- Instructions for installing a pellet boiler

- Preparatory work

- Boiler installation and piping

- Chimney connection, start-up and adjustment

- Rating of the best pellet boilers

- Heiztechnik Q Bio Duo 35

- Sunsystem v2 25kw/plb25-p

- Stropuva P20

- Kiturami KRP 20a

- Froling p4 pellet 25

- ACV Eco Comfort 25

- Pelletron 40 CT

- Teplodar Kupper PRO 22 with APG25

- Zota Pellet 15S

- Faci base 258 kW

- How to choose the right pellet boiler

- Type of heat exchanger

- Work automation

- Fuel supply

- Burner type

- Popular manufacturers

- 2 Kostrzewa Pellets Fuzzy Logic 2 25 kW

- Boilers from Wirbel - versatility and ease of installation

- Heat accumulators

- Boiler Assembly Manual

- Housing and heat exchanger

Instructions for installing a pellet boiler

The main and important stage in the installation is a professionally executed design. It is followed by the following steps for installing heating equipment:

- Preparatory stage. Includes the preparation of the boiler room, the erection of a hill for the boiler, the installation of a chimney, ventilation;

- Installation of the heating unit on a hill;

- Connection to the boiler pipes of the heating system and hot water supply;

- Connection of the chimney channel;

- Adjustment and start-up of the heating device.

Preparatory work

It is necessary to prepare the boiler room - level and strengthen the base, which must withstand weight up to 200 kilograms. According to the requirements, the boiler is installed vertically, so there should not be any slope. The base must have a fireproof surface.

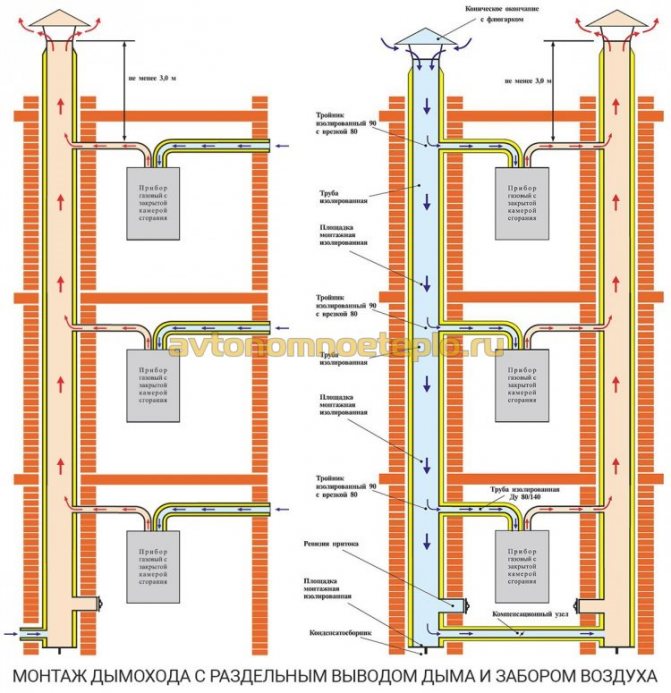

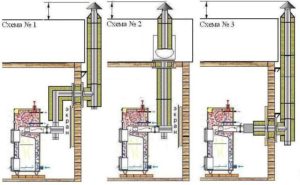

Laying electrical wiring is needed to automate the heater and to illuminate the boiler room, which will ensure convenience during operation. The construction of a chimney of the sandwich type, at least 5 meters high. A chimney and ventilation are also installed.

Boiler installation and piping

- The brought boiler is mounted on the podium;

- A fuel compartment and an auger supplying pellets are mounted;

- The distribution comb is connected;

- An expansion tank and shutoff valves are being installed;

- The boiler is connected to the circuit supplying the coolant and the return circuit.

Chimney connection, start-up and adjustment

The appropriate diameter will provide good traction regardless of wind strength and air temperature. Good traction is the key to the efficient operation of pellet equipment. But this type of boiler is afraid of strong traction, but too small will not work either. Therefore, to solve this problem, a thrust stabilizer or a slide gate is used.

Most often, the chimney is made of a metal pipe, in which hatches are built for further cleaning. Also, the chimney should be equipped with a device for removing condensate and insulating it. An important step is pressure testing, if it is done poorly, pyrolysis gases will leak, which will lead to a decrease in efficiency.

After that, a test run and adjustment are carried out. An improperly tuned device will entail such problems: the boiler will smoke, smoke, go out and the pellets will not burn out to the end.

Rating of the best pellet boilers

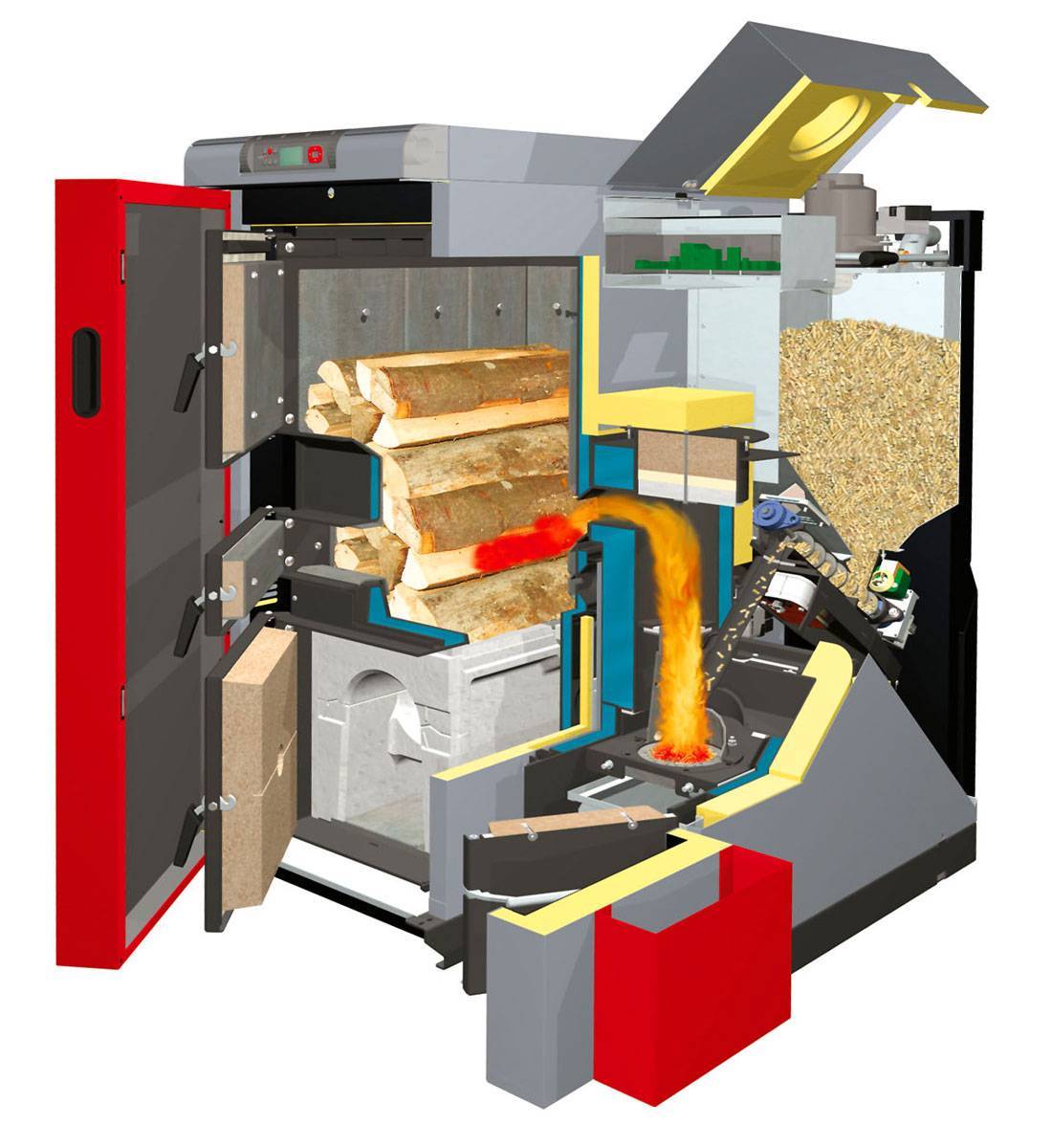

Heiztechnik Q Bio Duo 35

Considered universal. The device is equipped with 2 fire chambers, can work at firewood and pellets. The power range is 12-35 kW, but the efficiency is slightly lower than most models - 88%.

The features of the model are:

- automatic supply of air and fuel;

- adjustment depending on weather conditions;

- economical consumption of raw materials;

- microprocessor control.

Sunsystem v2 25kw/plb25-p

This is a Bulgarian boiler, reliable and efficient. With a power of 25 kW, it heats large rooms.

Of the advantages, the self-cleaning function, automated operation, and high-quality transport auger are distinguished.

Stropuva P20

The model is the development of a Lithuanian brand. The main advantages are considered high efficiency, simplicity of design. The machine does not have an auger for fuel supply, pellets enter the chamber under the action of their own weight and gravity. There is no automatic ignition system. You need to use a gas burner, but this is a safe and convenient way.

4 thermal sensors are responsible for monitoring the operation. The air supply is regulated by a built-in fan. The power of the unit is 20 kW. Taking into account the heat loss, this indicator is enough to heat a room up to 180 square meters. m.

Kiturami KRP 20a

This is a reliable and productive boiler of a South Korean brand. The power of the device is enough to heat an area up to 300 square meters. m. The capacity of the bunker is 250 liters.

The unit is equipped with overheating protection (the thermal valve is activated and cold water is supplied to the system). The equipment is characterized by a convenient function of vibration cleaning, low noise level during operation, piezo ignition.

A double-circuit boiler heats not only the room, but also water, and consumes 5 kg of fuel per hour.The advantage of the device is considered to be high efficiency for this category of equipment - 92%.

Froling p4 pellet 25

The model is characterized by high energy efficiency. The device can be equipped with a condensing heat exchanger with recuperation function. The latter means that thermal energy is returned to the technological cycle. Therefore, the efficiency of the equipment reaches 100%.

ACV Eco Comfort 25

The model of the Belgian brand has a power of 25 kW. This is enough to heat a room of 200 sq. m. The peculiarity of the boiler is a heat exchanger made of copper (the most durable and durable material).

The tank is designed for a volume of 97 liters, which allows you to quickly transfer hot water to the pipes. The body walls are made of 5 mm thick alloy, so heat is retained for a long time.

Pelletron 40 CT

The boiler of the Russian brand is distinguished by good performance and a power of 40 kW. The efficiency is 92.5%, which is a high figure for this category of equipment.

Characterized by a built-in fire extinguishing valve and a smoke exhauster, convenient cleaning of the burner. Granules are fed into the compartment under their own weight.

They also note economical fuel consumption - 230 g per hour. Therefore, when the bunker is fully loaded, the boiler operates for several days. The only drawback is the lack of automation. The device is controlled mechanically.

Teplodar Kupper PRO 22 with APG25

It is a modified model of "Cooper PRO". This is a single-circuit boiler with an automatic burner APG-25. It is supplied as a set, since the fuel hopper is equipped with a feeder and a control panel. A feature of the device is the unusual location of the tank (directly on the boiler itself).

The advantage of the model is space saving. However, loading fuel is inconvenient compared to other boilers. The power range of the device is 4-22 kW. The unit runs on pellets and wood.

Zota Pellet 15S

This is a Russian-made boiler. The power is 15 kW, the device is used to heat rooms up to 120 square meters. m (including heat loss). The volume of the bunker is 293 l.

Of the advantages, reliable automation is distinguished that regulates the amount of air supplied and the operation of pumps. Users note a convenient control panel equipped with a display that displays important indicators. A remote control module is also connected to the boiler.

The device has no shortcomings. But, like other devices in this category, the unit weighs a lot - 333 kg. This feature must be taken into account during installation.

Faci base 258 kW

An efficient device with a self-cleaning burner and a multi-pass heat exchanger allows you to achieve maximum results at a relatively low cost.

The model is unpretentious to the quality of fuel, it works on pellets, firewood. The function of controlling the air temperature in the room is provided.

How to choose the right pellet boiler

Prices for pellet boilers for heating a private house start at 70-75 thousand rubles. A little expensive, but for this money you will receive equipment with a capacious bunker and automatic supply of pellet fuel. For less money you will get a universal solid fuel boiler with manual loading. A pellet boiler for a private house can be more expensive - it all depends on its filling.

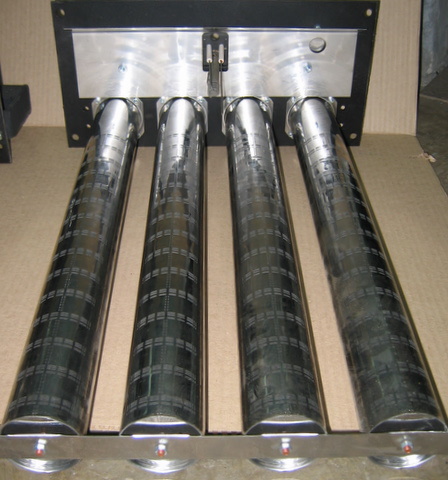

Type of heat exchanger

When choosing a pellet stove, pay attention to the heat exchanger, it is desirable that it be made of cast iron. We advise you to purchase pellet boilers with cast-iron heat exchangers, and multi-pass

Cast iron is an ideal material for creating heat exchangers - it is strong enough, warms up quickly and cools down slowly, and withstands temperature overloads well. If there are several moves in it, then this is a plus - the exchanger will be able to absorb the maximum amount of heat. The main disadvantages of cast iron are brittleness and lack of resistance to water hammer.

We advise you to purchase pellet boilers with cast-iron heat exchangers, and multi-pass ones. Cast iron is an ideal material for creating heat exchangers - it is strong enough, warms up quickly and cools down slowly, and withstands temperature overloads well. If there are several moves in it, then this is a plus - the exchanger will be able to absorb the maximum amount of heat. The main disadvantages of cast iron are brittleness and lack of resistance to water hammer.

Steel heat exchangers differ from their cast-iron counterparts in resistance to water hammer. True, they are more susceptible to corrosion and do not tolerate thermal overloads. Therefore, they are used only in the cheapest pellet boilers used for heating private households.

The recommended types of heat exchangers are fire tube or flat type made of cast iron. If the exchanger is vertical, then this is only a plus - they are well cleaned of ash, which simply falls down.

Work automation

We have already said that pellet boilers used for heating private houses can work without regular approaches from users - you just need to periodically add new portions of pellets and remove ash.The most advanced pellet boilers are endowed with the following features:

- Automatic temperature control in the heating system of a private house;

- Automatic ignition - no need to ignite the fuel yourself;

- Control of operating parameters - here the pressure in the heating system, the temperature of the coolant, the quality of fuel combustion and many other parameters are controlled.

In addition, some pellet boilers provide fuel availability control.

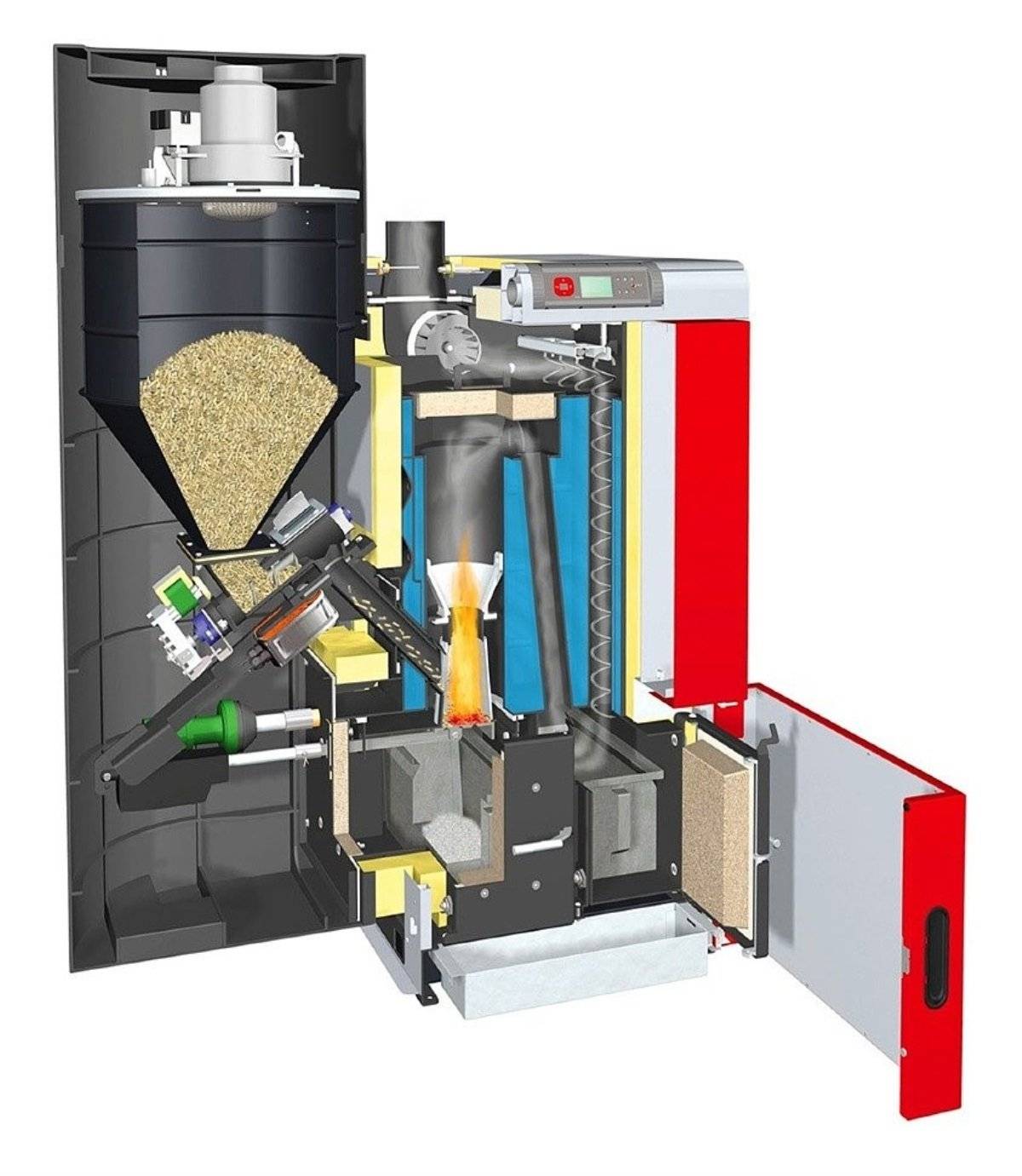

Fuel supply

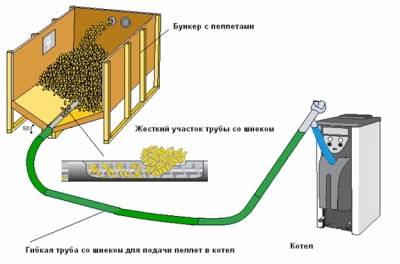

Using a flexible auger will allow you to place the fuel hopper away from the boiler itself.

Pellet boilers for heating a private house are endowed with two types of screws - flexible and rigid. Rigid augers are implemented in all boilers with automatic pellet feeding. By their design, they resemble a meat grinder, smoothly moving the granules from the hopper to the combustion chamber. The main feature of the rigid auger is the fixed length. That is, we cannot rearrange the bunker to another place.

Flexible augers allow you to place pellet bins at any point, for example, in a neighboring corner of the house. Fuel enters pellet boilers through a kind of flexible pipe in which a flexible screw rotates. Its length can reach 10 meters or more. To synchronize the standard rigid and external flexible augers, automation with electric motors is used.

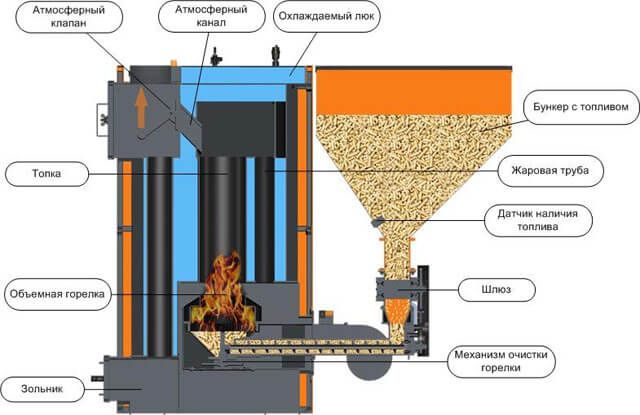

Burner type

We have come to a very important criterion for choosing a pellet boiler for organizing heating in a private house - this is the type of burner. There is no particular variety here; in pellet boilers, either retort burners or flare burners are found

The retort burner operates in a vertical plane, the flame bursts upwards, fuel enters it from below or from the side (in bulk). Air enters through the slots on the sides.The disadvantage of such a burner is that it can periodically go out, becoming clogged with ash.

If you want to get rid of this disadvantage, use low-ash pellet fuel - it burns almost completely and does not form a large amount of ash.

We advise you to choose pellet stoves with a torch burner, it works much more stable than a retort burner.

Horizontal flare burners are free from the disadvantages of retort burners. The flame here is literally blown out by a powerful fan, leaving in a horizontal plane. Pellet burning takes place on a special platform, the ash is discharged down. Due to the powerful blowing, such a burner is characterized by high efficiency, allowing you to organize good heating work in a private household.

Popular manufacturers

| Manufacturer, model. | Characteristic |

|---|---|

| D'ALESSANDRO Termomeccanika. SCA series model | Italian brand, which is certified in Russia. This is a double-circuit pellet boiler with a three-way heat exchanger and a cast-iron burner. Bunker in the form of a cylinder with an automatic inverter and a fire extinguishing function for 480 liters. Pressurization of air into the combustion chamber by an electric fan. Standard control panel. Electronic control system with GSM module. Automatic electric ignition and stable combustion support. Setting the intensity of the flame with a lambda probe. The heat transfer device in the combustion chamber is ceramic. Function of automatic cleaning from ashes. Hopper filling indicators. Function of pneumocleaning of slags. Additional heater of a contour of hot water supply. Allows work on pellets, shavings, sawdust, small chips. Feeding of raw materials is double-screw and with an intermediate bunker. |

| Kostrzewa. Pellets Fuzzy Logic II P range | Polish brand.The boiler operates in automatic mode on industrial, grain, household wood pellets, fine coal, and in manual mode - on fuel briquettes, firewood, coarse coal. The efficiency reaches 90%. There is an automatic ignition. Several modes of economy (summer, hot water supply, autonomous, weather). Built-in multilingual menu control system. Exhaust tabulator and lambda sensor. Three additional retort plates for different types of raw materials. Four-way mixing valve for controlling and dividing the flows of two circuits. Three-way steel heat exchanger. Enlarged ash pan. Cleaning is carried out once every five months. Steel auger. Economical gear motor. Individual pumps for heating and for hot water supply. Many sensors and control circuits. |

| Kiturami. KRP range | Manufacturer - South Korea. These are double-circuit pellet boilers. Efficiency - 92%. Pellets of the first and second categories are used. There is a built-in circulation pump and an expansion tank of the membrane type. Large volume ash collector, easy access. Efficient automatic large area electric igniter. The design has no reverse thrust. There is a function of protection against overheating and an anti-freeze system. Liquid level indicator sensor in the heating system. Programmer with a wide range of functions and ready-made economical modes (season adjustment, switching to hot water supply and autonomous operation). Remote control with program selection. Remote air temperature readings as standard. Increased volume of the bunker for pellets.The short screw path in the combustion chamber does not damage the wood pellets. |

As you can see, pellet boilers are gradually becoming more and more popular due to their undoubted advantages.

2 Kostrzewa Pellets Fuzzy Logic 2 25 kW

The highest productivity Country: Poland Average price: 315,000 rubles. Rating (2019): 4.9

Single-circuit boiler made of steel, the efficiency of which reaches 92%. It works mainly on pellets, but if necessary, fine coal can be used, and if there are specially installed grate segments, firewood can be used. Works in two modes: summer and winter. In summer mode, the boiler is connected to a boiler to provide hot water. In winter, it works to heat the house. Power varies at the discretion of the owner. The bunker is large, holds up to 220 kg of pellets, which at maximum power is enough for 38 hours of operation.

AT boiler owners reviews write about ease of use. Ashes have to be cleaned very rarely, provided that low-ash pellets are used, this should be done no more than once a month. It is convenient that the fuel tank can be installed on any side, adapting the configuration of the unit to the specifics of the boiler room. Of the minuses - many can not immediately find the optimal settings, it takes some time.

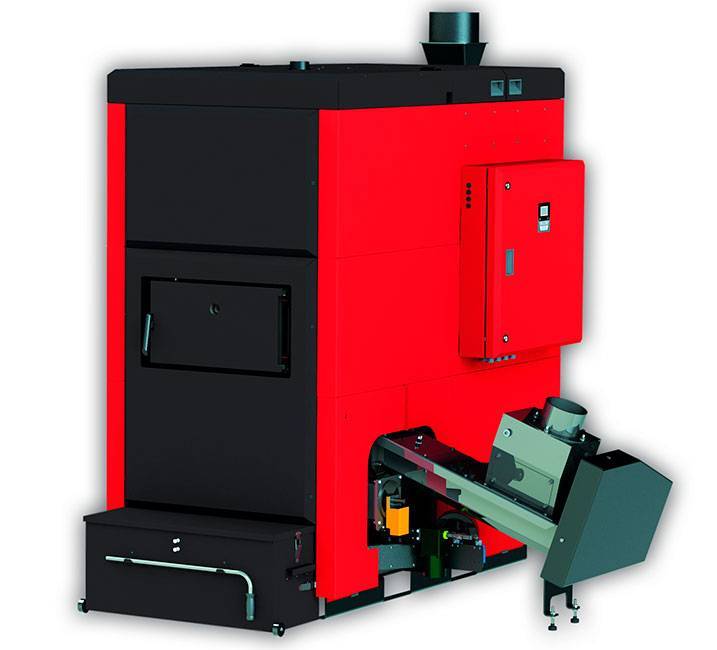

Boilers from Wirbel - versatility and ease of installation

Wirbel is based in Austria and manufactures automatic pellet boilers. The products of this manufacturer are of high quality and ease of installation. Wirbel EKO-CK PELLET-SET ovens are versatile and include an integrated pellet burner.

Raw materials are fed into the furnace of Wirbel pellet boilers automatically, so it can work continuously as long as there is a need for space heating

The body of such a unit is made of heat-resistant steel, the thickness of which is 5 mm. The pellet tank can be installed on either side of the boiler. The standard equipment of the furnace provides for the following functions: automatic ignition, supply of pellets to the furnace section. However, if necessary, the unit can also operate in manual mode.

The operation of a solid fuel heating device is controlled through a special remote control. Cleaning of Wirbel EKO-CK PELLET-SET models is a necessary event and is carried out at least once a week.

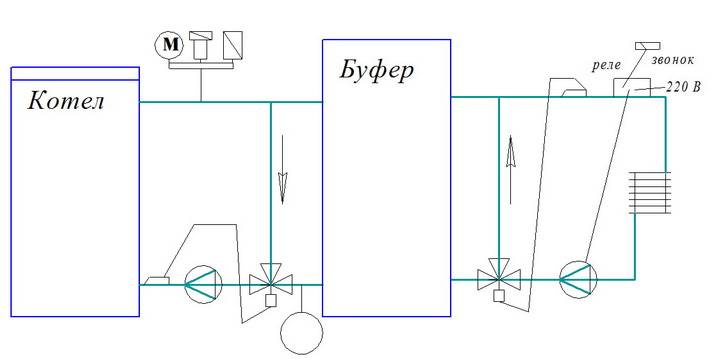

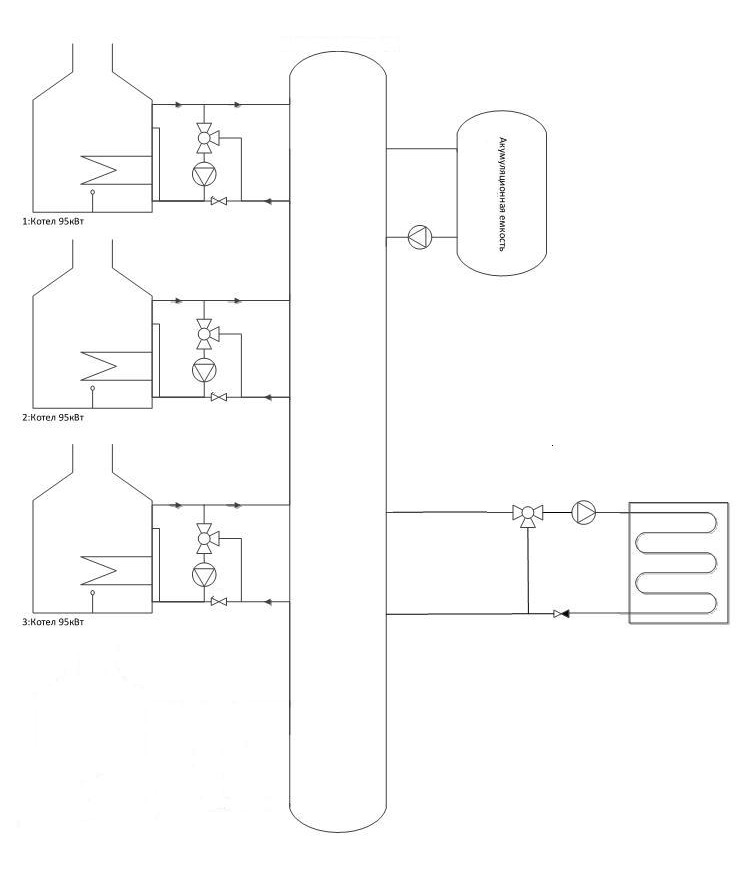

Heat accumulators

All boilers of these types are effective only when connected to a heat accumulator, otherwise the boiler will have to be fired several times a day:

All boilers of these types are effective only when connected to a heat accumulator, otherwise the boiler will have to be fired several times a day:

- clean;

- upload;

- melt.

Due to the high cost of TA and the cost of its installation, even the cheapest boiler will cost several times more than the average automatic boiler.

For a house with an area of 100 m2, the optimal capacity of the heat accumulator is 10 m3.

Reducing the capacity of the TA leads to a reduction in the heating time, so it is undesirable to reduce its volume by more than 3 times.

For example, a TA with a capacity of 3 m3 can heat a well-insulated house with an area of 100 m2 for 20–25 hours even in severe frosts. That is, the boiler will have to be heated once a day.

If the capacity of one TA is not enough, then several heat accumulators are installed using various schemes for their connection, the heating time of the house does not change from this.

Here is an approximate cost and a brief description of heat accumulators, as well as various types of boilers to work with them:

| Heat accumulators | |||||

| Model | Volume, m3 | Height and diameter in cm | Description and characteristics | Price thousand rubles | Website |

| TR 4500 | 3,5 | 230/160 | The tank is made of stainless steel grade 08X18H10, wall thickness 3-5 mm, maximum pressure 9 bar, insulated from the outside with mineral wool or foam plastic (as agreed with the customer). Installation of heat exchangers is possible. | 597 | profbak.rf |

| Alfa 1000 l | 1 | 210/99 | Heat accumulator with built-in heat exchanger. The body is made of carbon steel, the heat exchanger is made of stainless steel. The case outside is covered with polyurethane insulation, a protective layer of plastic. | 216 | |

| PSRR 5000 | 5 | 285/180 | Steel tank with heat exchanger. Warming must be purchased separately. The maximum pressure in the tank is 3 bar, in the heat exchangers 10 bar. | 445 | |

| Galmet Buffor 1500 | 1,5 | 270/110 with insulation, 270/90 without insulation | Steel tank with heat exchanger. Warming must be purchased separately. The maximum pressure in the tank is 3 bar, in the heat exchangers 10 bar. | 99 | mirtepla43.rf |

| Heatleader MB 10000 N | 10 | 415/220 | Stainless steel or carbon steel tank with 10 cm thick insulation and stainless steel heat exchangers. A temperature indicator is installed on the tank body. | 1600 | |

| Heating boilers | |||||

| Model | Power, kWt | Boiler type | Description and characteristics | Price thousand rubles | Website |

| Don KS-T-11 | 11 | Classical | Inexpensive boiler for any type of solid fuel, efficiency 82%. | 12,5 | |

| T-30 | 30 | Classical | Classic floor standing boiler for all types of solid fuels, efficiency 82%. | 65,9 | |

| VIKING K-WRM 18R | 18 | Classical | A classic solid fuel boiler with a gas afterburning system that increases efficiency. | 128 | |

| Suvorov 20k | 23 | Classical | A classic solid fuel boiler with a gas afterburning system that increases efficiency and burning time. | 59 | |

| VELES 8EVT | 8 | Classical | Classical solid propellant copper with system of afterburning of gases. | 24 | |

| Bourgeois-K Modern 12 | 12 | Pyrolysis | Pyrolysis (gas generating) boiler with automatic control. Efficiency 82-92%. Steel firebox without lining. | 63 | |

| BTS Standard 15 | 15 | Pyrolysis | Pyrolysis (gas generating) boiler with automatic control. Efficiency 86-92%. Ceramic firebox. | 128 | |

| Vitoligno 100s | 25 | Pyrolysis | Pyrolysis (gas generating) boiler with automatic control. Efficiency 86-92%. The furnace is lined with refractory bricks. | 168 | |

| Taiga 15 kW | 15 | Top burning | Upper combustion boiler with automatic mode control. Made of steel 09g2s 6 mm thick. The grates are cooled with water and do not burn out much longer than on boilers of other models. | 88 | |

| STROPUVA MINI S8 | 8 | Top burning | Upper combustion boiler with automatic mode control. Manufactured under the supervision of Stropuva. | 60 | |

| Flamap | 20 | Top burning | Upper combustion boiler with automatic mode control. Made on the basis of the design of the original Stropuva boilers. | 50 |

Boiler Assembly Manual

Pellet boilers have a fairly complex design. The instructions for assembling them will also be difficult and multi-stage. For greater convenience, the assembly process of each main unit is considered separately. Buy or make the necessary elements, and then simply assemble them into a single system.

This element of the pellet boiler is highly recommended to buy ready-made. It is on the burner that you will spend the most money.

Self-manufacturing of the burner is almost impossible for the reason that this part of the boiler is not just a container for igniting loaded pellets, but a complex control and regulation mechanism.

Pellet burners are equipped with special sensors and have several pre-installed programs that allow you to achieve the most rational fuel consumption and provide the most efficient home heating.

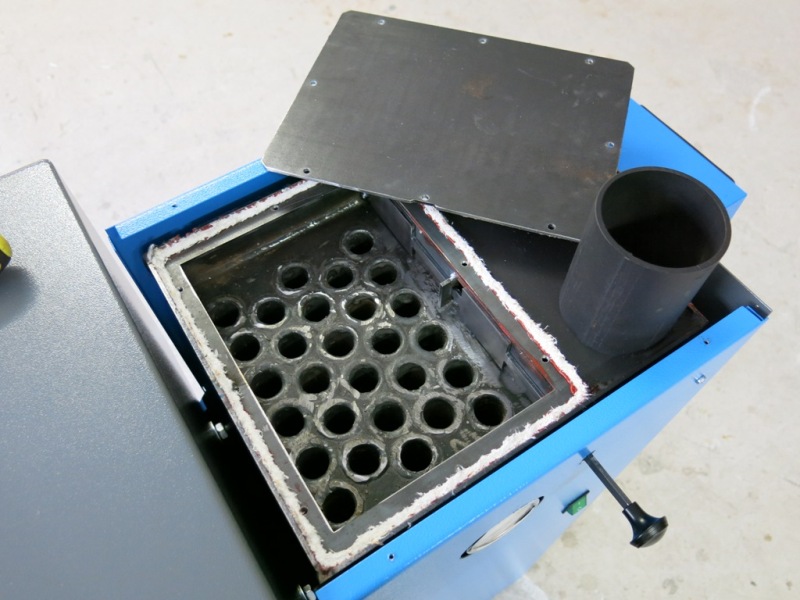

Housing and heat exchanger

You can handle the assembly of the case and the manufacture of the heat exchanger yourself. The boiler body is best done horizontally - with this placement of the unit, maximum heating efficiency is achieved.

For the manufacture of the case, it is recommended to use fireclay bricks. You simply assemble a kind of box without a top cover and place a heat exchanger in it with connected pipes and other elements. Brick is recommended for the reason that it accumulates heat much more efficiently than cast iron, steel sheets and other popular materials.

The pellet boiler heat exchanger is a system of pipes interconnected and connected to the heat supply pipes of a private house.

First step. Assemble a rectangular heat exchanger from square pipes. To do this, cut the pipes into pieces of the desired length and weld them into a single structure.

Second step. Make holes in the profile that acts as a vertical rack for connecting round pipes.

Third step. Prepare holes in the remaining front pipes for the water outlet and connection pipes. Hot water will be discharged through the top hole, cold water will be supplied from the bottom.

Use metal pipes with a length of 150 mm or more. Further it will be possible to use polypropylene pipes. In places where pipes are connected to the boiler, be sure to install ball valves. Additionally, you can set filters if you need them.

Fourth step.Weld the back of the unit to its front and weld the side pipes.

At the same stage, choose a convenient place for connecting a chimney pipe with a diameter of 10 cm. At the bottom of the heating unit, provide a small chamber for collecting ash. Also, the design of the pellet boiler necessarily includes a firebox. About him further.

In the firebox, as already noted, pellets are stored and from here they are fed into the burner.

First step. Prepare the necessary materials and fixtures. You will need an auger with a diameter of 7.5 or 10 cm, an electric motor and a metal casing. You will connect the engine to the pellet burner control unit.

The function of a metal casing can be performed by any container of a suitable volume with sufficiently thick walls.

Second step. Install the inlet of your auger into the outlet of the casing. Connect a corrugated plastic pipe to the other part of the auger to supply granular fuel to the burner.

In conclusion, you just have to assemble all the listed elements into a single design. Do this and proceed to the installation of the boiler.