- Principle of operation

- Features of pellet boilers with automatic fuel supply

- Pros and cons of pellet boilers for heating

- Design and principle of operation

- The best pyrolysis solid fuel boilers

- Attack DP 25 Profi

- Buderus Logano S171-50W

- Trayan T15 2-CT

- Kiturami KF 35A

- What criteria should be considered when choosing a pellet boiler

- What to look for when choosing a pellet boiler?

- Appliance burner type

- Level of automation

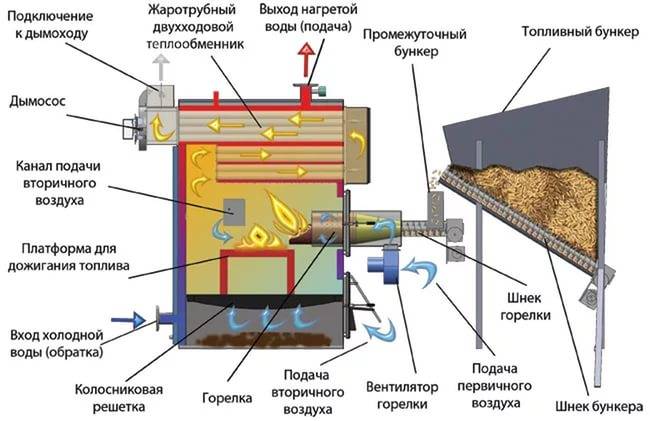

- Type of pellet feeding auger

- Heat exchanger design

- Key Features

- Thermal power, which is the smallest

- Efficiency

- Fuel consumption and hopper capacity

- Additional functions

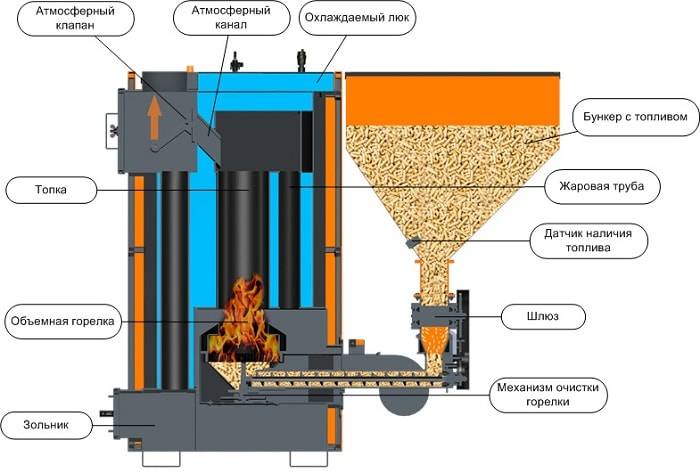

- The device and principle of operation of the pellet boiler

- The principle of operation of the pellet boiler

Principle of operation

Boilers Zota, which are manufactured by Russia, were developed taking into account modern consumption. They are able to function in two main modes. If there is an electricity network in the room, then the boiler works with the help of pellets. In automatic mode, the supply of fuel pellets is started, which are forced by air supply, and then the burnt products are removed.

If the electricity supply is turned off, the boiler continues to function, but according to the principle of a conventional solid fuel boiler that runs on coal, wood and similar fuels.

Pellet boiler Zota has the following characteristics:

- automatic ignition, if there is a power supply;

- the ability to connect temperature control and regulation sensors;

- due to the control unit, it is possible to regulate the temperature of hot water, the heating temperature of the underfloor heating system and the heating system circuits;

- such equipment is equipped with a capacious combustion chamber, which can be increased in case of automatic operation of the boiler;

- you can still equip the equipment with a heating element;

- a reliable protection system provided by sensors and valves, thus preventing the equipment from overheating and accumulating excess pressure.

If the buyer has a need or just a desire to complete the equipment with unusual additional functions, then, in agreement with the manufacturer, it can be supplemented with a warning system that will transmit signals to the owner’s smartphone. In order to control the process of work at a distance, the owner needs to install an application on the phone.

All boilers of this type have an automatic adjustment system that is able to constantly maintain the set temperature, but at the same time it monitors the safe operation of the device, that is, it does not allow excess air and flame to enter the combustion chamber. This safety is achieved because the device is equipped with a twin screw fuel supply.

After the boiler reaches the set temperature level, the combustion process is switched to standby mode. Power control in such equipment is also performed automatically. This adjustment is carried out due to the fact that less fuel is supplied to the combustion chamber.You can also configure this system remotely, as it is equipped with a remote control system using a remote control.

Features of pellet boilers with automatic fuel supply

Household units are characterized by the presence of a built-in hopper of a small volume, which provides autonomous operation from 12 to 48 hours. Loading pellets into the combustion chamber can be carried out both in a natural way and with the help of a screw conveyor. To increase the duration of burning, external bunkers are used, located in close proximity to the pellet unit and connected with it by a special conveyor.

A large volume tank or a separate room can be used as such a bunker. Often, underground storage facilities for pellets are equipped, which greatly simplifies the loading process.

If a separate room acts as additional storage, measures must be taken to ensure minimum humidity and effective ventilation in it. In addition, to prevent the granules from dumping, it is recommended to carry out their periodic mixing.

Pros and cons of pellet boilers for heating

The use of pellets as the main fuel allows you to achieve:

- Minimizing fuel consumption. In terms of efficiency, only centralized gas heating systems are more efficient than pellet equipment.

- Thanks to the automatic supply of pellets, the operation of the pellet boiler does not require manual loading and constant monitoring by the owner.

- The operation of the device is not accompanied by the emission of harmful substances into the atmosphere.

The main factor limiting the use of aggregates is the high cost. In addition, the operation of the unit is not possible without a connection to the mains.

Design and principle of operation

The center or the most important element of this apparatus is the burner, almost the entire process is concentrated in it, it is also connected to the boiler controller, to which, in fact, it obeys.

There are two types of burners:

- Retort.

- Torch.

The retort burner has the form of a bowl made of cast iron or heat-resistant steel, in which the fuel combustion process takes place. Fuel enters it from below. In order for the surface to cool in the combustion zone, primary air is supplied from the sides of the bowl.

Secondary air supply is also provided through the hole in the burner, or other technological holes in the design of the device. Ash, which is formed during combustion, falls from the retort burner under the influence of the incoming fuel. During operation, the flame is directed upwards, this must be taken into account in the design pellet boilers.

This type of burners is divided into mobile and fixed. The first type is capable of operating on high-ash fuel, as well as on fuel with dust impurities on chips, sawdust, coal with dust. The second type works exclusively on dry homogenized fuel, such as high-quality fine-grained coal, on wood pellets.

The flare is a pipe, which is the combustion chamber. Everything works as follows: pellets are fed from one side with the help of an auger, and a horizontally directed flame comes out of the other end. Air is injected from the side where the fuel enters.This type of burner is the most common, since in retort burners the fuel supply mechanism often goes astray due to its clogging.

So, let's consider how this device works in more detail using the example of a torch burner. The chamber where the combustion process takes place is located inside the boiler, the outer part of the burner is made in the form of a housing, where there is an auger, which serves to transport pellets and a fan for air supply.

In order for the electric ignition to work and to be able to maintain the flame, a control board, a photo sensor and an incandescent element are provided. At the top there is a hole for fuel supply.

In action, it looks like this: a command is received from the controller to the auger and it starts feeding a small amount of fuel into the chamber, then it stops. The incandescent element turns on and the fan starts to work, which causes the pellets to ignite.

Further, the photo sensor detects the presence of a steady fire, and sends a signal to the control unit, which turns off the incandescent element. Further works in the mode described above.

There are models on the market in which the storage hopper is installed above the burner nozzle, which in turn allows the fuel to enter it without passing through an additional conveyor.

The best pyrolysis solid fuel boilers

The principle of operation of such installations is based on the afterburning of pyrolysis gases resulting from the combustion of fuel in an oxygen-depleted environment. This solution provides greater energy efficiency and a long period of equipment operation on one tab.

Attack DP 25 Profi

5

★★★★★

editorial score

100%

buyers recommend this product

The novelty of 2019 from a well-known manufacturer of heat engineering from Slovenia has absorbed all the advanced ideas and technological solutions of the world leaders in this industry. The Attack DP 25 Profi pyrolysis boiler is a highly efficient and economical boiler plant with a capacity of 25 kW, designed to work with wood and its derivatives. Allows you to use firewood with a length of 1 m.

The main feature of the device is electronic control of combustion processes and coolant circulation with the display of all indicators on the display. Automation independently adjusts the power of the unit to the real need of the house for heat. The duration of work on one tab reaches 12 hours. The cost is 95,000 rubles.

Advantages:

- High efficiency heat exchanger.

- Impressive efficiency.

- power modulation.

- Auto shutdown after fuel burnout.

- Water after-cooling circuit (additional protection against overheating).

- Ease of maintenance.

Flaws:

Impressive weight and size indicators.

An excellent boiler plant for organizing economical heating of residential buildings, workshops, shops.

Buderus Logano S171-50W

4.9

★★★★★

editorial score

92%

buyers recommend this product

Buderus Logano is a classic wood-burning single-circuit boiler with electronic control. A power of 50 kW is enough to heat a rather large private house of 2-3 floors or a production facility. The efficiency of the unit reaches 90% due to the well-thought-out design of the afterburning of pyrolysis gases and control of the intensity of combustion.

The main feature of the model is the presence of electronics that allows you to control the boiler, remotely control the operation of the boiler, integrate it into the "smart home" system, etc.

Advantages:

- Energy efficiency.

- Manufacturability.

- Easy loading and easy maintenance.

- High security.

Flaws:

- Big weight (466 kg).

- The price is almost 220 thousand.

This model will be an excellent (albeit very expensive) solution when creating an autonomous heating system in a large cottage or at an enterprise.

Trayan T15 2-CT

4.8

★★★★★

editorial score

88%

buyers recommend this product

A modern wood-burning pyrolysis boiler is designed for heating and hot water supply of buildings and structures with an area of up to 150 m2. The case of the unit is made of heat-resistant steel 5 mm thick. With a power of 15 kW, the duration of burning on one tab is 8 hours.

The model is equipped with an automatic air supply regulator, which allows you to change the power in the range from 40 to 100%, where the highest efficiency of 82-85% is achieved.

Advantages:

- Two heating circuits.

- Possibility of installation of TEN.

- Long battery life.

- Reliability and safety.

- Affordable cost - a little more than 58 thousand.

Flaws:

- Installation is possible only in a system with natural circulation of the coolant.

- Not the highest efficiency.

Trayan is suitable for organizing heating and hot water supply in private houses, industrial and office premises, shops.

Kiturami KF 35A

4.7

★★★★★

editorial score

72%

buyers recommend this product

Kiturami is a modern pyrolysis boiler designed to work with wood waste, which can significantly reduce the owner's operating costs for heating. With a nominal power of 24 kW, the heating efficiency is 92%, and the DHW system is 91%. The duration of work (up to 16 hours) is provided by a large volume of the combustion chamber, which can hold up to 50 kg of firewood.

The main feature of the model is the heat exchanger made of stainless steel. This solution ensures a long service life and eliminates the appearance of scale. Management is electronic.

Advantages:

- Profitability.

- Good heat output.

- Impressive efficiency.

- Full electronic control.

- High level of security.

Flaws:

High cost - from 110 thousand rubles.

An excellent model for autonomous heating of a private house, up to 240 m2, which will also solve issues with hot water supply.

What criteria should be considered when choosing a pellet boiler

Given the high cost of the product, before buying a pellet boiler for home heating, you need to pay special attention to the following criteria:

- Power installation is selected at the rate of 1 kW per 1 m2;

- efficiency a properly configured boiler, when using high-quality pellets, it should be at least 85%;

- Heat exchanger material. Cast iron heat exchanger will last longer than steel, but its strength is less;

- Some models have two circuits: heating and hot water, the price of such boilers is much higher;

- Hopper capacity directly related to battery life;

- Availability of additional functions increases the cost of the unit, but makes its operation more comfortable.

Below is a description of the most popular models of pellet plants.

What to look for when choosing a pellet boiler?

In order not to make a mistake in choosing a device, you need to take into account several factors that affect the performance of the equipment

Appliance burner type

On sale you can find boilers with two types of burners.Retort release flame upwards. They are insensitive to the quality of the granules and do not require frequent cleaning. Stoker burners maintain a flame in a vertical plane. They are very demanding on the quality of pellets and "prefer" only low-ash grades of pellets. Such a burner clogs very quickly and requires frequent cleaning. Without timely maintenance, the heater simply stops. Thus, retort burners are more convenient to use and they are recommended to be purchased by experts.

Level of automation

Boilers for pellets are equipped with modern automation. Depending on the model and degree of complexity of the built-in automatic system, they can function autonomously for some time, without human intervention. The control function via SMS messages is very convenient. The phone number of the owner is entered into the system, after which, using messages, you can control the operation of the heater: turn it off and on, adjust the temperature, etc. In addition, in the event of an emergency or critical situation, the boiler can immediately inform the owner about this.

The retort-type pellet burner is distinguished by its unpretentiousness in terms of the quality and size of the pellets. It is easier to maintain and does not require frequent cleaning.

Type of pellet feeding auger

The equipment can be equipped with a rigid or flexible auger. The first type is simple in design and low in price. It delivers fuel to the combustion zone without interruption and has a simple fastening, which guarantees the reliability of the auger end parts. One of the disadvantages of rigid knots is the limitation in length. It cannot be more than 1.5-2 meters, otherwise the device will simply grind the pellets into sawdust.In addition, the bunker is rigidly attached to the burner, which does not allow changing its position. Thus, the space is used very irrationally.

To solve this problem, you can use an additional auger, which is connected through the interface module for the operation of electric motors. The necessary backfire prevention system in the rigid auger involves the use of a fire extinguisher or the installation of a second auger and an additional air chamber, which greatly complicates the system. The flexible screw is devoid of these shortcomings. It allows you to install a bunker of any size at a distance of up to 12 m and make a feed line of any geometry. The main drawback of the flexible design is the complex auger mounting system.

A rigid auger is the simplest version of the fuel supply mechanism. It is very reliable and inexpensive. However, it can not be used everywhere, since such an auger is limited in length and is rigidly tied to the burner.

Heat exchanger design

There are several types of heat exchangers for pellet boilers. They can be horizontal or vertical, flat or tubular, with a different number of turns and strokes, with and without exhaust gas swirlers, the so-called turbulators. Experts consider vertical heat exchangers with turbulators having two or three passes to be the most efficient. The devices allow to reduce flue gas temperature from 900-800C to 120-110C at the outlet. Thus, most of the thermal energy is spent on heating the coolant. In addition, the vertical design makes it difficult for ash to settle on the walls of the heat exchanger. The force of gravity contributes to the shedding of ash down.

And a few more tips for choosing a device.Other things being equal, preference should be given to a company whose boilers have been operated in the buyer's region of residence for at least two or three years. When buying a new model, the risk of getting big problems is very high. It is worth checking the availability of spare parts for equipment in the warehouse of the seller. After some time, they may be needed and it is better if everything is in stock. The heater must always be serviced by a certified service technician.

Key Features

The reliability of a pellet boiler, like any equipment, is expressed in the warranty period, overhaul and service intervals. As a device for generating energy and transferring it to a coolant, the device is characterized by:

- energy efficiency of fuel combustion;

- power;

- battery life on one tab.

Thermal power, which is the smallest

How much heat is generated per unit of time as a result of fuel combustion, shows the main characteristic of the heat generator - thermal power.

It is chosen based on the purpose of the room, area, ceiling height, heat loss when passing through the building envelope.

The power values of the pellet boiler are in the range of 12-500 kW.

Less power makes the device unprofitable, with more it loses its advantages over other heat generators:

- operates with efficiency < 0.8 - less efficient than gas, liquid fuel, coal-fired boilers;

- fails after 3-5 years.

Efficiency

The efficiency of the device shows what proportion the pellet boiler could "take" from the estimated amount of heat that the fuel "gave up" during combustion.Reduces the efficiency of insufficient or excessive loading of the furnace, low-quality fuel, improper operation of the equipment.

The fuel is more efficient, the higher the heat of combustion. Fuel oil and diesel lead in efficiency. The combustion heat of pellets is 2.4-4.3 times lower and depends on the type of feedstock:

- wood - 17.5-19 (MJ / kg);

- straw - 14.5;

- peat - 10.

According to this indicator, granules from woodworking waste are comparable to coal (15–25 MJ/kg) and surpass the original material - sawdust, wood chips, shavings (10 MJ/kg).

Fuel consumption and hopper capacity

The average annual consumption of pellets from recycled wood is 1/5 less than brown coal (by weight) and several times less than lump wood (it is more humid and less dense).

The exact figure depends on the properties of the boiler and the settings for its operation, as well as on the volume of the heated room, the material and design of the outer walls.

The volume of the pellet hopper determines how long the heating boiler will not require human intervention and varies from tens of liters to a cubic meter or more.

Reference. Automation of fuel supply is possible if it is initially provided for by the boiler design. Fire distances in the boiler room also depend on the volume of the bunker.

Additional functions

The automation of the operation of a pellet boiler is not limited to the mechanized supply of fuel from the operational reserve to the burner. Models of boilers with additional functions reduce manual labor for servicing the unit to a minimum:

- optical elements control the flame;

- the electric coil ignites the fuel filling;

- the temperature and pressure of water is measured by a thermomanometer;

- thermostats turn on and off the burner, pump, protect the system from overheating;

- the boiler power is adjusted by the potentiometer;

- the fuel burnout sensor responds to the temperature of the burner surface.

This is an incomplete list of electronic, mechanical, chemical devices with which the manufacturer is able to equip his products.

A high degree of automation allows the pellet boiler to work without human intervention for more than 7 days. Communication with a personal computer makes remote control. Cleaning or replacing the ash pan by hand takes no more than half an hour.

Important! The technical parameters of the pellet boiler declared by the manufacturer are the result of tests carried out with the prescribed fuel. The instruction for the device contains requirements for the quality of pellets: grain size (mm), calorific value (J / kg), humidity (%), ash content (%)

The properties of the fuel affect the power and efficiency of the heat generator.

The device and principle of operation of the pellet boiler

The unit includes three main components:

- fuel compartment, which houses a retort or flare burner. The chamber is equipped with two hinged dampers designed for loading and cleaning the unit.

- convection zone with built-in heat exchanger. It is in this zone that intensive heat exchange takes place between the coolant and hot gases.

- Ash pandesigned to collect combustion products. With proper adjustment, the formation of ash and soot is extremely low.

To ensure long-term autonomous operation, the pellet boiler is equipped with an automatic fuel loading mechanism, consisting of the following units:

- drive - a welded metal container designed to load pellet fuel. The overall layout of the product provides for both external and integrated storage.

- auger with a drive gearbox, with the help of which a uniform supply of granular fuel is made.

- fanproviding the flow of oxygen into the combustion zone. Since natural draft is not provided in most models, it is the fan that ensures complete combustion of the pellets.

In addition, the pellet unit is equipped with an electronic control system and a digital display. A special device controls the process of initial ignition and regulates the intensity of the flow of granular fuel into the combustion chamber.

The principle of operation of the pellet boiler

What does a boiler consist of and how does it work:

- Boiler with burner;

- Conveyor feeding pellets;

- Bunker for fuel.

Pellets are poured into the bunker, from where the pellets are conveyed as needed to the furnace, where they support combustion.

When burning this type of fuel, the efficiency of the boiler reaches 98%.

The boiler is equipped with an automatic control system that allows you to regulate the temperature of the heat carrier by supplying fuel to it. If desired, you can reconfigure the boiler to another type of fuel, if the main one is over. The device can work on wood or coal, any solid fuel.

Combustion of fuel occurs due to forced air injection by a fan. And when the pellets ignite, the ignition will turn off automatically. Flue gases that are formed during the combustion process and give heat to the heat exchanger. The combustion product enters the ash pan. Since the operation of the boiler is automated, it allows you to stably maintain heat in the house without the participation of the owner. When the temperature maximum is reached, the machine stops the fuel supply and resumes when the temperature reaches the minimum.