- Why are they in demand?

- How to choose the right pellet boiler

- Type of heat exchanger

- Work automation

- Fuel supply

- Burner type

- Rating of the best pellet boilers

- Heiztechnik Q Bio Duo 35

- Sunsystem v2 25kw/plb25-p

- Stropuva P20

- Kiturami KRP 20a

- Froling p4 pellet 25

- ACV Eco Comfort 25

- Pelletron 40 CT

- Teplodar Kupper PRO 22 with APG25

- Zota Pellet 15S

- Faci base 258 kW

- Types of boilers

- Manufacturers of pellet boilers

- Teploekos

- Teplodar

- Stropuva

- Yaik

- obshchemash

- TIS

- The first criterion is the availability of pellets

- Orange and Ridan

- Overview of domestic boilers

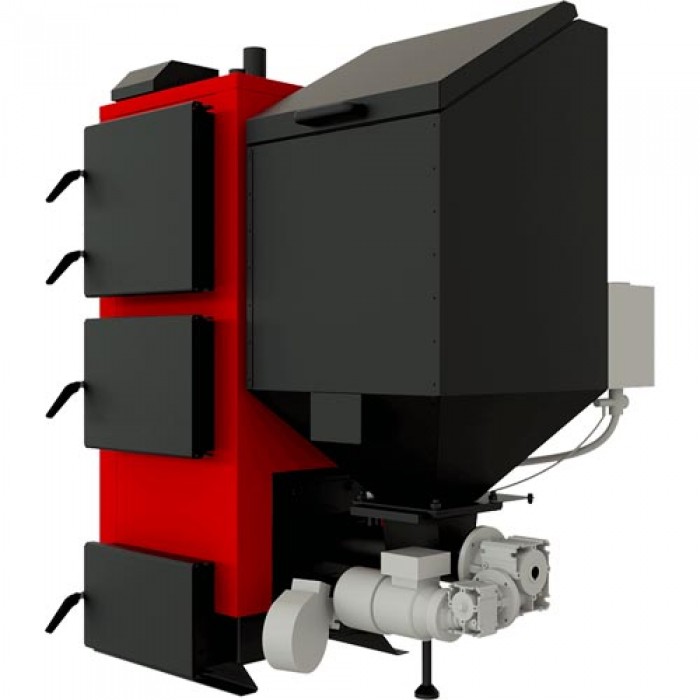

- Modifications of pellet boilers

- What it is

- Advantages of pellet boilers

- Flaws

- Manufacturers

- in Russia

- In the world

- Main characteristics

- Fuel for a pellet boiler - pellets

- Features of the national pellet boiler

Why are they in demand?

The demand for pellet boilers and the increasing demand for them is due to several reasons.

The lack of centralized heating lines in the regions encourages residents to look for the most efficient alternatives, focusing on autonomous heating systems

Most often, the boiler is installed in a separate room or outside the building.

Viessmann is a brand that manufactures heating, cooling and industrial systems for various types of buildings and structures

- During the period of price increase, it is natural that people want to save money, and it is profitable to heat with granular sawdust.

- The coefficient of performance (COP) of pellet boilers is out of competition - 90-95%.

- Improved models are constantly appearing, which are easier to maintain and lower cost.

High efficiency is one of the main advantages of pellet boilers

How to choose the right pellet boiler

Prices for pellet boilers for heating a private house start at 70-75 thousand rubles. A little expensive, but for this money you will receive equipment with a capacious bunker and automatic supply of pellet fuel. For less money you will get a universal solid fuel boiler with manual loading. A pellet boiler for a private house can be more expensive - it all depends on its filling.

Type of heat exchanger

When choosing a pellet stove, pay attention to the heat exchanger, it is desirable that it be made of cast iron. We advise you to purchase pellet boilers with cast-iron heat exchangers, and multi-pass

Cast iron is an ideal material for creating heat exchangers - it is strong enough, warms up quickly and cools down slowly, and withstands temperature overloads well. If there are several moves in it, then this is a plus - the exchanger will be able to absorb the maximum amount of heat. The main disadvantages of cast iron are brittleness and lack of resistance to water hammer.

We advise you to purchase pellet boilers with cast-iron heat exchangers, and multi-pass ones. Cast iron is an ideal material for creating heat exchangers - it is strong enough, warms up quickly and cools down slowly, and withstands temperature overloads well. If there are several moves in it, then this is a plus - the exchanger will be able to absorb the maximum amount of heat.The main disadvantages of cast iron are brittleness and lack of resistance to water hammer.

Steel heat exchangers differ from their cast-iron counterparts in resistance to water hammer. True, they are more susceptible to corrosion and do not tolerate thermal overloads. Therefore, they are used only in the cheapest pellet boilers used for heating private households.

The recommended types of heat exchangers are fire tube or flat type made of cast iron. If the exchanger is vertical, then this is only a plus - they are well cleaned of ash, which simply falls down.

Work automation

We have already said that pellet boilers used for heating private houses can work without regular approaches from users - you just need to periodically add new portions of pellets and remove ash. The most advanced pellet boilers are endowed with the following features:

- Automatic temperature control in the heating system of a private house;

- Automatic ignition - no need to ignite the fuel yourself;

- Control of operating parameters - here the pressure in the heating system, the temperature of the coolant, the quality of fuel combustion and many other parameters are controlled.

In addition, some pellet boilers provide fuel availability control.

Fuel supply

Using a flexible auger will allow you to place the fuel hopper away from the boiler itself.

Pellet boilers for heating a private house are endowed with two types of screws - flexible and rigid. Rigid augers are implemented in all boilers with automatic pellet feeding. By their design, they resemble a meat grinder, smoothly moving the granules from the hopper to the combustion chamber. The main feature of the rigid auger is the fixed length.That is, we cannot rearrange the bunker to another place.

Flexible augers allow you to place pellet bins at any point, for example, in a neighboring corner of the house. Fuel enters pellet boilers through a kind of flexible pipe in which a flexible screw rotates. Its length can reach 10 meters or more. To synchronize the standard rigid and external flexible augers, automation with electric motors is used.

Burner type

We have come to a very important criterion for choosing a pellet boiler for organizing heating in a private house - this is the type of burner. There is no particular variety here; in pellet boilers, either retort burners or flare burners are found

The retort burner operates in a vertical plane, the flame bursts upwards, fuel enters it from below or from the side (in bulk). Air enters through the slots on the sides. The disadvantage of such a burner is that it can periodically go out, becoming clogged with ash.

If you want to get rid of this disadvantage, use low-ash pellet fuel - it burns almost completely and does not form a large amount of ash.

We advise you to choose pellet stoves with a torch burner, it works much more stable than a retort burner.

Horizontal flare burners are free from the disadvantages of retort burners. The flame here is literally blown out by a powerful fan, leaving in a horizontal plane. Pellet burning takes place on a special platform, the ash is discharged down. Due to the powerful blowing, such a burner is characterized by high efficiency, allowing you to organize good heating work in a private household.

Rating of the best pellet boilers

Heiztechnik Q Bio Duo 35

Considered universal.The device is equipped with 2 fire chambers, can work at firewood and pellets. The power range is 12-35 kW, but the efficiency is slightly lower than most models - 88%.

The features of the model are:

- automatic supply of air and fuel;

- adjustment depending on weather conditions;

- economical consumption of raw materials;

- microprocessor control.

Sunsystem v2 25kw/plb25-p

This is a Bulgarian boiler, reliable and efficient. With a power of 25 kW, it heats large rooms.

Of the advantages, the self-cleaning function, automated operation, and high-quality transport auger are distinguished.

Stropuva P20

The model is the development of a Lithuanian brand. The main advantages are considered high efficiency, simplicity of design. The machine does not have an auger for fuel supply, pellets enter the chamber under the action of their own weight and gravity. There is no automatic ignition system. You need to use a gas burner, but this is a safe and convenient way.

4 thermal sensors are responsible for monitoring the operation. The air supply is regulated by a built-in fan. The power of the unit is 20 kW. Taking into account the heat loss, this indicator is enough to heat a room up to 180 square meters. m.

Kiturami KRP 20a

This is a reliable and productive boiler of a South Korean brand. The power of the device is enough to heat an area up to 300 square meters. m. The capacity of the bunker is 250 liters.

The unit is equipped with overheating protection (the thermal valve is activated and cold water is supplied to the system). The equipment is characterized by a convenient function of vibration cleaning, low noise level during operation, piezo ignition.

A double-circuit boiler heats not only the room, but also water, and consumes 5 kg of fuel per hour.The advantage of the device is considered to be high efficiency for this category of equipment - 92%.

Froling p4 pellet 25

The model is characterized by high energy efficiency. The device can be equipped with a condensing heat exchanger with recuperation function. The latter means that thermal energy is returned to the technological cycle. Therefore, the efficiency of the equipment reaches 100%.

ACV Eco Comfort 25

The model of the Belgian brand has a power of 25 kW. This is enough to heat a room of 200 sq. m. The peculiarity of the boiler is a heat exchanger made of copper (the most durable and durable material).

The tank is designed for a volume of 97 liters, which allows you to quickly transfer hot water to the pipes. The body walls are made of 5 mm thick alloy, so heat is retained for a long time.

Pelletron 40 CT

The boiler of the Russian brand is distinguished by good performance and a power of 40 kW. The efficiency is 92.5%, which is a high figure for this category of equipment.

Characterized by a built-in fire extinguishing valve and a smoke exhauster, convenient cleaning of the burner. Granules are fed into the compartment under their own weight.

They also note economical fuel consumption - 230 g per hour. Therefore, when the bunker is fully loaded, the boiler operates for several days. The only drawback is the lack of automation. The device is controlled mechanically.

Teplodar Kupper PRO 22 with APG25

It is a modified model of "Cooper PRO". This is a single-circuit boiler with an automatic burner APG-25. It is supplied as a set, since the fuel hopper is equipped with a feeder and a control panel. A feature of the device is the unusual location of the tank (directly on the boiler itself).

The advantage of the model is space saving. However, loading fuel is inconvenient compared to other boilers. The power range of the device is 4-22 kW. The unit runs on pellets and wood.

Zota Pellet 15S

This is a Russian-made boiler. The power is 15 kW, the device is used to heat rooms up to 120 square meters. m (including heat loss). The volume of the bunker is 293 l.

Of the advantages, reliable automation is distinguished that regulates the amount of air supplied and the operation of pumps. Users note a convenient control panel equipped with a display that displays important indicators. A remote control module is also connected to the boiler.

The device has no shortcomings. But, like other devices in this category, the unit weighs a lot - 333 kg. This feature must be taken into account during installation.

Faci base 258 kW

An efficient device with a self-cleaning burner and a multi-pass heat exchanger allows you to achieve maximum results at a relatively low cost.

The model is unpretentious to the quality of fuel, it works on pellets, firewood. The function of controlling the air temperature in the room is provided.

Types of boilers

Depending on the principle of operation, functionality and fuel consumption, pellet boilers are divided into several types:

- Pots for granules. Work exclusively with granules. Ensure reliable fuel supply to ensure trouble-free operation of the system.

- Conventional combi boilers. In such installations, the stove can be used universally, which allows the use of other types of fuel, such as briquettes or firewood. Other fuels are used only in extreme cases. In general, the boiler is designed for pellets.

- Combined boilers.The installation has several combustion chambers designed for a particular type of fuel. Universal boilers are bulky and quite expensive.

Depending on the type of fuel supply, boilers are divided into the following categories:

- Pellet boiler with automatic feeding. Fuel is supplied automatically. In order to set up the equipment to maintain optimal temperature conditions, it is necessary to use the services of professionals.

- Semi-automatic boiler. The capacity of the plant is adjusted manually. Power is supplied automatically. Such boilers are the best solution for country houses, due to their low cost and quality.

- Boiler without a machine. Fuel is supplied manually, which creates inconvenience.

As for the purpose of the heating system, there are several types of heating systems:

- Water heater. It is located mainly in the basement because the boiler is large and unsightly.

- Convection boiler. Often placed in living rooms, due to their small size. They are easily integrated into the interior and do not require the installation of chimneys.

- Hybrid boiler. The pyrolysis boiler simultaneously heats the room and the coolant in the form of water. Some models are equipped with an oven and a hob.

The main element of the boilers is a pellet burner, which can have various modifications (you can read about the types of pellet burners here). Depending on this, they are divided into the following categories:

- Burner. They are very common in everyday life. Often they are installed in a compact boiler. They are easy to adjust and very reliable in operation. High quality pellets are used as fuel.

- Bulk burners.They have high power and are often installed in industrial boilers. A feature of the system is that it can run on lower fuel.

- Smoke burner. They are original in design. The pellets are thrown into the cast-iron bowl of the boiler, where they burn. Externally, the installation looks like a fireplace.

Pellet boilers usually work with pellets. But some models can also use other fuels such as coal or wood.

Oh, yes, of course, the efficiency of the boiler in this case will lose weight a little, so experts recommend using the first type of fuel, and not alternative options. Various raw materials are used for the production of pellets. Wood pellets are the most efficient fuel.

Note: When used in pellet boilers, and not in pellets and other fuels, it should be taken into account that this leads to a reduction in emissions. Efficiency In addition, some materials emit pollutants during combustion.

The second place is occupied by straw tablets. Peat pellets and seed pellets are also used as fuel. As an alternative for the production of pellets wheat, rapeseed, flax and rye waste are used.

Manufacturers of pellet boilers

The market for manufacturers of such equipment is diverse. But not everyone can vouch for the quality of the proposed product.

Teploekos

A manufacturer who has improved process automation in models. Boilers can work autonomously for at least a month, it depends on its power and performance.The system is self-cleaning, and the granules are fed by vacuum methods, which makes the process more autonomous.

Teplodar

The leader of the Russian market for the creation of furnaces and boilers for solid fuels. The bunker in such models is installed on the boiler body. This emphasizes the individuality of the produced boilers and makes them more individual. It is allowed to use a burner device, which can be additionally mounted.

Stropuva

Lithuanian manufacturer, which has been on the boiler market for over 20 years. The most famous model was the P20 equipment, provided with four temperature sensors. The uniqueness of the boilers of this company lies in the fact that the pellets burn under the action of gravity, automatic ignition is not provided.

Models without an auger work, they are equipped with environmentally friendly filters, which makes it possible to clean the equipment much less frequently. The manufacturer guarantees continuous operation for 23 hours.

Yaik

The manufacturer in his boilers has created a universal heating system. All sorts of fuel options are allowed, from wood to peat. This is quite convenient, because there is a choice of heating method. Affordable cost and long operation are the undoubted advantages of a domestic manufacturer.

obshchemash

The boilers of this manufacturer are popular and successful due to the high level of performance and automation of maintaining a certain temperature in the room. All devices are protected from overheating, environmentally friendly and safe. Another domestic manufacturer whose boilers are distinguished by high power.

TIS

Belarusian manufacturer of boilers, which offers a wide range of fuel for equipment.Devices of this type can work both on standard wood or peat, and on cherry stones, grain and other very different pellets. The models have a room thermostat for temperature control. Able to work autonomously up to 35 hours.

The first criterion is the availability of pellets

The main question we ask our customers is: do you have access to fuel pellets? And no matter how simple it may seem, many people are perplexed. This issue is especially acute in areas with a shortage of forest resources (for example, in some areas of the Krasnodar Territory).

Let's give such a household example: you can buy a modern and reliable car with an internal combustion engine, but without gasoline it will not go anywhere, no matter how hard you try! If you are planning to buy a pellet boiler, then find out if fuel pellets are produced near you (approximately within a radius of 250 km). If not, then all the economic benefits of this type of heating are nullified. The whole reason is the considerable price of their delivery, especially for commercial facilities.

This is interesting: Willow for hedges: explaining the issue

Orange and Ridan

The models optimally combine cost and quality.

Consumers are happy to give preference to this product, because it is easy to set up and use.

The combustion process in this boiler is completely automated.

All performance indicators can be viewed on the display. The efficiency of the unit is 93%.

To date, Ridan is the largest manufacturer.

The company works together with the Danish company Sondex, which allows us to produce high quality equipment at an affordable price. All components and pressing are carried out under comprehensive quality control.

Advantages of Ridan units:

- Economical and easy maintenance.

- Low contamination of the boiler surface.

- Long service life.

- Inexpensive installation.

- Possibility to choose the configuration accordingly for both circuits.

Overview of domestic boilers

The growth in demand for solid fuel boilers was facilitated by the development of pellet production in Russia. A pellet granule made from pressed wood shavings is a cylinder with a diameter of 6 to 10 mm and a length of up to 30 mm.

Due to grinding and pressing (the press develops a pressure of up to 300 atm) of the source material, pellets with the same mass occupy a much smaller volume than conventional fuel and burn almost without residue. And the granular format of this fuel makes it possible to automatically feed it by means of screw and piston feeders. At the same time, the volumetric fuel consumption is so low that one filling of a standard-sized bunker is enough for a whole week of operation of the unit.

Solid fuel boiler START

- The most popular Russian-made pellet solid fuel heating boiler is manufactured by NCC BiyskEnergoproekt. A characteristic "trick" of this manufacturer is the bright orange color of the body, for which the people began to call the boiler "orange". The unit is equipped with an electronic control system and is even equipped with a display showing information about the operating mode and the state of the boiler.

- Boilers "Start" are also oriented to the use of pellets, but the design of these units allows the use of any other type of solid fuel. While other solid fuel boilers made in Russia are mostly loaded from above, in Starts the feed conveyor is located horizontally.This design is more tolerant of fuel with an uneven fraction and can work with it stably, without congestion and jamming.

- Boilers of the Elephant Trademark, which is also of domestic origin, have many advantages. The main one can be considered a surprisingly high efficiency - in the range of 95% - 97%. This efficiency was achieved due to the special design of the firebox and the surrounding water jacket. The service life declared by the manufacturer is 25 years.

- Russian-made pyrolysis boilers, also called gas-generating or long-burning boilers, are also well represented on the market. Given the limited space of the article, we will cover only a few brands.

Modifications of pellet boilers

Pellet boilers allow you to achieve high automation of the heating process. An electronic control unit is often used for this. With it, you can set the desired mode of operation for a certain period. Depending on the capacity of the bunker, the period of independent work (without human intervention) can reach 1-4 weeks. In addition, a number of models of boilers from some manufacturers are equipped with a GSM control module. Through it, using SMS, you can control the boiler and monitor its condition.

Another feature of pellet boilers is a lambda probe. This is an exhaust gas oxygen sensor. It is usually placed in front of the chimney, in the exhaust manifold. With its help, automation maintains the optimal mode of combustion of the flame (with the help of fans).

Of course, the presence of automation requires connection to the electrical network. The boiler becomes volatile.There are non-volatile models of pellet boilers, but they are few and functionally limited. If the boiler consumes little power from the mains, sometimes they install an uninterruptible power supply (UPS for heating boilers) with good external batteries.

What it is

The main types of pellets:

white - from high quality wood, low ash content up to 0.5%, but expensive;

agropellets - waste from agricultural crops (straw, sunflower husks) with a high ash content, as well as the need for regular cleaning of the boiler from slag;

industrial - gray-brown in color with a high content of bark, ash content more than 0.7%, not recommended for domestic use.

Advantages of pellet boilers

- high degree of automation with programming of operating modes, as well as long-term operation without operator intervention;

- equipment with remote sensors;

- simple maintenance;

- remote control from mobile applications or via a GSM module;

- high efficiency;

- economical consumption of pellets compared to diesel fuel, liquefied gas or electricity;

- long service life;

- minimal emissions of harmful substances.

Flaws

- high cost of pellets;

- sensitivity to their quality;

- the need for dry storage;

- dependence on electricity supply;

- impressive dimensions.

Manufacturers

in Russia

Among the abundance of domestic manufacturers of such boilers, only a few brands stand out that have won recognition from buyers as a reliable and high-quality product:

- Svetlobor - Teploekos company produces automatic Russian-made pellet boilers. They are distinguished by a good level of automation, which ensures the possibility of its autonomous operation up to a month.Equipped with a self-cleaning system, vacuum fuel supply and control of several heating circuits.

- Kupper OK - produced by Teplodar. They are distinguished by the design of the bunker, which is mounted on the boiler body.

- Roteks - highly automated pellet boilers for home heating, designed for a week of autonomous operation. They are equipped with a safety system that notifies of the approach of fuel to the end.

- Start is a manufacturer of pellet boilers, offering both household and industrial equipment. A distinctive feature is the large capacity bunker and ash box.

- Elephant - a module with a vertical arrangement of a fire-tube and two-pass heat exchanger. Elephant products use forced air supply to the combustion zone, which reduces fuel underburning to a minimum.

- Yaik - the company's products have won appreciation due to the versatility of the fuel used. The boilers of this company can be easily converted to work from diesel fuel, fuel briquettes, wood logs, wood chips or pellets. Heating elements are built into them for heating the coolant, they work on the principle of an electric boiler.

The products of Russian manufacturers are high-performance, reliable equipment at an affordable price.

In the world

Equipment from many foreign companies is sold on domestic shelves:

- Wirbel and OkoFEN from Austria;

- Biomaster and Ferroli from Italy;

- Rosh Chinese-Korean production;

- Grandeg from Latvia;

- Stropuva from Lithuania;

- Wirbel and Viessmann from Germany;

- Metal fach from Poland;

- Serbian ACVs from Serbia;

- Termax from the Finns;

- Termal and Viadruss from the Czech Republic.

Main characteristics

The main characteristic of the boiler is its heat output in kW.Based on this parameter, the possibility of heating a building of a certain area is estimated. An approximate calculation shows that 1 kW of thermal power allows you to heat 10 m2 of area.

Another important characteristic is the coefficient of performance (COP) as a percentage, which shows how much energy released during the combustion of the fuel is transferred to heat the coolant. The higher the efficiency, the more efficient the boiler

And another characteristic that you should definitely consider when choosing is the type and quality of the fuel used.

The efficiency of the device and the possibility of problems during its operation depend on the quality of the fuel.

Other characteristics of the devices are selected based on the wishes and financial capabilities of the buyer.

Fuel for a pellet boiler - pellets

- White pellets. They are made from peeled wood without bark. This type is used for housing heating, because it does not create emissions hazardous to human health and has a high calorific value.

Important to know: Properly produced pellets have a very smooth surface. This is an indicator of how natural materials were used for bonding.

Black pellets

In their production, wood is used with bark, and the material is used for heating industrial premises. This species produces less heat when burned, and is more dangerous for humans.

Features of the national pellet boiler

In the 90s, the market for heating equipment was dominated by foreign brands. However, the production of pellet boilers in Russia developed at an accelerated pace, and domestic manufacturers began to make themselves more and more loud.The main advantage of their products is that during its development, factors that are characteristic only for Russia and the CIS countries were taken into account:

- instability of power supply parameters in suburban settlements;

- low quality of the coolant in autonomous heating systems;

- periodic lack of pellet fuel on sale or its low quality.

Do not forget about the significant difference in price: imported equipment can cost several times more than ours with the same characteristics. Thanks to these advantages, a Russian-made pellet boiler competes confidently with its foreign counterpart and enjoys well-deserved respect from the consumer.

![Pellet boilers [reviews, rating and benefits]](https://fix.housecope.com/wp-content/uploads/f/c/b/fcb378f2c29296b9fdf080eb1122abbb.jpg)

![Pellet boilers [reviews, rating and benefits]](https://fix.housecope.com/wp-content/uploads/e/a/a/eaa0f502ab76169ceefc94ead479bf0a.jpeg)