- How to ensure optimal temperature conditions

- Features of the organization of furnace heating with a water circuit

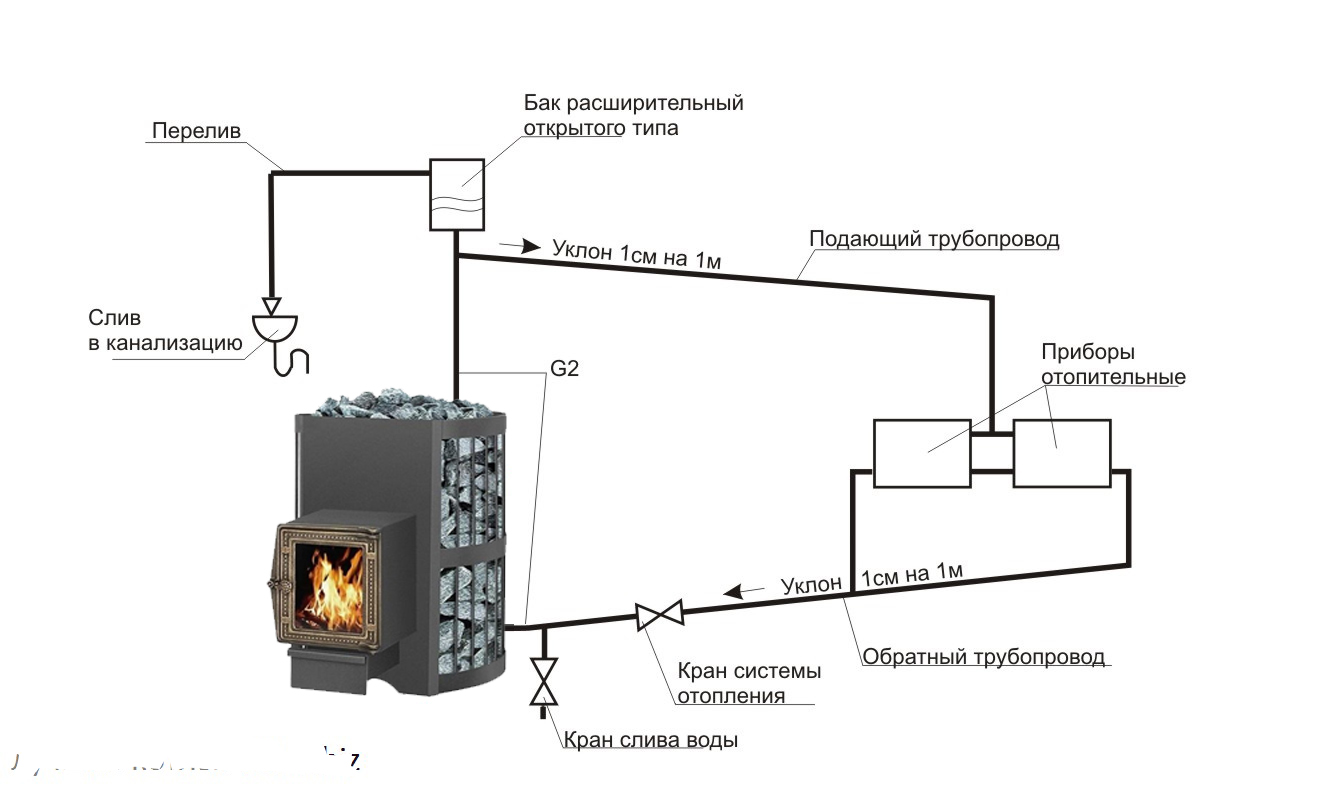

- Conditions for optimal system performance

- System Design Tips

- A few words about the register

- membrane tank

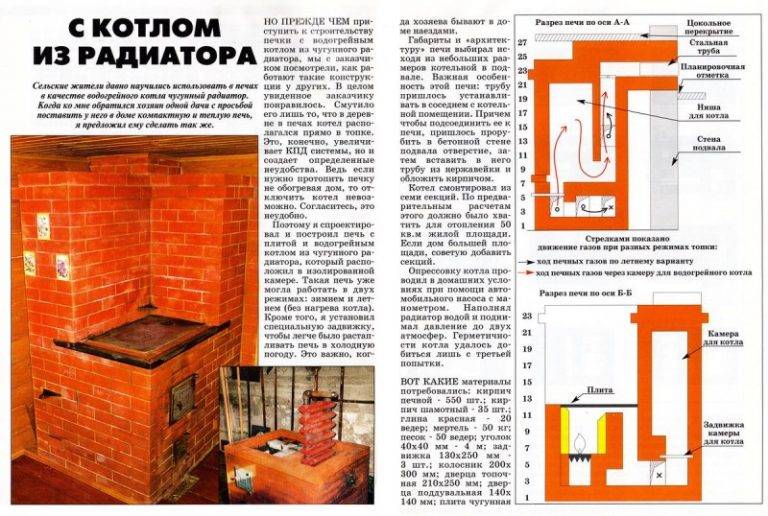

- Some moments of laying the furnace

- Making a heat exchanger with your own hands

- simple fixture

- Complex recuperator

- Stove heating with a water circuit: do-it-yourself installation

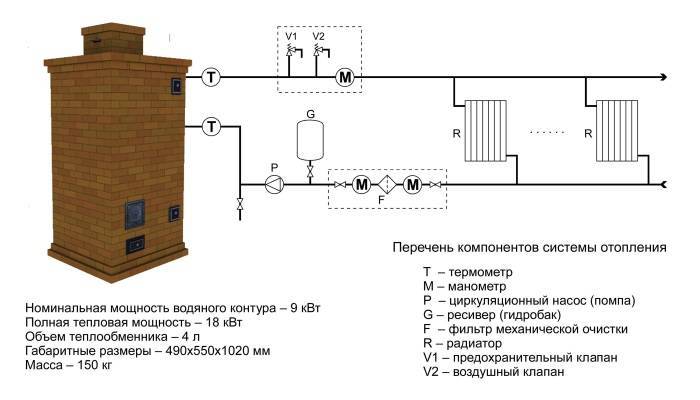

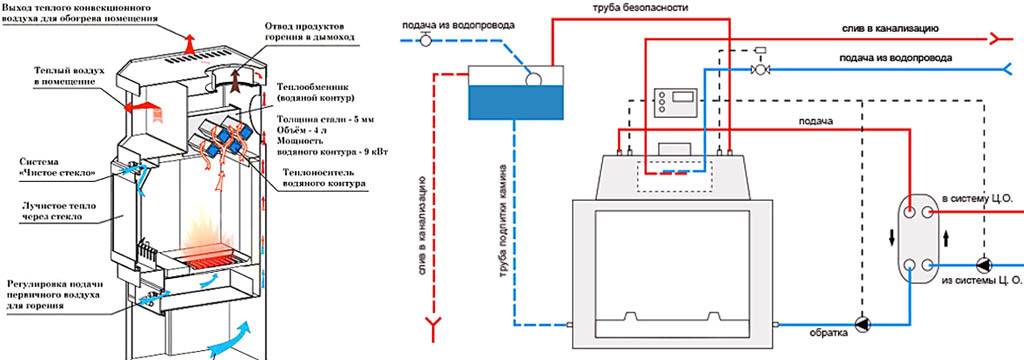

- Devices with a base in the form of a fireplace insert

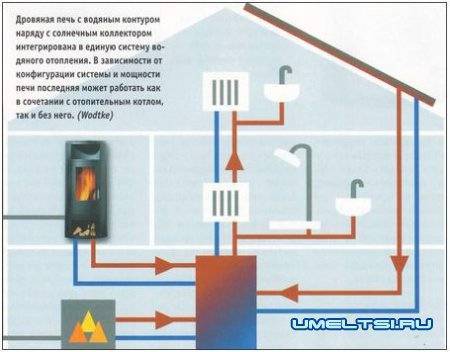

- Cast iron stoves with water circuit

- What should be considered when choosing and installing a furnace?

- Minuses

How to ensure optimal temperature conditions

When heating wooden houses with traditional stoves, there is a frank unevenness of heating. The warmest areas in such a house are located in the immediate vicinity of the brick heater. In the far corners, it can be quite chilly. The option with multiple ovens is very expensive. In addition, this leads to a significant reduction in living space.

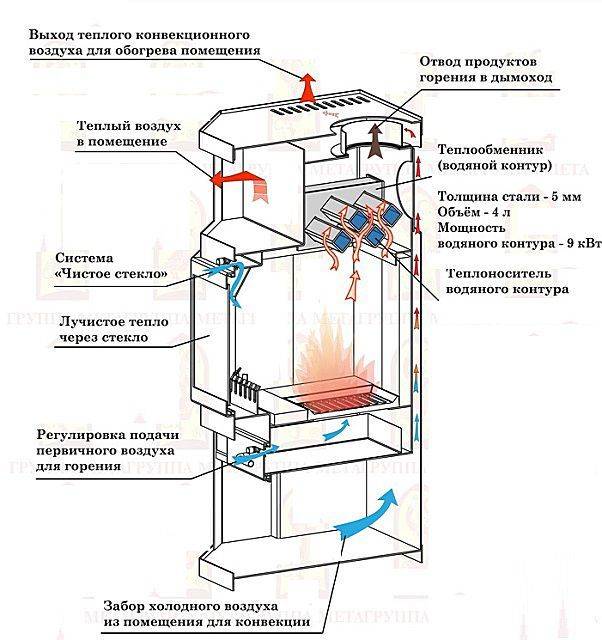

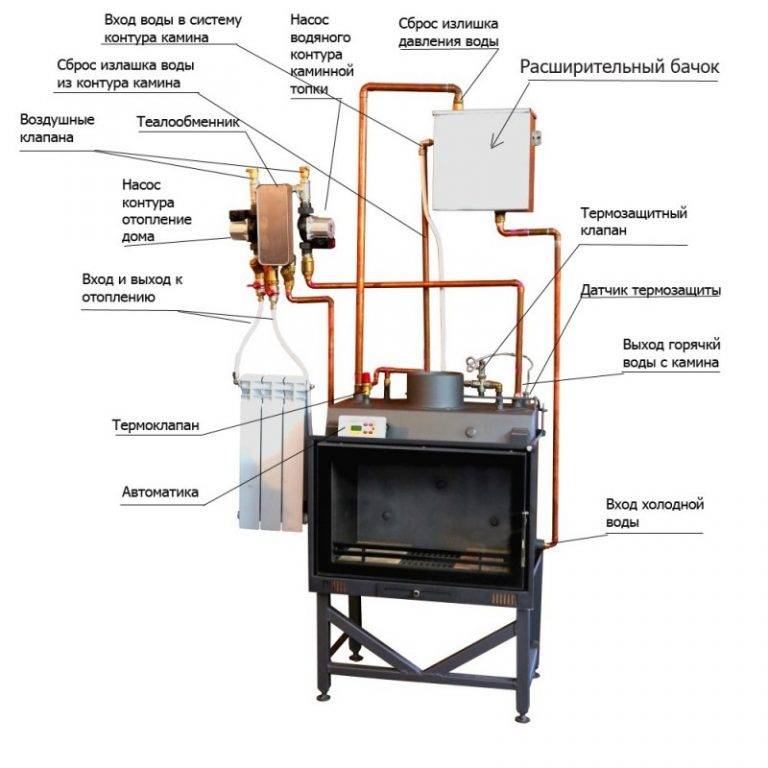

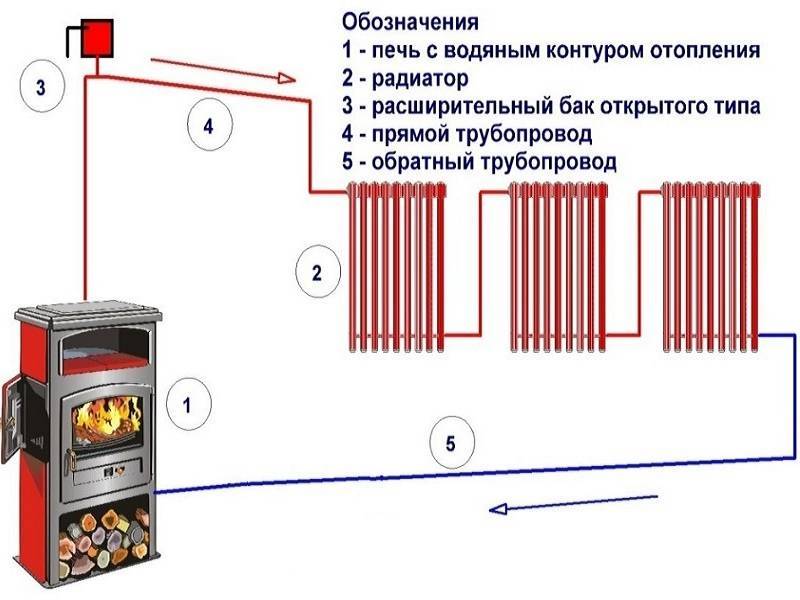

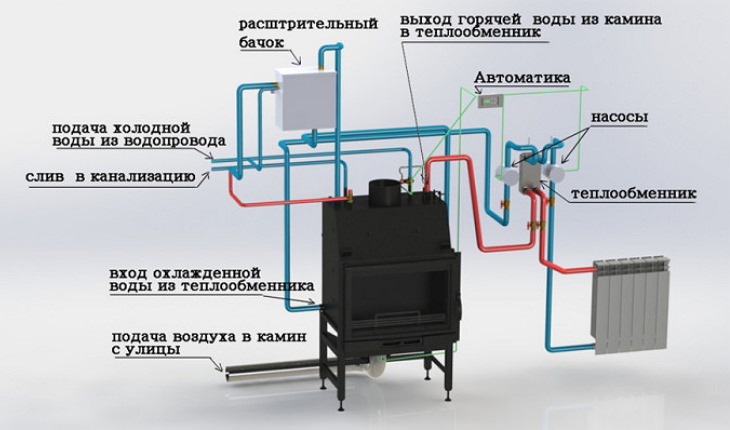

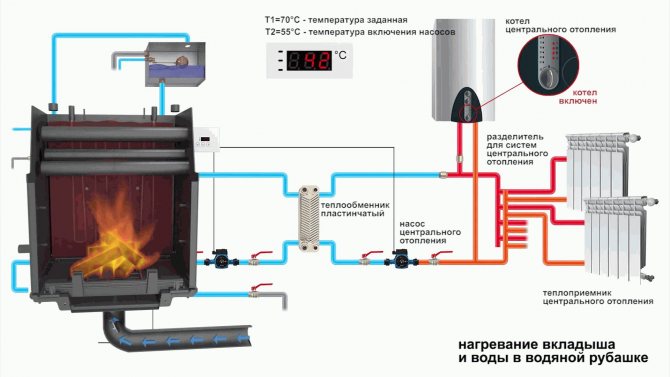

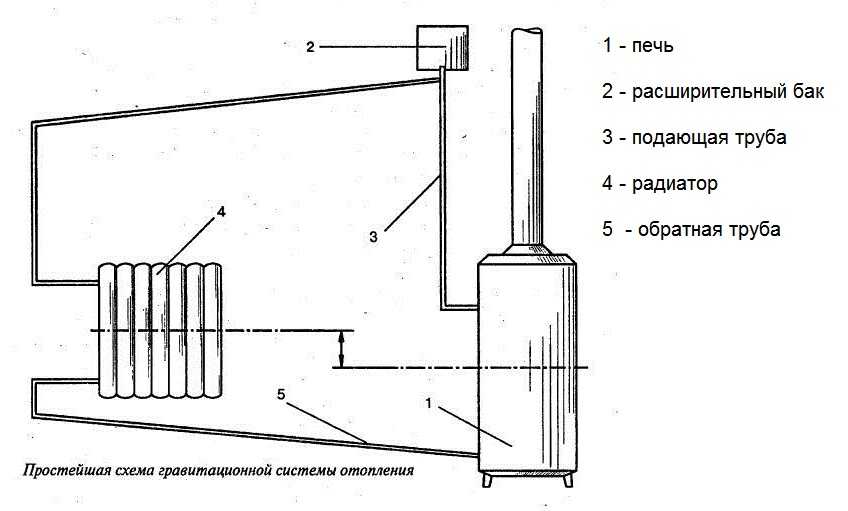

The most optimal solution is to use a combination of a brick stove with water heating. A similar experience already exists among many residents of our country who have managed to solve the problem of creating warmth and comfort in their homes. For this, a conventional brick oven is equipped with a heat exchanger that looks like a coil.The place of its installation is the firebox or the base of the chimney. Due to the heat generated, the water inside it begins to heat up, subsequently entering the radiator system. Thus, uniform heating of the dwelling is achieved.

Advantages of a stove with a heating circuit:

- Efficiency and uniformity of heating. This is facilitated by the location of radiators in different rooms and the constant heating of the coolant.

- Absolute independence. These designs do not depend on the presence of gas and electricity in the house. In this case, the owners themselves choose the time and intensity of heating.

- Possibility of independent maintenance of heating systems. For the implementation of these simple activities, the presence of specialists is not required.

- Profitability. Although such a system has to be launched every day, however, due to the cheapness of fuel, the costs of its operation are quite small.

Features of the organization of furnace heating with a water circuit

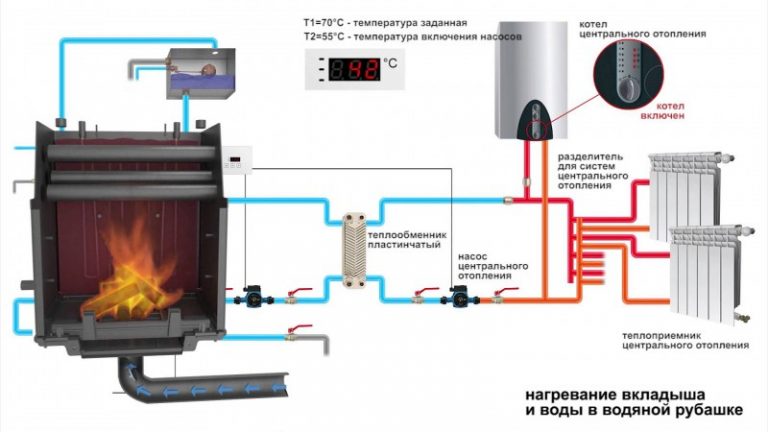

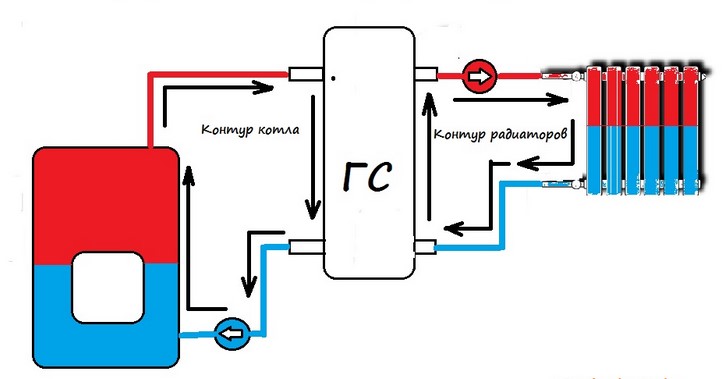

A water circuit stove combines the advantages of two types of heating and distributes heat evenly throughout all rooms. In fact, an ordinary stove becomes a kind of variation of a solid fuel boiler, only in addition to the coolant in the combined system, the body is also heated, which also provides heating.

At the end of burning, the batteries cool down quickly, but for some time the heat will come from the heated walls, which contributes to a smoother cooling of the room. A unit with a water circuit differs from a conventional wood-burning stove in the presence of a radiator (it is also a coil, boiler, heat exchanger).

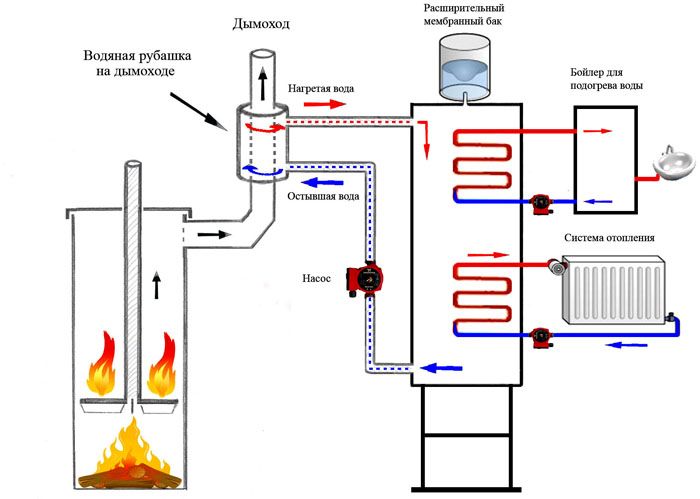

It can be installed directly into the furnace, but this is fraught with leaks or even an explosion caused by the boiling of the coolant.A safer option is to install the coolant in the chimney cap. In addition, this will increase the efficiency of the furnace, most of the hot vapors will go to heat the coolant, and not the street.

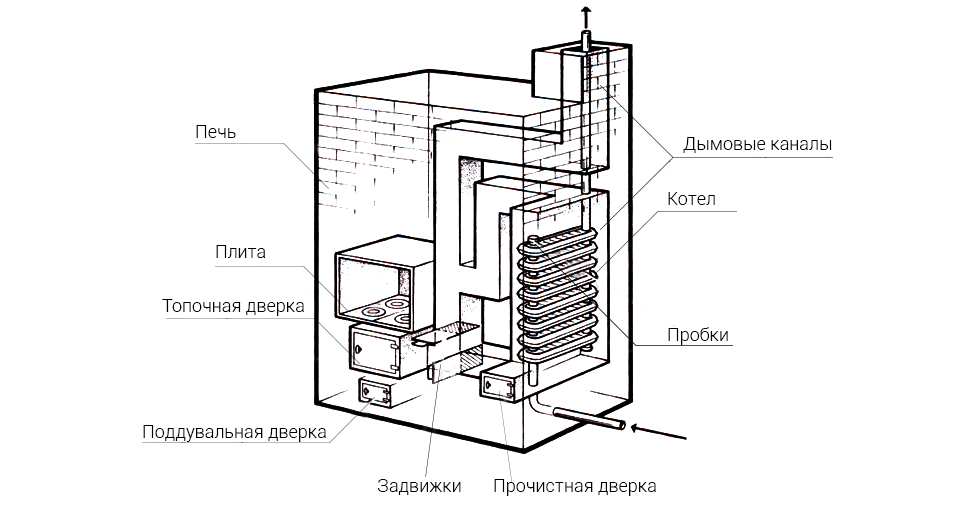

Furnace construction: heat exchanger installation

More often, a heat exchanger is made of a pipe or sheet steel with a wall thickness of at least 3-5 mm. The minimum value of the thermal jacket size is 4 mm. You can purchase a ready-made cast iron coil. In any case, the thermal gap between the furnace and the register must be at least 1-1.5 to ensure that it can be sufficiently expanded.

It is better to organize a stove heating system with a circuit even at the stage of planning a house, but only after weighing all the pros and cons. The stove model is chosen based on the size and layout of the heated housing. The water circuit is designed based on the rules for the arrangement of heating structures.

Sheet steel heat exchanger can be made independently

It is also possible to rebuild an existing furnace, but in such cases the heat exchanger often occupies a significant amount of the useful area of the furnace, which was not designed for it. To compensate for this factor, the heat exchanger is prepared in advance, and focusing on its dimensions, the furnace is rebuilt.

Conditions for optimal system performance

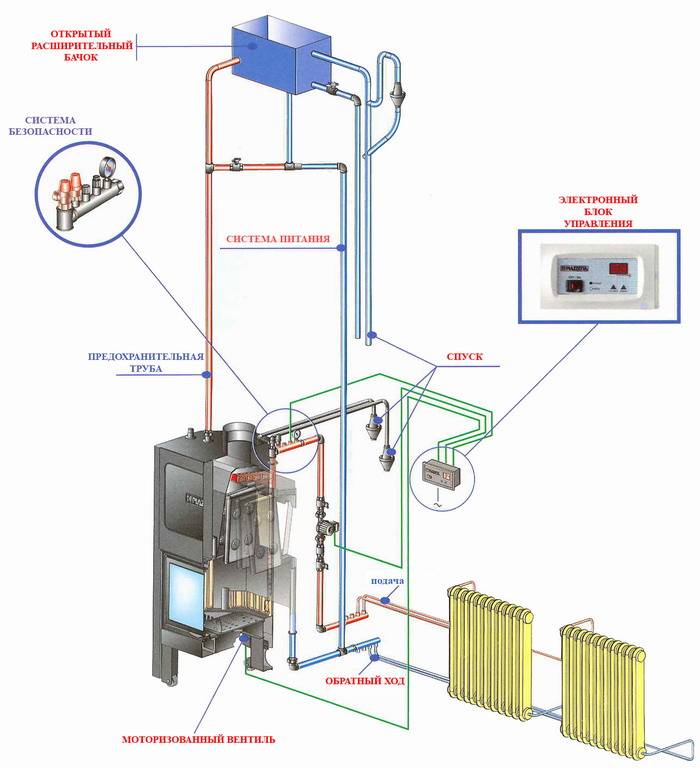

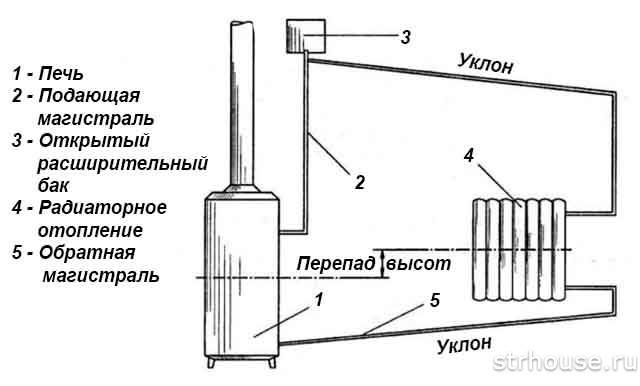

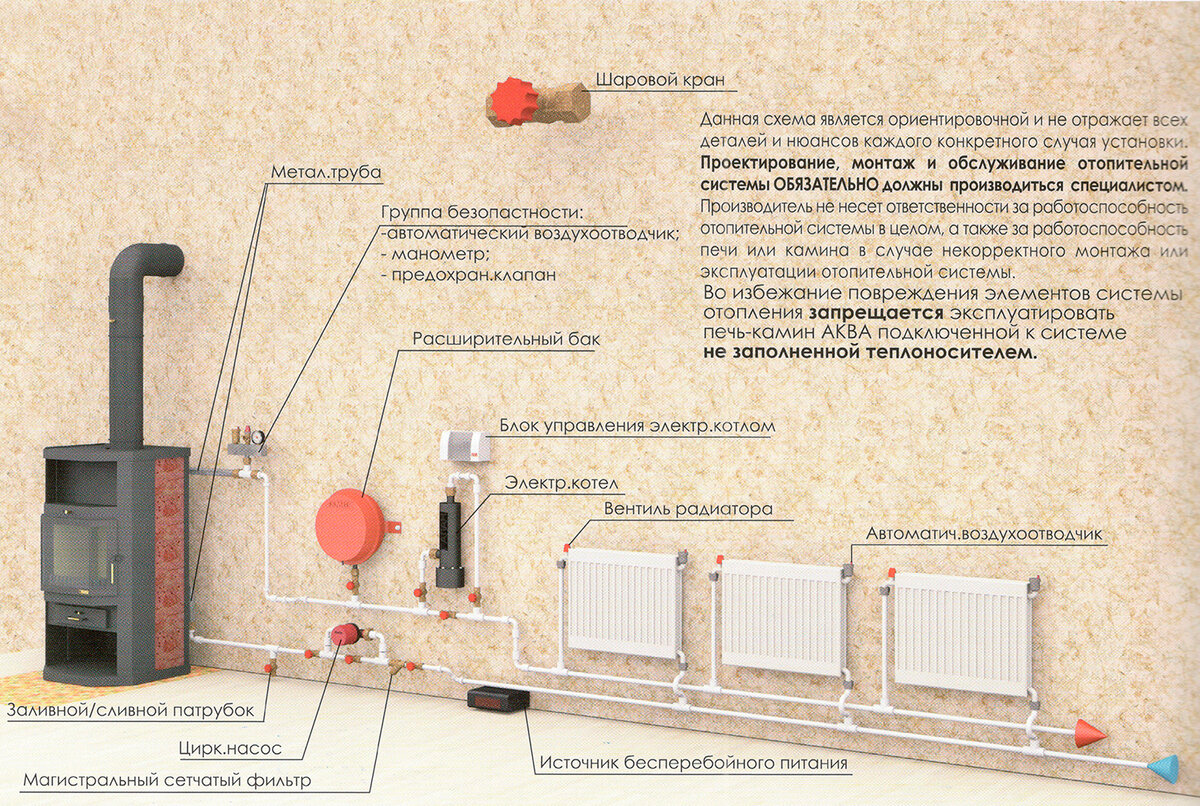

The system will be operational provided that there is a constant circulation of the coolant in the pipes. This is ensured by the obligatory slope, as well as the desirable installation of a circulation pump, which guarantees the necessary movement and prevents the water from boiling.

Small in size, but characterized by sufficient power, pumps guarantee good circulation. They are necessary especially with a large length of the heating system.The installation of such a pump is carried out on the return line, that is, on the pipe returning the coolant.

You should not rely only on the pump and install pipelines without a slope, since in the event of interruptions in the supply of electricity, boiling and failure of both the pump and the system itself can occur. In such cases, it is better to resort to installing expansion tanks that compensate for the expansion of water.

Design work is being completed by familiarization of specialists with the schemes. They will help eliminate errors leading to unstable operation of the water heating from stove. It is also an opportunity to avoid violations of security rules.

System Design Tips

At their core, such designs are the progenitors of modern solid fuel boilers. But unlike them, heat transfer is carried out not only through piping and a system of radiators, but also from the furnace itself.

Plus, do-it-yourself brick ovens with water heating are much easier and cheaper to mount than installing a solid fuel boiler.

A few words about the register

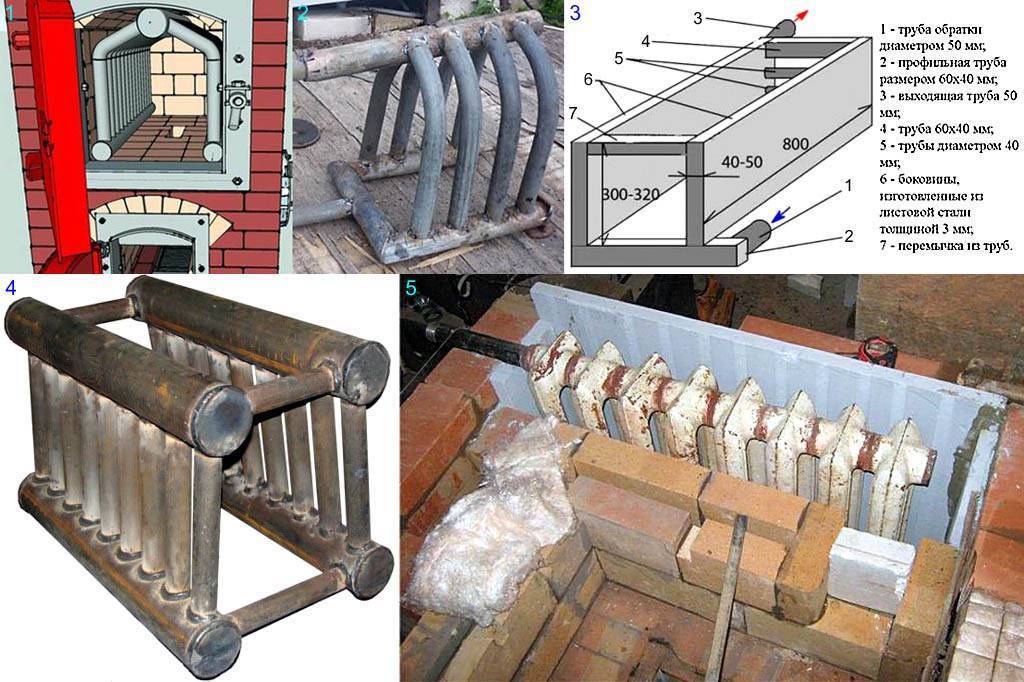

The metal register can, without exaggeration, be considered the heart of the entire heating system. This design is installed directly in the furnace itself and is responsible for the level of heating of the coolant.

Lateral arrangement of registers.

The simplest and most affordable option is to install a rectangular metal tank directly into the furnace. Such a tank is made of heat-resistant steel, with a thickness of 3 mm or more, most often from stainless steel.

To heat a house of 200 m², a tank 750 mm long, 500 mm wide and 300 mm high is enough.The conclusion is made on top of the structure, the return line cuts into the lower part of the tank.

Registers welded from a stainless steel pipe with a wall thickness of at least 3 mm are considered more functional. The heating area in this case increases many times, hence the efficiency of the system is disproportionately higher.

Tip: it is not difficult to find cast-iron registers on the market now, according to most experts, they are the best option. Firstly, cast iron is not very susceptible to corrosion, practically does not burn through, and most importantly, this material is considered the best heat accumulator.

Stainless steel registers.

During installation, pay attention to the location of the register. The more contact with fire, the higher the performance

But at the same time, regardless of the configuration of the tank, there must be a compensation gap of at least 5 mm between it and the furnace walls. Otherwise, during heating, the metal will begin to expand and the walls of the furnace will crack.

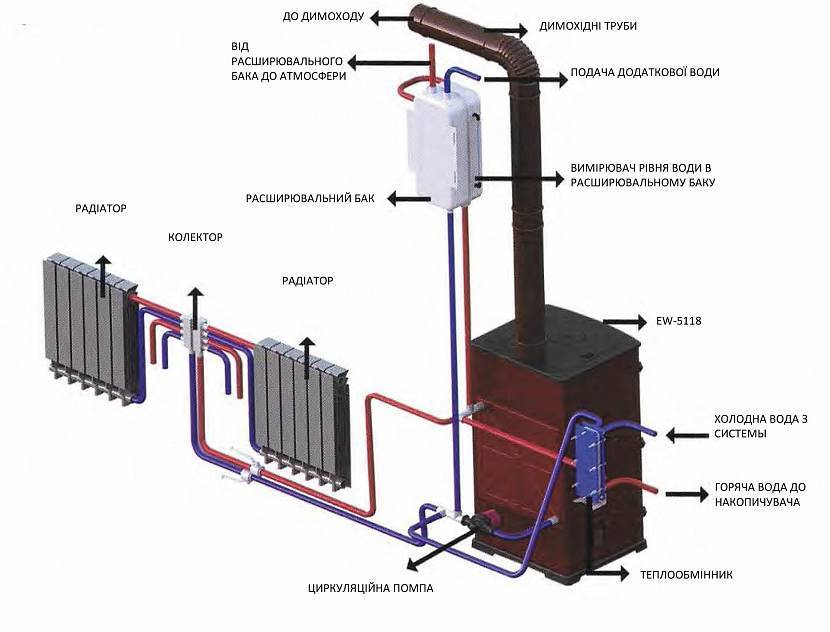

membrane tank

Installing a register in the firebox is only part of the matter; it is equally important to properly equip the pipe layout. Any heating system built according to this principle must be equipped with an expansion or membrane tank.

As a rule, it is installed on the return pipe, but this is not important, some masters prefer to mount it at the highest point of the system.

The principle of operation of the membrane tank.

In a system with natural circulation of the coolant, its function is performed by an ordinary metal container. But now, in most cases, the owners prefer to install circulation pumps. It is desirable to mount a real membrane tank in such a system.

The device is a sealed metal container, in the upper part of which there is a valve. Air is forced through the valve, creating excess pressure in the system. When the temperature rises, the coolant expands proportionally, squeezing out the excess into the membrane tank. During the cooling process, the air that presses on the membrane compensates for the pressure drop in the system.

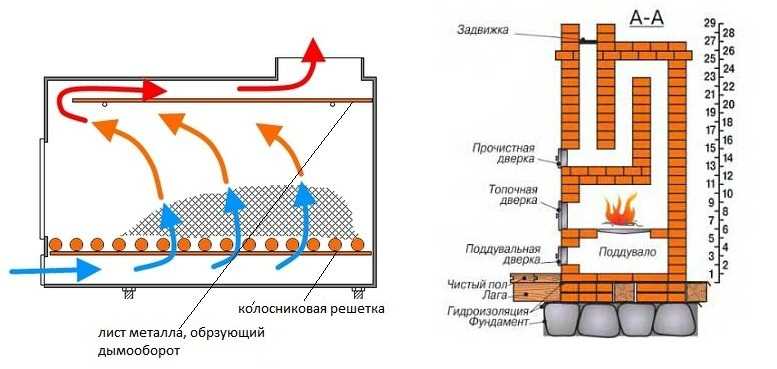

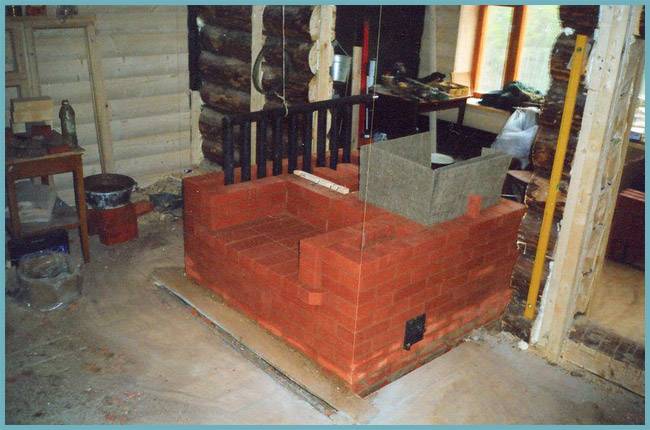

Some moments of laying the furnace

As mentioned earlier, do-it-yourself brick ovens with water heating can be folded, but if you are not confident in your abilities, it is still better to invite a specialist.

Although in any case, there are general rules that are not desirable to break.

- All brick ovens are made of solid red brick. Hollow brick is not desirable to use even for cladding. The fact is that hollow blocks are a heat insulator, and in this case it can only do harm.

- If it is supposed to heat with firewood, then the firebox can be folded from ordinary burnt bricks. But if there is a possibility of using coke or coal of high grades, such as anthracite, then we would advise you to build a firebox from a special fireclay brick, which is used for the construction of blast furnaces.

- There is no need to save on wall thickness, in addition to the weight of the furnace itself, the load from the registers will also be added here.

- And yet, any stone building needs a reliable foundation, as for stoves, here the foundation should be laid separately and in no case should be in contact with the common foundation of the house, the minimum distance between them should be 50 - 100 mm.

circulation pump in the system.

The video shows some of the intricacies of installing the system.

In this case, we were talking about heating the house.But it would not be out of place to note that if a metal water tank is inserted into the system in parallel, then it will play the role of a passive boiler, as a result of which hot water for domestic needs will still appear in the house.

Making a heat exchanger with your own hands

You can weld a flat heat exchanger from sheets of steel or stainless steel

It is allowed to build in flat, air and tubular heat exchangers with your own hands

When constructing a device, it is necessary to take into account the labor costs and the cost of the project.

simple fixture

A flat heat exchanger increases the efficiency of the stove; it is installed vertically or horizontally in the boiler. It is easy to remove soot and soot from the element, and due to the large volume it can be adapted to the needs of hot water supply.

The plate heat exchanger looks like a large diameter pipe, inside of which there is a smaller one. Water moves along it in a heated state, the cooling process takes place in a large pipe.

Do-it-yourself design is made of copper tubes. One should be larger than the other by 4 mm in diameter. The work is done like this:

- Fastening by welding of a lateral tee on two parties of a tube outside.

- Installation of a smaller diameter pipe.

- Welding the element to the ends of a large tube in a pre-fixed position.

- Installation of short tubes at the outlet to tees. They are needed for the movement of the coolant.

- Connection of parts by segments with alternate welding of tees to the side parts in the form of a snake.

Complex recuperator

More complex types of exchangers made of pipes and flat steel sheets

A heat exchange boiler for furnace heating looks like a container with pipes and a heater. It consists of two sectors with mutual heating. The coolant circulates, getting into the closed circuit of the tank, it heats up to 180 degrees. Water is directed to the main line after passing through small tubes.

To weld the heat exchanger yourself, you will need the following materials:

- ready-made tank with a capacity of 90 to 110 liters;

- sheet steel 2.5-3 mm thick, if the tank is made by hand;

- anode;

- 2 copper pipes up to 4 m long for heating elements;

- heating power control device.

Installing the heat exchanger in the furnace - the inlet and outlet pipes are marked with numbers

Before starting work, it is necessary to make a drawing of the finished product, and then proceed to assembly:

- Install the tank at a height of 1 m from the floor and 3 m from the oven.

- Make two holes on the right side of the stove and on the top left.

- Bring the outlet for water heaters from below, tilting it by 2-3 degrees.

- Connect the top outlet in the opposite direction with a slope of 20 degrees.

- Insert 2 drain taps into the lower outlet outlet - for the tank and for the system.

- Hermetically solder the holes for uniform heating of the rooms.

- Bend the copper tube into a spiral.

- Install the finished coil into the tank, bring the ends out and fix them.

- Attach threaded fittings to the end of the coil.

- Connect the finished power regulator to the pipe.

- Throw power terminals on the thermostat, and then wires.

- Install an anode to prevent wear of the tank from temperature fluctuations.

- Seal the seams and all parts with a special tool.

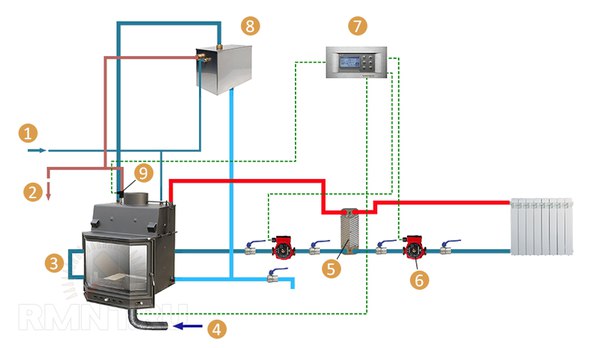

Stove heating with a water circuit: do-it-yourself installation

To install a heating system with your own hands, it will not be superfluous to already have experience in arranging fireplaces or laying bricks. In the absence of the necessary experience and skills, you should entrust the installation of the heating system to professionals, since the breakdown of any heating mechanism is potentially dangerous.

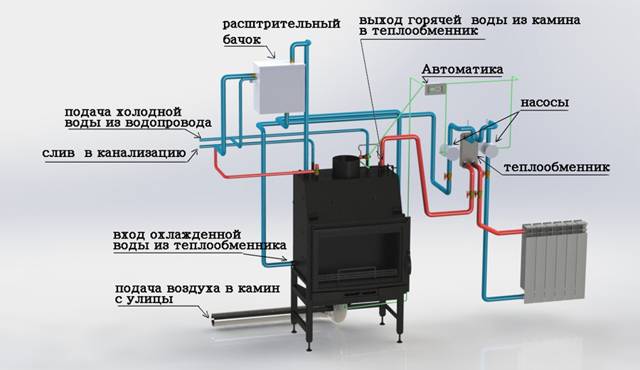

The most important detail in the finished design is the heat exchanger. You can buy it in the store, or you can make it yourself from pipes and sheets of iron. You can introduce a coil into an existing stove, or install a heat exchanger and later lay the fireplace masonry.

The walls of the coil must be at least five millimeters. When building a coal fireplace, they need to be made even thicker, otherwise they may burn out. In the heat exchanger, the thickness of the water layer must be more than four centimeters, otherwise it may begin to boil. It cannot be installed close to the furnace wall due to the expansion of the coil from the resulting heat - it is better to leave a gap of two centimeters.

The most important thing is to think over the nuances of the fire safety of your heating. Facing should be done with materials that are not amenable to fire, for example, brick. Between the fireplace and partitions made of wood, it is necessary to leave air gaps in order to avoid overheating and subsequent fire.

Between the fireplace and partitions made of wood, it is necessary to leave air gaps in order to avoid overheating and subsequent fire.

Detailed diagrams of heating systems can be found on the Internet. It is better not to take on a boiler with a water circuit for heating a house if there is no self-confidence.

Another way of heating is heating convectors - devices that allow you to heat almost any room.Learn how to properly install your bathtub here.

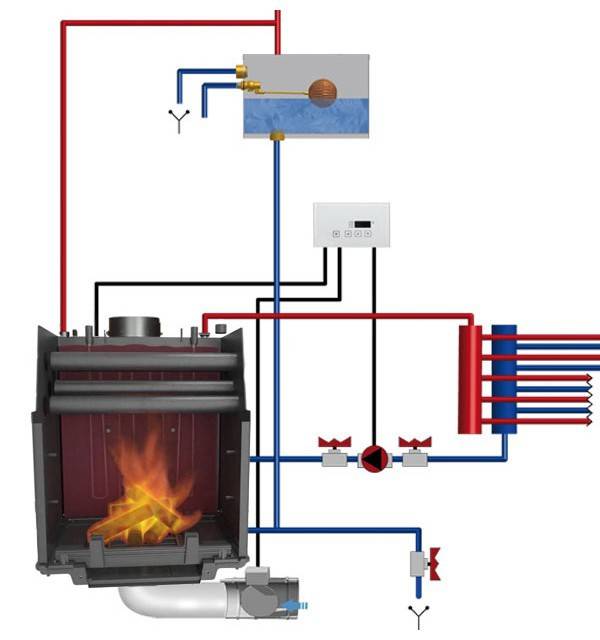

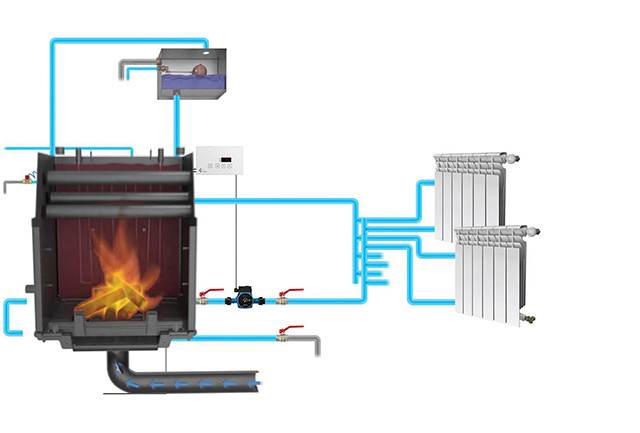

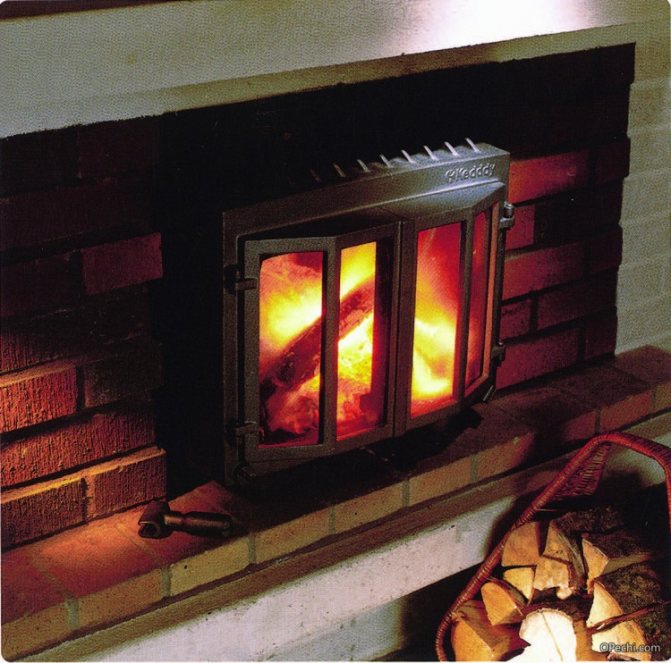

Devices with a base in the form of a fireplace insert

Externally, such a fireplace stove with a water circuit looks more like a classic fireplace, but in fact it is a more complex element for heating, which makes it possible to seriously increase the efficiency of the process. After all, in addition to heating the water heating coolant, effective air convection is ensured, caused by the technology and design of the device case.

There are two types of such fireboxes:

closed;

Closed hearth stove

open.

Fireplace with an open firebox The device has a heat exchanger that allows you to transfer the energy received from the firebox in the process of burning fuel (wood) to the heating system with a coolant, and therefore through pipes to radiators that can be placed in all rooms of the house.

The fire chamber is in the case made of a natural stone or a brick.

This design of the fireplace stove has obvious advantages:

- Attractive appearance. The device is very reminiscent of a classic fireplace, giving the room presentability.

- The firebox is much cheaper than the finished device, and you can make a brick case with your own hands.

- The dimensions of the metal firebox almost completely correspond to the dimensions of the classic fireplace.

Not without drawbacks:

- for the arrangement of such stoves, fireplaces require a reliable foundation;

- non-transportable - to move even to the next room, you will need to disassemble the masonry;

- lower efficiency than ready-made devices;

- require quite a lot of space.

If you take into account these disadvantages in advance, the operation of fireplace stoves will not bring inconvenience.

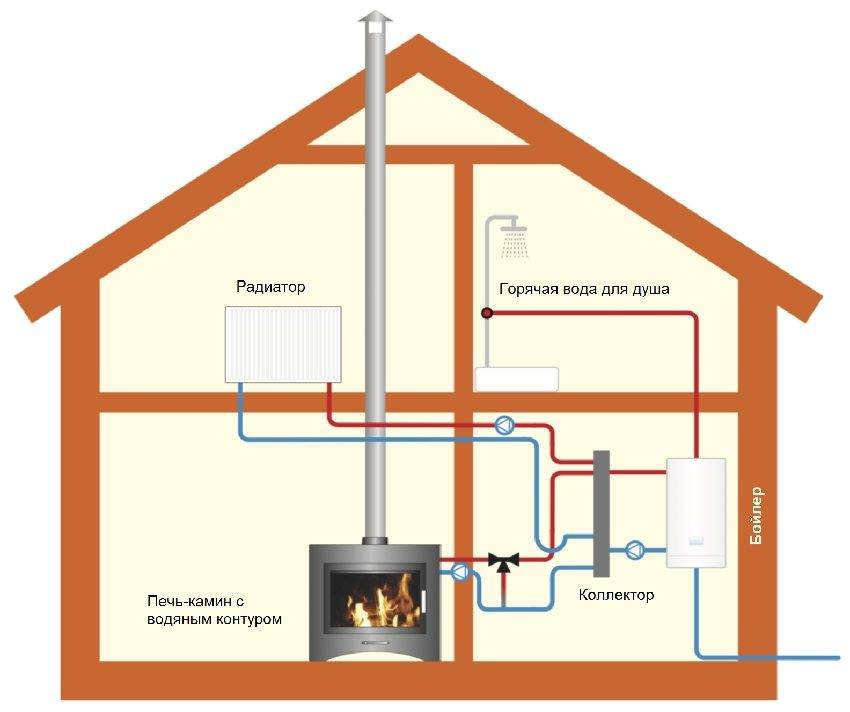

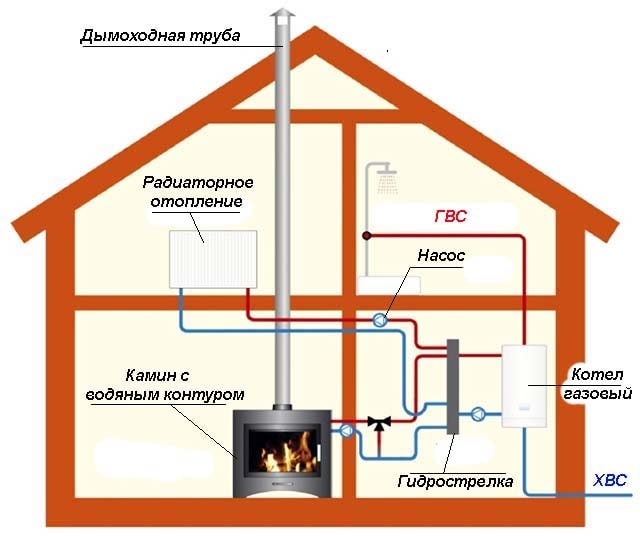

Cast iron stoves with water circuit

Cast iron stoves with a water circuit are produced in different capacities and are designed for heating of various areas. Some of them are able to heat a two- and three-story house. The device of the heating circuit is made according to the same system as for brick ovens.

Cast iron long burning stove with heating circuit

Furnaces are made of cast iron and combined type, i.e. having electric heating, which turns on automatically when the temperature of smoldering firewood decreases. This combination of oven functions will always help maintain the heating system at the desired temperature.

One of the possible heating schemes for a two-story private house

Cast iron boilers-furnaces can also be provided for a double-circuit heating system, i.e. In addition to the warmth in the house, the owners will also have heated water.

What should be considered when choosing and installing a furnace?

When choosing which heating stove will be installed in the house, you need to correctly formulate the requirements for it, and, based on them, purchase or build a heating device.

- The warming of the entire structure of a brick oven is very important. Therefore, if it is decided to install such a furnace, you need to choose the right project and ensure the perfect construction of the building.

- The efficiency of the heating system will also depend on the design and layout of the water circuit, as well as the choice of radiators for the heating system. There are furnace schemes that can operate in summer and winter mode - this factor also contributes to the economical operation of the device.

- Part of the savings can be attributed to the long cooling of the furnace, which will use less fuel.

- Ease of operation and maintenance is important.

- The design must comply with all fire safety regulations for its location and installation.

- A properly executed design will have the required traction, which will protect the house from carbon monoxide entering the premises.

- The furnace must be designed for a long period of operation.

- Of course, it would be nice if the oven became a real decoration of the house, and not only functional from a practical point of view.

Minuses

Along with the positive aspects, the furnaces have a number of disadvantages.

First, the heat will not spread evenly, the corners of the room warm up worse.

Secondly, the oven occupies a fairly large area, leaving little free space.

Thirdly, it is difficult to heat the whole house with one stove, especially if it is large and if there are many rooms in it.

In addition, there is no possibility of establishing and maintaining the desired temperature, if we talk about specific rooms.

Also, the efficiency of the furnace rarely exceeds 50 percent, while the gas boiler produces up to 90 percent of heat.

The disadvantages include the fact that the oven needs to be serviced quite often. Kindling, adjusting dampers, cleaning coals - this is a necessary list of actions that need to be repeated regularly. This takes time and requires some effort.

Thus, this heating device has disadvantages, but they can be completely eliminated. In addition, the water circuit allows you to overcome some of them.