- Fireplace connection diagrams

- Recommendations for choosing a home wood-burning stove

- Heated area

- Fuel used

- Material

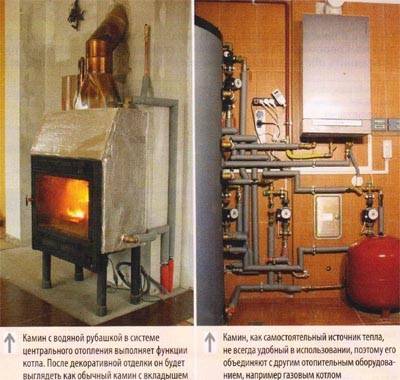

- Pros and cons of a metal fireplace with a water circuit

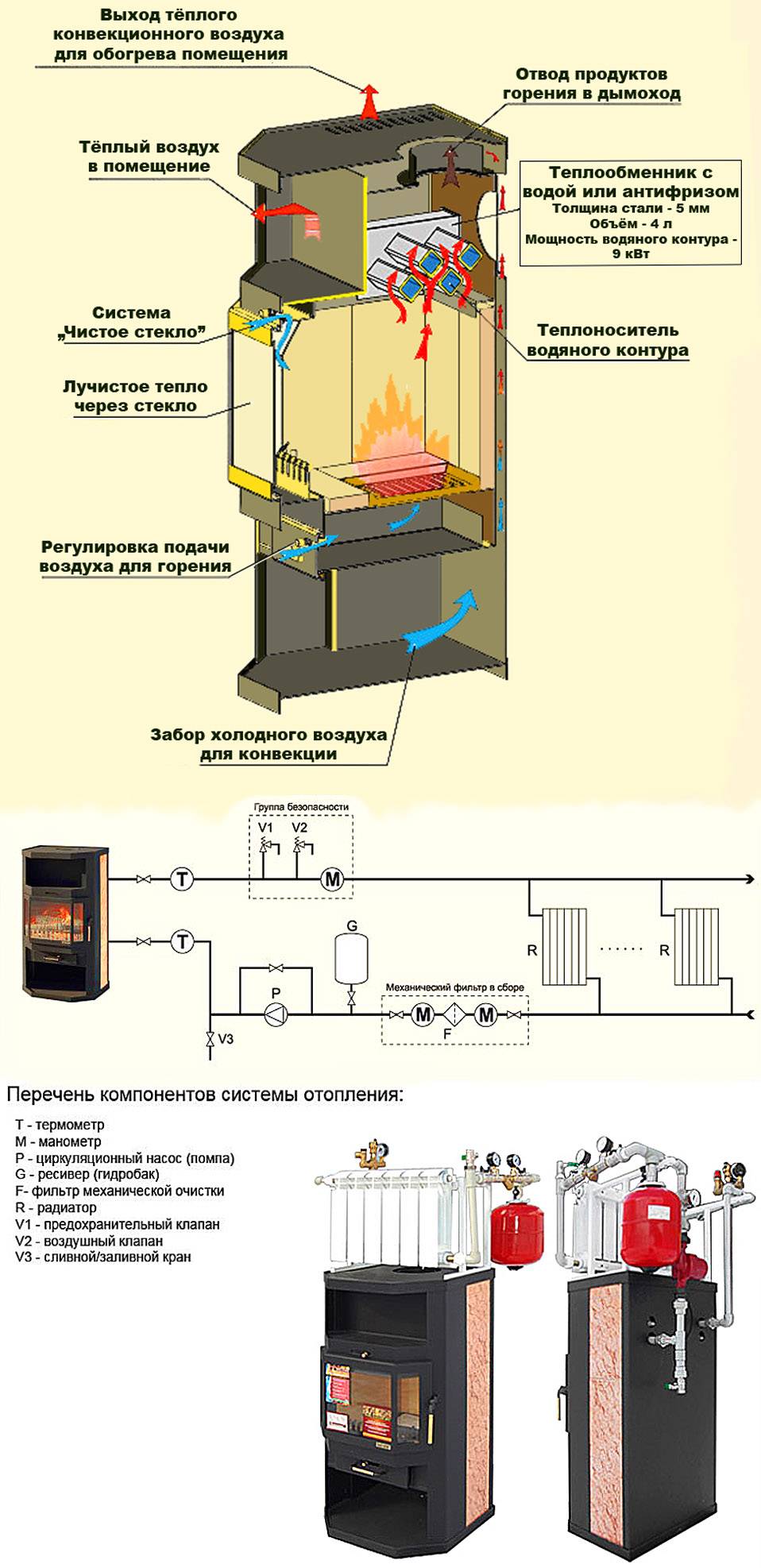

- The design of furnace heating with a water circuit

- Heat exchanger and power calculation

- materials

- Device

- Installation subtleties

- How to build a water oven at home?

- How to make such an oven yourself

- Manufacturing options and recommendations

- System installation

- Brick PVC - features of operation

- PVC installation

- Recommendations for the placement of elements of the heating system

- Conclusion

- Installing a fireplace

- Types of fireplace stoves by material

- brick structures

- Furnace Porfiriev

- Metal furnaces-fireplaces

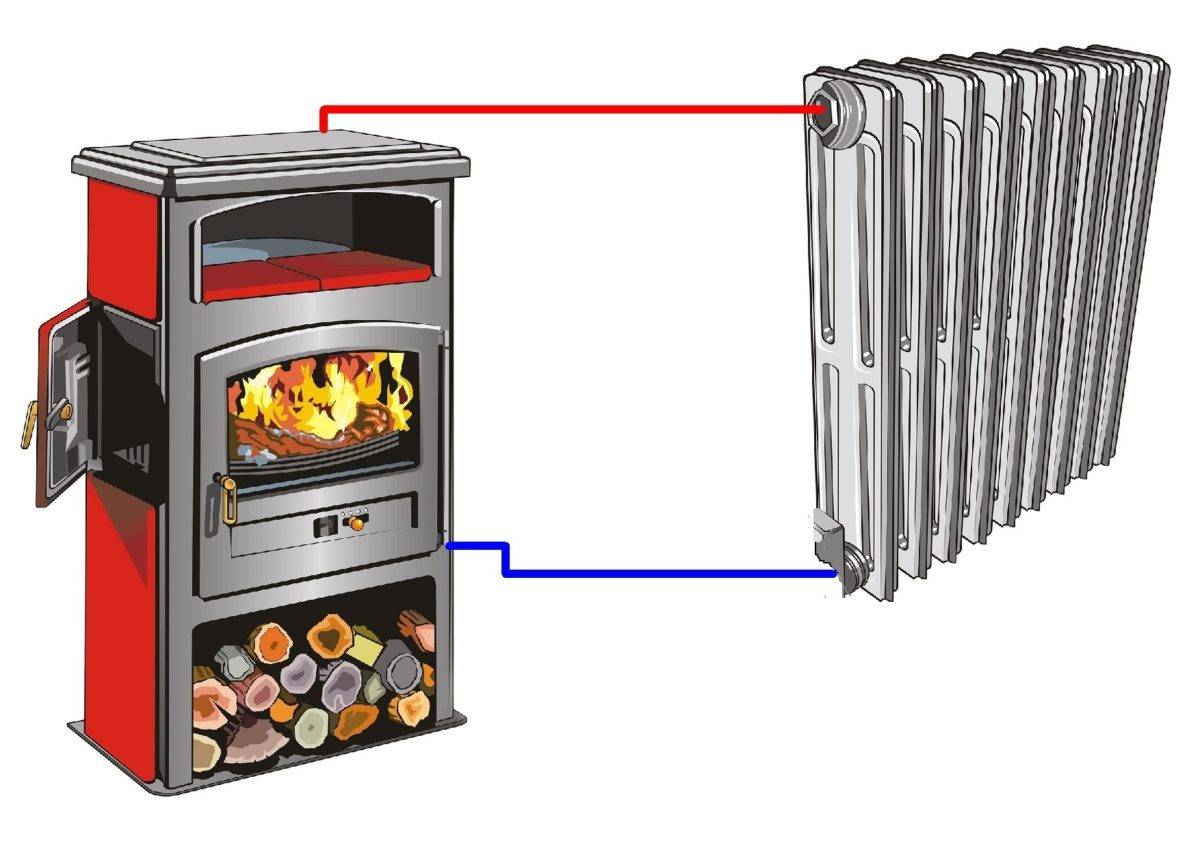

- The principle of operation of the water circuit

- fire safety requirements

- Possibilities of use

- As the main source of heating

- Supporting Role

- Traditional oven and water heating

- The device of the fireplace stove and the principle of its operation

- These systems include:

- The principle of operation of the fireplace stove is simple:

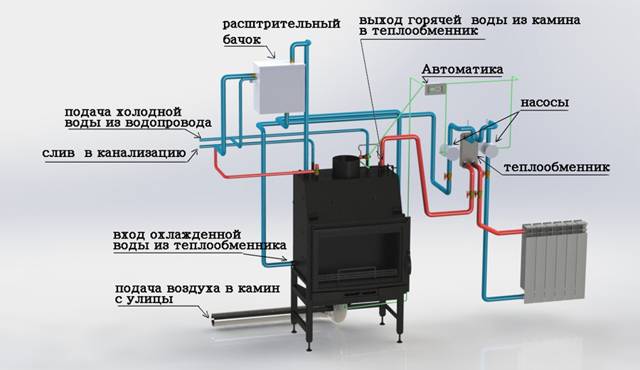

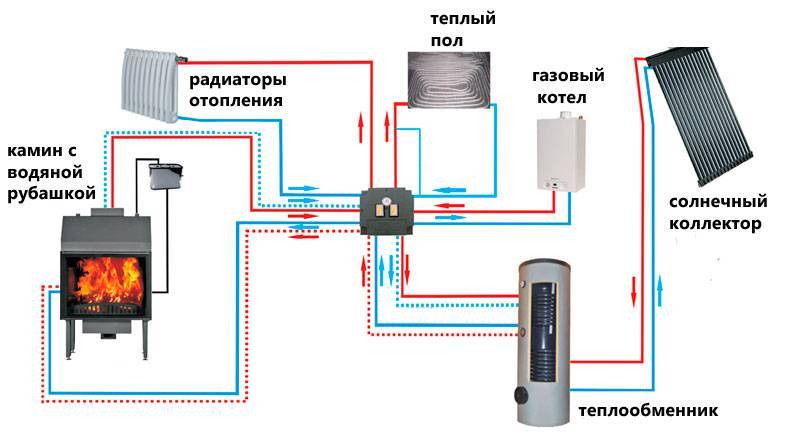

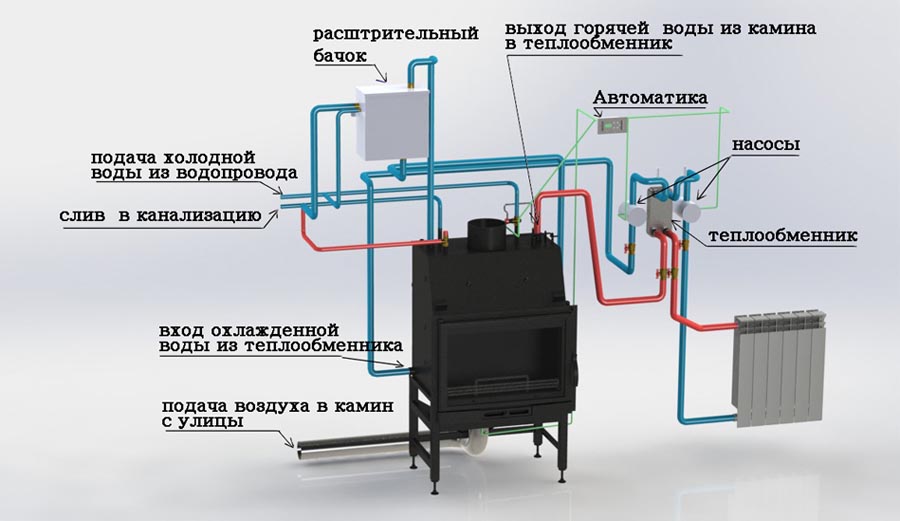

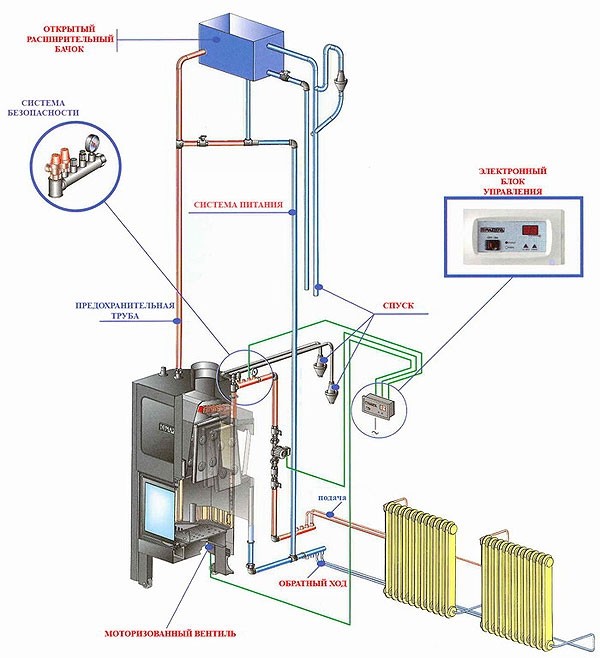

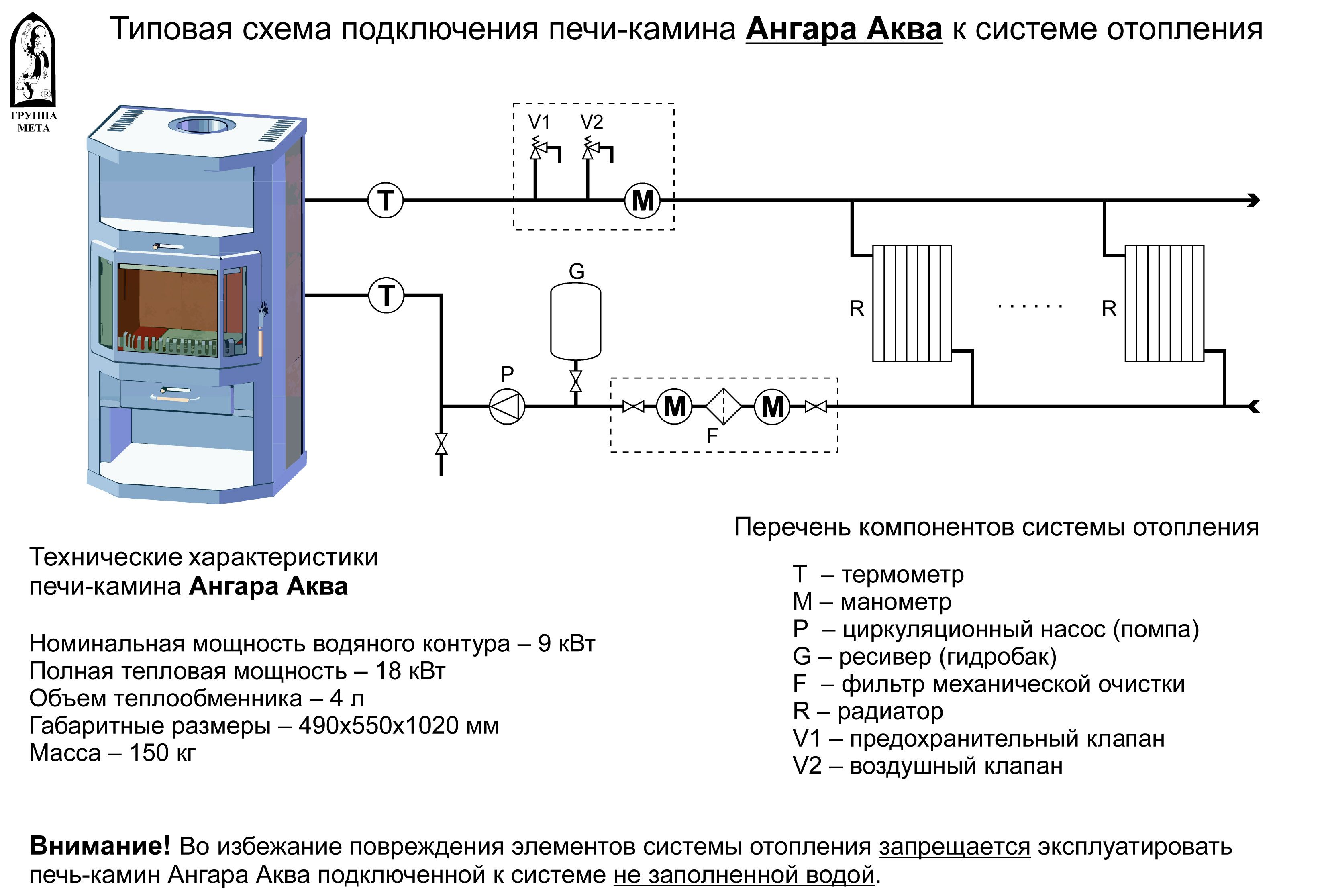

Fireplace connection diagrams

- Open. In this case, a special expansion vessel must be present, which must be located above the furnace and work as communicating containers. Then the water that is heated in the furnace is transferred from the heating system, passing through the heat exchanger.

- Closed.The hearth is connected immediately to the heating system, without passing through the expansion tank and heat exchanger.

The scheme is selected depending on certain situations. Experts believe that the open form of the system has increased security, but it is not always possible to connect it technically.

Scheme of autonomous fireplace heating

Recommendations for choosing a home wood-burning stove

Today there are quite a few types of ovens. When choosing a stove, consider:

- dwelling area;

- preferred type of fuel;

- the most suitable material.

Heated area

The dimensions of the building affect the choice of furnace power. For heating 10 sq. m of the house requires about 1-1.2 kW. This rule works for ceilings 2.5-2.7 meters high, if they are higher, a little more power will be required.

For factory models of furnaces, this indicator is indicated in the passport. For homemade designs, it is calculated approximately.

Fuel used

Water heating can work due to combustion:

- firewood;

- coal;

- fuel briquettes;

- peat.

All kinds of fuels differ in their characteristics. First of all, they give a different amount of thermal energy when burning the same volume.

But that's not the only thing that matters when choosing. The cost is important, as well as how easy it is to find fuel in the area where the house is located. It is better to choose the type that can be purchased from several suppliers. The storage space is also important.

Material

- brick;

- stainless steel;

- cast iron.

Brick ovens are the most massive. They need more space, and a separate foundation is installed under the structure. It is best to initially install a brick oven with a heating tank.Sometimes it is added later, although for this it is necessary to disassemble part of the masonry.

Such heating devices give off heat for a long time and evenly. If desired, volumetric oven chambers are placed in them, but they warm up for a long time. For laying the structure, you will have to look for a specialist.

Cast iron stoves also heat up quickly, and give off heat longer than steel ones. But cast iron is more brittle and at the same time a heavy metal.

Photo 2. Wood-burning stove with a water circuit, made of cast iron. Heating pipes are made of copper.

Steel structures are very popular. They heat up the coolant less and faster. Furnaces with water heating are devoid of the traditional disadvantages of metal appliances. They give off heat not only during the combustion of fuel, but also for a long time after it.

Metal and cast iron stoves do not require a separate foundation. It is enough to protect the floor from the effects of heat and accidental sparks. For this, refractory materials are used, for example, a metal sheet.

Reference. There are models with a furnace door made of heat-resistant glass. They allow you to admire the play of fire. The atmosphere in the room becomes more comfortable.

Factory models of furnaces are produced on legs with adjustable height. Thanks to this, they are easy to place even on uneven floors.

Pros and cons of a metal fireplace with a water circuit

The undoubted advantages include:

- Light weight, does not require the construction of a concrete base (foundation);

- Possibility of operation without electricity (a large number of models do not have electrical mechanisms);

- A variety of appearance of boilers can decorate any interior;

- Some models are equipped with a hob;

- Creation of an inimitable atmosphere of a safe fire element;

- Possibility of erecting a brick portal (a niche where the stove is placed);

- The heat carrier is water or non-freezing liquid. The water version of the coolant is more accessible, but when the system is defrosted, the consequences are unpredictable.

The disadvantages of this type of furnace are:

- Representatives of the category, weighing from 400 to 900 kg., The installation of which requires the construction of a concrete base. The wooden floor and wooden floors will not withstand such a load;

- The need for fire prevention measures;

- Stopping the circulation of the coolant will inevitably lead to an explosion of the stove, also in the absence of a security group, constant monitoring of the temperature of the coolant is required;

- Lack of autonomy of work (during operation, firewood is reported at least 2 times a day);

- Efficiency from 75 to 85%;

- This type of equipment does not allow heating large volumes of space without excessive fuel consumption and the acquisition of numerous additional devices.

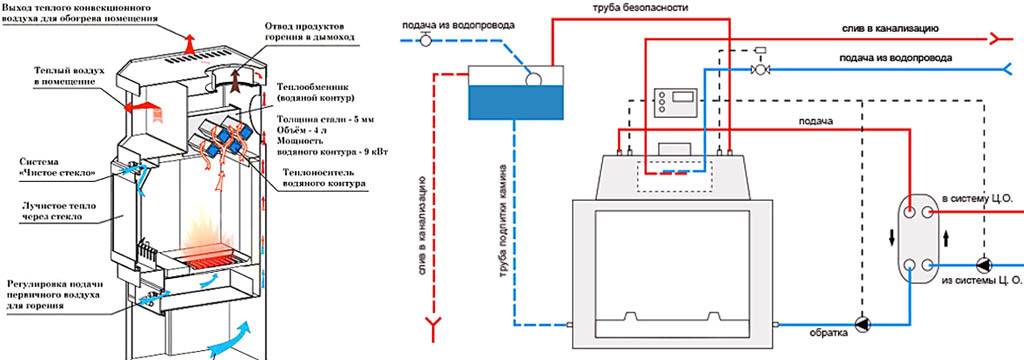

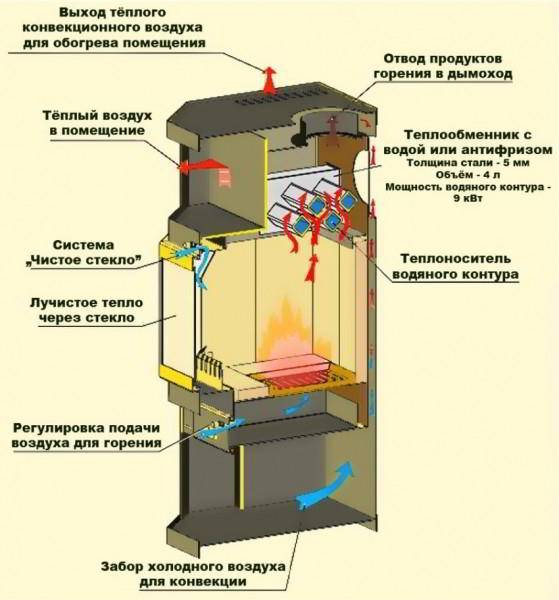

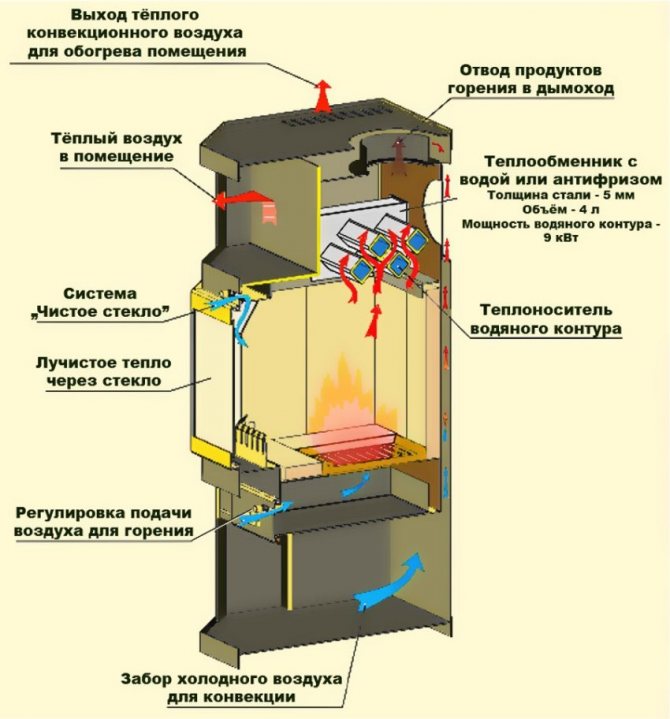

The design of furnace heating with a water circuit

The device of the fireplace stove with a water heating circuit includes a heat exchanger. But it may also contain a boiler or radiator appliance. Such a device provides heating of a significant volume of water. The parameters of the tank are determined by the capacity of the firebox. Such equipment is of closed and open type. The most commonly used materials are metal and brick. In open-type appliances, there is an open firebox, and water passes through the heat exchanger. Brick devices have a complex technical device. An expansion tank is installed.

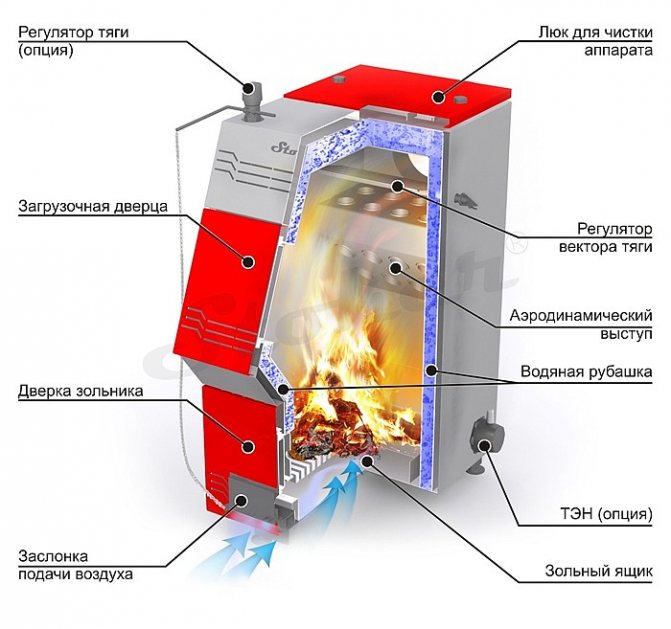

The main device of the furnace

Heat exchanger and power calculation

Calculating the dimensions and power rating of a heat exchanger is a difficult task. The standard design forms 6.5 thousand kcal, which is required to heat a small house. The water circuit will increase the amount of heat generated. When selecting a heat exchanger, special tables will help.

How the system works

materials

Before choosing a fireplace stove with a water heating circuit, it is important to choose the material of manufacture. There are such options:

- copper has a high thermal conductivity. It is able to withstand high temperature fluctuations. The condensate that appears when the lines are cooled includes harmful components that provoke corrosion;

- cast iron is resistant to corrosion, but is known for its brittleness. When cooling and heating, cracks may form;

- steel is one of the available materials that can be easily processed. Such a device as a heat exchanger is made of heat-resistant steel. In this case, seamless pipes are used;

- stainless steel is an expensive option for making radiators, but it has excellent quality.

Heat exchanger made of quality material is a guarantee of safety

Device

The most important device of a home heating furnace with water heating is the heat exchanger. It is made of rectangular and round profile lines. The nuances of installation are determined by the configurations of the mechanism:

- a device made of sheet steel can be placed in a hot place - in a firebox. For production, a sheet of steel and a special pipe are used. It is desirable to place the water supply line at the very top of the structure. This will avoid water hammer.To prevent the liquid from boiling inside, the gap inside must be at least 30 mm;

- the heat exchanger is also made from pipes, while rectangular and round pipes are used. When installing it, free access to the door for firewood, for smoke circulation lines and grates should be provided;

- the tubular type register is placed inside the equipment.

Configuration installation option

Installation subtleties

When installing a heat exchanger in a wood-burning stove with a water circuit, observe the following rules:

- this mechanism must be pressed before installation in the equipment and after that;

- the device is installed immediately after the construction of the base for the furnace. Only then is its laying carried out;

- there should be a space of 10-15 mm between the heat exchanger and the wall surfaces;

- when installing pipes, a gap of 5 mm should be left;

- at the exit, the section of the highway should be at least 12-15 mm;

- lines are combined with a heat exchanger using a heat-resistant sealant;

- connection of the water circuit to the main structure must be carried out by a specialist.

Installation of a structure with water supply lines

How to build a water oven at home?

- There are three ways to carry out stove heating with a water circuit with your own hands:

- buy a steel furnace from a manufacturer whose services include installation of the system;

- hire a craftsman - a specialist will select the material, make the device, lay out the furnace and install the boiler;

- do it yourself.

How to make such an oven yourself

The principle of the boiler for water heating

Can you make such a system yourself? Quite, just enough experience in welding and in laying bricks during the construction of the furnace. First you need to prepare the boiler (register, coil, heat exchanger).

Such a device can be bought or made independently using sheet metal and pipes. Since the complete process of manufacturing and installing a water circuit cannot be put into a short overview, the following are the main recommendations.

Manufacturing options and recommendations

Water heating from a wood-burning stove - scheme

For the boiler, a sheet of metal with a thickness of at least 5 mm is used, and its design is made such that there is maximum heating of the water for further circulation. The boiler, welded from sheet steel, is easy to manufacture and operate - it is easy to clean.

But such a heat exchanger has a smaller heating area, in contrast to the pipe register. It is difficult to make a pipe register at home on your own - you need an accurate calculation and suitable working conditions, usually such boilers are made to order by specialists who install the system on site themselves.

The easiest way to use a solid fuel heat exchanger is an ordinary potbelly stove with a built-in water system. Here you can take a thick pipe as a basis, then there will be much less welding work.

Attention! All welds must be doubled, since the temperature in the furnace is not lower than 1000 degrees. If you boil ordinary seams, then there is a chance that this place will quickly burn out.

The layout of the rooms of the house and the location of the furniture also need to be considered.Here it is necessary to pay attention that it is better to choose a scheme with sheet boilers - they do not have pipe bends connected into one inseparable circuit. Such a structure is not so troublesome to build. It is also convenient because after installation you can use the hob without problems, which cannot be said about some tube boilers

Follow the drawings of the register in accordance with the dimensions of the furnace at home. The layout of the rooms of the house and the location of the furniture also need to be considered.

Here it is necessary to pay attention that it is better to choose a scheme with sheet boilers - they do not have pipe bends connected into one inseparable circuit. Such a structure is not so troublesome to build.

It is also convenient because after installation it is possible to use the hob without problems, which cannot be said about some tube boilers.

Register of smooth pipes - drawing

When the coolant moves by gravity, then you need to raise the expansion tank higher, and use pipes of large diameters. If the pipes are of insufficient size, then a pump cannot be dispensed with, since there will be no good circulation.

Boilers equipped with pumps have their pros and cons: you can save money by installing pipes of smaller diameter and not raising the system so high, but there is one significant disadvantage - when the electricity is turned off or the circulation pump burns out, the heated boiler can simply explode.

It is better to assemble the structure at home, on site, since the device, like individual parts, has a very large weight and dimensions.

System installation

Cast iron battery heat exchanger

- Before installation, a solid foundation is poured, on top of which it is better to lay a layer of bricks.

- You can lay the grate at different stages: before the boiler, if the double structure, the lower part of which can be equal to or higher than the upper part of the grate, when the stove is low and the system is placed a little higher, then the grate, doors, corner on the stove are usually placed after the boiler is installed .

- A housing is installed - usually it consists of two containers connected by pipes.

- The entire heat exchange system is welded to the boiler: the outlet pipe goes to the expander, goes in a circle, through the radiators and, on the other side, the return pipe is welded to the boiler from the bottom.

Stove heating with a water circuit allows, firstly, to use firewood much more rationally, and secondly, to evenly distribute warm air throughout the heated room.

Having decided to independently make a heating system at home with a wood-fired water circuit, think through all the stages of work, and if there is any doubt about the successful outcome, then it is better to contact specialists.

Brick PVC - features of operation

Often, water heating is combined not only with a fireplace or a modern wood-burning stove. For many, the best option would be to install a classic brick oven as a source of thermal energy. Properly expanding the capabilities of a brick oven with the help of a water circuit, it is possible to warm up not only the nearest living rooms, but the entire building. To increase the efficiency of a brick kiln, various designs of heat exchangers have been developed (coils and registers act as them). The operation of such a system in suburban housing has features, which include:

- Arrangement. To fold a high-quality stove, and then carry out the installation of water heating, highly qualified craftsmen will be required.

- The size.The overall traditional Russian stove takes up a lot of usable space and does not fit in every kitchen. An alternative for modest-sized rooms would be a Dutch or Swedish brick oven. Such designs are characterized by smaller dimensions, but full functionality.

Heat exchanger installation diagram

- Efficiency improvement. The maximum efficiency of the furnace does not reach 50%; half of the heat (and money) irretrievably disappears in the pipe. The device of a full-fledged water heating system allows increasing this parameter to 80-85%, which is comparable to the characteristics of industrial boilers operating on solid fuels.

- Inertia. Unlike electric boilers, it will take a certain amount of time to warm up a system tied to a brick oven.

- Care. Burning wood leaves behind ash and dust. The room in which the brick oven is located will have to be cleaned often and thoroughly.

- security requirements. Improper operation of a brick oven for a house with water heating is a threat not only to fire, but also to carbon monoxide poisoning.

About laying a brick oven with a water circuit in the following video:

PVC installation

If in a country cottage it is planned to install water heating from a brick stove (on wood), the heat exchanger is designed individually, for a specific stove. Such a device is practically beyond repair, therefore, a stove-maker is involved in the installation, who will be able to professionally perform all the work:

- Fabricate a heat exchanger and double check its quality before and after installation.

- Mount the heat exchanger at the desired stage (after the foundation is completed), then continue laying, observing certain rules. When installing the heat exchanger, compensation gaps are left, leaving 1-1.5 cm to the walls of the combustion chamber. Gaps that take into account thermal expansion are also needed when installing pipes.

- When installing a heat exchanger with pipes and for insulation, use only heat-resistant seals.

Steel pipes for the manufacture of heat exchangers

Recommendations for the placement of elements of the heating system

Elements of the heating system can hardly be called a decoration of a modern interior. Under this definition, only pipes that organically look in some industrial interiors can fit. In general, building codes and architectural guidelines recommend that parts be placed in areas that are hidden but accessible for repair and maintenance. Placement is subject to the following rules:

- The heat generator is placed in an isolated room with heating and good ventilation. The circulation pump must operate under the same conditions. Small boilers (up to 30 kW) can be installed in the kitchen, in the hallway, in the basement or in a warm heated outbuilding. Furnaces intended for residential premises are installed taking into account fire safety rules.

- The place for an open-type expansion tank is in the attic; they tend to place supply and collection pipelines along the main wall structures.

Compliance with the rules of operation helps the smooth operation of the system

- The main riser passes openly in the corners of the living quarters, in the attic it is covered with thermal insulation.

- Radiators are installed openly under window openings.They participate in room circulation by heating the cold air coming from the windows. Attempts to decorate radiators with decorative screens are undesirable, since they reduce the thermal efficiency of the system.

Conclusion

The device of water heating from a wood-burning stove is becoming an increasingly frequent choice in private housing construction. A brick oven, built by a professional stove-maker and competently integrated into the system, will be an effective design that performs all the tasks assigned to it, from utilitarian to aesthetic.

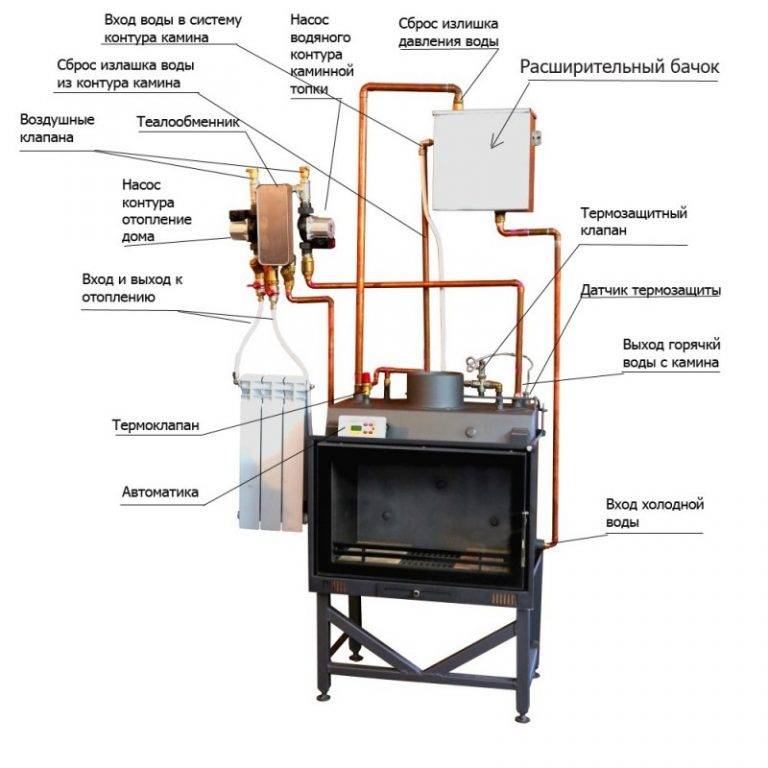

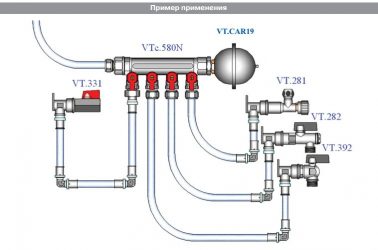

Installing a fireplace

In order for the stove to start heating the room, you need to connect it to the heating system. For this, special tools and materials are used:

- Fireplace stand.

- Expansion tank.

- Copper pipe to attach the structure.

- Controller to manage the heating process.

- Thermal protection - a sensor that protects the oven from boiling. That is, when the water temperature reaches 90 ° C, the water is transferred to the circuit.

- Explosion valve. In other words, this is the protection of the furnace from the fact that the pressure rises excessively.

- Connecting elements: valves with couplings, sanitary technical connections that are used during installation.

- Heat exchanger, if the form of connection is open.

Types of fireplace stoves by material

The material of manufacture determines such characteristics of the fireplace stove as strength, reliability, ease of use and cost. Consider some types of products intended for installation in the country or in a country house.

brick structures

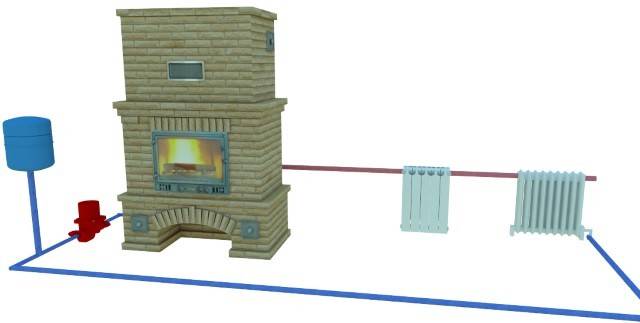

A water circuit stove made of brick provides for various options for mounting a heat exchanger near the firebox.The fire is maintained by supplying oxygen, which ensures uniform heating of the coolant.

For the construction of the structure, stone blocks or refractory materials are used. the shirt is made of steel sheets, between which heat exchangers are placed. Brick ovens require financial investments, but they can emphasize the unusual interior. In addition, the blocks have the ability to heat up and be an independent source of heat.

Furnace Porfiriev

Design engineer Ya. Porfiriev developed a fireplace design with stove options and a hob. It is made of brick, inside the fuel chamber there is a boiler to which radiators are connected. Based on the creator's project, you can make a large firebox, install a glass door - the product will acquire the functions of a fireplace. The hob is installed on top of the boiler. The installation does not contribute to quick cooking, but successfully heats a house of 200 sq.m.

Metal furnaces-fireplaces

A steel or cast iron stove with a water circuit is compact, easy to install. There are a number of differences between steel and cast iron products:

- steel structures are small in weight, do not deform due to temperature fluctuations or shock loads. The foundation does not need to be built;

- cast iron units with water heating do not corrode, retain heat well, but can crack due to cold water. To put the product, you need to equip the base.

The principle of operation of the water circuit

Units operating on the principle of heating water are made of boiler steel having a thickness of 4-5 mm. Sometimes thick cast iron with a density of 8 mm is used. The decorativeness of the device is given by a refractory coating and a lining of heat-resistant tiles.

The thermofireplace has a cavity where a 40-liter tank is mounted. The “pocket” is located between the walls of the case, and air supply channels are located near it. The system maintains long-term combustion by accessing oxygen. When heated, air masses penetrate through the holes to warm up the installation site of the furnace. Water heating is provided by a heat exchanger, and heat distribution throughout the house is provided by a radiator network.

fire safety requirements

To ensure your safety, you should follow a number of recommendations:

- The recommended distance from the furnace to the wall is at least 30 cm; a fire buffer in the form of a fire-resistant material is mounted on the wall;

- Fireproof cutting of the chimney;

- Preparation of a fire-resistant base for heating equipment;

- Installation of a ventilation system in a room equipped with a boiler;

- The chimney is mounted from sandwich pipes, in the case of using a conventional pipe, the chimney is covered with fire-resistant materials.

When installing a fire screen, the wall on which it is attached must be at room temperature when the furnace is in operation. In the case of the slightest heating of the wall, the thickness of the screen or the distance to the heating unit increases.

There are many varieties of fireproof screen. Suitable materials:

Fire resistant drywall

Fire resistant drywall

- fire-resistant drywall;

- heat-resistant mineral wool with aluminum coating;

- concrete;

- ceramic plate.

You should also follow the recommendations for preparing the base for the fireplace. The length and width of the base exceeds the dimensions of the heating unit. From the back side at least 5 cm, from the sides by 30 cm, from the front side by 70 cm.When cleaning and operating the fireplace, these measures serve to protect the floor covering.

When erecting a brick portal, the minimum distance from the metal case to the brickwork is observed; if this distance is not maintained, there is a possibility of overheating of the unit body, which entails deformation of the entire structure.

Possibilities of use

It is good when the suburban area is gasified. The choice of heating is unambiguous. In connection with the increase in energy prices, for many, the problem of finding alternative heating becomes relevant. The situation is not critical if you use stove fireplaces for heating. They are used in steam, water or air heating. The power of the device and the selected system will determine the degree of integration of the water heater.

As the main source of heating

Classic fireplaces and stoves are good for small houses and cottages. What should owners of townhouses and cottages expect? Solid fuel fireplaces with a water circuit will come to the rescue.

The water heating system is the most popular because of its functional simplicity, practicality and availability of materials. In addition, it can be completely autonomous with a device with natural circulation of the coolant. By connecting a fireplace with a heating circuit to the water system, uniform heating of a residential building is ensured.

The option of using a water fireplace as the main water heater in the heating system requires certain conditions:

- Daily work - to maintain a fire, permanent residence in the house is necessary.

- The ratio of power and area (volume) of premises. The larger the area, the more powerful the heating unit is required for operation.The condition is 1 kW per 25 cubic meters. m of premises.

- Business needs. In addition to heating, you need to get hot water and cook food.

- Type of fuel - for more efficient use, it is possible to use coal or pellets.

- Choice of equipment (furnace), wiring, wiring diagrams. Since the water heating system has various arrangement options - open or closed; single-circuit, double-circuit or three-pipe, the equipment is selected according to the selected scheme.

The heating system is designed individually for each house based on its features.

Supporting Role

Many people recommend using a fireplace with a water heating circuit as a backup heating device. Integrated into an existing heating system, it will perform several tasks:

- saving energy resources;

- preservation of decorative function;

- increase the efficiency of the heating system;

- maintaining a microclimate - does not dry the air.

Merging options can be different: the main sources are gas or electric heat generators, solid fuel boilers. At the same time, the operation of the main unit can be interrupted automatically or manually when an additional one is connected. Although they can work at the same time, say, in severe frosts. A successful combination is the operation of the fireplace during the day, and at night - an electric or gas boiler.

Traditional oven and water heating

water heating.heat is stored

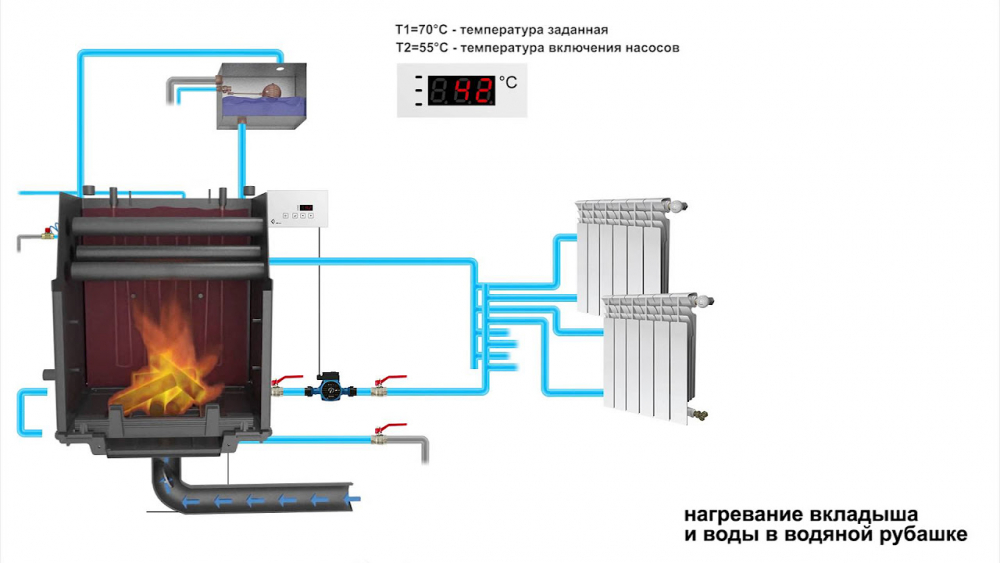

The device of a furnace with water heating differs from a conventional furnace by the presence of a heat exchanger installed in the firebox. The simplest water system is connected to the register.By design, the heat exchanger may be different, but in any case, it must warm up the coolant well and provide high-quality circulation. For the production of registers, metal pipes or sheet steel are used.

The system of furnace water heating is especially popular among residents of villages and villages where there is no gas pipeline. In this case, improved stove heating is the only way to heat the house during the cold season. Such heating works even during a power outage.

Many owners of furnace water heating install circulation pumps to improve the circulation of the coolant and increase the efficiency of the system. The combined installation of an expansion tank and a pump allows the entire heating system to work smoothly in any conditions. The main thing is to melt the firebox and periodically add fuel to maintain the optimum temperature in the system.

Stove heating device, combined with water, costs the owner of the house much cheaper than purchasing a factory-made boiler.

Disadvantages of using stove heating with a water circuit:

- to maintain the optimum temperature in the house, the stove is heated every day;

- when using this type of space heating, it is impossible to install the furnace in the basement as it is done when using a factory solid fuel boiler;

- it is necessary to strictly follow the installation rules for the entire system in order to ensure sufficient circulation of the coolant;

- high temperature differences during the operation of the furnace drastically limit the choice of material for the heat exchanger; only registers made of metal pipes or sheet steel can be installed in furnaces;

- this type of heating cannot be arranged only with the use of forced circulation.

If you are the owner of a small building, but really want to install stove heating in your house, purchasing a factory stove would be an excellent way out.

The device of the fireplace stove and the principle of its operation

The design of the fireplace stove is slightly different from the device of a conventional fireplace. It is simply supplemented with a heat exchanger, which houses a coil that is connected to the heating system of the house. The furnace chamber is closed by a door made of heat-resistant glass, which can have a different configuration. Doors can be hinged or slide up. Here, each consumer can choose the most convenient option for themselves. Sliding up glass is very convenient if there is not enough space for a swing door in front of the fireplace insert.

In the upper part of the fireplace stove there is a smoke collector attached to the chimney.

The ash pan is designed in such a way that ash removal is as convenient as possible. In addition, the ash pan almost always acts as a blower through which air enters the fuel combustion zone. The design of the ash pan also allows you to regulate the air circulation.

Depending on the manufacturer and model of the fireplace. It can be equipped with additional systems that allow you to control the intensity of heating.

These systems include:

These systems include:

- combustion intensity regulator;

- flame cutter;

- additional channels through which heated air can go outside.

The principle of operation of the fireplace stove is simple:

- The heating system itself is a fireplace stove, pipelines and heating radiators.

- Inside the furnace there is a coil through which water passes.

- During the combustion of the furnace, it heats up and enters the heating radiators located in different rooms of the house through pipes.

- At the same time, not only the room where the fireplace is installed is heated. But also everyone else.

If in an ordinary fireplace, excess heat went directly into the chimney, then here it is used much more appropriately. If the heating system is equipped with a circulation pump that accelerates the movement of the coolant along the main, then the efficiency of the entire system becomes even higher.

Fireplace stoves can be used both as an independent source of heat, and as a backup option in combination with a gas, solid fuel or electric boiler. This makes it easy to survive the failure of the main boiler even in winter.