- Useful tips for laying the stove

- Varieties

- Improved heater options

- Homemade long-burning metal stove

- The process of the Russian stove

- Furnace design features

- Which brick to choose for the oven

- The device of a traditional oven

- Design features of a brick oven for a summer residence

- How to paint the stove

- Cleaning

- Video description

- Conclusion

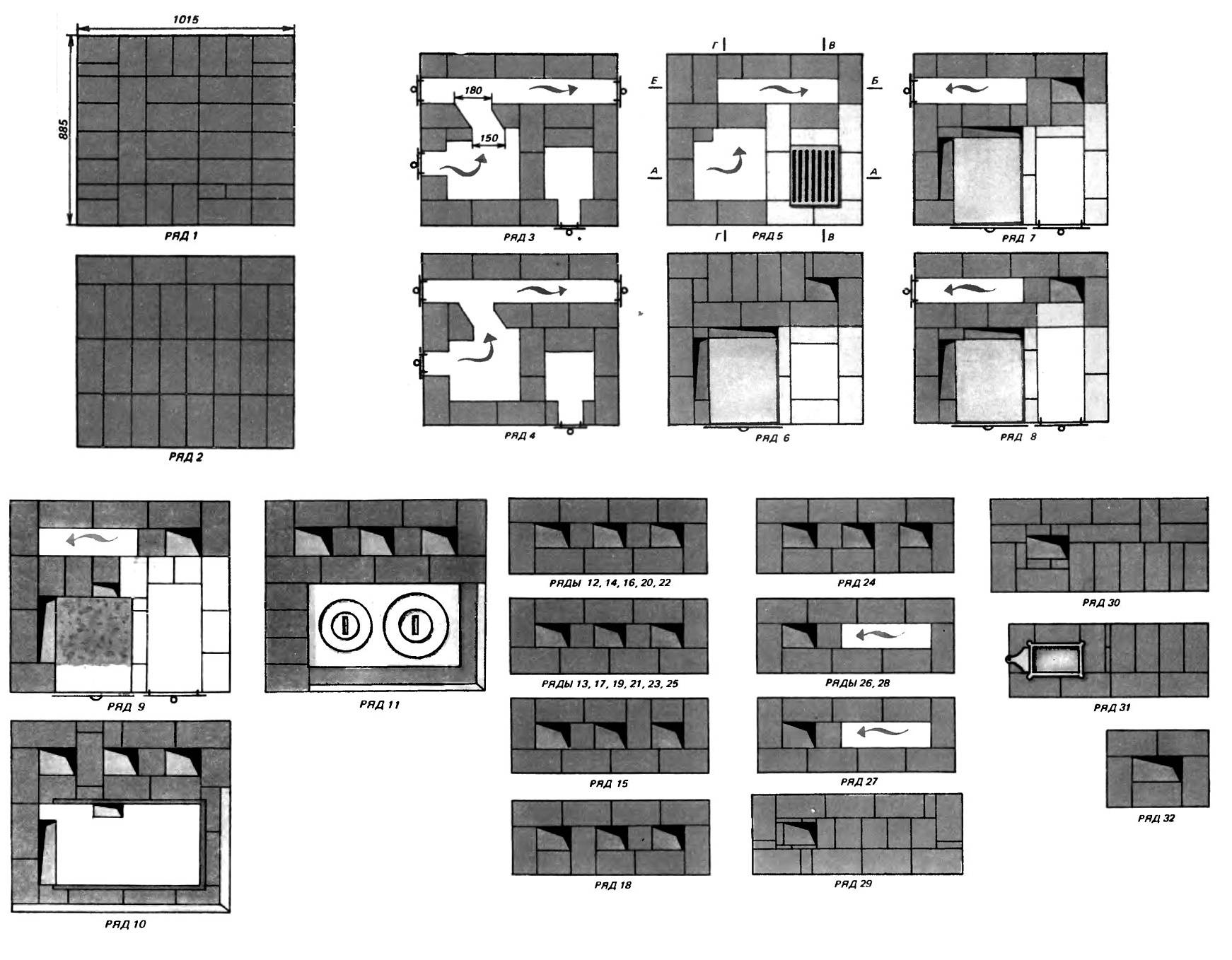

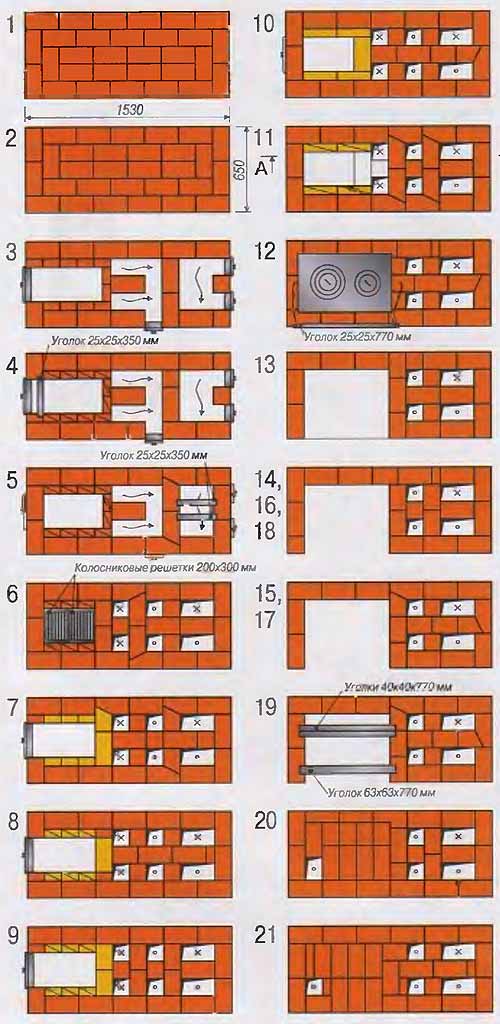

Useful tips for laying the stove

- They lay out the Swede oven with their own hands from ceramic red brick, and in this case only new material will do, but, in no case, has not been in use;

- In order for such a furnace to serve properly and for a long time, the foundation for it should be slightly larger than the dimensions of the furnace itself;

- To maximize adhesion on the surface of the bricks, each of them is rinsed in clean water for several seconds immediately before laying, removing dust particles from it;

- In order for the halves and three-four bricks used in the masonry to be even, they resort to the help of a grinder for their manufacture. Their size and number are determined in accordance with the order of the future Swede stove;

- Metal and brick are characterized by different characteristics when heat expands.Therefore, with their adjacent installation, there must certainly be a gap of at least half a centimeter.

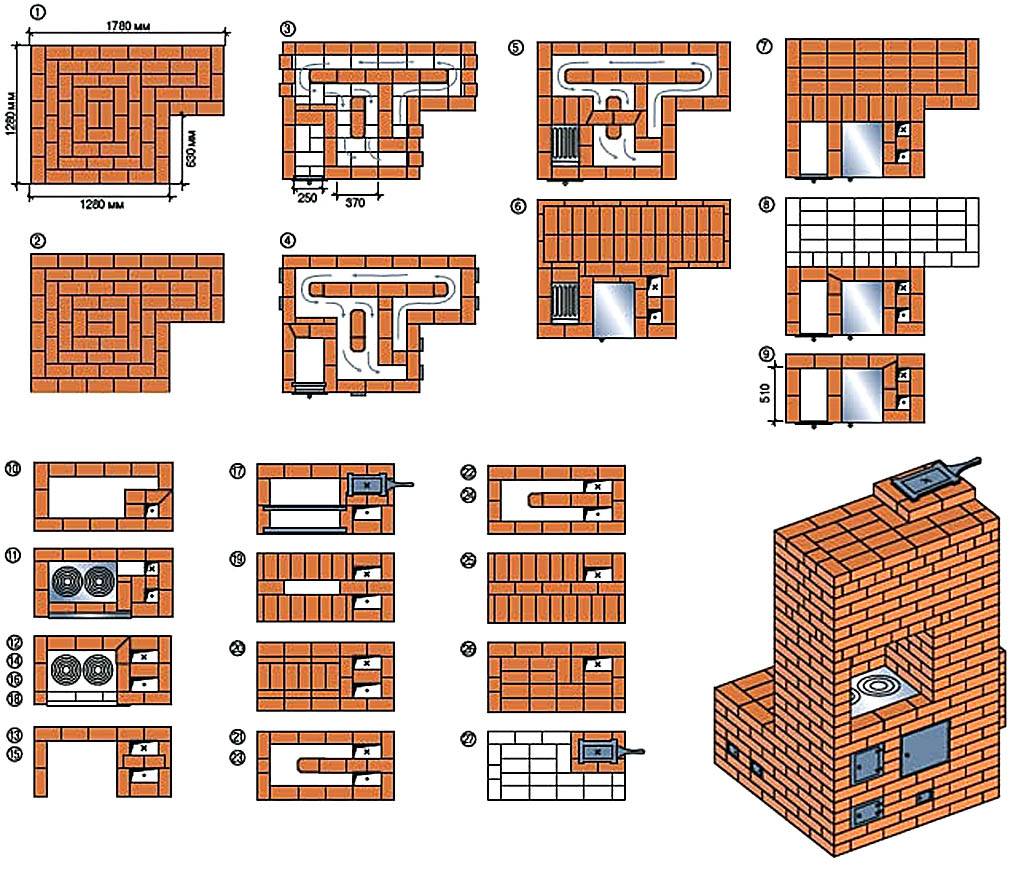

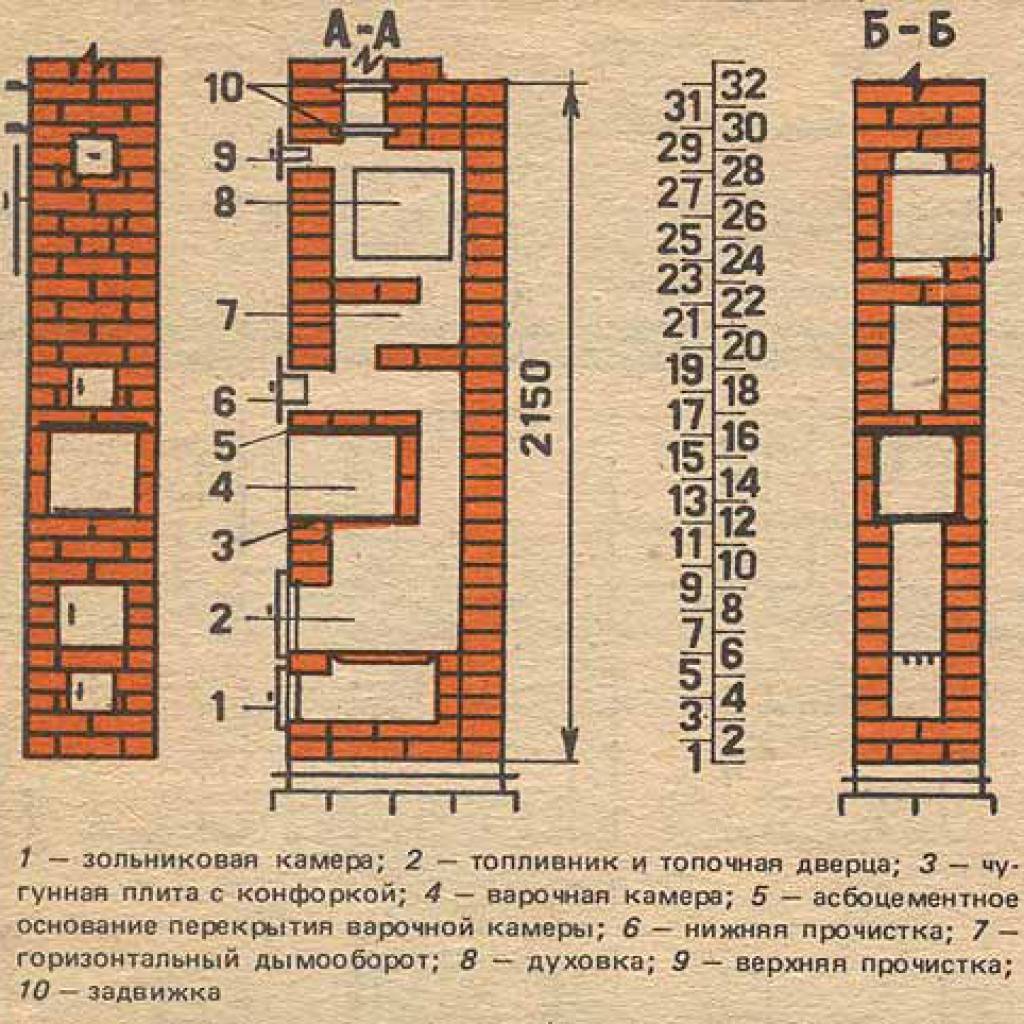

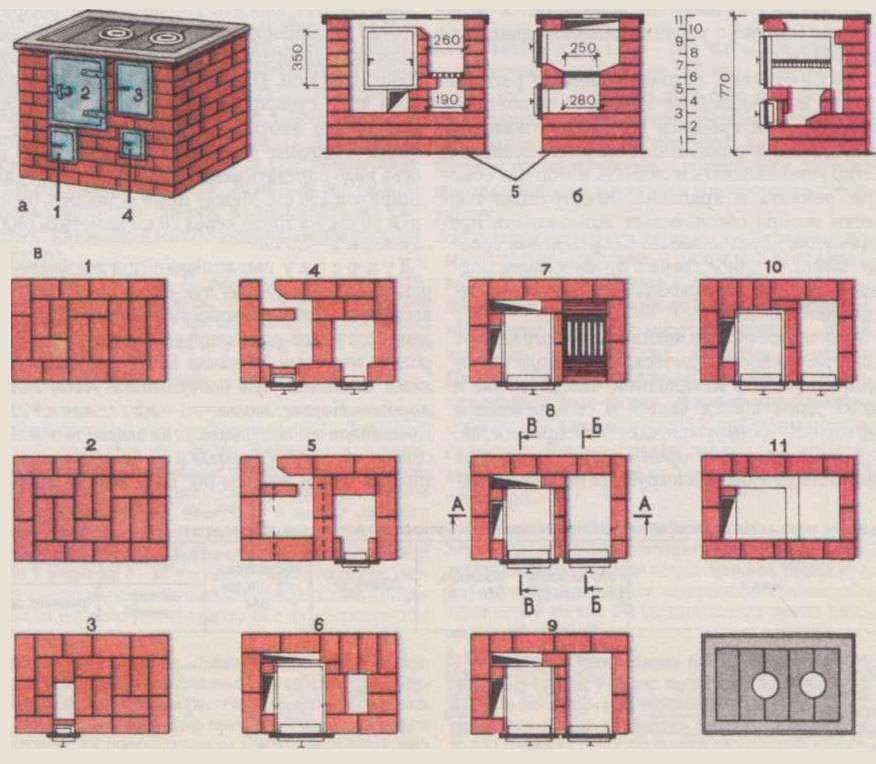

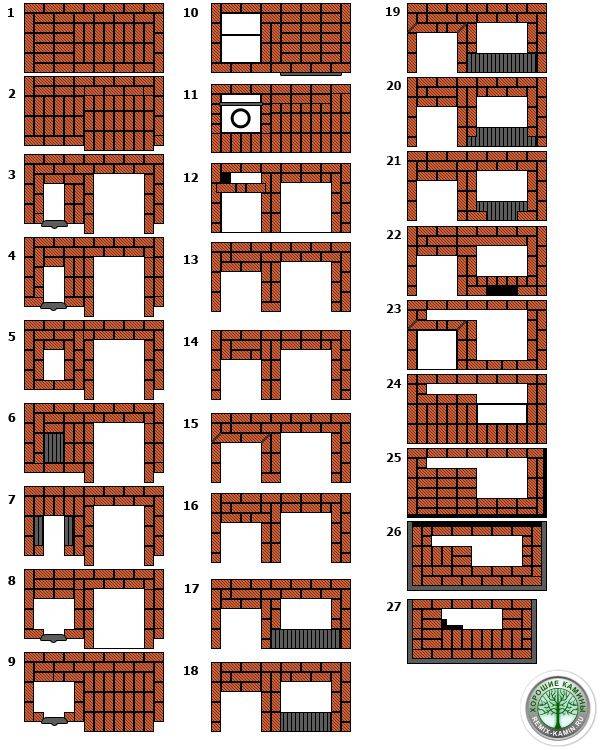

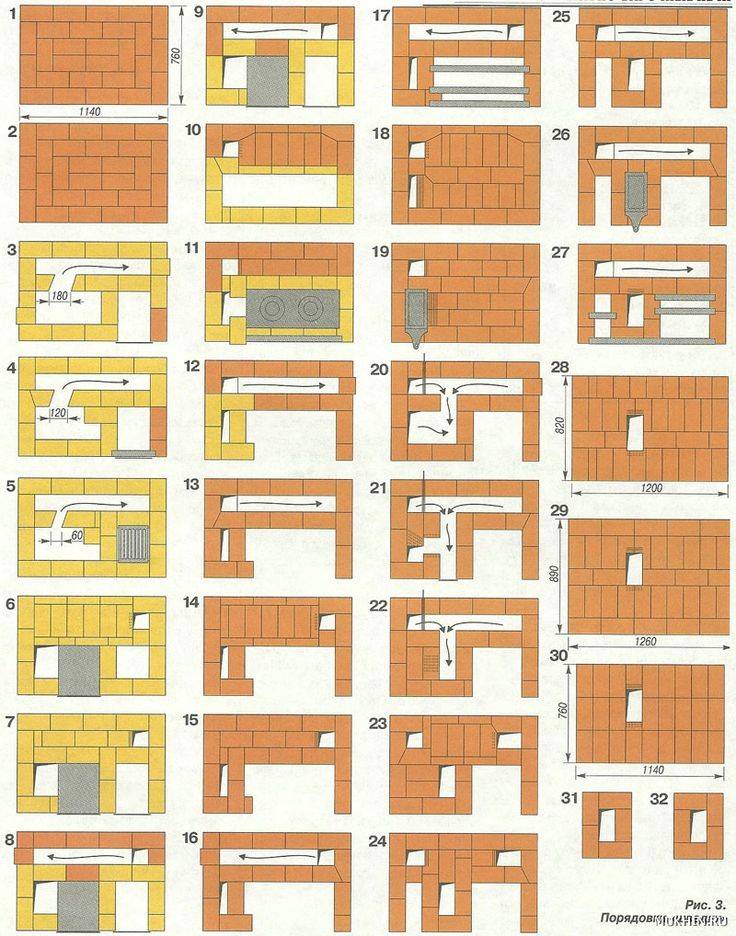

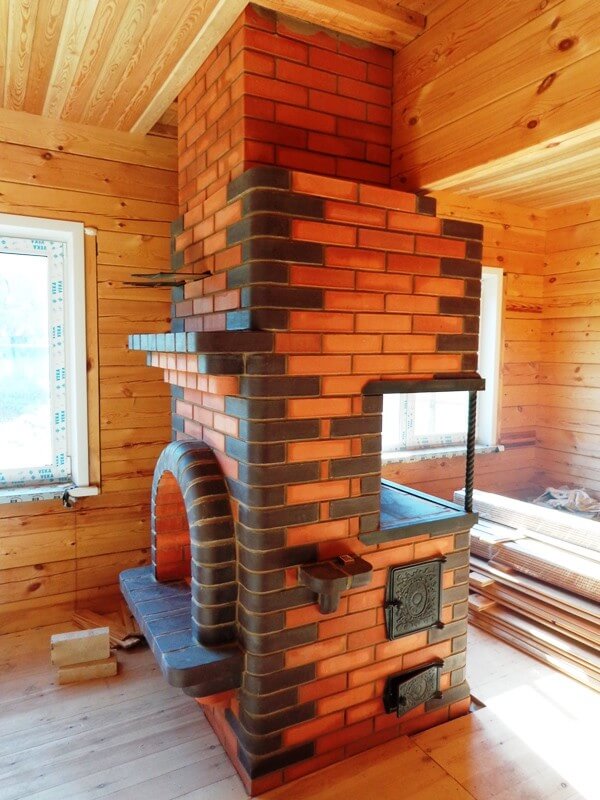

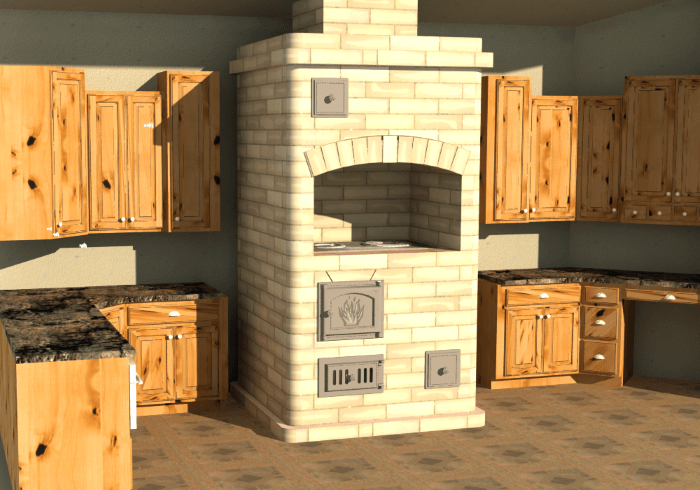

Swedish heating stoves

Swedish heating stoves

Swede brick ovens

Swede brick ovens

Swede ovens for the home

Swede ovens for the home

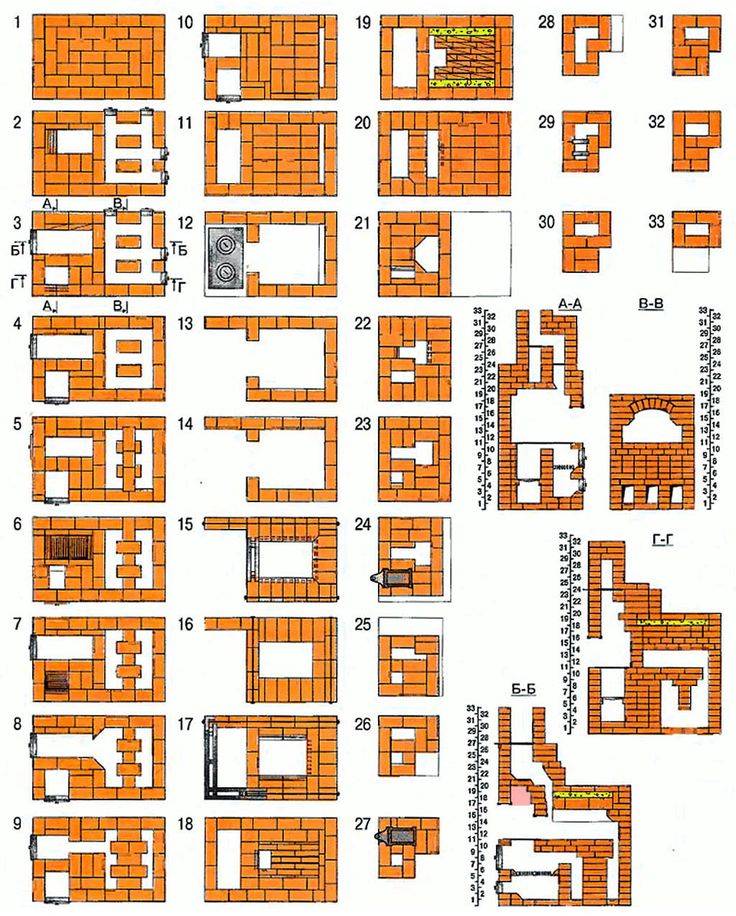

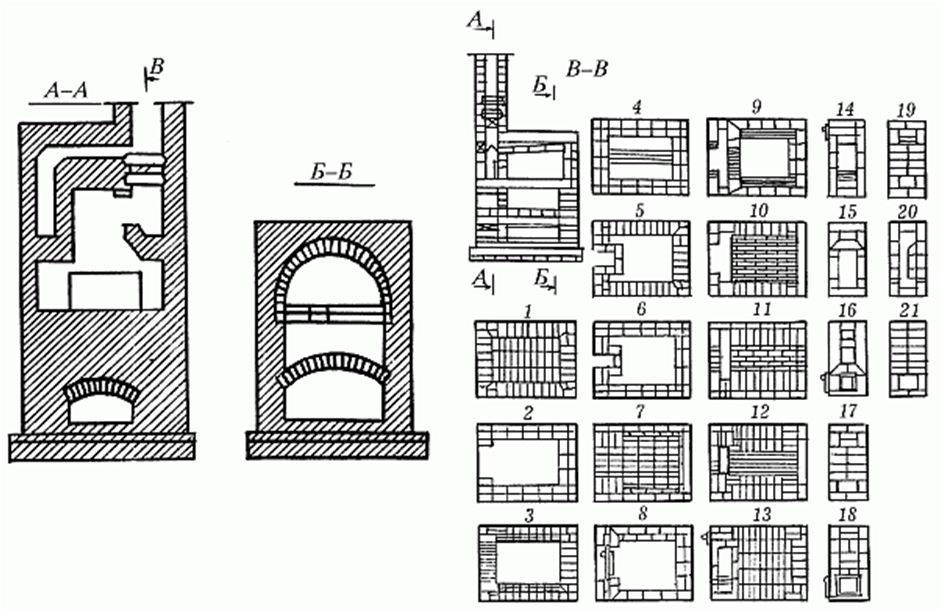

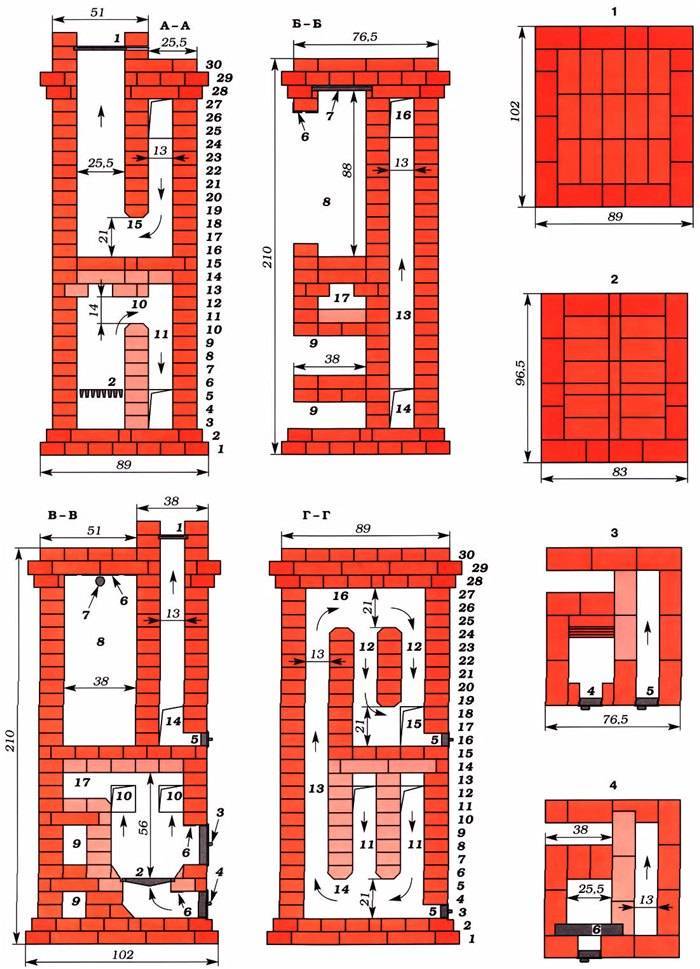

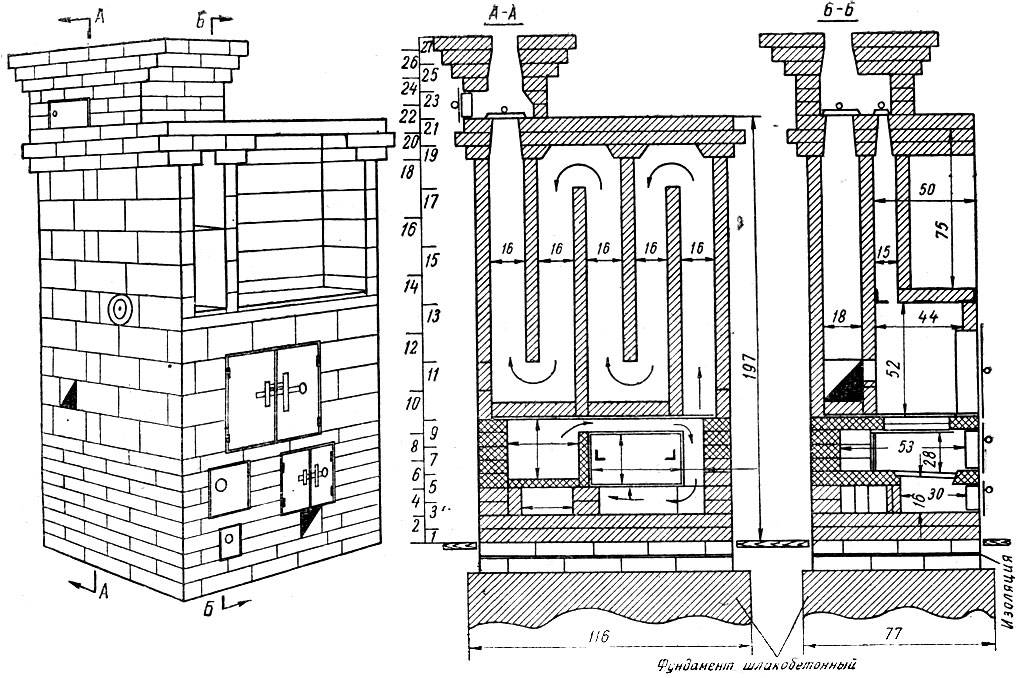

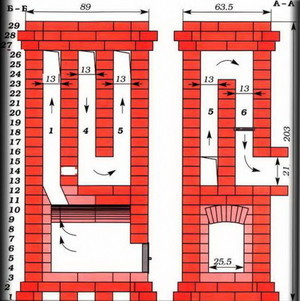

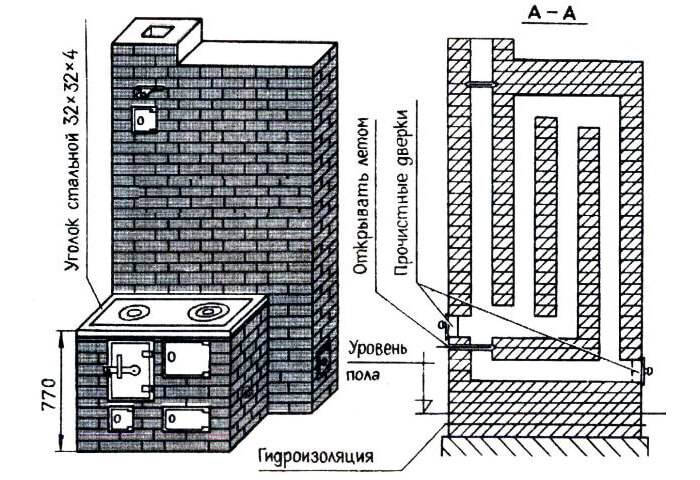

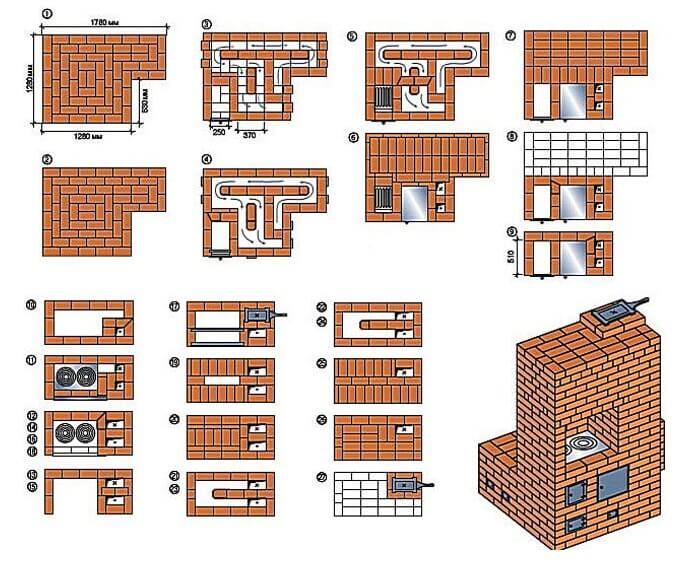

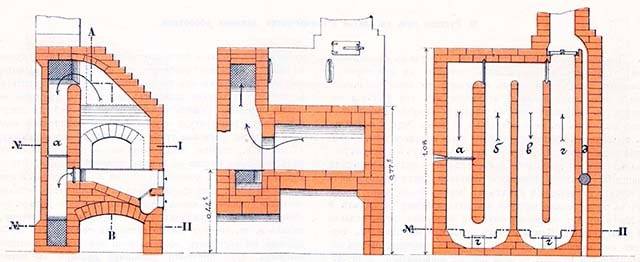

Swede oven drawings

Swede oven drawings

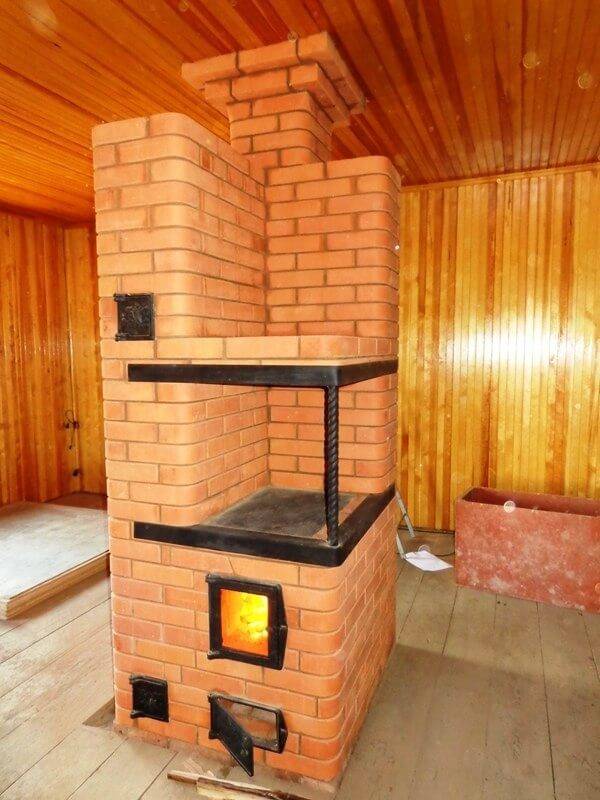

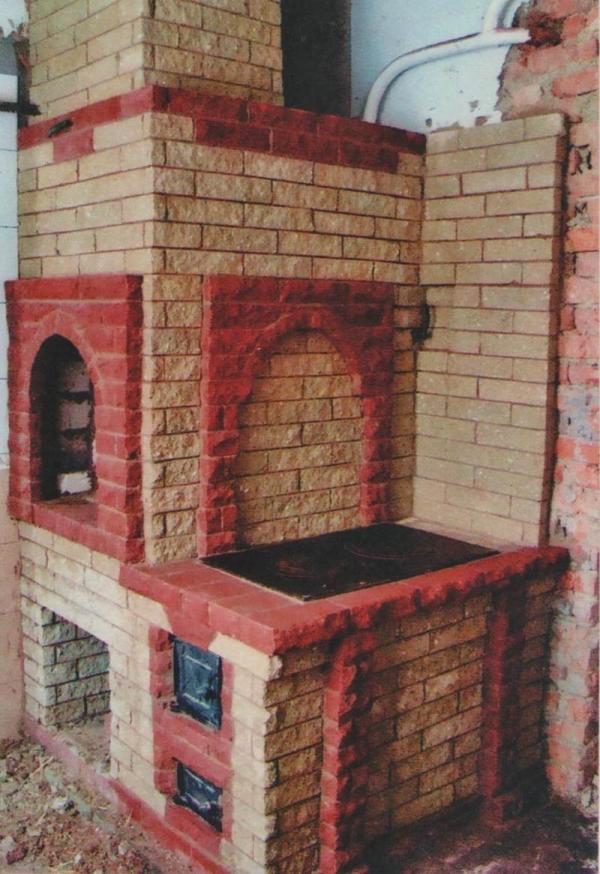

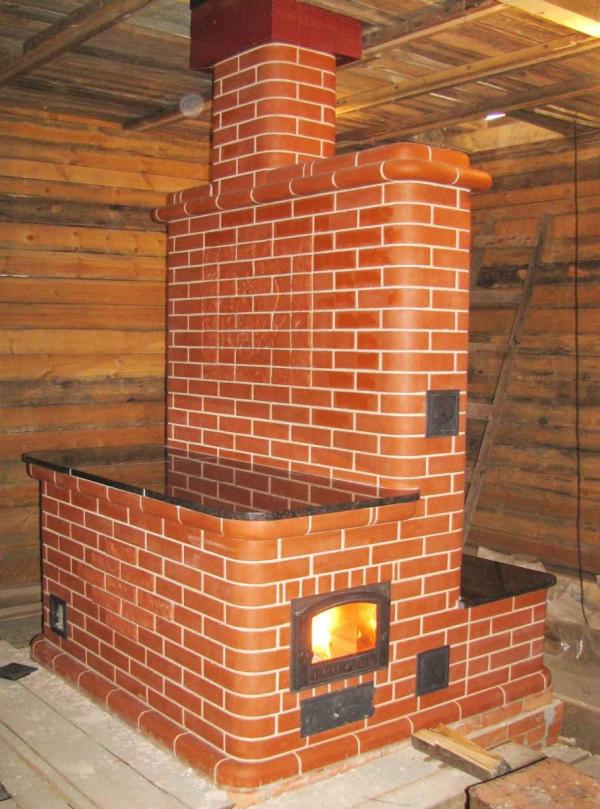

Swede brick oven photo

Swede brick oven photo

brick heating stove

brick heating stove

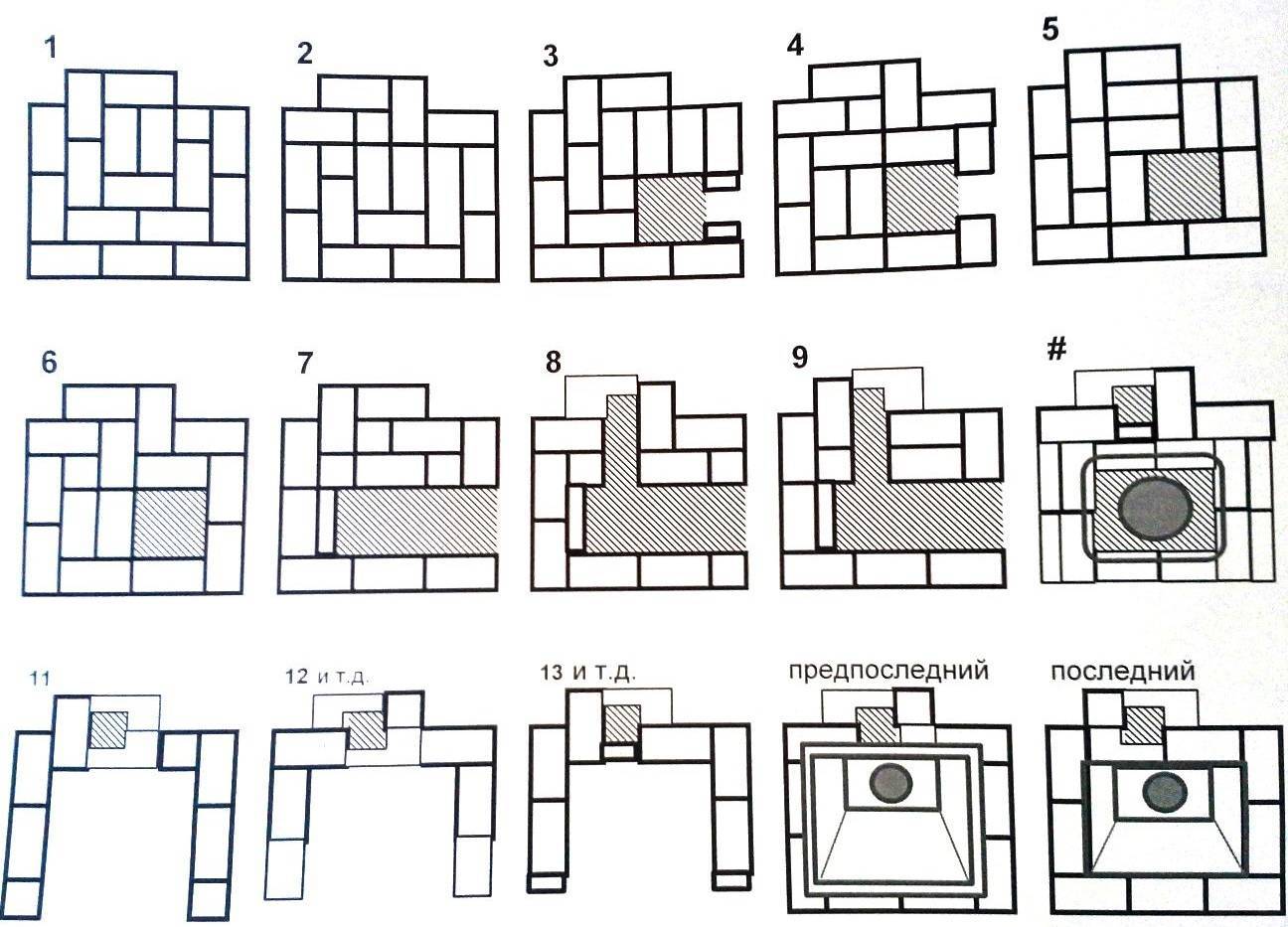

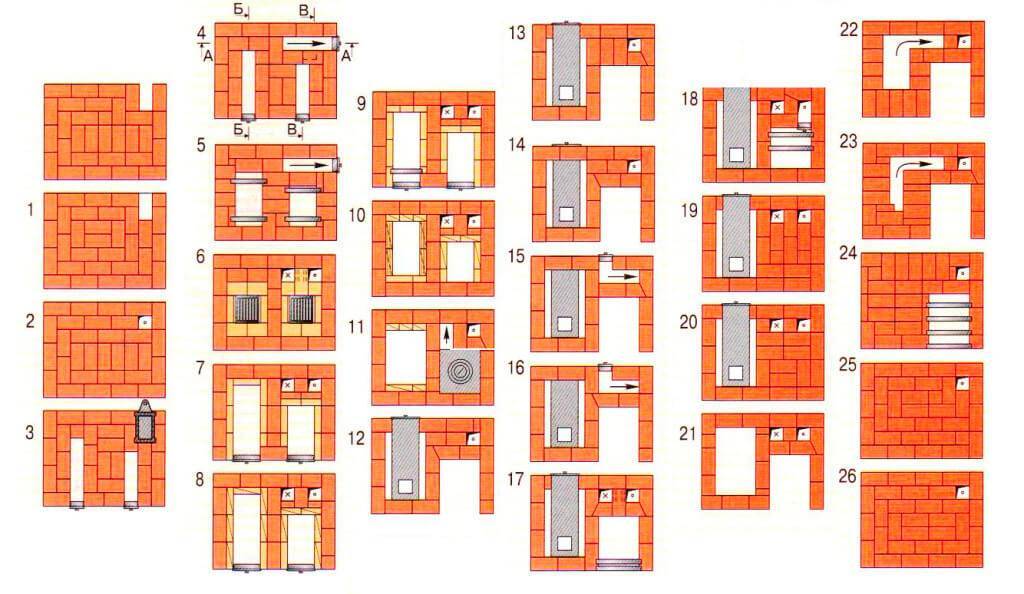

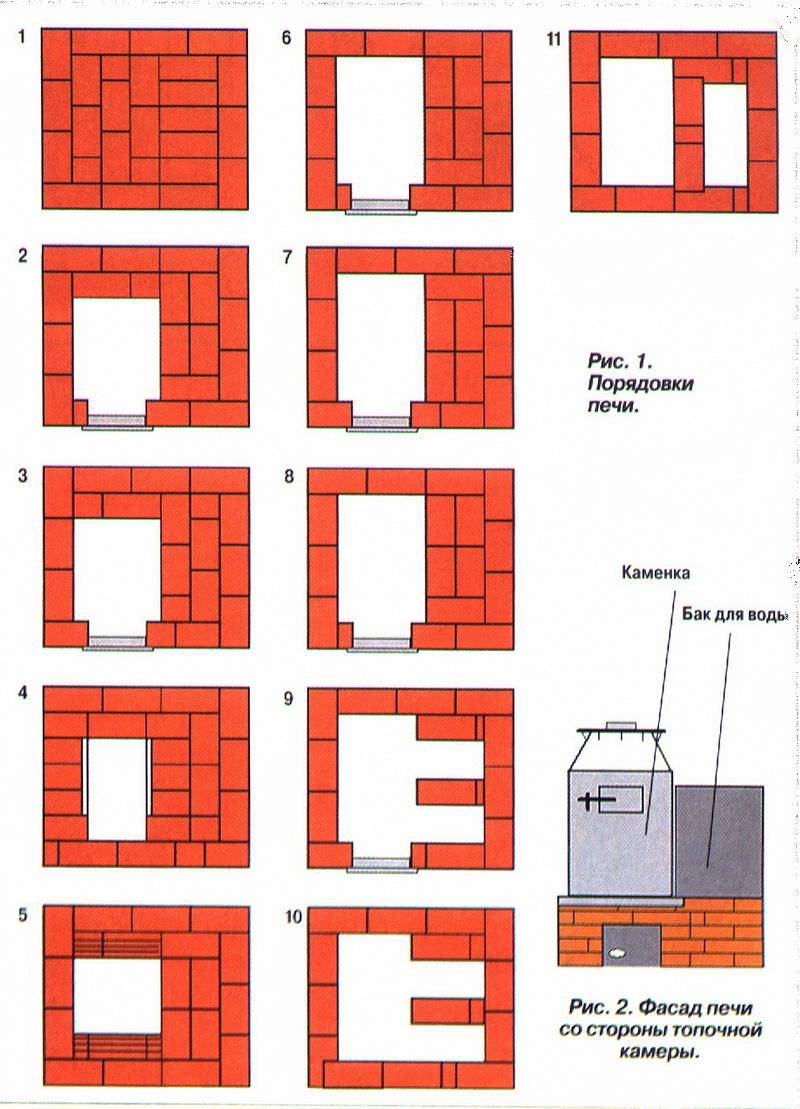

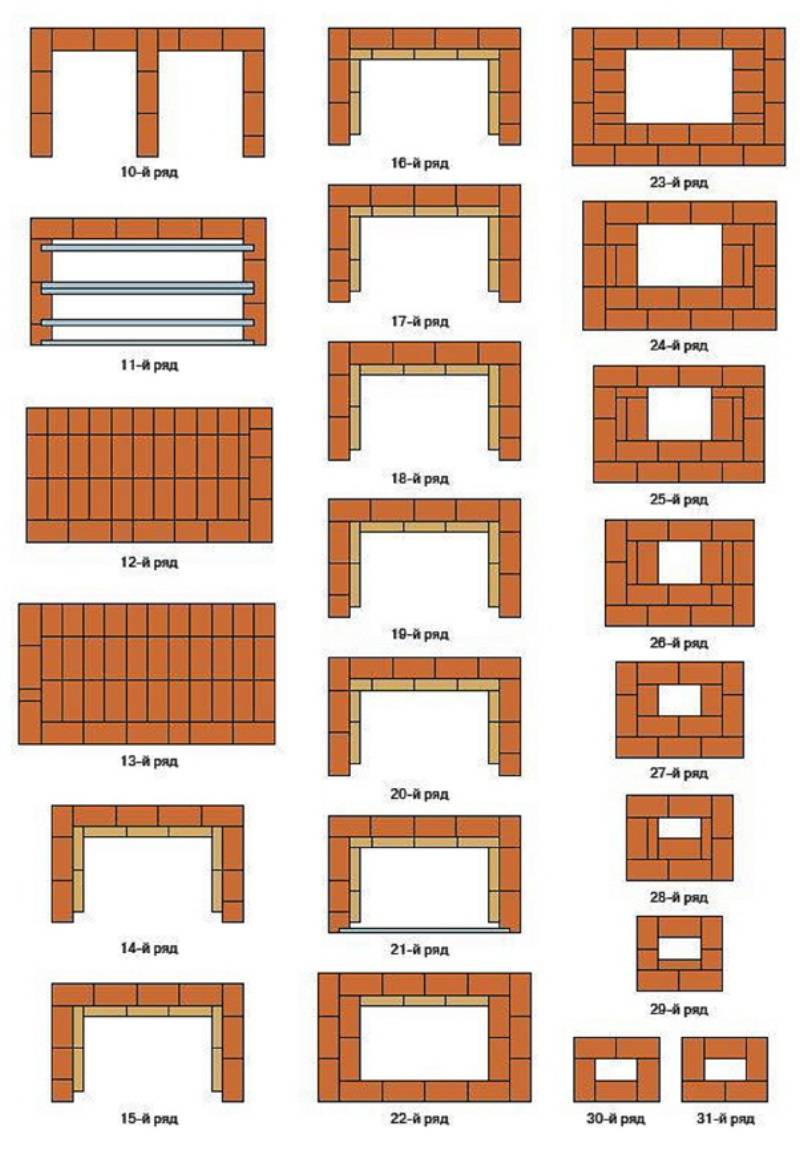

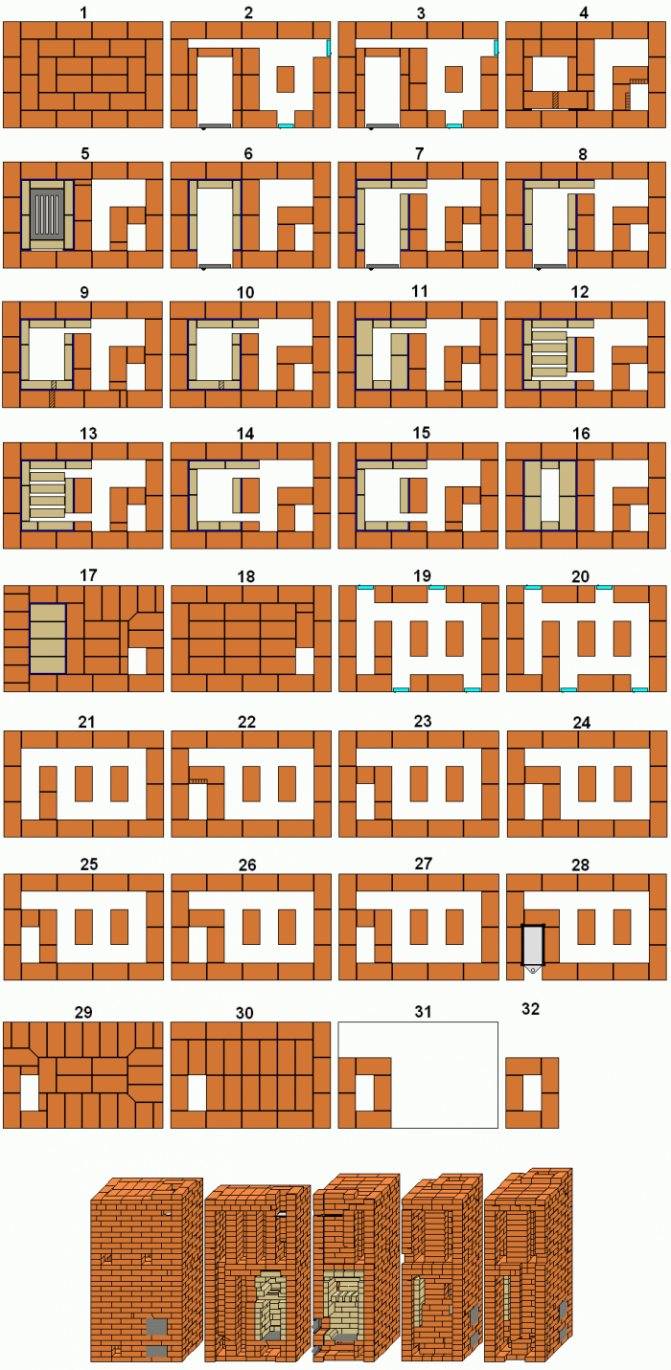

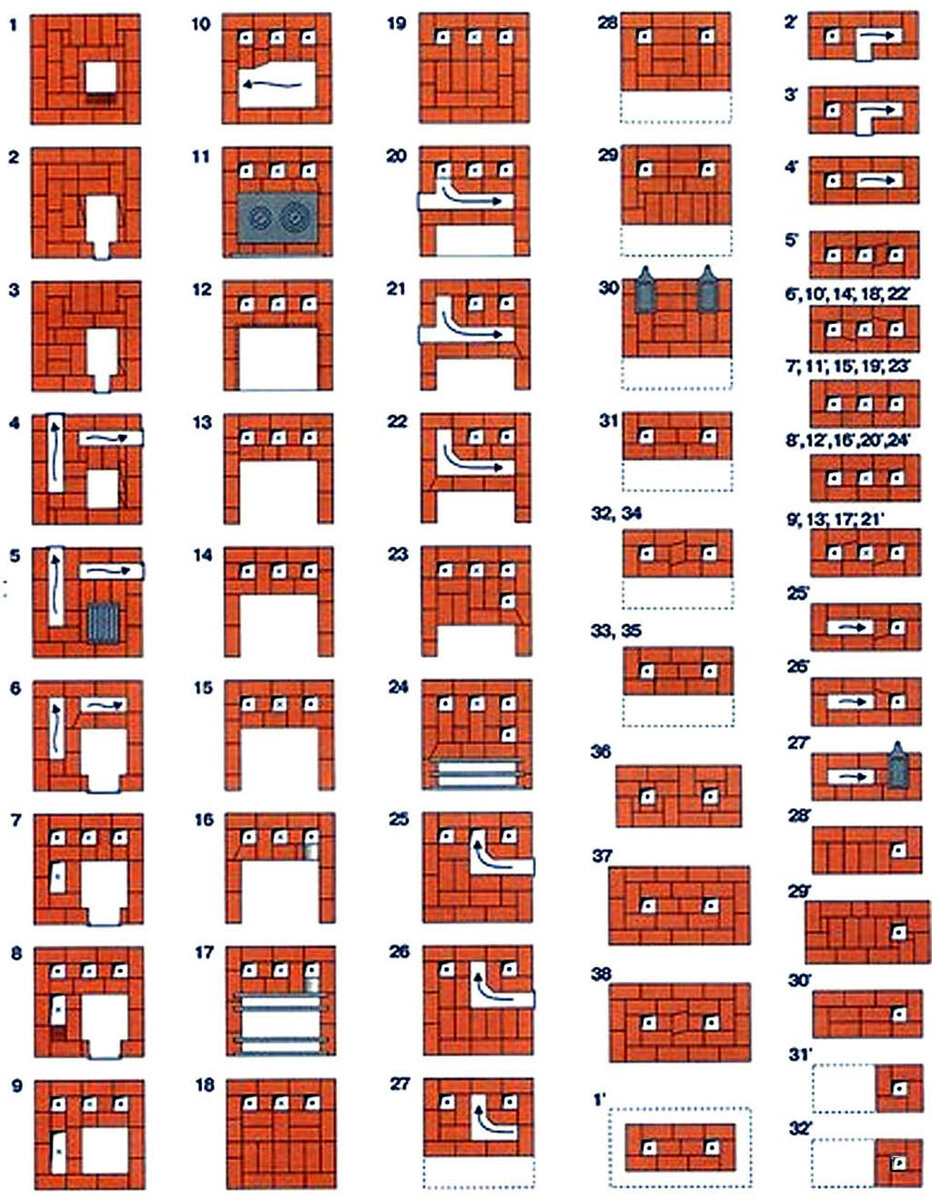

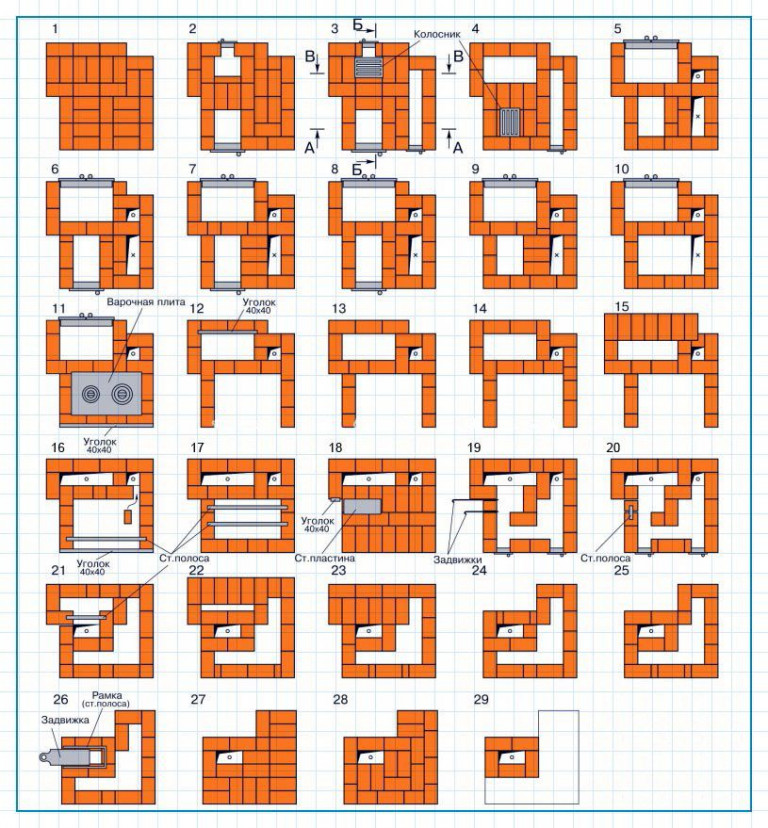

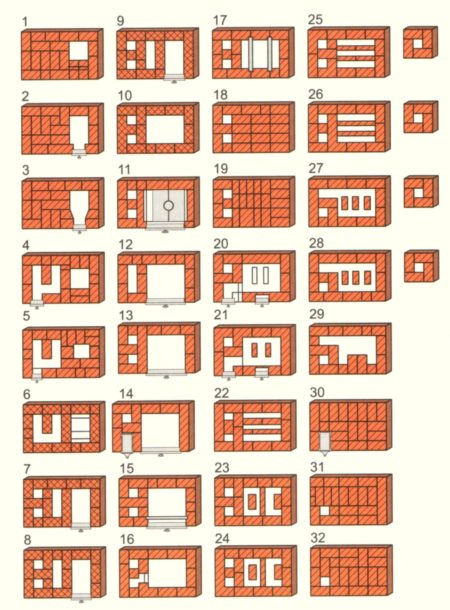

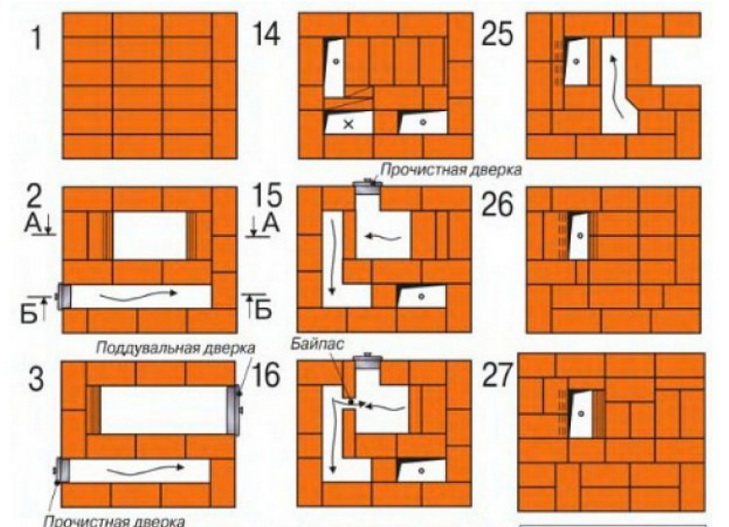

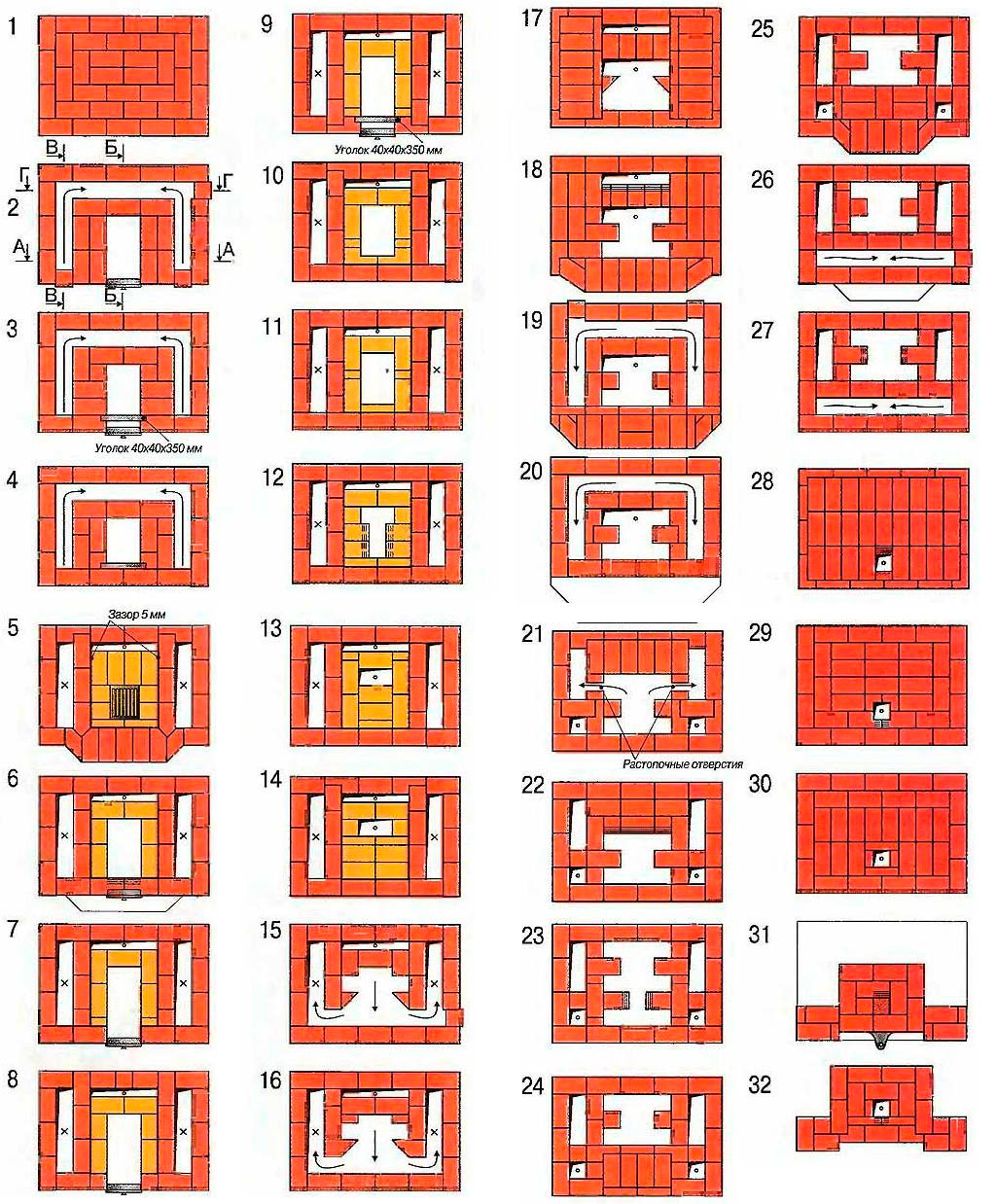

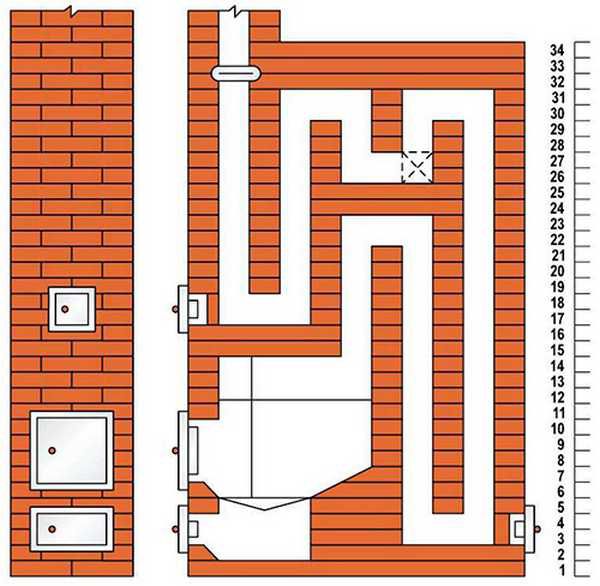

order oven

order oven

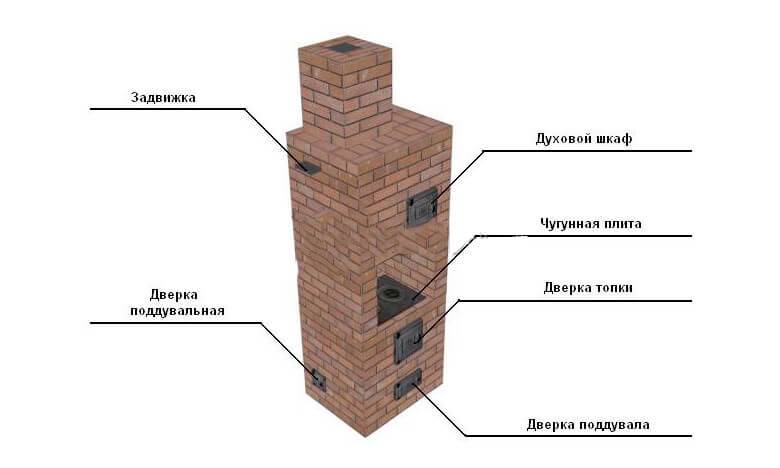

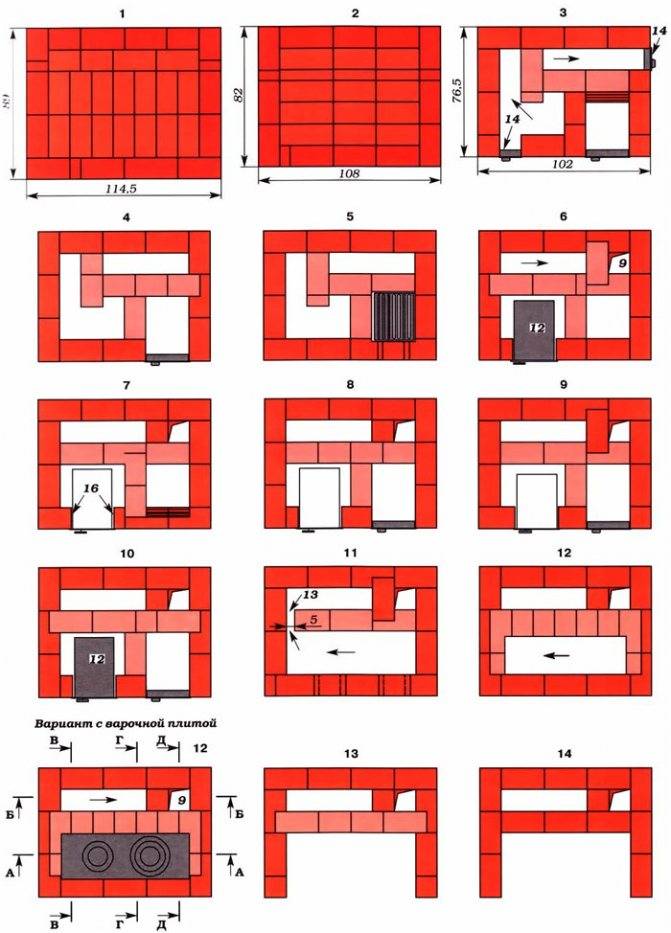

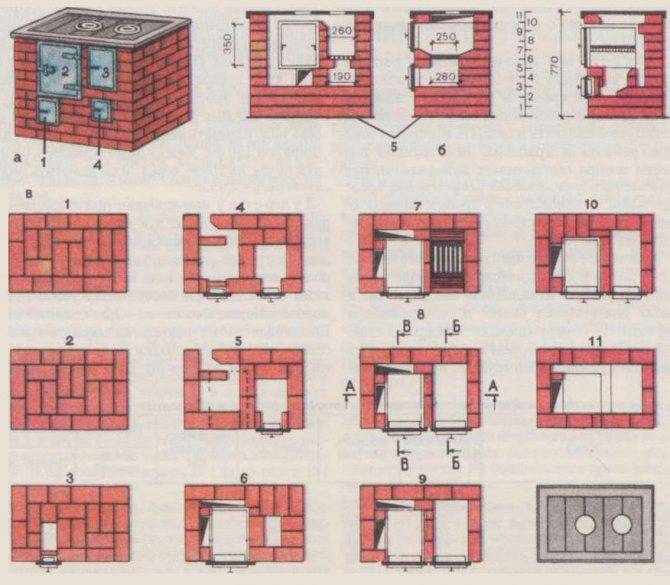

Swede oven with stove

Swede oven with stove

Swede oven

Swede oven

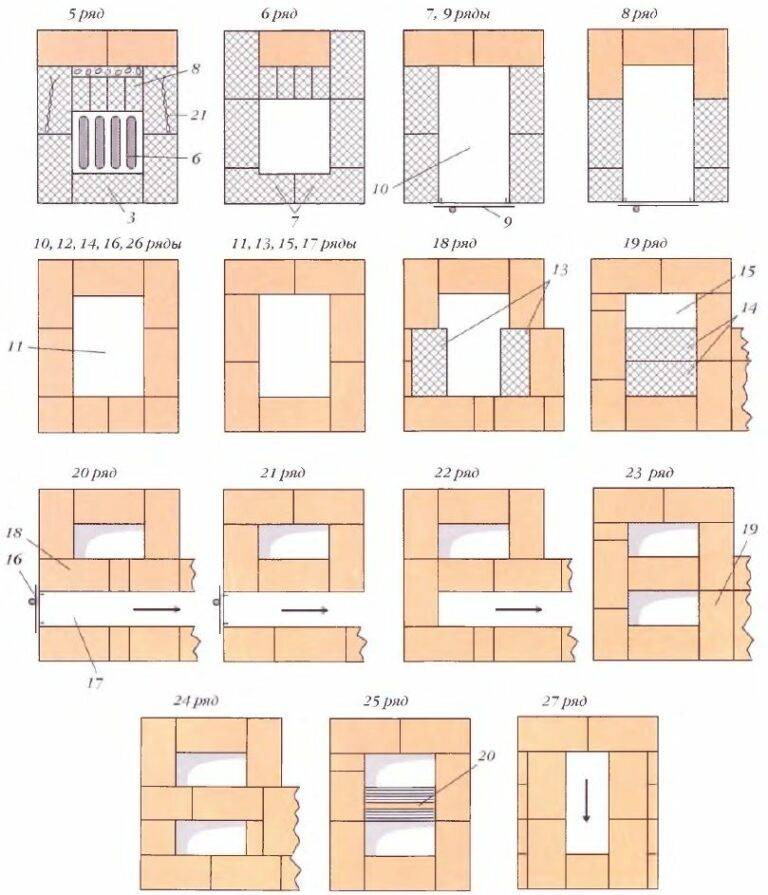

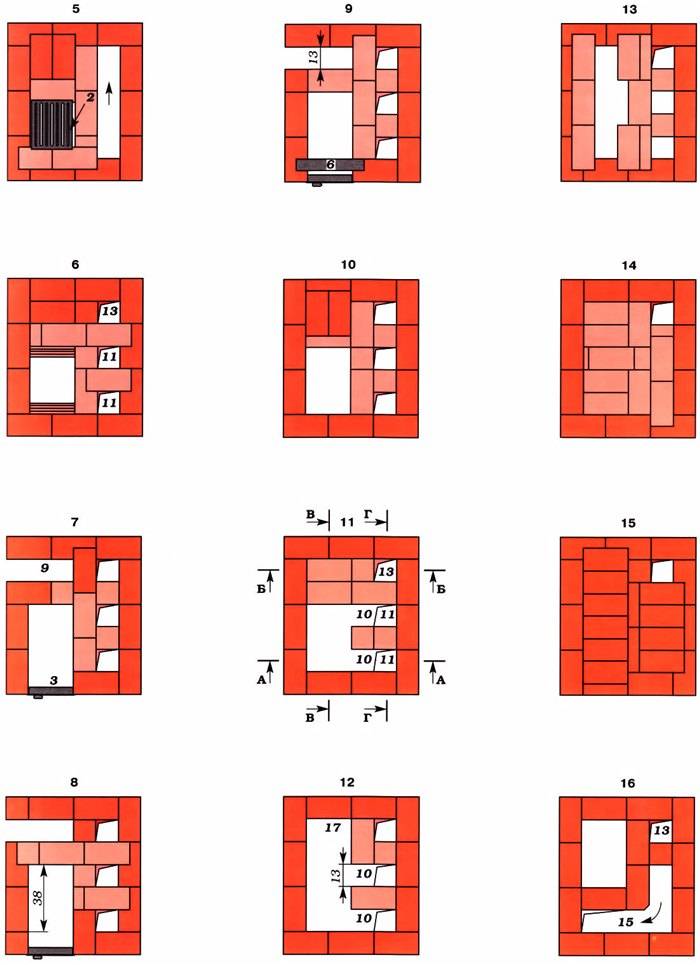

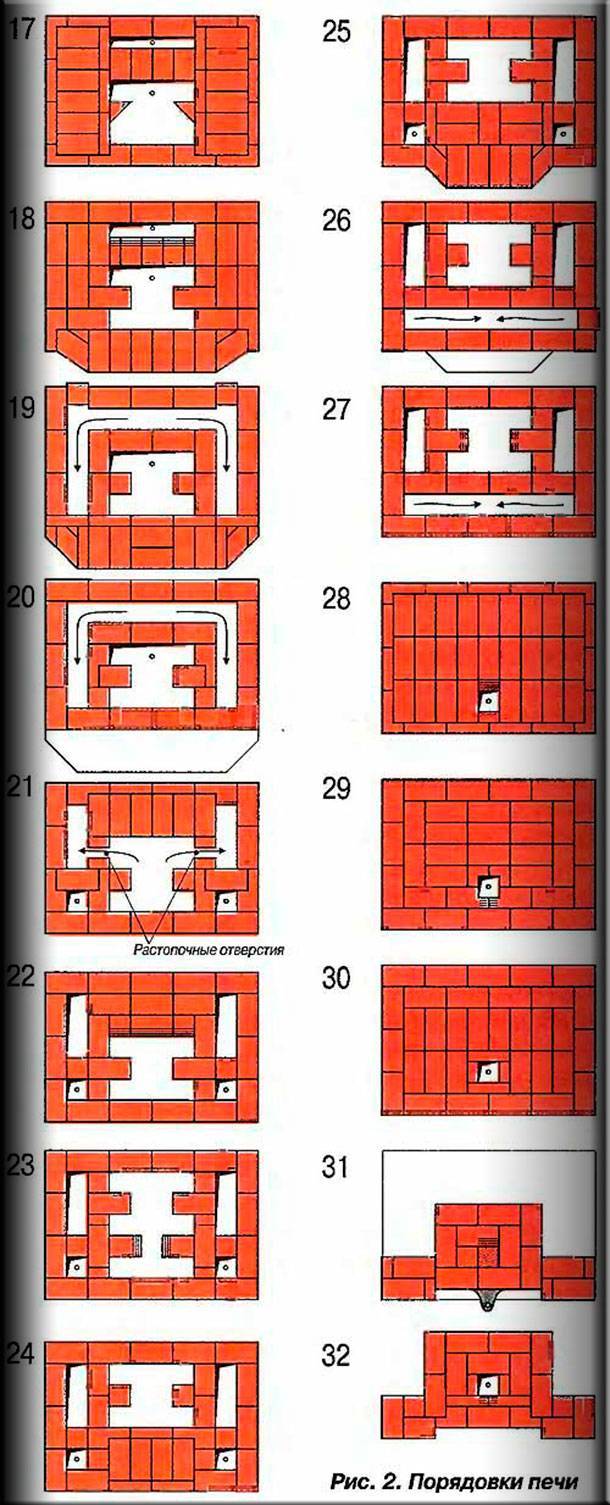

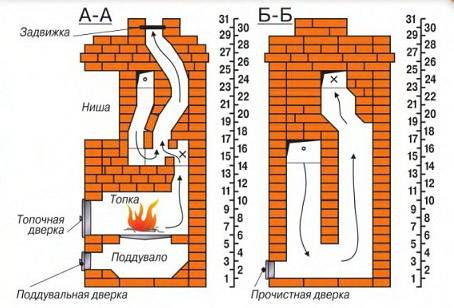

oven swede ordering

oven swede ordering

oven swede ordering

oven swede ordering

Varieties

There are many types of stoves. The simplest Dutch woman in execution is a channel unit with a gas convector. This type of structure can be adapted to any type of structure. But the efficiency is only 40%, no more.

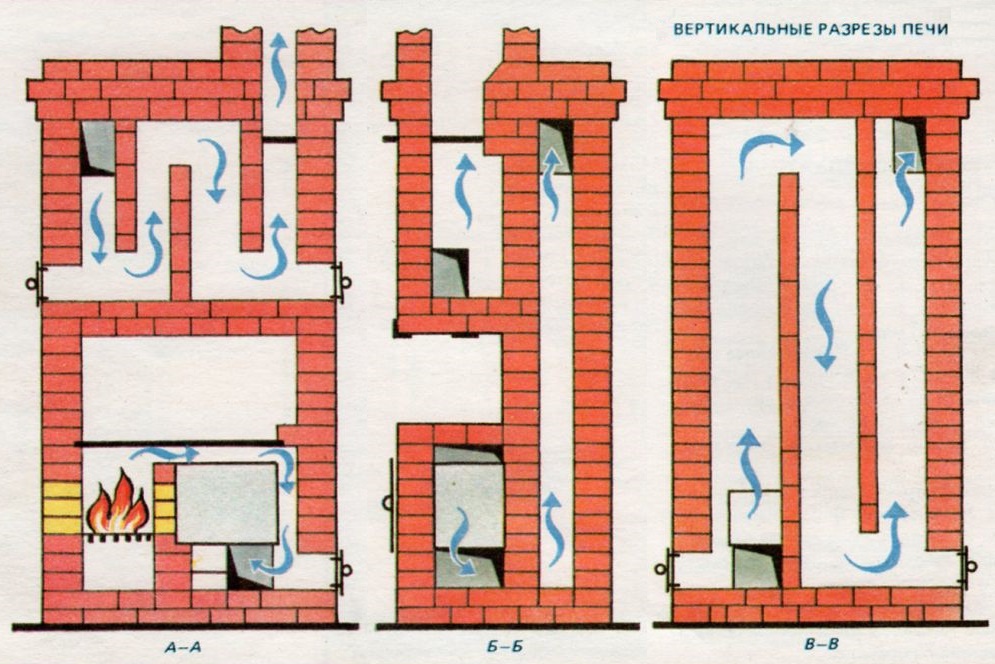

The most advanced design is a Swedish-type cooking heating furnace with an efficiency of 60%. This is a variant with a chamber around which hot gases circulate and a full-height convector placed behind it. Its advantages:

- heating the room from floor to ceiling;

- the possibility of equipping a storage tank;

- the possibility of saving materials, the oven is laid from a simple brick on a sand-cement mortar;

- high-quality heating of the bed;

- the possibility of heating three or more rooms;

- an open oven door is a great dryer.

The main disadvantage is the complexity of the device; only a competent stove-maker can fold it.

The bell-type furnace is also complex. The efficiency of the unit reaches 70%. The oven belongs to the self-regulating type, it is difficult to burn out with it.

Types of ovens:

- cooking with a separate shield;

- stove with built-in heating shield;

- flow furnace-fireplace;

- bath;

- B-B-Q;

- Russian oven.

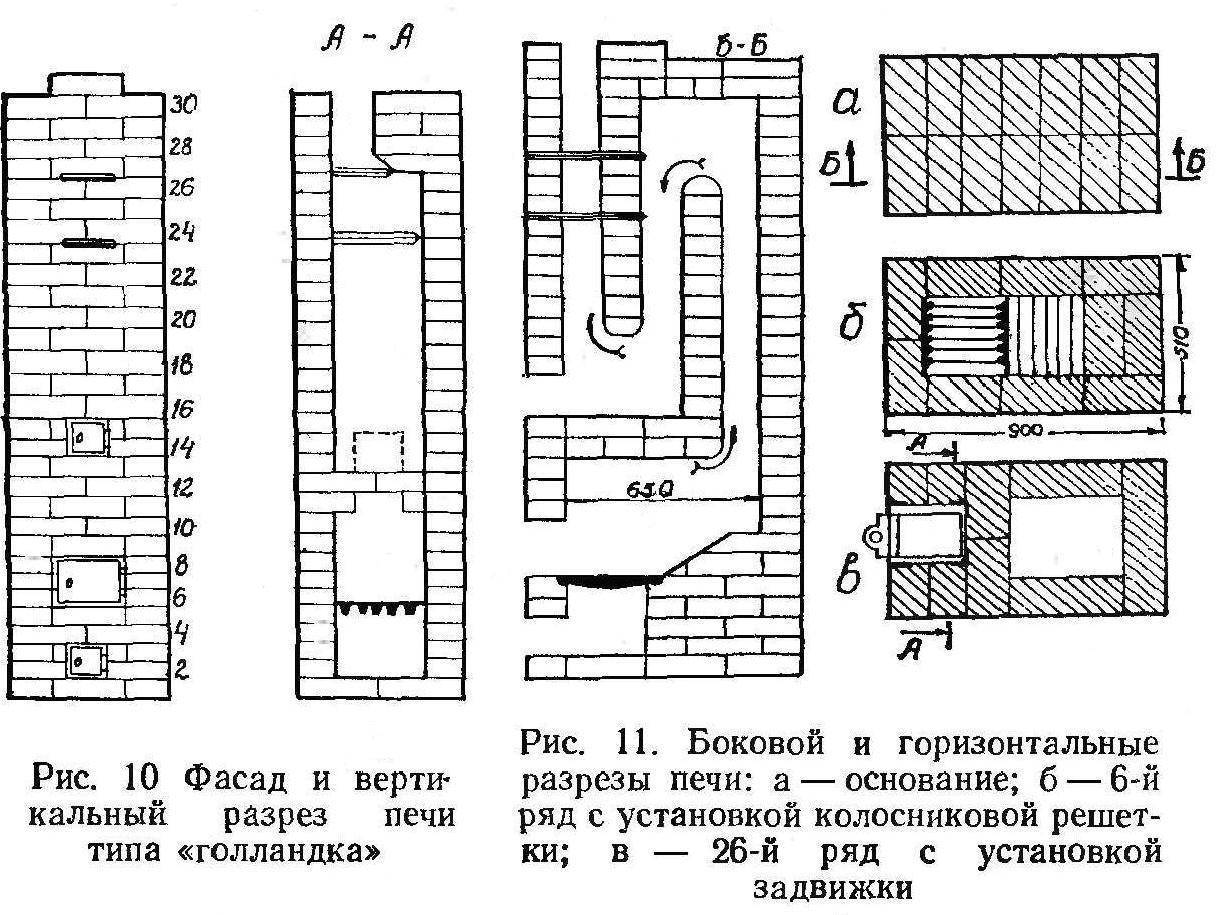

Dutch

There are many options for the Russian stove, the flow diagram of the device, without a convector, provides a connected unit that interacts through corners.Efficiency 80%! The outwardly beautiful building provides an opportunity to prepare traditional Russian dishes that are useful to our people. And you can fold it with your own hands, however, strict adherence to the instructions is required, any even the slightest deviation can ruin the whole thing.

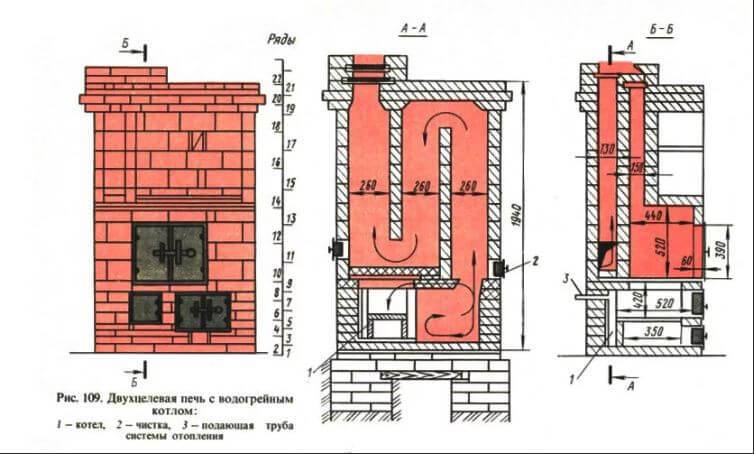

Improved heater options

Many Russian masters were engaged in the modernization of the classical furnace - I. Kuznetsov, I. Podgorodnikov, A. Emshanov, A. Batsulin. The essence of the changes is as follows: the details of the old design were taken as the basis - a vaulted furnace, a stump and a hail above the mouth. New functional elements were added to them:

- Instead of a hearth, a hob is placed, a small underflow is arranged from below. A parallel shaft of the summer course is laid out, combined with the main smoke collector at the top.

- The hot gases from the additional firebox are directed through the smoke circulations made in the lower part - guardianship. Then the combustion products are thrown into a common pipe.

- At the end or on the sides of the crucible, vertical channels are arranged, again leading to the lower zone under the firebox, then to the chimney.

- The channels from the firebox go to the attached heating shield and out through the combined pipe.

- The fire is made from below the crucible and communicates with it through a grate installed in the hearth (bottom) of the main furnace. Gas ducts from the crucible penetrate the guardianship, converge into a vertical shaft that goes into a chimney.

Another example - vertical passages are arranged in the side wall, forming a heating shield

We tried to describe common concepts in an accessible way, there are much more options. The purpose of the changes is to improve the heat dissipation and functionality of the basic design.If desired, a water circuit register or an oven is mounted inside the gas ducts (the cabinet is placed next to the firebox).

Now we will analyze in detail the updated options on specific examples - with drawings and orders.

Homemade long-burning metal stove

From the materials we need:

Elements of a homemade oven

- A round barrel that will serve as the body of the furnace. Do not use an old barrel with traces of corrosion - such a furnace will not last long. The barrel must have thick walls to withstand high temperatures.

- Steel pipe.

- Building level and marker.

- A hammer.

- Hacksaw for metal.

- Mallet.

- Channel.

- Axe.

- Steel sheet.

- Welding machine.

The work process will be associated with a certain noise and dirt, so it is better to assemble such an oven on the street or in the garage.

-

We determine the location of the homemade oven.

We prepare the case from a steel barrel

Given its low external qualities, it is better to use a non-residential area for this. If the cottage is equipped with only one room, then the stove can be placed in the corner, creating a small decorative screen that covers the structure.

-

Take a metal barrel and use a marker to mark the top of the markup, along which you will need to cut off the top. Immediately determine how much tank you need for laying firewood. The more wood you put in, the longer the stove will burn through.

Remove the top and weld the legs

- Using a grinder, remove the top lid of the barrel.

- From pieces of reinforcement, cut out the "legs" for the barrel and weld them to the base. Make sure the drum is in a perfectly horizontal position.

-

Now let's start making the chimney pipe.To do this, mark the pipe outlet in the upper part of the barrel and cut it out with a grinder.

Preparing a hole for the pipe

- Using sheet steel, make a pipe with a diameter of 100 mm and weld to the circle.

-

We proceed to the manufacture of a clamping device, with which the firewood will slowly smolder. We use the cut off top of the barrel for the clamping lid.

We weld the channel

You just need to cut off the sidewall first. Get a steel circle. With the help of a disc nozzle on the grinder, grind this circle from all sides - it should smoothly enter inside the barrel.

- We make a hole in the center of this circle, the diameter of which is equal to the diameter of the steel pipe.

- Take the channel and make markings on it for 4 parts, which, like blades, will be welded to the steel circle of the cover.

- Cut the channel into 4 parts with a grinder and weld them at the same distance along the diameter of the steel circle.

-

We weld a steel pipe in the center of the pressure circle.

Weld the pipe to the steel circle

-

From a sheet of steel we make a lid for a barrel, first we will mark it in accordance with the required diameter. In the center of the cover we make a hole for the clamping device pipe.

Making the oven lid

-

We are making a door for loading fuel, which, unlike a standard furnace, will be located in the upper part of the body. The door can be bought factory-made, or you can do it yourself by welding it to the barrel.

Hole in a circle

- Below the fuel loading hole, make markings for another door through which you will systematically clean the furnace from soot. Do not make it too big - it will be enough for the hand to pass.

-

After the oven is ready, you need to make a separate brick base for it, ensure the fire safety of the adjacent walls and install the structure.

base for oven

Given the low weight of the steel structure, there is no need to build a separate foundation for the furnace. It will be enough to lay out a brick base, which is larger than the oven itself.

-

We connect a homemade stove to the chimney.

Connecting the stove to the chimney

One rule applies here - put pipe sections on top of each other in the opposite direction of smoke movement.

In principle, this can be considered a design ready for operation. But in the process of firing, you may notice how much the walls of the furnace heat up. Therefore, for ease of use and ensuring life safety, it is better to equip a protective screen.

Brick protective screen

The protective screen can be folded out of brick. For this, an ordinary red brick is suitable, which should be laid out at a distance of 10-15 cm from the walls of the furnace. A brick screen, in addition to protection, will increase heat transfer even after the furnace stops burning.

If you plan to install a home-made long-burning stove in a separate boiler room by connecting a heating system to it, then there will be no point in installing a brick protective screen.

The process of the Russian stove

Despite serious competition and a solid history, the construction is still in demand among owners of suburban real estate.According to the way the Russian stove is arranged from the inside, it will be possible to focus on the dimensions from the outside and, accordingly, plan a place for it and lay the foundation.

Before you fold the Russian stove, you need to understand its principle of operation - the design is a periodic heating device, that is, when burning firewood, it accumulates heat, then gives it away for almost a day. So the building can warm or languish for almost a day, which makes it possible to cook baked milk in it, steam porridges and soups without controlling the process.

Before you make a Russian stove, you should build a separate foundation base that is not connected to the tape, since the structure usually has a lot of weight

This is especially important when the house "dances" on heaving soil during freezing and thawing. In this case, the stove will move along its own amplitude along with its foundation, without destroying the finish and without affecting the walls and openings.

Russian stove in section during heating and languishing

Work principles:

- the whole structure stands on a brick guardianship or concrete;

- firewood for kindling is stored in the stove, where it dries very well and lights up instantly when ignited;

- the top of the stove is made with a hemispherical vault, like a trough;

- sand, clay, brick battle - any heat-intensive material is poured on it, and on top of it is laid out under the furnace - the front part of the furnace (cooking chamber), it is laid without clay mortar.

If you ignore the filling, then you can forget about real hearth bread and pies. By the way, they are baked on cabbage leaves.

Next comes the bail with an overtube and a hail in the form of a tapering nozzle.Ash pans are provided on the sides in the wall near the walls - recesses for smoldering coals (for the next kindling) and ash. Sometimes they are raked into an ocholok - a part of a cast-iron or stone slab (pole), protruding from the face (chela) of the furnace.

To reduce costs and cleanliness in the room, an ash pan and an eyeglass can be omitted. Previously, they were raked into the corner of the mouth, then the coals of birch, maple, elm, oak and aspen kept heat only for a day.

Cooking in a cast iron stove

Most likely, this is where the belief came from that the Russian stove is quite picky in the form of fuel. But this is not so - it works on any solid fuel, including:

- brushwood;

- dung;

- deadwood;

- sawdust

- straw;

- peat briquettes.

The zagnetok, thanks to this configuration, acts as an economizer, where the following happens: the smoke circulation heats up the air, which enters the furnace, without extracting oxygen from it and without preventing combustion - there should be no mixing of heat flows. In fact, the zagnetok is an energy recuperator (heat exchanger).

Before building a Russian stove, you should check the dimensions in advance - this is important so that the building does not smoke, does not cool down quickly and does not use a lot of firewood. For the same purpose, perfectly smooth hail vaults are made.

Moreover, they cannot be plastered, so the bricks on the inside are hewn and polished to a gloss - then there will be no turbulence in the overtube.

The smoke from the oven goes up the chimney

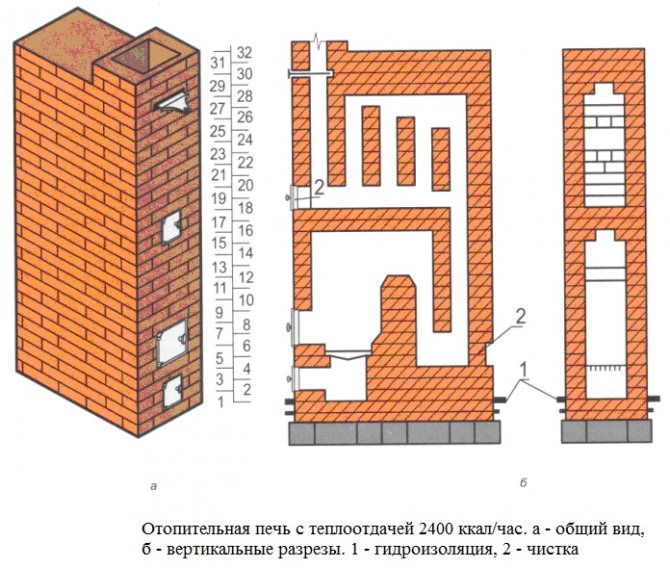

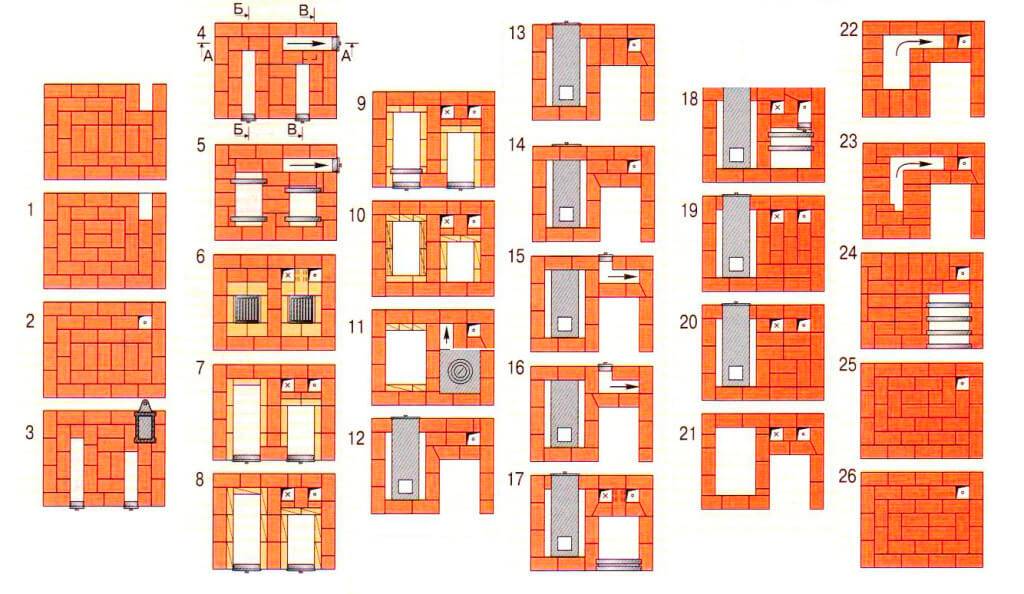

Furnace design features

Traditional brick ovens have a fairly simple design.However, the apparent simplicity at first glance allows achieving very high rates of productivity and efficiency.

The main elements of the body of a brick oven are the firebox and the chimney. Cooking ovens are additionally equipped with stoves and / or ovens, it is also possible to install a tank for heating water.

Scheme of the Russian stove

The firebox is the main part of the furnace unit. It is in the firebox that firewood or other fuel used for heating is loaded. The firebox can be of various sizes. When determining the appropriate dimensions, several important factors must be considered, such as:

- type of fuel used. If you will heat the stove with wood, make a firebox 50-100 cm high;

- required performance;

- required volume.

To equip the firebox, use refractory bricks. The wall thickness of the structure under consideration cannot be less than half a brick.

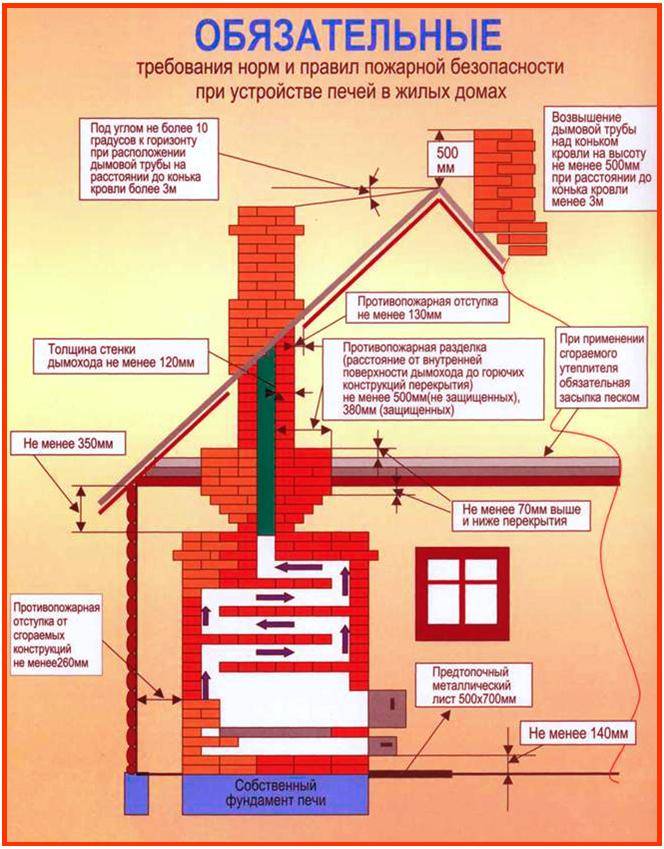

The chimney is also one of the main elements of any heating furnace. The chimney is designed to remove flue gases with various harmful inclusions formed during the operation of the furnace.

Rules for installing a brick chimney

At the design stage of the chimney, try to think through everything so that its design has a minimum number of bends and turns. Ideally, the chimney should be completely vertical. Any kind of bends will lead to a deterioration in traction and a decrease in the efficiency of heating the room.

An ash pan chamber is one of the important structural elements of a brick oven. Ash will collect in this compartment. Also, air is supplied through the ash pan to the inside of the unit, to the fuel.The ash chamber is arranged under the grate of the grate and is equipped with its own door. Traditionally, the height of the ash pan is 3 bricks.

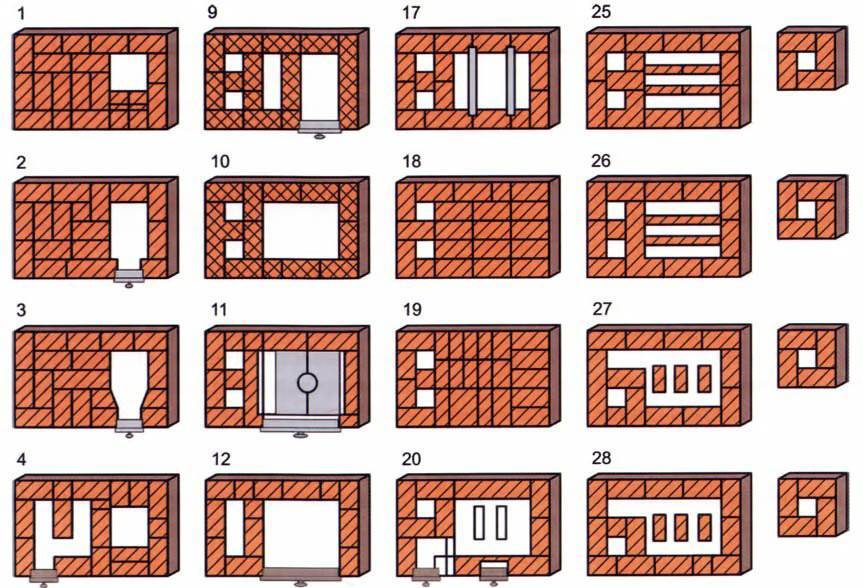

Which brick to choose for the oven

When choosing a brick, attention is primarily focused on its resistance to temperature effects. The building material must withstand repeated heating and cooling procedures.

It is from the characteristics of the brick from which the furnace will be made that the total period of its operation depends.

The next marking indicator is the level of frost resistance, which should be the highest. It plays an important role in the choice of products used for laying the chimney (especially the part protruding above the roof).

Marking bricks for stoves in comparison with other types of material

Frost resistance implies the ability of the product to absorb moisture. Its crystallization inside the material can cause deformation of the latter. Facing hollow ones are better suited.

When forming the inside of the chimney, a solid red brick is needed. Plastic molding is preferred. These products withstand temperature changes and do not crack even with significant downtime.

Use in the construction of furnaces is contraindicated:

- silicate and pressed bricks;

- bricks made using the slip casting method;

- unfired cheeses.

The maximum exposure of fireclay bricks (made in accordance with GOST) is up to 1350 °C. It is quite possible to use such products to create most of the structure or apply them separately for thermal protection (lining) of internal surfaces.

For the furnace, the Sh8 brand is suitable (such bricks have a straw-yellow color and darkish blotches).It is recommended to use fireclay products (Ш 22-Ш45) for the vault of the furnace. The only exception is bath stoves, where, due to high humidity, such a brick is contraindicated.

Refractory brick grade Sh8 has a straw-yellow color

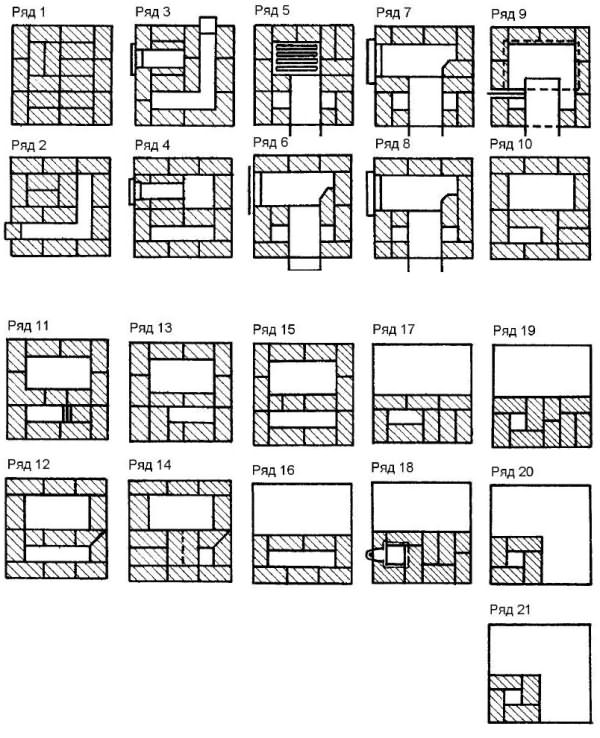

The device of a traditional oven

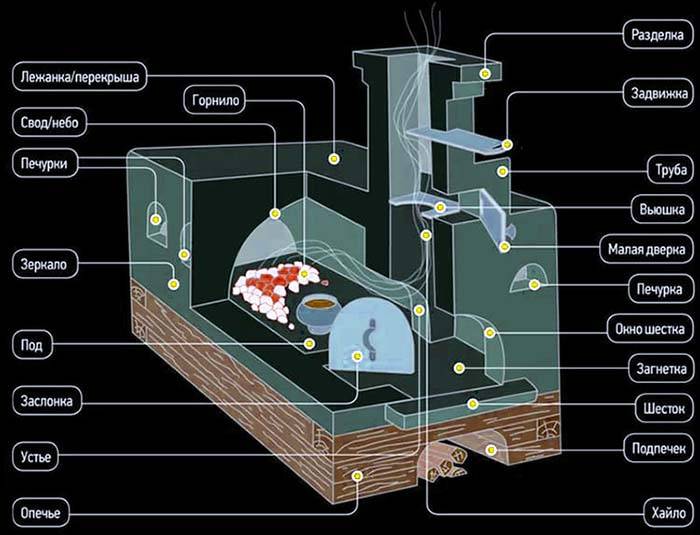

We will not describe the history of the Russian stove and its role in a village house - the topic is widely disclosed in fiction and technical literature. Let's get straight to the point - let's briefly analyze the traditional design shown in the figure below:

- The lower part of the building - guardianship - was built of stone or wood - cedar, larch. The walls of the base form a niche - the stoves, where firewood was dried and household utensils were stored.

- On top of the guardianship, the first arched vault and a large firebox of the furnace - the crucible were built. Under and the second arched vault was made with a slope towards the forehead - the front part of the structure.

- Over the crucible, a ceiling was arranged, where the stove bench was located. The cavity between the second vault of the firebox and the ceiling was covered with sand to increase the heat capacity.

- In front of the mouth of the crucible, a special niche was provided - a cap, ending on top with a hail (smoke box) and the chimney itself. The horizontal shelf at the bottom of the opening - the hearth - has a semicircular window that goes out.

- Stoves were arranged in the side walls of the brick heater - small niches for drying clothes and other things. The chimney was equipped with a valve and a view located above the hail.

A real Russian stove is fundamentally different from other brick heating structures in the following ways:

- deep vaulted firebox, made with a forward slope;

- the chimney is located in front - in the center or in the corner of the building;

- an indispensable attribute is a couch arranged above the fuel chamber.

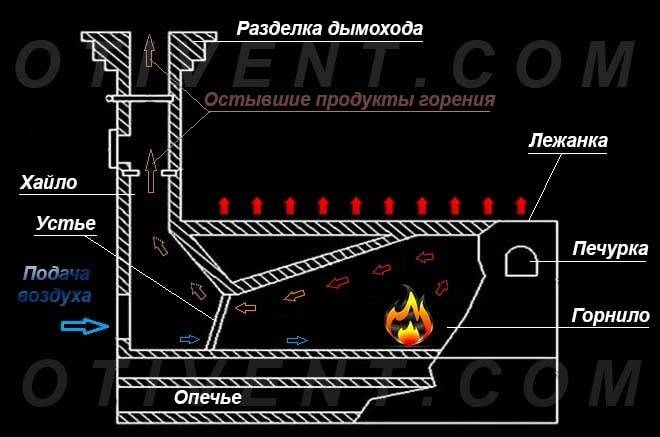

Now consider the principle of operation of the stove, shown in the diagram:

- Firewood is laid closer to the back wall of the furnace and kindled. Combustion air enters through the outer hearth window and the mouth of the firebox, and moves above the bottom of the chamber.

- The heat generated during combustion heats the body of the furnace - the side walls, sand filling and stove bench.

- Light products of combustion rise to the vault of the firebox. The slope does not allow the gases to immediately leave the chamber - at first they give off heat to the ceiling, then they become heavier and are displaced by a new hot stream.

- After passing under the arch of the crucible, the combustion products exit through the upper zone of the mouth, rise into the smoke collector and leave the stove through the chimney.

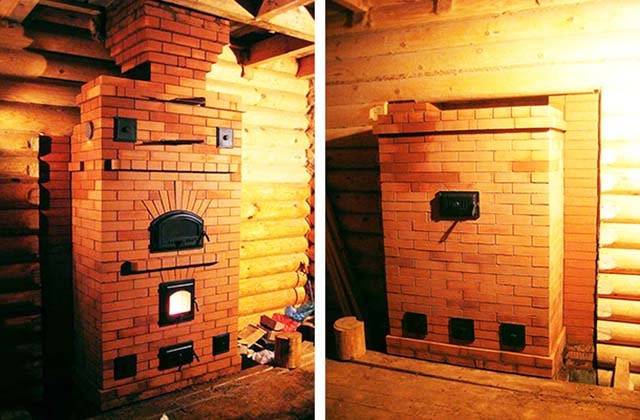

Brick heater with access to 2 rooms of a wooden house

Despite its many advantages, a Russian stove with a stove bench is rarely built in a traditional design. The usable area in a modern interior is worth its weight in gold, and a classic heater takes up a lot of space, while slightly warming the lower area of the room. For construction, it is better to consider projects of modernized structures, where this problem is solved.

Design features of a brick oven for a summer residence

Depending on the type and design, the oven can perform the following functions:

- Cooking (frying, boiling, stewing, baking, etc.).

- Drying shoes and clothes, as well as preparing food for the winter (mushrooms, berries).

- Heating beds.

- Opportunity to admire the open flames on winter evenings.

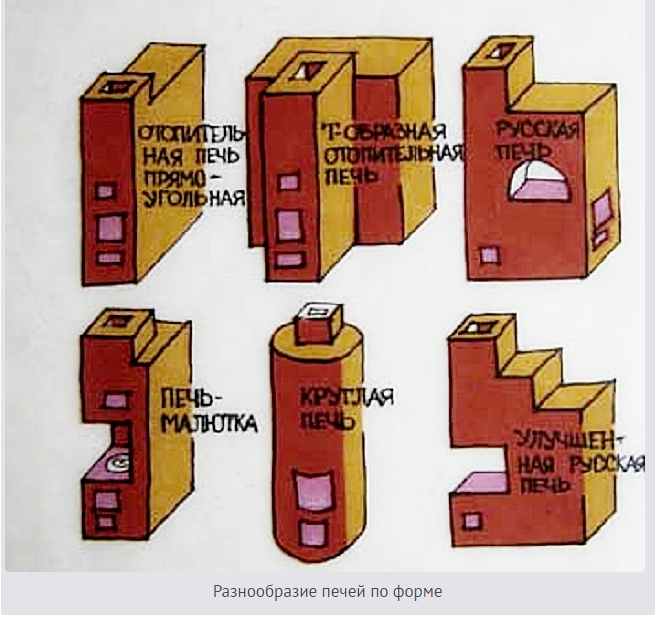

In addition to the functional classification, before building a brick oven for a summer residence, you need to decide on the configuration.

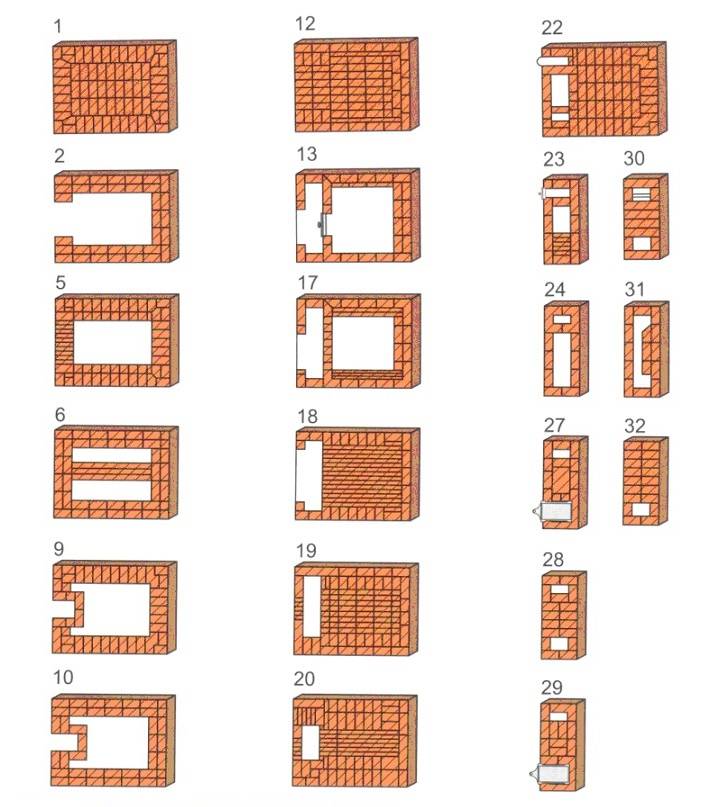

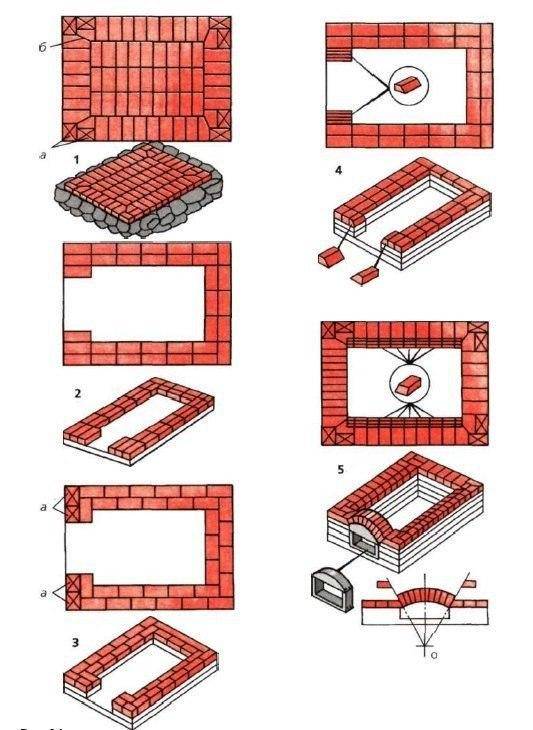

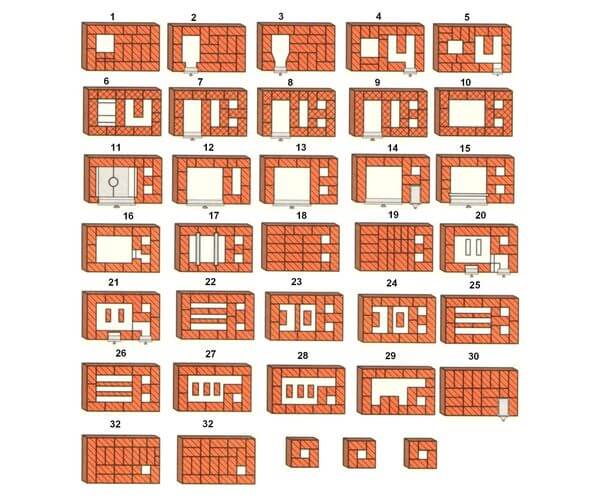

A variety of ovens in shape

- rectangular heating stove;

- T-shaped;

- round oven;

- Russian stove with stove bench;

- baby.

The size of the furnace is also important. The large, thick-walled furnace design is capable of distributing heat over 50 square meters.

But in order to warm them up well, it will take at least two hours, which is not always convenient.

This is especially uncomfortable in the country, where the owners drop in only for the weekend. A cold house will warm up for at least 3-4 hours before the room temperature returns to normal.

A small stove cannot heat a big house. Its heat is enough for a room of 15-20 square meters. meters. At the same time, it will warm up in 30-40 minutes, giving off heat around. In addition, we should not forget about the efficiency of the furnace. For a large stove, it is necessary to take care of the supply of firewood in advance and prepare a large firewood shed from the summer.

The stone stove also has a significant drawback - the impossibility of heating the distant premises of the house. That is why in large houses with several rooms, 2-3 stoves are placed, each of which has its own chimney and performs its own function.

According to the principle of construction, brick ovens can be:

- Channel with forced movement of gases.

- Bell-type furnaces with free movement of gases.

Channel stoves include the usual "Dutch" or "Swede". The combustion of firewood takes place in the firebox, from which the smoke channel departs. Under the action of draft, combustion products are discharged through this smoke channel.

The main task of this design is to maximize the heating of the furnace wall, and after that the heat will spread throughout the room for a long time.

Channel furnace in section

Despite the simplicity of design, such a furnace has several disadvantages.

- It all depends on the traction force. The narrow channel obstructs the airflow and a sufficiently high chimney is required to overcome this resistance to the flow. In houses with low ceilings, this is not always convenient. And in the end, after arranging the furnace, the owners are faced with the problem of poor draft in the furnace.

- In addition, the principle of the channel structure of the furnace involves the concentration of hot air at the top of the furnace. That is, most of the heat is removed to the top. Because of this, below, near the floor, it is quite cold.

- The efficiency of such units does not exceed 60-65%. And the average, with standard traction, is even less - 40-45%.

- Due to the large design, such an oven heats up for a long time. To heat the structure from scratch, it will take 2.5-3 hours.

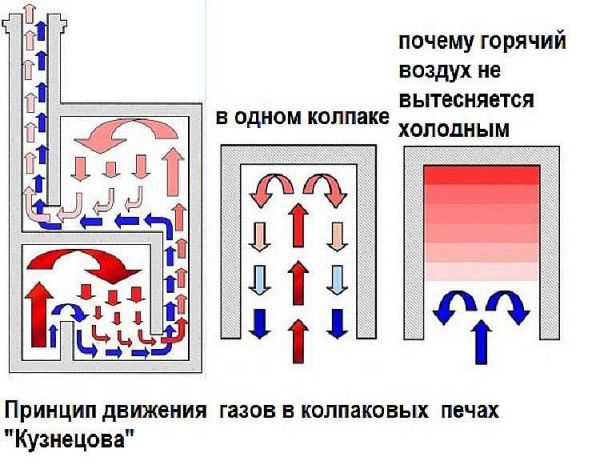

Furnaces with free movement of gases show themselves in a completely different way in everyday life. Their principle was first described by Lomonosov, and later modified by Kuznetsov, which is why in everyday life such furnaces were called "blacksmiths".

The principle of operation is based on the movement of free gases. As we know from physics, hot air rises, displacing cold air. In such a furnace, the furnace and combustion chamber are combined, and hot air circulates freely from one chamber to another.

Such furnaces also have a second and sometimes a third chamber, which are interconnected by a dry seam located at the bottom of the chamber.

The principle of operation of the bell-type furnace.

How to paint the stove

It is clear that the first time a newly-made master will not be able to lay down a beautiful stove due to lack of experience. But this is fixable, because outside you can make a brick wall cladding using staining. Previously, they were plastered and covered with two layers of whitewash of chalk or lime, but now there are simpler and more convenient means. In addition, lime is easily transferred to clothing when accidentally touched and constantly needs to be updated.

If we talk about how you can paint a brick oven, then there are such options:

- organosilicon heat-resistant enamel grade KO, designed for high temperatures;

- silicate or acrylic paints;

- heat-resistant varnish (for example, PF-238) mixed with dye.

In any case, the coating is applied for 2 times, the second layer is applied after the first has dried. The tool used is a brush and a roller. It is desirable to pre-treat the surface with a special primer composition designed specifically for such purposes.

Cleaning

Major cleaning, as well as repair work, is best organized in the summer, but in winter it is also necessary to periodically assess the amount of soot in the chimney. Sometimes, due to improper kindling, bad firewood or other reasons, pollution occurs much faster and additional cleaning is required. With the accumulation of soot, at best, the thermal efficiency of the furnace is reduced, and at worst, all the smoke and carbon monoxide can go into the room.

Video description

For cleaning a brick oven, see the following video:

The ash chamber and grate cleaning should be carried out in each firebox.

Conclusion

If the house has a stove, it means that there is warmth and homeliness.But regardless of the chosen design of the brick oven, its proper functioning will depend not only on how well it is made, but also on its proper maintenance by the residents of the house.