellet boilers are no different from gas devices or liquid fuels. Modern models are quite compact, differ from analogues in a small volume of the combustion chamber and a special burner with high efficiency. They are also characterized by a service life of up to twenty years (at least according to the instructions) and a high level of automation.

Manufacturers claim that if there is a special warehouse with a pellet supply system, the device can work without human intervention for the entire heating season. According to reviews, an autonomous supply system requires careful installation and precise observance of geometry, otherwise the granules will get stuck at pipe bends, disrupting the smooth operation of the system.

Pellet boilers are available in various capacities, from 15 to 100 kW. Manufacturers recommend determining the required boiler power at the rate of 1 kW per ten square meters plus fifteen percent for heat loss at home. Reviews of the owners of country houses confirm these data. Since houses are built and insulated for domestic winters, even without a margin of fifteen percent, the temperature in the rooms is maintained at a comfortable level.

The principle of operation of the pellet boiler

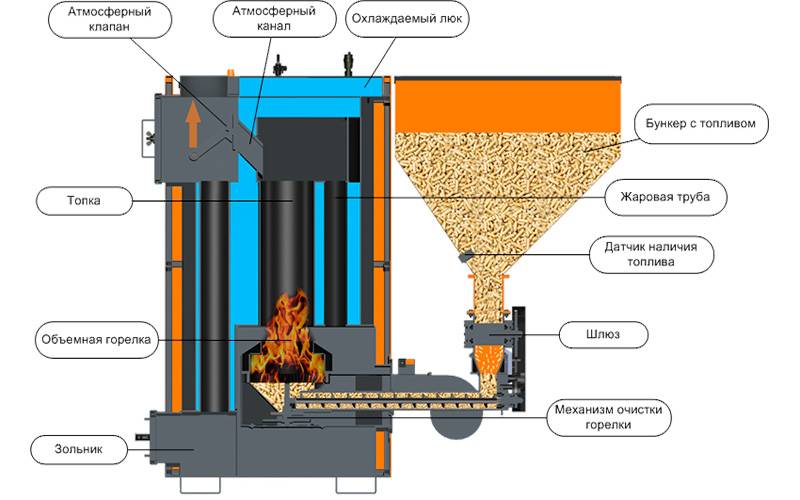

What does a boiler consist of and how does it work:

- Boiler with burner;

- Conveyor feeding pellets;

- Bunker for fuel.

Pellets are poured into the bunker, from where the pellets are conveyed as needed to the furnace, where they support combustion.

When burning this type of fuel, the efficiency of the boiler reaches 98%.

The boiler is equipped with an automatic control system that allows you to regulate the temperature of the heat carrier by supplying fuel to it. If desired, you can reconfigure the boiler to another type of fuel, if the main one is over. The device can work on wood or coal, any solid fuel.

Combustion of fuel occurs due to forced air injection by a fan. And when the pellets ignite, the ignition will turn off automatically. Flue gases that are formed during the combustion process and give heat to the heat exchanger. The combustion product enters the ash pan. Since the operation of the boiler is automated, it allows you to stably maintain heat in the house without the participation of the owner. When the temperature maximum is reached, the machine stops the fuel supply and resumes when the temperature reaches the minimum.

Advantages

The following advantages of the Svetlobor brand boiler should be noted:

- Automatic control within a month.

- Self-cleaning of caught ash in burners and heat exchangers.

- suitability of GSM and WI-FI .

Since the cleaning of the grate is carried out automatically, it is possible to use pellets of various qualities, as a rule, with impurities, as well as with European fuel. They are not afraid of excessive moisture and dust.

This is the main advantage of "Svetlobor" in comparison with other similar boilers of Western European production.

You need attention compared to Svetlobor. Only then can they work effectively and for a long time.

A pellet boiler is the right solution for people who want warmth in their home and low heating costs.

How the boiler house based on the Svetlobor boiler works, see the following video:

Disadvantages of pellet boilers

It would seem that pellet stoves have so many advantages that they should already be in every country house, but disadvantages interfere:

- Fairly high price. It has been declining in recent years, but still exceeds the cost of gas and electric counterparts. The cost of a pellet boiler is twice as high as that of a gas boiler of the same capacity. But there are separate burners that can be installed in an existing solid fuel boiler.

- The need for constant care. Throughout the heating period, almost every week, you need to clean the heat exchanger with a special brush and remove ash from the ash collector. True, this applies to older models. Modern devices have an automatic cleaning function. And the frequency of such work directly depends on the quality of the pellets. This drawback is noted by all owners of pellets.

- In the absence of a warehouse with automatic feeding of pellets, it is necessary to load the bunker manually at least once a week, depending on its size. But this is a common drawback of all solid fuel devices.

- The need for a sufficiently large dry room for storing pellets. Even for the smallest 10 kW boiler, according to reviews, 2 kg / hour or 2 bags of 25 kg pellets per day are required, that is, about one and a half tons of pellets are needed for a month, and they need to be stored in a dry room or large volume containers.True, environmental safety and the absence of odors in pellets allows you to use this volume for other purposes in the warm season.

- In remote areas, there may be complications with the purchase of high-quality pellets, their delivery and maintenance of imported equipment, which, to be honest, did not count on the harsh Russian winters and fuel quality.

The main requirements for the installation of a Svetlobor brand boiler

Pellet boilers of the Svetlobor brand are high-tech equipment, therefore, in order to avoid connection errors that affect efficiency and performance, it is recommended that the installation be carried out by a competent specialist, a representative of the company.

During installation, the following guidelines must be observed:

-

The boiler is mounted on a flat solid base. For high power units, a concrete base must first be poured.

Smoke exhaust systems are mounted in accordance with the current SNiP and SP. As a chimney, a pipe is used that can withstand operating temperatures up to 550 ° C and short-term heating up to 1000 ° C.

The supply of hot water needs is carried out by connecting indirect heating to the boiler. It is recommended that the storage tank have a volume of at least 200 liters.

The boiler design uses two heating circuits. The manufacturer recommends powering the primary circuit at maximum load. The second branch is used as a reserve or for other purposes.

The first launch of the Svetlobor pellet boiler takes place in the presence of a company representative, after which the unit is put on warranty service.

Regular inspection of working systems and removal of combustion products is required no more than once every 1-2 months.If the GSM-module is connected, information about malfunctions, the number of remaining pellets and errors in operation will be transmitted in the form of text messages to the phone number.

The power supply is connected through a voltage stabilizer and an uninterruptible power supply, directly from the switchboard. Mandatory installation of machines and RCDs.

What are the pros and cons of Svetlobor equipment

The company's products are constantly being improved, depending on the wishes of the consumer and operating experience. During the active use of the company's boilers in agriculture, industry and domestic heating, a certain reputation has developed about Svetlobor equipment, which helps to identify its strengths and weaknesses:

- Advantages - low cost, maximum automation of the combustion process and high energy efficiency can be distinguished as advantages. Unlike foreign analogues, the boiler is not whimsical to the quality of the fuel. For work, white and gray pellets, as well as wood chips are used. Another advantage is the installed self-cleaning system, which allows you to increase battery life.

Disadvantages - judging by customer reviews, there are minor flaws in the models, which, however, is traditional for domestic equipment. The present shortcomings do not affect the performance and usability. Most owners of a heat generator simply do not pay attention to them, especially when you consider that similar models from German manufacturers are 2 times more expensive.

Svetlobor boilers are optimally suited for domestic operating conditions: they are unpretentious in terms of fuel quality and pellet moisture content. A good solution to the issue of heating the building, in view of the lack of central gas supply.

Boilers from Wirbel - versatility and ease of installation

Wirbel is based in Austria and manufactures automatic pellet boilers. The products of this manufacturer are of high quality and ease of installation. Wirbel EKO-CK PELLET-SET ovens are versatile and include an integrated pellet burner.

Raw materials are fed into the furnace of Wirbel pellet boilers automatically, so it can work continuously as long as there is a need for space heating

The body of such a unit is made of heat-resistant steel, the thickness of which is 5 mm. The pellet tank can be installed on either side of the boiler. The standard equipment of the furnace provides for the following functions: automatic ignition, supply of pellets to the furnace section. However, if necessary, the unit can also operate in manual mode.

The operation of a solid fuel heating device is controlled through a special remote control. Cleaning of Wirbel EKO-CK PELLET-SET models is a necessary event and is carried out at least once a week.

What is a pellet boiler

One of the main disadvantages of long-burning wood-burning boilers is the fuel itself, it is bulky and requires a lot of storage space.

Classic solid fuel boilers for heating private houses are designed to burn wood, coal, coke and other solid fuels.To do this, they are equipped with a large firebox, in which fuel is burned with the release of a large amount of heat. Such boilers require constant tossing of more and more new portions of firewood and coal - they burn out quickly enough, which leads to a gradual cooling of the heating system.

Long-burning solid fuel boilers that have appeared on sale, used for heating private houses, pleased their owners with a reduced number of approaches for loading fuel - some of them can work up to 8-10 hours, depending on the fuel used. This approach allows you to count on long and uninterrupted work - you can be sure that by morning it will not get cold in the rooms.

Pellet boilers operating on special combustible granules - pellets - have become an alternative to long-burning boilers. Such fuel releases a large amount of thermal energy and has many advantages over wood and coal:

- Affordable cost - due to the fact that pellets are a product created from various wastes, their cost is in a very affordable range;

- Ease of storage - just fold the bags of pellets in any convenient place. Also for this you can provide a capacious bunker;

- Convenient dosage - pellets are free-flowing and very light combustible material, so they can be dosed with an accuracy of several grams. It is also very convenient to fall asleep - for this you can use a deep spatula.

Pellets burn almost completely, leaving behind a minimum amount of ash. Also on sale are low-ash modifications that burn almost 100%.

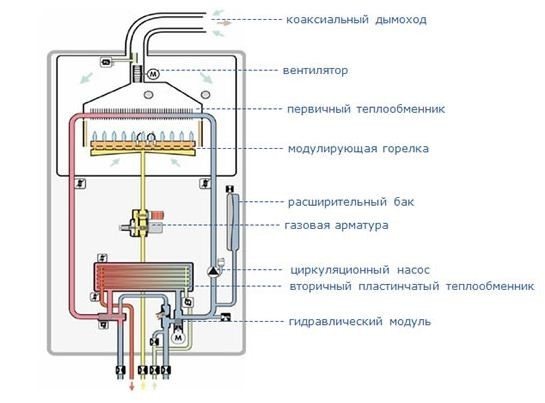

A pellet boiler for heating a house is a rather impressive unit that runs on pellets. Fuel storage is carried out in a bunker, the dimensions of which can be both small and very large. Pellet fuel gradually enters the combustion chamber, where it burns out with the release of a large amount of heat. The heat is then absorbed by the heat exchanger.

The temperature difference between the combustion chamber and the heat exchanger outlet is very large - the combustion products cool here from a temperature of + 800-900 degrees to + 100-120 degrees.

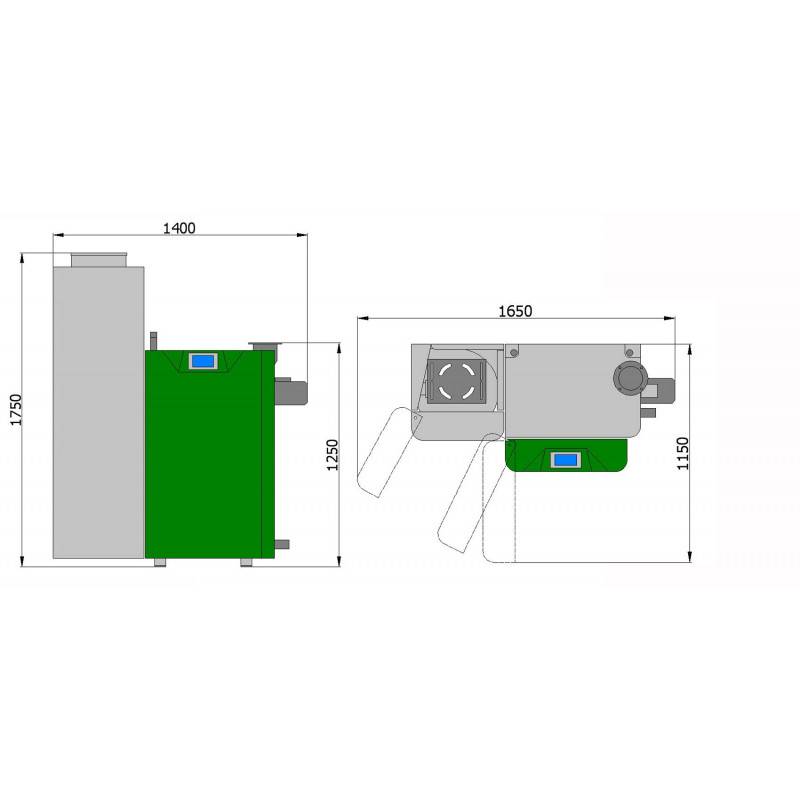

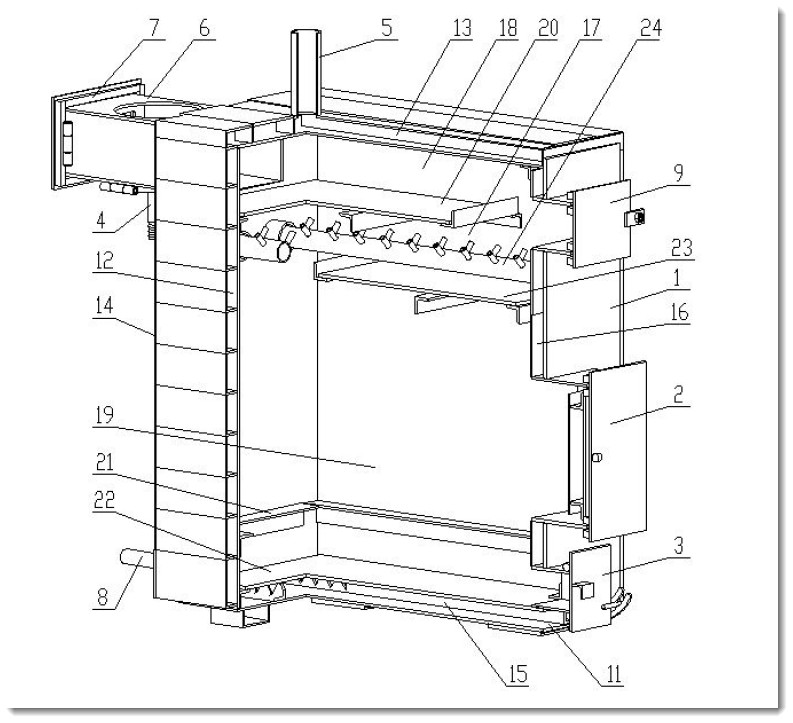

Pellet boilers for the home consist of the following units:

- Bunker - pellet fuel is stored here, which is taken into the combustion chamber. Some models of pellet boilers have very large bunkers, which allows you to count on the longest warm-up and continuous heating of a private house for several days in a row;

- Auger - provides a smooth flow of pellets into the working chamber, it is driven by an electric motor;

- Combustion chamber - here the combustion process takes place;

The main units and components of the pellet plant.

- Burner - pellets ignite and burn in this module. We can say that the combustion chamber and the burner are one and the same unit;

- Heat exchanger - here the heat is transferred to the heating system. Heat exchangers can be very different, ranging from flat steel to multi-pass cast iron;

- Control module - controls the fuel supply to the furnace, checks the operating parameters, monitors safety.

Pellet boilers used for heating private houses contain many other components - these are ash collectors, safety valves, ignition systems and much more.But the main ones are precisely the above modules - they are responsible for creating heat and transferring it to the heating system of a private house.

Pellet boilers for the home work in much the same way as conventional solid fuel boilers. The auger takes the pellets from the hopper and directs them to the burner, where they are burned. The received heat is taken away by the heat exchanger, and the remains are sent to the atmosphere. Many pellet boilers are equipped with forced air supply systems to the combustion chamber and smoke exhaust fans - all this allows for more efficient combustion of pellet fuel.

Due to the automatic supply of fuel, pellet boilers do not require frequent approaches. One download is enough for several hours, and even for several days. Moreover, the most advanced samples independently maintain the temperature in the system by regulating the supply of pellets and flame burning - for this they are equipped with multifunctional automation systems.

Selection Tips

Some tips from experts will help you quickly and deftly navigate all the variety of models in stores and make exceptionally successful purchases:

Decide on power first. It is quite simple to calculate it: 1 kW per 10 square meters. meters.

The priority will always be a boiler that can work with different types of fuel, since pellets are not always easy to get at an attractive price.

Heat exchangers made of steel are considered the best and highest quality.

The cast iron analogue is quite heavy and somewhat complicates the operation process.

It is recommended to buy equipment only from well-known manufacturers whose build quality, safety and efficiency have been tested by time and by many experts.

When buying, pay attention to the warranty period and ask the seller for a certificate of conformity.

Due to frequent maintenance, it is not recommended to buy older models. New boilers are not so demanding to maintain

It is enough to service them once every two months.

An important parameter is the presence of additional functions that provide comfortable use. Thanks to them, the user does not have to constantly monitor the work process. It has become more automated.

2 Kostrzewa Pellets Fuzzy Logic 2 25 kW

The highest productivity Country: Poland Average price: 315,000 rubles. Rating (2019): 4.9

Single-circuit boiler made of steel, the efficiency of which reaches 92%. It works mainly on pellets, but if necessary, fine coal can be used, and if there are specially installed grate segments, firewood can be used. Works in two modes: summer and winter. In summer mode, the boiler is connected to a boiler to provide hot water. In winter, it works to heat the house. Power varies at the discretion of the owner. The bunker is large, holds up to 220 kg of pellets, which at maximum power is enough for 38 hours of operation.

In the reviews, the owners of the boiler write about the ease of operation. Ashes have to be cleaned very rarely, provided that low-ash pellets are used, this should be done no more than once a month. It is convenient that the fuel tank can be installed on any side, adapting the configuration of the unit to the specifics of the boiler room.Of the minuses - many can not immediately find the optimal settings, it takes some time.

Boilers from Grandeg with increased fire safety

The Latvian company Grandeg is engaged in the production of convenient and reliable stoves operating on solid granules. The main advantage of the pellet heating boiler from Grandeg is its high fire resistance.

The body of the device is made of durable, heat-resistant steel. The furnace of such a unit has a sluice valve, the function of which is to protect the bunker from flames. The bunker itself can be mounted both on one side and on the other side of the boiler body.

A distinctive feature of Grandeg heating boilers is excellent quality, high efficiency, simplicity and reliability of design.

As fuel for such devices, not only pellets are used, but also firewood, as well as briquettes. The service life of the Grandeg oven can be up to 20 years (under normal use). The cost of devices depends on their power and additional technical equipment.

2 Froling P4 Pellet 25

Austrian Froling boilers do not have many competitors in quality. It is made extremely soundly, differs in functionality, high level of automation. The optimization system allows you to achieve maximum efficiency, operation is simplified thanks to the Lambdatronic P 3200 control system with a large touch screen. The operation of the equipment is maximally automated, all safety requirements are met. Another advantage of the model is quieter, almost silent operation compared to other similar boilers.The reduced operating volume is made possible by the use of a special cyclone design with integrated sound insulation and a low-noise exhaust fan.

The high cost is undoubtedly a disadvantage of this model. But for this amount, the buyer receives not a primitive boiler, but a modern device with protection against cold “return”, a fuel supply system, flame control, oxygen amount, and vacuum. It is possible to equip a pellet warehouse with a pneumatic screw supply system for automatic heating throughout the cold season.

What is a pellet boiler

The pellet boiler runs on solid fuel, pellets. These are wood pellets that have a small volume. They are highly flammable and help create enough heat to heat your home. The boiler complies with fire and technical safety, so it is often chosen for heating in a private house. The ability to provide heat and hot water to a cottage of any plan depends on the power of the boiler.

Foreign models of boiler heat exchangers are made of cast iron, due to this they are very heavy and expensive. But such material is not subject to corrosion and can serve for many decades. The Russian version of the pellet boiler heat exchanger is made of steel, so it will be cheaper and much lighter in weight, but may be vulnerable to corrosion. As an option, boiler heat exchangers are sometimes made of non-ferrous metals, this is more expensive, but they do not have rust.

Burners come in two varieties: flare and retort type. Retort ones get dirty quickly, so flare ones are more often chosen, but retort ones have a higher efficiency.