- What is a pellet boiler

- Manufacturers of pellet boilers

- Teploekos

- Teplodar

- Stropuva

- Yaik

- obshchemash

- TIS

- Pellet burners

- How to choose

- What to look for when choosing a pellet boiler?

- Appliance burner type

- Level of automation

- Type of pellet feeding auger

- Heat exchanger design

- Rating of the best pellet boilers

- Heiztechnik Q Bio Duo 35

- Sunsystem v2 25kw/plb25-p

- Stropuva P20

- Kiturami KRP 20a

- Froling p4 pellet 25

- ACV Eco Comfort 25

- Pelletron 40 CT

- Teplodar Kupper PRO 22 with APG25

- Zota Pellet 15S

- Faci base 258 kW

- How to choose a pellet boiler?

- Choice by power

- What kind of burner do you need?

- Choice by degree of automation

- What conveyor is needed?

- Selection by heat exchanger design

- 3 SOLARFOCUS pellet top

- Ecology and health

- Advantages of pellet boilers:

- Cons of pellet boilers:

- Unit device

- Kiturami KRP 20A

- Flaws

- TOP of the best models of double-circuit boilers

- ZOTA MAXIMA 300, two augers

- Double-circuit pellet boiler Dragon plus GV - 30

- Jaspi Biotriplex

What is a pellet boiler

Pellet boilers are fired with small pellets called pellets.

Solid fuel boilers have received demand among many consumers. Due to the lack of gas, firewood and coal remain the only cheap fuels.We do not take into account electric boilers - electricity is expensive, but it is consumed in gigantic quantities. And the larger the household, the higher the expense. Therefore, solid fuel models remain in demand in the heating market.

The improvement of heating technologies has led to the emergence of a new type of fuel - these are pellets. They are made from wood chips and other combustible waste, resulting in combustible pellets that produce a large amount of thermal energy. Here are the main advantages of pellets:

- Ease of storage - they come in bags that you can simply fold in a specific place;

- Convenience of dosage - unlike the same firewood, we can throw a strictly defined amount of fuel into the furnace of a pellet boiler. It should also be noted more convenient loading, which is associated with the flowability of the granules;

- Availability and cheapness - in essence, pellet fuel is a product of processing various wastes (wood chips, husks, plant residues), so it has an affordable cost;

- Good calorific value - 1 kg of pellets generates approximately 5 kW of energy;

- Safety - pellets do not tend to ignite spontaneously, they are not afraid of dampness and high ambient temperatures;

- The ability to work in automatic pellet boilers - creating an automated firewood supply system is problematic, but there are no such problems with pellets. Yes, and there are plenty of such boilers for sale.

Pellet boilers are really easy to use, they do not require frequent maintenance and high fuel costs.

The undoubted advantage of pellet fuel is that it can be used in almost any solid fuel boilers, and not only in specialized ones.

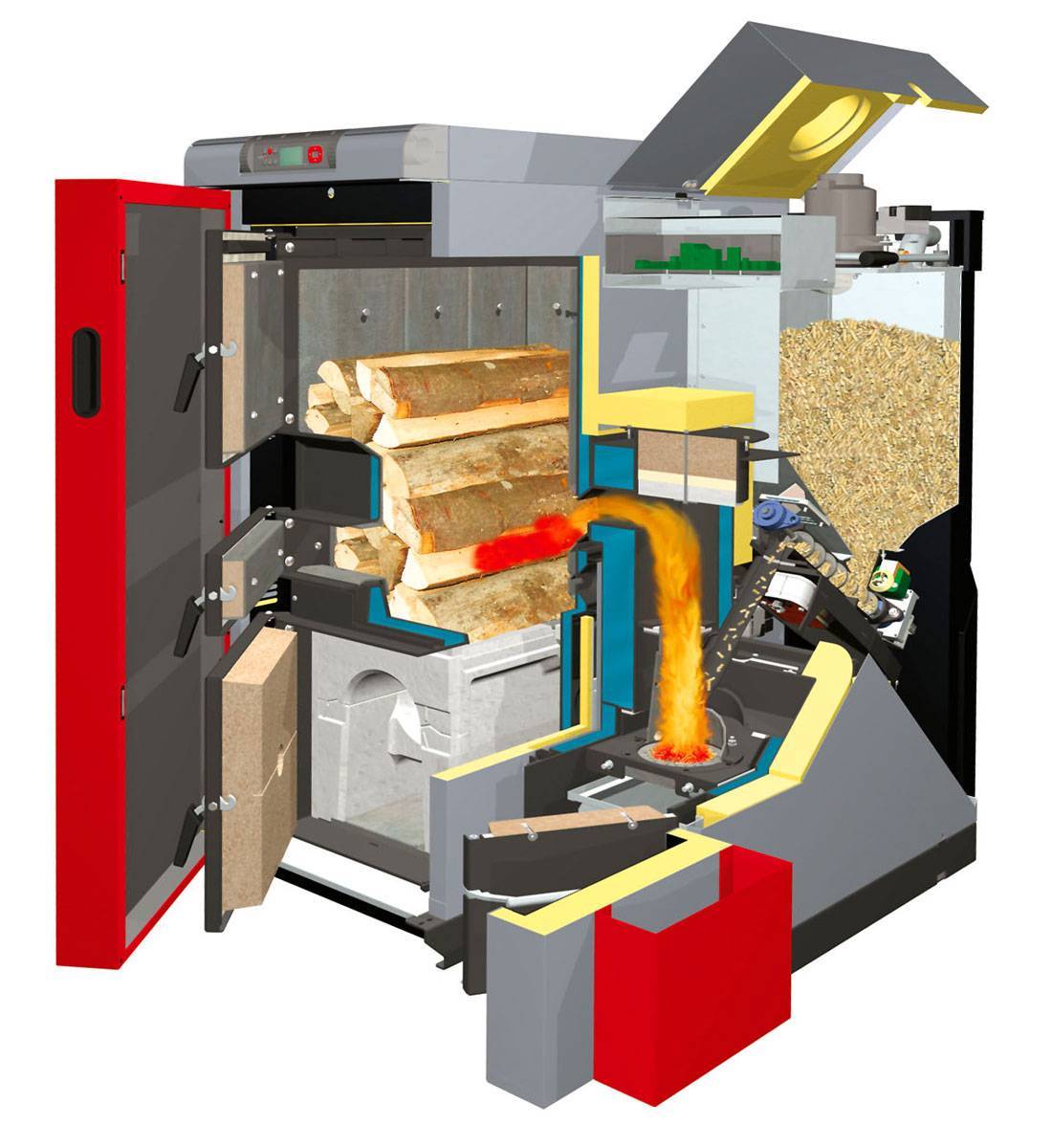

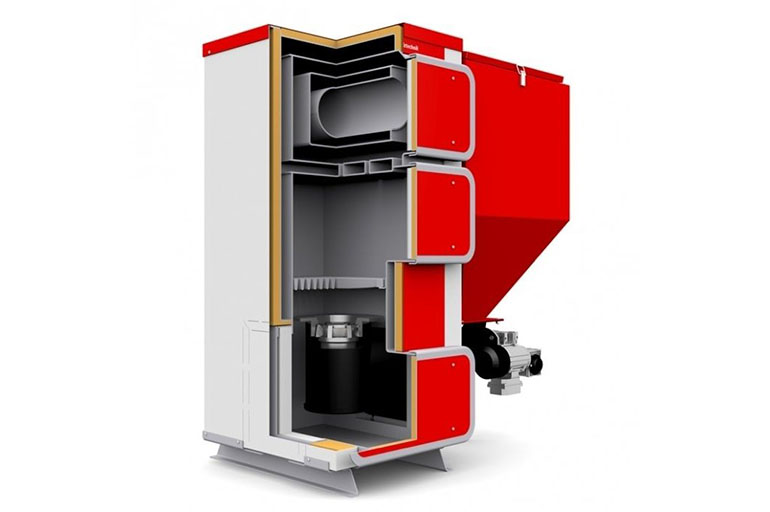

Let's take a look now what are pellet boilers and how they work. We will consider specialized boilers, not universal ones. Their design consists of several main parts - there is a burner, a heat exchanger, automation and a fuel supply system. The principle of operation is that pellet fuel is fed into the combustion chamber, ignites and gives off heat to the heat exchanger.

The device and principle of operation of boilers operating on pellets.

Unlike traditional solid fuel boilers, pellet modifications do not have the largest combustion chambers - large-sized firewood is not laid here, since the equipment only works on pellets. The exception is universal models that are designed to work not only with pellet fuel, but also with wood / coal.

Pellet boilers are often equipped with automated fuel supply systems. They are equipped with small (or very large) bunkers where fuel pellets are loaded. From here, through a pipe of small diameter, they enter the auger fuel supply system. It sends the pellets to the combustion chamber, where they are burned with the release of a large amount of heat. Further, hot air with combustion products passes through the heat exchanger, giving off heat to the heating system.

Manufacturers of pellet boilers

The market for manufacturers of such equipment is diverse. But not everyone can vouch for the quality of the proposed product.

Teploekos

A manufacturer who has improved process automation in models.Boilers can work autonomously for at least a month, it depends on its power and performance. The system is self-cleaning, and the granules are fed by vacuum methods, which makes the process more autonomous.

Teplodar

The leader of the Russian market for the creation of furnaces and boilers for solid fuels. The bunker in such models is installed on the boiler body. This emphasizes the individuality of the produced boilers and makes them more individual. It is allowed to use a burner device, which can be additionally mounted.

Stropuva

Lithuanian manufacturer, which has been on the boiler market for over 20 years. The most famous model was the P20 equipment, provided with four temperature sensors. The uniqueness of the boilers of this company lies in the fact that the pellets burn under the action of gravity, automatic ignition is not provided.

Models without an auger work, they are equipped with environmentally friendly filters, which makes it possible to clean the equipment much less frequently. The manufacturer guarantees continuous operation for 23 hours.

Yaik

The manufacturer in his boilers has created a universal heating system. All sorts of fuel options are allowed, from wood to peat. This is quite convenient, because there is a choice of heating method. Affordable cost and long operation are the undoubted advantages of a domestic manufacturer.

obshchemash

The boilers of this manufacturer are popular and successful due to the high level of performance and automation of maintaining a certain temperature in the room. All devices are protected from overheating, environmentally friendly and safe. Another domestic manufacturer whose boilers are distinguished by high power.

TIS

Belarusian manufacturer of boilers, which offers a wide range of fuel for equipment. Devices of this type can work both on standard wood or peat, and on cherry stones, grain and other very different pellets. The models have a room thermostat for temperature control. Able to work autonomously up to 35 hours.

Pellet burners

Ordinary solid fuel boilers are not well suited for burning pellets, so they are converted by inserting a pellet burner.

Ordinary solid fuel boilers are not well suited for burning pellets, so they are converted by inserting a pellet burner.

The same alteration can be made with floor gas boilers, because flame is produced at the exit of the burner with little smoke.

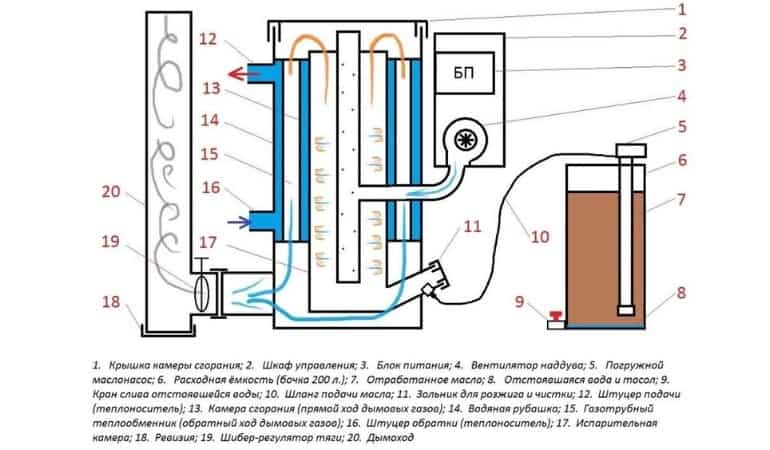

The burner includes:

- pellet hopper;

- feed system (most often screw);

- safety hose separating the hopper and auger feed from the burner;

- burner;

- lambda probe, which evaluates the amount of oxygen in the exhaust gases and determines the combustion mode of the pellets (not installed on all devices);

- Remote Control.

As a result, you will only:

- pour pellets into the bunker;

- remove ash;

- periodically clean the burner,

the burner automatics will do the rest.

Also, burners can be used in conjunction with brick ovens, including those equipped with coarse.

Here is the cost and a brief description of the most popular models of such burners:

| brand | Power, kWt | Description | Price thousand rubles | Website of the manufacturer or seller |

| Pelletron-15MA | 15 | Semi-automatic burner with small capacity hopper. The burner must be cleaned once a day. Ignition of fuel is made manually. The door for installation in the boiler must be purchased separately, choosing it according to the size of the boiler. | 18 | |

| РВ10/20 | 50 | Automatic burner for boilers such as Peresvet, Valdai, YaIK, Don and others, which have the same size of the furnace and door.Automatic ignition pellet. Automatic pneumatic cleaning, so without maintenance the burner can work for several weeks if there is enough fuel. Thanks to temperature sensors, the control unit automatically changes the operating mode of the burner. | 93 | |

| Terminator-15 | 15 | Automatic burner for burning any pellets. Thanks to the self-cleaning function, it can work without maintenance for 14 days. It is equipped with a GSM unit, so the burner operation mode can be controlled from a phone or tablet, as well as receive information about its operation mode. | 74 | |

| Pelltech PV 20b | 20 | Fully automatic burner with electric pellet ignition. Thanks to the self-cleaning function, it requires maintenance 2-3 times a month. Independently regulates the strength of the flame, providing the desired temperature of the coolant. In the event of a power outage, it switches to a backup battery. | 97 |

How to choose

When choosing pellet burners it is necessary first of all to pay attention to the suitability of the boiler, because some burners are produced for specific models of boilers, for others you can purchase transitional doors that correspond to a particular boiler. The second important parameter is power, because the maximum efficiency of the burner is achieved only when operating at full power.

The second important parameter is power, because the maximum efficiency of the burner is achieved only when operating at full power.

After that, you need to define:

- pellet type;

- operating time from one download;

- time between services;

- bunker volume;

- cost limit.

Most automatic burners work well on all pellets, but units that do not have a self-cleaning function are only suitable for use if white hardwood granular sawdust is used.

The average fuel consumption in most burners is 200–250 grams per 1 kW of boiler power per hour. From this formula, the required volume of the bunker is determined.

Burners without self-cleaning are inexpensive, but they have to be cleaned every day, so they are seriously inferior to automatic ones.

Therefore, you have to choose: either take an inexpensive burner that needs to be cleaned every day, or an expensive one that requires maintenance only once every 2 weeks.

What to look for when choosing a pellet boiler?

In order not to make a mistake in choosing a device, you need to take into account several factors that affect the performance of the equipment

Appliance burner type

On sale you can find boilers with two types of burners. Retort release flame upwards. They are insensitive to the quality of the granules and do not require frequent cleaning. Stoker burners maintain a flame in a vertical plane. They are very demanding on the quality of pellets and "prefer" only low-ash grades of pellets. Such a burner clogs very quickly and requires frequent cleaning. Without timely maintenance, the heater simply stops. Thus, retort burners are more convenient to use and they are recommended to be purchased by experts.

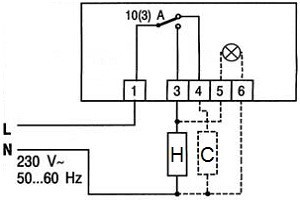

Level of automation

Boilers for pellets are equipped with modern automation. Depending on the model and degree of complexity of the built-in automatic system, they can function autonomously for some time, without human intervention. The control function via SMS messages is very convenient. The phone number of the owner is entered into the system, after which, using messages, you can control the operation of the heater: turn it off and on, adjust the temperature, etc.In addition, in the event of an emergency or critical situation, the boiler can immediately inform the owner about this.

The retort-type pellet burner is distinguished by its unpretentiousness in terms of the quality and size of the pellets. It is easier to maintain and does not require frequent cleaning.

Type of pellet feeding auger

The equipment can be equipped with a rigid or flexible auger. The first type is simple in design and low in price. It delivers fuel to the combustion zone without interruption and has a simple fastening, which guarantees the reliability of the auger end parts. One of the disadvantages of rigid knots is the limitation in length. It cannot be more than 1.5-2 meters, otherwise the device will simply grind the pellets into sawdust. In addition, the bunker is rigidly attached to the burner, which does not allow changing its position. Thus, the space is used very irrationally.

To solve this problem, you can use an additional auger, which is connected through the interface module for the operation of electric motors. The necessary backfire prevention system in the rigid auger involves the use of a fire extinguisher or the installation of a second auger and an additional air chamber, which greatly complicates the system. The flexible screw is devoid of these shortcomings. It allows you to install a bunker of any size at a distance of up to 12 m and make a feed line of any geometry. The main drawback of the flexible design is the complex auger mounting system.

A rigid auger is the simplest version of the fuel supply mechanism. It is very reliable and inexpensive. However, it can not be used everywhere, since such an auger is limited in length and is rigidly tied to the burner.

Heat exchanger design

There are several types of heat exchangers for pellet boilers. They can be horizontal or vertical, flat or tubular, with a different number of turns and strokes, with and without exhaust gas swirlers, the so-called turbulators. Experts consider vertical heat exchangers with turbulators having two or three passes to be the most efficient. The devices allow to reduce flue gas temperature from 900-800C to 120-110C at the outlet. Thus, most of the thermal energy is spent on heating the coolant. In addition, the vertical design makes it difficult for ash to settle on the walls of the heat exchanger. The force of gravity contributes to the shedding of ash down.

And a few more tips by device choice. Other things being equal, preference should be given to a company whose boilers have been operated in the buyer's region of residence for at least two or three years. When buying a new models the risk of getting big problems is very high. It is worth checking the availability of spare parts for equipment in the warehouse of the seller. After some time, they may be needed and it is better if everything is in stock. The heater must always be serviced by a certified service technician.

Rating of the best pellet boilers

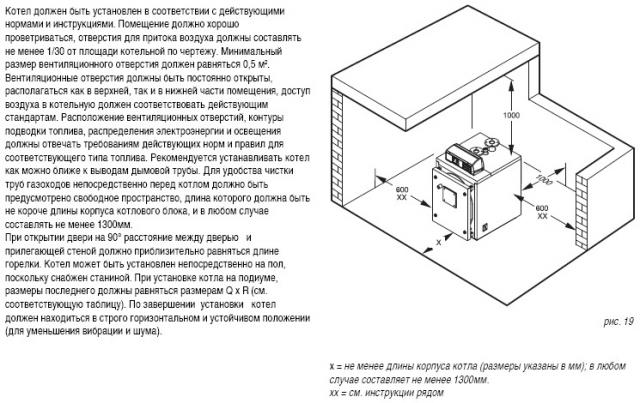

Heiztechnik Q Bio Duo 35

Considered universal. The device is equipped with 2 fire chambers, can work at firewood and pellets. The power range is 12-35 kW, but the efficiency is slightly lower than most models - 88%.

The features of the model are:

- automatic supply of air and fuel;

- adjustment depending on weather conditions;

- economical consumption of raw materials;

- microprocessor control.

Sunsystem v2 25kw/plb25-p

This is a Bulgarian boiler, reliable and efficient.With a power of 25 kW, it heats large rooms.

Of the advantages, the self-cleaning function, automated operation, and high-quality transport auger are distinguished.

Stropuva P20

The model is the development of a Lithuanian brand. The main advantages are considered high efficiency, simplicity of design. The machine does not have an auger for fuel supply, pellets enter the chamber under the action of their own weight and gravity. There is no automatic ignition system. You need to use a gas burner, but this is a safe and convenient way.

4 thermal sensors are responsible for monitoring the operation. The air supply is regulated by a built-in fan. The power of the unit is 20 kW. Taking into account the heat loss, this indicator is enough to heat a room up to 180 square meters. m.

Kiturami KRP 20a

This is a reliable and productive boiler of a South Korean brand. The power of the device is enough to heat an area up to 300 square meters. m. The capacity of the bunker is 250 liters.

The unit is equipped with overheating protection (the thermal valve is activated and cold water is supplied to the system). The equipment is characterized by a convenient function of vibration cleaning, low noise level during operation, piezo ignition.

A double-circuit boiler heats not only the room, but also water, and consumes 5 kg of fuel per hour. The advantage of the device is considered to be high efficiency for this category of equipment - 92%.

Froling p4 pellet 25

The model is characterized by high energy efficiency. The device can be equipped with a condensing heat exchanger with recuperation function. The latter means that thermal energy is returned to the technological cycle. Therefore, the efficiency of the equipment reaches 100%.

ACV Eco Comfort 25

The model of the Belgian brand has a power of 25 kW.This is enough to heat a room of 200 sq. m. The peculiarity of the boiler is a heat exchanger made of copper (the most durable and durable material).

The tank is designed for a volume of 97 liters, which allows you to quickly transfer hot water to the pipes. The body walls are made of 5 mm thick alloy, so heat is retained for a long time.

Pelletron 40 CT

The boiler of the Russian brand is distinguished by good performance and a power of 40 kW. The efficiency is 92.5%, which is a high figure for this category of equipment.

Characterized by a built-in fire extinguishing valve and a smoke exhauster, convenient cleaning of the burner. Granules are fed into the compartment under their own weight.

They also note economical fuel consumption - 230 g per hour. Therefore, when the bunker is fully loaded, the boiler operates for several days. The only drawback is the lack of automation. The device is controlled mechanically.

Teplodar Kupper PRO 22 with APG25

It is a modified model of "Cooper PRO". This is a single-circuit boiler with an automatic burner APG-25. It is supplied as a set, since the fuel hopper is equipped with a feeder and a control panel. A feature of the device is the unusual location of the tank (directly on the boiler itself).

The advantage of the model is space saving. However, loading fuel is inconvenient compared to other boilers. The power range of the device is 4-22 kW. The unit runs on pellets and wood.

Zota Pellet 15S

This is a Russian-made boiler. Power is 15 kW, the device is used for heating premises up to 120 sq.. m (including heat loss). The volume of the bunker is 293 l.

Of the advantages, reliable automation is distinguished that regulates the amount of air supplied and the operation of pumps. Users note a convenient control panel equipped with a display that displays important indicators. A remote control module is also connected to the boiler.

The device has no shortcomings. But, like other devices in this category, the unit weighs a lot - 333 kg. This feature must be taken into account during installation.

Faci base 258 kW

An efficient device with a self-cleaning burner and a multi-pass heat exchanger allows you to achieve maximum results at a relatively low cost.

The model is unpretentious to the quality of fuel, it works on pellets, firewood. The function of controlling the air temperature in the room is provided.

How to choose a pellet boiler?

Heating pellet boilers can be two-chamber and standard, water-heating and working only with a heating contour. But all this is trifles.

After all, the choice of a boiler, by and large, is influenced by only five factors, namely:

- Heater power.

- Burner type.

- degree of automation.

- Features of the design of the conveyor for pellets.

- Heat exchanger device.

Therefore, further in the text we will consider the influence of each of the above factors on the process of choosing each boiler model.

Choice by power

Boiler for a private house

The power of the boiler is considered very simple - 10 square meters of area with just one kilowatt. Moreover, the power of the hot water boiler needs to be increased by 25-30 percent. That is, you need a boiler, the power of which will be enough to heat the area of your house.

Of course, such a calculation formula gives only an approximate idea of \u200b\u200bthe power of the boiler.The exact value of this parameter can be calculated on a special program - a power calculator, which can be found on the website of any manufacturer of such equipment.

What kind of burner do you need?

Two types of burners are mounted on pellet boilers - a vertical (retort) version, which directs the flame upwards, and a horizontal (stoke) version, which directs the flame sideways.

Moreover, retort burners are practically insensitive to fuel quality and do not need to be cleaned. In turn, stoker burners “feed” only on special types of pellets that burn without ash residue. But even in this case, the stoker burners will have to be cleaned at a depressing frequency.

Therefore, only a retort (vertical) burner should be on the “correct” boiler.

Choice by degree of automation

Automatic pellet boilers operate without human intervention. That is, both the supply of fuel, and the adjustment of the intensity of combustion, and the operation of the circuits (in two-chamber boilers) are carried out automatically, under the control of the "artificial intelligence" of the boiler.

Pellet heating

Of course, such a scheme is good for its efficiency and economy: after all, fuel is dosed by a special control unit that turns on the conveyor only at the right time, and the signal to the unit is not even given by the boiler, but by the temperature sensor installed in the heated room.

However, when the power is turned off, such a boiler “dies”. After all, all drives of conveyors and throttle valves, as well as control circuits, operate on electricity.

But a conventional, non-automated boiler will work as much as you like and anywhere. Therefore, you need either this option or an automatic system supported by an independent source of electricity.

What conveyor is needed?

Equipment device

Conveyors in pellet boilers are rigid and flexible. Moreover, a hard auger is cheap and works flawlessly. But its length cannot exceed 2 meters - otherwise the auger will start working as a millstone, grinding granular pellets into sawdust.

A flexible auger is more expensive, but works with enviable efficiency even at a distance of 12 meters. Therefore, if the bunker is mounted at a distance of 2 meters, then you need a rigid conveyor, and if the pellet storage is 2-12 meters away from the firebox, then only a flexible auger will be mounted in the boiler.

Selection by heat exchanger design

The heat exchanger is selected according to the positioning of the assembly in the housing. There are vertical, horizontal heat exchangers, flat or tubular. Moreover, experts prefer vertical heat exchangers.

After all, such chambers can be equipped with efficient vertical burners. In addition, soot and ash do not accumulate in vertical heat exchangers - unburned particles fall to the bottom under the action of gravity. Yes, and the chimney turbulence system (a set of turns and swirlers that impede air convection) is easier to build on a vertical heat exchanger.

Published: 09.10.2014

3 SOLARFOCUS pellet top

This model will appeal to those who not only care about the warmth in the house, the quality and functionality of the boiler, but also pay no less attention to its appearance. The modern design of the equipment will perfectly fit into any interior, and the money spent will more than pay off with the functionality, convenience and efficiency of the boiler.

With it, you can create a fully automated heating system.High efficiency (94.9%) is achieved thanks to the technology of reverse combustion (fuel gasification), there is the possibility of vacuum supply of pellets from a remote storage, which provides a very long period of operation without user intervention.

The boiler is made in Austria, has an extended warranty of up to 10 years, which gives additional confidence in its reliability. In the reviews, users name many advantages of the model, but most of them highly appreciate the functionality, consistently high performance, ergonomic appearance, simplicity and ease of use.

Ecology and health

A pellet boiler can rightly be called an environmentally friendly unit. The unique air supply system in pellet boilers allows oxygen to be supplied to support the combustion process through a separate circuit. Complete combustion of the pellets leaves virtually no debris, and the combustion products are recycled in the process of photosynthesis. Thus, there is no threat to the ecology of your living space. The air supply to the burner is carried out through a pipe system from the outside. There is no effect of "burning" oxygen, so that the comfortable state is not disturbed.

Advantages of pellet boilers:

- Autonomy. A pellet boiler will heat your house, in the absence of a main gas supply to it;

- Low power consumption. Energy-saving fan, and the automation system copes with the task of operating the device by consuming no more than 70 watts;

- Small amount of waste. Compared to solid fuel boilers using wood or coal, a pellet boiler generates very small amounts of ash and soot. Manufacturers even produce an automatic self-cleaning pellet boiler;

- The body of the device is reliably protected by a layer of thermal insulation, keeping the heat inside the boiler and leaving the outer walls cold. The problem of burns is excluded;

- Automation of the heating process. An automatic pellet boiler can be operated without human intervention for up to 5 days;

- Possibility of programming continuous operation with weekly parameters.

Cons of pellet boilers:

The main disadvantage of a pellet boiler is predictably the price.

- High initial purchase price;

- High operating cost. It would seem that pellets are made from woodworking waste, but their cost is by no means like garbage.

- The heat released during the combustion of pellets is more expensive, in comparison with the same firewood;

- Storage space also entails certain costs. Folding pellets in the yard, like a woodpile, will not work. A dry area is required. Raw and swollen pellets pose a threat to the equipment, the screws become clogged and fail.

Current practice shows that the cost of operating a pellet boiler reaches the level of the cost of operating heating equipment using an electric boiler. Undoubtedly, the costs will exceed the use of gas-heating units.

Unit device

The pellet boiler itself consists of three main components:

- Furnace - equipped with a special burner (retort or flare) and two doors (control, cleaning).

- Convective zone - a heat exchanger is located in it: it can be vertical, horizontal or combined, tubular or plate type.In the convective zone, the heat carrier is heated in the heat exchanger by gases released during the combustion of pellets. Most units are designed for heating only and have one circuit, but in some models there are two circuits: heating and water heating.

- Ash pan - combustion wastes enter it (insignificant during normal afterburning), which are periodically removed through the cleaning door.

However, the listed nodes are, although the main, but only a part, for the operation of which the APT prefix (automatic fuel supply) is required. This attachment includes the following components:

- Bunker - a container for pellets of a certain volume, from which the pellets enter the furnace, can be built-in or external.

- Auger - portionwise delivers granules to the burner as needed, driven by a gearbox.

- Fan - necessary to maintain the combustion process, since the boiler does not provide for natural draft.

Since the pellet boiler is an automated system, its device also includes a control unit with a display, which displays information about the current state, and through which the main operating parameters are set. The controller regulates the ignition of the burner, the supply of granules and air, and the stop, as the desired temperature is reached, maintaining the heating mode selected by the owner.

Depending on the capacity of the bunker and the selected mode, one backfill can last for several days, or a week or even more.

To make the heating process fully automatic, the boiler can be connected directly to the storage - the pneumatic tube will feed the pellets into the hopper as it is emptied.

Kiturami KRP 20A

4.8

The second place in the ranking is occupied by a South Korean brand.The pellet boiler has a power of 30 kW and is suitable for heating a large house up to 300 m². The model heats water in the heat exchanger from 50 to 85 degrees. In case of overheating, a thermal safety valve is activated and cold water from the water supply is supplied to the boiler system, immediately eliminating the threat of equipment failure. The hopper holds up to 250 liters of pellets and features a convenient funnel for loading (located on the side of the burner, so maintenance is convenient). For an hour of operation, a pellet boiler is able to burn up to 5 kg of fuel. Users in the reviews note the convenience of auto-ignition and fast heating, thanks to the blower fan. To keep the heat exchanger clean, there is a vibration cleaning function.

We included the product in the rating due to its silent operation. The boiler is insulated with a special material that absorbs the sounds of burning fuel and the work of mechanics. Two circuits in the system allow it to be used for heating the house and heating water for bathing.

Flaws

- there is no circulation pump in the design;

- high price;

- weight 317 kg complicates transportation;

- no heating indication.

This is interesting: Finishing the balcony with laminate or linoleum

TOP of the best models of double-circuit boilers

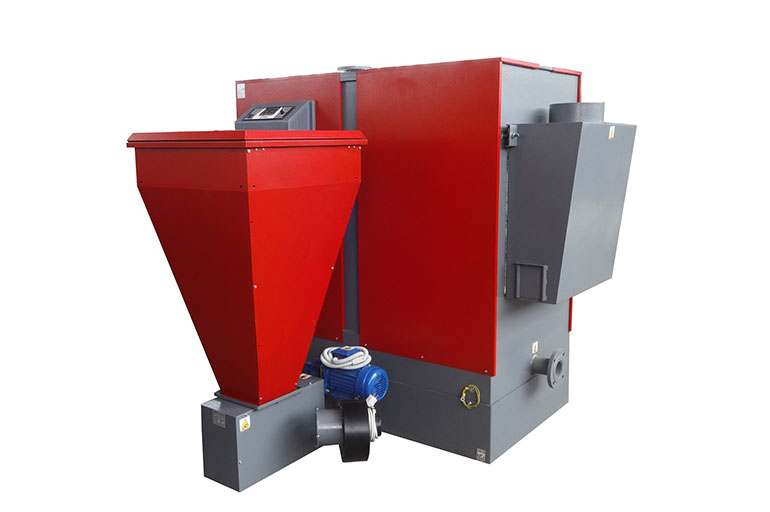

Double-circuit pellet boilers are used for the functioning of the heating system and the provision of water supply in the house with hot water. Such heating devices have high power ratings and are distinguished by good performance. However, compared to single-circuit models, dual-circuit counterparts have large dimensions.

ZOTA MAXIMA 300, two augers

The main advantage of this double-circuit boiler is its high power, which is 300 kW.You can control the operation of this equipment remotely using the Internet – network, as well as the GSM module. It is additionally equipped with contactless automatic ignition, which ensures a high level of operational safety.

The efficiency of this model of solid fuel boiler is 90%. Coal and pellets can be used as fuel. The duration of complete combustion of the loaded fuel is from 50 hours. Ease of operation is ensured thanks to the installed automatic system for removing accumulated ash.

ZOTA MAXIMA 300, two augers

Advantages:

- Ease of operation and maintenance;

- Equipped with a capacious bunker;

- High power and efficiency;

- Possibility of remote control.

Flaws:

- High cost (price 648011 rubles);

- Dimensions.

Double-circuit pellet boiler Dragon plus GV - 30

It is a reliable, fully functional heating equipment. Thanks to its use, it is possible to heat rooms in a house up to 300 sq.m. and heat large volumes of water for household needs. It is a universal device, it can work both on pellets and on other types of fuel (gas, wood, diesel fuel).

The boiler is made of high quality steel, the thickness of which varies from 5 mm. Equipped with a three-way heat exchanger. The efficiency level of this model, when using pellets, is 95%. The boiler is equipped with a high-quality burner, which is equipped with a mechanical self-cleaning system. This model of heating equipment is unpretentious in terms of the quality of the pellets used. The maximum boiler power is 36 kW.

Double-circuit pellet boiler Dragon plus GV - 30

Advantages:

- Unpretentious to the quality of the pellets used;

- Easy to operate and maintain;

- High level of power and efficiency;

- Boiler warranty 3 years;

- Existence of a mechanical system of self-cleaning of a torch.

Flaws:

- High price (229,500 rubles);

- Small volume of the bunker for storage of pellets.

Jaspi Biotriplex

It is a combined solid fuel heater, which is perfect for heating private houses up to 300 sq.m. After installing the burner, you can heat the house with pellets. In addition, this device in the same mode, together with wood pellets, can use firewood to heat the house or operate from the mains.

For water heating, it is additionally equipped with a coil made of copper, which allows you to produce up to 25 liters (at water temperatures up to +40 degrees Celsius). When using pellets, the power of the unit is 30 kW. In the case of using firewood, power indicators vary around 25 kW. The efficiency is over 85%.

Boiler Jaspi Biotriplex

Advantages:

- Functional;

- Versatility;

- Quickly heats large volumes of domestic water;

- Equipped with separate chambers for burning pellets and firewood;

- It is completed with an electric heating element with a power of up to 6 kW;

- The duration of operation is about 25 years;

- Equipped with thermal insulation.

Flaws:

- High cost (505100 rubles);

- Difficult to install.

Comparative characteristics of different models of pellet boilers

| Title, description | Type of | efficiency | Power, kWt) | Cost (in rubles) |

|---|---|---|---|---|

| ZOTA Focus 16 | single-loop | 80% | 16 | 112300 |

| TermoKRoss TKR-40U | single-loop | 91% | 40 | 132000 |

| Ecosystem PelleBurn PLB 25 | single-loop | Not specified | 25 | 325500 |

| FACI 130 | single-loop | Up to 95% | 130 | 335000 |

| Teplodar Kupper PRO - 28 with pellet burner APG - 25 | single-loop | 85% | 28 | 98634 |

| ZOTA MAXIMA 300 | double-circuit | 90% | 300 | 648011 |

| Dragon plus GV - 30 | double-circuit | 95% | 36 | 229500 |

| Jaspi Biotriplex | double-circuit | Over 85% | 25 | 505100 |

Pellet boilers are a type of solid fuel heating units that run on pellets. The main advantage of these devices is the presence of a fully automated control system, automatic fuel supply, as well as high efficiency.