- Fully automatic boilers

- The best manufacturers of automatic pellet boilers

- How does a pellet boiler work

- What is a pellet boiler?

- Burner types

- What is a pellet boiler

- Semi-automatic pellet boilers

- The ninth criterion is design

- Stropuva S20P

- Advantages

- Flaws

- How does a pellet boiler work

- Main models and prices on the market

- Kentatsu Furst VULKAN PE-30

- Valdai Bege Mott

- Kupper PRO

- popular models:

- Automatic pellet boiler kiturami korea

- Automatic pellet boiler pelletron pelletron 22 kW

- Mechanized pellet boilers

- Prices for pellet boilers

- How do the efficiency of boilers with different burners differ?

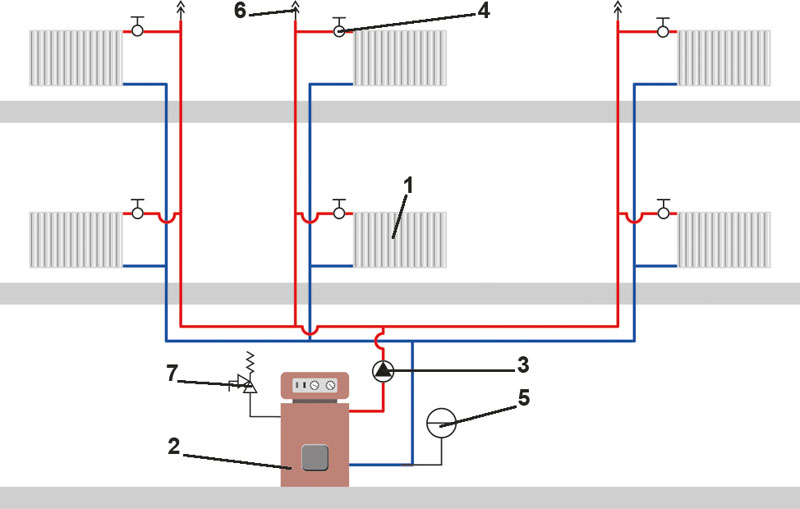

- Where and how to put a pellet boiler

- Requirements for the premises

- Chimney installation rules

- Where to store and how to fill up wood pellets?

- Maintenance

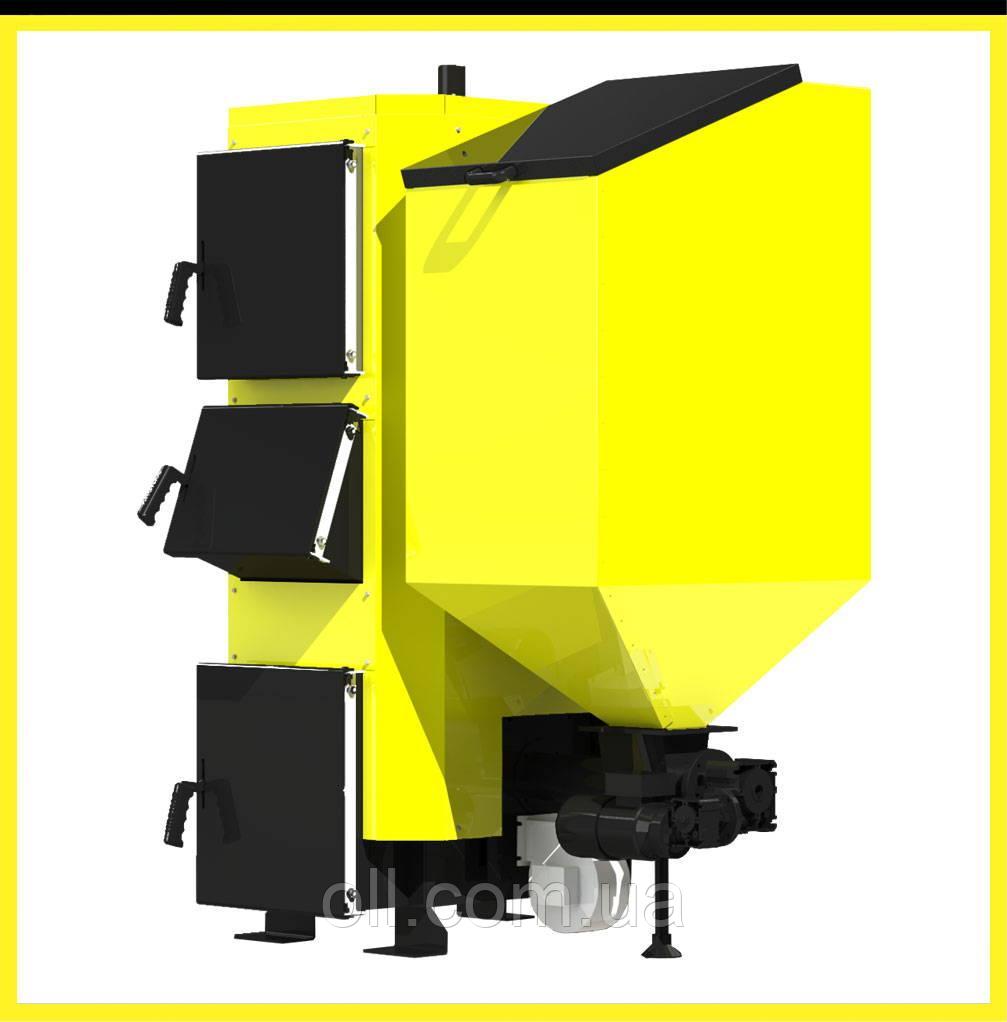

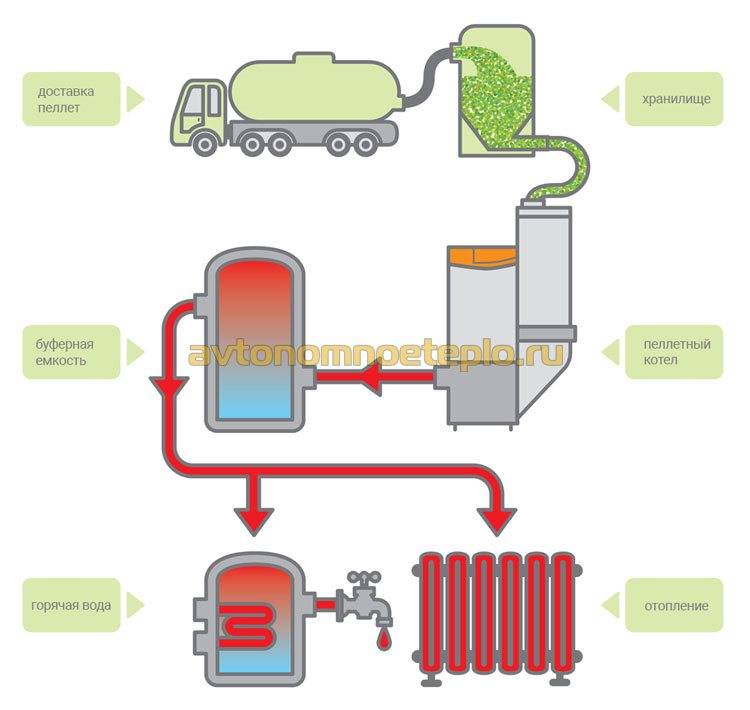

Fully automatic boilers

Fully automatic pellet boiler

The most advanced systems do not require the intervention of the owner. Everything is automated: fuel supply, ignition, ash removal, in which the waste is compressed, does not produce dust, and decreases in volume.

When a fully automatic pellet boiler is installed in the house, it is rational to involve specialists in solving the problem.They will calculate the volume of the intermediate storage bin, install and configure the system for supplying pellets from the storage room, as well as remote control of the heating and warning system.

When purchasing a fully automated boiler, it is wise to take care of creating a pantry that will fit the amount of pellets needed to get through the heating season. It is also rational to arrange a separate place for the accumulation of ash residues.

The best manufacturers of automatic pellet boilers

It is traditionally believed that the best automatic boilers are made in the EU countries. Gradually, domestic manufacturers have launched the production of pellet equipment that can work stably offline.

Imported boilers operating on pellets in automatic mode are offered by the following manufacturers:

- Viessmann - automatic systems that are easy to use, and have high build quality and reliability. Viessmann products, in particular pellet plants, are considered the best in their class. The only thing that slightly spoils the impression is the high cost of installation. Weisman boilers are equipment for those who appreciate comfort and are willing to pay for it.

Froling is an Austrian company that is advertised on the domestic market as a German concern. The technical parameters and characteristics declared by the manufacturer deserve respect. A special mention is the model that works on pellets and wood. The Froling brand has recently appeared on the Russian market, therefore, a normal service system does not yet exist.

Kostrzewa is a Polish version of budget automated pellet machines. The series includes boilers with a capacity of up to 100 kW.Thanks to the lambda probe built into the model, savings in fuel consumption are achieved, approximately 10% compared to analogues. Kostrzewa boilers operate in two modes, for heating hot water and coolant, and separately for heating water for domestic needs.

Domestic analogues are offered by the following companies:

- Kupper OK is a Teplodar product that has earned a lot of positive feedback from consumers due to its omnivorousness and unpretentiousness when using pellet granules of any quality. There is a security group in the Kupper OK design, it provides warranty (for 10 years) and post-warranty service.

Zota Pellet is one of the boilers closest to European units (in terms of quality and automation of combustion and fuel supply processes). Automation is designed taking into account domestic operating conditions. The design includes a complete set of control and monitoring fittings, making Zota Pellet work completely autonomous.

Over the years of operation, experience has been accumulated that makes it possible to identify the positive and negative aspects of boilers with automatic fuel supply to the burner. The advantages of this design are:

- Versatility - it is possible to work on wood chips, sawdust, with a maximum moisture content of not more than 25-30%.

Autonomy - you can leave the automatic boiler unattended for several weeks. Starting the unit, after installing the GSM module, is carried out remotely using SMS messages or a smartphone connected to the Internet.

The need for maintenance - a modern technical solution for the automatic supply of pellets from storage to the boiler, the presence of a self-cleaning system in the device, minimizes the personal involvement of a person in the process of operation.

The following shortcomings have been identified:

- The cost of automated wood pellet boilers, even from a domestic manufacturer, starts at $ 2,000. Polish and German counterparts will cost 1.5-3 times more.

Dependence on electricity - automatic volatile boilers cannot work without mains voltage. In addition to the costs of installing and connecting a mechanized storage, you will need to pay for the provision of backup power.

If you do not take into account some of the inconveniences associated with the last two points, in general, automatic pellet boilers stand out against the background of all solid fuel equipment and can even compete with gas units.

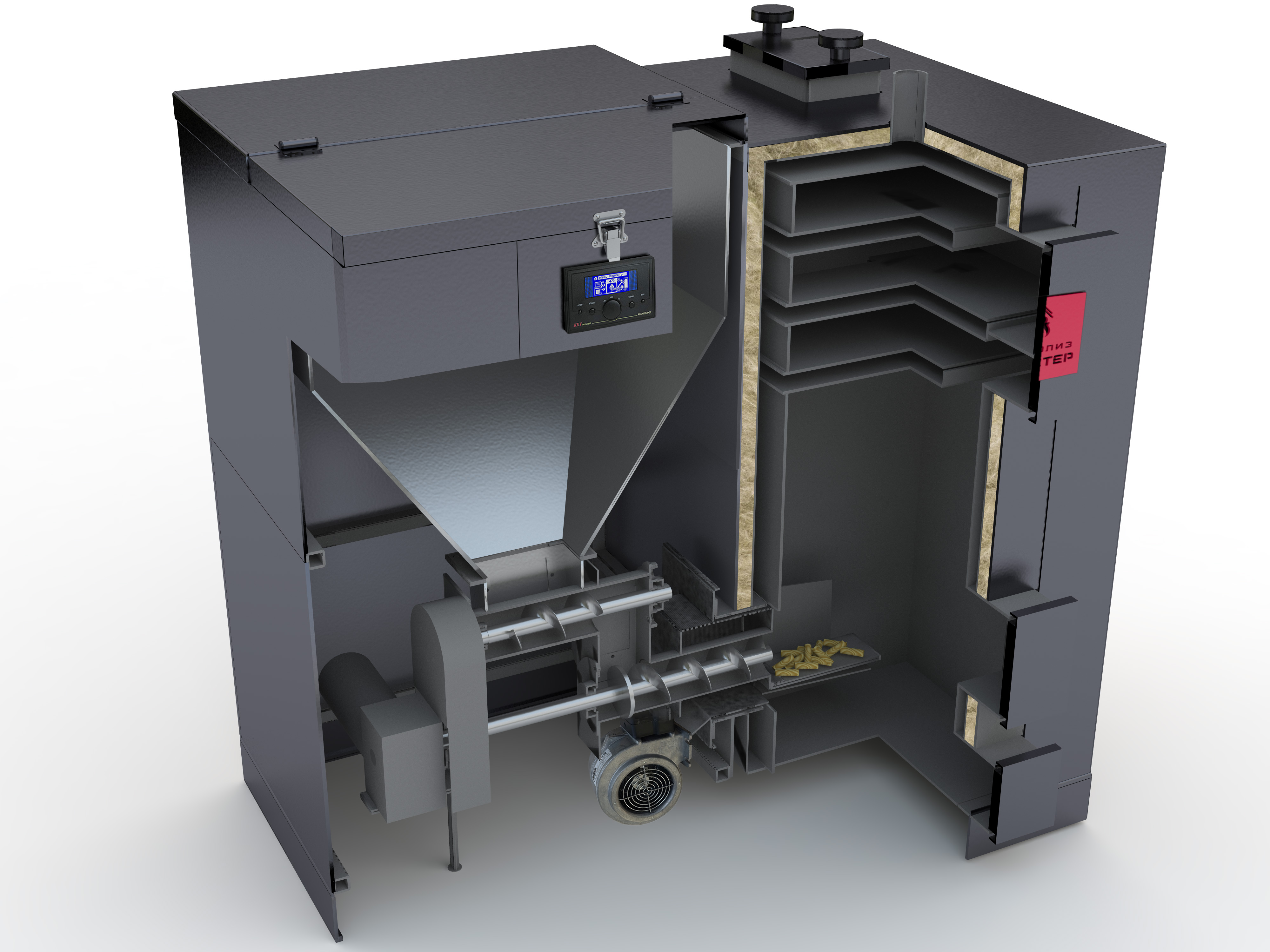

How does a pellet boiler work

The principle of operation of the pellet boiler

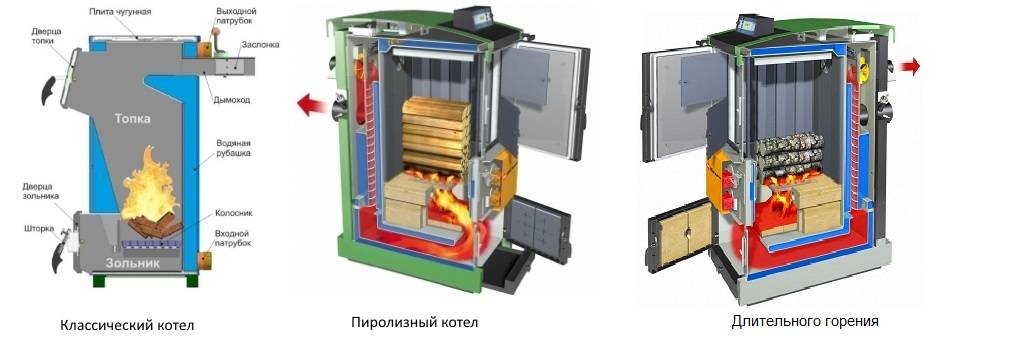

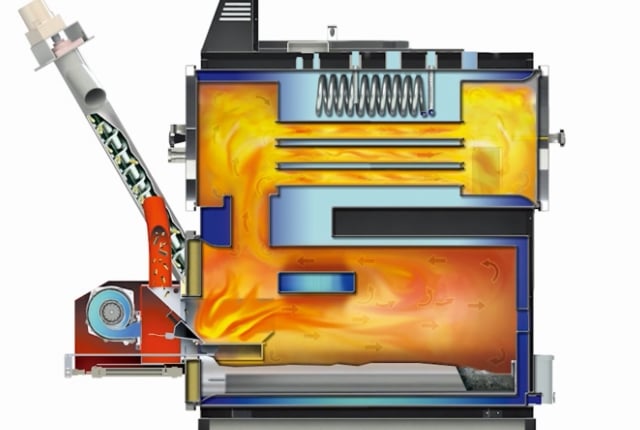

There are several schemes for the operation of pellet boilers. Classical - involves the pyrolysis of fuel, the decomposition of wood-containing raw materials at a low oxygen content. The gas formed during this process serves as the main energy carrier and is burned in a special chamber.

A classic-type pellet boiler is rarely found on the modern market. It requires a powerful power supply (the processing of pellets is carried out constantly by heating with a heating element), is sensitive to fuel quality, and is equipped with automatic metered air supply to the pyrolysis chamber. The equipment is difficult to set up, provides for periodic maintenance and diagnostics.

A medium-sized household and industrial pellet boiler, which can be bought in stores, operates according to the dual combustion of fuel and flue gas. Everything works like this:

- pellets are fed into the primary heating chamber. Pyrolysis takes place in it, under the influence of high temperature, combustible gas is released from the heating element granules, the ignition procedure takes place,

- The flue gas formed during the pyrolysis enters the secondary afterburner, where the pellet burners are located. They can be of different types, for example, volumetric, directional (torch), fireplace,

- Pellets are fed into the afterburning zone by auger, they are exposed to the direct action of the flame and burn out almost completely.

The efficiency that the boiler has depends directly on the type of burner and the quality of the fuel. In good systems, one kilogram of pellets burned can provide as much heat as half a liter of diesel fuel.

What is a pellet boiler?

Pellet boiler is a kind of solid fuel boiler that runs on compressed granular biomass. An important advantage of this type of equipment is that the pellet is an environmentally friendly type of fuel, and due to the relatively small size of the pellets, pellet boilers are overwhelmingly equipped with an automatic fuel supply system. This allows automation to maintain the desired temperature of the coolant and minimizes human involvement in maintenance, unlike wood-fired or coal-fired boilers (without automatic feed).

In this article, we will try to focus on household boilers (up to 100 kW), therefore, we will certainly not consider equipment that implements expensive industrial solutions, such as automatic ash collection, slag discharge from grates, and so on. Therefore, first of all, we will distinguish household pellet boilers according to the concept of fuel combustion, i.e. type of burner.

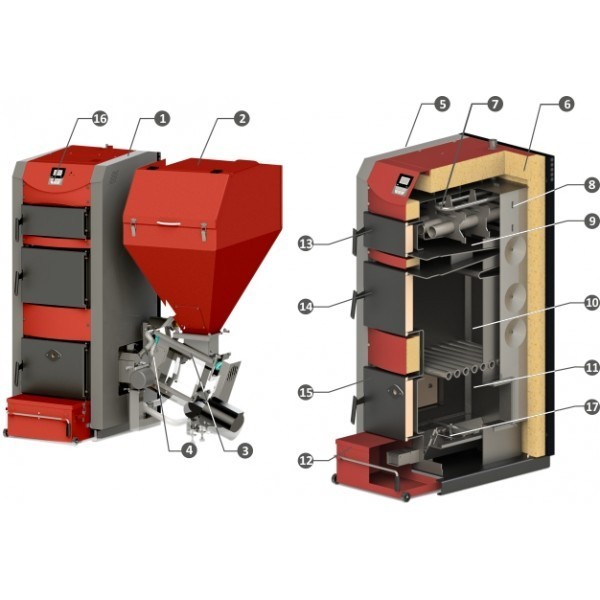

Burner types

To date, the most popular two types of burners:

- stoker (torch);

- retort.

Stoker (torch) burner.

In a stoker burner, the pellet is often fed from above onto a horizontal grate, which is blown with air. In this case, the torch opens horizontally. This is reflected primarily in the geometric dimensions of the boiler. Such boilers are not high, but more oblong. In retort burners, the fuel is supplied from the bottom up due to the screw feed. The torch opens up vertically accordingly. Such boilers are taller, but occupy a smaller area.

In stoker burners, the probability of entrainment of incompletely burned fuel outside the burner is higher than in retort burners. However, the risk of fuel ignition outside the boiler is higher in retort boilers. This is due to the peculiarities of the fuel supply (from bottom to top). In most retort boilers, pellets are taken directly from the hopper by an auger and fed to the burner. Thus, an inseparable layer is created between the burning pellet in the burner and the pellet in the fuel storage bin. The stoker burner is separated from the hopper by an air gap due to the feed from top to bottom.However, in retort boilers, this problem is solved by using two separate screw feeds, as well as by a fire protection system, which will be discussed in more detail below.

It is impossible to say unequivocally which of the burners is better and more efficient, since a well-designed both stoker and retort burners will work well (provided that the pellet boiler is set up correctly)

When choosing a type, it is better to pay attention to the efficiency of such a boiler indicated by the manufacturer, its environmental characteristics and, if possible, read the reviews.

Retort burner.

What is a pellet boiler

A pellet boiler is a device in which fuel is fed into the furnace from a special bunker in automatic mode. The fuel for these boilers are pellets.

Pellets are a fuel that is created from wood waste. Wood waste is compacted into small, shell-like pellets. The diameter of the granules is 6-10 mm, and the length varies from 10 to 50 mm.

Advantages of pellets over other types of solid fuels:

- Environmental friendliness. Pellets are produced without the use of chemicals. All that is needed for their manufacture is wood waste.

- Small amount of waste. When burned, pellets leave behind 20 times less waste than wood.

- Ease of use. To heat a room using pellets, you only need to fill the hopper with a sufficient amount of pellets. The rest will be done by automation. The pellet boiler is cleaned every 1-2 weeks. And also the waste will not pollute the room in which the boiler and other rooms are located.

- High heat release.One gram of pellet releases two and a half times more heat than one gram of wood.

- Cheap and easy delivery. The price of pellets is quite low, because they are made from waste. Also, thanks to their size, they can be easily transported anywhere.

Semi-automatic pellet boilers

Semi-automatic pellet boiler

More complex installations require minimal maintenance. The manufacturer does not offer a ready-made storage bin. The systems are equipped with screw or vacuum feed, automatic ignition and control of boiler operation parameters.

The owner is required to independently organize a storage bin or pellet storage room, as well as spend approximately 20 minutes per week cleaning the unit from ash. This figure is based on the experience of operating boilers on DINPlus class fuel, such pellets are high quality products.

The ninth criterion is design

As they say, they meet by clothes, see off by mind. Appearance, design, when deciding to buy a pellet boiler in Krasnodar, matters. But, in our opinion, these characteristics are of the least importance for such utility heating equipment as a solid fuel boiler with automatic pellet fuel supply.

Of course, if the selected pellet boiler is economical, easy to use, inexpensive, and even beautiful - this is always impressive. However, unfortunately, in the market of this heating equipment, we have to select a boiler for the customer not according to its pluses, but according to the smallest disadvantages. And they can only be recognized by direct handling of the pellet boiler and during long-term operation.

Warmth to all, the ability to distinguish a specialist from an ignoramus who wants to make money on your problem, and the ability to do it right away with high quality so that you don’t have to redo it later.

Stropuva S20P

4.3

The eighth place in the ranking is occupied by a product from the Lithuanian brand Stropuva. The model has a power of 20 kW and is suitable for heating a house area up to 200 m². The unit operates according to a single-circuit scheme, but an indirect heating boiler can be optionally connected to the chimney. The pellet boiler operates with a programmer located on the left side of the body. To increase traction, a fan operates at the outlet. It is allowed to burn both pellets and firewood in the firebox, and the length of the latter is allowed up to 45 cm, which the owners like in the reviews. To prevent accidental loss of heat from the furnace, the model is equipped with powerful handles-locks.

We have added a pellet boiler to the rating as the most compact. Although the unit is not small, but due to its cylindrical shape it takes up little space on the floor, so it will fit a boiler room with an area of 1.5 m². The manufacturer also offers seven body color options, from olive to red, which is convenient for choosing an interior in case the boiler is installed in a kitchen or bathroom.

Advantages

- automatic release of excess pressure;

- simple connection to the heating circuit through a branch pipe with a diameter of 32 mm;

- autonomous burning up to 31 hours;

- manometer on the body.

Flaws

- designed for pressure in the system no more than 1.5 bar;

- there is no automatic supply of pellets and a bunker;

- weight 235 kg;

- steel heat exchanger.

How does a pellet boiler work

The principle of operation of the pellet boiler

The principle of operation of the pellet boiler

There are several schemes for the operation of pellet boilers. Classical - involves the pyrolysis of fuel, the decomposition of wood-containing raw materials at a low oxygen content. The gas formed during this process serves as the main energy carrier and is burned in a special chamber.

A classic-type pellet boiler is rarely found on the modern market. It requires a powerful power supply (the processing of pellets is carried out constantly by heating with a heating element), is sensitive to fuel quality, and is equipped with automatic metered air supply to the pyrolysis chamber. The equipment is difficult to set up, provides for periodic maintenance and diagnostics.

A medium-sized domestic and industrial pellet boiler, which can be bought in stores, operates according to the double combustion of fuel and flue gas. Everything works like this:

- pellets are fed into the primary heating chamber. Pyrolysis takes place in it, under the influence of high temperature, combustible gas is released from the heating element granules, the ignition procedure takes place;

- The flue gas formed during the pyrolysis enters the secondary afterburner, where the pellet burners are located. They can be of different types, for example, volumetric, directed (torch), fireplace;

- Pellets are fed into the afterburning zone by auger, they are exposed to the direct action of the flame and burn out almost completely.

Main models and prices on the market

Are you going to buy a pellet boiler with automatic pellet feeding? Then you have to spend an impressive amount of money. Let's take a look at the most popular models and give an example of prices.

Kentatsu Furst VULKAN PE-30

This boiler has a power of 35 kW and can be used for heating residential, industrial and administrative premises.It does not require frequent user intervention in its work and has a fairly large hopper for pellets. Fuel is supplied by a screw mechanism, and the volume of the bunker is 60 liters. The device is single-circuit, its cost is about 230-240 thousand rubles.

Valdai Bege Mott

Quite an unusual outdoor pellet boiler with automatic fuel supply. If you find something cheaper than this device, then you are very lucky, since its cost is only 80 thousand rubles. The power of the unit is 15 kW, the heated area is up to 150 square meters. m. The storage holds up to 60 kg of granulated fuel. This model differs in profitability and can be used for heating of houses and dachas.

Kupper PRO

Another low-cost model with auger feeding of pellets from a storage installed above the boiler itself. The device does not require user intervention - it is enough to add fuel, set the required thermal regime and start. This equipment will do everything else by itself - it will set fire to the fuel and bring the temperature in the system to a predetermined parameter. Users are only required to remove ash and replenish fuel supplies. Consumers can choose from models with a capacity of 22 kW and 28 kW, their cost is 96-99 thousand rubles.

All prices presented in the review are valid as of mid-August 2016 and may vary in one direction or another, depending on the dollar exchange rate and other market factors (including not the most obvious ones).

popular models:

Automatic pellet boiler kiturami korea

South Korea has long been known for its engineering gadgets.The Kiturami concern, well known in Russia as a manufacturer of high-quality pellet boilers, was no exception. Despite the fact that in the domestic market, the models are represented by only two modifications: KRP-20A with 24 kW and KRP-50A with a power of 58 kW, the Kiturami automatic pellet boiler is very popular among domestic consumers.

Pellet boiler Kiturami KRP-20A is a two-circuit modification designed to heat a residential building up to 240 m2. The second circuit is involved in the preparation of warm water. Kiturami KRP-20A is equipped with a loading chamber for 150 kg, the volume should provide autonomous heating for four days during the winter period. The Kiturami pellet boiler is equipped with a torch burner and a ceramic heating element.

An attractive feature is the automatic removal of caked slag deposits and ash from the burner pan. The removal procedure is carried out by means of a mechanical drive during operation. Not high cost, becomes the main plus in favor of Kiturami, its price is one and a half times lower than imported models.

Automatic pellet boiler pelletron pelletron 22 kW

Together with the usual advantages related to the use of automatic pellet boilers, such as: an automation system, prolonged autonomous operation and high efficiency, there are a number of additional advantages for the domestic development of Pelletron KT:

- Convenient loading of granules.

Standard designs of pellet boilers, the installation of a loading hopper is located on top. Indeed, the overall dimensions can be reduced, but the laying process becomes more complicated.Pellet boiler "Pelletron" placed its loading tank only at the level of one meter relative to the ground, thus facilitating the filling of pellets: - Easy operation

Routine maintenance and cleaning of the Pelletron boiler is easy. Approaches are carried out by simple access to all structural elements. All cleaning processes take about 30 minutes a week: - low cost

A traditional pellet boiler is always expensive equipment. The engineers of the Pelletron design managed to produce an optimal apparatus; a boiler can be purchased at half the cost of European analogues. - Can be used without a chimney

Domestic pellet boiler "Pelletron" was designed for operation with forced draft. Equipped with a fan, the boiler does not require a traditional, bulky chimney, and the exhaust gases are pulled out by the fan of the smoke exhauster into a pipe facing the street. The chimney pipe is led directly to the wall of the room.

The disadvantages of the pellet boiler Pelletron include dependence on electrical power and lack of versatility. The Pelletron boiler does not allow the use of other solid fuels and operates exclusively on pellets. On the other hand, the disadvantage is compensated by heating elements built into the boiler. Heating elements allow you to heat the room from the mains, during the absence of pellet granules.

In addition, we note the domestic pellet boiler Kupper about 22 kW Teplodar Kupper, which has positive feedback from the owners and offers a very attractive price.

Mechanized pellet boilers

Mechanical pellet boiler

This type of semi-automatic boilers will be attractive to those who are limited in finances and are willing to devote time to cleaning and maintaining the system. The units do not impose strict requirements on the quality of fuel, the storage hopper is designed for a day or two of work. The owner needs to devote 5 to 15 minutes a day to cleaning the heat exchanger, reloading fuel, controlling ignition after the start command.

The main advantage of mechanized boilers is versatility. It is immediately laid down by the manufacturer. Installations not only work on pellets of any quality, but are also equipped with separate fireboxes for burning firewood, granulated coal, and other energy carriers in manual mode.

Prices for pellet boilers

The price of a pellet boiler designed for a private home can range from $1,500 to $17,000. The variation in prices can be explained by the fact that the quality of the boilers may differ, and the presence of automation also plays a significant role.

Today, the Russian-made boiler Svetlobor, which has an automatic cleaning system and a power of 20 kW, costs $4,150.

The P1 Pellet boiler from Froling with a full set of automation with the ability to install a boiler unit for heating domestic water will cost the buyer $ 13,000. The power of this boiler is 7 kW.

One of the most budget options, at the moment, is the Kupper OVK 10 pellet boiler from the Russian manufacturer Teplodar. This model does not have automatic cleaning systems and has 10 kW at a cost of $1,500.

A pellet boiler is the best option for a heating system in the absence of the possibility of using gas as a fuel.Thanks to a huge variety of models, everyone can choose a boiler for their needs.

How do the efficiency of boilers with different burners differ?

Fuel supply to the pellet boiler

From what pellet burners of boilers are used in the equipment - its efficiency depends. The most efficient are systems where a volumetric burner is used (it is also a retort burner). Boilers of this design allow the use of low quality pellets.

Boilers with a flare (directional) nozzle have average efficiency indicators, and the lowest ones are found in fireplace insert installations, where pellets burn naturally, in an isolated area, while the flue gases are burned in a separate chamber. For these types of installations, the use of high quality fuel is recommended.

Despite the low efficiency indicators in their class, pellet boilers with a fireplace chamber have an undoubted advantage: they smoothly release heat, operate silently and can be installed even in the residential area of houses.

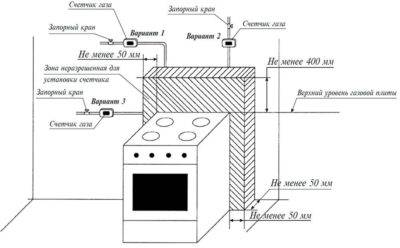

Where and how to put a pellet boiler

There are no uniform requirements for installing a pellet appliance, but there are a number of recommendations that make the boiler work safe.

Requirements for the premises

A heating solid fuel boiler with a pellet burner with a chimney can only be installed in non-residential, specially designated premises.

It is necessary to make a solid base with a refractory coating. Cement screed or ceramic tiles that are resistant to high temperatures are perfect.

Example of boiler room equipment

Example of boiler room equipment

There should be a large ledge around the fixture, and under the pellet boiler, the spade should be twice the area of \u200b\u200bits base.

The room is equipped with good ventilation, lighting, free access is maintained in case of manual adjustment, cleaning.

Storage of a large amount of fuel requires a separate room.

Chimney installation rules

The removal of combustion products from the room prevents the poisoning of people living in the house, so the correct assembly of the chimney is very important.

Design features include the presence of forced ventilation.

The parts must be made of a material that can easily withstand heating up to +1000 ºС, and at the highest point they put a spark arrester, a deflector that increases traction.

Where to store and how to fill up wood pellets?

Fuel supply is carried out using a vacuum pump or screw transmission.

Both options have their pros and cons, but before sending the pellets to the burner, they need to be stored somewhere.

Blanks can only be kept indoors with normal or low humidity levels (granules quickly absorb water and become unusable).

Fuel storage option

Fuel storage option

The timber transport system operates only from the mains, so it is necessary to provide a constant source of energy. In the event of a power failure or emergencies, it is better to provide an option for backup power supply with uninterrupted power. Then the required level of heat will be maintained, the boiler will be protected, which can break down from such power surges.

Maintenance

Any technique sometimes fails, but not always they can be fixed on their own.

If the control unit loses power or the equipment does not warm up to the set temperature, then the problems are most likely in the recorded algorithm.But it is impossible to say for sure, since there are several reasons for such problems.

Many problems are fixed only after running the wizard. Trying to repair the heater yourself is not recommended, unless its owner is a boiler repair specialist.