- The cost of boilers of different types

- Prices for diesel boilers

- Prices for gas units

- Boilers from Wirbel - versatility and ease of installation

- Instructions for use and setup

- Advantages and disadvantages

- "Obshchemash" pellet boilers: prices and specifications

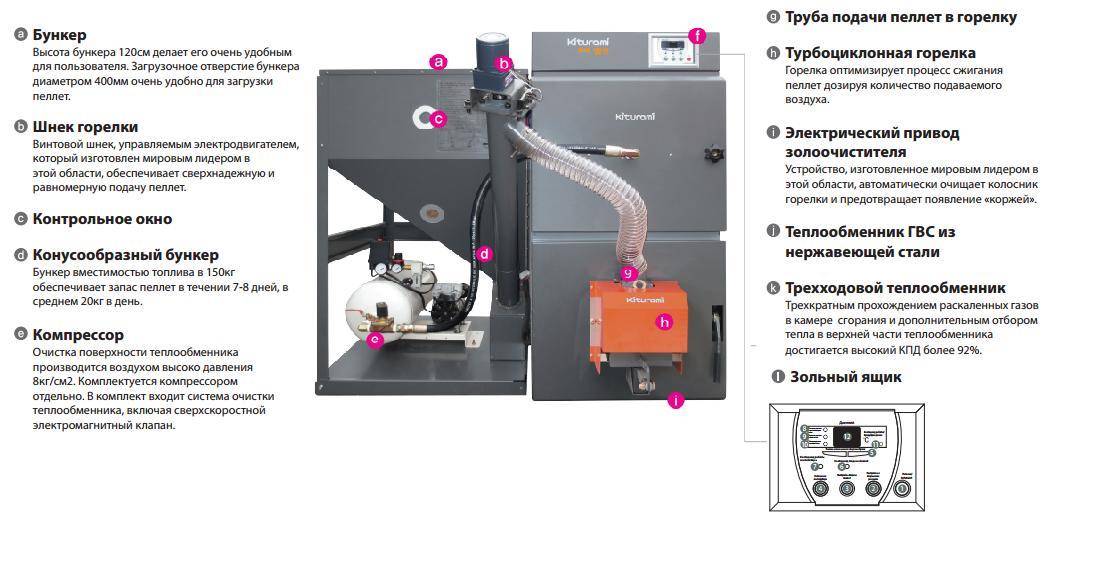

- Features of Kiturami boilers

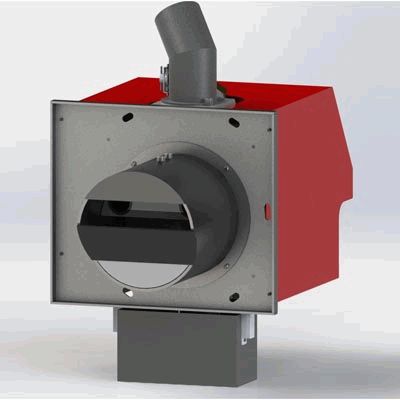

- Pellet burner Kiturami KRPB 20A (10-30 kW)

- Advantages of pellet boilers

- As a small conclusion

- Video - Kiturami Turbo-30R

- Pellet burner KRP-20A KITURAMI

- Long burning pellet boilers

- Boilers are also divided according to the type of combustion chamber:

- Boilers with an open combustion chamber

- Boilers with a closed combustion chamber

- Series of gas and models related to them

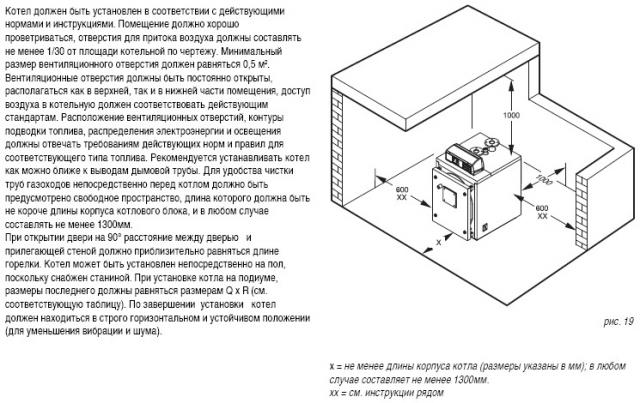

- How to install

- Main steps

- Common Mistakes

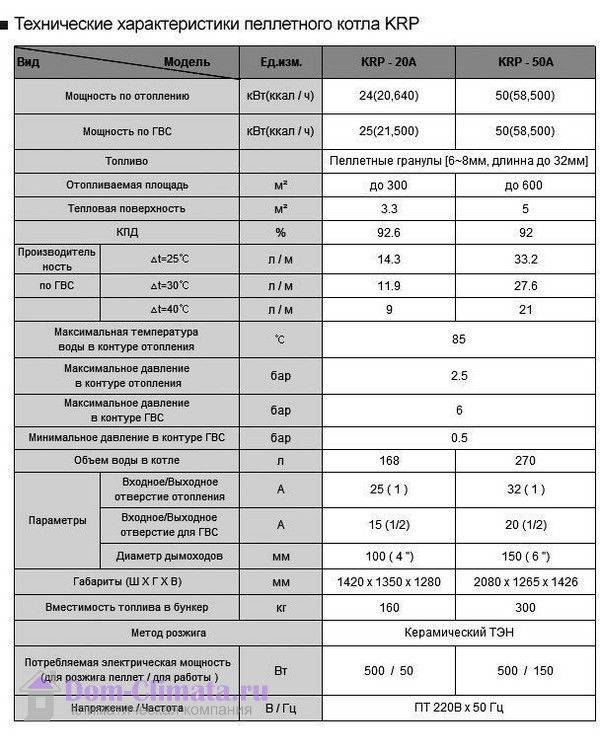

The cost of boilers of different types

A big plus of the manufacturer "Kiturami" is that all the necessary elements are included in the delivery. Other companies often sell parts such as a thermostat, control unit separately, which increases the cost of the complete product.

The cost of solid fuel models (in rubles):

- KF-35A - 127 199;

- KRP 20A - 270 799;

- KRP 50A - 318 499.

Dual-fuel heat generators are also represented by 3 devices.

Prices for them (in rubles):

- KRM-30 - 137,999;

- KRM-70 - 218 599;

- KRH-35A - 168 099.

Prices for diesel boilers

The cost of production directly depends on the power of the device and its efficiency.The higher these figures, the more expensive the purchase of the unit. Other parameters affect pricing indirectly.

Other factors:

- the area of the heated room;

- fuel consumption;

- materials used;

- DHW performance;

- security level: the presence of sensors and safety devices.

The comparative cost of liquid fuel units is shown in the table.

Prices for gas units

Kiturami Eco Condensing condensing units are available in 3 sizes.

Rates (in rubles):

- 16r - 52 360;

- 20r - 57,800;

- 25r - 59 440.

The TGB line includes one model: 30R. You can buy it for 61,613 rubles.

The cost of traditional gas appliances is presented in the table.

Boilers from Wirbel - versatility and ease of installation

Wirbel is based in Austria and manufactures automatic pellet boilers. The products of this manufacturer are of high quality and ease of installation. Wirbel EKO-CK PELLET-SET ovens are versatile and include an integrated pellet burner.

Raw materials are fed into the furnace of Wirbel pellet boilers automatically, so it can work continuously as long as there is a need for space heating

The body of such a unit is made of heat-resistant steel, the thickness of which is 5 mm. The pellet tank can be installed on either side of the boiler. The standard equipment of the furnace provides for the following functions: automatic ignition, supply of pellets to the furnace section. However, if necessary, the unit can also operate in manual mode.

The operation of a solid fuel heating device is controlled through a special remote control.Cleaning of Wirbel EKO-CK PELLET-SET models is a necessary event and is carried out at least once a week.

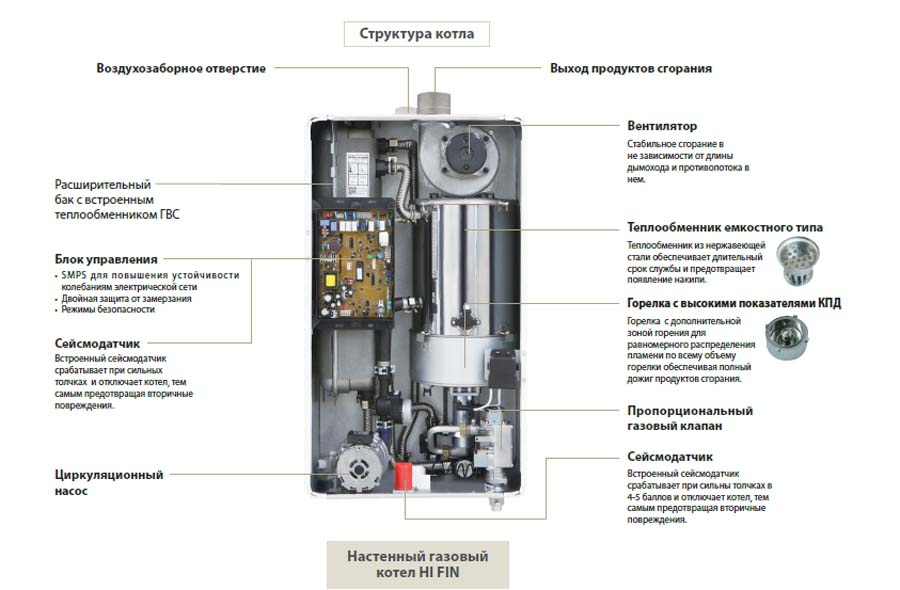

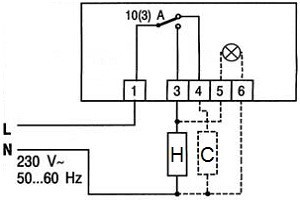

Instructions for use and setup

After delivery and installation of the boiler, all communications are connected:

- Gas.

- Direct and return lines of the heating circuit.

- Water.

After connecting the communications, it is necessary to check the tightness of the connections, paying special attention to the gas pipeline. The quality of attachment is tested with a soapy solution.

Then the system is filled with water, for which it is necessary to turn counterclockwise the filling valve located below, where all the connecting pipes are located. All distribution valves must be open, and the gas valve must be closed.

Filling is completed when the display shows a pressure value in the range of 0.5-1.0 kgf/cm. After that, the gas valve is opened.

The boiler starts up automatically after setting the operating temperature of the coolant.

Boilers Kiturami Twin Alpha have several operating modes:

- Presence. The operating mode of space heating, the comfortable temperature set by the user is maintained.

- Absence. The minimum temperature is maintained to protect the system from freezing during the absence of the owners.

- Timer. Allows you to set the operating time until the next preset mode is activated.

- Shower. The hot water supply is activated in priority mode.

Installation and configuration of these modes and the time of their action is made on the control panel.

Primary general settings are also made there, correcting the factory values for more efficient and economical operation of the boiler.

The boiler settings at the first start-up should be carried out only by specialists from the service center.

Advantages and disadvantages

All products of this manufacturer are a guarantee of high quality, the design is made in accordance with the trends of the times, maximum functionality and an affordable price range. The most popular models include STS boilers, because thanks to their power, it is possible to provide heating for a room of almost two hundred square meters.

As a fuel, it is possible to use not only kerosene, but also a light oil product. In case of changing the burner, it is possible to switch to natural gas.

Another advantage of this model is the presence of safety sensors in the equipment, which allow monitoring all the most important processes. During their creation, the latest technology for the removal of residual combustion elements was used.

The Turbo series consists of floor-mounted diesel heating boilers that can not only supply heat to the room, but also guarantee hot water for current domestic needs. Here you do not need to purchase additional equipment, since this equipment is a boiler type model.

An important advantage is the highest degree of protection, which became possible due to the use of:

- sensors;

- built-in thermostat;

- control panel;

- forced exhaust gas system.

An important factor in the entire product line of this manufacturer is the ability to work in any conditions, which is very important for Russian users. It is not difficult to purchase spare parts for the equipment of this company, since the manufacturer has a decent number of dealer companies.

The boilers of this South Korean company have a number of advantages in comparison with similar models of other manufacturers. They are among the most economical in terms of diesel fuel consumption. At the same time, the average level of productivity of this equipment is two dozen liters of hot water every minute.

The most significant advantage of this equipment for the consumer is an acceptable cost. It is possible to purchase a boiler from a company from South Korea in the price range from 20 to 29 thousand rubles.

However, it is necessary to keep in mind the "weak" points of the equipment of this manufacturer:

- Significant heating costs. Installation of equipment running on diesel fuel will not cost very large financial costs. However, the price of heating, even taking into account the use of a light type of fuel, will be the highest of all existing options. For the most part, the cost of electric heating will be less.

- The boiler requires regular human control and supervision. Despite the fact that the heating system as a whole operates in automatic mode, it requires regular human presence. Of course, it can be left in working condition for at least half a day, but in no case should this be done for a week or a month. The reason is not very high-quality fuel, as a result of which the boiler will stop working from time to time. If this happens during the cold season, and the equipment is turned off for a whole week, then the water in the heating system will freeze and disable the pipes.

"Obshchemash" pellet boilers: prices and specifications

The manufacturer of boiler equipment Obschemash is located in Russia and today produces two main lines of pellet stoves: Valdai and Peresvet. Both of these lines are distinguished by a high level of automation and an acceptable cost.

Consider the main functions that are built into this equipment:

- auto ignition;

- automatic delivery of granulated fuel;

- self-cleaning;

- controller.

If necessary, the operation of the Valdai furnace can be controlled via GSM. Boiler equipment "Peresvet" have several differences from "Valdai", including:

the ability to control via the Internet;

Pellet boilers Valdai are equipped with a fire-tube multi-pass heat exchanger, a cast-iron collapsible burner and auto-ignition

- more voluminous bunker;

- work not only on pellets, but also on other types of fuel (for example, firewood).

The prices of pellet stoves from the Obschemash company start at 150,000 rubles. At the same time, as a rule, Valdai devices cost about 10,000 rubles more than Peresvet.

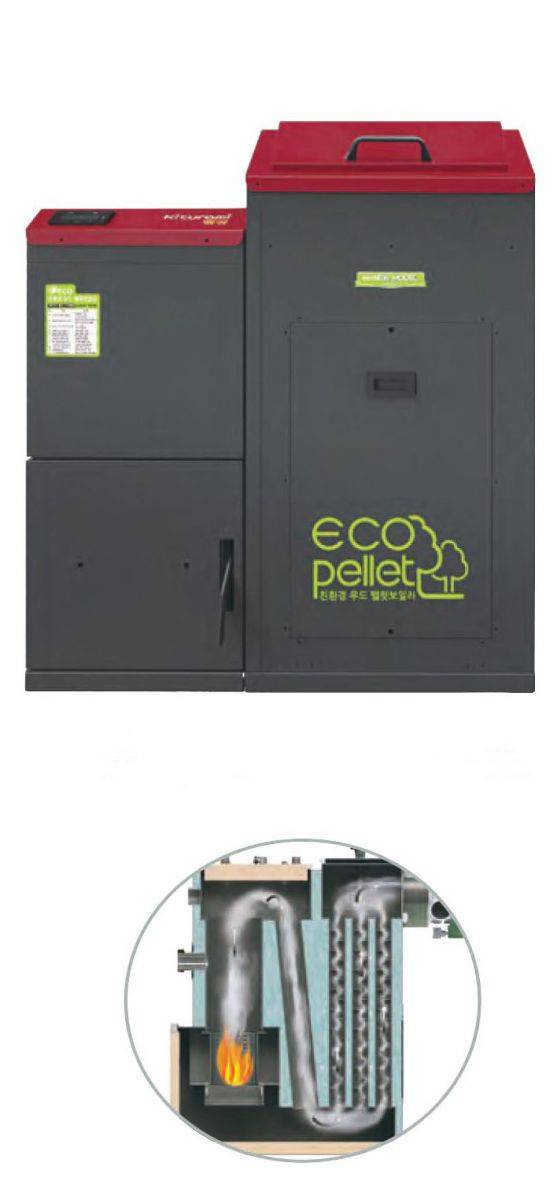

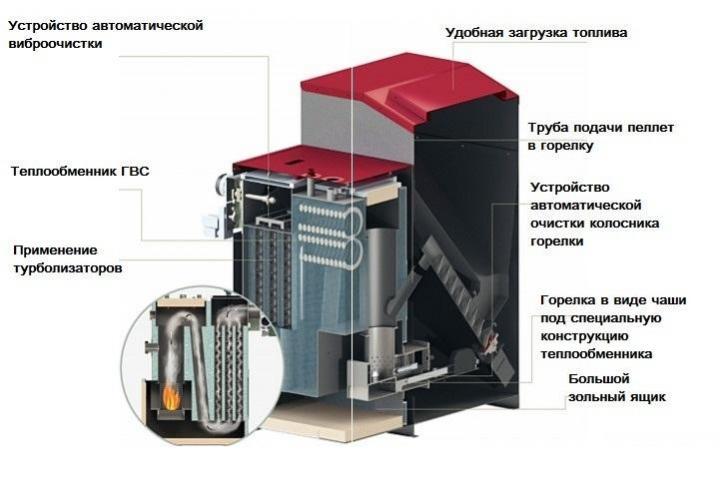

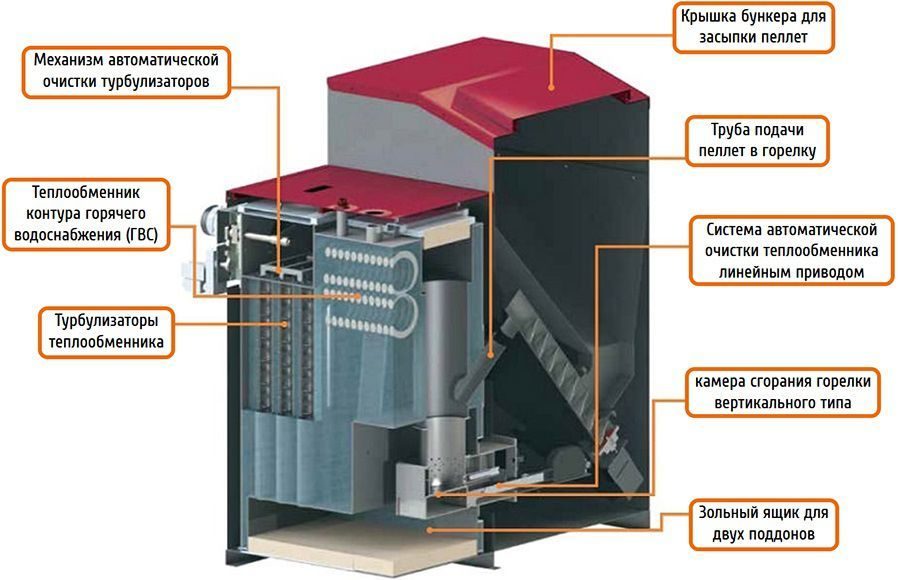

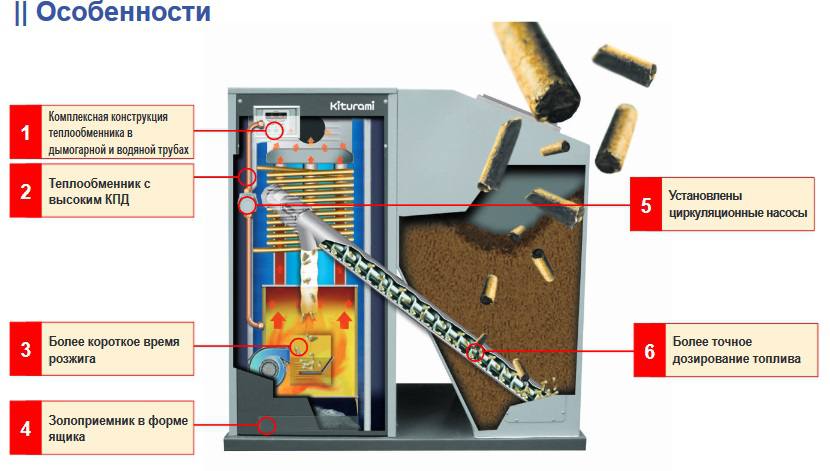

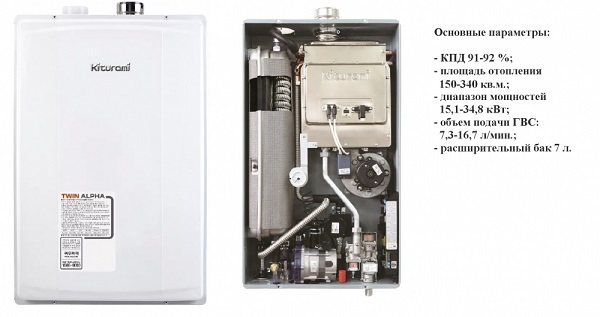

Features of Kiturami boilers

Kiturami is a South Korean company with more than half a century of experience in the design and manufacture of heating boilers and related equipment.

During this time, the company has become one of the leaders in the domestic Korean market, and has also found an extensive market in North America and nearby Asian countries. In our country, Kiturami boilers have been officially distributed for at least ten years and have already shown themselves on the good side.

The main emphasis in the promotion of boilers is on the introduction of innovative technologies and, in particular, their own developments, which have no analogues from other manufacturers or determine the narrow specifics of the equipment.

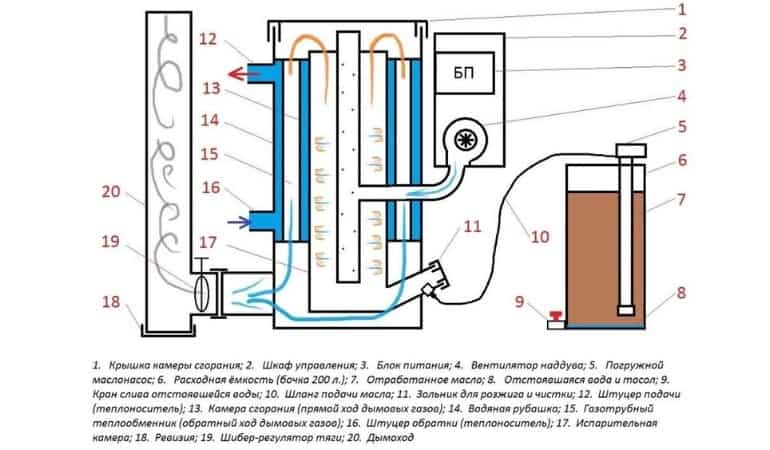

Diesel boilers, by definition, are not considered as the main model range for a wide range of applications. In terms of economic feasibility, they are inferior to gas, electric and even solid-state boilers. However, they are still in demand among consumers in view of a number of reasons why liquid fuels are becoming preferable.

In remote areas of residence, where there is no stable connection to the power grid, there is no gasification, the issue of fuel availability becomes acute. At the same time, the heating of the house should, by definition, work smoothly throughout the season. If for many countries such situations are rather an exception to the rule, then for us, on the contrary, they are commonplace, the cause of which is the vast expanses separating settlements.

Diesel fuel, unlike gas, is easier to transport and store with minimal risks to life and the environment. Unlike solid fuel boilers, when burned, diesel fuel provides uniform heating and a greater degree of control over the waste of resources. And finally, the design of the diesel boiler and in particular the burner does not limit the use of other heat sources.

With minimal changes, the diesel burner can be changed to use blue fuel, and boilers equipped with an extensive combustion chamber and grate can quickly switch to using coal, wood or pellets.

Diesel boilers Kiturami are highly technological and are a perfectly balanced equipment for the use of diesel fuel as a heat source, and at the same time they are excellent for the above types of conversion to work on gas or solid fuel.So constructive and functional flexibility is the first significant advantage.

Kiturami boilers often use their own designs and unique layouts. On the one hand, this reduces the maintainability of heating equipment, but on the other hand, it ensures the highest efficiency of the boiler and balanced operation while observing simple and transparent operating rules.

This is the second significant reason to turn your attention to diesel boilers from South Korea.

The last advantage is the cost of boiler equipment. Even taking into account the high performance and proven quality of the boilers, their cost does not exceed the average on the market among similar offers.

So it turns out that Kiturami boilers have three features: a balanced design, high efficiency and an affordable price.

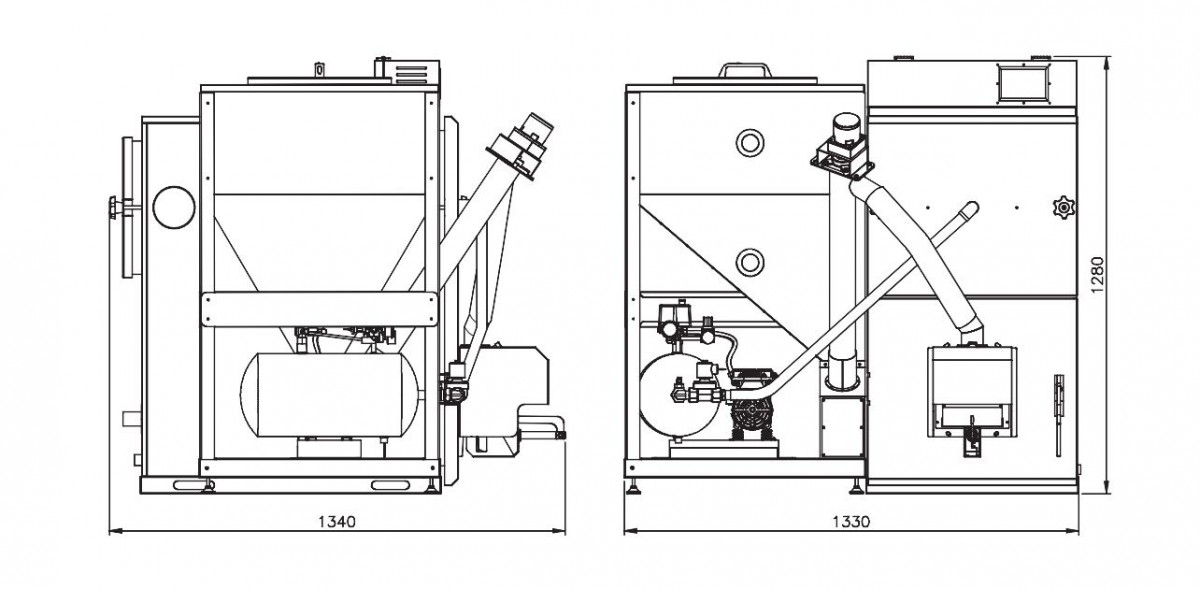

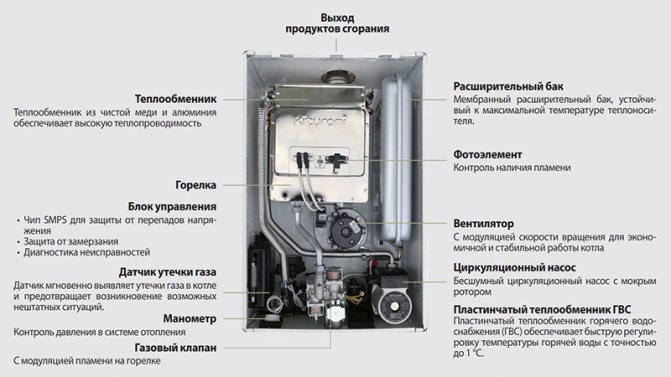

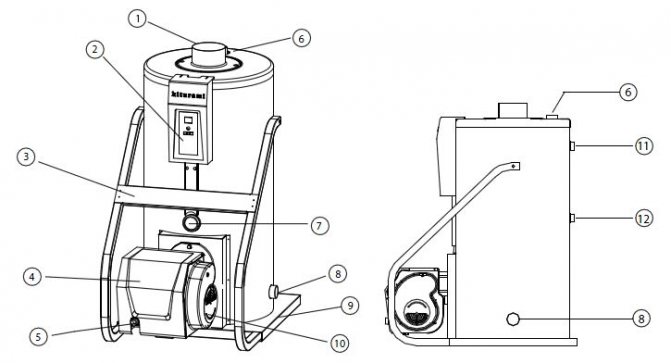

Kiturami boiler device

Pellet burner Kiturami KRPB 20A (10-30 kW)

Price: 99 500 rub.

In Moscow and the Moscow region - 1 - 2 days from the date of order.

When sending to the regions of Russia - the transfer of cargo to a transport company in 1-2 days from the date of payment for the order.

Delivery is carried out on weekdays from 10.00 to 19.00, Sat. – from 10:00 to 16:00.

Delivery to the terminal of the transport company - 1000 rubles.

Delivery in Moscow within the Moscow Ring Road: from 500 rubles.

Outside the Moscow Ring Road: from 500 rubles. + 50 rubles/km

Payment for the ordered goods is made to the forwarder upon delivery to the destination or by bank transfer.

to complete your facility!

Characteristics and features of the pellet burner Kiturami KRPB-20A:

Built-in automatic cleaning by Linak linear drive (Denmark). Such a system allows the use of pellets of any quality and ash content without the risk of rooting.Due to automatic cleaning, the Kiturami KRPB-20A burner works stably on low-quality or high-ash pellets. It does not allow the appearance of cakes, sintering of pellet particles, the appearance of soot, soot and resin. The grate cleaning interval can be set independently (from 1 to 10 hours) depending on the quality of the pellets.

On all KRPB-20A burners it will be possible to control the combustion of firewood simply by switching to the "Firewood" mode. In this case, nothing additionally needs to be removed or installed, the burner remains on the boiler door.

One press of a button and the boiler becomes a solid fuel wood-fired boiler with combustion control. The boiler will automatically turn on/off the fan, constantly maintaining the set temperature on the remote control.

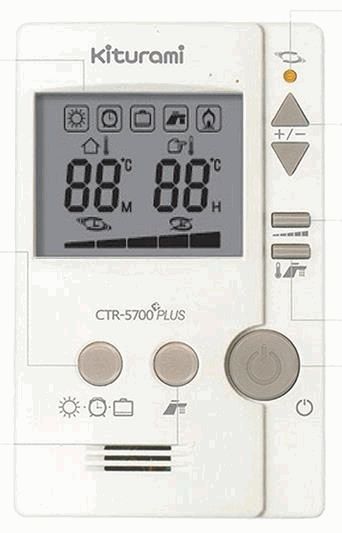

Remote room thermostat

For ease of control, the burner is supplied with a remote room thermostat. With the help of it, the water temperature and the air temperature in the room are controlled, all the parameters of the boiler operation are reflected on this remote control.

For ease of control, the burner is supplied with a remote room thermostat. With the help of it, the water temperature and the air temperature in the room are controlled, all the parameters of the boiler operation are reflected on this remote control.

Automatic fire safety solenoid valve To protect the burner from fire (in the event of a back draft), it is provided to turn off the supply of pellets to the burner. A special valve has been added to ensure maximum safety. It works in tandem with the burner temperature sensor, which reacts to heating above 95 °C. The burner grate will be flooded with water if there is little possible reverse draft through the burner. The damage from fire is so great that the presence of this valve is a huge plus of this burner, which ensures complete fire safety.

Integrity and compactness In the KRPB-20A burner, all power units and control units are mounted in a single housing. No extra wires, no extra connections, everything is convenient and compact.

Universal installation of the burner The burner can be easily mounted in any suitable solid fuel boiler in terms of power. Most solid fuel boilers are suitable for the installation scheme.

The presence of a water overheating sensor in the boiler, a water temperature sensor in the boiler, a low level sensor, a burner temperature sensor, a set of protective devices against backfire makes the KRPB-20A pellet burner reliable and safe.

This burner has automatic pellet ignition control using a flame control sensor (photocell). For automatic ignition of pellets, a ceramic heating element made in Japan by FKK is installed in the burner, which ignites the pellets within 1 minute.

Added a 220 V connector for connecting a smoke exhauster. This saves on expensive chimneys for boilers. It is very important for modular or free-standing boiler rooms.

– Pellet burner Kiturami with power units and automatic machines built into the burner body

– System for automatic cleaning of the burner grate with a linear drive (Linak, Denmark)

– Fire safety kit (solenoid valve, fire cock, burner overheating sensor)

– Remote controller-thermostat CTR-5700 Plus

– Pellet overflow control microswitch

– Corrugated hose for pellet supply + 2 clamps

– Sensor of low level and coolant temperature

– Small ash tray

Specifications of the KRPB-20A burner:

Advantages of pellet boilers

Kiturami pellet boilers use granular fuel for their work.It is made from sawdust, sunflower husks and other combustible waste. Being pressed under high pressure, it has a good calorific value. Separately, its ability to burn almost completely, without the formation of a large amount of ash, is noted.

Let's see what else pellet boilers are good for, including those from Kiturami:

- Automatic operation - the equipment is able to independently regulate the temperature in the heating circuit, focusing on the specified indicators;

- Automatic loading of fuel - users do not have to mess with firewood, it is enough to pour a solid portion of fuel from bags into the bunker;

- No need for frequent cleaning - pellets burn out almost completely, the amount of ash formed here is minimal;

- Normal security systems - if a conventional boiler can overheat, then the pellet machines turn off when overheated, saving themselves from damage.

True, there are certain disadvantages that are characteristic of all pellet boilers - and Kiturami products are not spared from them:

By installing a Kiturami pellet boiler, you will forget about the tedious fuss with firewood - you just need to pour new portions of fuel into the bunker in time.

- Pellets are more expensive than ordinary firewood - due to this, operating costs are higher;

- To store pellets, you need a place - exactly like with firewood, for which you need a woodpile. But if firewood can still be stored outside, sheltering it from direct precipitation, then pellets need dry storage. In addition, they occupy a large volume;

- High cost - when purchasing a Kiturami pellet boiler, you spend a lot of money. For example, the price for the KRP 20A model on the manufacturer's official website is 225,300 rubles.

Thus, the convenience of automation translates into some disadvantages.

The main advantage of Kiturami pellet boilers is high efficiency - its figure is 96-96%, which is difficult to achieve for traditional solid fuel units.

As a small conclusion

When analyzing some models, we found a lot of advantages for boilers of this brand over their competitors, although even here they could not do without drawbacks.

This applies in particular to liquid fuel (diesel) appliances. Each boiler that consumes diesel fuel is necessarily equipped with a special fuel tank, which in most cases has a very significant volume - from 2,000 to 5,000 liters. Boilers are equipped with such tanks, but in the absence of the latter, you will also have to fork out for the purchase of a “tank for diesel fuel”.

To install such a boiler, it is necessary to have a room with excellent ventilation, so that the user does not accidentally get poisoned by fuel combustion waste. In some cases, heat generators even smoke, which is why they need special care. Finally, one should not forget about the cost of diesel heating appliances - it is often higher than that of appliances using other types of fuel (even though Kiturami boilers are cheaper).

Despite all the strengths and weaknesses of such boilers, modern technologies make it possible to significantly increase the safety in the operation of space heating devices. And we all know that safety should come first. Moreover, this equipment can work autonomously, maintain the required temperature for a long time, even if there are no people nearby.

Video - Kiturami Turbo-30R

Assortment of Kiturami

All heating boilers from this Korean manufacturer are divided into three categories, each of which has its own characteristics, strengths and weaknesses. It:

- diesel;

- solid fuel;

- gas heaters.

Let's get acquainted with each of the types.

- Diesel devices, as the name suggests, operate on diesel fuel, which increases the efficiency of heating. The model range of such boilers will be discussed in more detail in the next paragraph.

- Solid fuel appliances are an alternative to the previous option, since they are quite capable of operating on both diesel and solid fuel, which is especially important in conditions of an unstable supply of energy resources. These boilers are made in such a way that after solid fuel is used, they begin to burn diesel itself. All diesel devices are combined into one model range - KRM. There is an automatic control, it is possible to use for domestic hot water purposes.

- Gas appliances use natural gas, which is why they are now very popular. They are floor or wall, for one or two circuits. They are quite convenient to operate, and the savings in their use are obvious.

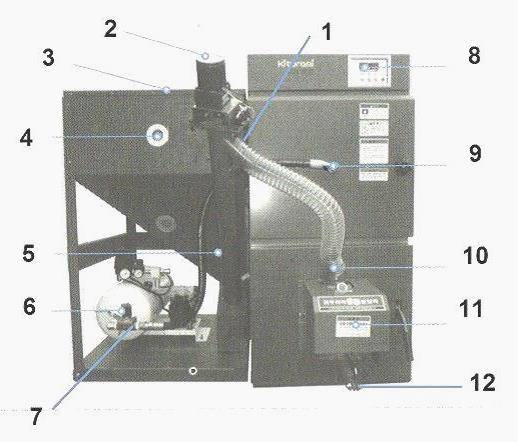

Pellet burner KRP-20A KITURAMI

The burner is the part of the boiler in which the complete combustion of fuel takes place.

- Description

- Specifications

- dimensions

- Presentation

- Manual

The burner is the part of the boiler in which the complete combustion of fuel takes place.

- Pellet burner Kiturami with power units and automatic machines built into the burner body

- System for automatic cleaning of the burner grate with a linear drive (Linak, Denmark)

- Fire safety kit (Solenoid valve, fire cock, burner overheating sensor)

- Remote controller-thermostat CTR-5700 Plus

- Axial auger

- Pellet overflow control microswitch

- Corrugated hose for pellet supply + 2 clamps

- Low level and coolant temperature sensor

- Small ash tray

- thermal pads

Features of the KRPB-20A KITURAMI pellet burner

Built-in automatic cleaning with Linak linear drive (Denmark)

Such a system allows the use of pellets of any quality and ash content without the risk of rooting. Due to automatic cleaning, the Kiturami KRPB-20A burner works stably on low-quality or high-ash pellets. It does not allow the appearance of cakes, sintering of pellet particles, the appearance of soot, soot and resin. The grate cleaning interval can be set independently (from 1 to 10 hours) depending on the quality of the pellets.

On all KRPB-20A burners it will be possible to control the combustion of firewood simply by switching to the "Firewood" mode. In this case, nothing additionally needs to be removed or installed, the burner remains on the boiler door. One press of a button and the boiler becomes a solid fuel wood-fired boiler with combustion control. The boiler will automatically turn the fan on and off, constantly maintaining the set temperature for remote control.

Remote room thermostat

For ease of control, the burner is supplied with a remote room thermostat. With the help of it, the water temperature and the air temperature in the room are controlled, all the parameters of the boiler operation are reflected on this remote control.

Automatic fire safety solenoid valve

To protect the burner from fire (in the event of a back draft), it is provided to turn off the supply of pellets to the burner. A special valve has been added to ensure maximum safety. It works in tandem with the burner temperature sensor, which reacts to heating above 95 °C. The burner grate will be flooded with water if there is little possible reverse draft through the burner. The damage from the fire is so great that the presence of this valve is a huge plus of this burner, which ensures complete fire safety.

Integrity and compactness

In the KRPB-20A burner, all power units and control units are mounted in a single housing. No extra wires, no extra connections, everything is convenient and compact

Universal burner mounting

You can easily mount the burner in any suitable solid fuel boiler in terms of power. Most solid fuel boilers are suitable for the installation scheme.

The presence of a water overheating sensor in the boiler, a water temperature sensor in the boiler, a low level sensor, a burner temperature sensor, a set of protective devices against backfire makes the KRPB-20A pellet burner reliable and safe. This burner has automatic pellet ignition control using a flame control sensor (photocell). For automatic ignition of pellets, a ceramic heating element made in Japan by FKK is installed in the burner, which ignites the pellets within 1 minute.

Added a 220 V connector for connecting a smoke exhauster. This saves on expensive chimneys for boilers. Very relevant for modular or freestanding boiler rooms

Long burning pellet boilers

As a fuel, pellets can also be used for long burning boilers – a new type of solid fuel boilers.Their peculiarity is that the combustion process is organized from top to bottom, and not from bottom to top, as in classical ones. Therefore, the combustion process is slow, and with a sufficiently large firebox, it can last several days. Such boilers have a somewhat limited ability to automate work, but the time of active work is calculated in days without human intervention. The loaded fuel burned out like a candle, the ash is unloaded, new fuel is loaded, the process is repeated.

Loading …

Boilers are also divided according to the type of combustion chamber:

Boilers with an open combustion chamber

They are used in houses where a chimney is provided. Combustion air is taken from the room where the boiler is installed, and all combustion products evaporate through the installed chimney. Therefore, it should be noted that such boilers are not suitable for apartments.

Boilers with a closed combustion chamber

In apartments and houses where there is no chimney, boilers with a closed combustion chamber are used. These boilers have a special exhaust fan that removes all processed gases from the furnace. The advantage of such boilers is that they do not consume oxygen in the room and do not require additional air supply.

Series of gas and models related to them

Among the Kiturami floor boilers there are the following series:

- KSG. Powerful heating installations developing from 50 to 200 kW. Designed only for heating, but can be connected to an external storage boiler, which makes them capable of providing the house with hot water. Able to heat large areas, if necessary, can be connected in a cascade of up to 4 units.

- STSG. 4 models of relatively low power (from 16 to 58 kW) designed for heating small and medium-sized private houses.All models are double-circuit, equipped with a separate heat exchanger, with a closed combustion chamber.

Series of wall-mounted boilers Kiturami:

- WORLD PLUS. The series is represented by 5 models with a capacity of 15, 16, 20, 29, 34.9 kW. All models are double-circuit, designed for heating and supplying hot water to rooms up to 350 m2. The series is manufactured specifically for use in Russia, adapted to technological and climatic conditions.

- TWIN ALPHA. 5 models with a capacity of 15-35 kW. Double-circuit boilers with a separate heat exchanger.

- TWIN ALPHA NEW COAXIAL. A slightly improved TWIN ALPHA series, which includes models with the same parameters. Designed for the use of a European type coaxial chimney (horizontal),

There is also the Kiturami Eco series made up of condensing boilers.

How to install

You can try to install a pellet boiler at home with your own hands with special knowledge or using the Internet, where step-by-step instructions are provided. However, it is better to entrust the solution of such an issue to professionals from a specialized organization that has a construction license, who will reliably mount the unit during repair or construction.

Main steps

1. Preparatory:

- preparation of the premises;

- strengthening and leveling a fireproof base that can withstand the unit;

- electrical wiring;

- installation of ventilation and chimney.

2. Installation and strapping:

- installation on a hill, connection to the chimney of the gas-air path;

- installation of the bunker, connection of the auger;

- control panel assembly;

- piping of the circulation pump;

- installation of an expansion tank;

- installation of automation for return control;

- backup power supply wiring, installation of a stabilizer;

- connection of the coolant and return circuit.

3. Commissioning activities:

- project compliance control;

- tightness check;

- automation check;

- crimping;

- control start and measurement of parameters;

- adjustment work.

4. First run:

- filling the container with pellets;

- checking water pressure, make-up to the standard if necessary;

- opening the smoke damper;

- ignition - remote control or manually;

- checking the compliance of the parameters with the project;

- stop after burnout;

- temperature control of the heat carrier to prevent the formation of condensate.

Common Mistakes

- No return temperature control.

- Unsatisfactory tightness of the gas circuit, reduced efficiency due to leakage of pyrolysis gas;

- Poor thermal insulation of the base, causing condensation and the release of harmful substances.

- Non-compliance of the dimensions of the boiler room with fire safety requirements, which does not allow servicing the bunker or auger.

Pellet boilers are characterized by efficiency, ease of operation, as well as long battery life. But it is possible to achieve optimal parameters only in case of the correct choice of equipment, installation and commissioning.

Enjoy the shopping! Take care of yourself and your loved ones!