- How to make a gas burner for a boiler with your own hands?

- Types of burners

- atmospheric

- Diffusion-kinetic

- Features of use

- Pellet stoves

- Installation Requirements

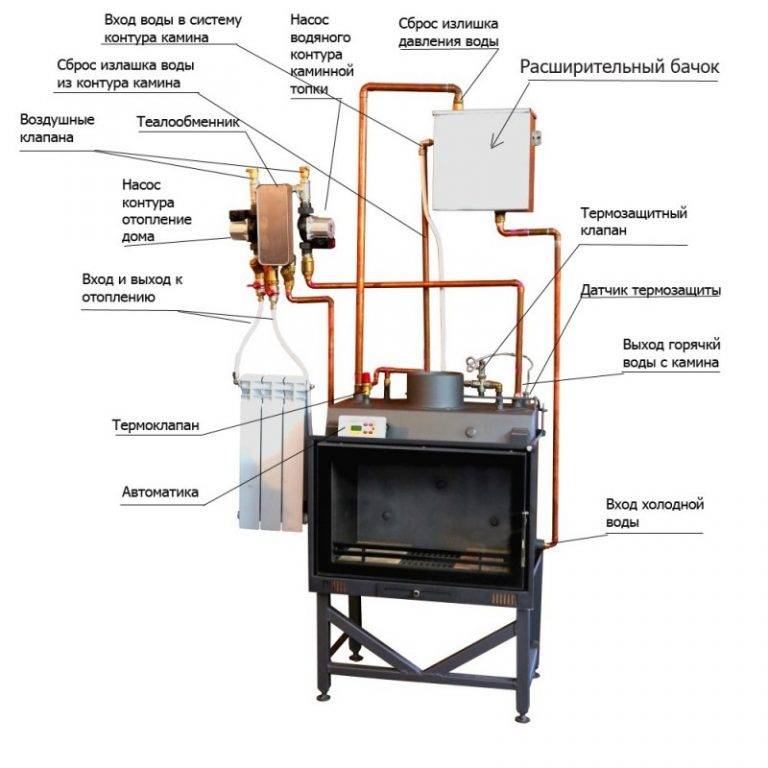

- 2 Built-in heat exchanger - types, design diagrams

- Advantages and disadvantages of furnace heating

- How to build a water oven at home?

- How to make such an oven yourself

- Manufacturing options and recommendations

- System installation

- Heating furnaces with water circuit

- Technical characteristics of fireplace stoves with a water heating circuit

- Stove-fireplace Bavaria

- Stove Meta

- Advantages and disadvantages of furnace heating

- Brick PVC - features of operation

- PVC installation

- Recommendations for the placement of elements of the heating system

- Conclusion

- The principle of operation of the furnace with a water circuit

- Boiler installation

- Advantages and disadvantages

- Main types

- With water circuit or without?

How to make a gas burner for a boiler with your own hands?

The main element of the gas boiler is the burner. It is around it that all other elements are exposed. Many aspects of the use of the equipment depend on the node design.

First of all, it is safety and economy. Therefore, many people want to make such a gas burner for the boiler with their own hands, which will meet all the requirements of the owners.

At first glance, this may seem like a complicated process, but in fact it is not.

Types of burners

Many people think that the burner is just a nozzle through which gas is supplied. But it is not so. It also mixes air into fuel.

At the same time, it is important to take into account that the product must have a special design that makes it possible to make the mixture stable.

The device can be of several types, depending on the method of adding oxygen to the gas:

- atmospheric burner;

- fan;

- diffusion-kinetic.

atmospheric

The principle of operation of this component is simple: the gas passes through the ejector, where its pressure is reduced. In this case, air enters due to different atmospheric indicators.

These devices have a lot of advantages:

- simple design;

- compactness;

- quiet work;

- acceptable cost;

- the possibility of converting a solid fuel boiler for this equipment - the burner is simply installed in the ash pan chamber.

At the same time, such devices cannot have high power. The fact is that due to their design, atmospheric heaters cannot draw in a large amount of oxygen.

Diffusion-kinetic

Basically, such equipment is found in large industrial heaters. The principle of operation is based on both atmospheric and fan heaters.

Features of use

Gas burners are unpretentious in service. The main feature is the annual cleaning. In this case, the procedure should be carried out only by highly qualified specialists, since for this it is necessary to disassemble the boiler. Most often, the service center is engaged in cleaning the burners.

Dirt is easily removed with compressed air

It is important to set the right pressure for this. The fact is that some modern parts may not withstand a flow of 10 atm.

To make the cleaning process faster and less frequently required, a special filter is placed on the gas supply. This is done by the master after submitting an application to the appropriate structure.

Well, despite the fact that the gas burner in the heating boiler, although it seems to be the most complicated engineering unit, you can nevertheless make it yourself without any problems. To do this, you need to prepare all the necessary materials and have the skills to work with metal. In addition, it is necessary to have several units of a special tool.

Pellet stoves

Pellets are now conquering the energy market. Somewhere they are available due to the fact that they are made from waste. Somewhere it is more and more difficult to get classic fuel (wood and coal), but someone likes the fact that pellets are suitable for automation at the feed.

An additional bunker is installed to the boiler, where a large volume of pellets is loaded at once and, as it is consumed, the fuel is fed into the chamber by an auger. The main element of any such boiler is a special pellet burner, which is almost impossible to repeat at home, and the price of which makes up a large part of the total cost of the boiler.

Pellet boiler Valdai 15M2

Examples of models with a water circuit:

- Valdai 15M2 - 15 kW. In emergency cases, it will be able to "digest" both coal and firewood. Efficiency on wood 76%, on pellets up to 90%. 120 - 125 thousand rubles.

- Kupper OVK 10 (from Teplodar, Russia). This is not strictly a pellet boiler. It can be a compact solid fuel burner with a hob. But by adding a tank and a burner, it turns into a pellet one. Another feature is that the tank is built on top and takes up less space in the boiler room than other similar devices. Open chamber, single-circuit, efficiency 75%, price: 75 - 90 thousand rubles.

- Peresvet 10MA (from Obshchemash, Russia). Reserve fuel - briquettes and firewood. The bunker is installed next to the boiler, single-circuit. Price - about 150 thousand rubles.

Many simple solid fuel boilers can be converted to pellets by purchasing a burner and a bunker (or even building the latter, on your own - it turns out to be somewhat cheaper).

Installation Requirements

The thickness of the water layer in the heat exchanger must exceed 4 cm, since the water will boil with a smaller thickness.

The walls of the coil must be at least 5 mm, and in the case of coal, even thicker. Failure to comply with the thickness can lead to burning of the walls.

Furnace building process

Under no circumstances should the heat exchanger be mounted close to the furnace wall. Leave at least 2 cm. This space is necessary for thermal expansion of the coil.

Particular attention must be paid to the fire safety of the system. Between the stove and wooden partitions, there must certainly be air gaps, since it is overheating of wooden structures that is the first cause of fires.

It is best to clad with brick or other refractory materials.

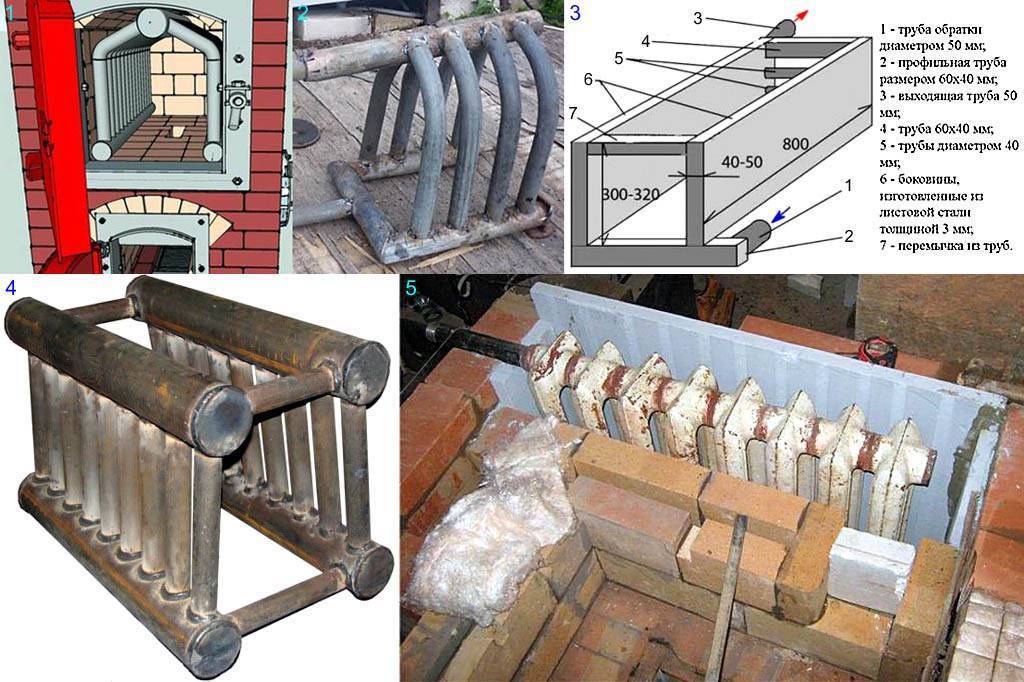

2 Built-in heat exchanger - types, design diagrams

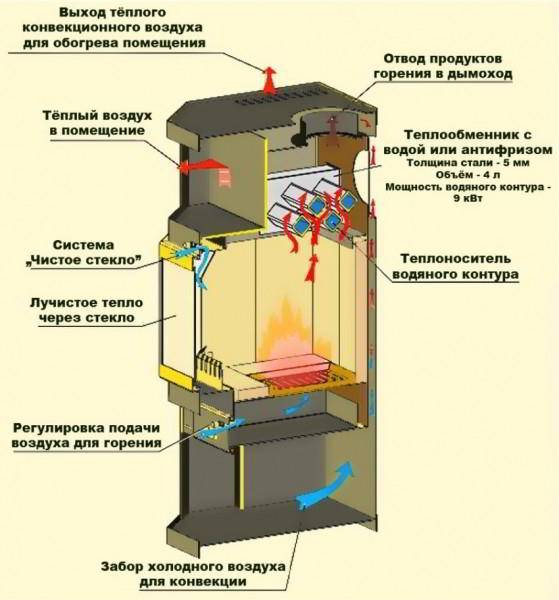

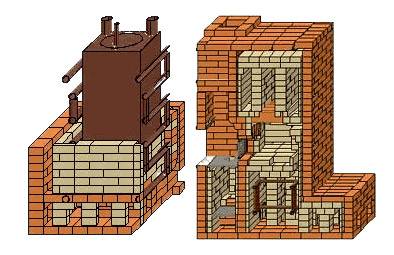

This is the heart of the installation, the efficiency of work depends on the correct choice and installation. Manufacturing begins with the calculation of the area with which the fire will contact - performance depends on it. Further, they determine the configuration, material and location in the furnace, make a drawing. The oven is designed according to the dimensions. The location of the structure is a firebox or a channel system, the return in the latter case is noticeably reduced. The first option is preferable, but the use of overall products limits the cramped space.

All heat exchangers are reduced to two varieties - from sheet metal or pipes. The area of the heated surface with the same dimensions differs significantly. This is easy to verify in a simple example, using the formula for calculating the circumference of the pipe: C=π×d. With a diameter of 5 cm, it is 15.7 cm, and a length of 0.5 m is already 0.0785 m2. Only 6 elements in total almost 0.5 m2, which perceive heat and give it away.

Such a design will take up a space of 0.5 × 0.25 m. A sheet metal boiler with such dimensions loses at least three times in efficiency. Its heating is most intense on one side facing the fire, the back receives heat from the gases, while the tubular product is completely engulfed in flames. One square meter water circuit gives 10 kW energy, which is enough to heat 100 m2 of a very cold house without thermal insulation.

Advantages and disadvantages of furnace heating

Traditional stove heating is preferred by many rural residents because of its time-tested benefits:

- Autonomy. The house does not need to be connected to additional communications, which is always costly and troublesome. The operation of the system is based on the principle of natural circulation.

- Savings on installation. Equipment for a furnace connected to water heating is cheaper than for other heating systems.

- Fuel availability. Firewood is a natural, common and cheap fuel in most of the country. There are combined furnaces that allow the use of coal, peat briquettes, coke.

- Savings in operation. Some stoves (long-burning designs) can significantly reduce wood consumption.

- Environmental friendliness.Combustion of natural fuel does not harm the environment.

- Aesthetics. Modern wood stoves can become a significant interior detail.

Autonomy of work is an important feature of a wood-burning stove

Along with the undoubted advantages, stove heating also has some disadvantages:

Relatively low efficiency. The efficiency (coefficient of performance) of the furnace will always be lower than the efficiency of a gas or diesel boiler. Significant losses of thermal energy occur through the chimney.

Permanent service. For the system to work smoothly, constant human supervision is required; it is impossible to establish automatic operation, it is necessary to monitor the supply of fuel and waste disposal.

Slow and uneven heating of rooms. The stove will warm up well only the room where it is installed; in the far corners of a spacious house it will be noticeably colder

Usage skills. It is more difficult to maintain the combustion process in a furnace than in a boiler.

Place. It is necessary to allocate a place to store a supply of firewood.

fire hazard

Separate parts of the structure need careful insulation (which is especially important if the building is wooden). Another difficulty is that burning cannot be stopped instantly.

Find a place to store firewood

How to build a water oven at home?

- There are three ways to carry out stove heating with a water circuit with your own hands:

- buy a steel furnace from a manufacturer whose services include installation of the system;

- hire a craftsman - a specialist will select the material, make the device, lay out the furnace and install the boiler;

- do it yourself.

How to make such an oven yourself

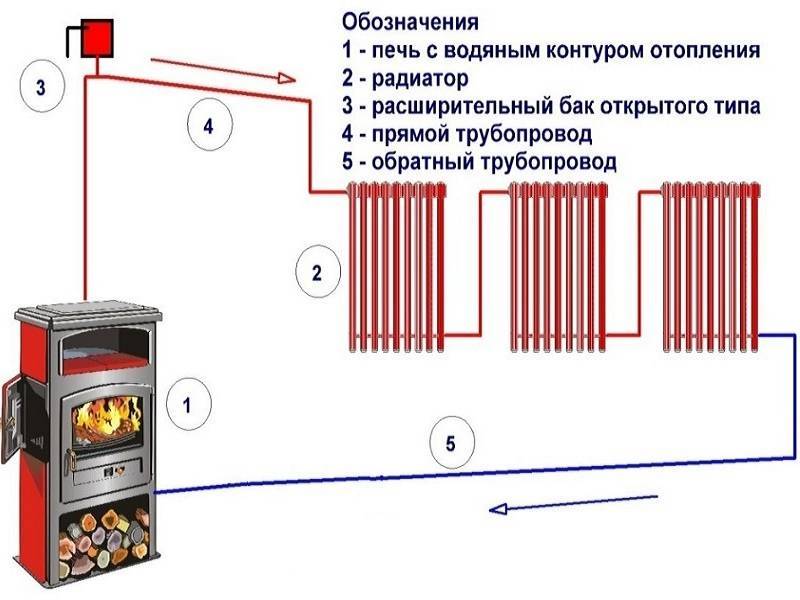

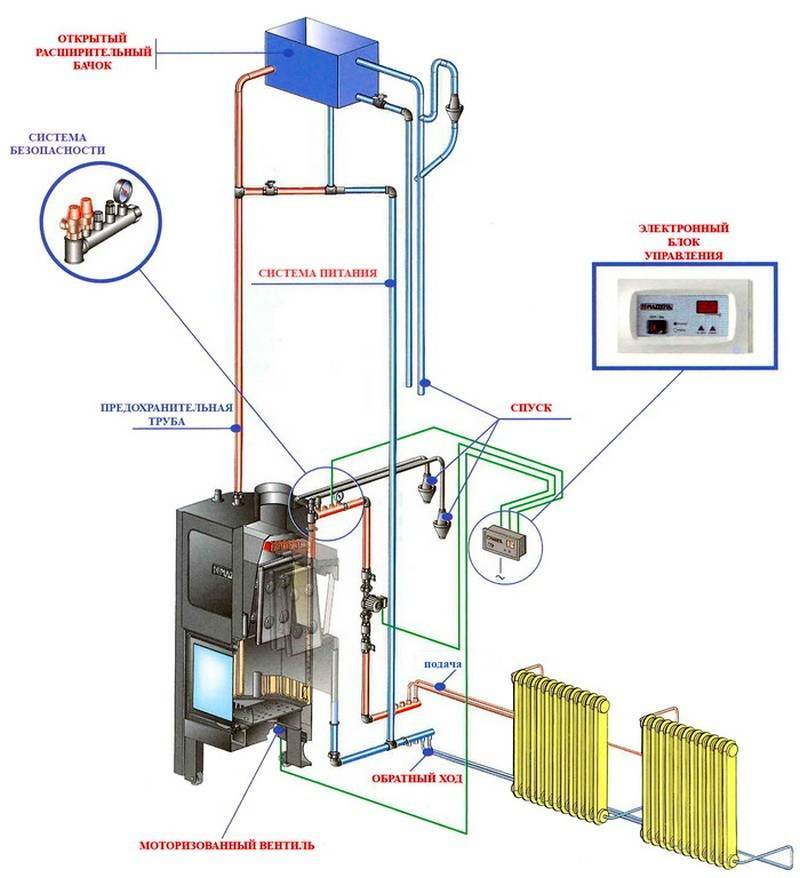

The principle of the boiler for water heating

Can you make such a system yourself? Quite, just enough experience in welding and in laying bricks during the construction of the furnace. First you need to prepare the boiler (register, coil, heat exchanger).

Such a device can be bought or made independently using sheet metal and pipes. Since the complete process of manufacturing and installing a water circuit cannot be put into a short overview, the following are the main recommendations.

Manufacturing options and recommendations

Water heating from a wood-burning stove - scheme

For the boiler, a sheet of metal with a thickness of at least 5 mm is used, and its design is made such that there is maximum heating of the water for further circulation. The boiler, welded from sheet steel, is easy to manufacture and operate - it is easy to clean.

But such a heat exchanger has a smaller heating area, in contrast to the pipe register. It is difficult to make a pipe register at home on your own - you need an accurate calculation and suitable working conditions, usually such boilers are made to order by specialists who install the system on site themselves.

The easiest way to use a solid fuel heat exchanger is an ordinary potbelly stove with a built-in water system. Here you can take a thick pipe as a basis, then there will be much less welding work.

Attention! All welds must be doubled, since the temperature in the furnace is not lower than 1000 degrees. If you boil ordinary seams, then there is a chance that this place will quickly burn out.

The layout of the rooms of the house and the location of the furniture also need to be considered. Here it is necessary to pay attention that it is better to choose a scheme with sheet boilers - they do not have pipe bends connected into one inseparable circuit.Such a structure is not so troublesome to build. It is also convenient because after installation you can use the hob without problems, which cannot be said about some tube boilers

Follow the drawings of the register in accordance with the dimensions of the furnace at home. The layout of the rooms of the house and the location of the furniture also need to be considered.

Here it is necessary to pay attention that it is better to choose a scheme with sheet boilers - they do not have pipe bends connected into one inseparable circuit. Such a structure is not so troublesome to build.

It is also convenient because after installation it is possible to use the hob without problems, which cannot be said about some tube boilers.

Register of smooth pipes - drawing

When the coolant moves by gravity, then you need to raise the expansion tank higher, and use pipes of large diameters. If the pipes are of insufficient size, then a pump cannot be dispensed with, since there will be no good circulation.

Boilers equipped with pumps have their pros and cons: you can save money by installing pipes of smaller diameter and not raising the system so high, but there is one significant disadvantage - when the electricity is turned off or the circulation pump burns out, the heated boiler can simply explode.

It is better to assemble the structure at home, on site, since the device, like individual parts, has a very large weight and dimensions.

System installation

Cast iron battery heat exchanger

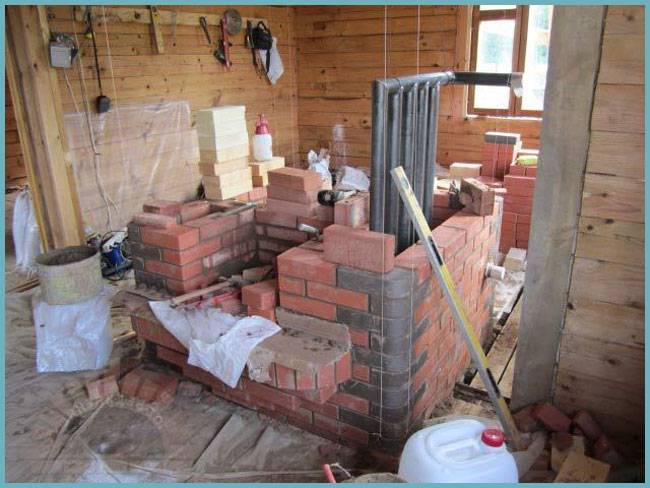

- Before installation, a solid foundation is poured, on top of which it is better to lay a layer of bricks.

- You can lay the grate at different stages: before the boiler, if the double structure, the lower part of which can be equal to or higher than the upper part of the grate, when the stove is low and the system is placed a little higher, then the grate, doors, corner on the stove are usually placed after the boiler is installed .

- A housing is installed - usually it consists of two containers connected by pipes.

- The entire heat exchange system is welded to the boiler: the outlet pipe goes to the expander, goes in a circle, through the radiators and, on the other side, the return pipe is welded to the boiler from the bottom.

Stove heating with a water circuit allows, firstly, to use firewood much more rationally, and secondly, to evenly distribute warm air throughout the heated room.

Having decided to independently make a heating system at home with a wood-fired water circuit, think through all the stages of work, and if there is any doubt about the successful outcome, then it is better to contact specialists.

Heating furnaces with water circuit

Room volume, m3 up to 100

Dimensions, (HxWxD) mm: 934x535x700

Chimney diameter, mm: 120

Door opening diameter, mm: 286

Room volume, m3 up to 400

Heating power, kW: 18

Dimensions, (HxWxD) mm: 1300x700x1000

Chimney diameter, mm: 150

Room volume, m³: 150

Dimensions, (HxWxD) mm: 760x370x680

Chimney diameter, mm: 120

Heat exchanger tank volume, l: 1.3

Room area up to 150 m²

Gross power, kW: 18

Furnace dimensions: HxWxD, mm: 1020x550x490

Chimney diameter, mm: 150

Room volume, m3 up to 600

Heating power, kW: 27

Dimensions, (HxWxD) mm: 620x685x1152

Chimney diameter, mm: 150

Room volume, m3 up to 200

Heating power, kW: 11

Dimensions, (HxWxD mm: 1300x700x900

Chimney diameter, mm: 120

Room volume, m3 up to 600

Heating power, kW: 27

Dimensions, (HxWxD) mm: 1400x700x1300

Chimney diameter, mm: 150

Room volume 250 cubic meters

Firebox depth, mm: 625

Chimney diameter, mm: 115

Dimensions (l*w*h), mm: 780x380x600

Room volume 350 cubic meters

Firebox depth, mm: 675

Chimney diameter, mm: 115

Dimensions (l*w*h), mm: 830x440x770

Room volume up to 160 m 3

Room volume, m3: 200

Furnace dimensions: WxDxH, mm: 370x805x760

Chimney diameter, mm: 120

Max. power, kW: 13

Room volume, m³: 250

Dimensions, (HxWxD) mm: 760x370x930

Chimney diameter, mm: 120

Heat exchanger tank volume, l: 1.3

Room volume up to: 90 m 3

Chimney diameter, mm: 115

Room volume up to: 140 m 3

Furnace dimensions: HxWxD, mm: 935x710x520

Furnace weight kg:177

Room area up to 90m²

Full power, kW: 9

Furnace dimensions: HxWxD, mm: 1040x750x490

Chimney diameter, mm: 150

Room volume, m 3: 100

Furnace dimensions WxDxH, mm: 370x555x760

Furnace weight kg: 42

Chimney diameter, mm: 120

Room volume, m3 up to 1000

Heating power, kW: 35

Dimensions, (HxWxD) mm: 1500x800x1700

Chimney diameter, mm: 180

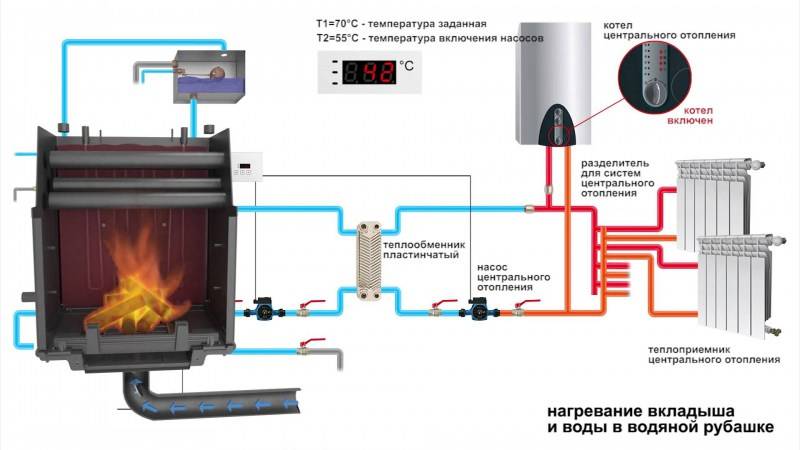

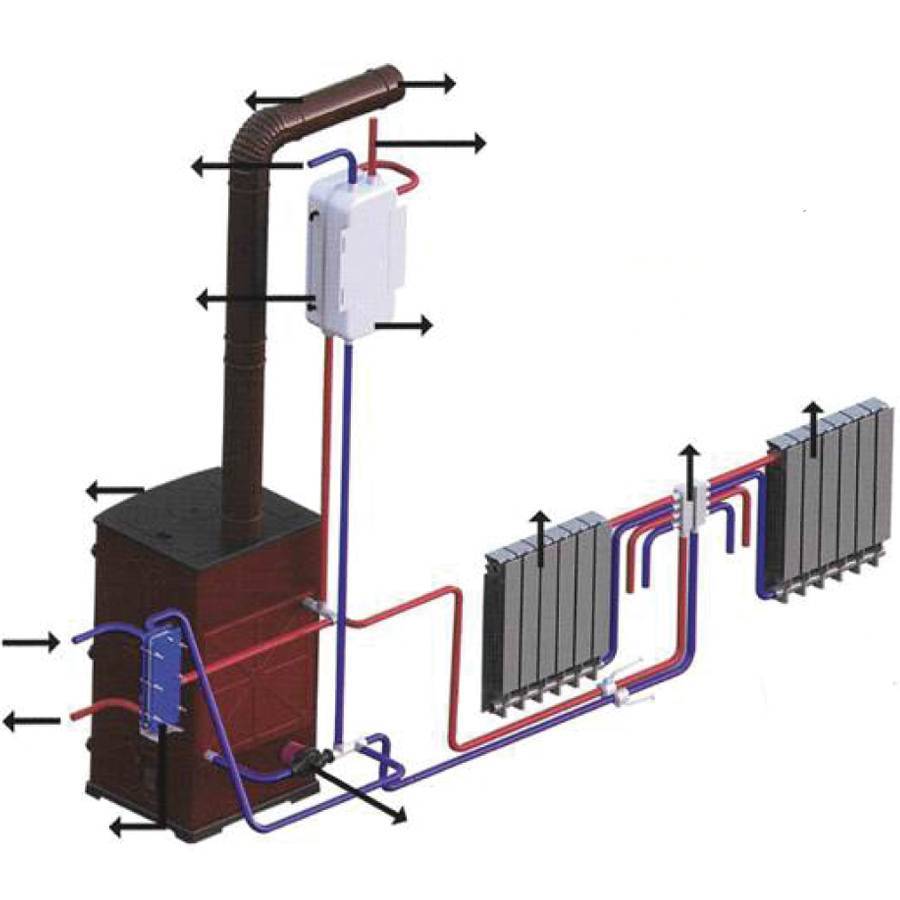

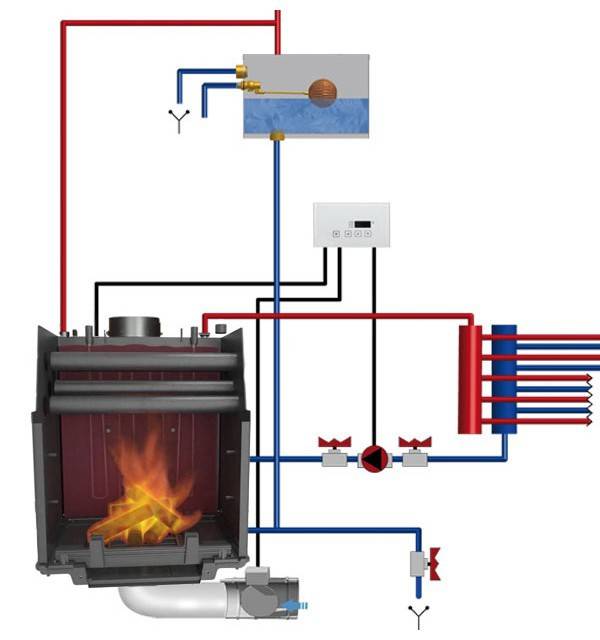

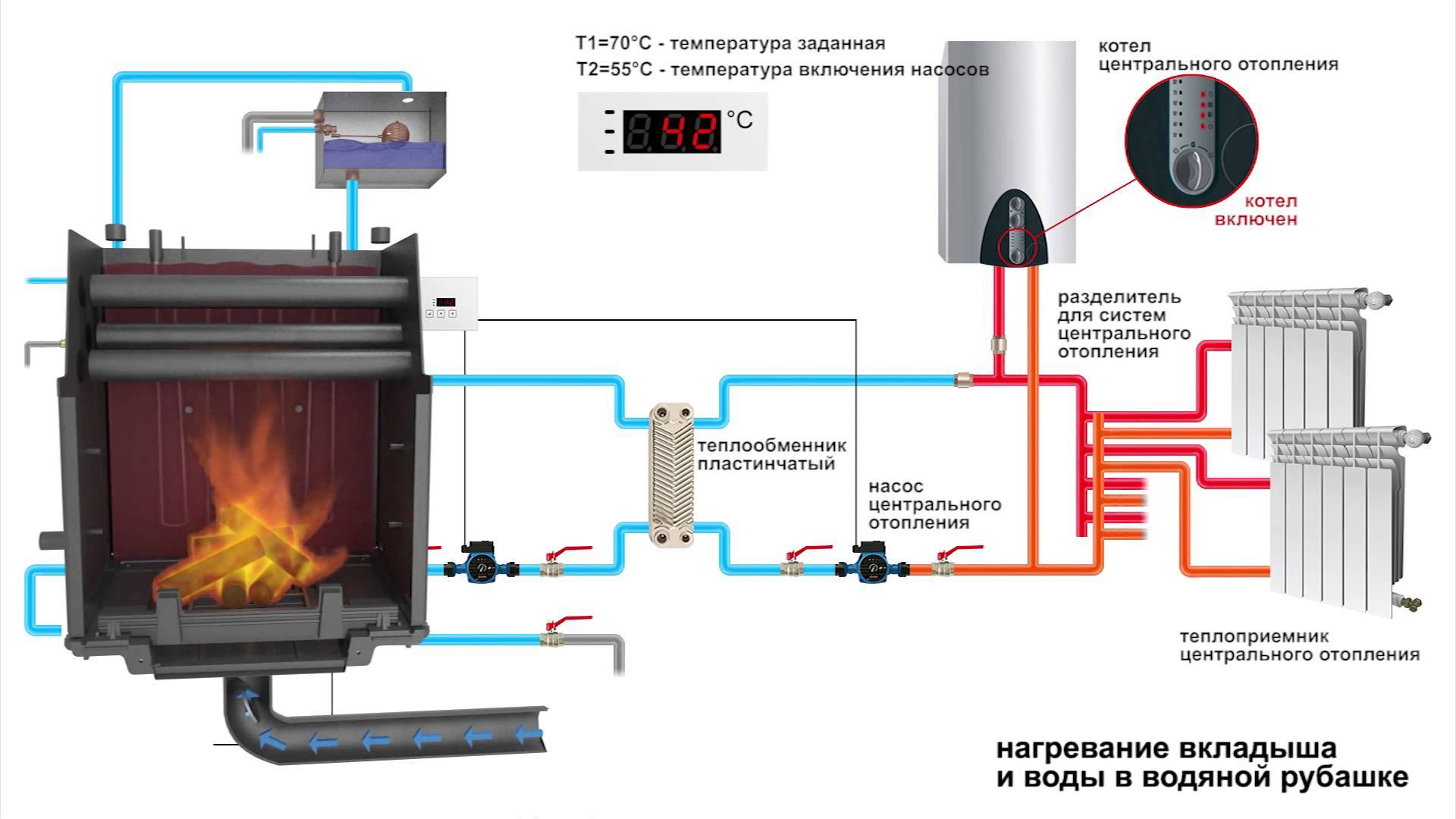

Heating furnaces with a water circuit (heat exchanger) will warm up the room not only due to the heating metal case, but also the heat of the heating water or technical fluid passing through the heating system. A water circuit stove uses the heat most efficiently, directing part of the energy to heat the water in the heating system.

Furnaces with a water circuit have a built-in water heating element, which is a metal oblong container with fittings for connecting water pipes and is mounted under the outer casing of the furnace, on the side of the furnace.

We will definitely contact you!

advise you on controversial issues

and organizes the delivery of the goods you are interested in.

Technical characteristics of fireplace stoves with a water heating circuit

Power is the main technical characteristic of the fireplace stove. But unlike a conventional stove or fireplace, on water stoves, the manufacturer indicates 2 power values: total heat output and heat exchanger power.

The total thermal power is the amount of heat that the stove can give off to the surrounding space through the furnace glass and convection channels and from the heating system.

The power of the heat exchanger is an integral part of the total power. The indicator means the amount of heat that is transferred to the radiators. For example, the total power of the furnace is 12 kW, and the power of the heat exchanger is 5 kW.

Important: for heating every 10 m2 of the area of the room, a power of 1 kW is required. Therefore, a water stove with a power of 11-12 kW will cope with heating a house with an area of 100-110 m2.

And for wood-burning heating equipment, this will be difficult, since firewood will have to be constantly thrown up. If you plan to heat the fireplace stove only during the day, then you need to increase the power value by 1.5-2 times

It should be borne in mind that the indicated power is designed for continuous operation of the stove. And for wood-burning heating equipment, this will be difficult, since firewood will have to be constantly thrown up. If you plan to heat the fireplace stove only during the day, then you need to increase the power value by 1.5-2 times.

The overall dimensions and weight of the furnace are important when there is a lack of space and limitations in the permissible load on the floors. If the floors in the house are made of concrete or reinforced concrete slabs, then you can place the fireplace stove anywhere.

For wooden floors, the maximum allowable load should not exceed 150 kg, and with a weight of 100 kg and a stove base area of \u200b\u200bless than 0.7 m2, this value will be exceeded.

In this case, it is necessary to choose a stove with a lower weight or build a 1.2 cm wide drywall podium with a non-combustible coating to redistribute the load.

Stove-fireplace Bavaria

Bavaria fireplace stoves have a fairly high power (up to 11-12 kW) and are ideal for heating a room from 80 to 200 m³.

Bavaria fireplace stoves have a fairly high power (up to 11-12 kW) and are ideal for heating a room from 80 to 200 m³.

They are designed to work in long burning mode (up to 5 hours) with economical use of firewood and can quickly warm up the room in just 1.5–2 hours. This allows them to be the main source of heating in the premises of houses for non-permanent residence. The efficiency of furnaces is up to 78%.

Important: the design of Bavaria furnaces provides free access for cleaning the combustion chamber.

| Parameter | Meaning |

| Total heat output | 9-12 kW |

| Heat exchanger power | 4-6 kW |

| The volume of the heated room | up to 200 m3 |

| Chimney diameter | 150-200 mm |

| Dimensions: height width depth | 75-110 cm 56-82 cm 43-54 cm |

| The weight | 110-170 kg |

Stove Meta

Meta fireplace stoves are popular among consumers due to the large prismatic glass, due to which the efficiency of the stove reaches 78%.

Meta fireplace stoves are popular among consumers due to the large prismatic glass, due to which the efficiency of the stove reaches 78%.

On one load of firewood, the stove can work up to 8 hours, as it is a long-burning device.

These stoves have the optimum power to heat a room up to 200 m³. The body of the furnaces is made of high quality steel and imported components.

Fireplace glasses are made on the basis of Japanese glass-ceramic and offer a panoramic view of the flame. To prolong the life of the firebox, the manufacturer lining it with fireclay and vermiculite plates, which perfectly equalize temperature differences.

Important: most stoves have a chamber at the bottom for drying and storing firewood, located under the ash box.

| Parameter | Meaning |

| Total heat output | 6-12 kW |

| Heat exchanger power | 4-6 kW |

| The volume of the heated room | up to 200 m3 |

| Chimney diameter | 150-200 mm |

| Dimensions: height width depth | 86-116 cm 55-82 cm 44-49 cm |

| The weight | 85-165 kg |

Advantages and disadvantages of furnace heating

A conventional wood-burning stove or fireplace heats a room through a combination of radiative and convection heat transfer. The heated massive walls of the furnace radiate thermal energy, transferring it to the air and furnishings of the room. Cold air is gradually replaced by warm air.

Furnace heating has a number of undoubted advantages:

- does not require connection to electrical and gas communications. Fuel: firewood, coal, peat briquettes - as a rule, cheap and environmentally friendly, its combustion does not harm the environment;

- radiative heat exchange is the most comfortable;

The Russian stove heated the houses of many generations of our ancestors

- most stoves for the home (long-burning or conventional) are multifunctional, can be used not only for heating, but also for heating water and cooking (both inside the stove and on the hob);

- in the hot season, a massive brick oven for the house contributes to the air conditioning of the room: due to the fact that it is always built on a separate foundation, excess heat is removed to the ground;

- a stove or a fireplace create a special atmosphere in the house and in many cases are an element that determines the style of the interior.

The fireplace creates a special atmosphere in the house and sets the style of the interior.

However, along with the advantages of furnace heating, there are also disadvantages:

- dimensions - the power of heating stoves for the home depends on their dimensions;

- inertia - a traditional oven for a brick house takes a very long time to warm up and enter the operating mode. True, modern cast-iron stoves for the home, fireplace stoves, potbelly stoves and buleryans are practically free from this drawback;

- high heat loss due to low efficiency (coefficient of performance) - a large amount of thermal energy goes through the chimney into the atmosphere;

- the inability to ensure uniform heating of the house. Hot air gradually displaces cold air, but this happens unevenly - the temperature may be too high near the stove and too low at a distance from it;

The principle of furnace heating - a hot furnace radiates thermal energy into the surrounding space (radiant heat exchange), then cold air is replaced by heated air (convection heat exchange)

- the need for constant maintenance - the stove requires laying firewood, cleaning ash pans from slag and chimneys from soot and debris, maintaining the combustion process, and regulating draft;

- control complexity - it is more difficult to control the process of fuel combustion in a furnace than in boilers;

- the need for good traction - traction is needed for intensive combustion, as well as for the removal of carbon monoxide;

- fire hazard - to ensure fire safety, insulation of chimneys is necessary, especially for a stove in a wooden house. An additional fire hazard factor is created by the fact that it is impossible to instantly stop the combustion process in the furnace;

- the need for constant replenishment and storage of fuel, as well as waste disposal: slag and ash.

To ensure the operation of the stove, its constant maintenance is required: laying firewood, cleaning ash pans and chimneys, monitoring the combustion process, adjusting draft

Brick PVC - features of operation

Often, water heating is combined not only with a fireplace or a modern wood-burning stove. For many, the best option would be to install a classic brick oven as a source of thermal energy. Properly expanding the capabilities of a brick oven with the help of a water circuit, it is possible to warm up not only the nearest living rooms, but the entire building. To increase the efficiency of a brick kiln, various designs of heat exchangers have been developed (coils and registers act as them). The operation of such a system in suburban housing has features, which include:

- Arrangement. To fold a high-quality stove, and then carry out the installation of water heating, highly qualified craftsmen will be required.

- The size.The overall traditional Russian stove takes up a lot of usable space and does not fit in every kitchen. An alternative for modest-sized rooms would be a Dutch or Swedish brick oven. Such designs are characterized by smaller dimensions, but full functionality.

Heat exchanger installation diagram

- Efficiency improvement. The maximum efficiency of the furnace does not reach 50%; half of the heat (and money) irretrievably disappears in the pipe. The device of a full-fledged water heating system allows increasing this parameter to 80-85%, which is comparable to the characteristics of industrial boilers operating on solid fuels.

- Inertia. Unlike electric boilers, it will take a certain amount of time to warm up a system tied to a brick oven.

- Care. Burning wood leaves behind ash and dust. The room in which the brick oven is located will have to be cleaned often and thoroughly.

- security requirements. Improper operation of a brick oven for a house with water heating is a threat not only to fire, but also to carbon monoxide poisoning.

About laying a brick oven with a water circuit in the following video:

PVC installation

If in a country cottage it is planned to install water heating from a brick stove (on wood), the heat exchanger is designed individually, for a specific stove. Such a device is practically beyond repair, therefore, a stove-maker is involved in the installation, who will be able to professionally perform all the work:

- Fabricate a heat exchanger and double check its quality before and after installation.

- Mount the heat exchanger at the desired stage (after the foundation is completed), then continue laying, observing certain rules.When installing the heat exchanger, compensation gaps are left, leaving 1-1.5 cm to the walls of the combustion chamber. Gaps that take into account thermal expansion are also needed when installing pipes.

- When installing a heat exchanger with pipes and for insulation, use only heat-resistant seals.

Steel pipes for the manufacture of heat exchangers

Recommendations for the placement of elements of the heating system

Elements of the heating system can hardly be called a decoration of a modern interior. Under this definition, only pipes that organically look in some industrial interiors can fit. In general, building codes and architectural guidelines recommend that parts be placed in areas that are hidden but accessible for repair and maintenance. Placement is subject to the following rules:

- The heat generator is placed in an isolated room with heating and good ventilation. The circulation pump must operate under the same conditions. Small boilers (up to 30 kW) can be installed in the kitchen, in the hallway, in the basement or in a warm heated outbuilding. Furnaces intended for residential premises are installed taking into account fire safety rules.

- The place for an open-type expansion tank is in the attic; they tend to place supply and collection pipelines along the main wall structures.

Compliance with the rules of operation helps the smooth operation of the system

- The main riser passes openly in the corners of the living quarters, in the attic it is covered with thermal insulation.

- Radiators are installed openly under window openings.They participate in room circulation by heating the cold air coming from the windows. Attempts to decorate radiators with decorative screens are undesirable, since they reduce the thermal efficiency of the system.

Conclusion

The device of water heating from a wood-burning stove is becoming an increasingly frequent choice in private housing construction. A brick oven, built by a professional stove-maker and competently integrated into the system, will be an effective design that performs all the tasks assigned to it, from utilitarian to aesthetic.

The principle of operation of the furnace with a water circuit

As a result, the full potential of the fuel is not used, and a person has to replenish the supply of coal or firewood very often.

Long-burning stoves mean all designs designed to slow down the burning process, “squeeze” all their capabilities out of firewood and automate the supply of fuel or increase the gap between manual bookmarks.

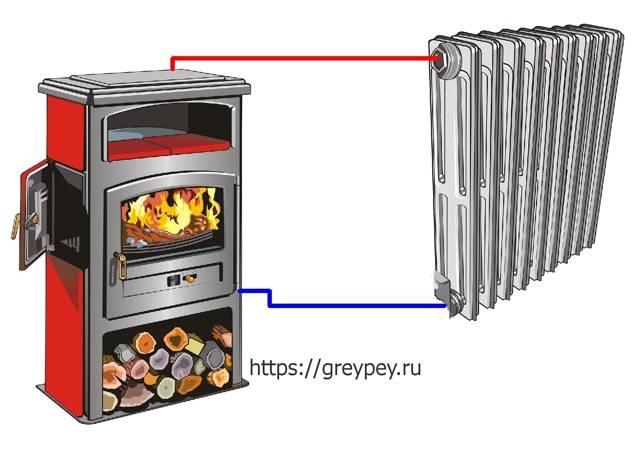

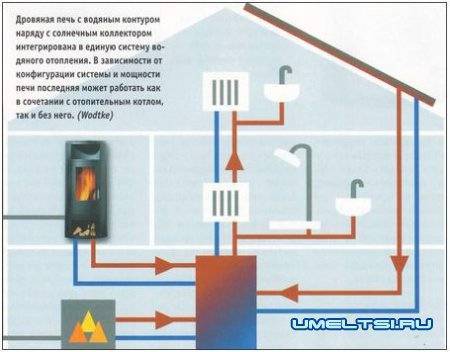

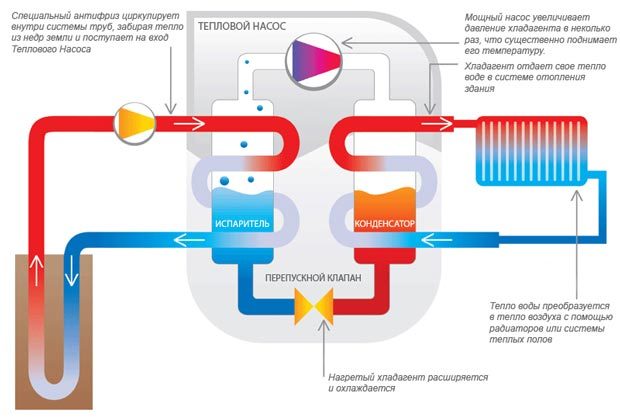

A water circuit is necessary when it comes to a large house. The transfer of energy to water through a heat exchanger allows you to distribute heat to all rooms and floors of the building. Otherwise, it would be possible to heat only those rooms with which the furnace body is in contact (convection and radiant heat).

Boiler installation

If your choice is on a combined system, then you need to pay special attention to some nuances. Kuznetsov furnaces with water heating can be made in various versions. It depends, first of all, on the materials used or on what type the main component of the heating system belongs to.

Also, do not forget that it is necessary to comply with some construction requirements or technical nuances, since even a minor mistake can lead to a malfunction of the entire heating system.

It depends, first of all, on the materials used or on what type the main component of the heating system belongs to. Also, do not forget that it is necessary to comply with some construction requirements or technical nuances, since even a minor mistake can lead to a malfunction of the entire heating system.

The boiler must be mounted in such a way that it is completely placed in the furnace. The boiler must be made in a U-shape, and the main material for manufacturing must be sheet metal or pipes. All components of the boiler are hollow, as their main purpose is the extraction of heat.

Attention also requires such nuances as:

- Dimensions. Some mistakenly believe that heating a large house requires a large device. However, this is not the case. To heat a house with an area of approximately 200 square meters. meters, you need a boiler with dimensions such as 75x50x30 cm. You can increase the performance of the boiler by 50% if you install a pump. Such a device is necessary to ensure forced circulation of the coolant.

- Boiler. The shape of this device is made in such a way as to heat the largest possible surface. The boiler must be installed in the very center of the hearth. If you comply with this condition, then you can achieve maximum efficiency of the stove with water heating.

Some Features

It is important that at least a small gap remains between the surface of the economy water heating furnace and the walls of the boiler.The most optimal gap distance will be 5-6mm

Advantages and disadvantages

Speaking about the advantages of this type of heating devices, I would like to note several factors.

- Sufficiently high capacity of the unit. Such stoves can heat houses with a large area.

- Reasonable prices, at least when compared with heating solid fuel boilers.

- Cheapness and availability of fuel.

- These are non-volatile installations.

There are, however, disadvantages.

- Low efficiency, again, when compared with boilers.

- It is simply impossible to automate stoves or fireplace inserts with a water circuit. Therefore, only manual control.

There is one more point that I would like to discuss separately. For those who do not know, there are two types of radiator heating in which the coolant circulates in different ways.

- With natural circulation.

- With forced.

In small buildings, the first option is most often used. That is, in the system, the coolant moves through the pipes under the influence of the laws of physics - hot water rises, cold water goes down. But in order for such a movement to occur, it is necessary to lower the heating device below the installation level of the radiators. Only in this case the heating system will work correctly.

Furnace in radiator heating system

Unfortunately, in this case, it is impossible to compare the stove with a water heating boiler. As a boiler, it cannot be lowered, for example, below the floor. After all, this heater is part of the interior, and besides, laying firewood very low will be inconvenient and unsafe. It turns out that the installed stoves with a water circuit are a heating element for a system with forced circulation of the coolant.

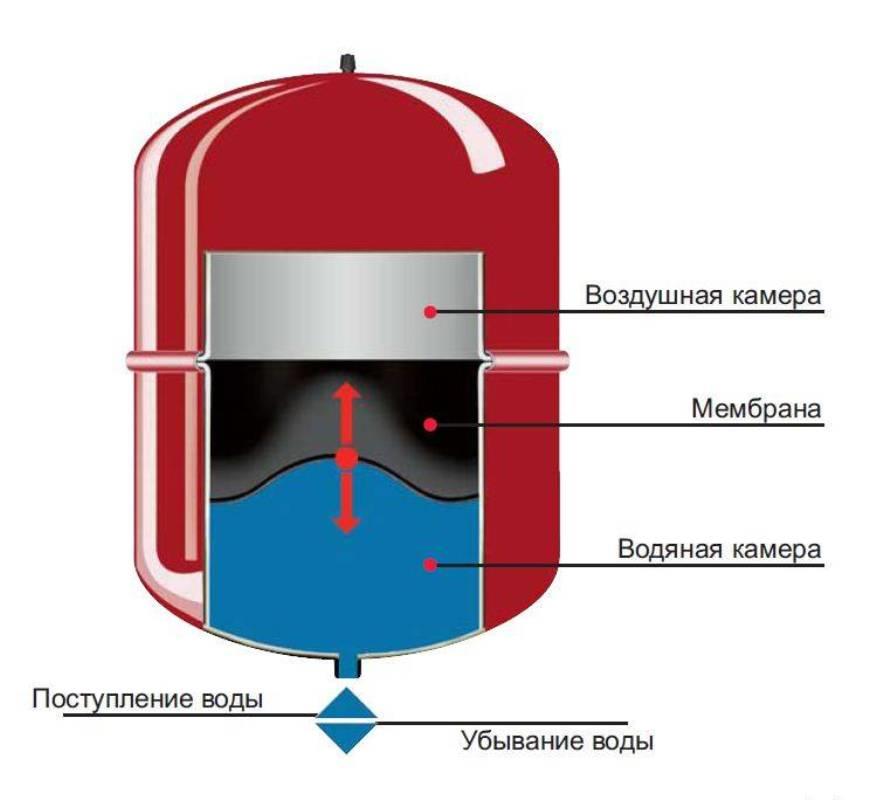

Therefore, when connecting this type of heater to a radiator heating system, it must be borne in mind that several more devices will definitely be included in this system. And this is a circulation pump and an expansion tank. In fact, we end up with a volatile heating system.

And one important piece of advice, which concerns the quality of operation of the entire heating system. The circulation pump must be installed in the return pipework near the stove. It is in this place that the coolant is the carrier of the lowest temperature. The thing is that the composition of the circulation pump includes rubber gaskets, cuffs and seals, which quickly become unusable under the influence of high temperature. We add that the expansion tank is installed right there near the pump.

Main types

When constructing stove water heating, you can go one of two ways:

- If the house already has a stove, then it is necessary to make a coil for installation inside the structure. This technique is rarely used due to its complexity. In this case, it is quite difficult to make a firebox for the existing dimensions of the structure.

- Construction of a thermal installation on its own, taking into account the size of the register. If everything is done correctly, the reliability and durability of the furnace is guaranteed. The inner dimensions of the shirt deserve special attention. Its thickness should start from 4-5 cm, in order to avoid the threat of boiling water. To protect yourself from problems with the circulation of the coolant, a suitable pump is usually mounted.

- When choosing the wall thickness, the calorific value of the selected fuel is taken as a guideline.If it is supposed to use only firewood as energy carriers, then 3 mm will be enough. If you plan to use coal, the thickness should be increased to 5 mm. The distance from the register for the furnace to its walls is recommended within 10-20 mm. This will completely neutralize the thermal expansion of metal elements, saving them from premature destruction.

With water circuit or without?

You can do without radiators in a small 1-2 room house if you ensure good air circulation or place a heater in both rooms. But even then it is difficult to keep the walls from freezing in the corners.

It is also worth refraining from installing a water circuit if the housing is periodically left without an owner (but there are alternative solutions for this - modern technology allows you to set economical modes that maintain t at around +5 ° C without human intervention).

The distribution of pipes with a coolant will allow you to heat all the rooms in the house, distributes heat more evenly. Most long-burning boilers are equipped with good built-in heat exchangers that are easy to connect to the heating system at home.