- Advantages and disadvantages

- Features of the distribution of pipes of the water circuit

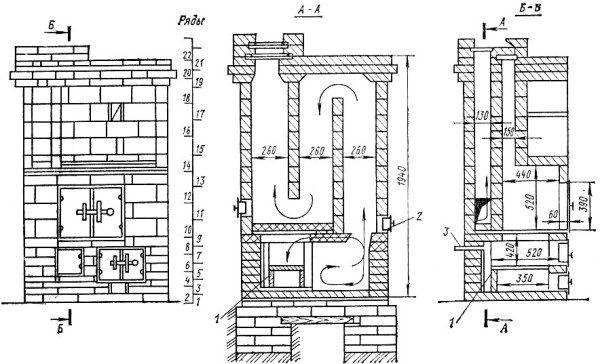

- brick oven

- Construction of a furnace building

- room heating process

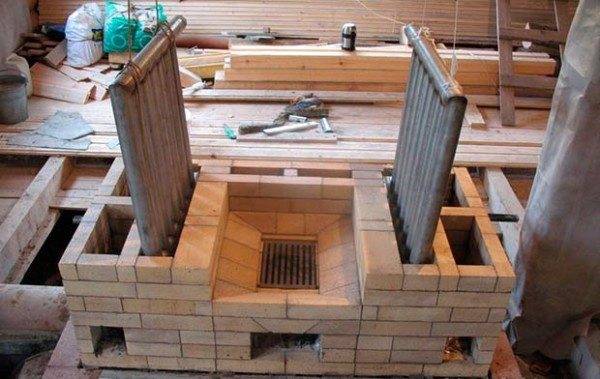

- Sheet steel coils

- Cast iron stoves with water circuit

- What should be considered when choosing and installing a furnace?

- Types of wood stoves according to the material of manufacture

- Brick wood stoves

- Cast iron wood stoves

- Metal wood stove

- Features of brick ovens

- How good is this option?

- System flaws

- Brick PVC - features of operation

- PVC installation

- Recommendations for the placement of elements of the heating system

- Conclusion

- Installation Requirements

- System Design Tips

- A few words about the register

- membrane tank

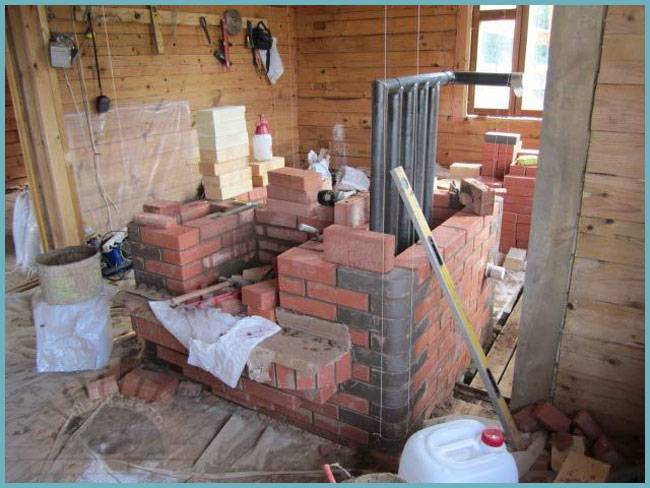

- Some moments of laying the furnace

- Conventional stove heating: advantages and disadvantages

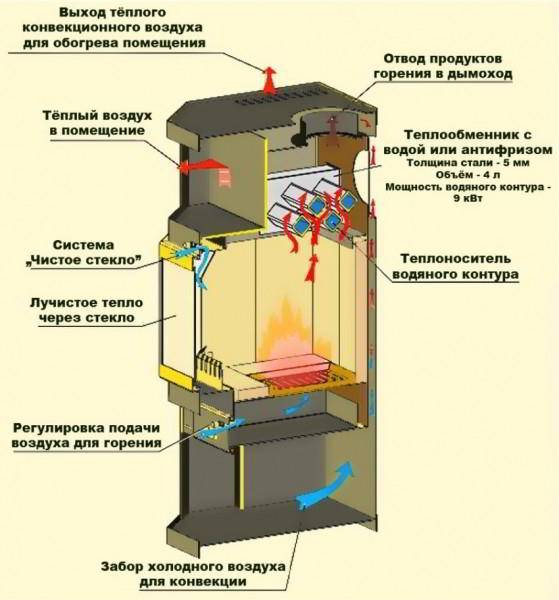

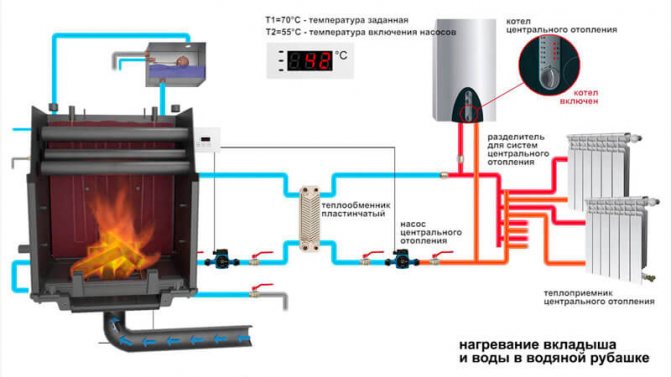

- 2 Types of heat exchangers

Advantages and disadvantages

Speaking about the advantages of this type of heating devices, I would like to note several factors.

- Sufficiently high capacity of the unit. Such stoves can heat houses with a large area.

- Reasonable prices, at least when compared with heating solid fuel boilers.

- Cheapness and availability of fuel.

- These are non-volatile installations.

There are, however, disadvantages.

- Low efficiency, again, when compared with boilers.

- It is simply impossible to automate stoves or fireplace inserts with a water circuit. Therefore, only manual control.

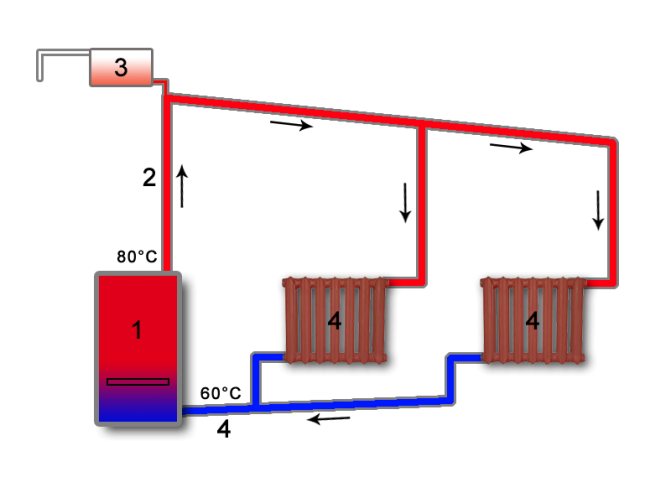

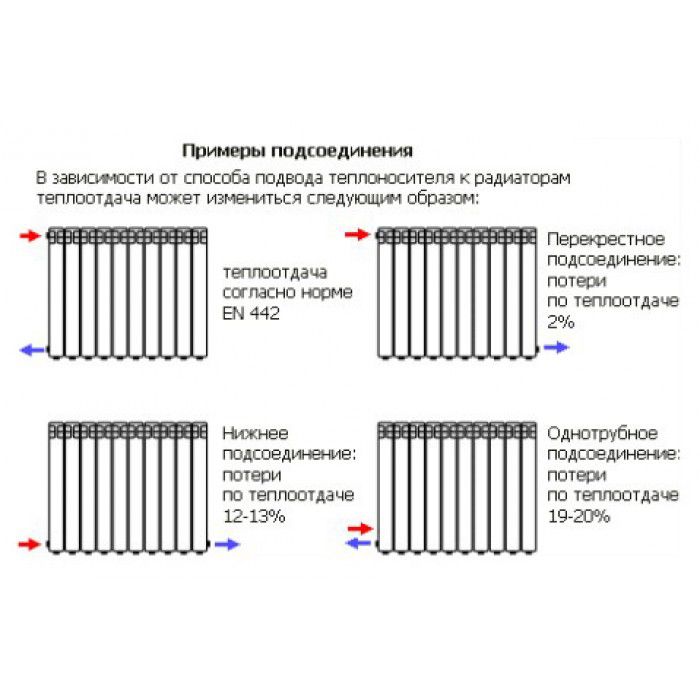

There is one more point that I would like to discuss separately. For those who do not know, there are two types of radiator heating in which the coolant circulates in different ways.

- With natural circulation.

- With forced.

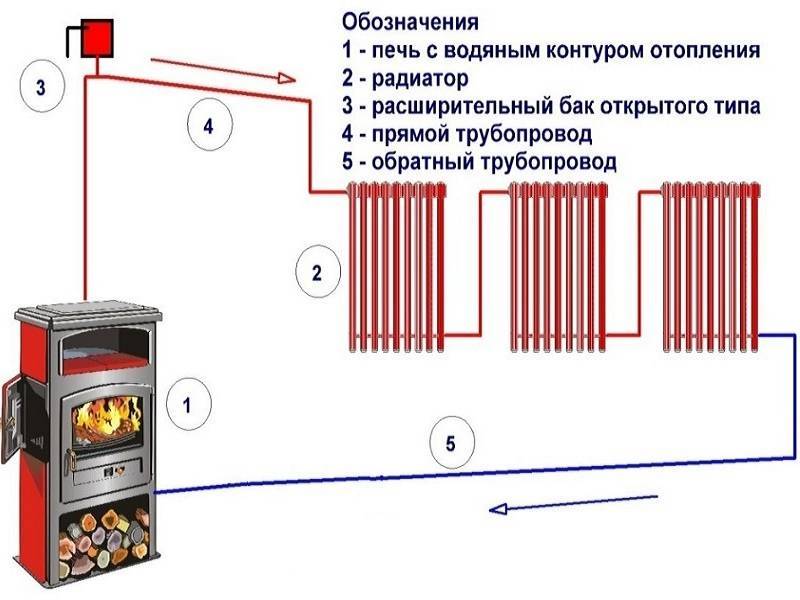

In small buildings, the first option is most often used. That is, in the system, the coolant moves through the pipes under the influence of the laws of physics - hot water rises, cold water goes down. But in order for such a movement to occur, it is necessary to lower the heating device below the installation level of the radiators. Only in this case the heating system will work correctly.

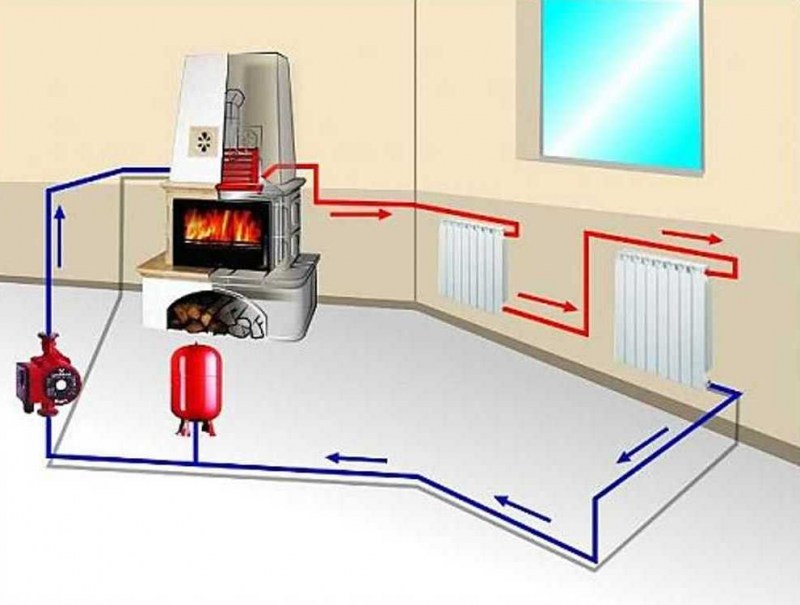

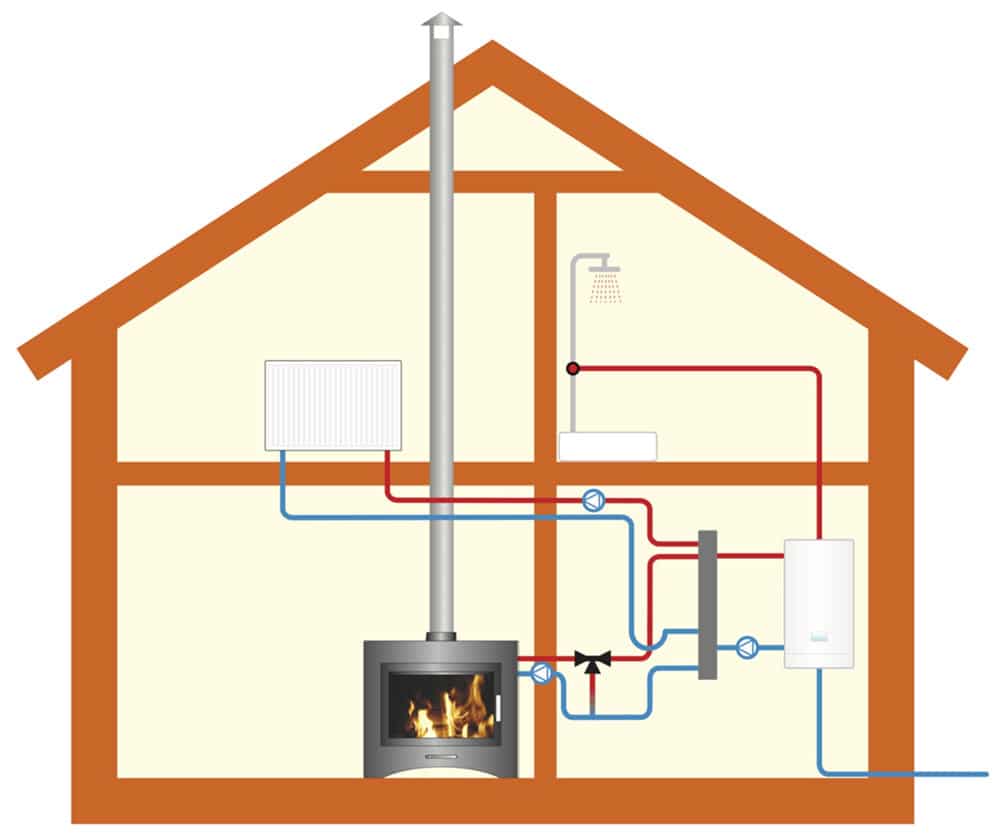

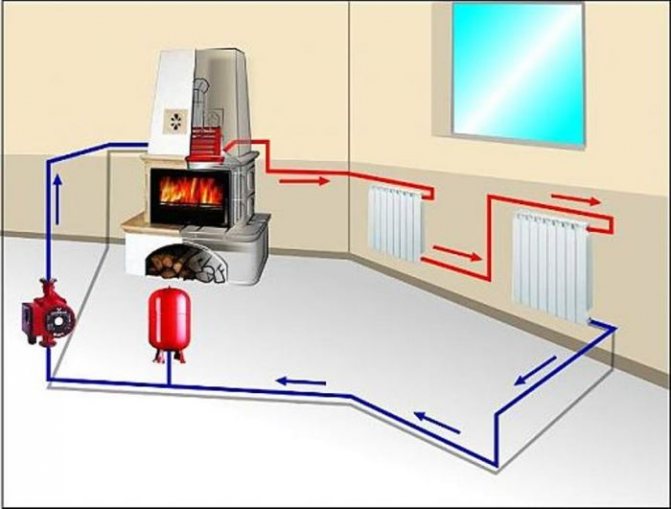

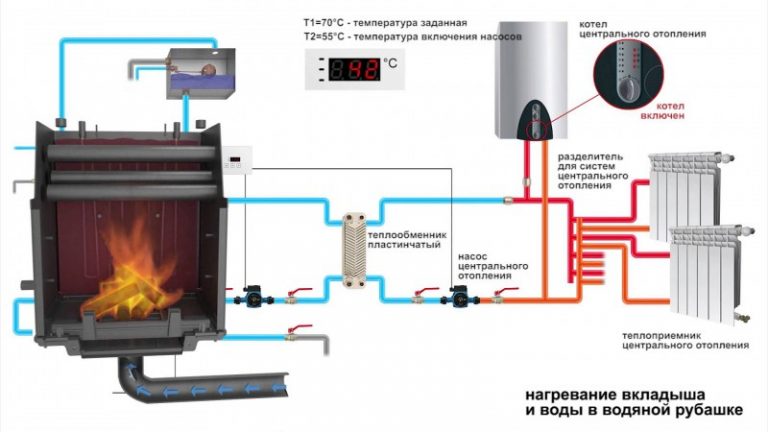

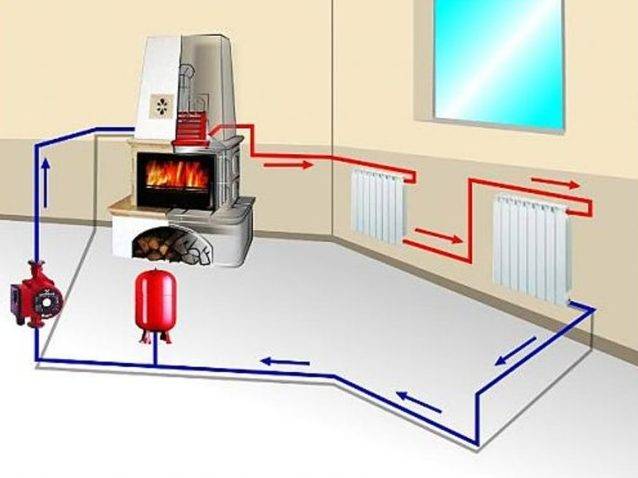

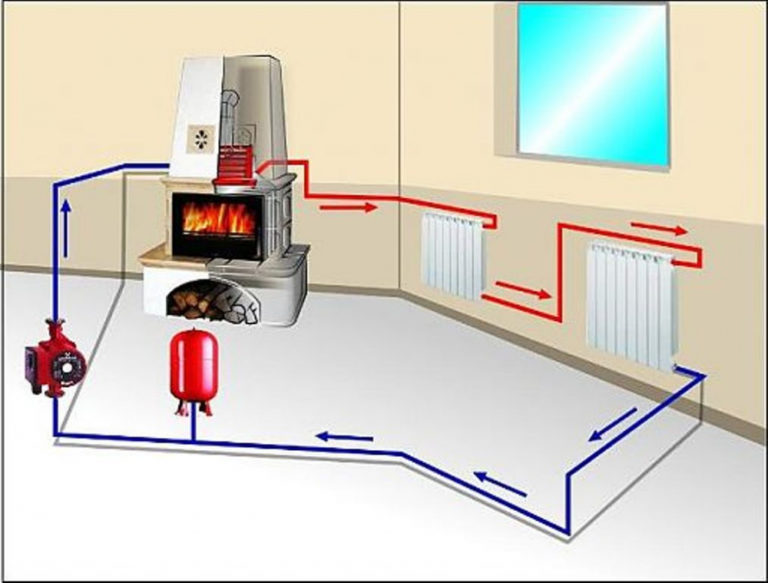

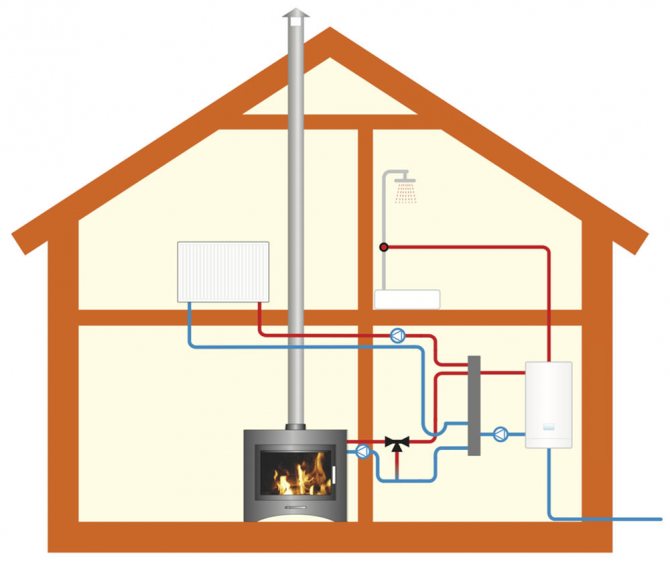

Furnace in radiator heating system

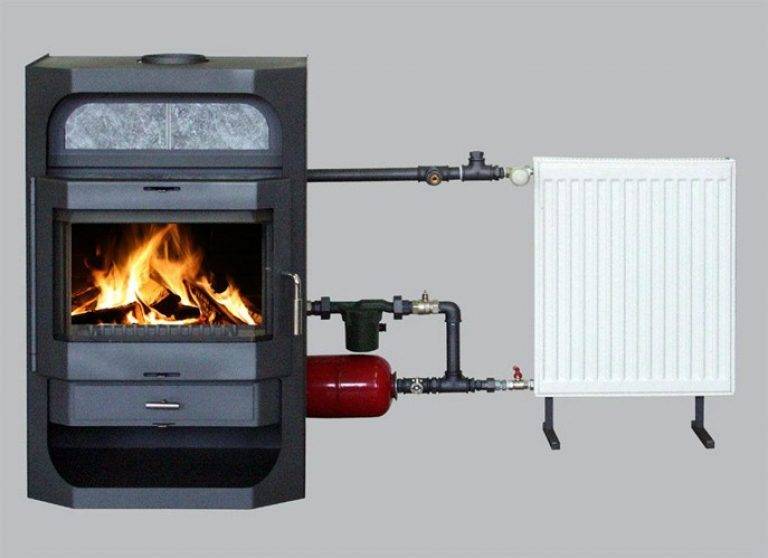

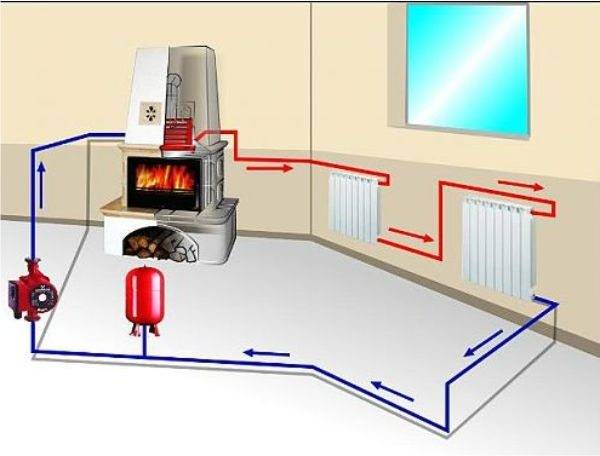

Unfortunately, in this case, it is impossible to compare the stove with a water heating boiler. As a boiler, it cannot be lowered, for example, below the floor. After all, this heater is part of the interior, and besides, laying firewood very low will be inconvenient and unsafe. It turns out that the installed stoves with a water circuit are a heating element for a system with forced circulation of the coolant.

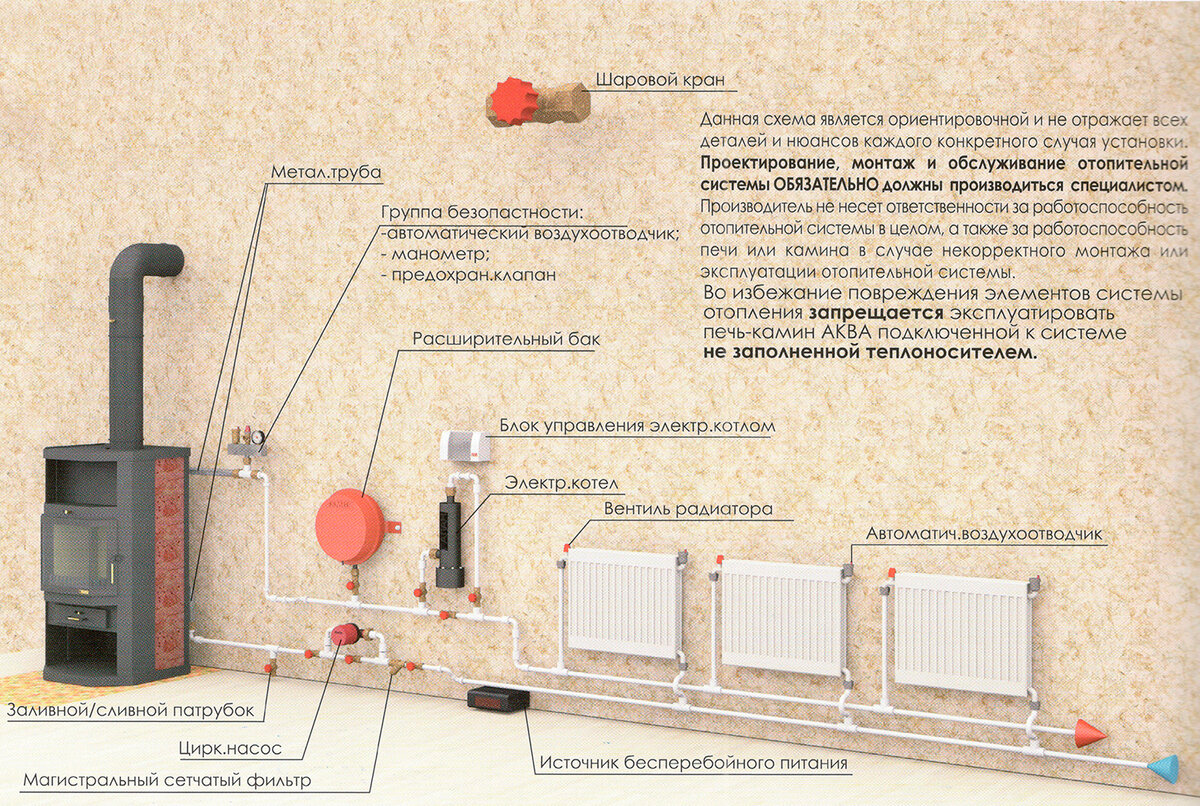

Therefore, when connecting this type of heater to a radiator heating system, it must be borne in mind that several more devices will definitely be included in this system. And this is a circulation pump and an expansion tank. In fact, we end up with a volatile heating system.

And one important piece of advice, which concerns the quality of operation of the entire heating system. The circulation pump must be installed in the return pipework near the stove.It is in this place that the coolant is the carrier of the lowest temperature. The thing is that the composition of the circulation pump includes rubber gaskets, cuffs and seals, which quickly become unusable under the influence of high temperature. We add that the expansion tank is installed right there near the pump.

Features of the distribution of pipes of the water circuit

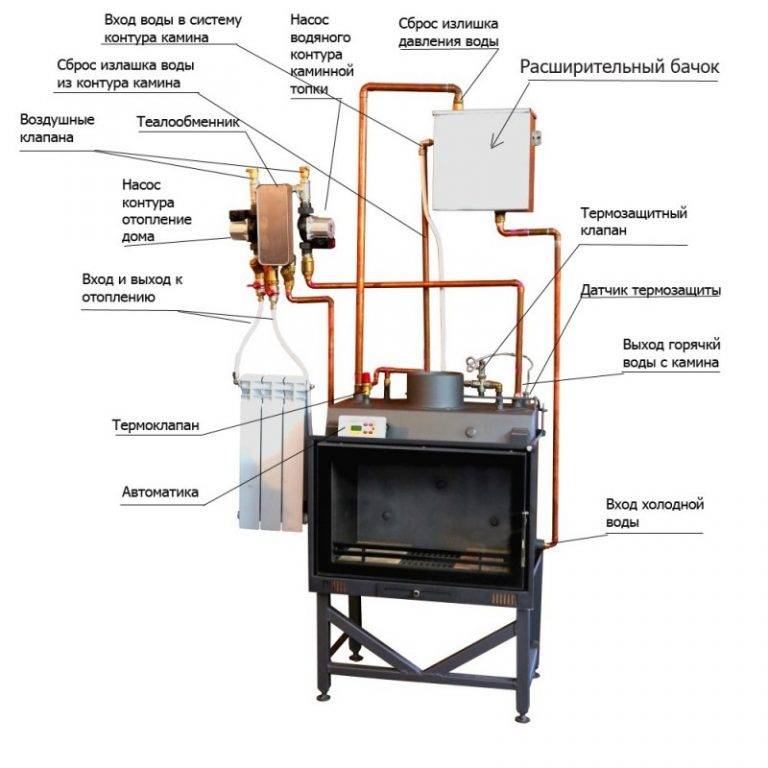

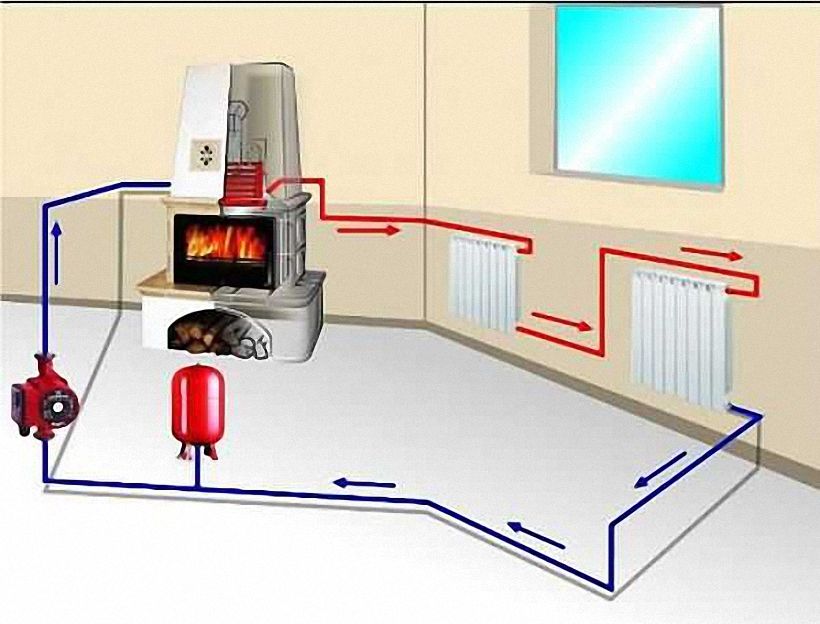

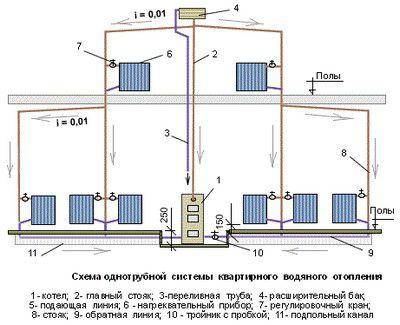

The piping system is connected to the heat exchanger installed in the furnace through sockets that are inserted through one of the walls. The water circuit in such a system is often arranged in the form of a two-pipe system. The wiring can be both lower and upper.

Register for the furnace from the old battery

Register for the furnace from the old battery

Naturally, the heating circuit must be fully equipped. The expansion tank is installed at the highest point of the line, safety and air valves are installed, and a safety unit with a pressure gauge is also included in the system, valves are connected at the inlet and outlet of the radiators.

The water circuit can be connected to a circulation pump, it significantly increases efficiency and allows for a more flexible approach to solving the issue of piping. But there is a problem with this approach. If the pump stops working due to a power outage, the water will not circulate and will begin to boil in the coil.

In the cold winter season, when the boiler is working at full capacity, one minute may be enough for the consequences to be disastrous. The stove, unlike a gas boiler, cannot be quickly turned off. For these reasons, it is recommended to arrange a combined wiring method.

Conclusion of pipes for heating

Conclusion of pipes for heating

In the supply pipe, after it leaves the furnace, an acceleration collector is arranged, raising the pipe vertically by 1-1.5 m, and then lowering it to the level of the radiators.Sections of the highway have a slope of 3-5 °. In case of emergency mode, the coolant circulation will be natural.

It is better to mount the circulation pump in the return circuit as close as possible to the expansion tank using a bypass, while the pump axis must be strictly horizontal.

brick oven

The stove is not only a device for heating the house, but also an element of decor.

In a small house, you can install one stove, for which firewood or coal is required. Modern stove heating of a private house provides for many types of designs of heating structures. It should be chosen so that it is intended not only for space heatingbut also for cooking. Before installing the stove, you need to choose a suitable place so that its use is as efficient as possible:

- The firebox should be directed towards the corridor or kitchen, and the heated surfaces - into the rooms. When designing a stove, you should know that 1 m² of its area heats up to 30 m² of the room.

- You can not put furniture near the stove or install partitions, do not build a stove in the corner of the room. Its large wall should go into the living quarters, then it will always be warm in them.

- The design of the stove should be chosen according to its purpose. They are only for heating the room or also for cooking. In this case, the hob and oven should be taken into account.

Heating furnace:

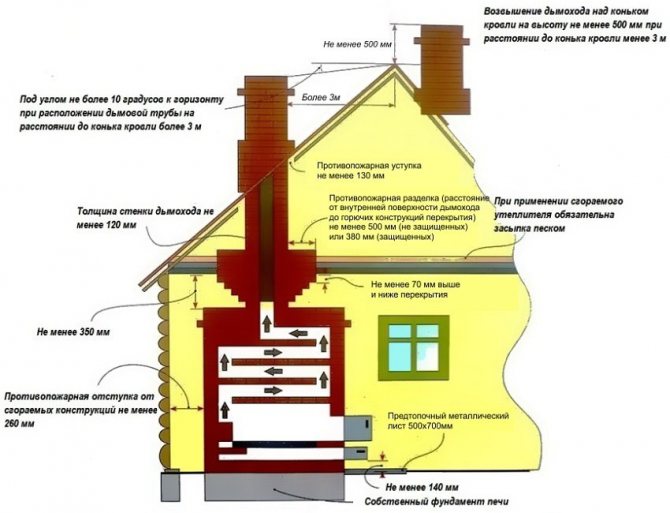

Construction of a furnace building

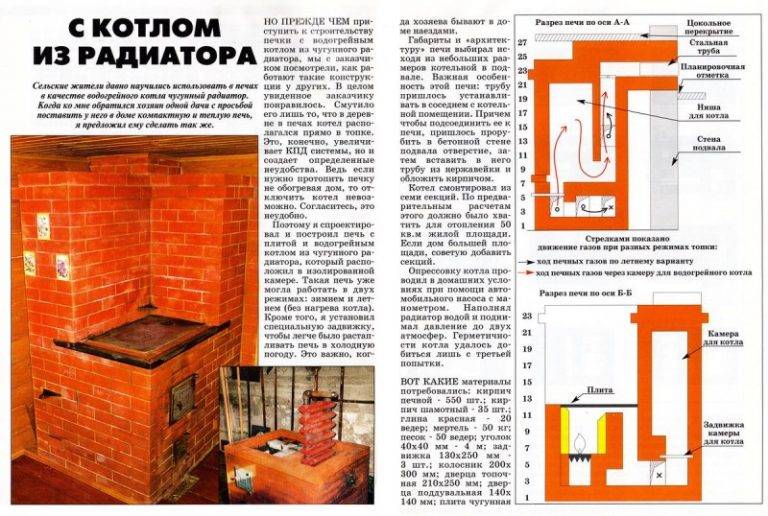

The furnace structure is erected during the construction of the house, but the foundation is built separately from the general laying.It is possible to install a stove in an already built house, but then you will need to raise part of the floor and make holes in the ceiling and roof for installing a chimney.

Detailed laying of the furnace:

The size and depth of the foundation depends on the type of furnace structure. It is erected immediately after the manufacture of the common foundation of the house. Under a brick oven, it should be monolithic reinforced concrete, 10-15 cm more than its parameters on each side. It is required to observe the depth size - from 0.5 m to 1 m. If the soil is loose, or groundwater is close, the foundation should not be deepened, but its area should be increased.

For the construction of the furnace, well-burnt red brick should be used. When tapped, it gives off a metallic sound. When falling, if it breaks, then into large pieces. It is easy to work with it, as it lends itself to the correct fracture. The sections of the furnace in contact with the fire are laid out with refractory bricks (firebox and part of the chimney).

Detailed laying of the furnace:

room heating process

The well-thought-out device of the stove in a private house predetermines the effective heating of the room. An air-fed furnace burns solid fuel (usually wood or coal). Natural draft contributes to the movement of flue gases through the channels to the outlet vertical passages, from where they go outside. During this time, the brick walls of the furnace warm up, and the heat from the hot stone spreads to all rooms.

A well-thought-out stove device in a private house determines the quality of space heating

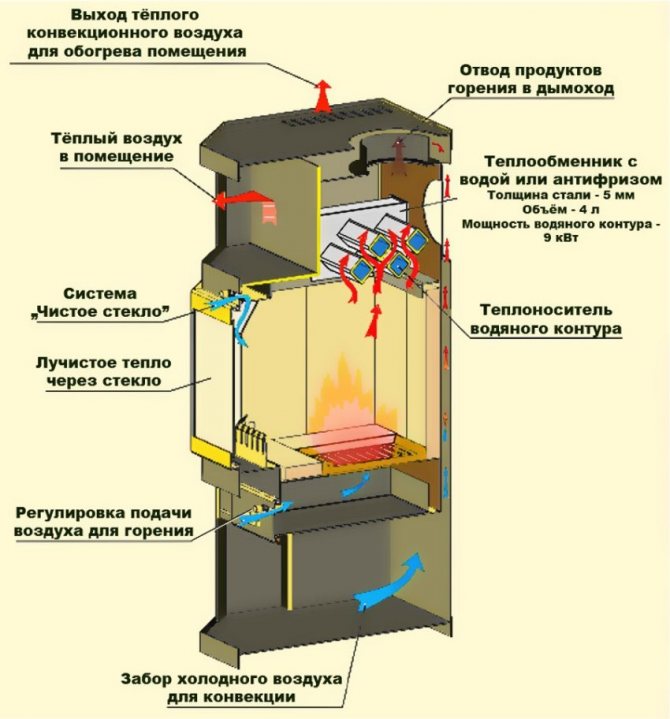

Sheet steel coils

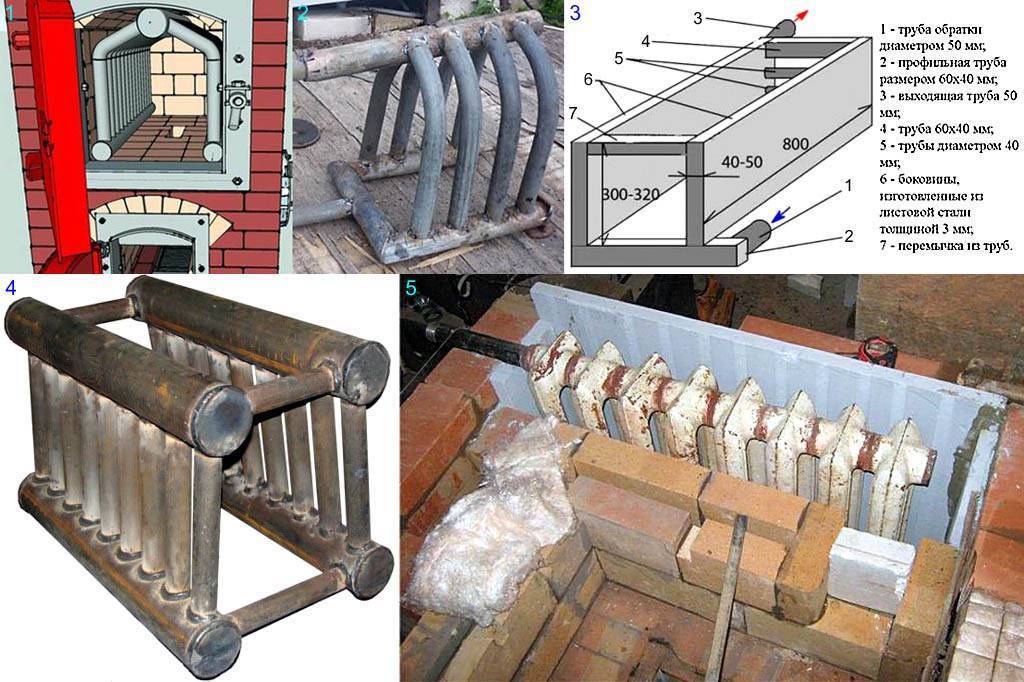

In the photo - an example of a heat exchanger made of sheet steel

Please note that its thickness should be from 5 mm.Also, to create a structure, you will need 50 mm pipes and a profile of 0.6 X 0.4 centimeters

The dimensions of the coil can be changed based on the dimensions of the furnace.

Sheet steel coils

If your stove is with a hob, you need to arrange the system so that the hot gas is directed to the flue located in front of it

It is important that it flows around the top shelf. This will allow you to cook food over the firebox.

If you choose a heat exchanger, in which the walls in the form of a book are connected by a profile, pipes, the upper shelf will be absent. You can improve circulation by welding additional pipes on top. In this case, the side walls and the back of the exchanger are suitable for organizing the input and output.

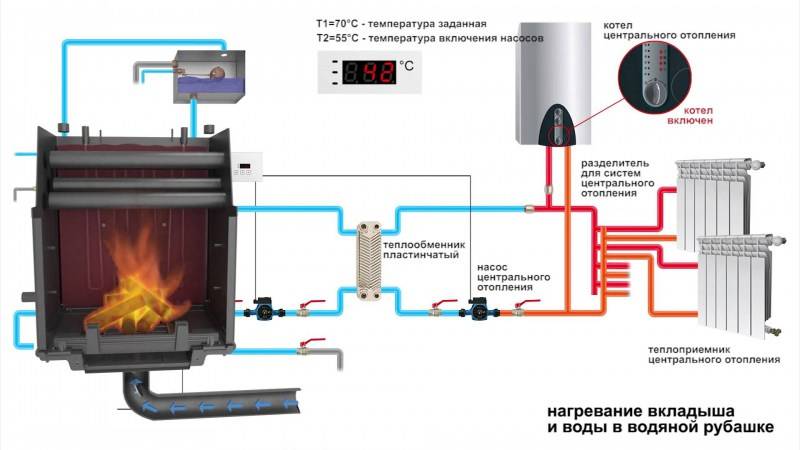

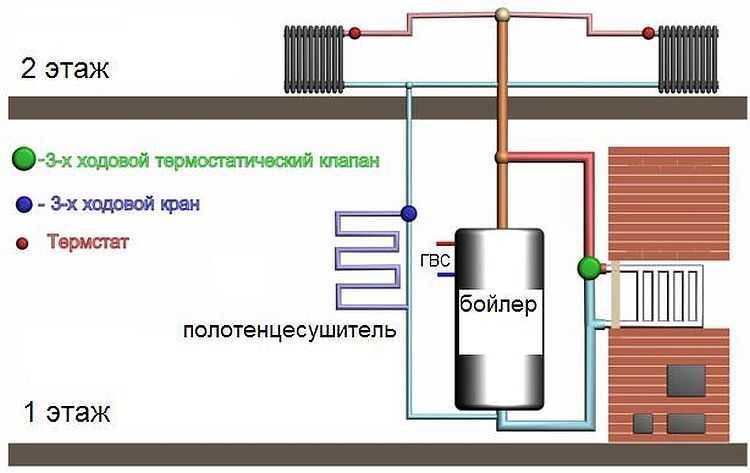

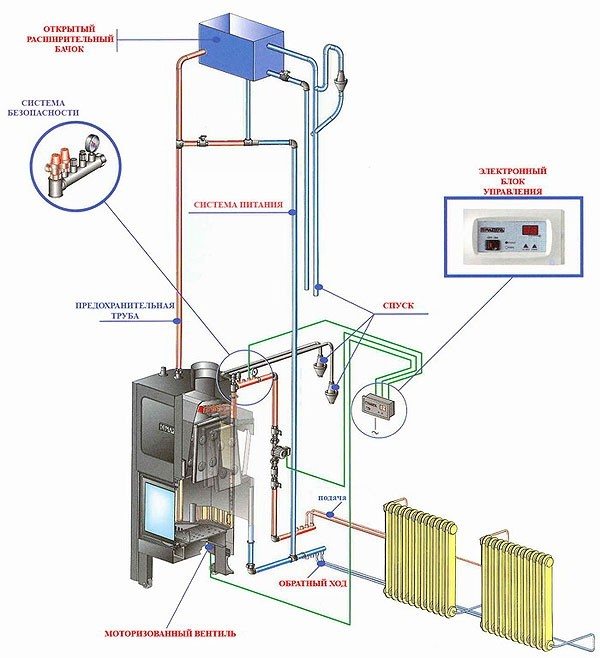

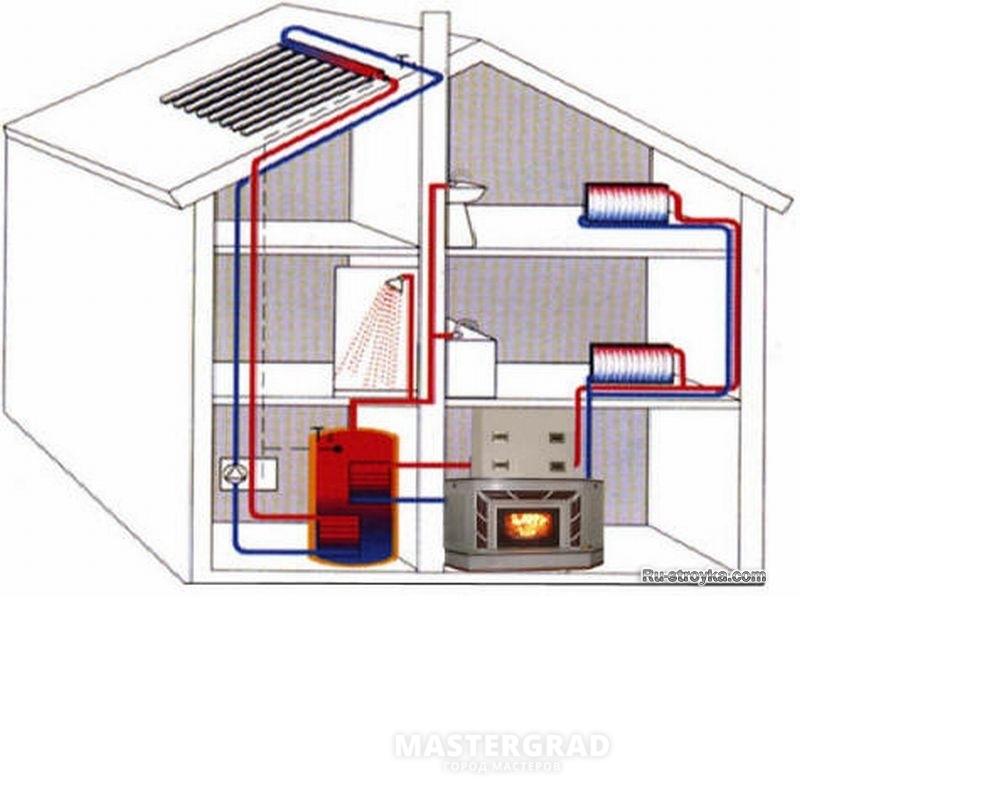

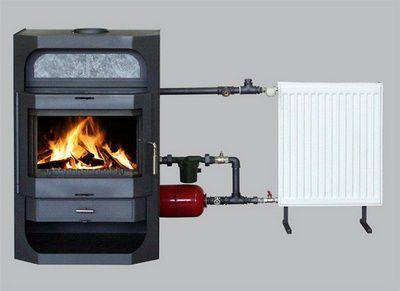

Cast iron stoves with water circuit

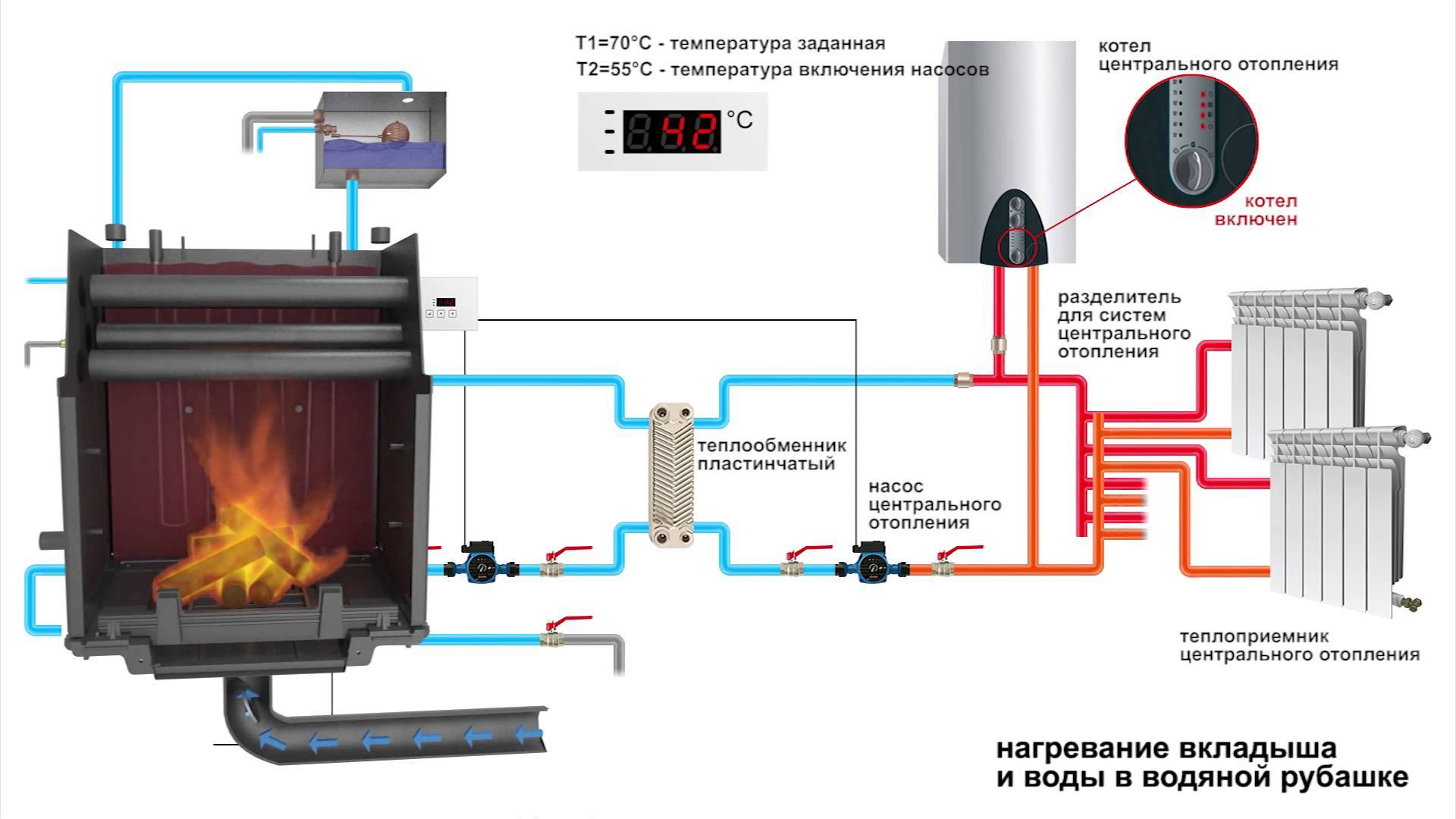

Cast iron stoves with a water circuit are produced in different capacities and are designed for heating of various areas. Some of them are able to heat a two- and three-story house. The device of the heating circuit is made according to the same system as for brick ovens.

Cast iron long burning stove with heating circuit

Furnaces are made of cast iron and combined type, i.e. having electric heating, which turns on automatically when the temperature of smoldering firewood decreases. This combination of oven functions will always help maintain the heating system at the desired temperature.

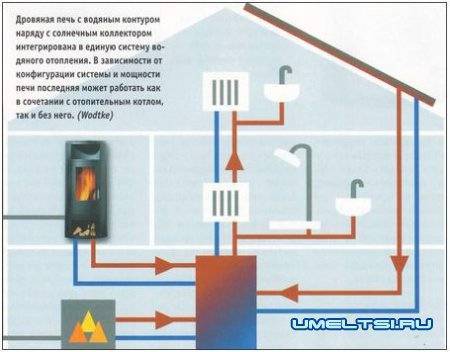

One of the possible heating schemes for a two-story private house

Cast iron boilers-furnaces can also be provided for a double-circuit heating system, i.e. In addition to the warmth in the house, the owners will also have heated water.

What should be considered when choosing and installing a furnace?

When choosing which heating stove will be installed in the house, you need to correctly formulate the requirements for it, and, based on them, purchase or build a heating device.

- The warming of the entire structure of a brick oven is very important. Therefore, if it is decided to install such a furnace, you need to choose the right project and ensure the perfect construction of the building.

- The efficiency of the heating system will also depend on the design and layout of the water circuit, as well as the choice of radiators for the heating system. There are furnace schemes that can operate in summer and winter mode - this factor also contributes to the economical operation of the device.

- Part of the savings can be attributed to the long cooling of the furnace, which will use less fuel.

- Ease of operation and maintenance is important.

- The design must comply with all fire safety regulations for its location and installation.

- A properly executed design will have the required traction, which will protect the house from carbon monoxide entering the premises.

- The furnace must be designed for a long period of operation.

- Of course, it would be nice if the oven became a real decoration of the house, and not only functional from a practical point of view.

Types of wood stoves according to the material of manufacture

Wood-burning stoves, while still being an excellent source of heat, fit well into modern heating systems for private households. Wood stoves can be divided by material of manufacture into the following main groups:

- brick (stone);

- cast iron;

- steel.

Brick wood stoves

Brick ovens are the most durable and expensive to build.A good stove is not cheap, and it is not easy to find an experienced master for its installation. For the construction of such a stove are used fireclay and refractory red bricks, as well as when laying a wood-burning fireplace, special mastics for masonry, cast-iron doors, grates, and chimney valves. The brick oven heats up for a long time, but also retains heat in the room for a long time.

Cast iron wood stoves

Cast iron stoves are usually used as an additional source of heat. Manufacturers create from cast iron not only heat sources, but also beautiful products that fit perfectly into the interior of any home. Heated cast iron retains heat perfectly, and the presence of a hob allows you to cook food or warm water for domestic needs.

Metal wood stove

A metal wood-burning stove can quickly raise the temperature in a room using a minimum of fuel, but the thin steel they are made of makes it difficult to keep the heat out for long. The simplest type of metal stove is the well-known "potbelly stove", which is often used to heat small country houses or garages.

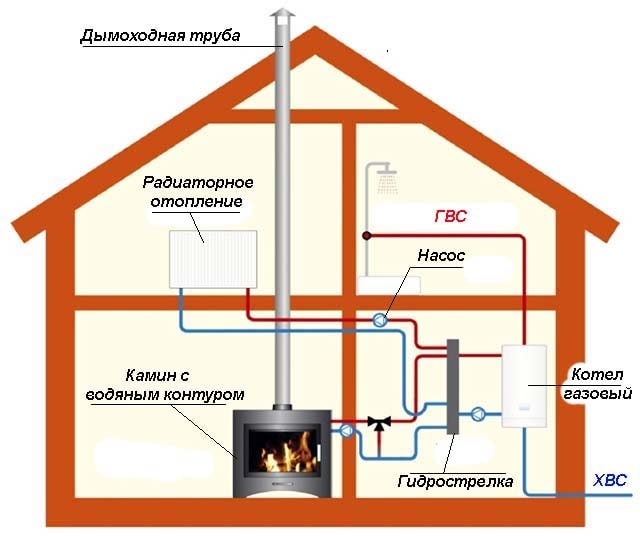

As mentioned above, the stove itself heats only the room in which it is located. In order to carry out the transfer of heat to other rooms, there are two ways - the organization of air heating with an air duct system, or water heating from a stove with a heat exchanger, piping and heating radiators. Air heating is easier to arrange, but has a number of disadvantages, which together outweigh the use of a traditional water heating circuit.

The disadvantages of air heating include:

- installation of air ducts through which warm air is distributed must be carried out at the stage of building a house, since they are quite bulky;

- the need to install fans with a flow rate controller that improve air circulation, but make noise. Installing a stove with fans in the basement of the house can destroy this problem.

- The need to install additional air filters to eliminate the transfer of dust.

The advantage of air heating, which at the same time is also a disadvantage, is low inertia. That is, the premises begin to warm up immediately after the stove is kindled, but they also cool quickly.

Another advantage of air heating is the absence of heating radiators. Air ducts, as a rule, are hidden under the ceiling of the building, and the space under the windows remains free.

In most cases, the owners of houses with stove heating make a choice in favor of the water heating circuit of a private house, so we will analyze this option in detail.

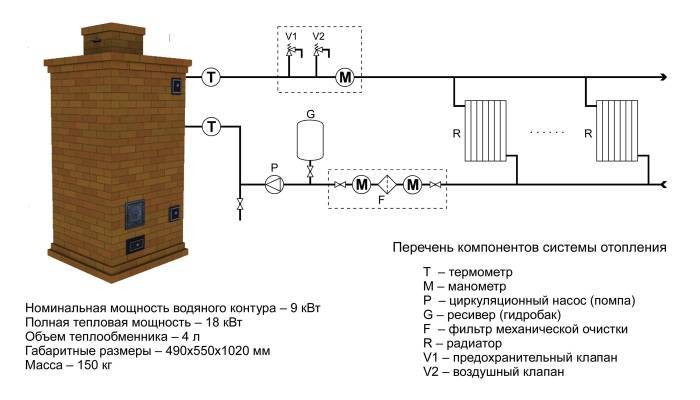

Features of brick ovens

All types of structures of this kind have been known for several hundred years and have long proven their reliability. But giving preference to such heating, you need to weigh the pros and cons.

How good is this option?

- If you try to heat a house with a conventional solid fuel stove, then on average 1m² of construction can heat 30m² of a standard house with ceilings up to 3m. Accordingly, it turns out that the larger the house, the more you need to build a furnace. A system with built-in water registers generates 2.5 times more heat and at the same time can be quite modest in size.

- If the instructions for laying structures were completed in accordance with all requirements, then the stove will serve faithfully for more than a dozen years. Preventive inspection and cosmetic repairs are within the power of any owner, in contrast to the option with a solid fuel boiler.

The principle of register heating.

- At the moment, there are several common projects, if the Russian stove is not suitable for every room, plus its installation requires high qualifications, then you can fold Swedish or Dutch brick stoves with water heating with your own hands, if you wish.

- Another positive aspect of such heating is that in this case it is not at all necessary to build complex multi-channel structures, if there is no question of the presence of a frying surface, then such a system can be mounted on the basis of a conventional fireplace.

Important: if the maximum efficiency of a traditional brick structure does not exceed 50%, then when using good registers, competent piping and embedded in circulation pump system for heating. Efficiency can reach up to 85%, which is quite comparable with modern solid fuel boilers

Scheme of a furnace with a heating boiler.

- Not the last role is played by the price of building materials and fuel. The structure itself can be folded from the material remaining after the construction of the house. As for fuel, firewood, coal or briquettes are not exorbitantly expensive types and are quite affordable for almost everyone.

- Most designs are equipped with a frying surface and an oven, which allows you to cook food in parallel.

System flaws

It will take time to start the system at design capacity, unlike electrical units, it will take at least half an hour to warm up the brick walls of the structure and the coolant in the piping.

Scheme of heating from a fireplace.

- When compared with solid fuel boilers of comparable power, the dimensions of such structures will be much larger. Plus, they need to be installed, as a rule, in the center of the dwelling, which takes up a lot of usable space.

- Any solid fuel heating system provokes the formation of a sufficiently large amount of dust. No matter how hard you try, you will need to clean the room where the brick oven is installed much more often.

- All structures of such a plan are objects of increased fire danger. They cannot work offline. In addition to the likelihood of a fire, there is also the risk of carbon monoxide spreading due to improper operation or boiling of the coolant in the system, which is also fraught with unpleasant consequences.

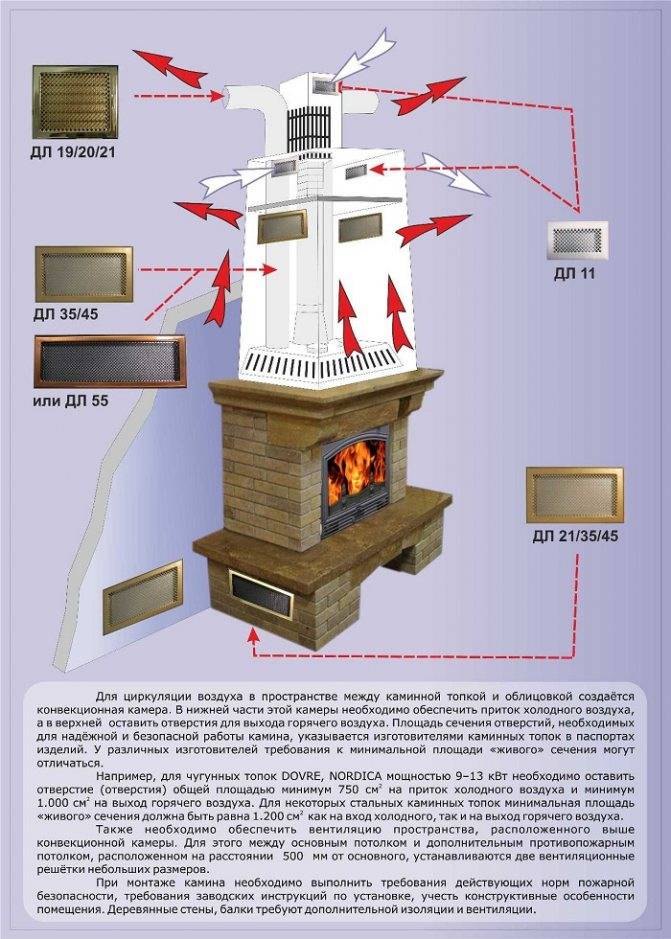

Brick PVC - features of operation

Often, water heating is combined not only with a fireplace or a modern wood-burning stove. For many, the best option would be to install a classic brick oven as a source of thermal energy. Properly expanding the capabilities of a brick oven with the help of a water circuit, it is possible to warm up not only the nearest living rooms, but the entire building. To increase the efficiency of a brick kiln, various designs of heat exchangers have been developed (coils and registers act as them). The operation of such a system in suburban housing has features, which include:

- Arrangement.To fold a high-quality stove, and then carry out the installation of water heating, highly qualified craftsmen will be required.

- The size. The overall traditional Russian stove takes up a lot of usable space and does not fit in every kitchen. An alternative for modest-sized rooms would be a Dutch or Swedish brick oven. Such designs are characterized by smaller dimensions, but full functionality.

Heat exchanger installation diagram

- Efficiency improvement. The maximum efficiency of the furnace does not reach 50%; half of the heat (and money) irretrievably disappears in the pipe. The device of a full-fledged water heating system allows increasing this parameter to 80-85%, which is comparable to the characteristics of industrial boilers operating on solid fuels.

- Inertia. Unlike electric boilers, it will take a certain amount of time to warm up a system tied to a brick oven.

- Care. Burning wood leaves behind ash and dust. The room in which the brick oven is located will have to be cleaned often and thoroughly.

- security requirements. Improper operation of a brick oven for a house with water heating is a threat not only to fire, but also to carbon monoxide poisoning.

About laying a brick oven with a water circuit in the following video:

PVC installation

If in a country cottage it is planned to install water heating from a brick stove (on wood), the heat exchanger is designed individually, for a specific stove. Such a device is practically beyond repair, therefore, a stove-maker is involved in the installation, who will be able to professionally perform all the work:

- Fabricate a heat exchanger and double check its quality before and after installation.

- Mount the heat exchanger at the desired stage (after the foundation is completed), then continue laying, observing certain rules. When installing the heat exchanger, compensation gaps are left, leaving 1-1.5 cm to the walls of the combustion chamber. Gaps that take into account thermal expansion are also needed when installing pipes.

- When installing a heat exchanger with pipes and for insulation, use only heat-resistant seals.

Steel pipes for the manufacture of heat exchangers

Recommendations for the placement of elements of the heating system

Elements of the heating system can hardly be called a decoration of a modern interior. Under this definition, only pipes that organically look in some industrial interiors can fit. In general, building codes and architectural guidelines recommend that parts be placed in areas that are hidden but accessible for repair and maintenance. Placement is subject to the following rules:

- The heat generator is placed in an isolated room with heating and good ventilation. The circulation pump must operate under the same conditions. Small boilers (up to 30 kW) can be installed in the kitchen, in the hallway, in the basement or in a warm heated outbuilding. Furnaces intended for residential premises are installed taking into account fire safety rules.

- The place for an open-type expansion tank is in the attic; they tend to place supply and collection pipelines along the main wall structures.

Compliance with the rules of operation helps the smooth operation of the system

- The main riser passes openly in the corners of the living quarters, in the attic it is covered with thermal insulation.

- Radiators are installed openly under window openings.They participate in room circulation by heating the cold air coming from the windows. Attempts to decorate radiators with decorative screens are undesirable, since they reduce the thermal efficiency of the system.

Conclusion

The device of water heating from a wood-burning stove is becoming an increasingly frequent choice in private housing construction. A brick oven, built by a professional stove-maker and competently integrated into the system, will be an effective design that performs all the tasks assigned to it, from utilitarian to aesthetic.

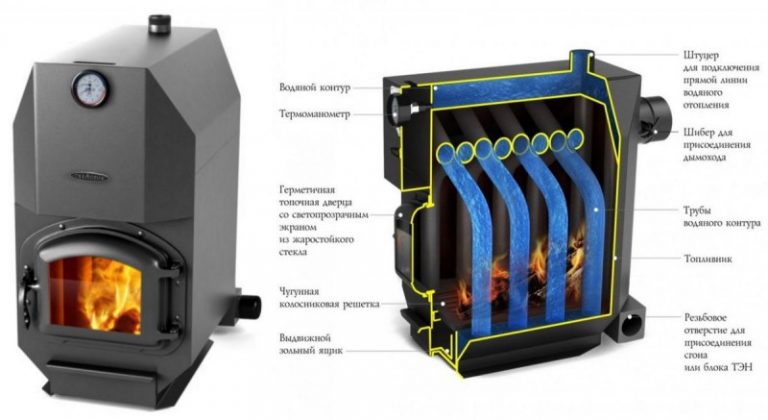

Installation Requirements

The thickness of the water layer in the heat exchanger must exceed 4 cm, since the water will boil with a smaller thickness.

The walls of the coil must be at least 5 mm, and in the case of coal, even thicker. Failure to comply with the thickness can lead to burning of the walls.

Furnace building process

Under no circumstances should the heat exchanger be mounted close to the furnace wall. Leave at least 2 cm. This space is necessary for thermal expansion of the coil.

Particular attention must be paid to the fire safety of the system. Between the stove and wooden partitions, there must certainly be air gaps, since it is overheating of wooden structures that is the first cause of fires. It is best to clad with brick or other refractory materials.

It is best to clad with brick or other refractory materials.

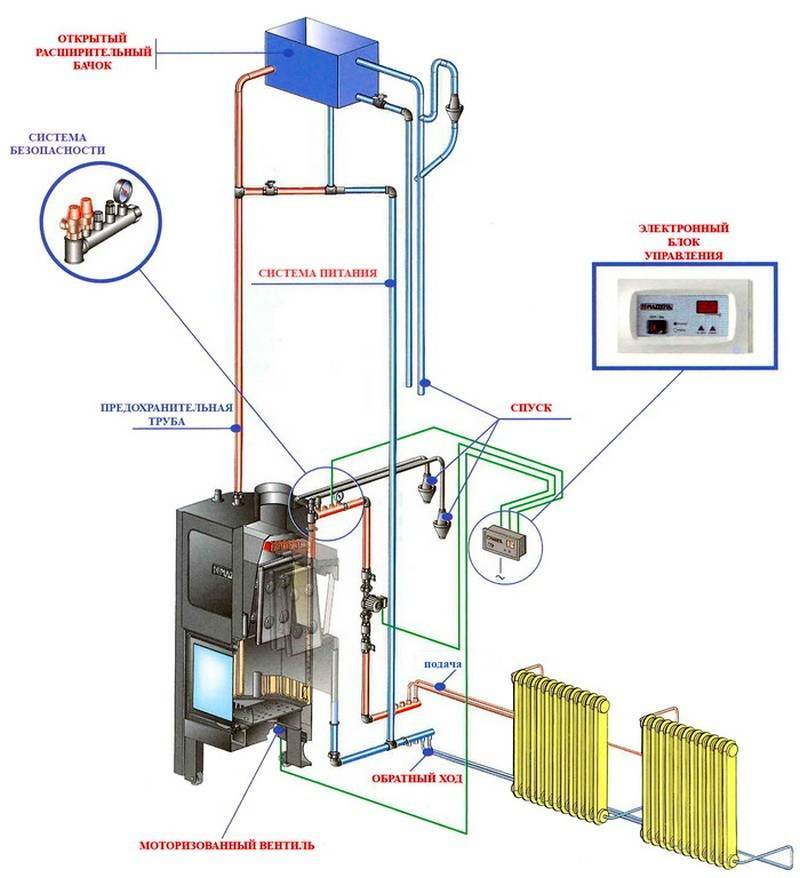

System Design Tips

At their core, such designs are the progenitors of modern solid fuel boilers. But unlike them, heat transfer is carried out not only through piping and a system of radiators, but also from the furnace itself.

Plus, do-it-yourself brick ovens with water heating are much easier and cheaper to mount than installing a solid fuel boiler.

A few words about the register

The metal register can, without exaggeration, be considered the heart of the entire heating system. This design is installed directly in the furnace itself and is responsible for the level of heating of the coolant.

Lateral arrangement of registers.

The simplest and most affordable option is to install a rectangular metal tank directly into the furnace. Such a tank is made of heat-resistant steel, with a thickness of 3 mm or more, most often from stainless steel.

To heat a house of 200 m², a tank 750 mm long, 500 mm wide and 300 mm high is enough. The conclusion is made on top of the structure, the return line cuts into the lower part of the tank.

Registers welded from a stainless steel pipe with a wall thickness of at least 3 mm are considered more functional. The heating area in this case increases many times, hence the efficiency of the system is disproportionately higher.

Tip: it is not difficult to find cast-iron registers on the market now, according to most experts, they are the best option. Firstly, cast iron is not very susceptible to corrosion, practically does not burn through, and most importantly, this material is considered the best heat accumulator.

Stainless steel registers.

During installation, pay attention to the location of the register. The more contact with fire, the higher the performance

But at the same time, regardless of the configuration of the tank, there must be a compensation gap of at least 5 mm between it and the furnace walls.Otherwise, during heating, the metal will begin to expand and the walls of the furnace will crack.

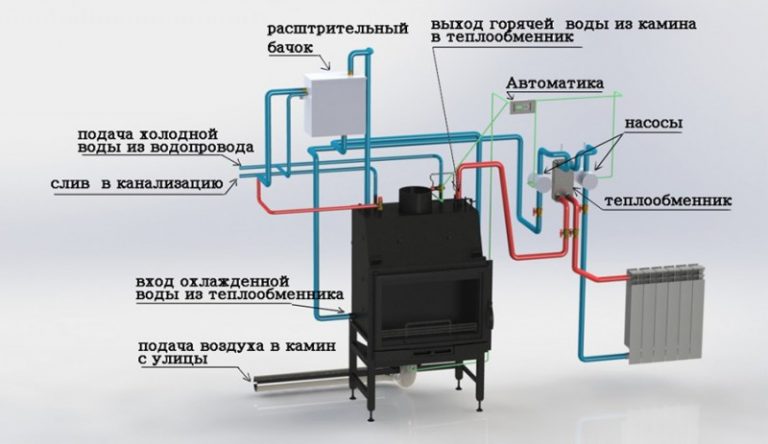

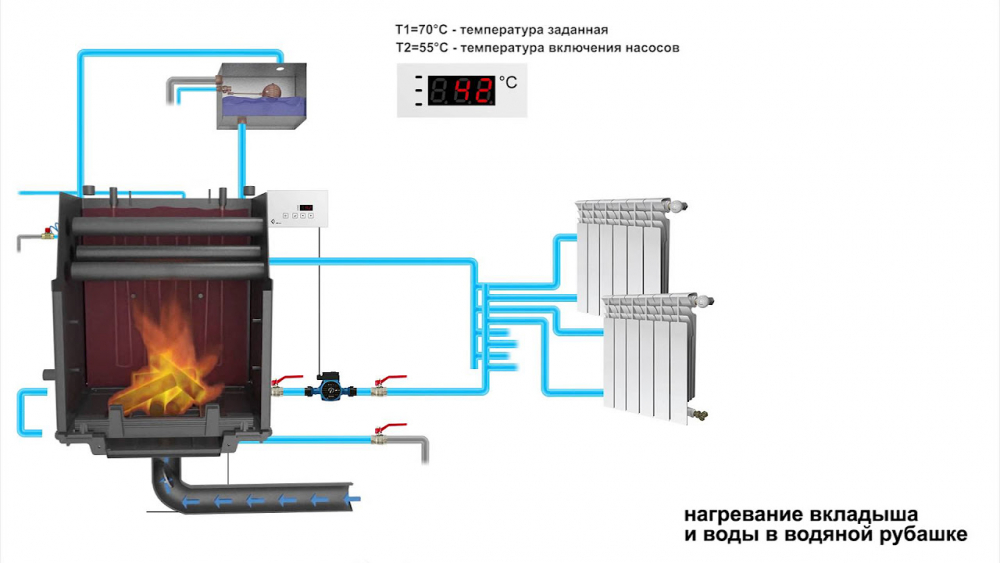

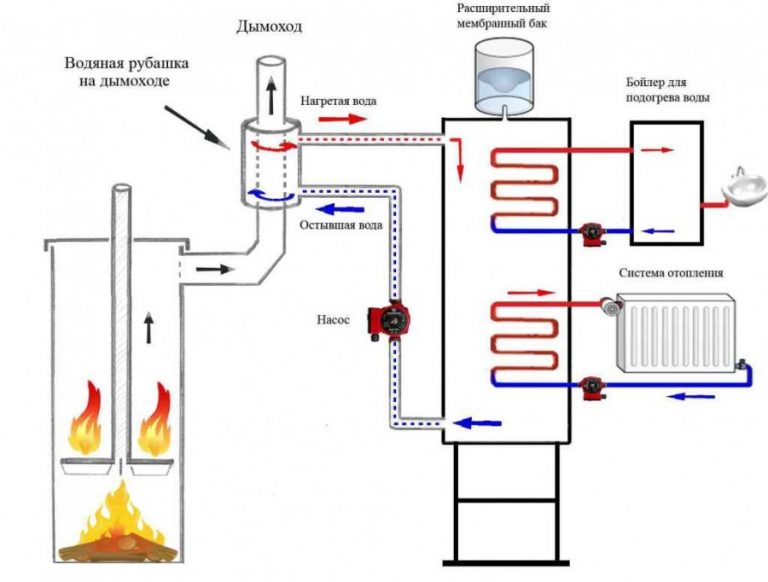

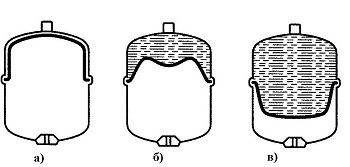

membrane tank

Installing a register in the firebox is only part of the matter; it is equally important to properly equip the pipe layout. Any heating system built according to this principle must be equipped with an expansion or membrane tank.

As a rule, it is installed on the return pipe, but this is not important, some masters prefer to mount it at the highest point of the system.

The principle of operation of the membrane tank.

In a system with natural circulation of the coolant, its function is performed by an ordinary metal container. But now, in most cases, the owners prefer to install circulation pumps. It is desirable to mount a real membrane tank in such a system.

The device is a sealed metal container, in the upper part of which there is a valve. Air is forced through the valve, creating excess pressure in the system. When the temperature rises, the coolant expands proportionally, squeezing out the excess into the membrane tank. During the cooling process, the air that presses on the membrane compensates for the pressure drop in the system.

Some moments of laying the furnace

As mentioned earlier, do-it-yourself brick ovens with water heating can be folded, but if you are not confident in your abilities, it is still better to invite a specialist.

Although in any case, there are general rules that are not desirable to break.

- All brick ovens are made of solid red brick. Hollow brick is not desirable to use even for cladding. The fact is that hollow blocks are a heat insulator, and in this case it can only do harm.

- If it is supposed to heat with firewood, then the firebox can be folded from ordinary burnt bricks. But if there is a possibility of using coke or coal of high grades, such as anthracite, then we would advise you to build a firebox from a special fireclay brick, which is used for the construction of blast furnaces.

- There is no need to save on wall thickness, in addition to the weight of the furnace itself, the load from the registers will also be added here.

- And yet, any stone building needs a reliable foundation, as for stoves, here the foundation should be laid separately and in no case should be in contact with the common foundation of the house, the minimum distance between them should be 50 - 100 mm.

circulation pump in the system.

The video shows some of the intricacies of installing the system.

In this case, we were talking about heating the house. But it would not be out of place to note that if a metal water tank is inserted into the system in parallel, then it will play the role of a passive boiler, as a result of which hot water for domestic needs will still appear in the house.

Conventional stove heating: advantages and disadvantages

In our country, houses were traditionally heated with brick stoves, but gradually this type of heating was replaced by water systems. All this is because, along with the advantages, simple stove heating has a lot of disadvantages. First about the benefits:

- The furnace transfers most of the heat by thermal radiation, and, as scientists have found, it is better perceived by our body.

- Russian or some other heating stove has a colorful appearance, it is often possible to observe an open flame.

- You can make a brick oven with chimneys for a more complete use of the generated heat.

- Heating of this type is non-volatile - does not depend on the availability of electricity.

-

There are models of stoves for heating the second floor (due to the heating shield with smoke channels).

Today, stove heating is perceived more as exotic, as it is very rare. It is impossible to argue that it is very pleasant to be near a warm stove. A special atmosphere is created. But there are also many serious drawbacks:

- Uneven heating - it is hot near the stove, cold in the corners.

- Large area occupied by the oven.

- Only those rooms into which the walls of the furnace go out are heated.

- The inability to regulate the heating temperature in individual rooms.

- Low efficiency. For conventional stoves, 60% is already a very good indicator, while modern heating boilers can produce 90% or more (gas).

-

The need for frequent maintenance. Melt, adjust the dampers, clean the coals - all this regularly and constantly. Not everyone enjoys it.

As you can see, the shortcomings are significant, but some of them can be leveled if a heat exchanger is built into the furnace, which is connected to the water heating system. Such the system is also called furnace water heating or stove heating with a water circuit.

2 Types of heat exchangers

For an autonomous heating system using a stove, two types of heat exchangers are used: flat and tubular. Both the first and the second have their advantages and disadvantages.

Flat-type heat exchangers are a practical option for country houses, baths, cottages, etc. Their manufacture is very simple, exactly the same as operation. The devices are both vertical and horizontal. Efficiency at a high level.Due to the flat design of the device, the water heats up quickly, and its amount is quite large in order to heat the house or take water treatments.

A significant drawback of the design is the low level of heat transfer from the furnace walls. device in the form of the letter P is installed around the entire perimeter of the furnace, so the efficiency of this design is small. It is advisable to install it only when the stove is used constantly for cooking or other purposes. Then the room will have time to warm up.

The tubular heat exchanger differs from the flat-mounted heat exchanger in the dimensions of the structure itself. The main advantage is the possibility of easy dismantling and maintenance.

The tubular type furnace heat exchanger is made of a seamless tube. This ensures the reliability and durability of the structure. It also has a fairly high level of security.

When designing and manufacturing a tubular-type heat exchanger, it must be remembered that its shape must exactly repeat the shape of the furnace opening - this is how ideal heat transfer can be achieved.