- Know

- How to load fuel

- Should I use a reflector in the boiler?

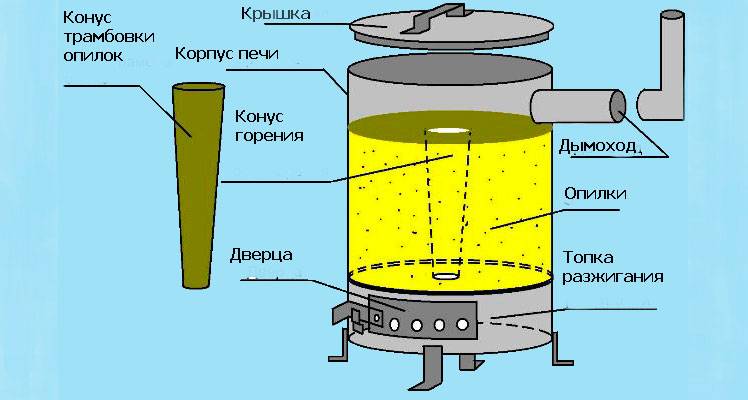

- Bubafonya - the most popular long-burning potbelly stove scheme

- How bubafoni works

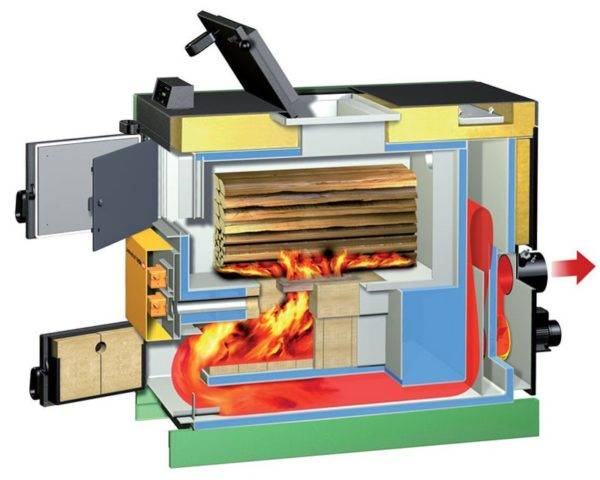

- Advantages of long-burning boilers

- How to increase the efficiency of a long burning wood stove?

- Useful tips for making a TT boiler

- Types of ovens

- Furnaces fireplaces for giving wood long burning

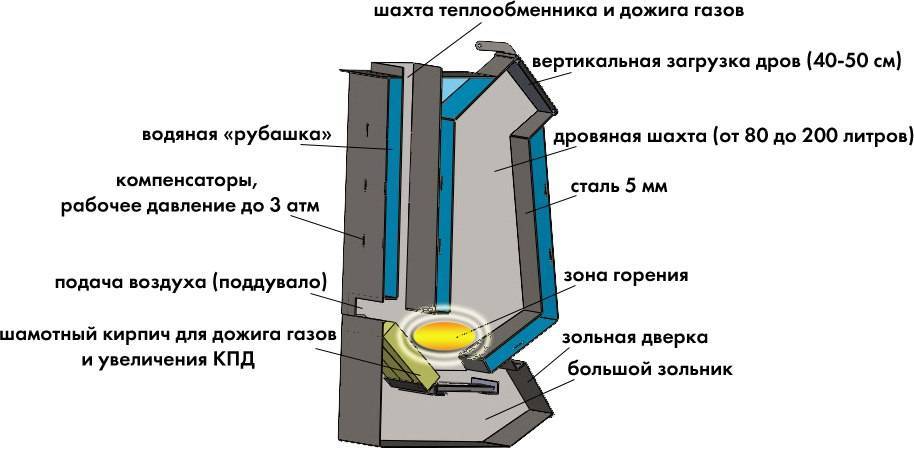

- Boilers for long burning on wood

- Wood-burning stoves for heating a long-burning house with a hob

- We make a potbelly stove

- Features of the pyrolysis furnace and its application

- Advantages and disadvantages

- Furnace without external circuit

- The first stage is the preparation of the fuel tank

- The second stage - the chimney

- The third stage - a cover for the stove

- What is the advantage of a long burning stove

- What to Consider Before Assembling a Long Burning Furnace

- The algorithm of actions when assembling a home-made long-burning stove

- Preparation of the foundation and construction of the chimney for the furnace

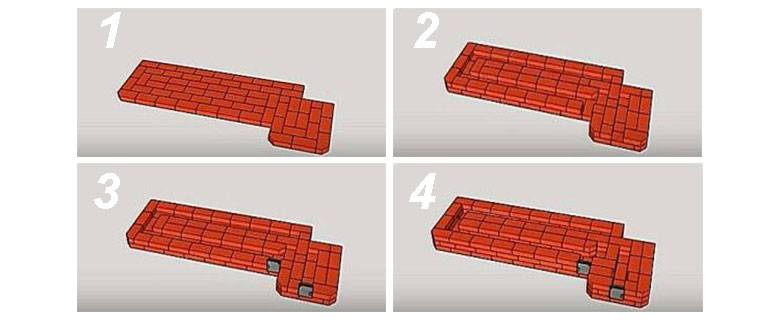

- Large rocket stove with bench

- 5 How does a homemade installation work?

- Chimney device

- Requirements for heating appliances

Know

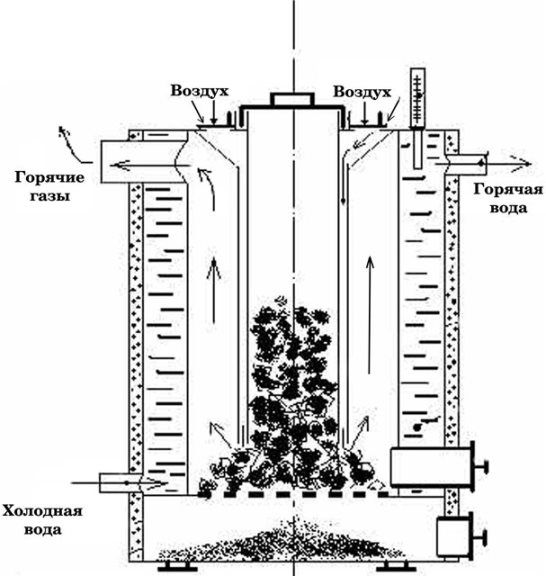

- If the sawdust boiler is to be used for heating the house, it should be slightly modified to ensure indoor safety.For this purpose, holes are made in the skin of the water jacket and fittings for temperature and pressure control devices are attached. The best option would be to install a relief safety valve, which would be put into action when the temperature reaches 3 bar. The pipe from the valve will need to be brought outside.

- Another problem is the hot surface of the boiler and chimney. Since heat is distributed in the furnace, where it is completely unnecessary. Therefore, sawdust-fired boilers must be insulated. You can create a thermal insulation effect with your own hands using basalt wool, which is highly resistant to high temperatures. Wool can be sheathed with a layer of polymer-coated sheet metal, at the same time giving the boiler an aesthetic appearance.

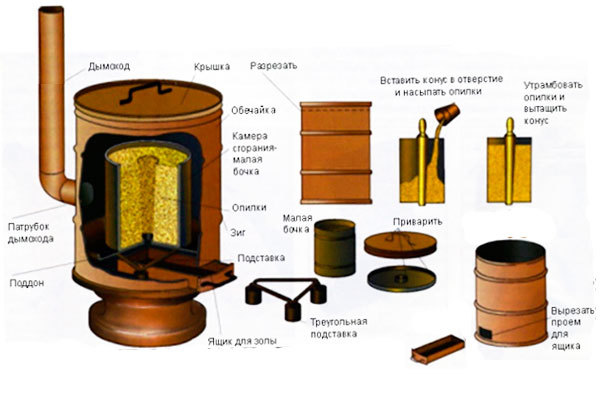

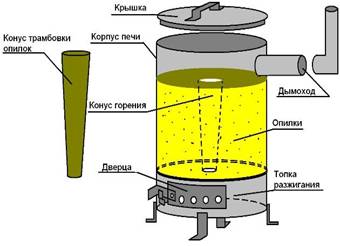

How to load fuel

The process of putting fuel into sawdust boilers is not at all complicated. To begin with, a cone-shaped pipe is inserted into the hole in the lid. This form is very convenient, because it is easy to get it at the right time. Sawdust falls asleep until it reaches the level of the chimney. Each portion of fuel must be rammed. Then the pipe is carefully removed. Through the hole, oxygen will enter the device, and the smoke will go outside. Next, you need to cover the oven with a lid and set fire to the sawdust from the outer end of the vertical pipe. The melting process can be accelerated by pouring a little flammable liquid onto the metal baffle up to the biomass loading level. In a boiler with a volume of about 200 liters, sawdust burns from 8 hours, and the furnace must not be opened until complete combustion. Thus, a new portion of fuel can be filled up only after the end of this process.

Fuel is loaded from above

Should I use a reflector in the boiler?

When making a sawdust boiler with their own hands, many do not know whether it is necessary to insert a reflector into it. Experts advise doing this, especially if the boiler will be used in small rooms. They explain this by the fact that during the operation of the device, the temperature of its case is extremely high. In the case of a sawdust boiler, the heating output is even higher than in other devices. The reflector will allow you to correctly redistribute heat flows and ensure uniform heating of the entire room. That is why it also helps to save money on heating - the use of a reflector reduces fuel costs by a third!

A sawdust boiler does not always need to be lined with bricks. The decision will depend on the situation: if it costs in a garage, greenhouse or utility room, such work will only be a waste of time and money. But the device for the living quarters should be finished and placed in a brick firebox. This will have its drawbacks - it will become much more difficult to use the device and maintain it.

Before DIY device assembly You need to familiarize yourself with some of the features of their operation:

- Chimney parts are assembled in the direction opposite to the movement of smoke and combustion products.

- The design of the chimney should be convenient for disassembly and regular cleaning.

- Since the boiler body becomes very hot, care must be taken that there are no flammable objects near it. The walls next to which the appliance will be located must be finished with heat-resistant materials.

- After completing the assembly of the device with your own hands, it must be tested in different modes of operation.Testing will allow you to find the optimal temperature regime and determine the required amount of fuel for one cycle of operation.

This is interesting: Installing a gas boiler with your own hands - work technology and standards

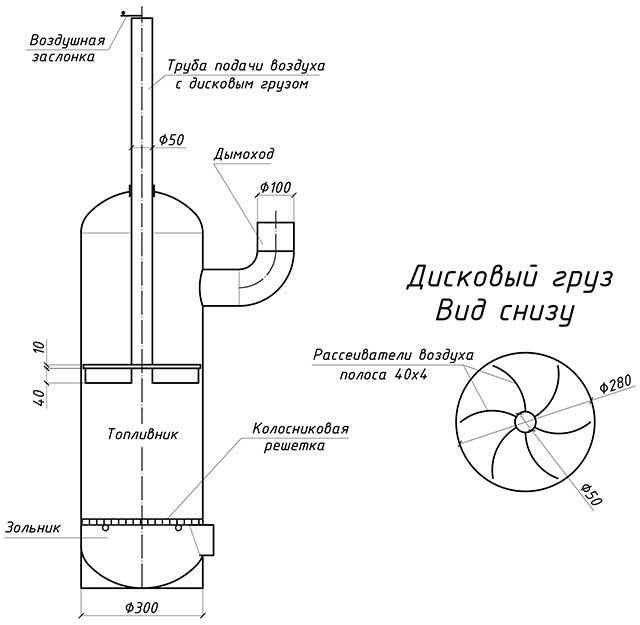

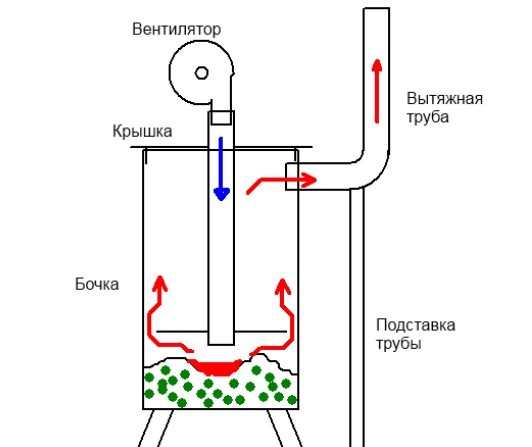

Bubafonya - the most popular long-burning potbelly stove scheme

The practicality of the bubafonya stove is proven by its popularity. The fact that this is one of the most popular long-burning stoves is evidenced by the fact that it is used in almost all small greenhouses.

The big advantage of this stove is its practicality and ease of use - it is practically omnivorous, it is possible to burn both dry firewood and sawdust, pellets and briquettes from straw or sunflower in the furnace. And this furnace also shows one of the highest results in terms of fuel burning time.

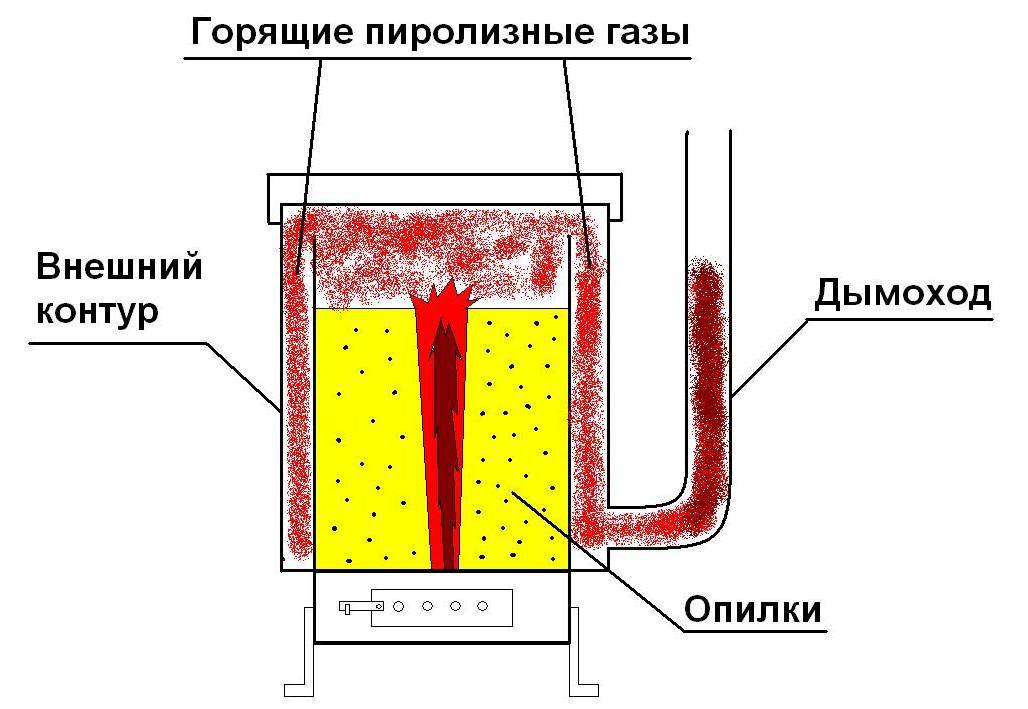

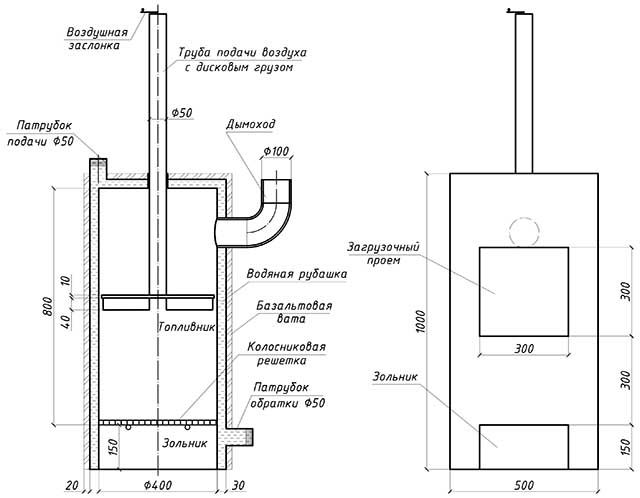

The principle diagram of this heater is that the fuel combustion process combines the combustion of conventional fuel with controlled oxygen supply and the pyrolysis process. The design of the furnace is a metal case with an open top. For the case, a 200 liter thick-walled metal barrel is most often used. It contains a central rod, made of a thick-walled pipe, with a rigidly welded metal disk slightly smaller than the inner diameter of the barrel. The height of the pipe is 10-15 cm higher than the barrel. Ribs are welded on the underside of the disk so that there is a small space between the disk and the bottom of the barrel - this is necessary for oxygen to enter the furnace. The third element of the design is a design similar to a guide with a disk. The difference lies in the fact that the diameter of the pipe is larger than the guide, and the disk itself has holes over the entire area.It is put on the inner guide and when the fuel is burned, it gradually goes down. The cover is made of thick metal, so that the hole allows the press to lower evenly as the fuel burns. The chimney makes airtight in the upper part of the body at a distance of 5-7 cm from the top.

How bubafoni works

Before operation, a central guide is inserted into the housing. The entire volume of the hull is filled with fuel - firewood, briquettes, flights. Firewood is stacked vertically very tightly. The height of the bookmark should be 5-7 cm below the upper cut of the barrel. After that, the upper press is installed on the guide and the cover is put on. Ignition is carried out from above. After the start of the fuel combustion process, a process of gradual temperature rise takes place - oxygen enters through the pipes into the combustion chamber. When the temperature rises to 300 degrees, the process of gas formation begins. The gases rise up and the flame moves into the space between the lid and the top press. Thus, the process of combustion of gases begins. To regulate the burning rate, an adjustable damper is installed on the tube of the upper press. When using such a stove, one bookmark of firewood is enough for 48-72 hours of burning.

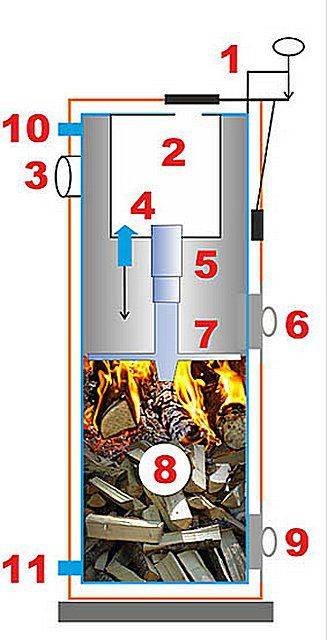

Advantages of long-burning boilers

Home-made long-burning devices have some advantages over their factory counterparts:

- With the same efficiency of 80-85%, the duration of burning can be increased, it depends on the dimensions of the furnace. The case can be made according to arbitrary dimensions on its own.

- In order to be able to load and kindle a small amount of firewood in the chamber for one-time heating of the dwelling in wet weather, an additional door can be made in the case. It should be placed between the boot and ash openings. There is no such door in factory devices.

- For the manufacture of the furnace body and the casing of the water jacket, it is possible to use thicker metal than in the factory unit. Then a home-made wood-fired boiler will be able to operate at a coolant pressure of up to 4 bar.

- The cost of manufacturing a home-made heat source for long-term combustion is 2-3 times lower than factory analogues.

- It is possible to install automation elements of your choice, as well as put a relief safety valve, which will make the product safe to use.

How to increase the efficiency of a long burning wood stove?

There are situations when it is required to increase the interval between the next loading of firewood into the furnace. To do this, you can perform a number of measures that will improve heat transfer and will contribute to more economical fuel consumption. Can:

- To intensify the heat transfer of the furnace surface due to forced air supply. To do this, it is enough to put a small fan near the stove, which can activate the movement of air masses in the room. If the room is small, you can use the cooler from the power supply.

- Install a water heat exchanger on the chimney. Such a device will take heat from the exhaust gases and transfer them through the water into the room.

- Use only dry fuel.The use of damp firewood will lead to the formation of a dense coating on the walls of the fuel, which worsens heat dissipation.

- Add a small amount of fuel briquettes along with wood. Due to the high heat transfer, such fuel will be able to compensate for the lack of heat.

The fuel to be loaded must be dry.

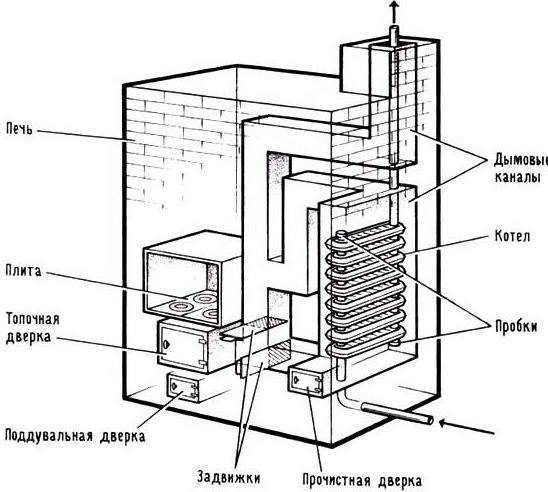

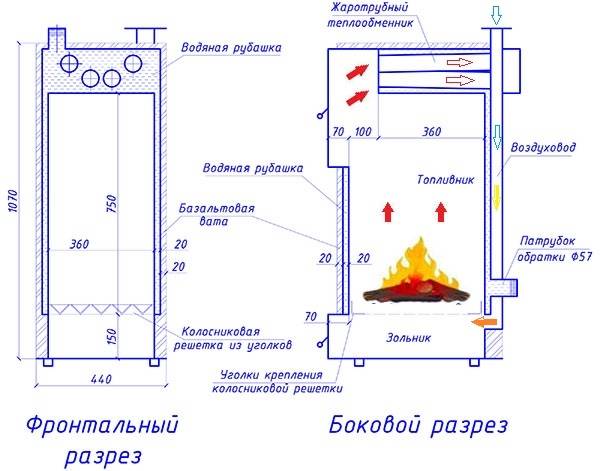

Useful tips for making a TT boiler

-

If you want to make a TT boiler universal in terms of the use of raw materials, then use a pipe made of heat-resistant alloy steel for the combustion chamber.

You can significantly reduce the cost of building a unit if you take a seamless steel pipe of grade 20.

- Before installing the boiler in the place determined for this unit, carry out the first kindling on the street, equipping the boiler with a temporary chimney. So you will be convinced of the reliability of the design and see if the case is assembled correctly.

- If you use a gas cylinder as the main chamber, then keep in mind that such a unit will provide you with combustion for 10-12 hours due to the small amount of fuel being put in. So the small volume of the propane tank will decrease after cutting off the lid and ash pan. To increase the volume and ensure a longer burning time, two cylinders must be used. Then the volume of the combustion chamber will definitely be enough to heat a large room, and there will be no need to lay firewood every 4-5 hours.

-

In order for the ash pan door to close tightly, preventing air from entering, it must be well sealed. To do this, lay an asbestos cord around the perimeter of the door.

If you will make an additional door in the boiler, which allows you to “reload” the fuel without removing the cover, it must also be tightly sealed with an asbestos cord.

For the operation of a TT boiler, the diagram of which we attach below, any solid fuel is suitable:

- hard and brown coal;

- anthracite;

- firewood;

- wood pellets;

- briquettes;

- sawdust;

- shale with peat.

There are no special instructions for the quality of fuel - any will do. But keep in mind that with a high moisture content of the fuel, the boiler will not give a high efficiency.

Types of ovens

Currently available for purchase long burning wood stove different power and with a variety of designs. Some models are made with additional features:

- a hob that can be used for cooking;

- in the form of a fireplace, if you want to add exclusivity to the interior. In this case, Finnish stoves for heating a house look especially advantageous.

Appearance is very important

Furnaces fireplaces for giving wood long burning

Related article: To date, many have come to the consensus that the fireplace stove for giving long burning, it is the most efficient and safe way to heat. In the article we will talk about the advantages of devices, their types, consider popular models, average prices, how to choose the right one.

Modern models are easy to use. They are economical. Differ in long service life. Easily ignited and quickly warm up the room. Some long-burning wood-burning fireplaces are universal: they are equipped with hobs.

Fireplace stoves are compact mobile devices that do not create problems during operation. Ash can be removed from the furnace directly during operation. The stylish appearance of the equipment allows you to transform any interior.

Their main disadvantage is the uneven distribution of heat, due to the design features of the equipment. The temperature near the ceiling is always higher than near the floor. As a result, the smoke, heated to a sufficiently high temperature, condenses with the formation of soot on the inner surface of the pipe. If the stove is operated continuously, the chimney should be cleaned every six months.

Stove-fireplace - a stylish solution for the interior

Boilers for long burning on wood

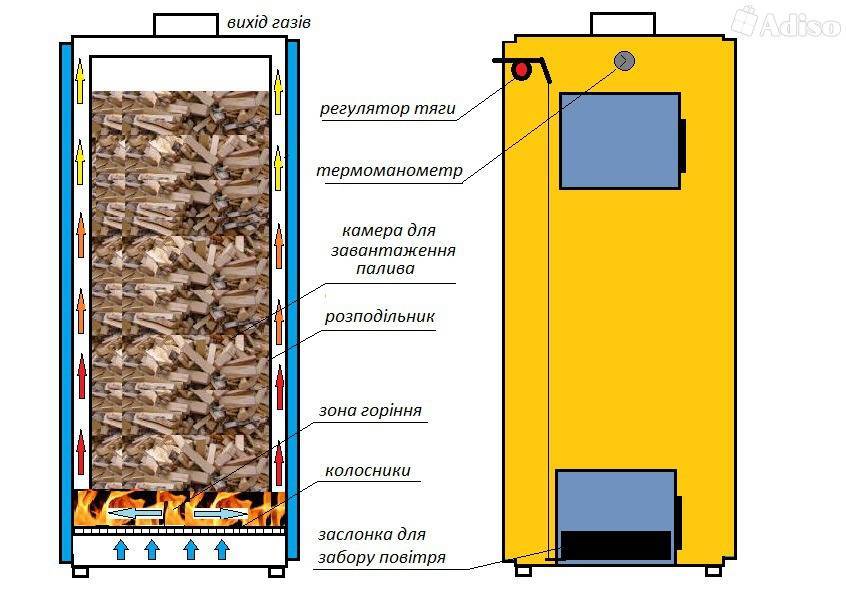

The operation of such heating equipment is based on the principle of smoldering firewood in conditions of limited oxygen supply. Such boilers do not need a constant supply of firewood. Depending on the technical characteristics of a particular model, one bookmark can last from 3 to 12 hours. At the same time, instead of firewood, solid fuel of a different type can be used. Thanks to the special design execution for space heating does not require connection of heating equipment to other communications.

The disadvantages of long-burning boilers include the high cost of equipment and the low heat transfer of firewood, which does not exceed 89%. In addition, to ensure the efficiency of the boiler, constant human intervention is required. Such equipment does not allow you to adjust the temperature.

Solid fuel boiler for long burning

Wood-burning stoves for heating a long-burning house with a hob

Furnaces equipped with a flat iron surface can be used not only for heating the room, but also for cooking. Such products are distinguished by reliability, durability, cost-effectiveness. They are able to harmoniously fit into the atmosphere of the kitchen space: manufacturers offer products with different designs.

Such equipment does not create problems during transportation. Easy to mount. However, during the installation process, you should carefully follow the rules. To achieve optimal results, when operating the device, you should use fuel of the right quality. However, the lack of the possibility of adjustment does not allow to reduce the degree of heating of the metal surface in most models. Some units are equipped with an additional sash, which helps to reduce the temperature.

Long burning stove with hob

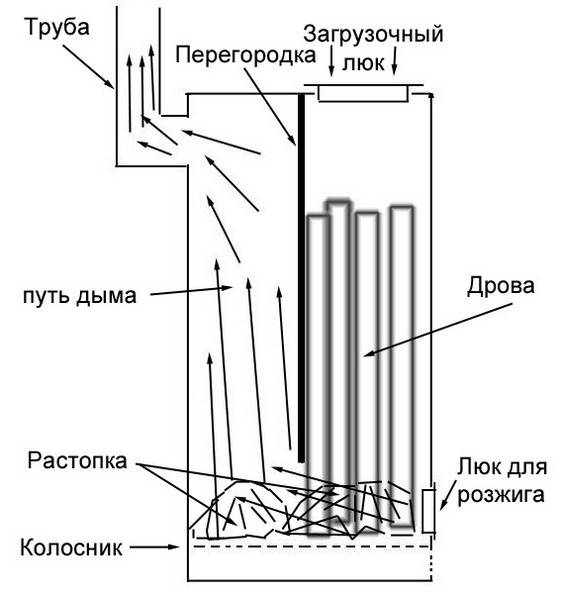

We make a potbelly stove

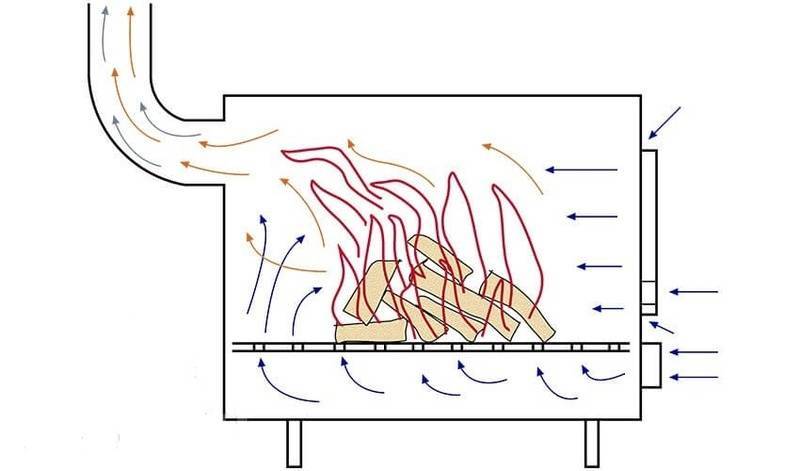

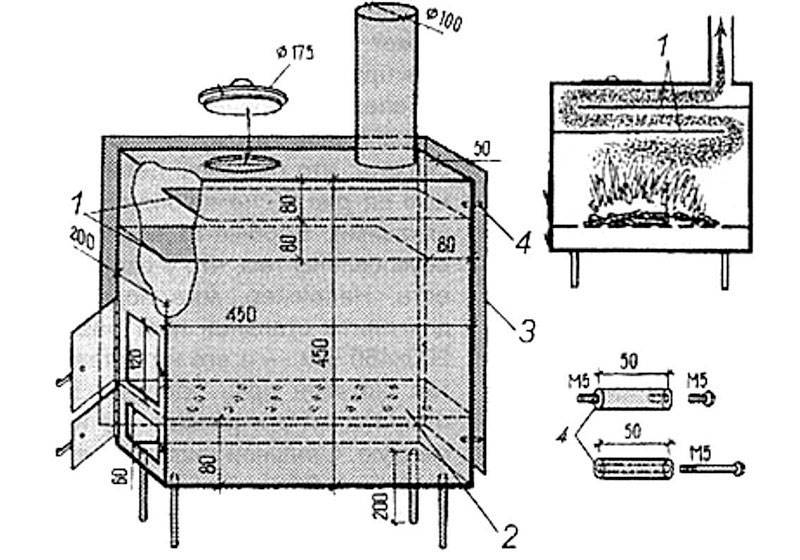

Long-burning stoves of potbelly stoves are good because they are made from any available materials - these are various barrels, old roomy cans, pieces of large-diameter pipes, or just sheet metal. We chose sheet steel as the starting material - it is a more convenient material in processing. You can adapt a barrel for this, but doing work in its internal volume is not very convenient.

All sizes are presented more as guidelines, some average best option. You, in turn, can deviate from the dimensions of the parts to create a stove that meets your specific wishes.

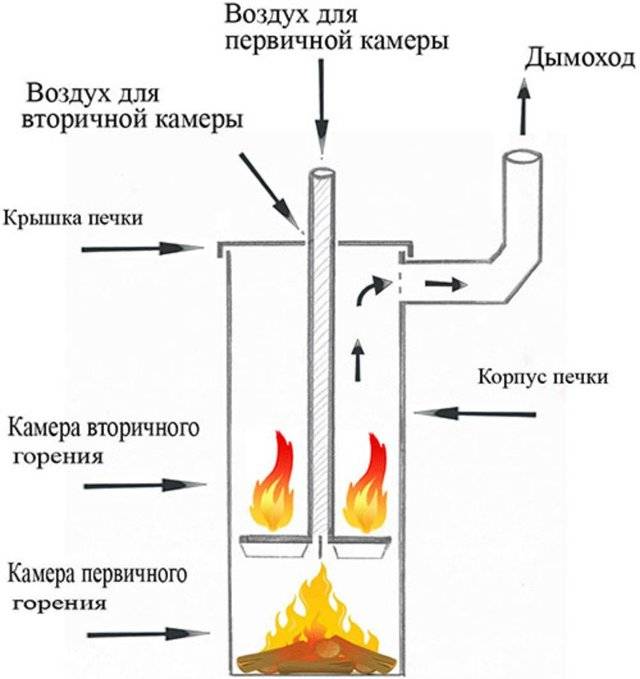

The design of the long-burning furnace is quite clear from the above drawing. Here are its main nodes:

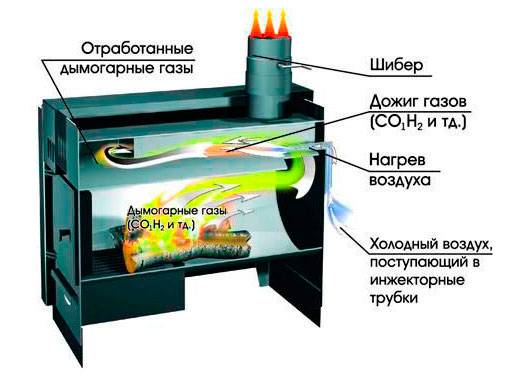

- Combustion chamber - firewood burns in it with the formation of pyrolysis gas;

- Afterburner - in it the combustion of pyrolysis products occurs;

- Doors of the combustion chamber and ash pan - they are purchased at the store, but they can be made with your own hands;

- Chimney - in most cases it is a pipe with a diameter of 100-150 mm.

You can deviate from the drawing in one direction or another. But remember that with a decrease in size, the burning time decreases and the power of the long-burning furnace decreases.

The lower the power, the smaller the heated area. Therefore, it is best to provide a small margin.

For the manufacture of a long-burning furnace such as a potbelly stove, we need sheet steel with a thickness of at least 3 mm - this will ensure a long service life of heating equipment. If the steel is thin, it will begin to burn through - after a couple of seasons, holes form in it

Therefore, special attention is paid to the thickness of the steel. The optimal thickness value is 3-5 mm

For our example, we will take the classic scheme of a potbelly stove, refine it and get at our disposal an effective stove for home on wood. At the initial stage, we prepare the side sheets - in our drawing they have dimensions of 450x450 mm. Next, we make the lower walls, front and rear walls - their dimensions are 200x450 mm. As a result, we should get a rectangular box. But do not rush to weld it together - there is a lot of work ahead.

First you need to make a base - this is the bottom wall and two side ones. We weld them together, at a height of 80 mm from the bottom we weld the grate. Now we need to prepare the front wall of the long-term heating furnace - we weld both doors into it, after which we weld it to our structure.

We prepare two metal sheets measuring 200x370 mm. We weld the first of them to the front and side walls at a height of 160 mm from the top. Next, we prepare the back wall - we weld small metal tubes into it, which should enter the space between the two inner sheets that form the afterburner chamber - secondary air will be supplied through them. Then we weld the back wall and the second metal sheet at a height of 80 from the top (welded to the side and back walls).

The damper is used to regulate air flow. It is he who increases the efficiency and quality of traction.

Our do-it-yourself long-burning stove is almost ready - it remains to deal with the top cover. In it we make a hole with a diameter of 100 mm and weld a piece of pipe for the future chimney. Now it remains to find out whether you need a hob or not - it is also welded into the top cover. At the last stage put the cover in place and weld it - the stove is ready, now it can be installed on a non-combustible base, attach a chimney and run.

When starting the long-term combustion furnace presented above, let it flare up, then cover the blower so that the firewood barely smolders and the generation of pyrolysis gas begins.

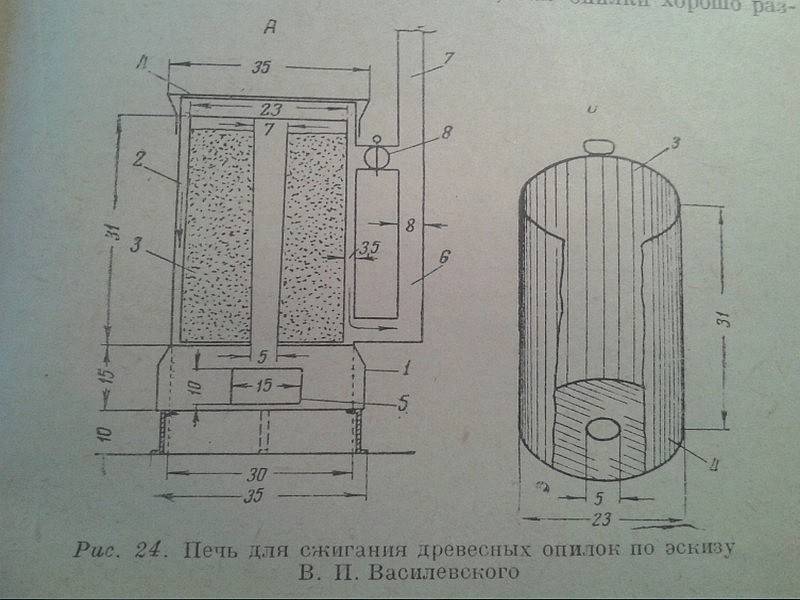

Another interesting long-burning pyrolysis furnace is shown in the following figure. It is made from a barrel or a piece of large diameter pipe and is supplied with a suitable lid. In the lower part, at a distance of 80-100 mm from the bottom, a metal disk with a hole in the middle is welded. Between the disk and the bottom, on the side wall, a door is welded. The resulting space forms our firebox. In the upper part we weld a chimney with a diameter of 70-100 mm.

In terms of low cost of use, such a stove is a real gift, since there is no shortage of sawdust in a private house.

The resulting long-burning furnace receives heat by burning pyrolysis gases formed during the heating of sawdust. The sawdust itself is poured into the main volume, and so that they do not wake up in the furnace, they are rammed with a wooden cone. When the furnace is started, a fire is made in the furnace, the cone is removed - after a while the unit will begin to produce heat.

Features of the pyrolysis furnace and its application

Pyrolysis furnaces are called long burning furnaces. The combustion of solid fuel in them occurs without access to oxygen: volatile gases are first saturated with a fine fraction of wood, and then burnt at a high temperature (from 450 ° C), mixing with residual air in the second chamber. Fuel and gas burn almost completely, providing high efficiency (up to 85-95%).

The simple design of the furnace allows you to build her own hands and makes the device easy to use

The furnace of such an action is installed in the garage, in the country, in your house and in any small room where long-term heating is needed. The devices are easy to operate and provide the maximum amount of heat with significant fuel savings. At the same time, solid material is processed almost completely: gas and coal are burned, so smoke, soot and ash are almost not formed. This principle of operation is relevant for all models of pyrolysis furnaces, but different designs may differ in characteristics, appearance and internal structure.

Advantages and disadvantages

The heating device is efficient and economical, but also has a number of features.Knowing the pros and cons of pyrolysis furnaces allows you to make the right choice. The positive features of these devices are expressed in the following:

- Efficiency up to 95%, fast heating;

- minimum percentage of smoke and soot, environmental friendliness;

- no need for constant monitoring (fuel is loaded once a day);

- the use of different types of fuel;

- the availability of assembling and installing the furnace with your own hands.

The simple principle of operation ensures the practicality of the unit

The main disadvantage of operating such a stove is the need for proper storage of firewood, selecting the optimal level of their humidity. Otherwise, the material will not burn effectively, because wet vapors will not allow the gas to be processed.

When burning waste (raw wood, car tires, industrial waste), there is an unpleasant smell, so it is recommended to use only clean and high-quality fuel, or additionally install a ventilation system in the room. And also it is worth considering that condensate forms in the chimney, for the collection of which a special drive is provided. The outlet pipe and chimney have a larger diameter than the accumulator, so proper installation of the stove is important.

Furnace without external circuit

Sawdust stove scheme

Sawdust stove scheme

The main advantage of such a furnace is the maximum convenience of its cleaning from waste generated during the combustion process.

For the manufacture of a heating unit, prepare an empty gas cylinder, barrel or pipe of suitable sizes. The walls of the case should not be thinner than 0.5 cm. Additionally, prepare a grinder, hacksaw, hammer, chisel, rebar, steel sheets, welding machine, chimney, studs.

sawdust stove

The first stage is the preparation of the fuel tank

It is most convenient to work with a large diameter metal pipe or with a barrel. If using a balloon, cut off the top first. In the future, it will be used to make a cover.

Cut a 10 cm hole closer to the top of the container for attaching the chimney.

Closer to the bottom of the case, make a 5-centimeter hole. To it you will attach a pipe with pre-prepared holes (more than 50 holes with a diameter of about 1 cm).

Seal the top hole of the perforated pipe tightly.

The second stage - the chimney

Weld a metal pipe to the side wall of the stove body. A flue pipe will be connected to this pipe. This design is very convenient - if necessary, you can easily disconnect the pipe from the nozzle for cleaning.

The third stage - a cover for the stove

Cut the cover out of the sheet metal and further reinforce it along the edges with corners or reinforcing bars. Weld a handle to the top of the lid for easier handling of the product.

If your oven is made from a used cylinder, make a cover for the unit from the top of the container cut off earlier. The edges of such a cover also need to be further strengthened.

For maximum convenience in cleaning the stove from fuel combustion waste, weld a pair of studs to the outer side walls. In addition, weld a support to the furnace, previously welded in the form of a square from two corner-racks.

To clean such an oven, it will simply need to be turned over.

What is the advantage of a long burning stove

Any person who undertakes to assemble a long-burning stove sets himself the main task: to make a thing with his own hands that will work efficiently with minimal consumption of materials and fuel. It is worth noting that most of the finished furnaces of this type have an efficiency much lower than home-made models.

A conventional factory stove is different in that the fuel in it burns out very quickly, so the room heats up quickly and then cools down quickly if no more fuel is added to it. This is extremely inconvenient and not rational.

There is also an alternative on sale: these are stoves that run on solid fuel, which are able to delay the process of its combustion and, accordingly, insulate the room for a longer period. Such designs work on coals, firewood and all kinds of waste. However, such a unit in finished form is not cheap and has such disadvantages as:

- low efficiency;

- lack of automatic fuel filling;

- the need for regular bookmarking.

All of the above does not apply to long-burning furnaces. So, one filling of fuel can ensure the operation of the structure for about 18 hours due to the fact that over time, combustion in the furnace is replaced by smoldering, and automatic loading in this case is no longer needed. In addition, the design can be thought out in such a way that sawdust or wood chips can be used as fuel, rather than whole firewood.

What to Consider Before Assembling a Long Burning Furnace

Please note that building a long-burning stove with your own hands is a dusty and noisy job, so think carefully about the place where the work will be done.Also, make sure there is a source of electricity at the site, as electric welding will be required.

Tools for work should be prepared as follows:

- Metal barrel for 200 l.

- Two steel pipe sections, one larger, the other smaller.

- Metal channel.

- Hacksaw, steel hammer, axe, mallet.

- Roulette or answer for measurements.

- High quality red brick (about 50 pieces).

- Reflector (if any).

- A set of electrodes and a welding machine.

- Sheet steel.

- Building mix or materials for preparing mortar for laying bricks.

The algorithm of actions when assembling a home-made long-burning stove

The assembly of this unit consists of the following:

- Prepare a metal barrel: cut off its top with a grinder and leave it for later. If there is no barrel, you can take a pipe segment of a large diameter.

- Weld the bottom from a piece of a round steel sheet to the segment.

- We cut out another circle of steel with a diameter slightly less than a barrel or pipe, and in it another one for a small pipe about 12 cm. The pipe segment is welded to the steel circle.

- Weld the channels to the bottom of the circle, measuring them so that they can be freely in the pipe. Then they will be applied to fuel pressure depending on its burnout.

- The length of the pipe to be welded must exceed the height of the main part by 10 cm.

- We take the upper part of the structure: take the part of the barrel that was first cut off and cut a hole in it for a small diameter pipe.

- Cut out a hatch for laying fuel, then a door will be welded to it, which can be purchased ready-made or made by yourself.A handle must be welded to the door so that it can be conveniently opened.

- Below, install another smaller door so that it is possible to dispose of fuel waste.

Preparation of the foundation and construction of the chimney for the furnace

To install the furnace, a capital foundation is required, since the furnace metal will become very hot during operation. It is strictly forbidden to install it on fragile or insufficiently refractory material.

Deepening is not worth doing, since the specific gravity of the structure is not very large. It is necessary to pour a slab laid next to one brick with a special mortar or mixture.

Now let's move on to the issue of installing a chimney. It is needed so that the products of combustion quickly evaporate from the room into the atmosphere. For its construction, you can take a metal pipe with a 15-centimeter diameter. It should be welded to the top or sides of the furnace structure.

Then it is bent, but not more than 40 degrees. In general, you need to make sure that there are as few knees as possible before leaving the room.

Sometimes it is necessary to install a reflector, especially for small rooms. Thanks to them, heat flows will be redistributed, and regulate the uniform heating of the entire room.

The stove does not need to be lined with bricks if it is located in a boiler room or other utility room where children do not have access. If it is installed in front of everyone, then for safety reasons it is better to do the cladding.

Large rocket stove with bench

The main advantage of the rocket modification over the Russian stove is its compactness. Even being equipped with a couch, it will please you with its small size.Having made it out of brick, you will have at your disposal an effective source of heat with a comfortable bed - the household will fight for the right to occupy this warm place.

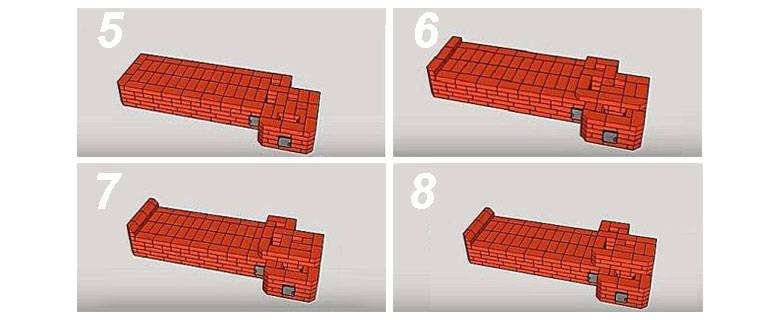

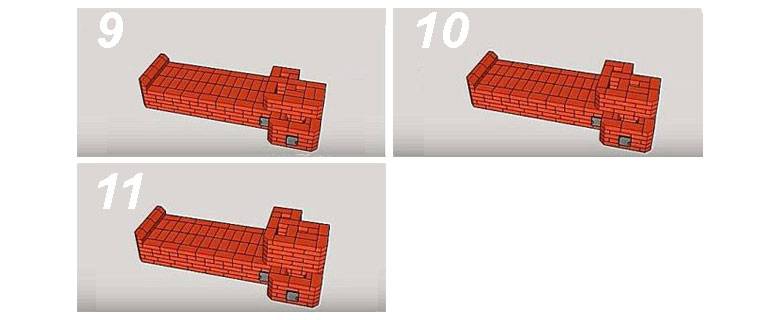

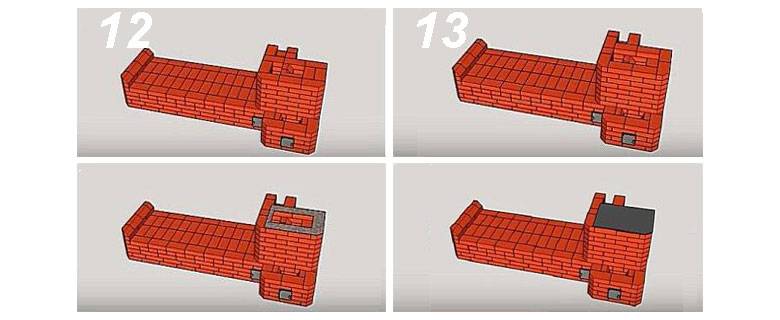

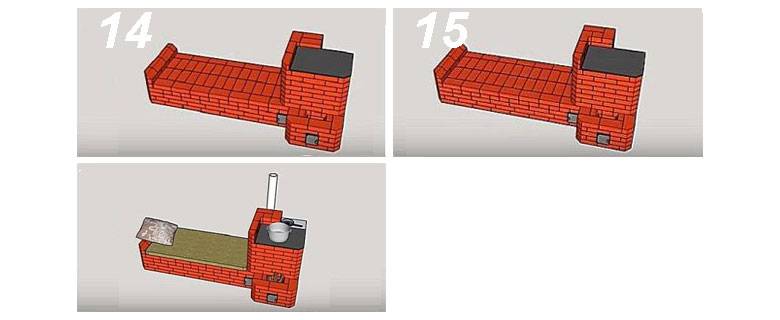

The presented ordering allows you to assemble a brick oven without the use of metal. Only the doors will be made of iron. Subsequently, the bricks can be smeared with clay, which will make the stove more rounded.

The first row forms the base of our rocket oven. It consists of 62 bricks laid according to the pattern shown in the figure. The second row forms channels for heating the couch - they run along its entire length. Here, cast-iron doors are mounted, fixed with metal wire - it is held between the rows. The number of bricks used - 44 pcs. The same amount will be required for the third row, completely repeating the contour of the second. The fourth row completely closes the channels that heat the bed. But here a vertical smoke channel and a firebox are already beginning to form - the row includes 59 bricks.

Another 60 is needed for the fifth row. The stove bench has already been formed, it remains to finish off the chimney channel and build a hob. The sixth row, which includes 17 bricks, is responsible for this. Another 18 are needed for the seventh row, 14 for the eighth.

The ninth and tenth row will require 14 bricks, the eleventh - 13.

Row number 12 is our key one - the chimney will start from here. Also, a hole begins from here, through which the air that has risen to the hob will go down to the bench - 11 bricks are required (this is the top of the riser). In row No. 13, this process is completed, 10 bricks are spent on it. Now we lay the asbestos gasket, which is covered with a piece of thick sheet steel - this will be the hob.

5 bricks are spent on rows No. 14 and No. 15, they close the chimney channel and form a low wall between the hob and the stove bench.

A metal surface is mounted in the back of the rocket stove, under which a small compartment is formed - here you can dry the firewood.

5 How does a homemade installation work?

The firebox of the mine structure is loaded to the lower edge of the opening for loading firewood. The combustion chamber must not be loaded to the top. The unit works according to the following algorithm:

- Firewood (sawdust, briquettes, coal) is put into the furnace.

- The compartment doors are hermetically sealed.

- The required temperature is selected on the control module (from +50 °C and above).

- The fuel is ignited.

- The fan starts blowing air.

- When the heat carrier is heated to the set value, the ventilation unit turns off (automatically). Air stops flowing into the combustion chamber.

- Firewood smolders, maintaining a certain temperature. When its value decreases, the control module starts the fan again.

The principle of operation of the mine installation is clearly shown in the drawing.

If desired, it is easy to make some additions to a home-made unit that will make it more versatile and safe to use. It is allowed to modify the design of the boiler in the following ways:

- Set up a security group.

- Integrate an additional jacket into the tank of the unit for heating the coolant to provide the house with hot water.

- Install an electric heater (heater), which will heat the heating device when the firewood burns out.

After such improvements, a home-made design will surpass expensive factory installations in many respects.

Chimney device

When it comes to heating equipment that runs on solid fuel, it is imperative to arrange a chimney. In this case, the chimney is made from a pipe with a diameter of 100 mm.

At a distance of 50–100 mm from the upper cut of the furnace, a chimney pipe is cut in. This is a piece of steel pipe into which the chimney will fit tightly. The smoke channel is made with a small horizontal section - 50 - 60 cm of a straight pipe is enough to weaken the draft. A large number of knees are not allowed before leaving the premises.

In operation, a chimney made of several segments is convenient. So it can be cleaned without problems.

Requirements for heating appliances

For heating with sawdust it is necessary to use long-burning boilers and furnaces that meet the following conditions:

combustion of fuel from top to bottom;

big outer surface area (important for ovens);

large area of the heat exchanger or water jacket;

large volume of the firebox;

the possibility of supplying air to the combustion zone.

Due to the small size of sawdust, they can be fed into the oven or boiler automatically, which further increases the battery life of the heater. Most often, auger feed is used for this - a rotating auger raises or lowers sawdust from the bunker and scatters them in the combustion zone.

For heating with sawdust, boilers and long-burning stoves of the Stropuva type (the Russian analogue of Bubafonya) are well suited. In these devices, the principle of upper combustion of firewood is implemented, and air enters directly into the combustion zone.

Furnaces and long-burning boilers that run on sawdust can not only be bought, but also made with your own hands.In home-made devices, the requirements for heaters described above are also implemented.