- Brick PVC - features of operation

- PVC installation

- Recommendations for the placement of elements of the heating system

- Conclusion

- Advantages and disadvantages

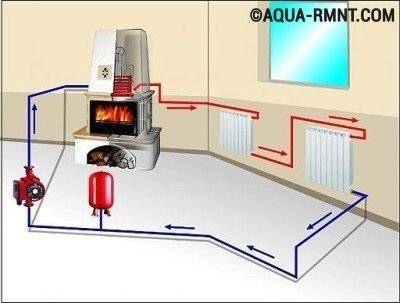

- Characteristic features of heating based on the stove

- Stove heating with coolant

- The device of the furnace with a water boiler

- Register: purpose and device

- Furnace with a water circuit for home heating: advantages

- Conventional stove heating: advantages and disadvantages

- The choice of coolant

- Mounting

- Features of furnaces with a water circuit

- 5 Do-it-yourself erection

- Criteria for the selection of long-burning furnaces

- How the system works

Brick PVC - features of operation

Often, water heating is combined not only with a fireplace or a modern wood-burning stove. For many, the best option would be to install a classic brick oven as a source of thermal energy. Properly expanding the capabilities of a brick oven with the help of a water circuit, it is possible to warm up not only the nearest living rooms, but the entire building. To increase the efficiency of a brick kiln, various designs of heat exchangers have been developed (coils and registers act as them). The operation of such a system in suburban housing has features, which include:

- Arrangement.To fold a high-quality stove, and then carry out the installation of water heating, highly qualified craftsmen will be required.

- The size. The overall traditional Russian stove takes up a lot of usable space and does not fit in every kitchen. An alternative for modest-sized rooms would be a Dutch or Swedish brick oven. Such designs are characterized by smaller dimensions, but full functionality.

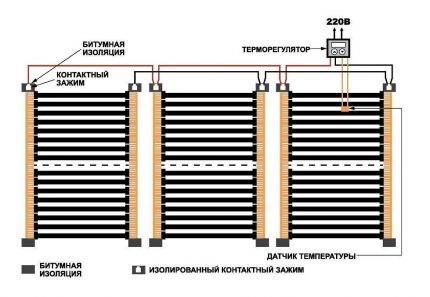

Heat exchanger installation diagram

- Efficiency improvement. The maximum efficiency of the furnace does not reach 50%; half of the heat (and money) irretrievably disappears in the pipe. The device of a full-fledged water heating system allows increasing this parameter to 80-85%, which is comparable to the characteristics of industrial boilers operating on solid fuels.

- Inertia. Unlike electric boilers, it will take a certain amount of time to warm up a system tied to a brick oven.

- Care. Burning wood leaves behind ash and dust. The room in which the brick oven is located will have to be cleaned often and thoroughly.

- security requirements. Improper operation of a brick oven for a house with water heating is a threat not only to fire, but also to carbon monoxide poisoning.

About laying a brick oven with a water circuit in the following video:

PVC installation

If in a country cottage it is planned to install water heating from a brick stove (on wood), the heat exchanger is designed individually, for a specific stove. Such a device is practically beyond repair, therefore, a stove-maker is involved in the installation, who will be able to professionally perform all the work:

- Fabricate a heat exchanger and double check its quality before and after installation.

- Mount the heat exchanger at the desired stage (after the foundation is completed), then continue laying, observing certain rules. When installing the heat exchanger, compensation gaps are left, leaving 1-1.5 cm to the walls of the combustion chamber. Gaps that take into account thermal expansion are also needed when installing pipes.

- When installing a heat exchanger with pipes and for insulation, use only heat-resistant seals.

Steel pipes for the manufacture of heat exchangers

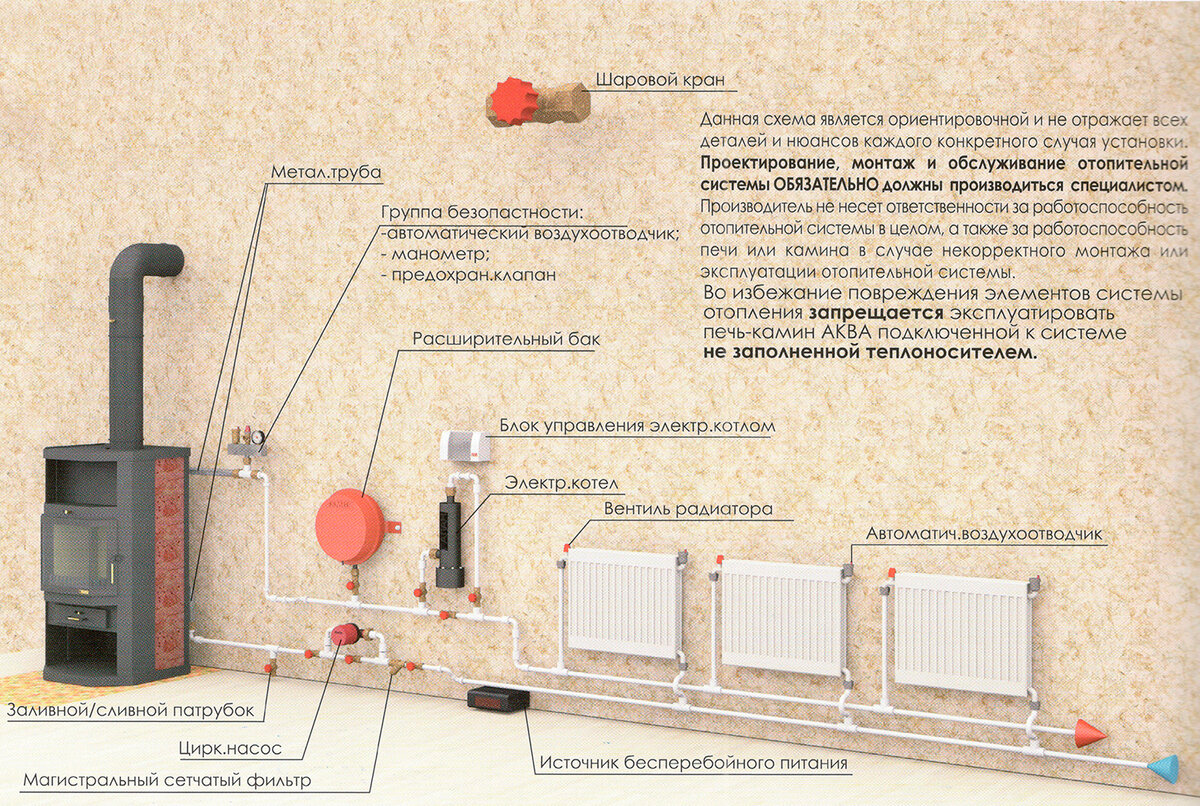

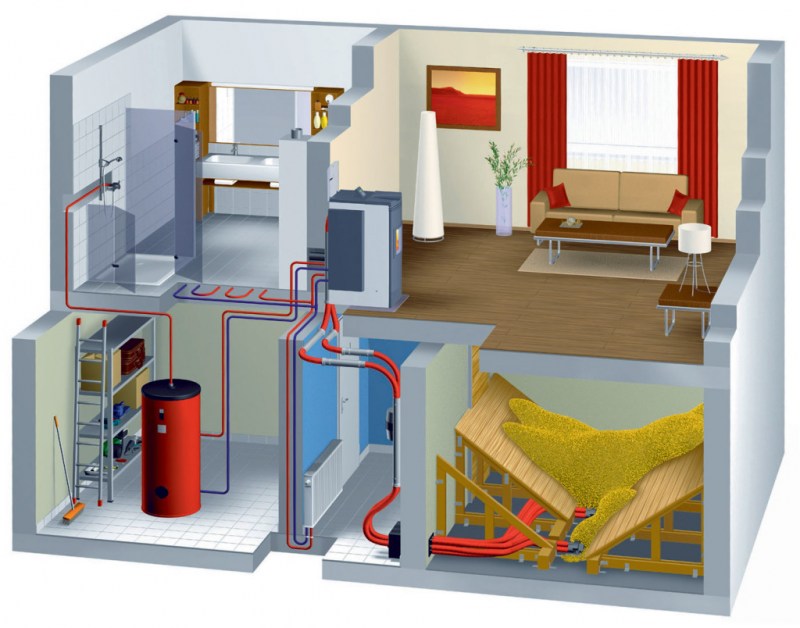

Recommendations for the placement of elements of the heating system

Elements of the heating system can hardly be called a decoration of a modern interior. Under this definition, only pipes that organically look in some industrial interiors can fit. In general, building codes and architectural guidelines recommend that parts be placed in areas that are hidden but accessible for repair and maintenance. Placement is subject to the following rules:

- The heat generator is placed in an isolated room with heating and good ventilation. The circulation pump must operate under the same conditions. Small boilers (up to 30 kW) can be installed in the kitchen, in the hallway, in the basement or in a warm heated outbuilding. Furnaces intended for residential premises are installed taking into account fire safety rules.

- The place for an open-type expansion tank is in the attic; they tend to place supply and collection pipelines along the main wall structures.

Compliance with the rules of operation helps the smooth operation of the system

- The main riser passes openly in the corners of the living quarters, in the attic it is covered with thermal insulation.

- Radiators are installed openly under window openings.They participate in room circulation by heating the cold air coming from the windows. Attempts to decorate radiators with decorative screens are undesirable, since they reduce the thermal efficiency of the system.

Conclusion

The device of water heating from a wood-burning stove is becoming an increasingly frequent choice in private housing construction. A brick oven, built by a professional stove-maker and competently integrated into the system, will be an effective design that performs all the tasks assigned to it, from utilitarian to aesthetic.

Advantages and disadvantages

Designs with a built-in heat exchanger have many advantages:

- The system is energy efficient and economical. Brickwork will not require serious financial investments, the costs for pipes and radiators will be in any case, and the heat exchanger is an order of magnitude cheaper than finished boilers. When operating the stove, the cost of heating the house will amount to several thousand rubles for the purchase of firewood for the winter period.

- The design of a brick oven hides unsightly elements; if desired, a fireplace or decor can be added to the system.

- Space heating does not depend on the location of the structure, radiators are installed anywhere

- The brick oven cools down for a long time, the water circuit will be hot for several more hours after the firewood burns out.

Some publications refer to the advantages of the water circuit system as the possibility of installing it in an already finished furnace, which in principle is possible, but in practice this option is associated with a large number of problems to be solved.

Dismantling and subsequent assembly of the furnace is the most necessary thing to do. The price of correcting an incorrectly installed register is comparable to the cost of a new stove, so contact professionals for such work.

The disadvantage of this design is a continuation of its advantages, in order to make a stove with heat exchangers yourself, experience is needed, both in laying bricks and in installing heating systems. If experience comes with years and the amount of material studied, then when building a furnace with a water circuit, its disadvantages should be taken into account:

The hearth is a fire hazardous element, it is necessary to take measures to prevent fire from entering flammable objects; The stove occupies a significant area of the house, design the rooms in advance, include a large heating element in the design of the room; Near the stove, the temperature will always be higher than in the rest of the room; The heating process of the furnace cannot be stopped instantly. If you are using a closed loop system with a circulating pump, a power outage (even a short one of a few minutes) and the pump stop will cause the water in the heat exchanger to boil. To avoid this, provide a combined system for the movement of water in the circuit. If the heating system is used irregularly, water must be drained from it, which leads to premature wear of the entire structure. Otherwise, the water will freeze, which will lead to the destruction of the entire complex of devices. Do not light the stove without water in the circuit. This will lead to the destruction of the register and the reconstruction of the furnace in order to use the furnace in the summer, without "turning on" the battery, use the original design of the installation of heat exchangers

There is a risk of carbon monoxide poisoning, as with all solid fuel heating products, special attention must be paid to the correct manufacture of the chimney

Making a heating system in the house based on a furnace with a heat exchanger and batteries is a cost-effective solution, but design and construction must be approached competently, taking into account all the nuances of the work.

Characteristic features of heating based on the stove

Let's consider in more detail characteristic features of heating based on the stove.

Stove heating is the norm for Russian villages, the reliability and practicality of which has been proven for centuries. And today in many village houses there are ovens with a stove for cooking food and a hearth for baking bread.

_

Norm — a provision that establishes quantitative or qualitative criteria to be satisfied. (SNiP 10-01-94)

Heating — maintenance of normalized temperature in enclosed spaces with an average unavailability of 50 h/g. (SNiP 2.04.05-91)

Reliability - in management, this is a property of systems to perform the functions assigned to them for a specified period of time under certain operating conditions. The N. of a system is often determined by the reliability of its least reliable link. In this connection, to improve the performance of production control systems, it is of great importance to identify bottlenecks in the administrative apparatus and to develop measures to eliminate them. Common measures for different systems to ensure the required N. are redundancy of insufficiently reliable elements, duplication, and functional redundancy.

Some of them are set up water circuit heating system, while others do not. But the owners of rural housing are in no hurry to throw them out and change them to modern boilers. A more trouble-free and hassle-free method of heating has not yet been invented.

As fuel in such village stoves they burn:

- peat;

- briquettes (euro firewood).

- coal;

- firewood;

The fundamental difference between these types of fuel in terms of the design of the stove inside and the wiring of the water system heating in a private house no. And others burn out longer, some of them give more heat. But the design of the furnace and the layout of the pipes with the coolant in the rooms are the same in all cases.

_

Device - a set of elements representing a single design (multi-contact relay, a set of transistors, a board, a block, a cabinet, a mechanism, a dividing panel, etc.). The device may not have a specific functional purpose in the product. (GOST 2.701-84)

Among the advantages of the oven heating are:

- low cost of solid fuel and the possibility of using its different types;

- ultimate ease of use;

- versatility - suitable for heating and cooking at the same time.

- long-term heat transfer (for brick structures);

- relatively low cost of the heating system device;

- no dependence on the availability of electricity in the network;

_

Exploitation - the stage of the life cycle of an object, at which its quality is implemented, maintained and restored (healthy state). (GOST R 51617-2000)

Wood burning stove would be the best choice for him heating, in case a private house cannot be connected to the main gas.

The only exception is when coal or firewood is not available in a certain area. But this option in Russia is the exception rather than the norm.

Also from the shortcomings of the oven heating should be mentioned:

- the large weight of the brick oven structure;

- long warm-up of the system before the start of heat transfer;

- loss of mass of usable space in the house due to the massiveness of the furnace;

- low efficiency due to the departure of a significant amount of heat into the pipe;

- high fire hazard if misused.

_

Weight - GROSS (from lat. massa - lump, piece + it. brutto) - the total weight of the cargo.

Brick heating and cooking stove for a private house with water heating, taking into account the design and number of rows, it can weigh from 1.5 to 10 tons. Plus, the weight of the pipe is added here.

The foundation for such a mass will require a powerful and expensive cost, which can also be called a minus of the heating systems under consideration.

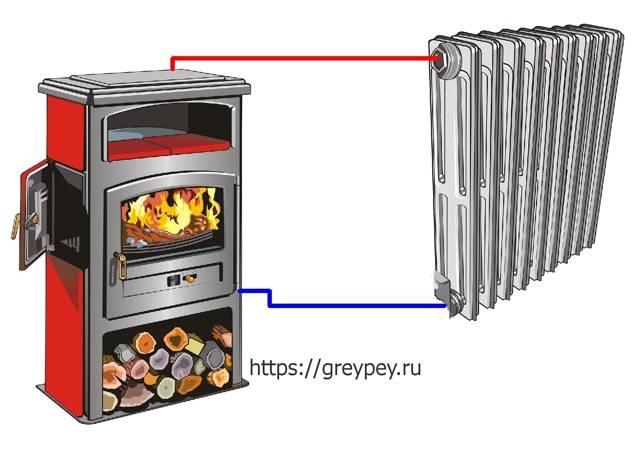

Stove heating with coolant

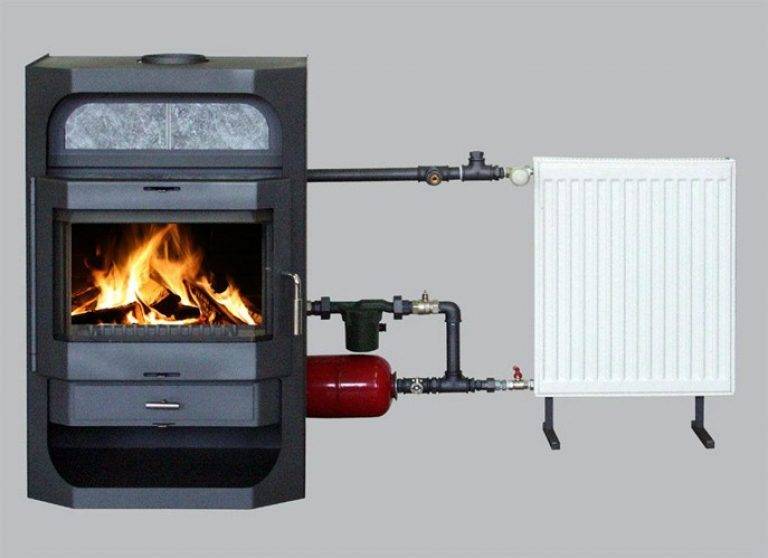

A very successful variation of traditional stove heating is a system with a water circuit. It successfully combines the advantages of water and stove heating, which allows it to evenly and rationally distribute heat throughout the room. At the same time, such a system is able to heat several rooms at the same time.

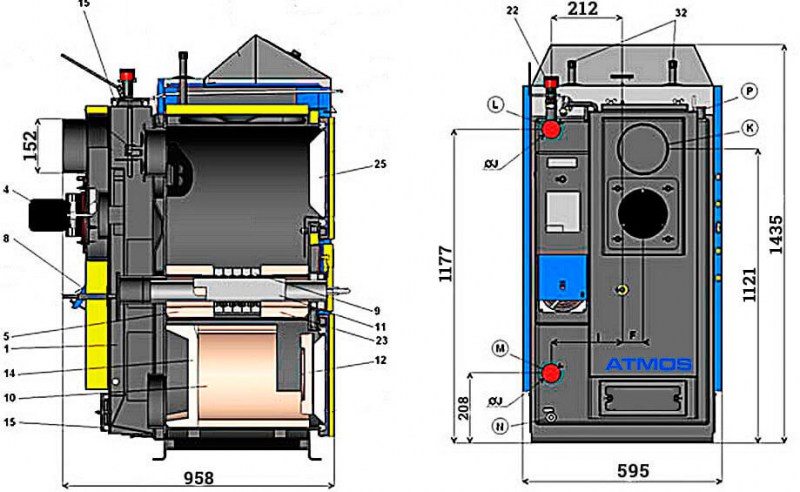

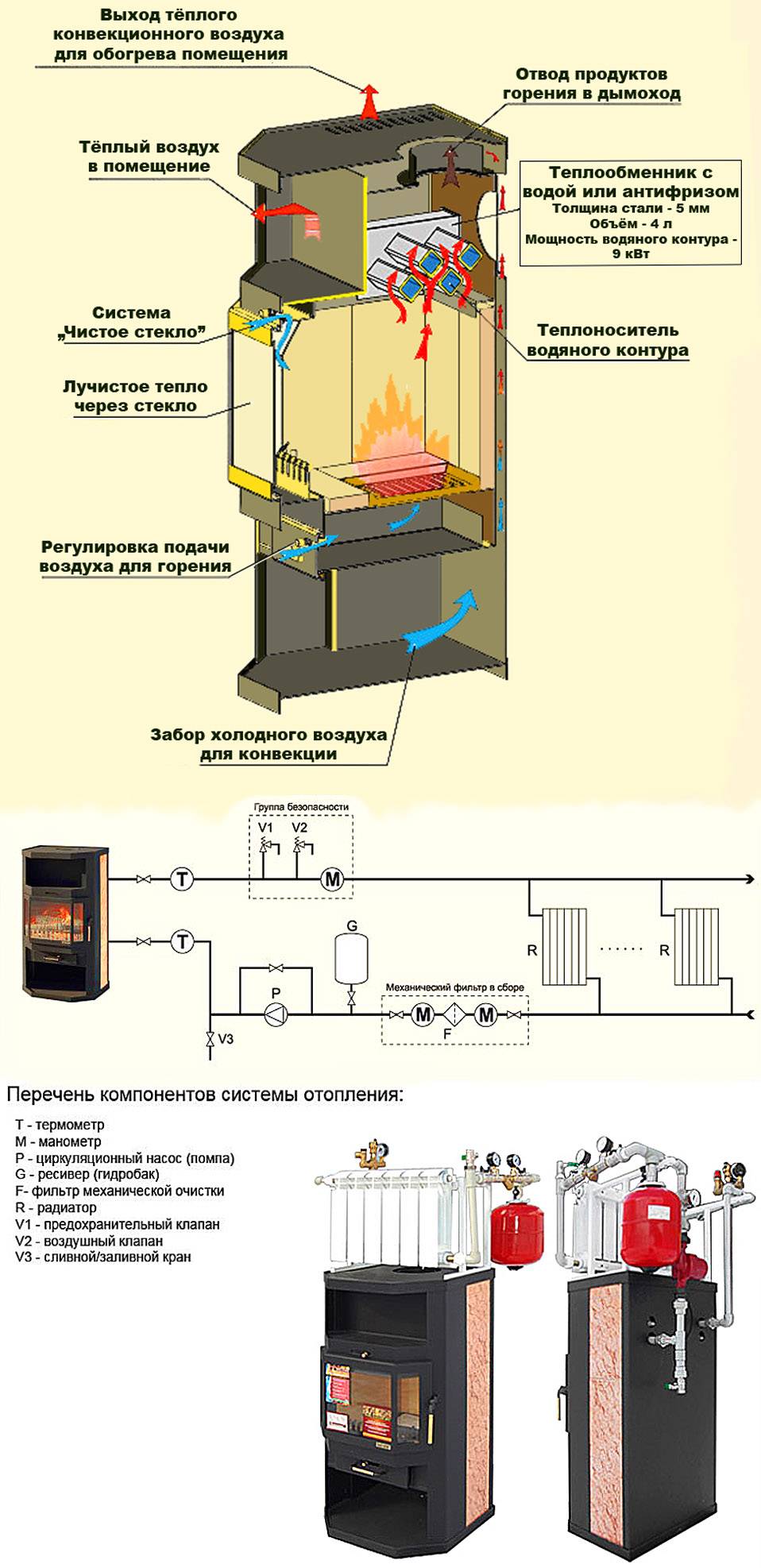

The device of the furnace with a water boiler

The furnace used in such a system works like a solid fuel boiler. However, unlike it, it heats not only the coolant, but also its own walls and smoke channels, which are also involved in heating the room. Thus, furnace heating with a water circuit ensures that heat is transferred to the radiators only during the combustion process. However, the heated surface of the furnace radiates heat until it cools completely.

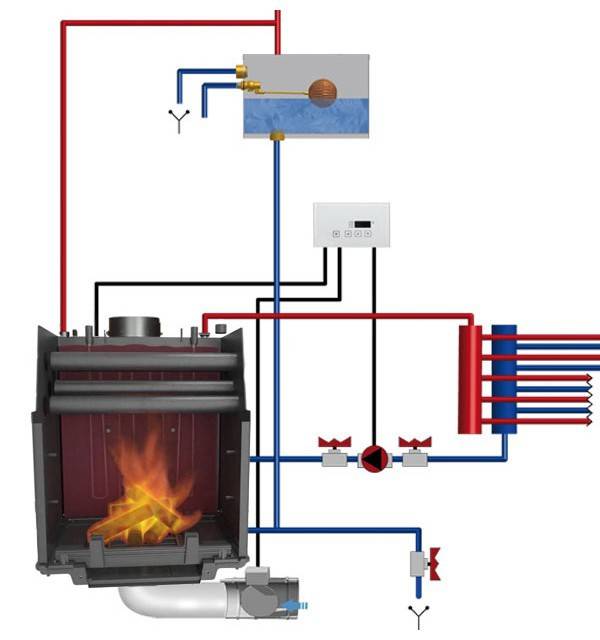

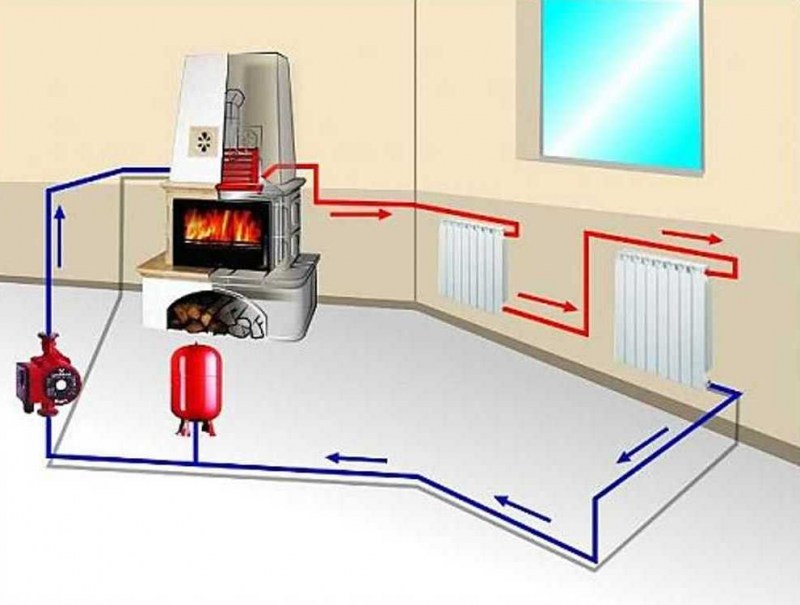

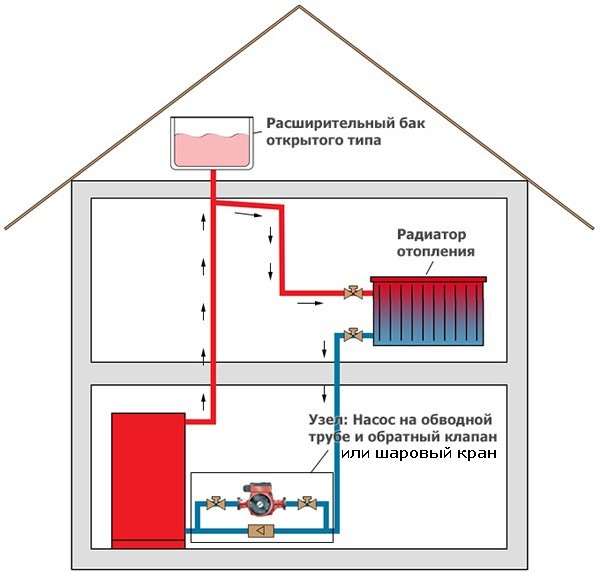

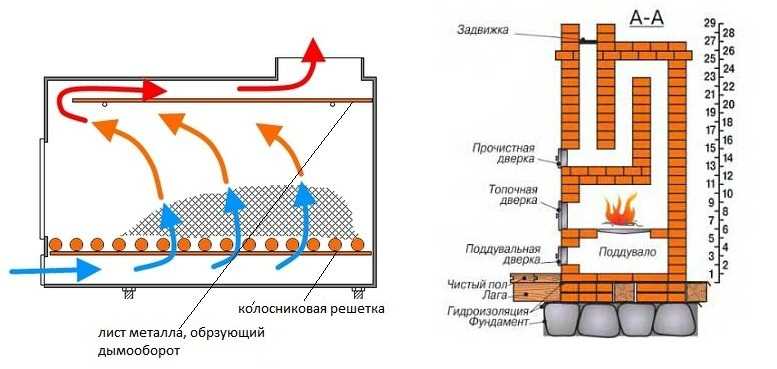

Scheme of operation of furnace heating with a water circuit - a simple one-pipe system

Register: purpose and device

The main structural difference between a furnace for heating with a heat carrier is the presence of a so-called register or heat exchanger or coil. This is the name of the part installed in the firebox, through which the coolant circulates.It is to it that the traditional water heating system is connected.

The design of the part can be the most diverse, the main thing is that it provides the maximum of all possible temperatures of the coolant in it and does not interfere with its constant and uniform circulation.

The form of the register may be different and, most likely, you will have to make it to order.

For the manufacture of the register, sheet steel with a thickness of 3 to 5 mm or metal pipes is used. Heat exchangers made of sheet steel, which is quite simple to process, are very popular. In addition, such products are relatively easy to clean from combustion products. The main disadvantage is a small heating area, which distinguishes them unfavorably from registers made of metal pipes. Most often, coils are made to order, for a specific model and size of the furnace. In some cases, you can even make them yourself.

Furnace with a water circuit for home heating: advantages

Let's move on to the section: stove with water circuit for home heating: Benefits.

As already mentioned, a conventional stove is not able to provide uniform heating of all rooms in the house. But it moves in a limited space of pipes and is regulated by valves, dampers, grilles and other additional devices, as a result, the flow of warm air from the stove is not left to itself. the chamber to which the duct system is connected, in modern stoves and fireplaces this problem is solved to some extent.

_

Camera - windows. profile cavity formed by its walls. The chambers are arranged sequentially along the width of the profile.The chamber may consist of a number of sub-chambers separated by partitions, usually along its height. (GOST 30673-99)

However, the air ducts are bulky, eat up usable space, with an increase in their length and the number of turns, heat losses increase. They need monitoring and maintenance: soot, soot, periodic cleaning of dust. To transfer heat to a room remote from the furnace, forced injection of heated air masses by a fan will be required, the air itself has a low specific heat capacity. as a result, water, as a heat carrier, is in many respects preferable to air.

_

Water - a chemical compound of hydrogen and oxygen that exists in liquid, solid and gaseous states.

Observation - economy. a bankruptcy procedure applied to a debtor from the moment the arbitration court accepts an application for declaring the debtor bankrupt until the moment determined in accordance with the Federal Law, in order to ensure the safety of the debtor's property and analyze the financial condition of the debtor.

room - a unit of a complex of real estate (a part of a residential building, another real estate object associated with a residential building), allocated in kind, intended for independent use for residential, non-residential or other purposes, owned by citizens or legal entities, as well as the Russian Federation, subjects of the Russian Federation and municipalities. ; - the space inside the building, which has a certain functional purpose and is limited by building structures.(SNiP 10-01-94); - the space inside the house, which has a certain functional purpose and is limited by building structures. (SNiP 31-02-2001)

<-

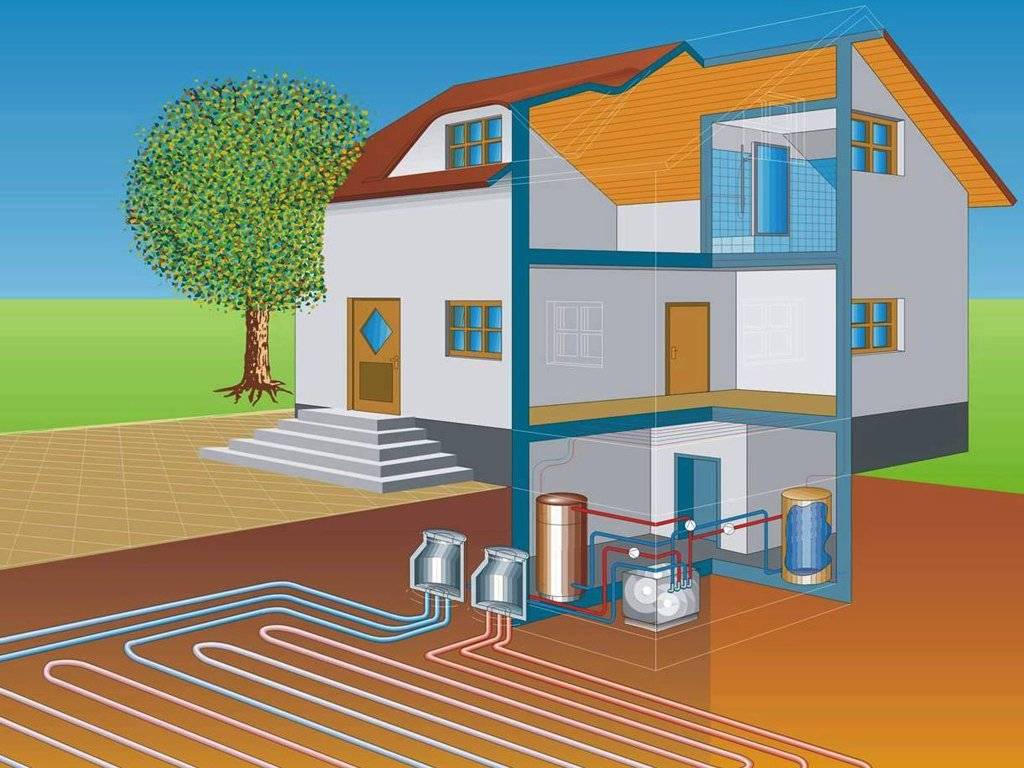

Combined system heating cottage with a fireplace stove with water circuit and solar collectors

While transmitting thermal energy over considerable distances, hot water can be easily transported through pipelines of small diameter. Moreover, water is a harmless, non-flammable, non-toxic, chemically neutral and always available substance.

Conventional stove heating: advantages and disadvantages

In our country, houses were traditionally heated with brick stoves, but gradually this type of heating was replaced by water systems. All this is because, along with the advantages, simple stove heating has a lot of disadvantages. First about the benefits:

- The furnace transfers most of the heat by thermal radiation, and, as scientists have found, it is better perceived by our body.

- Russian or some other heating stove has a colorful appearance, it is often possible to observe an open flame.

- You can make a brick oven with chimneys for a more complete use of the generated heat.

- Heating of this type is non-volatile - does not depend on the availability of electricity.

- There are models of stoves for heating the second floor (due to the heating shield with smoke channels).

Stove heating

Today, stove heating is perceived more as exotic, as it is very rare. It is impossible to argue that it is very pleasant to be near a warm stove. A special atmosphere is created. But there are also many serious drawbacks:

- Uneven heating - it is hot near the stove, cold in the corners.

- Large area occupied by the oven.

- Only those rooms into which the walls of the furnace go out are heated.

- The inability to regulate the heating temperature in individual rooms.

- Low efficiency. For conventional stoves, 60% is already a very good indicator, while modern heating boilers can produce 90% or more (gas).

- The need for frequent maintenance. Melt, adjust the dampers, clean the coals - all this regularly and constantly. Not everyone enjoys it.

The principle of organization of smoke circulation - horizontal and vertical

As you can see, the shortcomings are significant, but some of them can be leveled if a heat exchanger is built into the furnace, which is connected to the water heating system. Such a system is also called furnace water heating or furnace heating with a water circuit.

The choice of coolant

When choosing one or another heating system with a water circuit, it is important to consider which coolant will be used. In winter, country houses and country houses are not often visited, and heating in them is necessary only at the time of the owners' arrival.

Therefore, owners prefer non-freezing liquids, the consistency of which does not change with the onset of severe frosts. Such fluids eliminate the possible problem of pipe bursting. If water is used as the heating medium, then before leaving it must be drained and refilled before use. Also as a coolant can be used:

antifreeze is a special liquid that prevents freezing. The heating system uses 2 types of antifreeze - propylene glycol and ethylene glycol

When choosing this method, it is important to know that ethylene glycol is extremely toxic, so its handling must be appropriate.

coolant on glycerin. Considered more efficient and safer (not explosive or flammable)

Glycerine liquid is expensive, but since the oven is only filled with it once, it makes sense to invest in the purchase. In addition, glycerin freezes only if the temperature drops below -30 degrees.

saline solution or a solution of the natural mineral bischofite. The standard ratio is 1:0.4. Such a water-salt solution does not freeze up to -20 degrees.

How to choose a coolant

Detailed instructions for choosing a coolant for heating systems and technical specifications can be found here.

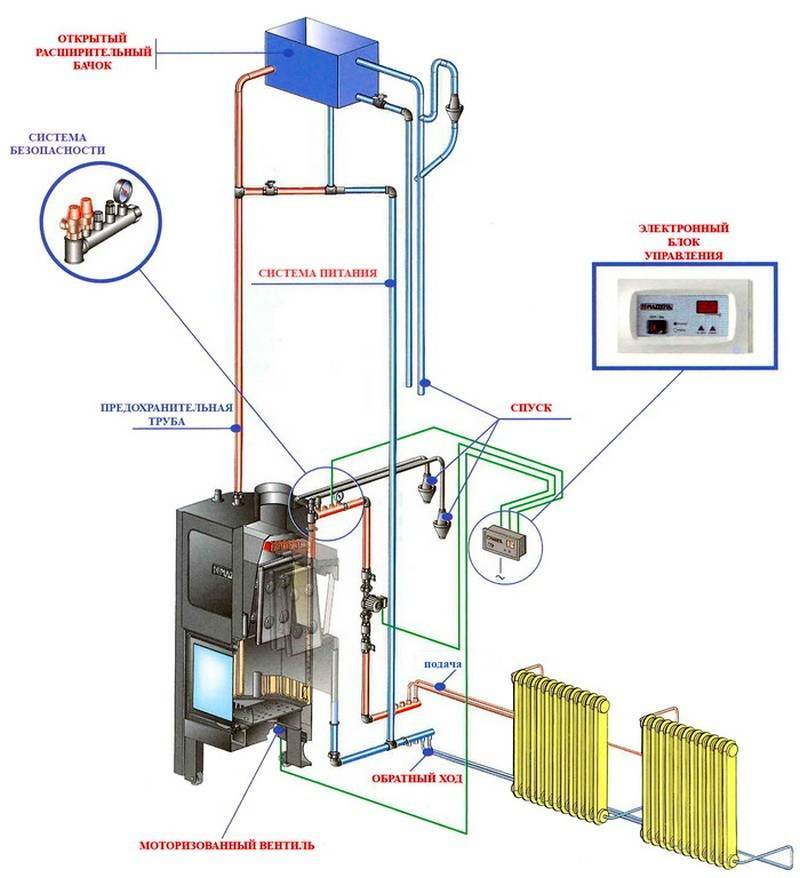

Mounting

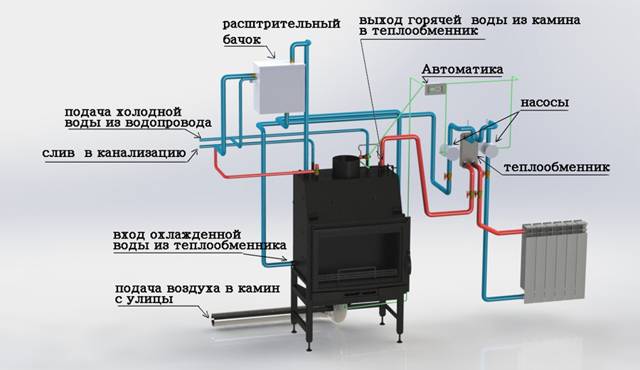

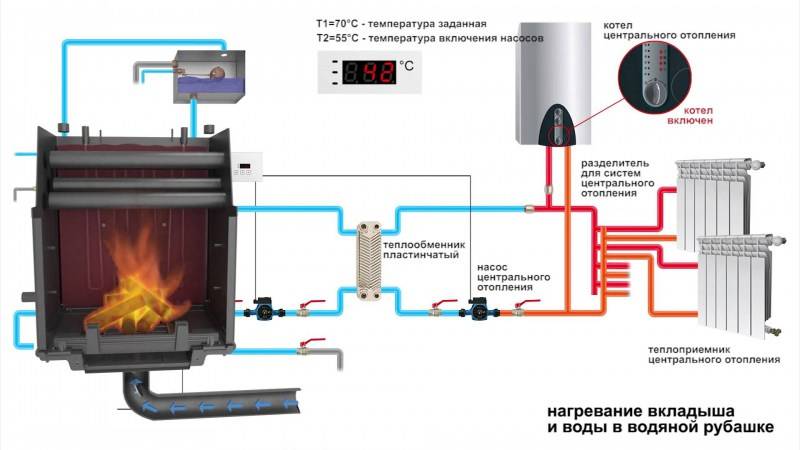

Installation of a furnace with a water circuit can be carried out according to two schemes. The first scenario involves the circulation of the liquid in this way: cold water goes down, and warm water rises

Then, when installing the furnace, it is important not to violate the correct height difference

The second scenario is used when fluid circulation is not naturally possible. Then pumps are mounted, providing an artificial circulation of water.

For convenience, the installation of the heating system takes place in several approaches. First, a wood-burning stove or fireplace is mounted, chimneys are removed, observing fire safety rules. Later - a water circuit is bred throughout the house.

Features of furnaces with a water circuit

Before rushing to purchase equipment, it is important to familiarize yourself with the features of the heating system. Advantages:

Advantages:

- The ability to efficiently heat several rooms with a large area.

- Uniform distribution of heat.

- Safety of use.

- They can be autonomous heat sources or work together with a centralized heating system.

- Using a temperature sensor that allows you to control the operation of the device.

- Autonomy (independence from sources of electricity and gas communications).

- Relatively low maintenance cost.

- The furnace functions on coal, peat, wood and coke coal.

- Economy and environmental friendliness of the heating system.

- Modern design and matching to any style and interior.

Flaws:

The boiler reduces the useful volume of the firebox

To eliminate this fact, it is important in the process of laying the firebox to think over the mandatory width of the boiler and the furnace itself. Long burning stoves can also be used.

Low level of automation

Only manual control is possible.

The thermal energy received as a result of burning wood is spent on heating the boiler and the liquid in it, and the walls of the firebox heat up more slowly and to a lesser extent.

In severe frosts, the coolant can freeze. There is a risk of freezing if the house is not intended to be permanently occupied. In order to prevent this, special additives should be added to the purified water to protect the system. Also, experts recommend using antifreeze - a universal coolant that freezes only at very low temperatures.

The use and maintenance of heating furnaces with a water circuit is not particularly difficult. Attached is a video for further explanation.

Having decided to purchase a heating furnace with a water circuit, study in advance the models offered by foreign and domestic companies. They are distinguished by size, design, cost and accessories.For a small country house, a brick stove with water heating, low power and no designer frills is quite enough. The owner of a large mansion is unlikely to be satisfied with such a model. A spacious living room can be decorated with a stylish foreign-made stove.

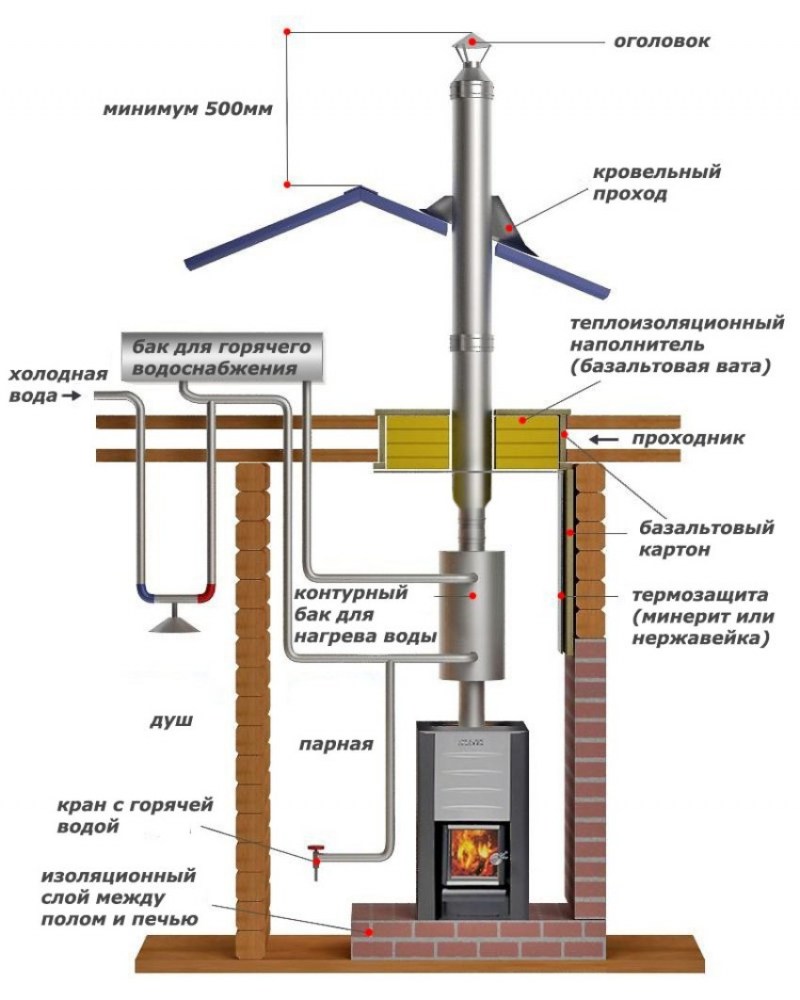

5 Do-it-yourself erection

To begin with, a project is being prepared, after which a heat exchanger is made according to the drawings, which should subsequently be mounted in the stove. Actually, the stove is being built according to its dimensions.

When designing, you need to think about how the device will be located in the room. The place should be convenient for use and publicly accessible.

After the foundation is installed, the brick is prepared for masonry. It must be fireproof, without any chips, damage and cracks. It is also necessary to provide in the project the location of the blower and combustion chamber, chimney, hob. The latter may not be mounted, it all depends on the preferences of the owners of the house.

Construction takes place in a certain order:

- 1. To begin with, a solution is prepared. It consists of water, clay and sand. Such a mixture can be purchased ready-made in specialized stores, but experienced craftsmen make it on their own.

- 2. The foundation is insulated with a layer of film or roofing material.

- 3. A uniform layer of mortar is laid on top and the first rows of bricks are laid.

- 4. A firebox and an ash pan are being set up. The accuracy of the masonry must be checked using the building level.

- 5. Next, the door is fixed and a vault is made. A chimney is also installed. For the walls of the chimney, you need to use semicircular bricks.

- 6. At the final stage, the water circuit is installed.Pipes and batteries are connected, a container for heat exchange. After that, liquid is poured. You can use plain water or prepared solutions.

Also, if desired, you can make a decorative finish of the furnace. An economical stove device can be made independently. Such a device is durable, has a high efficiency, so the house will receive an installation that is independent of central heating.

Criteria for the selection of long-burning furnaces

When choosing a long-burning stove, you should give preference only to trusted manufacturers from various European brands, as their products are always marked with quality and safety certificates.

It is worth noting that today there are a large number of different types and styles, which are expanded with additional functions, have a special lining and are installed in different ways. There are various options that are equipped with fans, oven, solid fuel compartments, etc.

The main criterion when choosing a heating device with a long combustion cycle on solid (wood) fuel is its power.

It must correspond to the volume of the heated room. It makes no sense to install a high-power stove in a small room, since part of the heating material will burn out irrationally. In addition, a large appliance will take up a lot of space, and the room temperature will be too high.

Conversely, a low-power stove in large rooms will work to the limit, which will quickly disable it.

When choosing, you should decide on the type of fuel that is supposed to be used - firewood, pellets, coal, fuel briquettes, etc.

You should be aware that the moisture content of wood fuel is of great importance, since water vapor diluting gases interferes with combustion, reduces the power of the device and contributes to the formation of condensate.

In some cases, excessive moisture content of the combusted material can lead to spontaneous combustion of the furnace. Firewood for long-burning fireboxes, for example, should have a moisture content of no higher than 20-35%.

The metal or alloy from which the long-burning furnace is made is also an important selection criteria. The thicker the body material of the device, the slower the device cools down and the longer its service life.

Some models of long-burning stoves made of cast iron last up to 50 years and, moreover, are not subject to corrosion.

The elements of many modern stoves - a firebox, a hob, a finish, a door - are made from different materials (cast iron, vermiculite, steel, stainless steel, heat-resistant glass, etc.), which allows you to increase the service life, improve design, increase ease of use and long time to keep the look.

The appearance of the heater often plays no less important role than other factors. A stove for a living space should have a modern design and harmoniously fit into the interior.

There are many imported models on the market, among which you can choose a ready-made stove for any home.

All long-burning stoves are supplied with instructions, but they often do not mention some of the nuances that must be taken into account:

- around the furnace it is necessary to provide free space and protection against fire;

- for convenient maintenance (cleaning), the chimney should, if possible, have a collapsible design;

- pipes must be installed in the direction of gas flow;

- due to the small draft, the chimney should not have a curved shape;

- Condensation may form in the chimney during operation.

It should also be noted that liquid fuel cannot be used in long-burning furnaces, some models are quite difficult to set up and require constant supervision.

How the system works

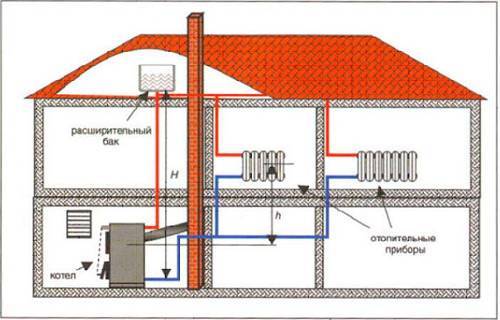

The simplest water circuit is with natural circulation of the water flow. Its basis is a simple physical phenomenon: the expansion of liquids when they are heated. The node that creates pressure is an expansion tank (water collection tank) installed in the attic, attic.

The water circuit is a closed system. The boiler heats the water in it and it, expanding, is sent through the pipe to the storage tank. The movement is carried out under pressure created by the cooled water constantly entering the boiler, which has passed through the entire system. Boiling water from the expansion tank is directed by gravity down the pipes leading to the batteries. Having given off heat, it returns to the tank and heats up again.

The installation of a pump will help to significantly increase the pressure in the system, to speed up the circulation of the coolant. At average air temperatures outside, it can be turned off and the circuit will function on the natural movement of water. This will save you money on your electricity bills. Water enters the pump when the check valve is closed. Turning it off (leaving it open), the entire volume of the coolant is directed to bypass the pump.

Such a stove can be loaded not only with wood or coal. When using alternative fuels, it is possible to complicate the structure of the system by adding it:

- pellet storage tank;

- a mechanism that feeds pallets into the furnace (pneumatic or screw).

It is possible to facilitate the operation of the furnace by installing an automatic system for regulating its operation, forced ventilation.