- Pros and cons

- Selection Tips

- Pellet consumption for home heating 200m2

- Device advantages

- Environmental friendliness

- Efficiency

- Convenience

- Pellet burners

- How to choose

- Characteristics of gas heaters

- Ecology and health

- Advantages of pellet boilers:

- Cons of pellet boilers:

- TOP of the best models of double-circuit boilers

- ZOTA MAXIMA 300, two augers

- Double-circuit pellet boiler Dragon plus GV - 30

- Jaspi Biotriplex

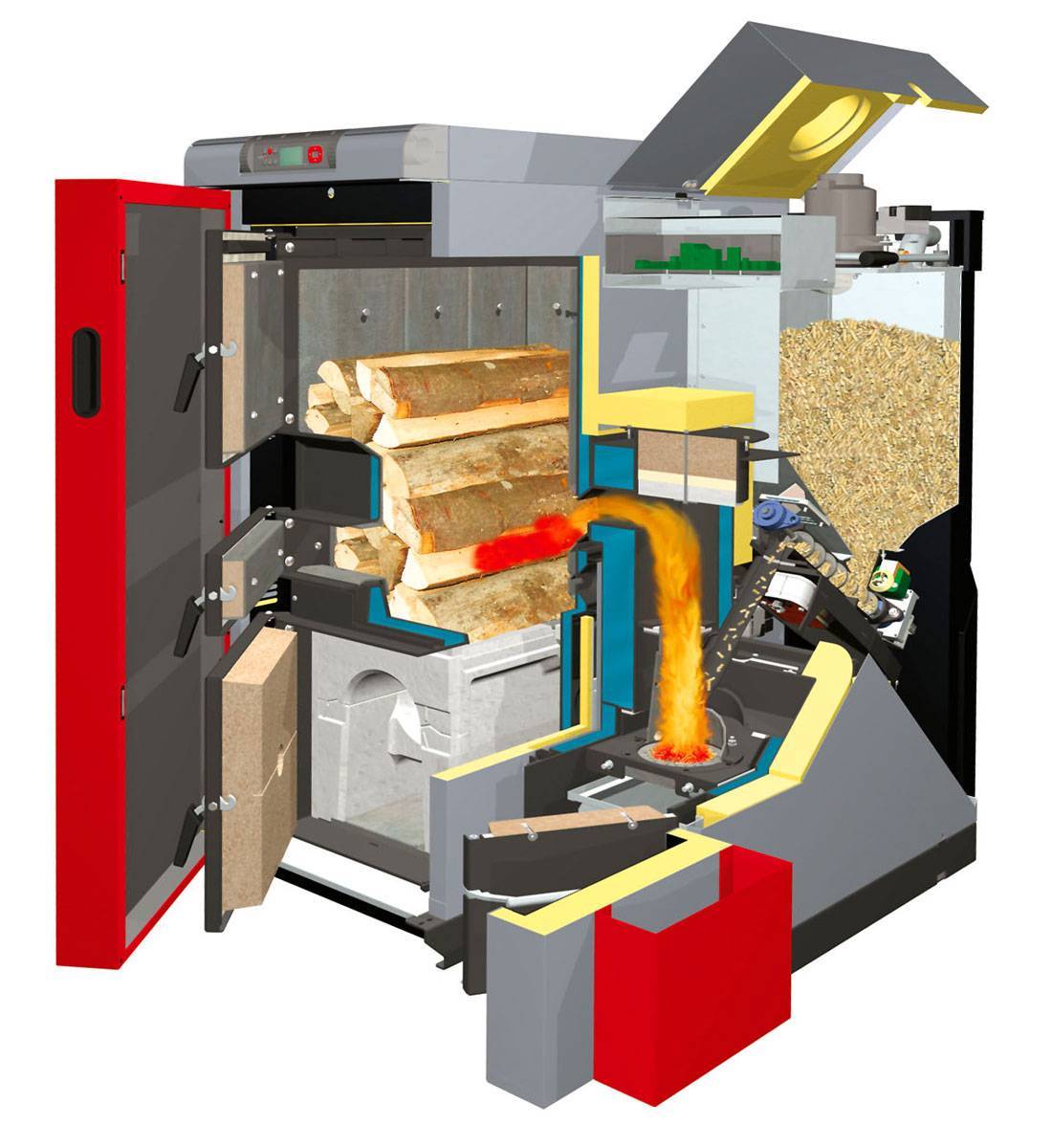

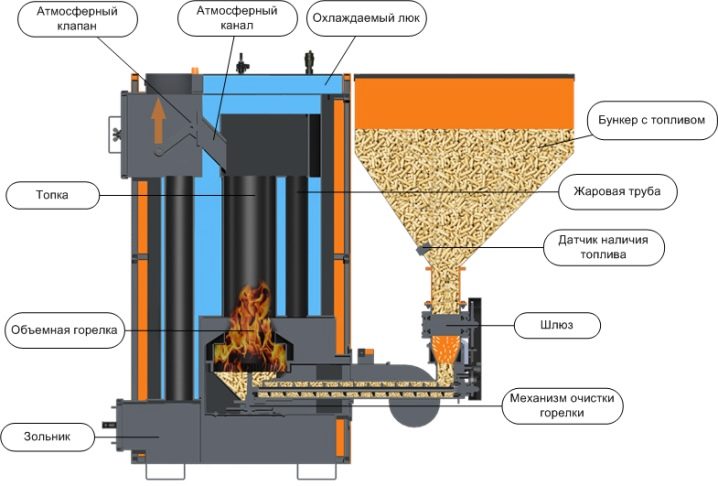

- Device

- How to remove ash from the boiler?

- How to choose the right pellet boiler

- Type of heat exchanger

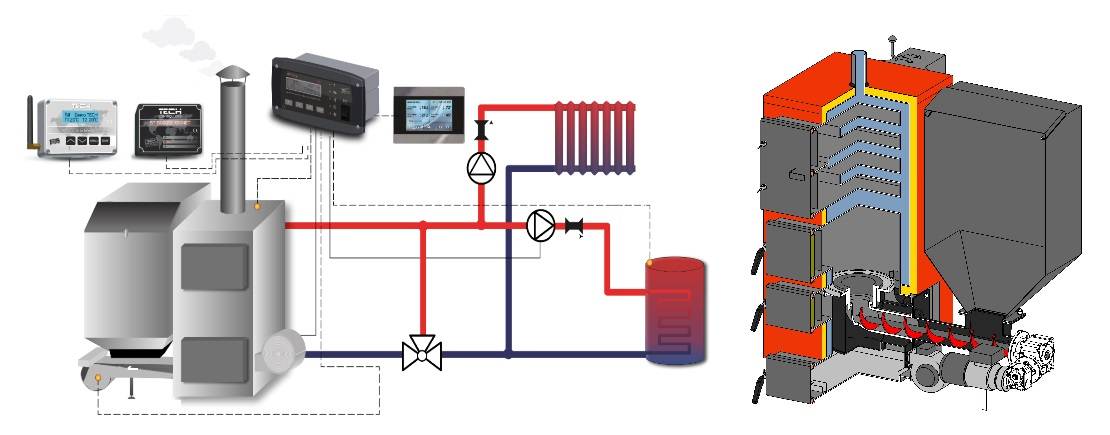

- Work automation

- Fuel supply

- Burner type

- Rating of the best wall-mounted gas boilers - the most purchased models

- Baxi LUNA-3 COMFORT 240 Fi with remote control

- Navien DELUXE 24K - cheaper in cost, but not inferior in function

- Protherm Cheetah 23 MOV for connecting a warm floor

- BOSCHGAZ 4000 WZWA 24-2 A - nothing special

- Condensing boiler VAILLANT ecoTEC PLUS VUW INT IV 246

Pros and cons

It should be noted that solid fuel pellet boilers will be much more convenient than wood-fired solutions.

If we talk about the advantages of pellet boilers, then we should name:

- Simple service. If possible, then you can service the boiler yourself.

- Environmental friendliness. Such boilers do not make harmful emissions into nature at all.

- Automatic type work.Such heating solutions with small bunkers require a couple of approaches per day. Where there are more bunkers, you can not approach them for a week or more, which will be very convenient. There are even models that can work according to predetermined characteristics.

- Almost zero formation of ash, as well as soot - pellets burn out almost completely, because of it it is necessary to clean such a boiler less often than if you use wood. In addition, low-ash pellets that burn 100 percent are quite easy to pick up on sale.

- Safety. Pellet boilers do not run on combustible liquid fuels, gas or electricity.

- Fuel is easy to load. Any granule weighs a couple of grams and this fuel belongs to the category of bulk. Usually, pellets are poured into bunker tanks directly from the bags or with the help of a spatula. And boilers generally take such fuel on their own.

- High efficiency. These models have an efficiency of up to 94-96 percent, while conventional solid fuel boilers cannot boast of rates above eighty-eighty-five percent.

- Inexpensive heat. Pellet type boilers can be an extremely profitable solution. But here everything will depend on operating conditions. When compared to wood, electric or liquid solutions, they are quite an economical option.

At the same time, one cannot fail to name several shortcomings of these boilers. Firstly, pellet boilers require constant ash removal. Of course, this minus is easily leveled, because ash is considered a wonderful fertilizer for indoor flowers, plants in a garden plot or a vegetable garden.Secondly, pellets can fill with moisture, which will cause them to burn poorly. They must be stored exclusively in a dry place and in sealed storage bags. Thirdly, such equipment is very expensive. We are talking about automatic type fuel feed models.

In general, it should be noted that compact pellet boilers are a good solution for the home, as evidenced by the reviews of the owners of such devices. And a serious drawback of the above will be perhaps the price. But such a non-volatile step is worth taking.

Selection Tips

A few tips from experienced buyers and connoisseurs will help you make the right purchase and not regret it after some time of use:

- If you want to save on your purchase, then choose a non-volatile boiler with a simple circuit.

- If you want to save on fuel, then you should buy an expensive boiler with well-thought-out automation.

- It is better to choose a capacious bunker so that you do not often add fuel.

- Choose a model with high efficiency.

- The most convenient to use are models with autonomous operation and fuel supply. They themselves calculate the portions of pellets in accordance with the set temperature.

Pellet consumption for home heating 200m2

When changing the square of the house by 200 sq.m and the same calculated indicators:

- Heat loss per season (190 days): 200 x 190 x 24 x 0.7 x 70 = 44688 kW.

- The required weight of fuel pellets per season: 44688 / 4.3 = 10393 kW.

It should be noted that these indicators can vary significantly, including due to the different values of the room temperature indicator (comfort and economy modes).

The obvious advantages of this type of fuel include the following:

- no harm with proper storage;

- adequate, stable price in the commodity market;

- use of automated equipment.

Of the shortcomings, we note:

- the need for a large warehouse for storage in winter;

- with the onset of the warm season, it is necessary to control the humidity in the pellet warehouse;

- the price of such a fuel plant is much higher than when buying electric or gas boilers.

Device advantages

The advantages of pellet boilers are due to the qualities of the energy carrier processed by them. Solid fuel boilers are profitable in operation, they are not demanding on the quality of the heated water and the purity of the surrounding air.

Solid fuel makes equipment working with it:

- independent of centralized energy sources (including their availability);

- explosion-proof and flame-retardant;

- not requiring costs for connections or for a tank for liquid fuel.

Photo 3. Boiler on pellets with closed (left) and open firebox (right). The control panel is located at the top of the device.

The woody nature of the fuel endows pellet boilers with its positive features:

- environmental safety;

- the ability to use ash to deoxidize and enrich the soil;

- aesthetic value - the places of storage and use of firewood, pellets remain clean, only the smell of wood gives them away.

Environmental friendliness

The form of existence of raw materials (dense homogeneous granules), the technology of its production give pellet boilers new qualities that distinguish them favorably from heat generators using traditional fuels. Like lump wood, pellets are environmentally friendly and hypoallergenic (there are no binders, modifiers).

The flue gases of coal contain from 1 to 3% sulfur, the smoke from wood pellets - 0.1%. There is practically no carbon dioxide in the combustion products of pellets (only the amount that the plant absorbed during growth), which cannot be said about other types of fuel:

- hard coal - 60 kg / GJ;

- fuel oil - 78;

- gas - 57;

- peat-based biofuel - 70.

Efficiency

The calorific value of wood pellets is more than one and a half times higher than that of firewood and is commensurate with the specific heat of combustion of coal.

The efficiency of a pellet boiler is higher than a wood-burning one - 8.5-9.5. The temperature of the outgoing gases of the first is only 120-140 ° C, the rest of the heat has time to "assimilate" the gas ducts.

Convenience

The ash content of wood pellets (0.5-1% by weight) is lower than firewood, and 10-60 times less than coal. The ash content of straw and peat pellets is slightly higher: 4 and 20%, respectively. The ash pan of a 25 kW boiler is cleaned twice a month.

Attention! Ash removal starts only after the burner has cooled down. Granular and packaged material is convenient to transport, unload, store

The invariance of the given physical, mechanical and metric parameters of the fuel filling elements guarantees long-term burning at a constant temperature. Burning, pellets do not "shoot", do not spark

Granular and packaged material is convenient to transport, unload, store. The invariance of the given physical, mechanical and metric parameters of the fuel filling elements guarantees long-term burning at a constant temperature. When burning, the pellets do not “shoot”, they do not spark.

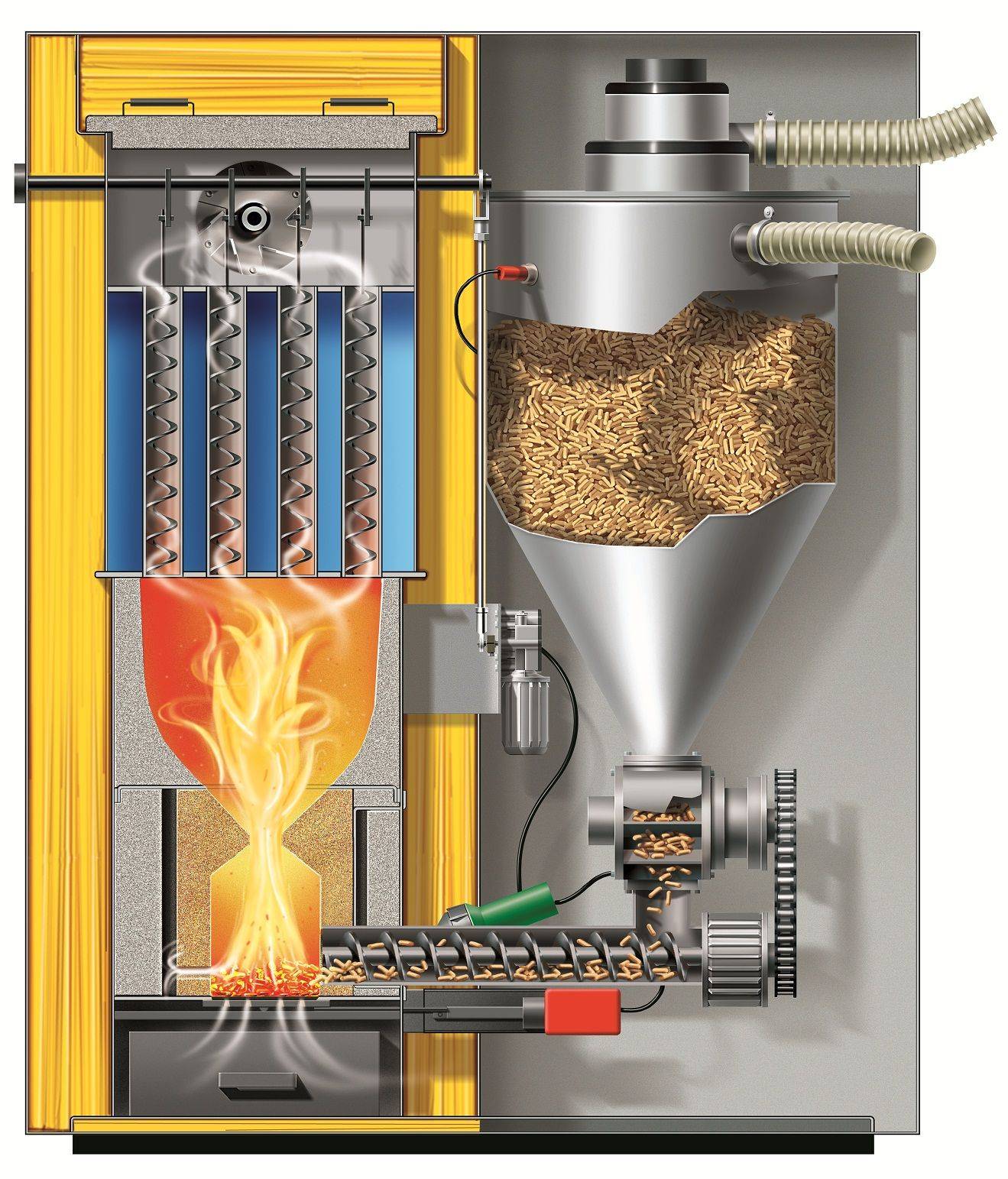

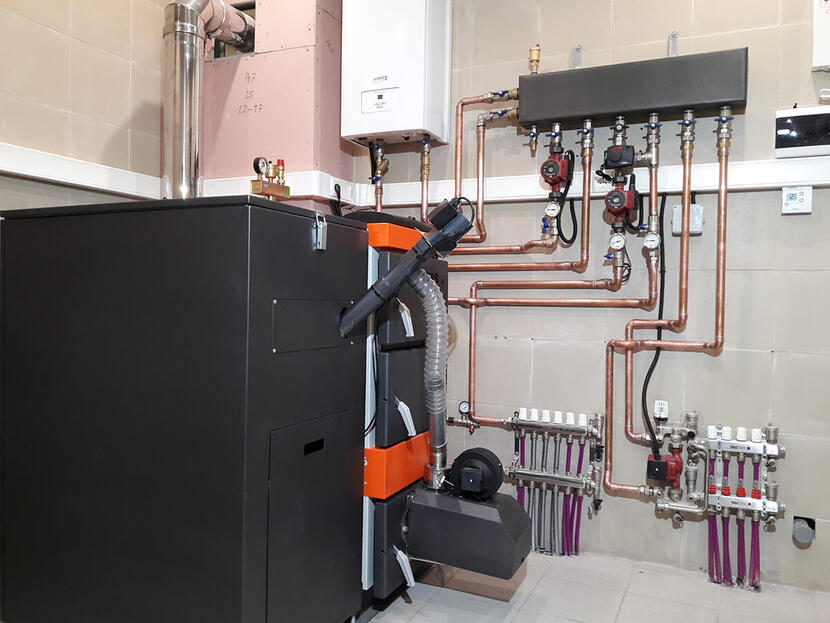

Pellet burners

Ordinary solid fuel boilers are not well suited for burning pellets, so they are converted by inserting a pellet burner.

The same alteration can be made with floor gas boilers, because the burner exits a flame with a small amount of smoke.

The burner includes:

- pellet hopper;

- feed system (most often screw);

- safety hose separating the hopper and auger feed from the burner;

- burner;

- lambda probe, which evaluates the amount of oxygen in the exhaust gases and determines the combustion mode of the pellets (not installed on all devices);

- Remote Control.

As a result, you will only:

- pour pellets into the bunker;

- remove ash;

- periodically clean the burner,

the burner automatics will do the rest.

Also, burners can be used in conjunction with brick ovens, including those equipped with coarse.

Here is the cost and a brief description of the most popular models of such burners:

| brand | Power, kWt | Description | Price thousand rubles | Website of the manufacturer or seller |

| Pelletron-15MA | 15 | Semi-automatic burner with small capacity hopper. The burner must be cleaned once a day. Ignition of fuel is made manually. The door for installation in the boiler must be purchased separately, choosing it according to the size of the boiler. | 18 | |

| РВ10/20 | 50 | Automatic burner for boilers such as Peresvet, Valdai, YaIK, Don and others, which have the same size of the furnace and door. Automatic ignition pellet. Automatic pneumatic cleaning, so without maintenance the burner can work for several weeks if there is enough fuel. Thanks to temperature sensors, the control unit automatically changes the operating mode of the burner. | 93 | |

| Terminator-15 | 15 | Automatic burner for burning any pellets. Thanks to the self-cleaning function, it can work without maintenance for 14 days.It is equipped with a GSM unit, so the burner operation mode can be controlled from a phone or tablet, as well as receive information about its operation mode. | 74 | |

| Pelltech PV 20b | 20 | Fully automatic burner with electric pellet ignition. Thanks to the self-cleaning function, it requires maintenance 2-3 times a month. Independently regulates the strength of the flame, providing the desired temperature of the coolant. In the event of a power outage, it switches to a backup battery. | 97 |

How to choose

When choosing pellet burners, it is necessary first of all to pay attention to the suitability of the boiler, because some burners are produced for specific models of boilers, for others you can purchase transitional doors that correspond to a particular boiler. The second important parameter is power, because the maximum efficiency of the burner is achieved only when operating at full power.

The second important parameter is power, because the maximum efficiency of the burner is achieved only when operating at full power.

After that, you need to define:

- pellet type;

- operating time from one download;

- time between services;

- bunker volume;

- cost limit.

Most automatic burners work well on all pellets, but units that do not have a self-cleaning function are only suitable for use if white hardwood granular sawdust is used.

The average fuel consumption in most burners is 200–250 grams per 1 kW of boiler power per hour. From this formula, the required volume of the bunker is determined.

Burners without self-cleaning are inexpensive, but they have to be cleaned every day, so they are seriously inferior to automatic ones.

Therefore, you have to choose: either take an inexpensive burner that needs to be cleaned every day, or an expensive one that requires maintenance only once every 2 weeks.

Characteristics of gas heaters

The main fuel of the units is a natural mixture of gases based on methane obtained from main pipelines. When it is required to organize autonomous gas heating, it is possible to switch to a propane-butane liquefied mixture supplied from a gas tank or a ramp with cylinders.

According to the installation method, the units are wall-mounted and floor-standing, and the latter usually do not need electricity. Mounted heat generators are mini-boiler rooms equipped with an expansion tank, a circulation pump and an electronic control unit.

According to the method of fuel combustion and efficiency, gas heaters are divided into 3 categories:

- Atmospheric, open combustion chamber, efficiency - up to 90%. Air is supplied to the burner in a natural way from the boiler room, the gases that give off heat are emitted into a traditional chimney.

- Turbocharged (supercharged), the combustion chamber is completely closed, efficiency - 93%. The air is blown by a fan, the smoke goes outside through a double-walled coaxial pipe.

- Condensing units use the latent heat of combustion of hydrocarbons, so the efficiency reaches 96-97%. The design is similar to a turbocharged boiler, but the closed chamber and burner are cylindrical in shape.

Turbocharged model of a suspended boiler equipped with a plate heat exchanger for heating water

All of these heaters can be supplied with a DHW water circuit. For this purpose, 2 types of heat exchangers are used - a separate stainless steel plate heat exchanger and a copper shell-and-tube heat exchanger (mounted inside the main heater).

The price of boilers increases in the order listed - atmospheric devices are considered inexpensive, followed by heaters with a turbine. The cost of condensing equipment is about twice as high as conventional heat generators (one manufacturer).

Low temperature condensing units are well suited for underfloor heating

Advantages of gas boilers:

devices are quite economical and reliable in operation;

a high degree of automation - the homeowner does not need to pay attention to the device;

ease of operation, maintenance - 1 time per year;

the boiler room is clean, the noise level is low;

for a pressurized model, you do not have to build a classic chimney - the pipe is led horizontally through the wall.

On the shortcomings: the gas heat generators themselves are impeccable, the problem is different - connecting the main to a private house and obtaining the necessary permits. The first service costs a lot of money, the second takes a lot of time. An intermediate option is a device for autonomous supply of liquefied gas from cylinders or an underground tank.

Ecology and health

A pellet boiler can rightly be called an environmentally friendly unit. The unique air supply system in pellet boilers allows oxygen to be supplied to support the combustion process through a separate circuit. Complete combustion of the pellets leaves virtually no debris, and the combustion products are recycled in the process of photosynthesis. Thus, there is no threat to the ecology of your living space. The air supply to the burner is carried out through a pipe system from the outside. There is no effect of "burning" oxygen, so that the comfortable state is not disturbed.

Advantages of pellet boilers:

- Autonomy. A pellet boiler will heat your house, in the absence of a main gas supply to it;

- Low power consumption.Energy-saving fan, and the automation system copes with the task of operating the device by consuming no more than 70 watts;

- Small amount of waste. Compared to solid fuel boilers using wood or coal, a pellet boiler generates very small amounts of ash and soot. Manufacturers even produce an automatic self-cleaning pellet boiler;

- The body of the device is reliably protected by a layer of thermal insulation, keeping the heat inside the boiler and leaving the outer walls cold. The problem of burns is excluded;

- Automation of the heating process. An automatic pellet boiler can be operated without human intervention for up to 5 days;

- Possibility of programming continuous operation with weekly parameters.

Cons of pellet boilers:

The main disadvantage of a pellet boiler is predictably the price.

- High initial purchase price;

- High operating cost. It would seem that pellets are made from woodworking waste, but their cost is by no means like garbage.

- The heat released during the combustion of pellets is more expensive, in comparison with the same firewood;

- Storage space also entails certain costs. Folding pellets in the yard, like a woodpile, will not work. A dry area is required. Raw and swollen pellets pose a threat to the equipment, the screws become clogged and fail.

Current practice shows that the cost of operating a pellet boiler reaches the level of the cost of operating heating equipment using an electric boiler. Undoubtedly, the costs will exceed the use of gas-heating units.

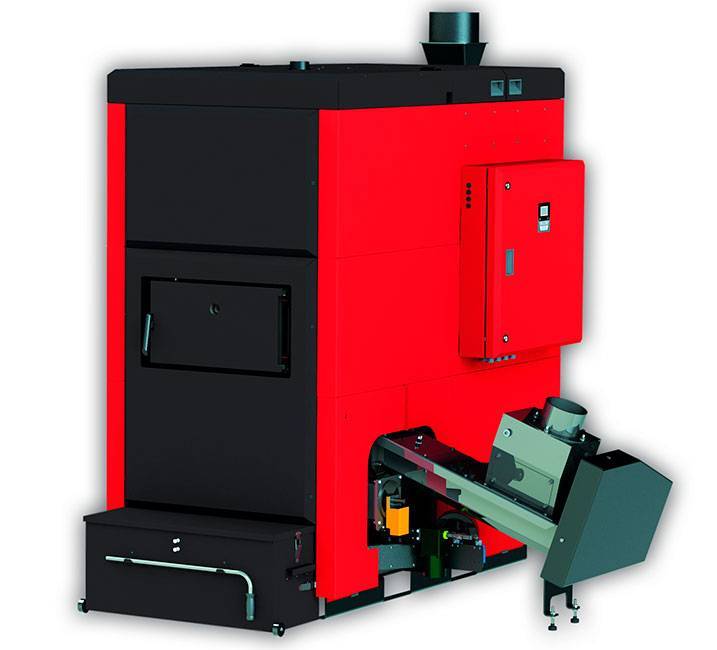

TOP of the best models of double-circuit boilers

Double-circuit pellet boilers are used for the functioning of the heating system and the provision of water supply in the house with hot water. Such heating devices have high power ratings and are distinguished by good performance. However, compared to single-circuit models, dual-circuit counterparts have large dimensions.

ZOTA MAXIMA 300, two augers

The main advantage of this double-circuit boiler is its high power, which is 300 kW. You can control the operation of this equipment remotely using the Internet network, as well as the GSM module. It is additionally equipped with contactless automatic ignition, which ensures a high level of operational safety.

The efficiency of this model of solid fuel boiler is 90%. Coal and pellets can be used as fuel. The duration of complete combustion of the loaded fuel is from 50 hours. Ease of operation is ensured thanks to the installed automatic system for removing accumulated ash.

ZOTA MAXIMA 300, two augers

Advantages:

- Ease of operation and maintenance;

- Equipped with a capacious bunker;

- High power and efficiency;

- Possibility of remote control.

Flaws:

- High cost (price 648011 rubles);

- Dimensions.

Double-circuit pellet boiler Dragon plus GV - 30

It is a reliable, fully functional heating equipment. Thanks to its use, it is possible to heat rooms in a house up to 300 sq.m. and heat large volumes of domestic water. It is a universal device, it can work both on pellets and on other types of fuel (gas, wood, diesel fuel).

The boiler is made of high quality steel, the thickness of which varies from 5 mm. Equipped with a three-way heat exchanger. The efficiency level of this model, when using pellets, is 95%. The boiler is equipped with a high-quality burner, which is equipped with a mechanical self-cleaning system. This model of heating equipment is unpretentious in terms of the quality of the pellets used. The maximum boiler power is 36 kW.

Pellet boiler double-circuit Dragon plus GV - 30

Advantages:

- Unpretentious to the quality of the pellets used;

- Easy to operate and maintain;

- High level of power and efficiency;

- Boiler warranty 3 years;

- Existence of a mechanical system of self-cleaning of a torch.

Flaws:

- High price (229,500 rubles);

- Small volume of the bunker for storage of pellets.

Jaspi Biotriplex

It is a combined solid fuel heater, which is perfect for heating private houses up to 300 sq.m. After installing the burner, you can heat the house with pellets. In addition, this device in the same mode, together with wood pellets, can use firewood to heat the house or operate from the mains.

For water heating, it is additionally equipped with a coil made of copper, which allows you to produce up to 25 liters (at water temperatures up to +40 degrees Celsius). When using pellets, the power of the unit is 30 kW. In the case of using firewood, power indicators vary around 25 kW. The efficiency is over 85%.

Boiler Jaspi Biotriplex

Advantages:

- Functional;

- Versatility;

- Quickly heats large volumes of domestic water;

- Equipped with separate chambers for burning pellets and firewood;

- It is completed with an electric heating element with a power of up to 6 kW;

- The duration of operation is about 25 years;

- Equipped with thermal insulation.

Flaws:

- High cost (505100 rubles);

- Difficult to install.

Comparative characteristics of different models of pellet boilers

| Title, description | Type of | efficiency | Power, kWt) | Cost (in rubles) |

|---|---|---|---|---|

| ZOTA Focus 16 | single-loop | 80% | 16 | 112300 |

| TermoKRoss TKR-40U | single-loop | 91% | 40 | 132000 |

| Ecosystem PelleBurn PLB 25 | single-loop | Not specified | 25 | 325500 |

| FACI 130 | single-loop | Up to 95% | 130 | 335000 |

| Teplodar Kupper PRO - 28 with pellet burner APG - 25 | single-loop | 85% | 28 | 98634 |

| ZOTA MAXIMA 300 | double-circuit | 90% | 300 | 648011 |

| Dragon plus GV - 30 | double-circuit | 95% | 36 | 229500 |

| Jaspi Biotriplex | double-circuit | Over 85% | 25 | 505100 |

Pellet boilers are a type of solid fuel heating units that run on pellets. The main advantage of these devices is the presence of a fully automated control system, automatic fuel supply, as well as high efficiency.

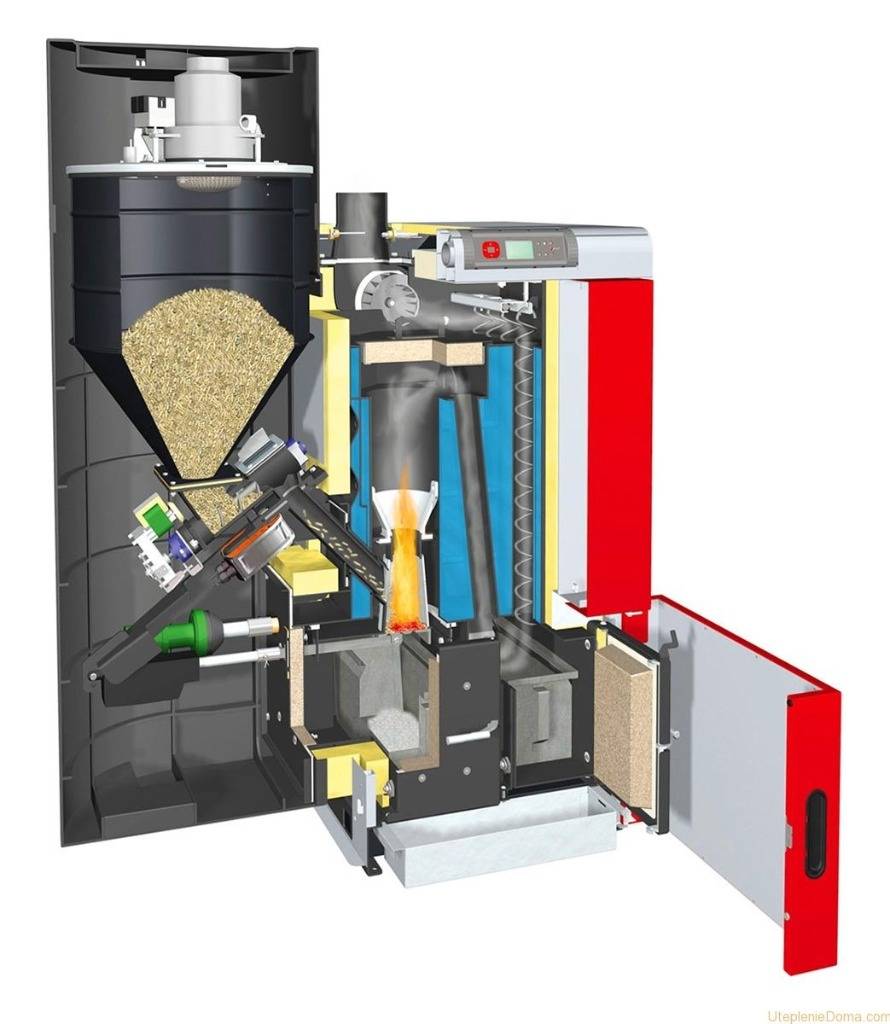

Device

So, a pellet boiler is one of the categories of a solid fuel type boiler for heating, where there is an automatic supply of fuel material that runs on pellets, which are called fuel pellets made of wood.

The first element of which such a device consists is the combustion chamber. As a rule, it has small dimensions. This is due to the fact that a boiler with a lining does not need more pellets at the same time to provide heat to the room.

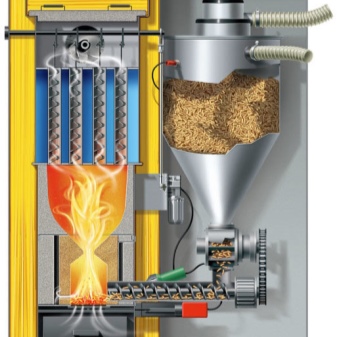

As a rule, pellet burners are installed inside such a chamber. They represent the part of the boiler where the pellets enter and where their combustion process is directly carried out.Pellet burners can have a power of 10 to 750 kilowatts and be either retort or flare. That is, they differ in the ways of supplying air and fuel to the combustion area.

Pellet burners produced by different manufacturers may have completely different automation and they may have a different design. But all of them can quite accurately regulate the amount of pellets that is fed into the combustion chamber, as well as air. Properly selected such ratio makes it possible to achieve the highest quality burnout of pellets in order to obtain gases with a maximum temperature, which allows good heat transfer. Thanks to this, the efficiency of such boilers reaches 93 percent.

The next part will be a heat exchanger, after which the heat is transferred to the heating system, which can be made based on water or antifreeze

Note that heat exchangers can have a different design. They can be flat, horizontal, tubular, vertical, with a different number of strokes, as well as turns equipped with turbulators and so on. The best solution would be vertical type heat exchangers, which have a couple of moves and are equipped with a turbulator. The use of such models allows you to give more heat to the gas.

In all modern models of the considered long-burning boilers, heat exchangers and combustion chambers are placed in a special additional casing of a heat-insulating nature. This makes working with the boiler safer, more comfortable, and also allows you to significantly reduce boiler losses. The next component of such a system will be a special fuel bunker, in which the pellets are usually stored and from where they enter the burner.The capacity of such parts can be different: from a couple of tens of kilograms to several tons.

These parts are different:

- freestanding;

- tight;

- built-in;

- leaky.

The size of this element will determine how long such a boiler will work autonomously. It should be said that, as a rule, the average dimensions of the bunker of such a boiler with a capacity of 25 to 40 kilowatts is about two hundred kilograms. This may be enough for three to seven days of uninterrupted operation.

To transport pellets, almost all manufacturers of such solutions use an electrically driven screw auger system, which makes it possible to quickly and carefully feed the required amount of pellets. If you need to transport pellets over a considerable distance, then either a pneumatic mechanism or elongated augers of a special design are used.

In addition, pellet solutions can be equipped with various additional technical devices, such as:

- automatic control of the heating system;

- automatic weather-dependent type;

- pneumatic or mechanical ash removal system;

- self-cleaning mechanism.

In addition, each model has a temperature sensor that will display the temperature inside the device, as well as a special control unit that will allow you to control the operation of such a boiler.

How to remove ash from the boiler?

Pellet boilers have special ash containers in which ash accumulates. In simple models, a manual ash removal method is used. As it accumulates, you need to stop the boiler, remove the container, empty it and install it back. The frequency of this procedure depends on the settings of the boiler and the quality of the fuel.So, you need to remove the ash:

- every 5-7 days when fired with quality pellets;

- every 2-3 days when using agropellets;

- every day when burning coal.

The automatic pellet boilers are equipped with automatic ash removal equipment. The ash is transported to the bulky outer ash container by means of a screw conveyor. At the same time, in the process of moving the ash is compacted, which leads to a decrease in its volume. The drive of this mechanism works either from the boiler controller, or from autonomous automation. The presence of a fuel warehouse, automatic ash removal and cleaning of gas ducts make it possible to make maintenance of the pellet boiler system minimal.

Warmth in the house is one of the main conditions for comfortable living in it. Along with heating with natural gas, coal, firewood, for several years now, on parity terms, the option of using pressed pellets has been considered. But is it beneficial to use the latter option, both from an environmental, aesthetic, and economic point of view? Having calculated the average consumption of pellets for heating a house, we can draw preliminary conclusions regarding the economic aspect.

As for environmental friendliness, there is no doubt about it - the use of renewable energy sources, in particular pressed pellets, emits several times less CO2 into the atmosphere. And this source of energy, as the name implies, is practically inexhaustible. In addition, waste from the woodworking and agricultural industries is used for production.

How to choose the right pellet boiler

Prices for pellet boilers for heating a private house start at 70-75 thousand rubles.A little expensive, but for this money you will receive equipment with a capacious bunker and automatic supply of pellet fuel. For less money you will get a universal solid fuel boiler with manual loading. A pellet boiler for a private house can be more expensive - it all depends on its filling.

Type of heat exchanger

When choosing a pellet stove, pay attention to the heat exchanger, it is desirable that it be made of cast iron. We advise you to purchase pellet boilers with cast-iron heat exchangers, and multi-pass

Cast iron is an ideal material for creating heat exchangers - it is strong enough, warms up quickly and cools down slowly, and withstands temperature overloads well. If there are several moves in it, then this is a plus - the exchanger will be able to absorb the maximum amount of heat. The main disadvantages of cast iron are brittleness and lack of resistance to water hammer.

We advise you to purchase pellet boilers with cast-iron heat exchangers, and multi-pass ones. Cast iron is an ideal material for creating heat exchangers - it is strong enough, warms up quickly and cools down slowly, and withstands temperature overloads well. If there are several moves in it, then this is a plus - the exchanger will be able to absorb the maximum amount of heat. The main disadvantages of cast iron are brittleness and lack of resistance to water hammer.

Steel heat exchangers differ from their cast-iron counterparts in resistance to water hammer. True, they are more susceptible to corrosion and do not tolerate thermal overloads. Therefore, they are used only in the cheapest pellet boilers used for heating private households.

The recommended types of heat exchangers are fire tube or flat type made of cast iron. If the exchanger is vertical, then this is only a plus - they are well cleaned of ash, which simply falls down.

Work automation

We have already said that pellet boilers used for heating private houses can work without regular approaches from users - you just need to periodically add new portions of pellets and remove ash. The most advanced pellet boilers are endowed with the following features:

- Automatic temperature control in the heating system of a private house;

- Automatic ignition - no need to ignite the fuel yourself;

- Control of operating parameters - here the pressure in the heating system, the temperature of the coolant, the quality of fuel combustion and many other parameters are controlled.

In addition, some pellet boilers provide fuel availability control.

Fuel supply

Using a flexible auger will allow you to place the fuel hopper away from the boiler itself.

Pellet boilers for heating a private house are endowed with two types of screws - flexible and rigid. Rigid augers are implemented in all boilers with automatic pellet feeding. By their design, they resemble a meat grinder, smoothly moving the granules from the hopper to the combustion chamber. The main feature of the rigid auger is the fixed length. That is, we cannot rearrange the bunker to another place.

Flexible augers allow you to place pellet bins at any point, for example, in a neighboring corner of the house. Fuel enters pellet boilers through a kind of flexible pipe in which a flexible screw rotates. Its length can reach 10 meters or more.To synchronize the standard rigid and external flexible augers, automation with electric motors is used.

Burner type

We have come to a very important criterion for choosing a pellet boiler for organizing heating in a private house - this is the type of burner. There is no particular variety here; in pellet boilers, either retort burners or flare burners are found

The retort burner operates in a vertical plane, the flame bursts upwards, fuel enters it from below or from the side (in bulk). Air enters through the slots on the sides. The disadvantage of such a burner is that it can periodically go out, becoming clogged with ash.

If you want to get rid of this disadvantage, use low-ash pellet fuel - it burns almost completely and does not form a large amount of ash.

We advise you to choose pellet stoves with a torch burner, it works much more stable than a retort burner.

Horizontal flare burners are free from the disadvantages of retort burners. The flame here is literally blown out by a powerful fan, leaving in a horizontal plane. Pellet burning takes place on a special platform, the ash is discharged down. Due to the powerful blowing, such a burner is characterized by high efficiency, allowing you to organize good heating work in a private household.

Rating of the best wall-mounted gas boilers - the most purchased models

Having dealt with the most famous brands and models of gas boilers, you can move on to the most popular ones. After all, the higher the demand for a particular brand, the more confidence in it. It is for this reason that it is worth considering the 6 most popular gas boilers presented on the shelves of household appliances stores in our country.

Gas boiler WOLF CGG-1K-24 - what attracts attention

This is a double-circuit gas boiler with a power of 24 kW. The type of its location is wall-mounted. Of the advantages, one can note the heating temperature, which is 90C for heating and 60C for hot water supply, as well as the presence of a tank with a volume of 8 liters. Also, one cannot but rejoice at the presence of control of gas shutdown, protection against overheating and prevention of freezing.

The cost of a double-circuit hinged turbocharged gas boiler WOLF CGG-1K-24 is about 66,000 rubles, which is relatively small. That is why we can safely give this model the first place in our rating.

The appearance of WOLF CGG-1K-24 is ascetic, but not bad

Baxi LUNA-3 COMFORT 240 Fi with remote control

This double-circuit boiler has a power rating of 25 kW, with an efficiency of 93%. Quite an interesting electronic filling allows you to control this gas equipment using a remote control. In the advantages, you can safely write down such a function as the ability to connect a warm floor to it. The price of double-circuit gas boilers for heating private houses of this model in the Russian market varies from 53,000 to 57,000 rubles.

Navien DELUXE 24K - cheaper in cost, but not inferior in function

A similar model of a double-circuit boiler has a power of 24 kW with an efficiency of 95.5%. Just like the previous one, it has the ability to control from the remote control. The cost of a gas boiler Navien DELUXE 24K is 24,000 rubles.

Navien DELUXE 24K - although inexpensive, it has enough functions

Protherm Cheetah 23 MOV for connecting a warm floor

An open-type combustion chamber prevents this gas boiler, with a power of 23 kW and an efficiency of 90%, from breaking out into the leaders of our rating.But for connecting a warm floor, this model is almost ideal, and it can work on both natural and liquefied gas.

BOSCHGAZ 4000 WZWA 24-2 A - nothing special

In this model, the power of which is 24 kW, there is nothing particularly distinguishing it from others. The cost of 36500 rubles, most likely, the consequences of the promotion of the brand. The same reason can be called about the popularity of this model. Although German quality has always been at its best, nowadays you can find cheaper models that are not inferior to this work in terms of durability.

BOSCH GAZ 4000 WZWA 24-2 A - payment only for the brand

Condensing boiler VAILLANT ecoTEC PLUS VUW INT IV 246

But this model of a wall-mounted double-circuit gas boiler really deserves attention. Its power is 20 kW, but the efficiency of 108% is achieved due to the fact that the boiler is condensing. The device has the ability to connect an external control, which means that when installing it in the basement, the temperature control panel can be taken out to any convenient place. The cost of such equipment is on average 94,000 rubles.

A good gas boiler VAILLANT ecoTEC PLUS VUW INT IV 246, but the price "bites"

Summarizing all the information, we can say that before choosing a gas boiler for heating a private house, it is necessary to carry out "preparatory work", i.e. to study the characteristics of various models, having calculated the required power, to understand what kind of boiler is needed. And the number of contours, in the end, plays an important role. In general, each of the characteristics needs to be studied, to understand what functions the gas boiler should perform. And only after that you can go to the store, continuing the choice already there.

Save Time: Featured Articles Every Week by Mail