- Required Tools

- What is a potbelly stove

- The device and principle of operation of a potbelly stove for long burning

- We make a potbelly stove at work

- The main models of homemade bourgeois

- Advantages and disadvantages

- Principle of operation

- Secrets of long-term operation of solid fuel units

- Economical and energy efficient garage ovens

- The sequence of manufacturing a stove in a garage, functioning at a test

- Disadvantages of a furnace for a garage for working out, features of operation

Required Tools

- To make such a device as a potbelly stove of high-quality long-term burning with your own hands, you need to prepare the following materials and important tools:

- You will need a large metal barrel, the use of a cylinder is also allowed;

- Two small pipes made of steel (one should be slightly larger than the other);

- If this is a bubafon stove, then you will need to build a piston;

- Channel made of steel;

- Mallet, axe, hammer, hacksaw;

- Measuring devices are required;

- Steel sheet, brick and reflector;

- Protective elements for welding and other necessary materials.

Only after preparing all the required tools and materials, you can begin the process of creating with your own hands such an effective device as a potbelly stove. It is also advisable to pre-prepare carefully designed drawings that will help to make not only a furnace for a long combustion process - a potbelly stove, but such a device as a piston bubafon.

What is a potbelly stove

Potbelly stoves have been known among our compatriots for a very long time. They gained their popularity due to their extreme simplicity. A simple metal box with a door and a blower - and the simplest version of the stove is already ready. Given the ingenuity of our people, this world has seen a lot of the most diverse bourgeois women, delighting their owners with the coveted warmth. Let's see what you can assemble such a furnace from:

You can make a potbelly stove not only from a used safe or a battered gas cylinder, but simply by welding several sheets of durable metal together.

- From an old gas cylinder - a great option, it remains only to find the cylinder itself (you will get a horizontal or vertical furnace). Plump modifications are suitable here, since thin and high oxygen cylinders are too narrow;

- From an old flask - probably someone had such a thing lying around in a garage or in a barn. There is already a door, it remains only to attach a chimney;

- From an old barrel - home-made potbelly stoves of long burning are often made from them, since the capacity of the barrels allows you to organize a large combustion chamber;

- From the old safe - there is no need to throw the old man away, he will still serve.

Homemade potbelly stoves can also be made from sheet metal - for this you need to arm yourself with the right tools.

The device of the potbelly stove is extremely simple. Its basis is a certain capacious capacity, which plays the role of a combustion chamber. A pipe is removed from its upper or rear part, to which a chimney is attached. Two doors are organized in the front part (less often one) - fuel is loaded through the large one, and ash is removed through the small one. The internal space is divided by a metal grate, through which air is supplied - ash formed during the combustion of firewood is removed through the waste.

The lower door simultaneously acts as a blower - by adjusting the degree of its opening, you control the intensity of the flame and the temperature in the room.

The dimensions of the potbelly stove can be very different, for example, 250x450x450 mm (WxDxH). From the gas cylinder you get a larger and more efficient stove. The largest size will be at the stove from the barrel - after all, the internal volume of 150-200 liters can accommodate a huge amount of firewood. You can make a unit of almost any size - you don’t even have to bother too much with the exact observance of the dimensions indicated in the drawings.

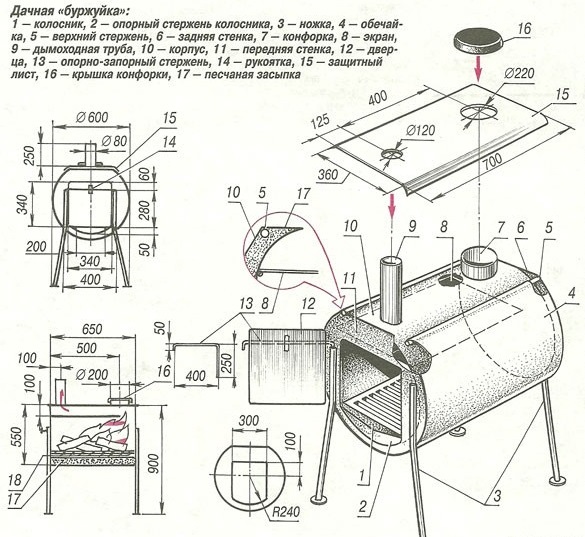

The device and principle of operation of a potbelly stove for long burning

The methods described above for increasing the time of continuous operation of the furnace have been successfully implemented in the design of the potbelly stove, which we offer for manufacturing. The unit consists of only a few parts and is distinguished by its extraordinary simplicity, which, however, does not prevent it from successfully competing with more complex heating devices.

Firewood is laid in the body, which is most often made in the form of a cylinder.From above, the fuel is pressed by an air distribution device in the form of a hollow rod with a piston (a heavy metal disk, in the center of which there is a hole for air supply). Support vanes (blades) are welded to the bottom of the steel pancake, the width of which determines the height of the gap between the fuel and the piston. In other words, the volume of the combustion chamber depends on the size of the blades. A pipe is welded to the back of the disk, through which air enters the furnace. To regulate its amount, the channel can be completely or partially blocked using a sliding damper.

The device and principle of operation of a potbelly stove for long burning

A pipe for connecting a chimney is cut into the upper part of the potbelly stove body. To ensure normal draft, the height of the pipe must be at least 4 m. From above, the unit is closed with a lid, which has an opening for the air distribution device.

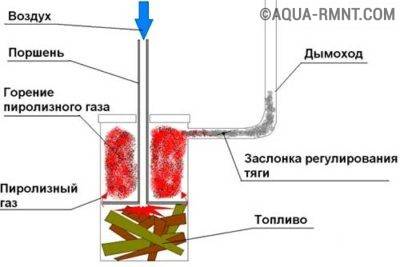

Primary air is supplied directly under the piston, which divides the working space into two chambers. Precise dosing of oxygen makes it possible to reduce the intensity of the flame, facilitating the transition to the gas generation mode. At the same time, thermal energy is released not only by burning fuel, but also by pyrolysis gases, which are actively afterburned under the cover. Secondary oxygen for their oxidation is supplied through a special window in the upper part of the furnace, and in the simplest case - through the gap between the air supply pipe and the top cover. After the top layer of firewood burns out, the metal disc lowers under its own weight, providing oxygen access to the new fuel horizon.

The products of combustion are removed from the furnace through a chimney cut into the upper part of the body. In order to further increase heat transfer, the chimney is connected to the heater through a small horizontal transition, which plays the role of an air heat exchanger.

We make a potbelly stove at work

Diesel fuel and used engine oil are very high-calorie fuels. If you get it inexpensively, then it makes no sense to mess with firewood and coal, it’s easier to make a reliable furnace - a dropper. Its principle of operation is to burn mining, dripping into a red-hot bowl. Moreover, along the way, liquid fuel has time to warm up, as it passes through the oil pipeline built into the pipe - the afterburner. The drip-type potbelly stove device is shown in detail in the drawing.

For efficient combustion of oil, air is forced into the stove using a fan, and mining flows naturally from a tank suspended from the wall next to the heater. Another option is the forced supply of fuel by pressurizing the fuel tank (for example, with a hand pump).

Both a pipe Ø219 mm and a propane cylinder with a diameter of 30 cm can act as a furnace body. Making an oil potbelly stove with your own hands is a simple task, the main thing is to make holes and slots in the afterburner correctly and lay the fuel pipe to the bowl installed at the bottom. A complete assembly guide is provided in our other article. You can get a closer look at the operation of the heater from the video:

The main models of homemade bourgeois

According to its principles, a potbelly stove is practically no different from models of a special solid fuel device. This is a specific variation of a very simple fireplace category stove.There are also special models that are equipped with cooking hobs and special bath devices.

The material used to make the stove Often a potbelly stove is made of high-quality steel, but in some cases cast iron can be used. With different types of metal, elements made of natural stone are often used. If cast iron is used, then you should count on low heat capacity parameters, it is very difficult to find it and it is not easy to cook it. Many people prefer steel for this very reason, it is much easier in the process. At the same time, the thicker the material, the longer it will last. If you plan to make a device for rare use, for example, for emergencies with a heating system, then make it from simple iron, which has a thickness of 1 mm. In the process of manufacturing the furnace, the entire style may well be used factory. This applies to elements such as grates, necessary doors, burners and valves. Many craftsmen make them with their own hands using steel.

The shape and material for the case If you want to make a potbelly stove using drawings or photos, you must use the method of cutting a metal sheet.

- In addition, elements such as:

- Molded profiles;

- Square tube;

- Special corners;

- fittings;

- Rod.

As a basis, various case products made of metal, boxes can be used. Often these are elements of a cylindrical shape, for example, large-diameter pipes, cans, gas cylinders.

In the process of making a furnace with your own hands, you will definitely need to use welding

If the metal is not very thick, the furnace can be made using bolts, screws and a drill. Regardless of the model chosen, it is important to use drawings as a basis for manufacturing, because. despite the relative simplicity, it is required to follow certain instructions for the implementation of the heating means.

Advantages and disadvantages

Let's see how good home-made potbelly stoves made by craftsmen are:

- Cheapness - most materials can be found for free or pay mere pennies for them;

- Omnivorous - in fact, any solid fuel can burn in a potbelly stove;

- Simple construction - if we look at the drawings, we will not find anything complicated in them;

- Possibility of cooking - for this, potbelly stoves are equipped with cooking holes with lids;

- Ease of operation - provided that there is a good chimney, the potbelly stove will work properly and not smoke on the whole room.

Unfortunately, heating with a potbelly stove has its drawbacks:

- Low efficiency of the stove - without proper modernization, most of the heat will fly into the pipe;

- Not the most solid appearance - although some craftsmen make real works of art out of bourgeois women;

- High body temperature - fraught with burns;

- High fuel consumption - in order for the stove to retain heat for a long time, without requiring the burning of tons of firewood, you will have to use tricks.

Despite some shortcomings, simple wood-fired potbelly stoves are still in demand among those who need warmth in the absence of a gas main.

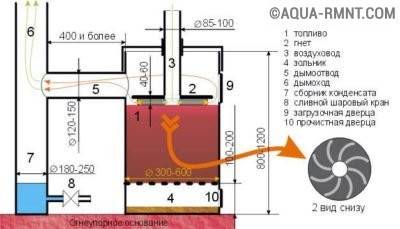

Principle of operation

The operation of the furnace is based on the combustion of engine oil vapor in a closed container. The product is not just the cheapest, but junk.Most often, used oil and its disposal is a headache for service stations, garage owners. After all, it is absolutely impossible to pour mining into the ground, domestic sewage. And here "harmful" oil is poured into the stove, and serves for the benefit of man.

The design of the most common modification, made of metal, consists of cylindrical tanks, lower and upper, a short transitional compartment and a chimney. It's easier and harder to imagine. First, the fuel is heated in the first tank: the oil boils, begins to evaporate, the gaseous product passes into the next compartment (short pipe). Here, oil vapors mix with oxygen, ignite intensely and burn out completely in the last, upper tank. And from there, the exhaust gases are released into the atmosphere through the chimney.

Secrets of long-term operation of solid fuel units

The whole secret of long-term burning of a potbelly stove is hidden in the way fuel is put into it. Firewood in such a stove is ignited from above, so there is no danger of simultaneous ignition of all logs placed in the fuel chamber.

Despite the unpretentious appearance, a home-made long-burning potbelly stove successfully competes with many factory-made wood-burning stoves.

Additionally, this is facilitated by the method of air supply. The oxygen necessary for combustion is supplied only to the top layer of the fuel. Such solutions make it possible to increase the size of the bookmark as much as the dimensions of the furnace allow. Of course, the time of continuous operation of such units increases tenfold.

The secret of long burning stoves is an efficient way to burn fuel

The pyrolytic decomposition of solid fuel, which occurs at high temperature and lack of oxygen, allows to further increase the duration of one heating cycle. At the same time, firewood does not burn, but smolders, simultaneously forming a large amount of volatile hydrocarbon compounds. Pyrolysis gases burn under the roof of the furnace with the release of a large amount of heat. Thus, smoldering contributes to the lengthening of the continuous burning period, and pyrolysis makes it possible to increase the efficiency of the heat generator many times over.

Economical and energy efficient garage ovens

A waste oil furnace is considered the most economical, as it eliminates additional fuel costs. If you correctly calculate the materials and strictly follow the manufacturing instructions, then it will not smoke and pollute the air excessively. The operation of such furnaces on transmission, machine or transformer oil is provided. A diesel oven for a garage functions on the same principle.

Structurally, the unit consists of two containers, which are interconnected by a perforated pipe with many holes. If a decision is made in favor of installing a working furnace in the garage, then it is necessary that it meets the following requirements:

- maximum weight - 30 kg;

- capacity - up to 12 liters;

- standard size - 70x50x30 cm;

- average fuel consumption - 1 l / hour;

- exhaust pipe diameter - 100 mm.

The wood-burning garage stove from two gas cylinders is very economical and easy to maintain

To build such a structure is quite simple.No nozzles and droppers are needed to create it, so special knowledge, skills or experience are not needed to make it.

Directly for the manufacture of the furnace will require the following materials:

- steel pipe;

- two metal containers;

- steel corner.

The container can be the case of an old unusable refrigerator compressor or a gas cylinder. A furnace for a garage for mining should be made of a material with a thickness of at least 4 mm, since it is supposed to be heated up to 900 ° C, so thin metal will simply burn out.

The sequence of manufacturing a stove in a garage, functioning at a test

A garage oven for mining is beneficial if there are large stocks

The process of creating this type of stove in the garage with your own hands includes the following steps:

- Installing the lower container on the legs. For this purpose, parts with a size of 20 cm are produced from a metal corner, onto which the container is welded in a horizontal position.

- Cutting a hole in the middle of the lower part of the body, which serves as a firebox and a fuel tank, welding a vertical pipe to it, connecting both containers. It is desirable that the upper part is removed. This is necessary for cleaning the burner.

- Drilling about a dozen holes in the pipe at a height of half a meter. The first hole must be at least 10 cm from the main body of the oven.

- Making a hole on the top of the furnace tank for pouring oil and a lid that will help regulate the level of heating of the room and the combustion process itself.

- Welding a branch pipe on the upper tank.

- Construction of a galvanized steel exhaust pipe at least 4 meters long and fastening it to the nozzle.

Painting will give a presentable look to the garage stove.For this purpose, a mixture of silicate glue, crushed chalk and aluminum powder is used.

Disadvantages of a furnace for a garage for working out, features of operation

To use such a stove, in order to avoid emergency situations, it is necessary in accordance with clear instructions. To do this, using the lower opening of the furnace, it is necessary to put a small amount of kindling paper into the fuel tank. Next, approximately 1 liter of used oil is poured. The paper is set on fire and wait a couple of minutes until the oil boils. When the oil begins to burn slowly, it must be added as necessary in the amount of 3-4 liters.

Despite the many advantages of this type of garage oven, it is necessary to mention their disadvantages, in particular:

- a very long chimney, which must be at least 4 meters in height;

- it is required that the chimney device be strictly vertical, without bends and horizontal sections;

- The oil containers and the chimney must be cleaned regularly - about once a week.

The oil consumption in the furnace during mining is regulated by the air supply damper and is 0.3 - 1 l. in hour

The process of creating a heating system in a garage must be approached responsibly so that such structures as a mining boiler, a brick oven, a do-it-yourself potbelly stove are profitable and bring maximum heat. It should be noted that economical options must be carefully looked after, and brick structures require a certain time for kindling. To create a long-burning metal furnace, certain skills and knowledge will be required. At the same time, any of the options considered, under the conditions of proper construction and subject to the rules of operation, will make the garage warm and comfortable.