- Other oil boiler manufacturers

- Varieties of designs

- Waste oil heating for a private house

- Features of use

- Types of fuel. How much heat is produced by burning one liter?

- Pros and cons

- How is oil processed?

- What does not apply to such fuel?

- Advantages and disadvantages of a miracle stove

- Tips & Tricks

- Types of homemade stoves in development

- The device and disadvantages of an open-type potbelly stove

- Pros and cons of a dropper

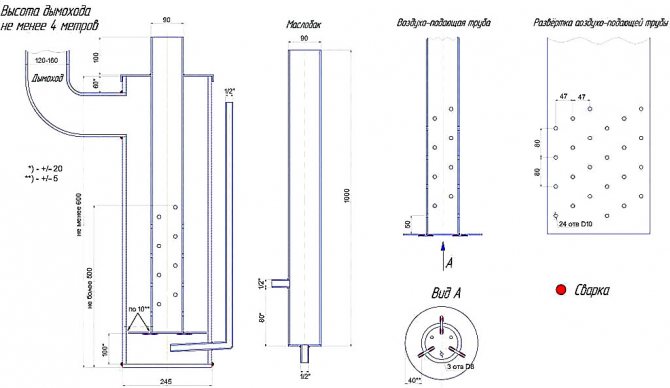

- In development: sketches and drawings

- From a metal pipe with a water circuit

- From a profiled pipe

- From a gas bottle

- Distinctive characteristics of structures in development

- Installation and trial ignition

- Types of homemade stoves in development

- The device and disadvantages of an open-type potbelly stove

- Pros and cons of a dropper

- How to build a stove from a pipe?

- The pipe is an excellent "semi-finished product" for the construction of the furnace

- Part preparation

- Furnace manufacturing

- Production of a water heating tank

- Conclusions and useful video on the topic

Other oil boiler manufacturers

Double-circuit liquid fuel boilers Energylogic of the American manufacturer are of high quality, reliability and durability. Models have a power of 41-218 kW.The heat exchanger works on the wet effect, cooling the water. This eliminates the formation of burnout points and helps slow down the wear of the metal.

A special head is located in the fan burner, which forms and holds the flame, normalizing the combustion process of the fuel. The devices have the ability to heat the fuel before it enters the nozzle. The boilers are equipped with a reversible two-way furnace.

The heat exchanger of the Energylogic boiler works on the wet effect, cooling the water

Chinese waste oil boiler plants Nortec have a capacity of 15-7000 kW. Due to the presence of a mesh filter, the fuel enters the nozzle in its pure form. The devices are equipped with a fuel overflow sensor and a reliable sliding secondary air control damper.

Another Chinese manufacturer, Smart Burner, makes boilers with a capacity of 24-595 kW. The devices have a smooth ignition system and the option of adjusting the fuel supply, which contributes to great efficiency.

Korean-made two-pass boilers operate on the basis of single-stage OLB burners. They have a power of 15-1600 kW. The devices are equipped with a pressure regulator, with which the fuel flow to the nozzle is adjusted, which is determined by the viscosity of the fuel. They have the function of protecting the system in the event of a malfunction of one of the boiler elements.

Korean boilers Kiturami operate on different types of fuel. They are equipped with a self-diagnostic device, thanks to which the operating mode is adjusted. In the secondary afterburning zone, the boilers have a burner with cyclone flow aerodynamics technology.

Kiturami boilers are equipped with a self-diagnosis device, thanks to which the operating mode is adjusted

Currently, waste oil heating is very popular. This is primarily due to the economic feasibility of such an option. Working out boilers are characterized by a number of distinctive advantages, however, factory-made devices have a rather high cost. To save money, the device can be made independently, having studied all the details of the process.

Varieties of designs

The oil that was drained from the car during the replacement will not burn itself. Firstly, it has already been worked out and is very difficult. Secondly, almost all manufacturers add impurities to it. The process of oil combustion and its thermal decomposition is built on the principle of pyrolysis. In simple words: the oil heats up, evaporates and then only burns with a lot of air.

Babbington burner fuel can be left unfiltered

Babbington burner fuel can be left unfiltered

There are three types of devices that work on this principle:

- "Wonder oven". This is the simplest design in which the remaining vapors are burned in an open perforated pipe.

- Drip stove with a closed pipe for burning out the remaining vapors of decomposed fuel.

- Babington burner.

Read also: production waste burners handmade oil.

If you have extensive experience in the production of such structures at home, you can make flare structures no worse than factory ones. But due to the complexity of the work, not everyone will be able to repeat this with their own hands.

A self-made supercharged mining furnace according to the drawings can use from 0.8 to 1.5 liters of supercharged fuel. These indicators must be taken into account when building the installation.

Waste oil heating for a private house

Waste oil for heating was originally used together with diesel fuel. This method has proven to be effective and economical. Then they decided to reduce the cost of the product even more and removed the diesel fuel from the composition. Waste oil is similar in its characteristics to diesel fuel, but it costs an order of magnitude cheaper.

Photo 1. This is what used oil looks like, which is used for heating. Dark brown liquid.

Features of use

Mining as fuel is used in a special boiler or in a furnace. Only this guarantees complete combustion of the product without the formation of a fumes. The refurbishment of the heating system or the installation of a new circuit pays off in the first year of using the product.

Types of fuel. How much heat is produced by burning one liter?

Burning one liter of such fuel gives 10-11 kW of heat in 60 minutes. The pre-treated product has more power. Burning it gives 25% more heat.

Types of used oils:

- engine oils and lubricants used in various modes of transport;

- industrial products.

Pros and cons

Fuel advantages:

- Economic benefit. Consumers save money on fuel, but businesses benefit the most. The implementation of mining eliminates the costs of storage, transportation and disposal of the product.

- Conservation of energy resources. Refusing to use gas and electricity for heating prevents the depletion of sources.

- Environmental Protection. Due to the high cost of disposal, business and vehicle owners disposed of oil by dumping it into water bodies or into the ground. This had a negative impact on the environment.With the beginning of the use of mining as a fuel, such manipulations ceased.

Fuel cons:

- represents a health hazard if the product does not burn completely;

- large dimensions of the chimney - 5 m in length;

- the difficulty of ignition;

- the plasma bowl and chimney quickly become clogged;

- the operation of the boiler leads to the combustion of oxygen and the evaporation of moisture from the air.

How is oil processed?

Mining is obtained by burning any type of oil, but oil refining from internal combustion engines is usually used for space heating.

Also from industrial mechanisms, compressors and power equipment.

What does not apply to such fuel?

List of products not related to mining:

- processed oils of vegetable and animal origin, which are used for domestic purposes;

- solid waste with mining;

- solvents;

- products that are not subject to the same processing as mining;

- oil fuel of natural origin from the spill;

- other unused petroleum products.

Advantages and disadvantages of a miracle stove

A two-chamber waste oil furnace has one significant advantage - simplicity and low cost of manufacture. Making it is not a problem for any person with welding skills. The second plus is the ability to burn the most polluted oils, since they are poured directly into the chamber without any tubes that can become clogged.

Now for the disadvantages:

- low efficiency, as indicated by the high temperature of the exhaust gases (you can’t touch the chimney);

- average fuel consumption - 1.5 liters / hour, maximum - up to 2 liters, which is a lot;

- the stove smokes into the room during ignition and smokes a little after warming up;

- high fire hazard.

Scheme of a mini-oven

These shortcomings have been tested in practice and are confirmed by numerous reviews of real users. So that you have no doubts about this, we suggest that you familiarize yourself with the video, which shows the operation of the furnace in oil mixed with water:

Tips & Tricks

Experienced craftsmen advise installing a potbelly stove in the corner of the garage, and leading the chimney to the opposite side. Thus, maximum heat transfer is achieved. To prevent heat from escaping with smoke, the pipe must be pulled at an angle of 30 degrees. If possible, it is recommended to avoid horizontal straight sections.

The location of the chimney must be stepped. The fewer straight horizontal sections, the better.

A metal sheet is placed under the furnace. Installing a potbelly stove in a garage requires a supply ventilation and an exhaust system.

A homemade potbelly stove will be a practical addition to any garage. Thanks to the function of uniform heat distribution, you can install the stove anywhere, but experts recommend mounting the heater in a corner.

Types of homemade stoves in development

Engine oil contaminated with impurities does not itself ignite. Therefore, the principle of operation of any oil potbelly stove is based on the thermal decomposition of fuel - pyrolysis. Simply put, to obtain heat, mining must be heated, evaporated and burned in the furnace furnace, supplying excess air. There are 3 types of devices where this principle is implemented in various ways:

- The simplest and most popular design of direct combustion with afterburning of oil vapors in an open-type perforated pipe (the so-called miracle stove).

- Waste oil drip furnace with closed afterburner;

- Babington burner. How it works and how to make it yourself is described in detail in our other publication.

The efficiency of heating stoves is low and amounts to a maximum of 70%. Note that the heating costs indicated at the beginning of the article are calculated based on factory heat generators with an efficiency of 85% (for a complete picture and comparison of oil with firewood, you can go here). Accordingly, fuel consumption in home-made heaters is much higher - from 0.8 to 1.5 liters per hour versus 0.7 liters for diesel boilers per 100 m² of area. Consider this fact, taking up the manufacture of the furnace for testing.

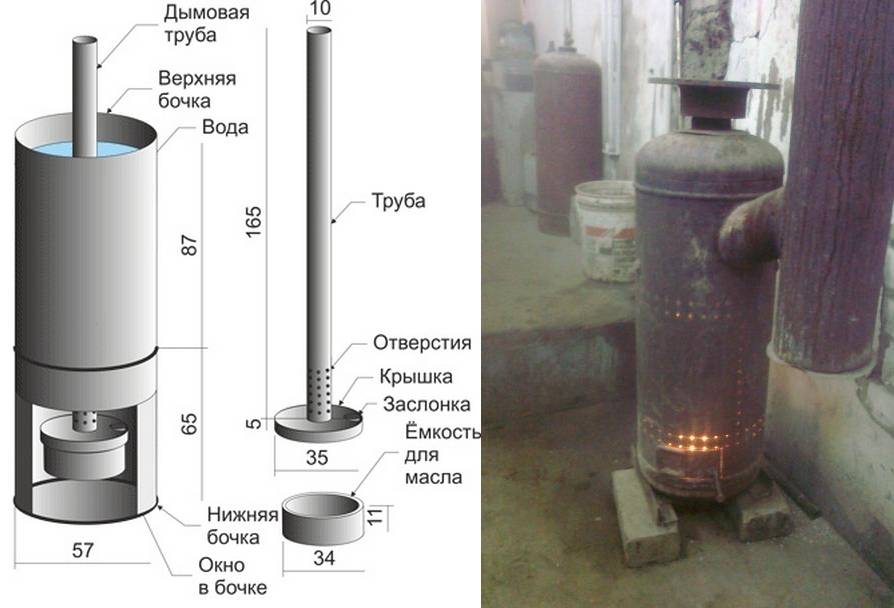

The device and disadvantages of an open-type potbelly stove

The pyrolysis stove shown in the photo is a cylindrical or square container, a quarter filled with used oil or diesel fuel and equipped with an air damper. A pipe with holes is welded on top, through which secondary air is sucked in due to the chimney draft. Even higher is the afterburning chamber with a baffle to remove the heat of combustion products.

The principle of operation is as follows: the fuel must be ignited using a flammable liquid, after which the evaporation of mining and its primary combustion will begin, causing pyrolysis. Combustible gases, getting into a perforated pipe, flare up from contact with an oxygen stream and are completely burned. The intensity of the flame in the firebox is regulated by an air damper.

This mining stove has only two advantages: simplicity with low cost and independence from electricity. The rest are solid cons:

- stable natural draft is required for operation, without it the unit begins to smoke into the room and fade;

- water or antifreeze that gets into the oil causes mini-explosions in the firebox, which causes fire drops from the afterburner to splash in all directions and the owner has to put out the fire;

- high fuel consumption - up to 2 l / h with poor heat transfer (the lion's share of energy flies into the pipe);

- one-piece housing is difficult to clean from soot.

Although outwardly the potbelly stoves differ, but they operate according to the same principle, in the right photo, fuel vapors burn out inside a wood-burning stove

Some of these shortcomings can be leveled with the help of successful technical solutions, which will be discussed below. During operation, fire safety rules should be followed and used oil should be prepared - defended and filtered.

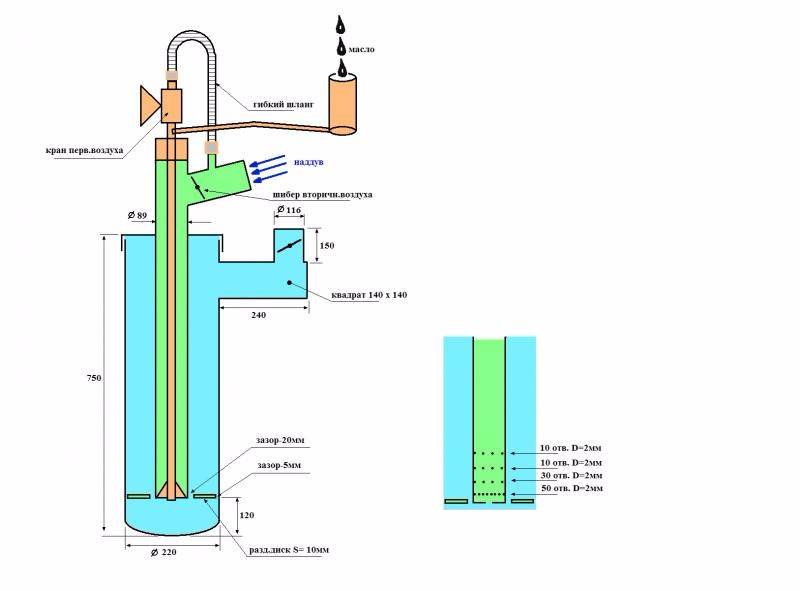

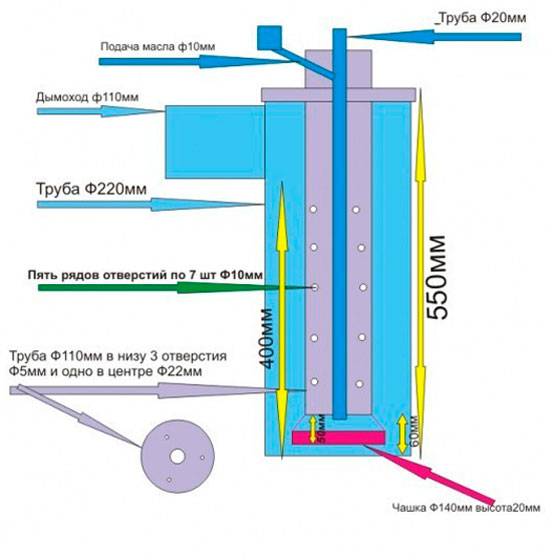

Pros and cons of a dropper

The cardinal difference of this furnace is as follows:

- the perforated pipe is placed inside a steel case from a gas cylinder or pipe;

- fuel enters the combustion zone in the form of droplets falling to the bottom of the bowl located under the afterburner;

- To increase efficiency, the unit is equipped with forced air by means of a fan, as shown in the diagram.

Scheme of a dropper with a bottom supply of fuel from a fuel tank by gravity

The real disadvantage of a drip stove is the difficulty for a beginner. The fact is that you cannot rely entirely on other people's drawings and calculations, the heater must be manufactured and adjusted to suit your operating conditions and properly organize the fuel supply. That is, it will require repeated improvements.

The flame heats up the body of the heating unit in one zone around the burner

The second negative point is typical for supercharged stoves. In them, a jet of flame constantly hits one place of the body, which is why the latter will burn out pretty quickly if it is not made of thick metal or stainless steel. But the listed disadvantages are more than offset by the advantages:

- The unit is safe in operation, since the combustion zone is completely covered with an iron case.

- Acceptable waste oil consumption. In practice, a well-tuned potbelly stove with a water circuit burns up to 1.5 liters in 1 hour to heat 100 m² of area.

- It is possible to wrap the body with a water jacket and remake the furnace for working out into a boiler.

- The fuel supply and power of the unit can be adjusted.

- Undemanding to the height of the chimney and ease of cleaning.

Pressurized air boiler burning used engine oil and diesel fuel

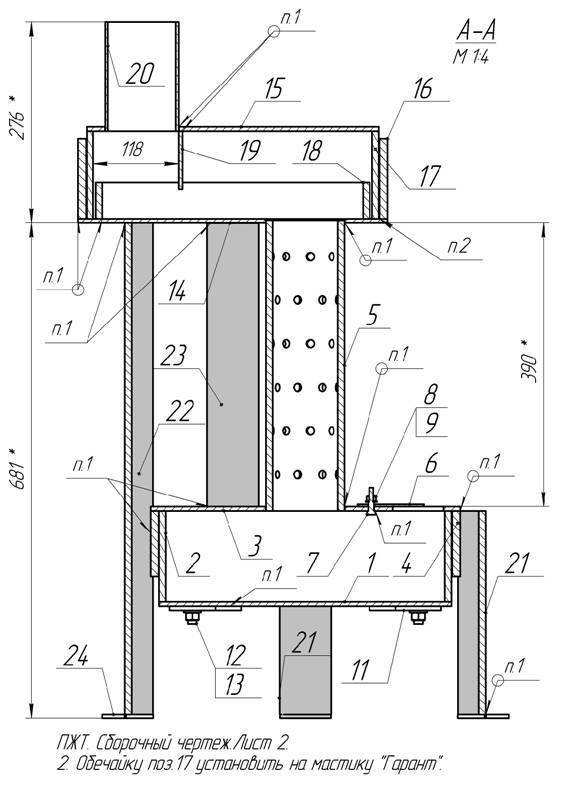

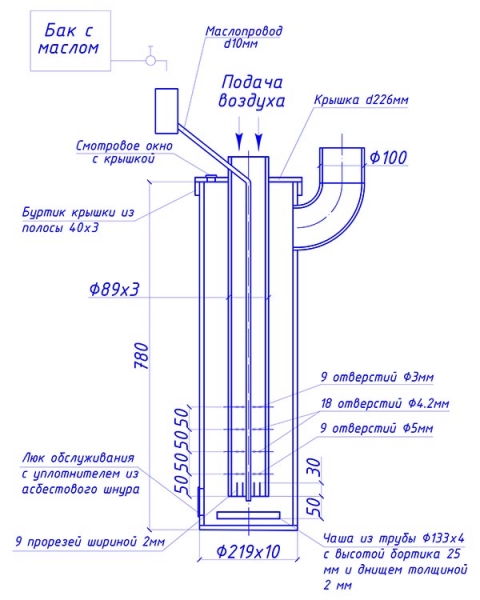

In development: sketches and drawings

Mining stoves can be made in any shape and size. As a rule, sheet metal, pipe trimmings, or used oxygen cylinders are used to make them with their own hands. A few sketches with explanations are given below, and here you can learn how to make a mining burner from a blowtorch.

From a metal pipe with a water circuit

By design, such a furnace resembles a samovar, its walls do not heat up to excessively high temperatures. Therefore, its installation is recommended for greenhouses, buildings for keeping animals and premises with small dimensions, in which accidental contact and burns from a red-hot furnace are possible. The large size of the tank allows you to create the effect of a heat accumulator.

From a profiled pipe

For the manufacture of the furnace with their own hands, they use a profiled pipe of square section 180x180 mm and 100x100 mm. Differs in the compact sizes and simplicity of production. The surface of the oven can be used as a cooking surface.

From a gas bottle

The water circuit is made in the form of a boiler through which the chimney passes.

Another option for connecting the water circuit is a copper heat exchanger tube wrapped in several turns around the stove body. Heating in this case will be weaker, but with this method of connecting the heat exchanger, the risk of boiling water in the system is reduced.

The sizes of the presented furnaces can be slightly changed. The main thing is to observe the location of the main elements and cameras.

Distinctive characteristics of structures in development

The principle of operation of the stove is based on the thermal decomposition of fuel - pyrolysis. It uses the heat of combustion of mining, such a process is independently supported and regulated. But first, the fuel must be evaporated, and the vapors are heated to 300-400℃, then the pyrolysis will increase in the furnace.

In the lower section of the furnace, heating and evaporation of mining is carried out. Combustible vapors rise and, flowing through the pipe, interact with oxygen dissolved in the air.

In the upper section of the stove, the composition ignites and is burned in another section. During the combustion of vapors, a significantly larger volume of heat is released and little smoke is produced.

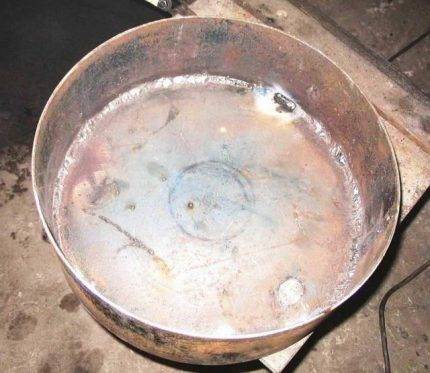

The second method of dividing the liquid into "light-burning" elements is more effective, but more difficult to implement. For evaporation, a metal bowl is placed in the lower section of the oil furnace. It heats up, droplets falling on it are immediately converted into combustible vapors.The glow in the oven is beautiful, has a white-blue tint.

To achieve the greatest effect from fuel combustion, fuel is supplied to the lower section in very small doses: drops or a thin stream.

Installation and trial ignition

The place for installing the stove should be chosen as far as possible from objects and materials that are sensitive to heat. The device gets really hot. If handled carelessly, it can damage property and even cause a serious fire.

There must be a non-flammable base under the device. Do not place such a device in places of active movement of air currents. Under the influence of a draft, the flame can be knocked out, and this is dangerous. Ready and installed in a suitable place, the furnace is connected to a vertical chimney.

Then a test firing is performed. To do this, oil is poured into the fuel tank, and about 100 ml of liquid for fireplaces or another similar composition is added on top. At first, this liquid will burn, but soon the oil will boil, the device will begin to make noise. This means that the oven is made correctly, it can be used for its intended purpose.

All welding work must be done carefully, a tight and even seam is required so that the device is safe and easy to clean

All welding work must be done carefully, a tight and even seam is required so that the device is safe and easy to clean

Oil before pouring into the tank must be defended for some time so that unnecessary impurities settle down and do not get inside. Only two-thirds of the capacity should be filled, then the primary combustion process will be more efficient and safer.

From time to time it is necessary to clean the inside of the fuel tank from accumulated contaminants. The cover is removed and the remaining oil is simply drained, deposits are removed, etc.From time to time, you need to tap the perforated pipe and chimney to remove the collected soot and soot.

Types of homemade stoves in development

Engine oil contaminated with impurities does not itself ignite. Therefore, the principle of operation of any oil potbelly stove is based on the thermal decomposition of fuel - pyrolysis. Simply put, to obtain heat, mining must be heated, evaporated and burned in the furnace furnace, supplying excess air. There are 3 types of devices where this principle is implemented in various ways:

- The simplest and most popular design of direct combustion with afterburning of oil vapors in an open-type perforated pipe (the so-called miracle stove).

- Waste oil drip furnace with closed afterburner;

- Babington burner. How it works and how to make it yourself is described in detail in our other publication.

The efficiency of heating stoves is low and amounts to a maximum of 70%. Note that the heating costs indicated at the beginning of the article are calculated based on factory heat generators with an efficiency of 85% (for a complete picture and comparison of oil with firewood, you can go here). Accordingly, fuel consumption in home-made heaters is much higher - from 0.8 to 1.5 liters per hour versus 0.7 liters for diesel boilers per 100 m² of area. Consider this fact, taking up the manufacture of the furnace for testing.

The device and disadvantages of an open-type potbelly stove

The pyrolysis stove shown in the photo is a cylindrical or square container, a quarter filled with used oil or diesel fuel and equipped with an air damper. A pipe with holes is welded on top, through which secondary air is sucked in due to the chimney draft.Even higher is the afterburning chamber with a baffle to remove the heat of combustion products.

The principle of operation is as follows: the fuel must be ignited using a flammable liquid, after which the evaporation of mining and its primary combustion will begin, causing pyrolysis. Combustible gases, getting into a perforated pipe, flare up from contact with an oxygen stream and are completely burned. The intensity of the flame in the firebox is regulated by an air damper.

This mining stove has only two advantages: simplicity with low cost and independence from electricity. The rest are solid cons:

- stable natural draft is required for operation, without it the unit begins to smoke into the room and fade;

- water or antifreeze that gets into the oil causes mini-explosions in the firebox, which causes fire drops from the afterburner to splash in all directions and the owner has to put out the fire;

- high fuel consumption - up to 2 l / h with poor heat transfer (the lion's share of energy flies into the pipe);

- one-piece housing is difficult to clean from soot.

Although outwardly the potbelly stoves differ, but they operate according to the same principle, in the right photo, fuel vapors burn out inside a wood-burning stove

Some of these shortcomings can be leveled with the help of successful technical solutions, which will be discussed below. During operation, fire safety rules should be followed and used oil should be prepared - defended and filtered.

Pros and cons of a dropper

The cardinal difference of this furnace is as follows:

- the perforated pipe is placed inside a steel case from a gas cylinder or pipe;

- fuel enters the combustion zone in the form of droplets falling to the bottom of the bowl located under the afterburner;

- To increase efficiency, the unit is equipped with forced air by means of a fan, as shown in the diagram.

Scheme of a dropper with a bottom supply of fuel from a fuel tank by gravity

The real disadvantage of a drip stove is the difficulty for a beginner. The fact is that you cannot rely entirely on other people's drawings and calculations, the heater must be manufactured and adjusted to suit your operating conditions and properly organize the fuel supply. That is, it will require repeated improvements.

The flame heats up the body of the heating unit in one zone around the burner

The second negative point is typical for supercharged stoves. In them, a jet of flame constantly hits one place of the body, which is why the latter will burn out pretty quickly if it is not made of thick metal or stainless steel. But the listed disadvantages are more than offset by the advantages:

- The unit is safe in operation, since the combustion zone is completely covered with an iron case.

- Acceptable waste oil consumption. In practice, a well-tuned potbelly stove with a water circuit burns up to 1.5 liters in 1 hour to heat 100 m² of area.

- It is possible to wrap the body with a water jacket and remake the furnace for working out into a boiler.

- The fuel supply and power of the unit can be adjusted.

- Undemanding to the height of the chimney and ease of cleaning.

Pressurized air boiler burning used engine oil and diesel fuel

How to build a stove from a pipe?

Do-it-yourself sauna stove from a pipe

One of the most common homemade options is a pipe sauna stove. Consider how such construction is carried out.

The pipe is an excellent "semi-finished product" for the construction of the furnace

Metal furnaces can be made from a sheet of steel or, for example, from an old barrel. But if there is a piece of pipe of a suitable diameter on the farm, then you should use this "blank".

A home-made stove in a bath from a pipe can be made with a vertical or horizontal direction of the pipe section. The use of prefabricated furnace tubes reduces the amount of welding required when making sheet metal furnaces.

For the manufacture of furnaces, only high-quality pipes are suitable, without signs of corrosion.

If the pipe has lain on the street for a long time, then it should be preliminarily inspected and reinforced in problem areas by welding patches.

Part preparation

To make a good stove from a pipe, you need a piece of pipe rolled with a diameter of 50 cm and a length of 1.5 meters. The wall thickness of the pipe must be at least 10 mm.

The workpiece should be cut into two parts, 0.6 and 0.9 meters in size, respectively. A longer section is needed for the construction of a firebox and a heater, and the remaining piece will be used to make a tank.

Furnace manufacturing

An example of using a stove from a pipe in a bath

- First of all, you should do blower. A hole 5 cm high and 20 cm wide is cut out at the bottom of a long piece of pipe. A thick rounded steel plate is welded above the hole.

- Next, a niche for the firebox is formed and a door is made for it. The door is hung on hinges or hooks.

- A piece of pipe is welded over the firebox, which will be used as a heater. The height of the segment is 30-35 cm.

Rounded cobblestones should be used to fill the heater, in extreme cases, ceramic electrical insulators can be poured.

A steel sleeve is installed in the upper part of the future furnace, which will be required to fix the water heating boiler.

Production of a water heating tank

A range of stoves for a bath from pipes

When building a stove for a bath with your own hands, a water-heating tank is also formed from a pipe.

- For its manufacture, a piece of pipe 0.6 m high is used.

- A steel circle is welded to the end part of the pipe section - the bottom.

Advice! The thickness of the metal for the manufacture of the bottom of the water tank is at least 8 mm

A hole is cut in the bottom of the tank, necessary for the chimney. It should be moved to the rear wall of the tank.

The chimney is fixed to the bottom of the tank by welding

It is important that the seam is of high quality in order to prevent water from leaking into the furnace.

The upper part of the tank is closed with a metal lid with holes made for passing the chimney and for filling water. The chimney is welded tightly to the lid, and a neck with a lid is installed in the hole for filling water.

Conclusions and useful video on the topic

Craftsmen do not make secrets from their own developments and are always ready to share their achievements, show homemade products at work

Pay attention to the video, which shows the same oven as in option #2, but with some modifications

See how it works, what is the result of its use in conditions of external frost to heat a fairly spacious garage space.

Once again, we draw your attention to the safety precautions that should be observed when using home-made stoves for testing.

Waste fuel, which you can get, if not for nothing, then for mere pennies, always attracts the attention of handy owners of garage workshops, greenhouses or other non-residential premises that require heating. Yes, talented people can literally make a necessary household item out of waste

But skill does not come from outside: it is acquired. Perhaps our information will help not only those who already know how, but also those who want to learn how to do everything with their own hands.

Yes, talented people can literally make a necessary household item out of waste. But skill does not come from outside: it is acquired. Perhaps our information will help not only those who already know how, but also those who want to learn how to do everything with their own hands.

Do you want to share your own experience in the construction of a heating device for testing? Do you have information that will be useful to site visitors who want to make a garage stove with their own hands? Please write comments in the block below, post photos on the topic, ask questions.