- Furnace heat exchangers

- Installation process

- Foundation preparation

- Strapping device

- Creating a chimney

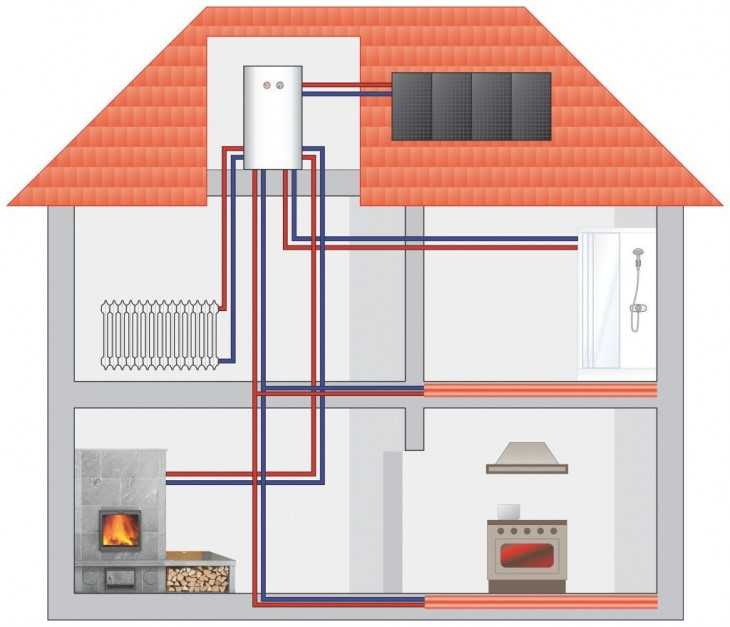

- Bivalent hybrid heating systems based on heat pumps

- Functioning of the bivalent system

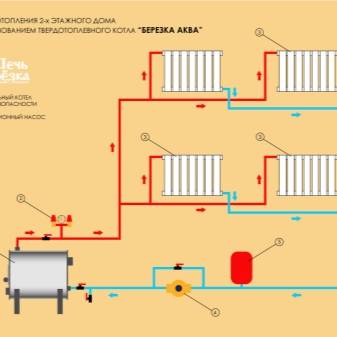

- Single pipe schemes

- Single pipe horizontal

- Single pipe vertical wiring

- Leningradka

- The choice of coolant

- Mounting

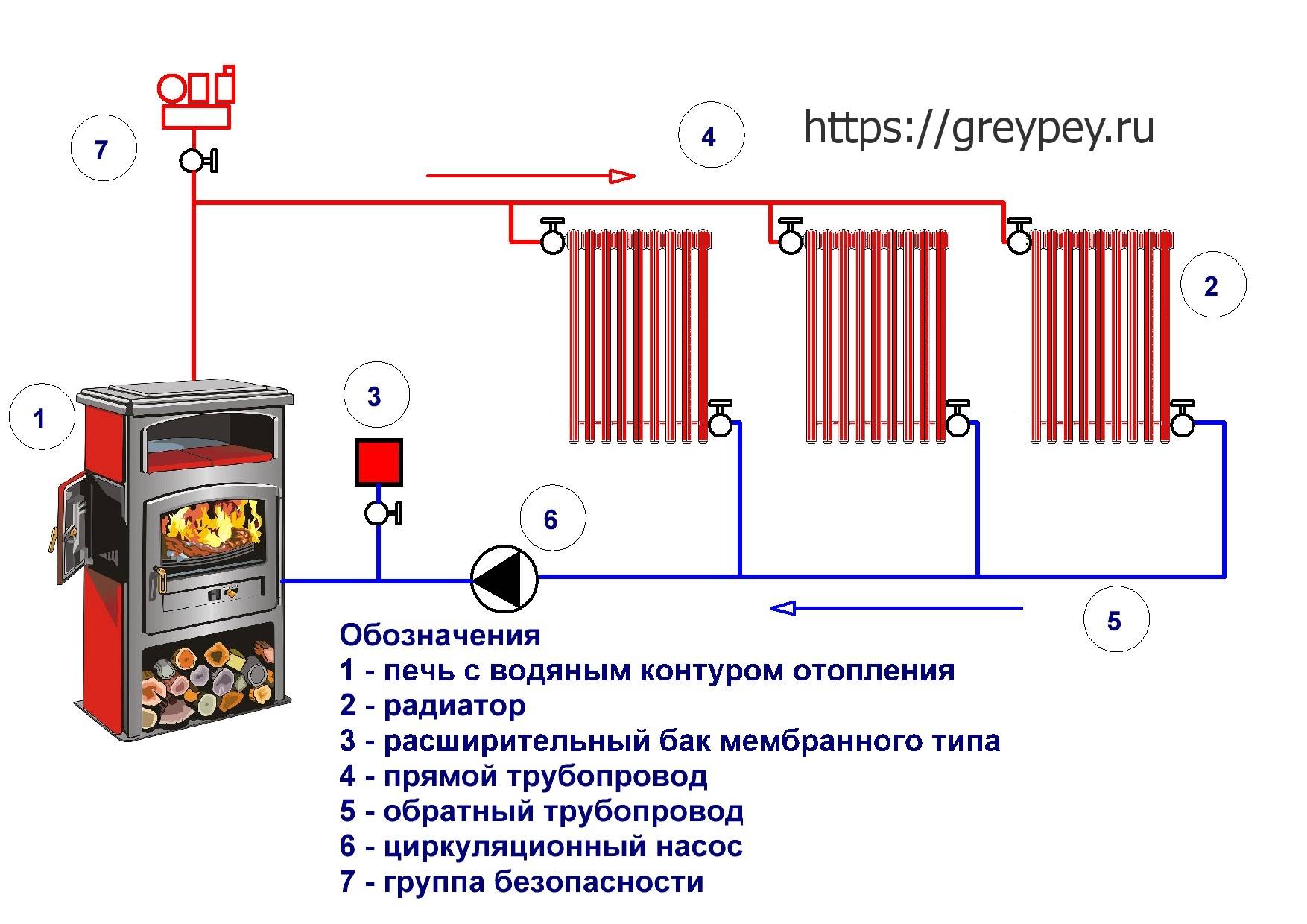

- Features of furnaces with a water circuit

- Advantages of a combined heating system

- The main advantages of installations

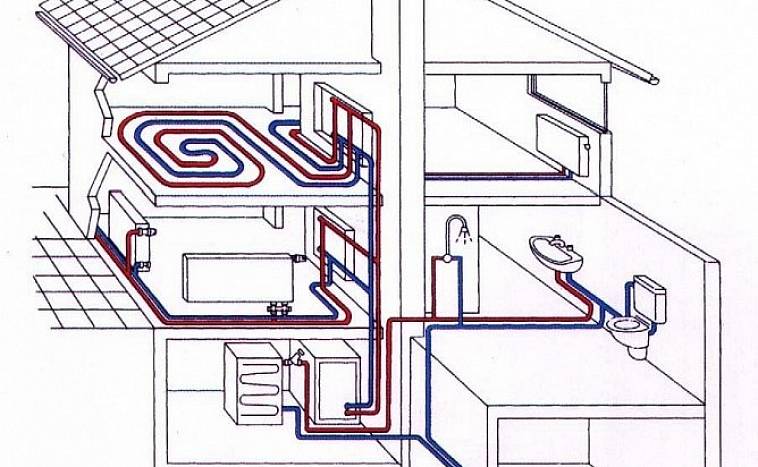

- How is the water heating system arranged?

- Option #1 - natural or gravity

- Option #2 - forced system

- Heating registers

- Collector scheme for heating a one-story house with forced circulation

- Stove heating device in a private house: the design of modern stoves

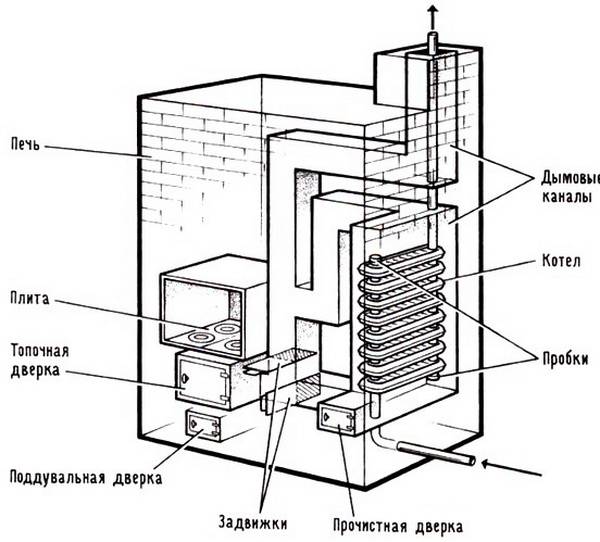

Furnace heat exchangers

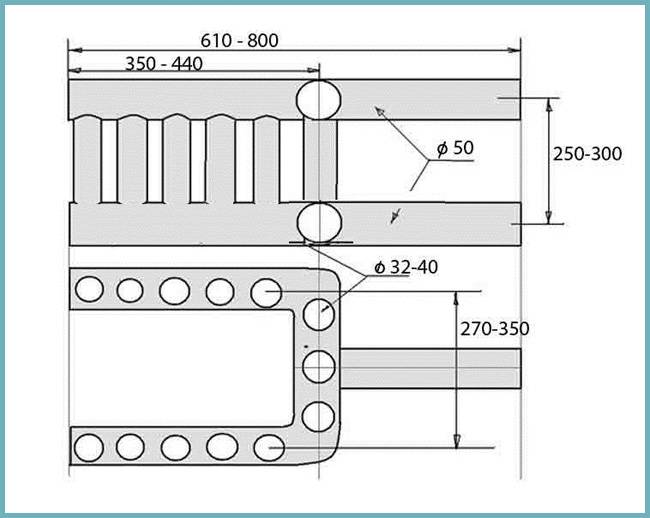

Scheme of arrangement of the coil

The diagram shows one of the options for the coil. It is good to place this type of exchanger in heating and cooking furnaces, because its structure easily allows you to place a stove on top.

In order to reduce the complexity of the manufacturing process, you can make some changes to this design and replace the upper and lower U-shaped pipes with a profile pipe. In addition, vertical pipes are also replaced with rectangular profiles if necessary.

If a coil of this design is installed in ovens where there is no cooking surface, then to increase the efficiency of the exchanger, it is advisable to add several horizontal pipes. Processing and withdrawal of water can be done from different sides, it depends on the design of the furnace and the design of the water circuit.

Coil-heat exchanger

Installation process

Installation is not very difficult, which means it can be done by hand. Further, it is recommended that you familiarize yourself with the main stages that you will have to go through during the installation of the heater. With proper installation, the heating system will serve for many years.

Foundation preparation

Regardless of the solid fuel boiler connection scheme used, a supporting structure on the floor is prepared in the room. Usually it rises 10-20 cm above the main part of the lower plane. The most popular option is a reinforced concrete screed.

This is what a reliable boiler platform looks like.

It is recommended to lay a metal sheet on the surface of the podium to protect it from thermal effects. As an alternative, asbestos plates at least 5 mm thick can be used.

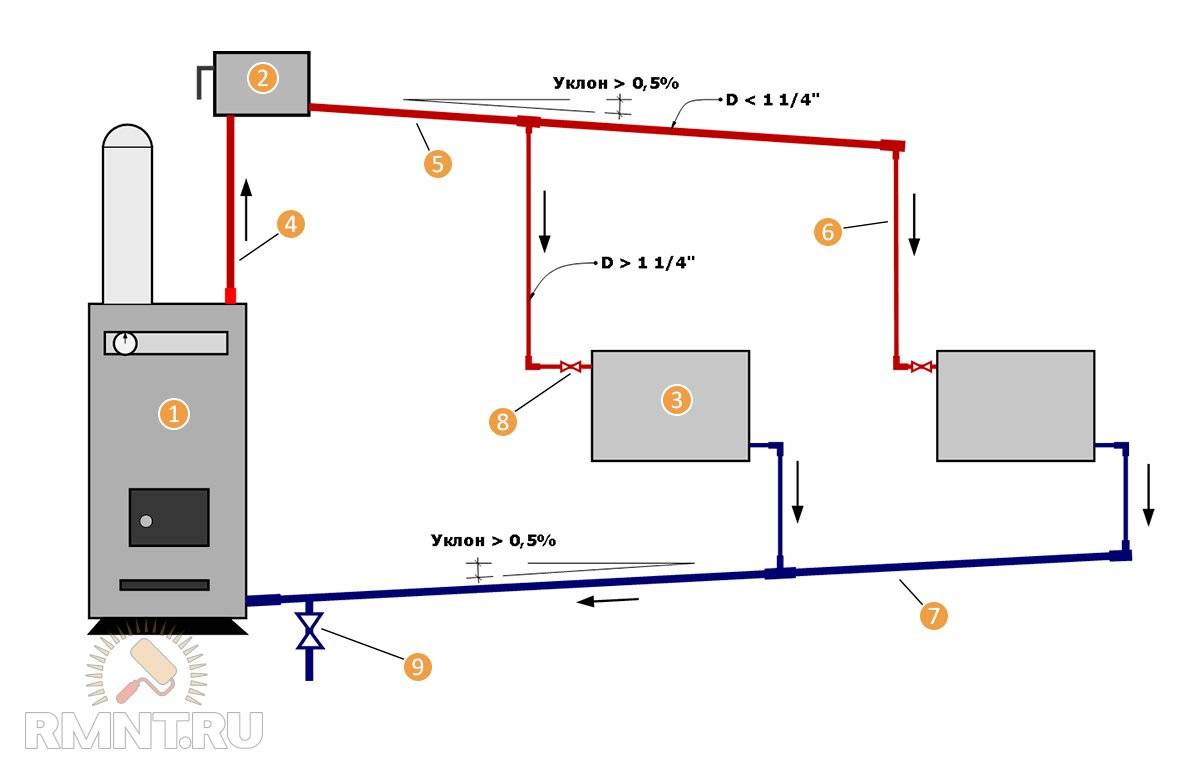

Strapping device

When organizing the system, special attention should be paid to the selection of the most efficient mode of operation and temperature control. Provided that the strapping is carried out correctly, it is possible to save money, since the thermal energy in this case is optimally distributed

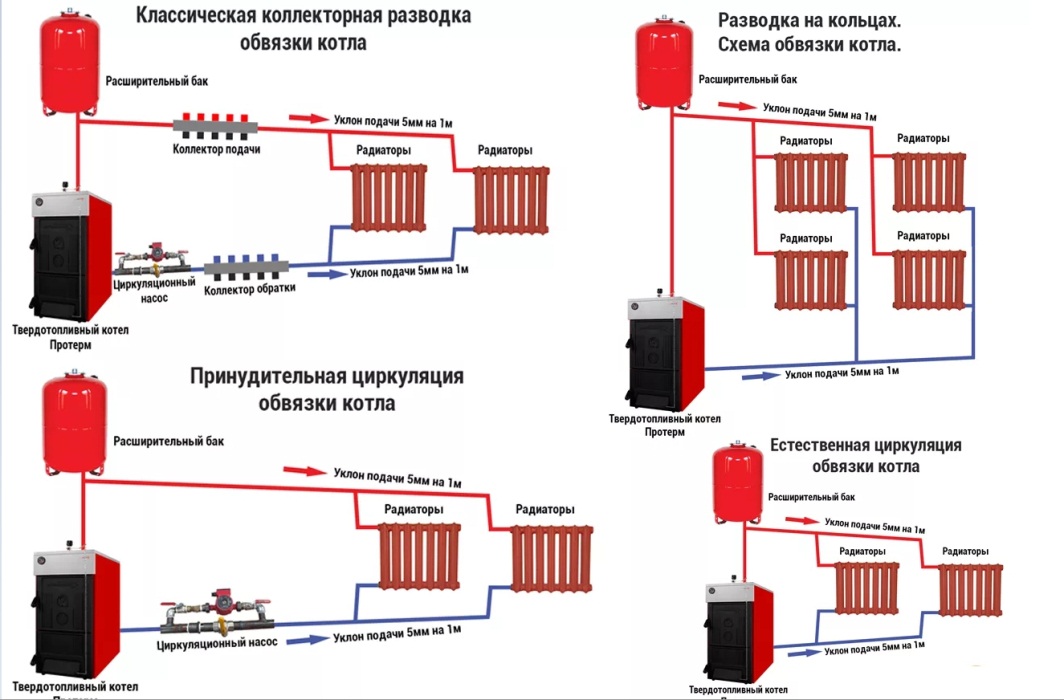

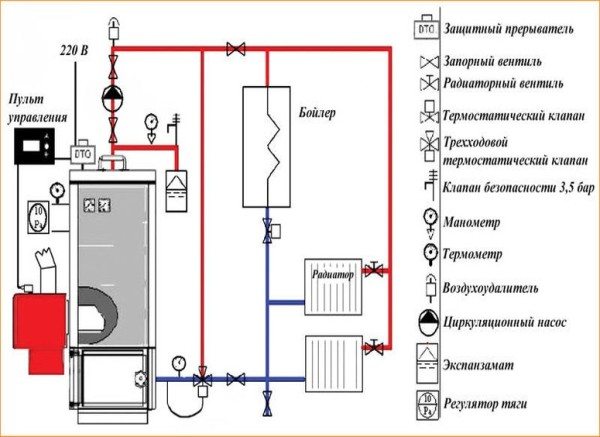

The installation can use one of several schemes.

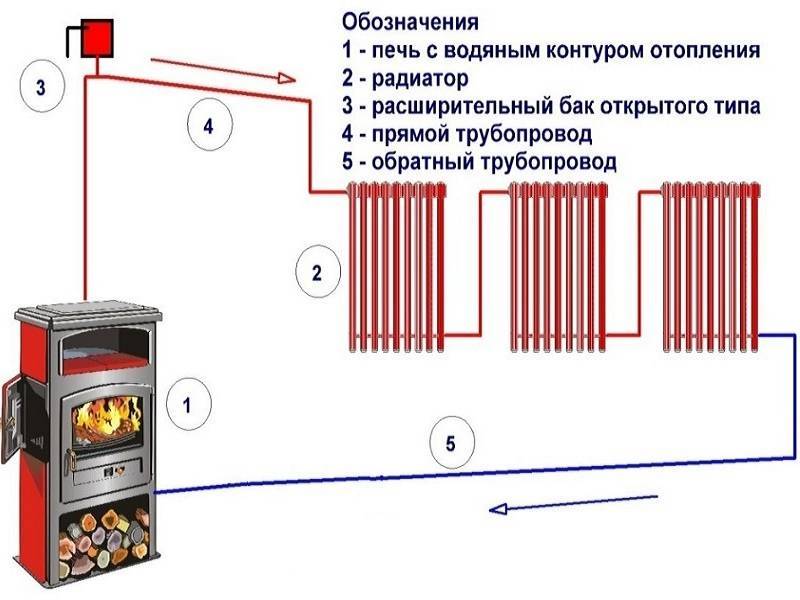

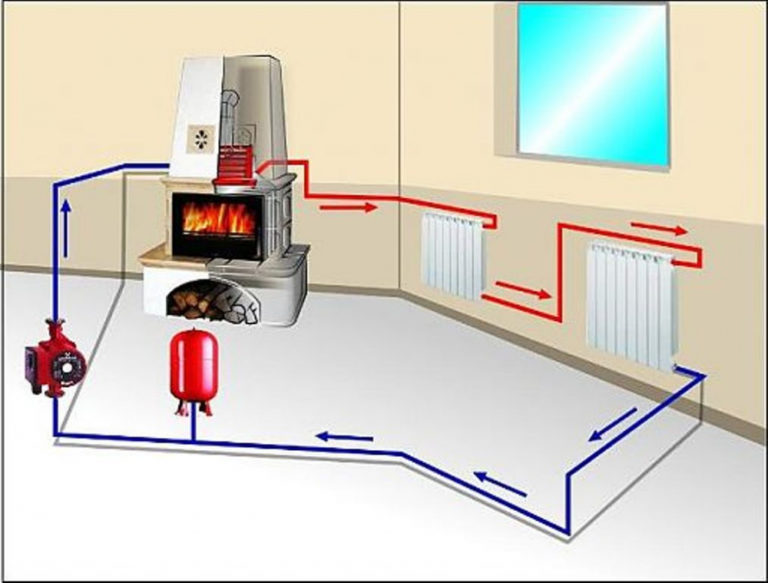

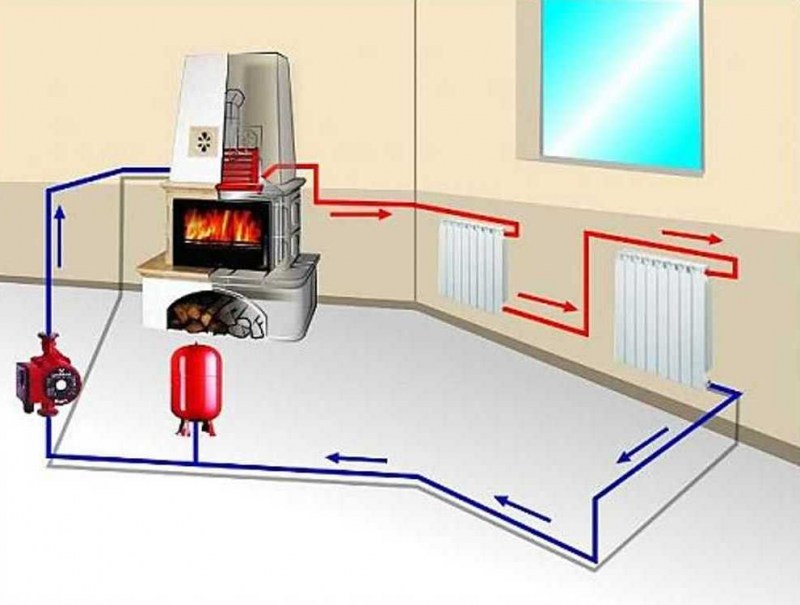

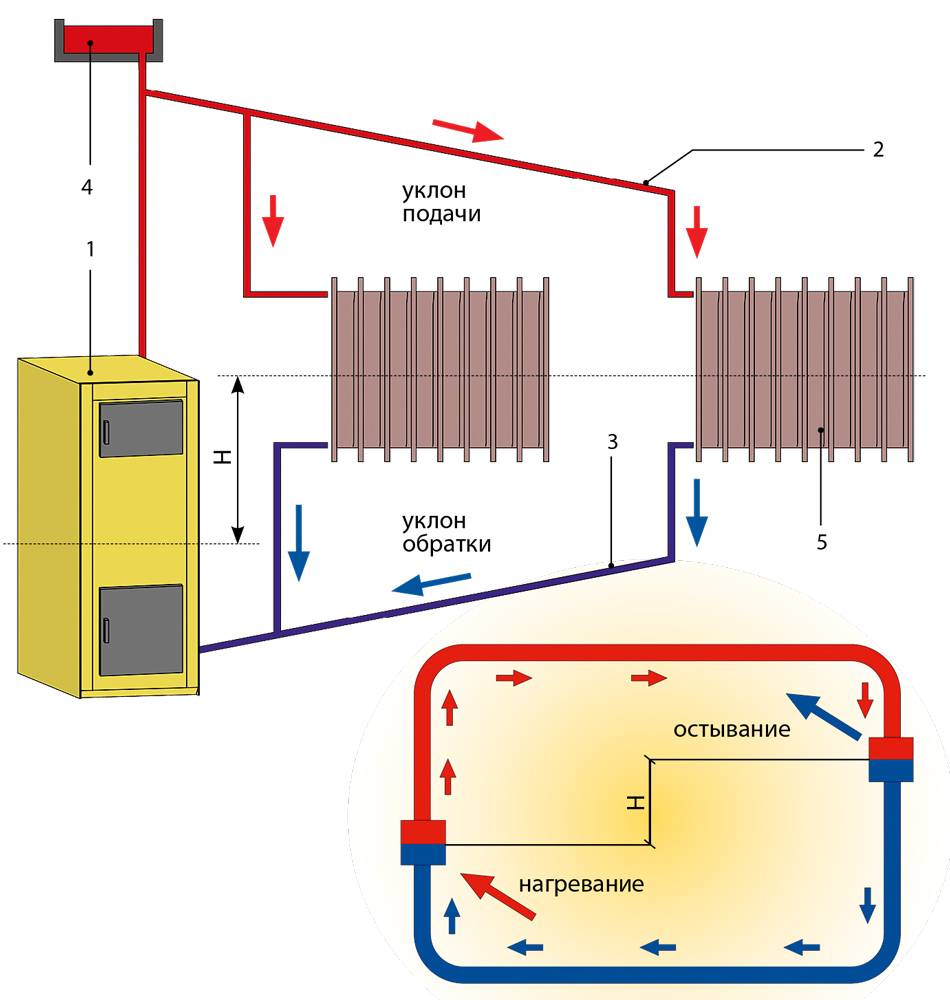

The simplest system with natural circulation.

- Piping in a natural circulation heating system is the simplest option. as it does not require additional devices.All adjustments are made manually, fuel is added as it burns. Such a scheme assumes the presence of pipes with a large diameter.

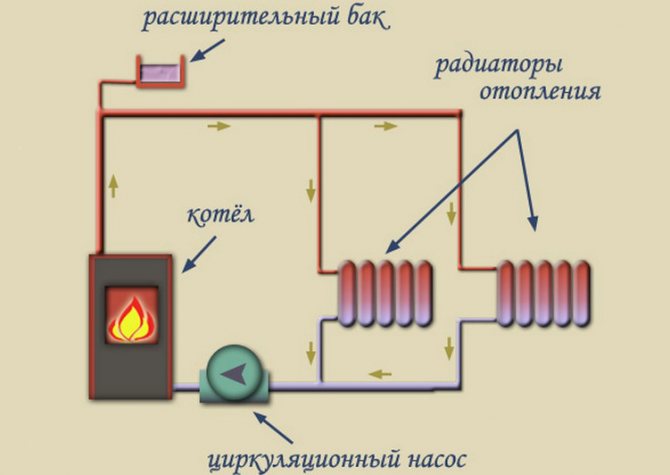

- A system with forced circulation must necessarily include a special pump for pumping fluid. With its help, the coolant moves evenly along a closed circuit. Thanks to this device, it is possible to adjust the heating radiators separately. However, electricity must be present in the building for the circulation pump of the heating system to work.

- Collector wiring is considered the most difficult. which is due to the presence of a large number of different devices - valves, air vents, gate valves, taps and other devices for controlling the necessary parameters. The price of such a heating network is quite high.

- The ring piping scheme with primary and secondary circuits is used, as a rule, in residential buildings with many consumers. The device requires the installation of several devices at once to organize the circulation of the coolant.

The most complex piping of the heating device.

Important! Solid fuel heating units that are dependent on electrical energy must be equipped with emergency circuits so that when the light goes out, normal operation continues

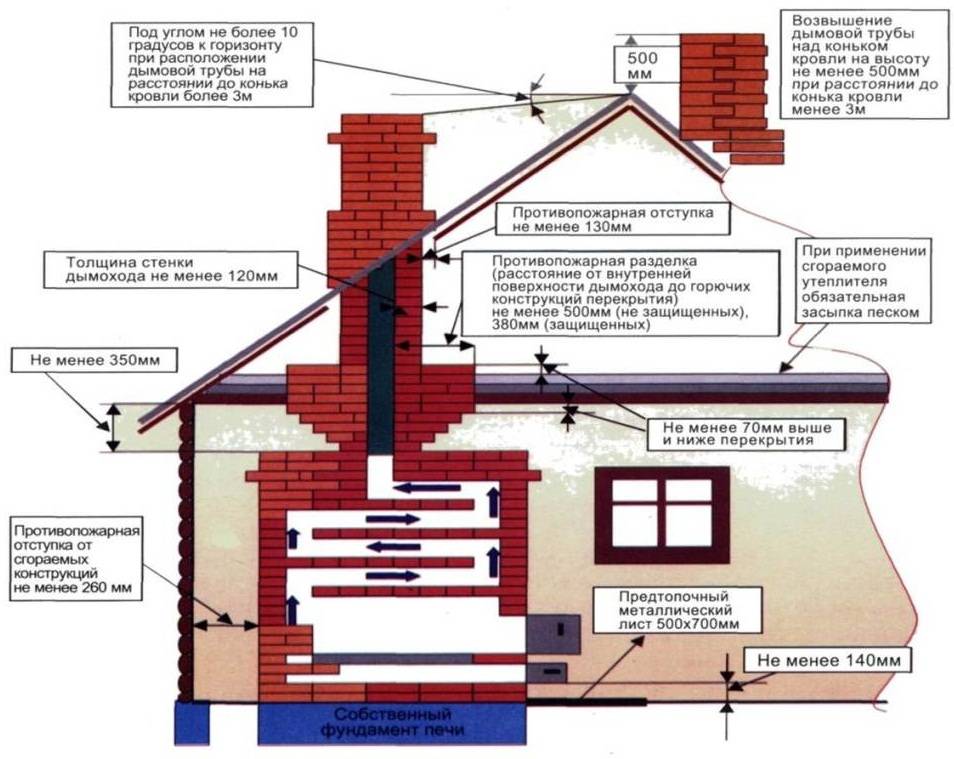

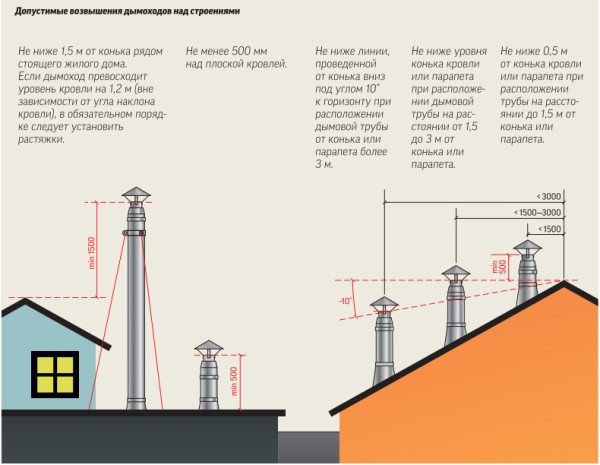

Creating a chimney

The devices are equipped with a pipe for the removal of combustion products, the cross section of which must correspond to the dimensions of the outlet located in the upper part. Most often, ready-made elements are used, consisting of metal inserts and heat-insulating material.

Ideally, the chimney should not have turns, but if they are still present, then they should be made as smooth as possible.All joints between the components of the pipeline must be sealed so that the smoke from the boiler does not penetrate into the heated room. For these purposes, a heat-resistant tape or a special composition can be used.

Basic rules for the location of the chimney.

Particular attention should be paid to the release of the pipe above the roof, as the quality of traction will depend on this.

- If the distance from the ridge to the chimney does not exceed 150 cm, then you need to make a release above the highest point by 50 cm.

- At a distance of up to 300 cm from the intersection of the slopes, the pipe should be led out so that the upper part is flush with the ridge.

- If the chimney is at a decent distance, then it should be located below the top of the roof with an angle of no more than 10 degrees.

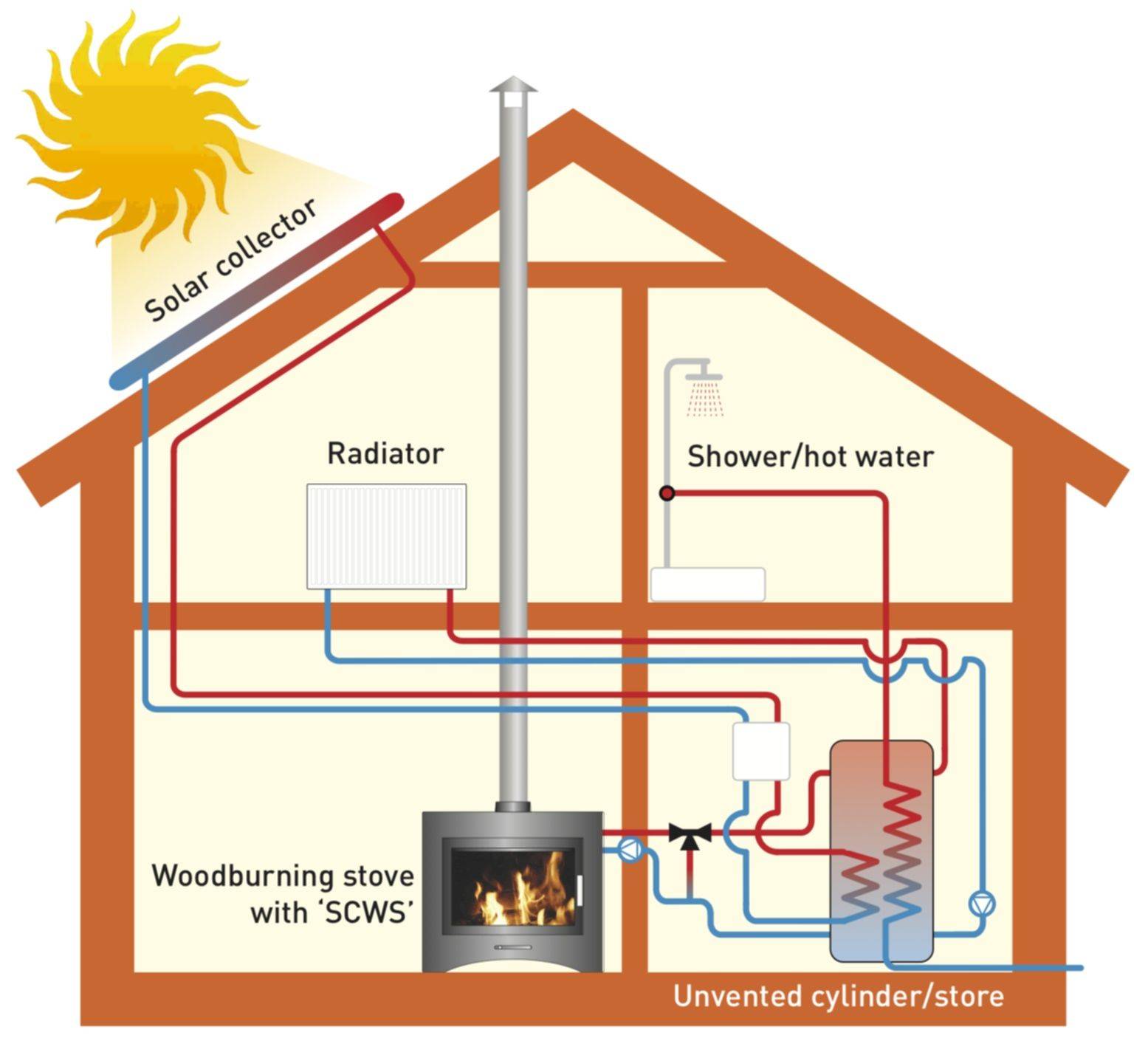

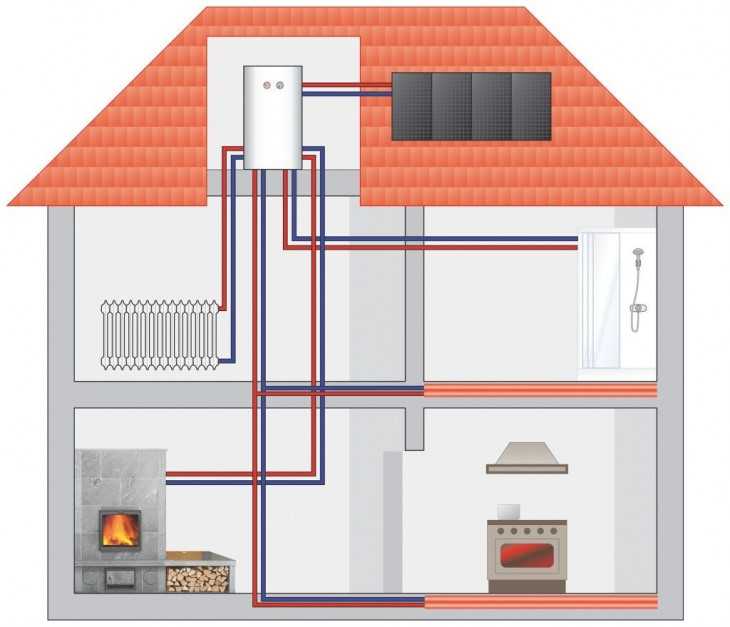

Bivalent hybrid heating systems based on heat pumps

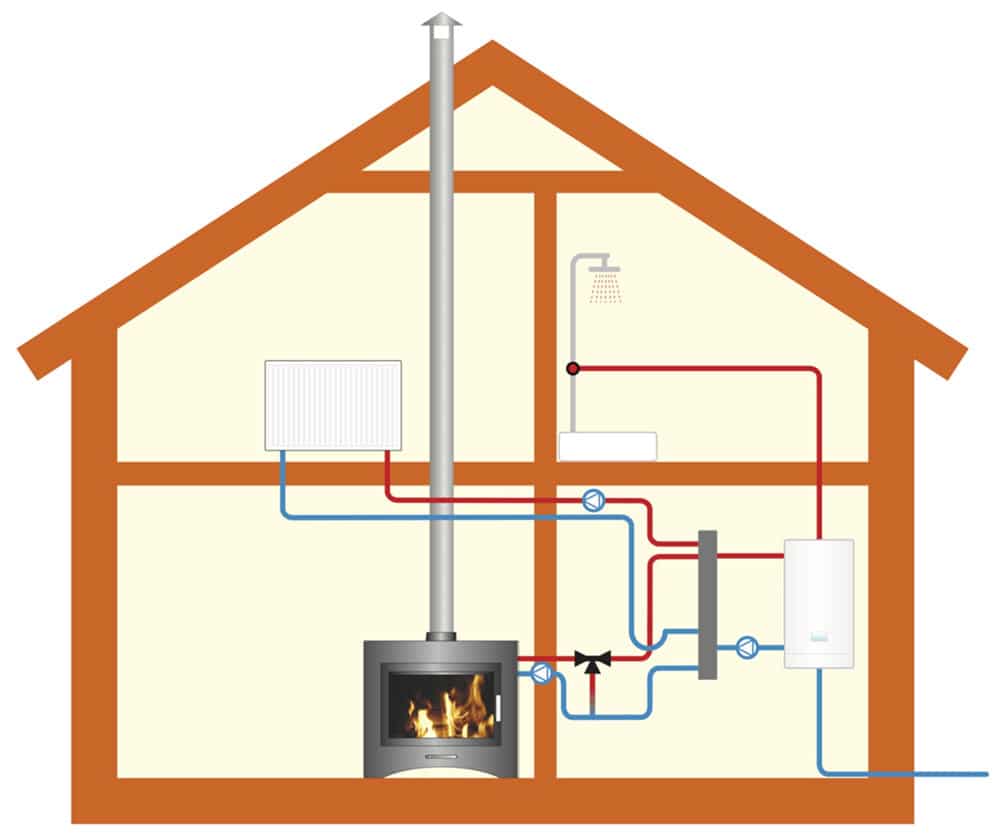

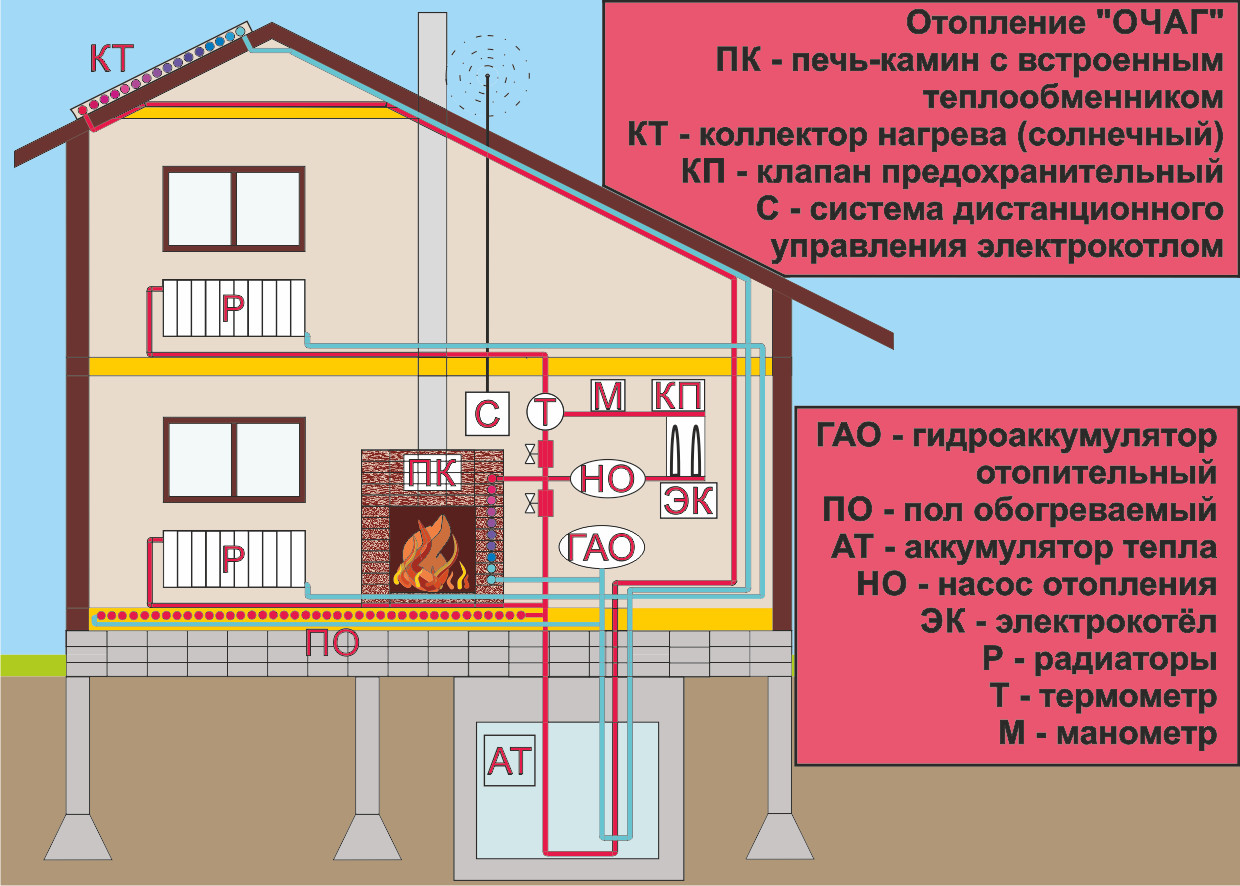

A hybrid heating system (bivalent) consists of a main heat source, a peak reheater and a buffer tank. This system allows you to maximize the use of the heat pump with minimal investment.

Functioning of the bivalent system

As you know, heating equipment is selected according to the heat loss of the room at a minimum outdoor temperature (for Kyiv -22 ° C). This means that the selected boiler should heat your room in the temperature range: from -22 to +8 °C. If we analyze Climatology, it turns out that the number of days in the heating season when the temperature drops below -15 ° C is less than 5%.Therefore, it is not advisable to select a heat pump for the lowest possible outdoor temperature, it is much more profitable to purchase a heat pump of lower capacity and an inexpensive backup heat source (a peak heater is the cheapest electric boiler) that will be switched on only at a temperature below the divalence point (usually -15 °C). The advantage of this system is also the redundancy of the heating system.

Main Pros:

- Reservation of the heating system

- Possibility to purchase a heat pump with lower heat output

Main Cons:

Not

5. How much power do you need a heat pump?

If you have a new house made of gas block, insulated with 100-120-150 mm of mineral wool or foam (walls and foundation to the freezing depth), good double-chamber energy-saving double-glazed windows, insulated roof (150-200mm), insulated floor on the ground (minimum 100 mm.), then the heat loss of your house is 50 W/m2 (at -22 °C):

- House 100 m2 - 5 kW

- House 150 m2 -7.5 kW

- House 200 m2 - 10 kW

- House 250 m2 - 12.5 kW

- House 300 m2 - 15 kW

- House 350 m2 - 17.5 kW

- House 400 m2 - 20 kW

- House 450 m2 - 22.5 kW

- House 500 m2 - 25 kW

- Building 1000 m2 – 50 kW

In principle, such body losses can be easily covered by a Zubadan air-to-water heat pump:

- House 100 m2 - 5 kW - PUHZ-SW50VHA

- House 150 m2 -7.5 kW - PUHZ-SHW80VHA

- House 200 m2 - 10 kW - PUHZ-SHW112VHA/PUHZ-SHW112YHA

- House 250 m2 - 12.5 kW - PUHZ-SHW140YHA

- House 300 m2 - 15 kW - PUHZ-SHW140YHA + reserve 3 kW

- House 350 m2 - 17.5 kW - PUHZ-SHW230YKA

- House 400 m2 – 20 kW – PUHZ-SHW230YKA

- House 450 m2 - 22.5 kW - PUHZ-SHW230YKA + reserve 3 kW

- House 500 m2 - 25 kW - PUHZ-SHW230YKA + reserve 5 kW

- Building 1000 m2 - 50 kW - Cascade of 2 heat pumps PUHZ-SHW230YKA + reserve 4 kW

When choosing the power of the heat pump, one should also take into account the power required for heating the ventilation, swimming pool, hot water, etc. Therefore, before purchasing, consult an expert and calculate heat loss.

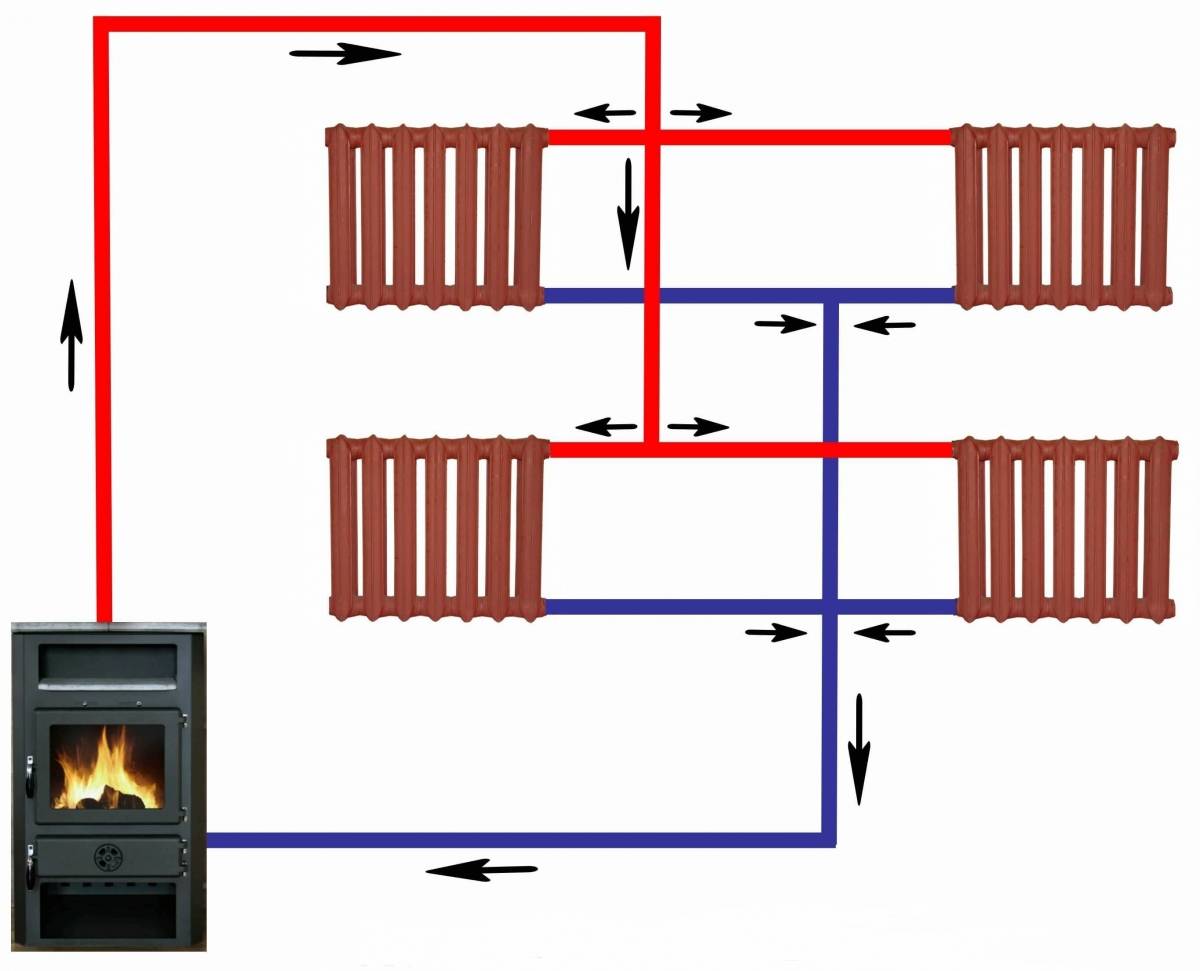

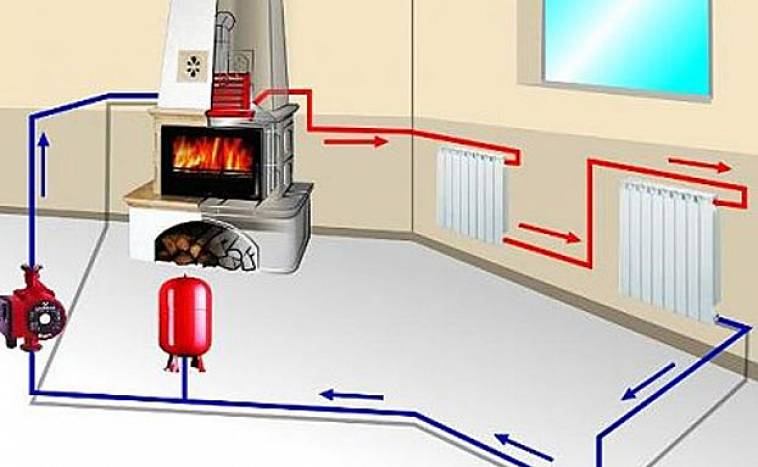

Single pipe schemes

The easiest way is to perform calculations and assemble a heating system with a single-pipe piping scheme for the coolant. The heated water in it sequentially passes from the boiler through all the batteries in the house, starting with the first and ending with the last in the chain. At the same time, each subsequent radiator gets less and less heat.

With the installation of the pipeline according to this scheme and connecting it to the boiler with your own hands, with even minimal skills, you can handle it in two to three days. Plus, the cost of creating a water heating system in the house for single-pipe wiring is the most minimal in comparison with other options.

Fittings, fittings and pipes are required here a little. Savings on materials are significant

And it does not matter whether glued beams or bricks are chosen for the construction of the cottage. If the housing is well insulated, then even a simple one-pipe system for heating it is more than enough

In order to level the shortcomings, a circulation pump has to be built into a single-pipe system. But these are additional costs and potential equipment breakdowns. Plus, in case of any problems in any section of the pipe, the heating of the entire cottage stops.

Single pipe horizontal

If a private house is small and one-story, then a single-pipe heating system is best done horizontally.To do this, in the rooms around the perimeter of the cottage, a ring of one pipe is laid, which is connected to the inlet and outlet of the boiler. Radiators cut into the pipeline under the windows.

Single-pipe horizontal layout - ideal for small spaces

Batteries are connected here with a bottom or cross connection. In the first case, heat losses will be at the level of 12-13%, and in the second case they will be reduced to 1-2%. It is the cross-mounting method that should be preferred. Moreover, the coolant supply to the radiator should be done from above, and the outlet from below. So the heat transfer from it will be maximum, and the losses will be minimal.

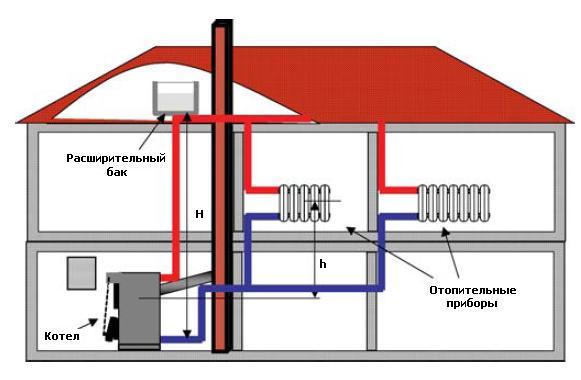

Single pipe vertical wiring

For a two-story cottage, a single-pipe heating system of a vertical subspecies is more suitable. In it, the pipe from the water heating equipment goes up to the attic or second floor, and from there it descends back to the boiler room. The batteries in this case are also connected in series one after the other, but with a side connection. The pipeline for the coolant is usually laid in the form of a single ring, first along the second, and then along the first floor, with such a distribution of heating in a low-rise building.

Single-pipe vertical scheme - save on materials

But an example with vertical branches from a common horizontal pipe at the top is also possible. That is, first a circular circuit is made from the boiler up, along the second floor, down and along the first floor back to the water heater. And already between the horizontal sections, vertical risers are laid with the connection of radiators to them.

The coldest battery in such a heating system of a private house will again be the last one in the chain - at the bottom of the boiler. At the same time, there will be an excess of heat on the upper floor.It is necessary to somehow limit the amount of heat transfer at the top and increase them at the bottom. To do this, it is recommended to install jumper-bypasses with control valves on the radiators.

Leningradka

Both schemes described above have one common minus - the water temperature in the last radiator turns out to be very low, it gives off very little heat to the room. To compensate for this cooling, it is recommended to improve the single-pipe horizontal version of heating a private house by installing bypasses at the bottom of the battery.

Leningradka - advanced one-pipe system

This wiring was called "Leningrad". In it, the radiator is connected from above to a pipeline running along the floor. Plus, taps are placed on the taps to the batteries, with which you can adjust the volume of the incoming coolant. All this contributes to a more even distribution of energy in individual rooms in the house.

The choice of coolant

When choosing one or another heating system with a water circuit, it is important to consider which coolant will be used. In winter, country houses and country houses are not often visited, and heating in them is necessary only at the time of the owners' arrival.

Therefore, owners prefer non-freezing liquids, the consistency of which does not change with the onset of severe frosts. Such fluids eliminate the possible problem of pipe bursting. If water is used as the heating medium, then before leaving it must be drained and refilled before use. Also as a coolant can be used:

antifreeze is a special liquid that prevents freezing. The heating system uses 2 types of antifreeze - propylene glycol and ethylene glycol

When choosing this method, it is important to know that ethylene glycol is extremely toxic, so its handling must be appropriate.

coolant on glycerin. Considered more efficient and safer (not explosive or flammable)

Glycerine liquid is expensive, but since the oven is only filled with it once, it makes sense to invest in the purchase. In addition, glycerin freezes only if the temperature drops below -30 degrees.

saline solution or a solution of the natural mineral bischofite. The standard ratio is 1:0.4. Such a water-salt solution does not freeze up to -20 degrees.

How to choose a coolant

Detailed instructions for choosing a coolant for heating systems and technical specifications can be found here.

Mounting

Installation of a furnace with a water circuit can be carried out according to two schemes. The first scenario involves the circulation of the liquid in this way: cold water goes down, and warm water rises

Then, when installing the furnace, it is important not to violate the correct height difference

The second scenario is used when fluid circulation is not naturally possible. Then pumps are mounted, providing an artificial circulation of water.

For convenience, the installation of the heating system takes place in several approaches. First, a wood-burning stove or fireplace is mounted, chimneys are removed, observing fire safety rules. Later - a water circuit is bred throughout the house.

Features of furnaces with a water circuit

Before rushing to purchase equipment, it is important to familiarize yourself with the features of the heating system. Advantages:

Advantages:

- The ability to efficiently heat several rooms with a large area.

- Uniform distribution of heat.

- Safety of use.

- They can be autonomous heat sources or work together with a centralized heating system.

- Using a temperature sensor that allows you to control the operation of the device.

- Autonomy (independence from sources of electricity and gas communications).

- Relatively low maintenance cost.

- The furnace functions on coal, peat, wood and coke coal.

- Economy and environmental friendliness of the heating system.

- Modern design and matching to any style and interior.

Flaws:

The boiler reduces the useful volume of the firebox

To eliminate this fact, it is important in the process of laying the firebox to think over the mandatory width of the boiler and the furnace itself. Long burning stoves can also be used.

Low level of automation

Only manual control is possible.

The thermal energy received as a result of burning wood is spent on heating the boiler and the liquid in it, and the walls of the firebox heat up more slowly and to a lesser extent.

In severe frosts, the coolant can freeze. There is a risk of freezing if the house is not intended to be permanently occupied. In order to prevent this, special additives should be added to the purified water to protect the system. Also, experts recommend using antifreeze - a universal coolant that freezes only at very low temperatures.

The use and maintenance of heating furnaces with a water circuit is not particularly difficult. Attached is a video for further explanation.

Having decided to purchase a heating furnace with a water circuit, study in advance the models offered by foreign and domestic companies. They are distinguished by size, design, cost and accessories. For a small country house, a brick stove with water heating, low power and no designer frills is quite enough. The owner of a large mansion is unlikely to be satisfied with such a model. A spacious living room can be decorated with a stylish foreign-made stove.

Advantages of a combined heating system

- Economy of the system. The construction of a furnace or the re-equipment of an already finished one will not require serious financial investments, and as a heating device, it does not need complex and expensive maintenance.

- You can combine a stove with a fireplace and get not only a heating device, but also a unique decorative element that can become the main attraction of the interior.

The appearance of the stove can be chosen by the owner of the house

- A special comfort and atmosphere is created in the house, which can only be created with the help of this living heating method.

- Relatively high efficiency. If the furnace is built by a competent specialist according to a good scheme, its productivity will be quite high, up to 60% in comparison, for example, with a liquid fuel boiler.

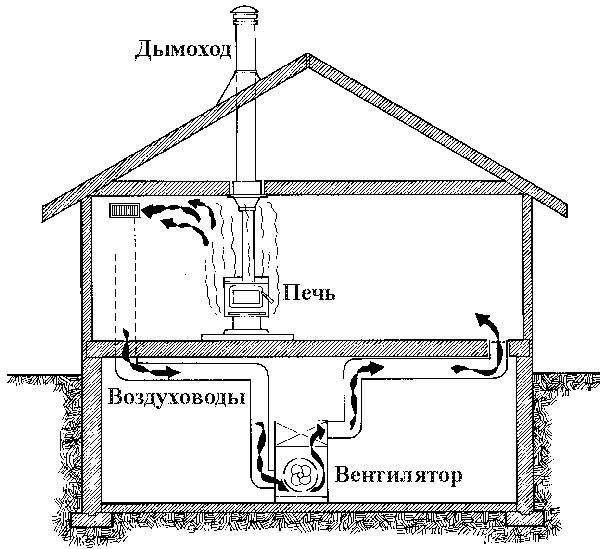

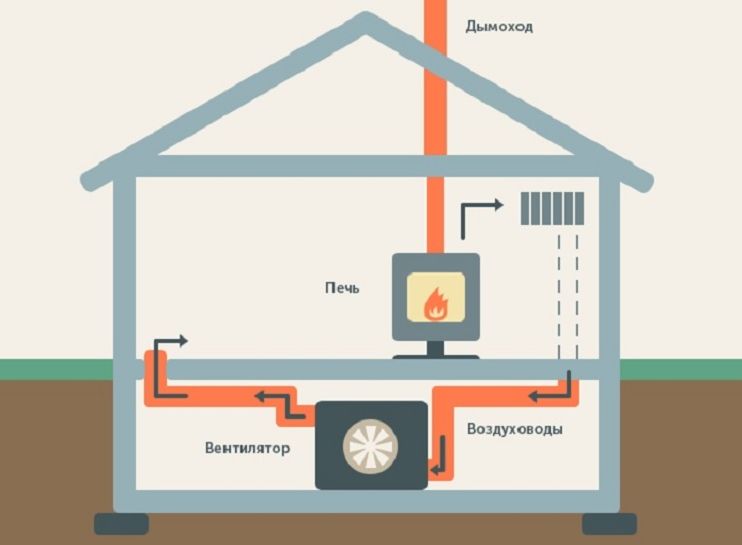

The main advantages of installations

Standard stoves cannot provide uniform heating of air in a large house or cottage. In modern units, to solve this problem, convection chambers are installed, followed by the connection of branched air ducts. As a result of such actions, a warm air flow is created.It is forcibly moved through the space inside the pipes, while its regulation is ensured by specially equipped dampers, valves and gratings.

But the channels for moving air are cumbersome, they absorb useful space in the room, and with an increase in the number of turns in the system, heat losses increase proportionately. An important factor is the periodic removal of soot, soot, dust accumulations, etc. As for air, it is characterized by an insignificant specific heat capacity.

To ensure the supply of heat to the most remote areas of the building, only the forced injection of heated masses by installing a special fan will help. Considering such nuances, it is safe to say that water as a heat carrier over air has a lot of advantages.

If we consider the specific heat capacity of the water mass, then its indicator is 4 times higher than the similar value of air. Water easily moves through pipes of small diameters, while thermal energy is supplied over long distances. It is worth noting such advantages of the water mass as chemical neutrality, safety, lack of toxicity and flammability.

Video tutorial about a wood-burning stove with a water circuit:

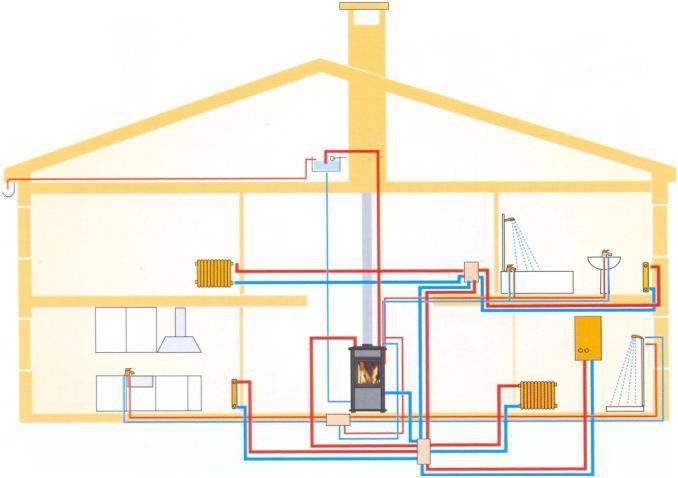

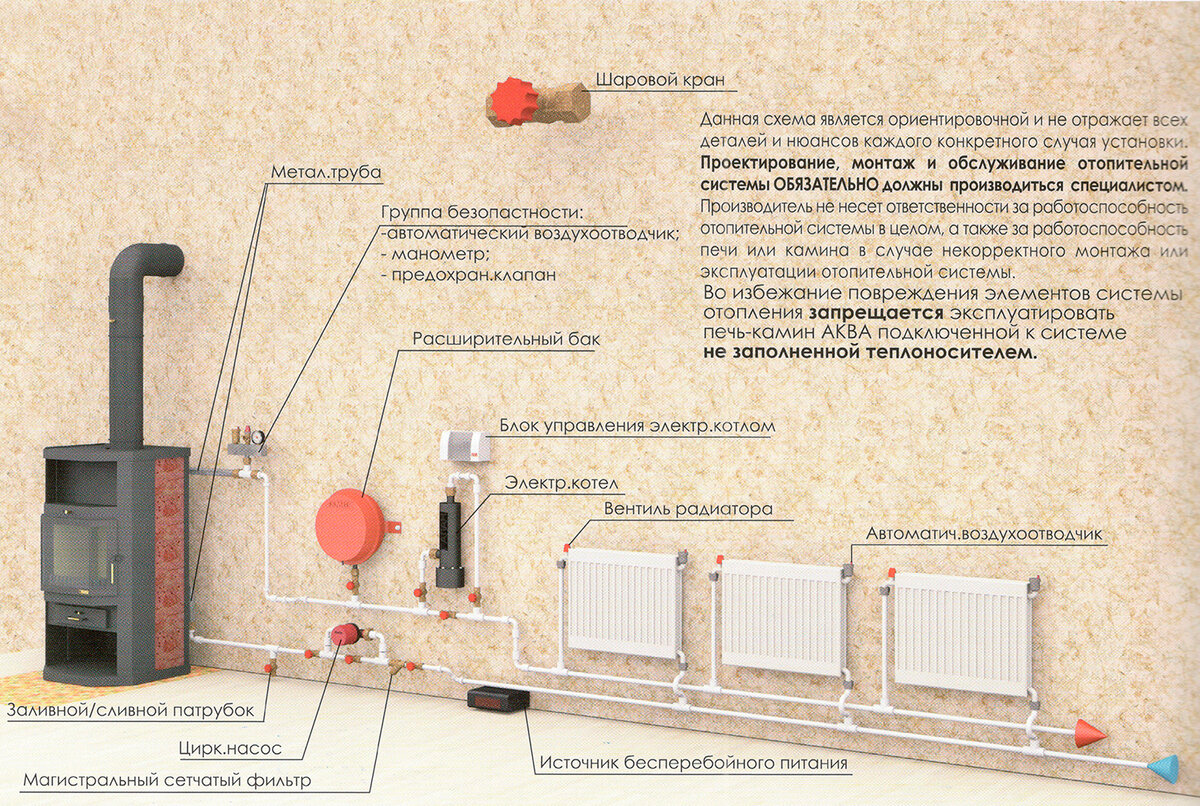

How is the water heating system arranged?

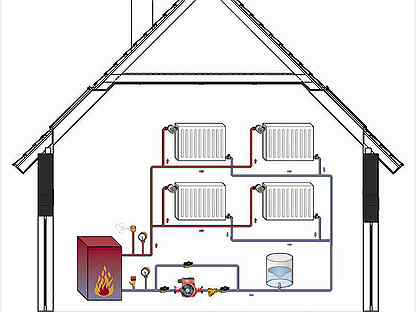

The principle of operation of water heating is quite simple. The design is a closed system consisting of a heating boiler, piping and radiators.

The boiler heats up the coolant, it can be water or a solution based on one of the glycols, which enters the radiators located in the heated room through pipes. The batteries heat up and give off heat to the air, due to which the room itself heats up.The cooled coolant returns through the pipes to the boiler, where it heats up again and the cycle repeats.

Water heating is a closed system in which the coolant circulates: 1 - expansion tank; 2—automatic control unit; 3—vortex generator; 4 - circulation pump; 5—tank thermos

The circulation of the coolant, on which all water heating systems are based, can be carried out in two ways - natural and forced.

Option #1 - natural or gravity

The process is carried out due to different densities of cold and hot water. The heated liquid becomes less dense and, accordingly, weighs less, so it tends to move upwards through the pipes. As it cools, it thickens and then returns to the boiler.

The natural circulation system works due to the action of natural gravitational forces.

The main advantage of a natural system is autonomy, since it does not depend on electricity, and the utmost simplicity of design. The disadvantages include the need to use a large number of pipes, and their diameter must be large enough to provide natural circulation. As well as the inability to use modern models of batteries with a small cross section and the need for strict adherence to a slope of at least 2 °.

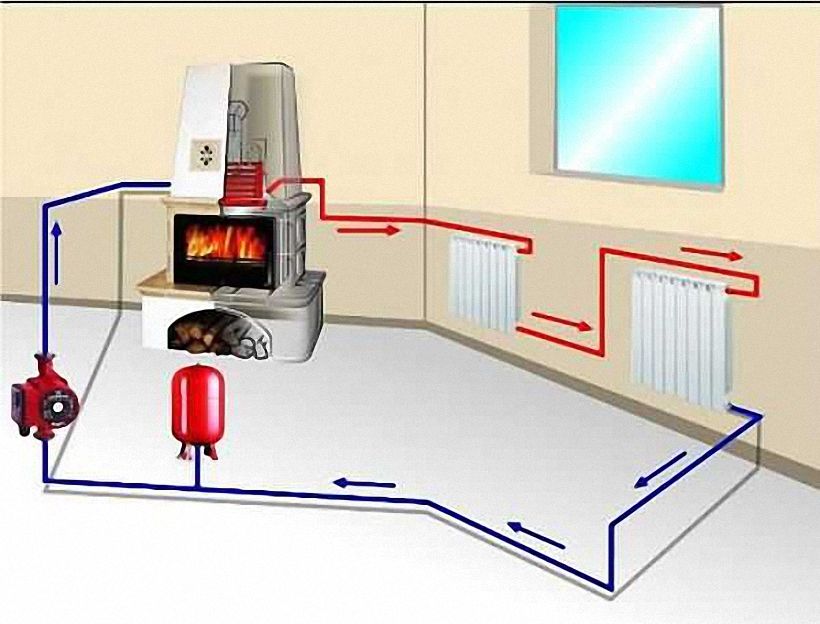

Option #2 - forced system

The movement of the coolant through the pipes occurs due to the operation of the circulation pump. The excess liquid formed during heating is discharged into a special expansion tank, most often closed, which prevents water from evaporating from the system. If a glycol solution is chosen as the coolant, the expansion tank must be closed without fail.In addition, the system has a pressure gauge that monitors pressure.

The forced system implies additional costs for the expansion tank, pressure gauge, pump, thermostats, etc.

The advantages of the design are undeniable: a small volume of coolant, which can be used not only water, less consumption of pipes, the diameter of which is smaller than in the previous case. The ability to control the temperature of heating radiators, batteries can be of any type with any pipe diameter. The main disadvantage is the dependence on the supply of electricity, with which the pump works.

For a more detailed comparison of the two options, check out this video:

Heating registers

Before carrying out furnace heating, it is worth deciding on the type of heating water circuit, also called a register, heat exchanger, coil or water jacket. Most often, it is a rectangular flat container or several tubes connected together.

But before connecting the heating to the stove, two pipes must be welded to the register. The first serves to take the hot coolant from the furnace, and the second feeds the cooled water back to the heat exchanger.

You can determine the size of the heat exchanger by the level of heat loss in a particular house. So, if you need 10 kW of thermal energy, the area of \u200b\u200bthe heat exchanger should be 1 m2. It should be borne in mind that the oven does not work all day, but about 1.5-3 hours, depending on the temperature outside. This time should be enough to warm up the water in the heat accumulator. Therefore, to calculate the area of the register, the daily consumption of thermal energy in the house is determined.

So, with a house heat loss of 12 kW / h, daily consumption will be 288 kW of energy. Let's say the oven is running 3 hours a day. It turns out that every hour 288÷3=96 kW of energy should be allocated. Then the area of the heating register will be 96÷10=9.6 m2. The shape of the heat exchanger in this case is not important, the main thing is that the surface area is not less than the data obtained.

When using antifreeze as a coolant, you can further increase the volume of the heat accumulator, since water and antifreeze have different heat capacities.

If the buffer tank is additionally insulated, then the heat in it will be stored further, and the efficiency of furnace heating will increase.

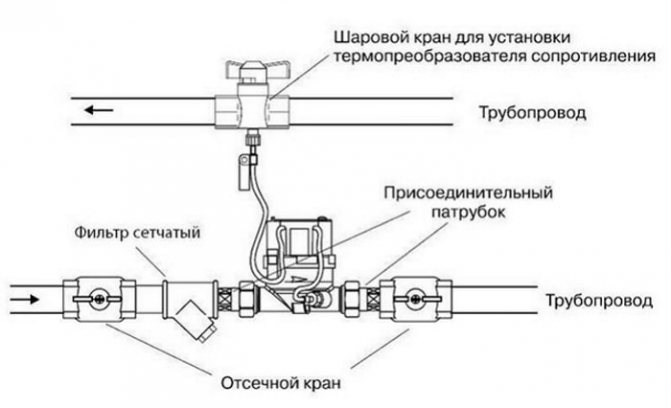

Collector scheme for heating a one-story house with forced circulation

Another type of wiring is collector. This is the most complex system, involving the use of a large number of different pipes and special distribution devices, which are called collectors. The principle of operation of a system with a collector circuit for heating a one-story house with forced circulation is that boiling water from the boiler goes to special collectors that serve as distributors between various radiators. Each battery is connected to it by two pipes. Such a system, while effective, cannot boast of being cheap. It can regulate the temperature not only on each circuit, but also on each battery, which allows you to create your own temperature regime in any room.

For the development and installation of a collector heating system, it is better to invite specialists

They make such a heating scheme for a one-story house with forced circulation, since naturally water cannot circulate efficiently through numerous pipes and collectors. The essence of this scheme is that directly near the boiler a centrifugal circulation pump crashes into the return pipe, which continuously pumps water using an impeller. Due to this, the system develops the pressure necessary to completely pump the entire line, heating all the batteries evenly. If you purchased an expensive wall-mounted automatic boiler, then it most likely already has a circulation pump installed, which is set to the optimum pressure for this boiler. If your boiler is simple, then when buying a centrifugal pump, you need to consult about its compatibility in terms of pressure generated with this boiler in order to avoid an emergency.

Collector heating system compiled by a specialist

The collector circuit is rarely used in two-story houses, since it, although effective, is very cumbersome. The wiring for two floors will be too complicated. That is why it is in demand only in the heating scheme of a one-story house with forced circulation.

Useful advice! To install a collector water heating system in your country private house, you need to take care of purchasing the required number of thermostats and shut-off valves. This will allow you to adjust the climate in the house in a semi-automatic mode.

Circulation pump for forced water recirculation in the heating system

Summarizing the above, it can be noted that the choice of the three existing types of water heating wiring should be carried out deliberately. In a small one-story house, only one pipe can be laid. This scheme is also called "Leningrad". If the area of \u200b\u200bthe house is significant or it is two-story, then it is better to make a two-pipe heating system with a return pipe. To create a modern and efficient heating system in the house, you can mount it according to the collector scheme. It will cost more, but it will also be much more effective. The main thing is that any created system always works well and reliably in any, even difficult, conditions. To do this, you need to build it according to all the rules and recommendations.

Stove heating device in a private house: the design of modern stoves

The main structural elements in the furnace heating devices of a private house are: foundation, trenches, ash chamber, firebox, smoke channels (smoke circulation), chimneys.

The foundation is the base of the furnace, which takes on the loads from the furnace and chimneys. This structural element must be reliable, since the safety of the operated structure depends on its strength. The correct placement of the furnace foundation implies its separate location from the foundation of the house. The minimum gap between them is 3 cm, which is filled with sand.

First of all, they dig a well, which is then filled with small fragments of stone or burnt brick, after which everything is carefully compacted. Thus, prepare a pillow for the foundation. Then a liquid cement mortar is poured into the pit. The laying of a brick or stone foundation is carried out with dressing of the seams.The last layer of cement mortar is carefully leveled.

After the foundation has been erected, they begin to carry out such a structural element of the furnace as slats. They are rows of brickwork that raises the stove on top of the foundation. Two or three rows of brickwork are made for the device of the slats. The bottom of the furnace is thus also involved in heat transfer.

Such an element of the design of heating furnaces as a blower, or an ash chamber, serves to supply air to the firebox and to accumulate the ash coming from it. A special grate in the form of iron or steel rods is installed between the firebox and the ash chamber. During the operation of the furnace, the chamber door must be open, and at the end of the furnace it is closed to prevent rapid cooling of the air inside the furnace.

The firebox in the device of heating furnaces is a furnace chamber in which fuel is burned - firewood and coal. A special hole is arranged in the upper part of the firebox for the removal of flue gas. The dimensions of the chamber are selected in such a way that it is possible to load into the furnace the amount of fuel necessary to heat the furnace.

In the lower part of the firebox, slopes are arranged to the grate, ensuring the free movement of ash into the blower. In order to prevent coal and ash from falling out of the furnace chamber, its door is installed above the grate by one row of brickwork. You can extend the life of the firebox by lining it with refractory bricks.

The principle of operation of the furnace heating system in a private house is based on the intake of heat by smoke channels, or smoke circulations. They can be placed both vertically and horizontally, as well as rise and fall.How efficiently a stove works depends on the size of the flues and their location.

Flue gas, passing through the channel, gives off energy in the form of heat to the walls, which heat the furnace. In order to increase heat transfer, the smoke channels are made in such a way that they are long and often change direction.

The smoke circulation of a modern furnace heating of a private house can be 13 x 13, 13 x 26, 26 x 26 cm, their walls are made smooth (they are not plastered, since if the plaster is destroyed, the channels may become clogged). Access to smoke circulations for their cleaning from soot is carried out through special doors.

To obtain traction, which contributes to the removal of gases from the burned fuel, a chimney is arranged, which is placed outside the house - on the roof. Most often, it is made of a circular cross section, since the movement of gas is somewhat difficult in pipes with corners. In addition, round pipes are more convenient to clean. As a material for their manufacture, ceramic or asbestos-cement pipes are used.