- Pellet burners

- How to choose

- Choice of coal

- Principle of operation

- Pellet boilers Kiturami: technical specifications

- The heater is the warmth in the house

- Fuel

- Types and arrangement of heating systems with natural circulation

- Boiler Assembly Manual

- Housing and heat exchanger

- Pellet boilers - features and differences

- Features of electric boilers ZOTA

- Electric boilers ZOTA Econom

- Electric boilers ZOTA Prom

- Electric boilers ZOTA Smart

- Electric boilers ZOTA MK

- Electric boilers ZOTA Lux

- How to choose the right boiler

- Features of piping

- Basic installation rules

- Page 4

- Operating tips

- Pellet boiler Zota

- The choice of heat exchanger material

- Pellet boiler Zota Pellet Pro

- Feedback on the boiler Zota

- Price overview of pellet boilers with automatic fuel supply

Pellet burners

Ordinary solid fuel boilers are not well suited for burning pellets, so they are converted by inserting a pellet burner.

The same alteration can be made with floor gas boilers, because the burner exits a flame with a small amount of smoke.

The burner includes:

- pellet hopper;

- feed system (most often screw);

- safety hose separating the hopper and auger feed from the burner;

- burner;

- lambda probe, which evaluates the amount of oxygen in the exhaust gases and determines the combustion mode of the pellets (not installed on all devices);

- Remote Control.

As a result, you will only:

- pour pellets into the bunker;

- remove ash;

- periodically clean the burner,

the burner automatics will do the rest.

Also, burners can be used in conjunction with brick ovens, including those equipped with coarse.

Here is the cost and a brief description of the most popular models of such burners:

| brand | Power, kWt | Description | Price thousand rubles | Website of the manufacturer or seller |

| Pelletron-15MA | 15 | Semi-automatic burner with small capacity hopper. The burner must be cleaned once a day. Ignition of fuel is made manually. The door for installation in the boiler must be purchased separately, choosing it according to the size of the boiler. | 18 | |

| РВ10/20 | 50 | Automatic burner for boilers such as Peresvet, Valdai, YaIK, Don and others, which have the same size of the furnace and door. Automatic ignition pellet. Automatic pneumatic cleaning, so without maintenance the burner can work for several weeks if there is enough fuel. Thanks to temperature sensors, the control unit automatically changes the operating mode of the burner. | 93 | |

| Terminator-15 | 15 | Automatic burner for burning any pellets. Thanks to the self-cleaning function, it can work without maintenance for 14 days. It is equipped with a GSM unit, so the burner operation mode can be controlled from a phone or tablet, as well as receive information about its operation mode. | 74 | |

| Pelltech PV 20b | 20 | Fully automatic burner with electric pellet ignition. Thanks to the self-cleaning function, it requires maintenance 2-3 times a month. Independently regulates the strength of the flame, providing the desired temperature of the coolant. In the event of a power outage, it switches to a backup battery. | 97 |

How to choose

When choosing pellet burners, it is necessary first of all to pay attention to the suitability of the boiler, because some burners are produced for specific models of boilers, for others you can purchase transitional doors that correspond to a particular boiler. The second important parameter is power, because the maximum efficiency of the burner is achieved only when operating at full power.

The second important parameter is power, because the maximum efficiency of the burner is achieved only when operating at full power.

After that, you need to define:

- pellet type;

- operating time from one download;

- time between services;

- bunker volume;

- cost limit.

Most automatic burners work well on all pellets, but units that do not have a self-cleaning function are only suitable for use if white hardwood granular sawdust is used.

The average fuel consumption in most burners is 200–250 grams per 1 kW of boiler power per hour. From this formula, the required volume of the bunker is determined.

Burners without self-cleaning are inexpensive, but they have to be cleaned every day, so they are seriously inferior to automatic ones.

Therefore, you have to choose: either take an inexpensive burner that needs to be cleaned every day, or an expensive one that requires maintenance only once every 2 weeks.

Choice of coal

In order to have an idea of how to properly heat a long-burning boiler, it is necessary to consider the fuel used for this. Coal is a natural material that contains carbon and non-combustible elements. The latter, when burned, become ash and other solid deposits.The ratio of components in the composition of coal can be different, and it is this parameter, coupled with the duration of the occurrence of the material, that determines the grade of the finished fuel.

There are the following grades of coal:

- Lignite has the shortest age of occurrence among all coal grades, which is characterized by a rather loose structure. It is pointless to consider this material, since it is not suitable for heating private houses.

- Older deposits are brown and hard coal, as well as anthracite. Anthracite has the highest heat capacity, followed by hard coal, and brown coal is the most inefficient.

When deciding which coal to heat the boiler, it is necessary to evaluate the characteristics of a particular brand of raw material. Good coal for heating is distinguished by a rather high heat transfer and a long period of complete burn-out - one bookmark of fuel can burn up to 12 hours, which reduces the number of bookmarks per day to two. The presence of different types of coal on the market allows you to choose the most suitable material, depending on financial capabilities.

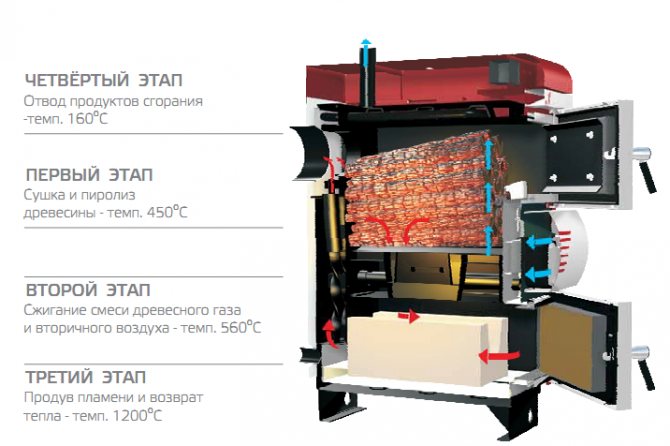

Principle of operation

To automate the work, a controller with a fan is installed

To automate the work, a controller with a fan is installed

The fuel in the Zota furnace is supplied in small portions if it is small in size.

The amount of fuel required is determined by the boiler automatically, taking into account the required amount of fuel for heating the house. The principle of operation is that the fuel from the bunker is sent to the burner in such a volume that is necessary to create one or another temperature in the room. The exact temperature is calculated by the built-in controller.

Another option is the gravitational feed of raw materials. Fuel is poured onto the burner due to its weight. This happens after the previous portion burns out and frees up space for a new one.

With the help of a fan, air is supplied to the burner, the controller also calculates the required amount and adjusts the rotation speed independently.

Pellet boilers Kiturami: technical specifications

Kiturami is a manufacturer of solid pellet stoves in South Korea. To date, the most popular model of this campaign is the Kiturami KRP 20-A Premium.

Among the positive qualities of Premium brand pellet boilers, first of all, it is worth noting the high level of efficiency, which reaches 94%. The burner in such devices is controlled electronically. And also they have a modified version of the bunker.

Kiturami Premium 20-A has a high fire resistance and has a special protection against overheating. Such a boiler is controlled remotely (using a remote control).

Pellet boiler Kiturami, a South Korean manufacturer - an excellent alternative to devices operated on gas, outside the reach of a gas pipe

Consider the main technical features of this unit:

- the power of the device is 24 kW;

- weight - 310 kg;

- the hopper has a capacity of 160 kg;

- the area that such a boiler can heat is 300 m²;

- pellet consumption rate - 5.5 kg / h.

Model KRP 20-A Premium has a two-circuit design and is used for heating as well as hot water. The South Korean manufacturer provides a 2-year warranty for its products. The approximate price of a pellet boiler of this type is 210,000 rubles.

The heater is the warmth in the house

Many settlements today have not yet been gasified. Therefore, residents of such villages have to look for an alternative to gas equipment. The best solution in this case is heating a country or private house with a solid fuel boiler.

It is gaining more and more popularity not only due to the ability to work on wood or coal, but also due to its complete autonomy.

After all, a solid fuel boiler does not need either gas or electricity. It can only work on wood, while maintaining a comfortable temperature in the room. However, such devices are available in various modifications, and in order to make the right choice, it is necessary to at least briefly get acquainted with each of them.

Fuel

The fuel for combustion in the Zota Master 25 boilers can be:

- Anthracites (piece size not less than 10 mm);

- Uncalibrated coal, brown or stone (piece size not less than 10 mm);

- Firewood. Depending on the calorific properties of the wood species, the rate of its combustion will depend. The maximum log length must not exceed the depth of the firebox (660 mm).

- Briquettes coal, peat, etc.

Boilers differ in extreme unpretentiousness to quality and the size of fuel. But the heat output of the device can be significantly reduced if poor quality fuel is used. For example, when using raw firewood (at a humidity of 80%), the heating output will decrease by 70%!

Types and arrangement of heating systems with natural circulation

Each heating option without a pump consists of the following main elements:

Heat source, which can be presented in the form of a boiler with various types of fuel; Expansion tank used to stabilize the pressure in the system; Pipelines for coolant circulation; Radiators that heat the living space.

Depending on the type of coolant, the natural circulation system is usually divided into the following two types:

Hot water preparation; Steam heating.

Let us consider in more detail all the features of these two types of domestic heating systems.

Boiler Assembly Manual

Pellet boilers have a fairly complex design. The instructions for assembling them will also be difficult and multi-stage. For greater convenience, the assembly process of each main unit is considered separately. Buy or make the necessary elements, and then simply assemble them into a single system.

This element of the pellet boiler is highly recommended to buy ready-made. It is on the burner that you will spend the most money.

Self-manufacturing of the burner is almost impossible for the reason that this part of the boiler is not just a container for igniting loaded pellets, but a complex control and regulation mechanism.

Pellet burners are equipped with special sensors and have several pre-installed programs that allow you to achieve the most rational fuel consumption and provide the most efficient home heating.

Housing and heat exchanger

You can handle the assembly of the case and the manufacture of the heat exchanger yourself. The boiler body is best done horizontally - with this placement of the unit, maximum heating efficiency is achieved.

For the manufacture of the case, it is recommended to use fireclay bricks.You simply assemble a kind of box without a top cover and place a heat exchanger in it with connected pipes and other elements. Brick is recommended for the reason that it accumulates heat much more efficiently than cast iron, steel sheets and other popular materials.

The pellet boiler heat exchanger is a system of pipes interconnected and connected to the heat supply pipes of a private house.

First step. Assemble a rectangular heat exchanger from square pipes. To do this, cut the pipes into pieces of the desired length and weld them into a single structure.

Second step. Make holes in the profile that acts as a vertical rack for connecting round pipes.

Third step. Prepare holes in the remaining front pipes for the water outlet and connection pipes. Hot water will be discharged through the top hole, cold water will be supplied from the bottom.

Use metal pipes with a length of 150 mm or more. Further it will be possible to use polypropylene pipes. In places where pipes are connected to the boiler, be sure to install ball valves. Additionally, you can set filters if you need them.

Fourth step. Weld the back of the unit to its front and weld the side pipes.

At the same stage, choose a convenient place for connecting a chimney pipe with a diameter of 10 cm. At the bottom of the heating unit, provide a small chamber for collecting ash. Also, the design of the pellet boiler necessarily includes a firebox. About him further.

In the firebox, as already noted, pellets are stored and from here they are fed into the burner.

First step. Prepare the necessary materials and fixtures. You will need an auger with a diameter of 7.5 or 10 cm, an electric motor and a metal casing.You will connect the engine to the pellet burner control unit.

The function of a metal casing can be performed by any container of a suitable volume with sufficiently thick walls.

Second step. Install the inlet of your auger into the outlet of the casing. Connect a corrugated plastic pipe to the other part of the auger to supply granular fuel to the burner.

In conclusion, you just have to assemble all the listed elements into a single design. Do this and proceed to the installation of the boiler.

Pellet boilers - features and differences

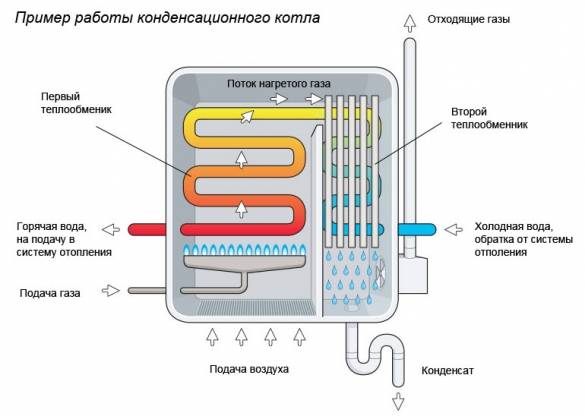

Pellet, or as they are also called, pellet boilers have a number of features and differences from other solid fuel boilers. The maximum heat transfer in them is carried out through a developed convection system of the gas duct - at the outlet, the gas temperature does not exceed 100-200 degrees. And of course, the main distinguishing feature is the bunker for storing and supplying pellets to the boiler.

There are methods for reworking and refining the burners of traditional solid fuel boilers, but in this case, all the benefits of pellets cannot be extracted.

Due to the need to make a volumetric multi-pass gas duct-heat exchanger, pellet boilers have relatively large dimensions - for example, the dimensions of the Zota “Pellet” boiler with a power of 15 kW are 1x1.2x1.3 m, and the weight is more than 300 kg. True, this is together with a bunker for storing a supply of fuel - a volume of 290 liters.

Features of electric boilers ZOTA

Being engaged in the development of ZOTA electric boilers, the manufacturer is doing everything possible to make the equipment high-quality and modern. Therefore, today it is one of the leaders in the heating market.Produced boilers are reliable and economical, they can be controlled remotely, and their functionality fully meets the requirements for modern technology.

For remote ZOTA boilers are controlled by GSM-module and special application.

ZOTA manufactures equipment for heating buildings for various purposes - it can be private houses, industrial premises, office buildings, warehouses and much more. The power of the models varies from 3 to 400 kW, which corresponds to the area of heated premises from 30 to 4000 square meters. m. Remote or built-in remote controls are used for control, as well as mobile phones that control boilers via GSM channels. There are five models to choose from:

- ZOTA Econom - low-cost ZOTA electric boilers for houses and buildings up to 480 sq. m. The line is distinguished by its simple and affordable prices;

- ZOTA Prom is a special line of extremely powerful boilers designed for space heating from 600 to 4000 sq. m;

- ZOTA Smart - electric boilers with GSM modules for remote control. They are literally crammed with all sorts of electronics;

- ZOTA MK - mini-boilers with remote control. Designed for space heating from 30 to 360 sq. m;

- ZOTA Lux are small boilers with many functions and advanced design. They are equipped with GSM modules and temperature correction circuits.

Let's look at these lines in more detail.

Electric boilers ZOTA Econom

This line includes simple electric boilers used for heating buildings for various purposes. Low-power models are well suited for creating home heating systems.The boilers are equipped with remote controls that provide automatic temperature control. Despite its simplicity, there are self-diagnostic systems in the boilers of the ZOTA Econom line. To ensure reliability and long service life, we equipped them with systems of rotation of power units and heating elements.

Electric boilers ZOTA Prom

This line includes especially powerful electric boilers designed for heating large buildings. They are also used to prepare hot water. All models in the range are designed for outdoor installation. To ensure efficiency, the boilers are equipped with automation systems, and a long service life is ensured with the help of a heating element rotation system. Management is carried out using remote controls.

Electric boilers ZOTA Smart

ZOTA compact electric boilers are distinguished by the presence of well-thought-out electronic control. They are equipped with automation systems, weather-dependent modules, heating and pump control systems, as well as self-diagnostic systems. All models supplied to the market have built-in GSM modules for remote control. The design of the boilers includes stainless steel heating elements, numerous sensors, as well as ports for controlling three-way valves and circulation pumps.

Electric boilers ZOTA MK

These are no longer just boilers, but entire mini-boiler rooms. A distinctive feature is the presence of a built-in piping - inside there is an expansion tank of 12 liters, a circulation pump and a safety group. Management is carried out using a built-in remote control, new models provide for the possibility of installing GSM modules. The model range is characterized by small dimensions and neat execution.

Electric boilers ZOTA Lux

ZOTA Lux electric boilers are designed for heating homes and industrial premises. They are equipped with smooth power control, protection systems, remote control, external equipment control systems, as well as durable heating elements. A nice addition will be the presence of weather-dependent automation and the ability to work with two-tariff meters.

If you need to provide excellent heating for private households, then ZOTA Lux electric boilers will be the best choice - they are distinguished by a long service life and advanced functionality.

How to choose the right boiler

When choosing a heating unit, the buyer should focus on their individual needs and capabilities.

Significant criteria:

- Available type of fuel resource. Depending on what it is planned to heat the boiler with, choose a solid fuel or mixed option.

- Convenience. Operation should not cause difficulties for the user.

- Price. Usually choose the most inexpensive of the models with similar suitable parameters.

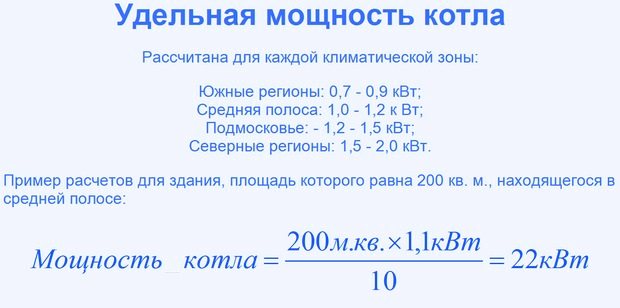

- Power. It is believed that to heat an area of 10 square meters. m. requires an average of 1.5 kW of thermal power. For example, for a house measuring 100 square meters, a 15 kW boiler is suitable.

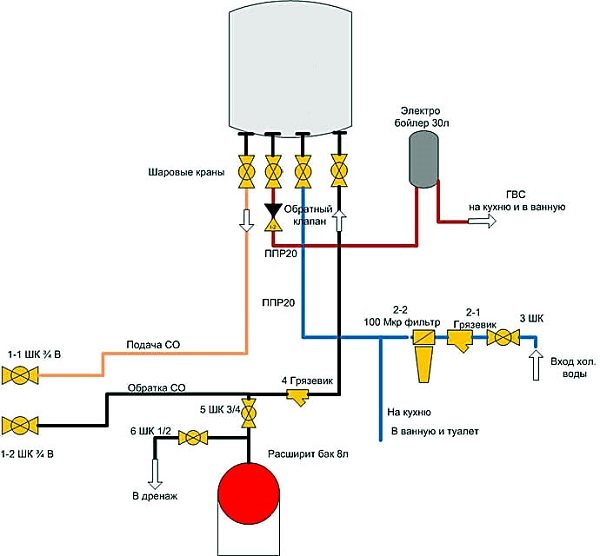

Features of piping

In addition to the correct installation of the circulation pump itself, it is necessary to correctly position a number of other elements and fulfill the technological requirements. Specifically, it's like this:

during the coolant flow, but a strainer is installed in front of the pump; shut-off valve installed on both sides; High power models require vibration damping liners (optional for low power pumps); If there are two or more circulation pumps, each pressure connection is equipped with a check valve and a similar redundant device; No pressure and pressure loading and twisting at the ends of the pipeline.

There are two ways to install devices for efficient circulation in the system:

separate division; directly into the heating system.

The second option is the most preferred. There are two approaches to implementation. First, the circulation pump is simply inserted into the supply line.

The second is to use a U-piece attached in two places to the main pipe. In the middle of this version, a circulation pump is installed. This implementation is characterized by the presence of a bypass.

In the event of frequent power outages by the central system, this design ensures that the system remains operational. Although less efficient.

Basic installation rules

For a high-quality installation of a natural circulation heater, the following important steps must be taken:

It is preferable to place radiator heaters under windows at the same height. Install the boiler. Install expansion tank. Connect the installed elements with pipes. Place the coolant in the heating system and check all components for leaks. Start the boiler and enjoy the warmth of your home.

Important information from installers:

The boiler must be installed as low as possible. Pipes must be laid with a backward slope.It is recommended to avoid a large number of windings in the system. Use large diameter pipes.

We hope that we have revealed all the nuances of a heating system without a pump that will help heat your home.

For information on installing a heating system without a pump, see the explanation of the gravity circuit in the following video:

Page 4

When defrosting and transporting firewood and scaffolding, cubic meters and storage space sizes are commonly used - the difference between these values is not well known.

Operating tips

The technical parameters and performance features that are declared by the manufacturer of the products themselves do not always coincide with what even a short experience in using the purchased unit demonstrates. It is from the reviews of other users that you can quickly find out how Zota units really work, and what operational features they have.

Ignition of boilers must be carried out in a special mode. As soon as the fuel has flared up perfectly, the firebox door is closed and the control lever switches to the firebox mode.

Solid fuel-type Zota devices should be fired with dry logs or quality coal. This is the main condition for excellent heating of the building. The coolant quickly picks up the desired temperature, and when it leaves the boiler, the heat that heats the room is proportional to the quality of the fuel that you used. But also the device will heat the water if necessary.

It is very easy to clean the product from soot. During rotation, a special grate helps to clean the firebox from carbon deposits, without even stopping the combustion process in the unit. Large doors give access to the smoke extraction system.

Zota devices are one of the best and unpretentious types of heating equipment, which has a long service life and low cost: in comparison with imported products, the price of domestic products is 2 times lower. Consumer reviews indicate that there are still certain shortcomings in these devices, but they fully compensate for the special versatility of the device during its operation.

You can learn how to properly connect a heating boiler in the video below.

Pellet boiler Zota

Trends in the development of heat generating equipment require radical changes in relation to the quality indicators of existing units. Outdated designs are being replaced by more efficient and economical products. The main demanded indicators are: increased productivity, security system, ease of maintenance and attractive appearance.

Similar requests are met pellet boiler ZotaIn addition, the specialists of the enterprise pay attention not only to technical characteristics, but also to the development of service centers. Convenient warranty service for manufactured models ultimately has a strong influence on the choice of the buyer of ZOTA products.

Pellet boiler under the ZOTA brand, today the plant is represented by two models:

– Zota Pellet S with power up to 100 kW - Zota Pellet Pro up to 300 kW

The choice of heat exchanger material

cast iron model

cast iron model

The range of boilers from various manufacturers is represented by models with a heat exchanger made of cast iron or steel. Each of the materials has its pros and cons, so it is difficult to say with certainty which variety is better.

Products with a cast-iron heat exchanger are a sectional design.In case of breakage, any part can be easily replaced. Such options are convenient to use in private homes during transportation and in case of repair. Cast iron is subjected to wet corrosion more slowly, so the heating element can be cleaned less frequently. Thermal inertia is higher, cast iron boilers heat up longer and cool down more slowly, therefore they are considered economical. Devices are unstable to a sharp change in temperature. If cold liquid enters a hot heat exchanger, thermal shock can occur, causing cracking.

The steel heat exchanger is a one-piece monoblock, which is industrially welded. Cleaning and maintenance may be a problem, as it is impossible to dismantle the boiler. The steel device is not afraid of temperature fluctuations due to its elasticity. Heats up quickly and cools down quickly.

Pellet boiler Zota Pellet Pro

Modifications of Zota pellet boilers for industrial use with increased power have acquired the commercial name Pellet Pro. The line includes four PRO units with indicators of 160; 200; 250 and 300 kW.

All the functionality and working potential, inherited by the Zota Pellet S model range with domestic power, remained untouched. Engineers retained the main features of the device control, as before, all adjustments are available via the control panel, and the ability to control using commands sent to the GSM module has remained in its place.

The holistic architectural design of the device also remained the same: the Zota boiler itself, the bunker tank for fuel pellets, the screw conveyor module with a burner.

We note the newly acquired features and capabilities that the Zota Pellet Pro Boiler fully possesses:

– contactless auto-ignition (hot air); – The loading of the tank with pellets can be increased by building external sections on the partitions of the bunker; - a vertically standing heat exchanger for efficient combustion of a large mass of granules; - increased volume of the combustion chamber; – the boiler Zota Pellet Pro has a semi-automatic cleaning of the heat exchanger as standard, which facilitates routine maintenance; – as an option, it is possible to order a complete automatic ash removal module; – increased heat-receptive surfaces, thanks to which 100% combustion of pellets became possible, increasing the efficiency of the equipment.

Feedback on the boiler Zota

It was difficult to find a review on the Zota Pellet Pro boiler, this is due to the fact that it is usually installed by commercial organizations, and company employees rarely write reviews about the work done.

We purchased a 160 kW Zota Pellet boiler, the need was for heating the school. Our area is remote from the gas main, so there are not many options left: either a gas tank or a long-burning solid fuel. The diesel fuel boiler was rejected immediately, firstly, the supply hoses freeze, and secondly, it is too flammable to keep a supply of fuel near children. We opted for Zota pellet, mounted without problems. The object is heated for the second winter, there are no problems. True, the local janitor was charged with the duty of regular cleaning. The price for heating is comparable to a gas boiler if a gas tank were installed, but the initial costs are higher there. So, I advise you to consider if there is no gas nearby. ch. engineer Semyon Vasilyevich, Tashtypsky district, Republic of Khakassia

In fact, the Zota Pellet Pro industrial boiler finds its place in the central regions everywhere, even where there is gas, but access to it is limited for various reasons. So it can be: a roadside cafe, a car wash, a car service and much more. About one such complex there is a video review on the YouTube channel:

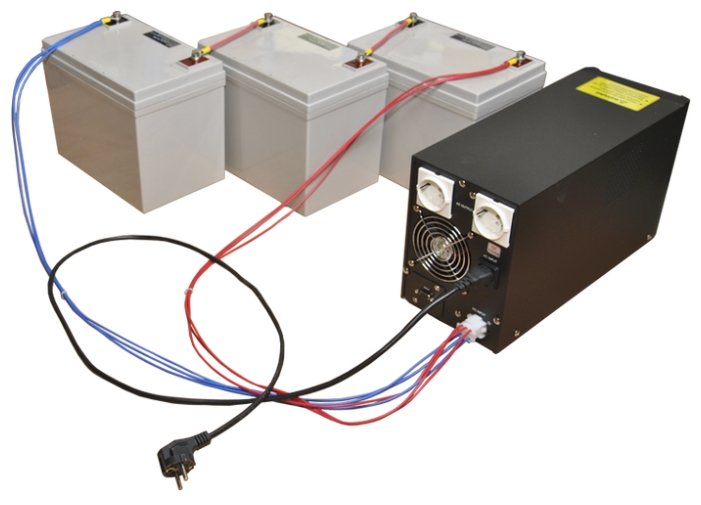

Since the Zota boiler is provided with highly intelligent electronic control, we strongly advise you to use a UPS for the boiler when connecting. Carefully study the list of service centers available for your area, this will help solve many problems in difficult times and will not become a headache in finding spare parts.

Price overview of pellet boilers with automatic fuel supply

Foreign manufacturers of pellet stoves produce high-quality products. The cost of the most budgetary models of the Austrian company Wirbel is 110,000 rubles. South Korean, Czech and Latvian boiler models are more expensive.

Prices for foreign brands of pellet boilers:

| brand name | Producing country | Price in rubles |

| Kiturami | South Korea | 210 000–265 000 |

| OPOP BIOPEL | Czech | 240 000–1 500 000 |

| Wirbel | Austria | 110 000–400 000 |

| Grandeg | Latvia | 200 000–1 400 000 |

Products from domestic manufacturers are usually 2 times cheaper. The most expensive foreign models will cost buyers 1,500,000 rubles, while stoves from Russian companies rarely exceed the price of 750,000 rubles. The cheapest models are produced by the Teplodar brand. The price of automatic pellet boilers "Cooper" in the basic configuration is approximately 80,000 rubles.

Prices for domestic brands of pellet boilers:

| brand name | Price in rubles |

| "Zota" (Zota) | 180 000–725 000 |

| "Teplodar-Kupper" | 80 000–115 000 |

| "Svetlobor" | 220 000–650 000 |

| "Obshchemash" | 150 000–230 000 |

For people who live in areas without a centralized gas supply system, solid fuel pellet boilers are a good alternative. They are able to satisfy all the household needs of the residents of a private house. A high level of automation, high power and productivity make such furnaces very popular and in demand among consumers.