- How to create a do-it-yourself oven

- Garage stove and its features

- DIY heater

- From two jars

- Dropper model

- Installing and testing the device

- How to make a potbelly stove from steel

- Manufacturing sequence

- What metal to use

- We make a potbelly stove at work

- warm brick

- Garage stoves and their varieties

- DIY jigsaw

- Pros and cons

- Metal ovens

- Advantages

How to create a do-it-yourself oven

Furnaces, created independently, and working in used oil are the most popular garage heating units. No special skills or knowledge are required to make the simplest model of such a furnace. The fuel for this device can be any oil (shale, machine, industrial, transmission), diesel and heating oil, waste paint and varnish production. All this can give heat transfer, which is similar to an electric heater.

need for regular cleaning

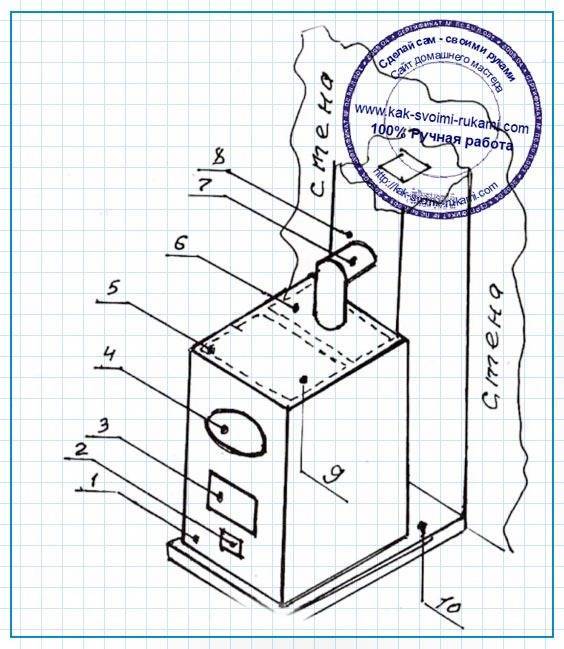

The whole furnace consists of two containers, which are interconnected by a vertical pipe with many holes. It is recommended to adhere to certain standards:

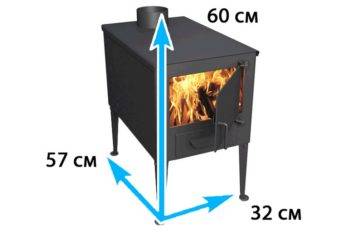

- General dimensions of the furnace - 70 * 50 * 35 cm;

- Make the cross section of the hood within 105 cm;

- The capacity of the containers is about 12 liters;

- Total weight - 30 kg;

- Fuel consumption should not exceed 1−1.5 l/hour.

To make such an oven, you need:

- Two metal containers;

- Steel pipe;

- Metal corner;

- Pipe branch;

- Galvanized or finished chimney.

Important tools:

- Bulgarian;

- Welding machine;

- measuring tool;

- Bolts or rivets, small tools.

Garage stove and its features

The stove in the garage is made of metal or wall material - bricks, blocks, stones.

Given the specificity of the stove in the garage, the following requirements are put forward for it:

- small size;

- budget cost;

- ease of use;

- high heating rate;

- maintaining a high temperature for a long time;

- ease of construction;

- ability to use solid and liquid fuels.

Dimensions of the oven for the garage.

Dimensions of the oven for the garage.

Furnaces are divided into several types, depending on the type of fuel:

- Gas oven.

A gas heater is most practical when there is central heating nearby. The cost of such a heating system is low, but you should be aware of the risk of explosion. - Wood burning stove.

Solid fuel materials are quite convenient and inexpensive in heating. They quickly heat any area, while the cost of materials is small. - Electric heaters.

An electric heater is very efficient in terms of heat output, but the cost of this type of utility room heating is not cheap. - The furnace on the fulfilled materials.

Often after long-term use of engine oil, materials are used for space heating.Since oil does not self-extinguish, and is also a liquid material that breaks down into harmful chemical compounds, this method can be a dangerous option not only for fire safety, but also for human health.

A wood-fired stove is the most popular and inexpensive option among consumers for heating a garage.

DIY heater

Of course, a solar oven for residential premises, garages, greenhouses and other small facilities can be purchased at the store. Their prices are reasonable. But no less high-quality model can be made independently.

There are several types of stoves for kerosene, diesel fuel or waste oil, that is, for liquid fuel. Each has its own merits and demerits.

A do-it-yourself liquid fuel stove will not differ much in quality from that bought in a store

From two jars

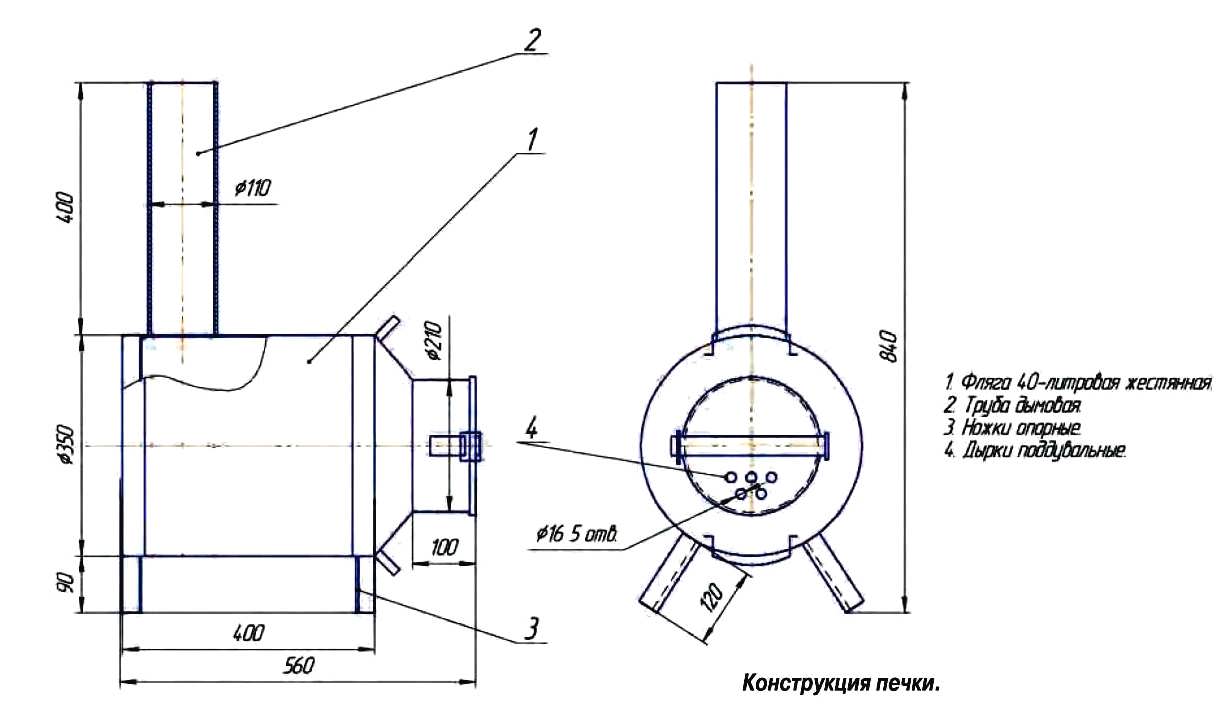

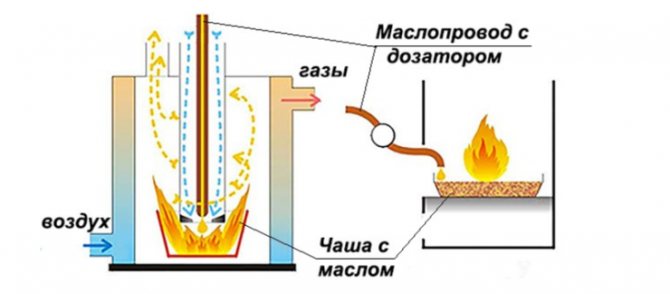

This version of the furnace consists of two parts of a round or rectangular shape. In the lower, made in the form of a container with legs, spent little or diesel fuel is poured. Here, liquid fuel, evaporating, goes through the stage of primary combustion. The lower container is connected to the upper one by means of a perforated pipe, in which secondary combustion takes place. A lot of holes are made in the pipe itself, which supply secondary air.

The lid on the lower tank has two openings: for pouring fuel and with a damper to help regulate the intensity of combustion. The combustion itself is carried out due to the natural supply of air, that is, thrust.

Such a stove has a high efficiency and heats the room well, but it has a number of disadvantages.

First, when even a small amount of water enters a combustible liquid, unpleasant loud exhausts begin to occur, often with flames or sparks from burning oil, which can cause a fire.

Secondly, both during ignition and during operation, such a model spreads an unpleasant odor. This can be a serious problem when using the stove in a residential area.

Such a modification does not require the use of special materials and can be made from improvised raw materials. This explains its immense popularity.

More about the balloon stove:

Dropper model

A similar version of the stove, although technically more difficult for home-made production, is safer and more efficient. Previously, it was used in the field. The stove can be called an army one, since it was often the military or geologists who made such devices.

The operation of the stove for a greenhouse on diesel fuel or other liquid fuel is based on the method of drip feeding into the combustion chamber. To implement such a project, you can use an old gas cylinder or a large diameter pipe. At the bottom there is a small container, like a bowl, where diesel fuel will burn.

A perforated pipe is installed from above to the bowl itself, through which air enters. Due to this, the furnace turns out to be especially economical, since not only the combustion of fuel vapors, but also pyrolysis gases occurs.

A tube is installed inside the air supply pipe through which fuel is supplied.And the fuel tank itself is located at a distance from the main structure, which makes the installation safer. Fuel dosing is interesting. Here an ordinary dropper finds its application, and the flow is regulated by a dispenser from it.

Such a furnace can work not only on diesel fuel, but also on mining

It would be useful to make two additional holes, one of which acts as a viewing window, and the second is designed to clean the unit from the inside. They will also act as an explosive valve when needed.

In order to increase the performance of such a heater, it is possible to add an adjustable fan to blow air. This will give not only better combustion, temperature increase and efficiency, but also the possibility of more accurate temperature control.

The resulting model of a homemade stove can work both on diesel fuel and on used oil.

Installing and testing the device

The stove is installed in a fireproof place, not on a wooden (linoleum) floor. It is advisable to provide a container with sand in the garage in case of fire. Drafts, installation in cramped conditions (under hinged shelves, racks) are excluded. Pour oil into the bottom tank. It is advisable to clean it before use, let it stand.

A chimney must be installed, otherwise the stove in the garage cannot be used. Water impurities are not allowed in the oil. First, pour a small portion, a couple of liters. Then, with the help of a paper wick, the oil in the tank is ignited. By opening or closing the damper, stable traction is achieved. After 2-3 minutes, the stove goes into operation, the oil boils. The unit is ready for use.

How to make a potbelly stove from steel

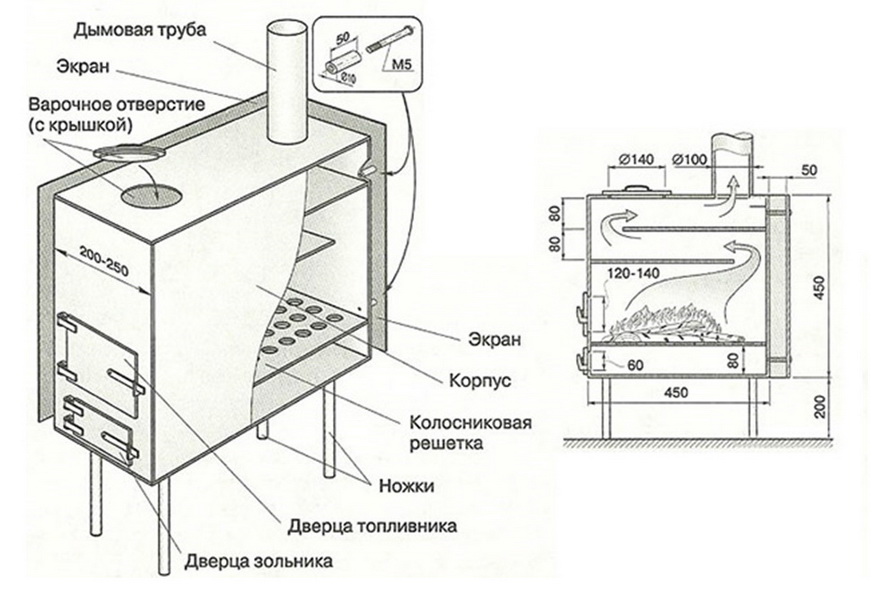

Stove potbelly stove convection type.

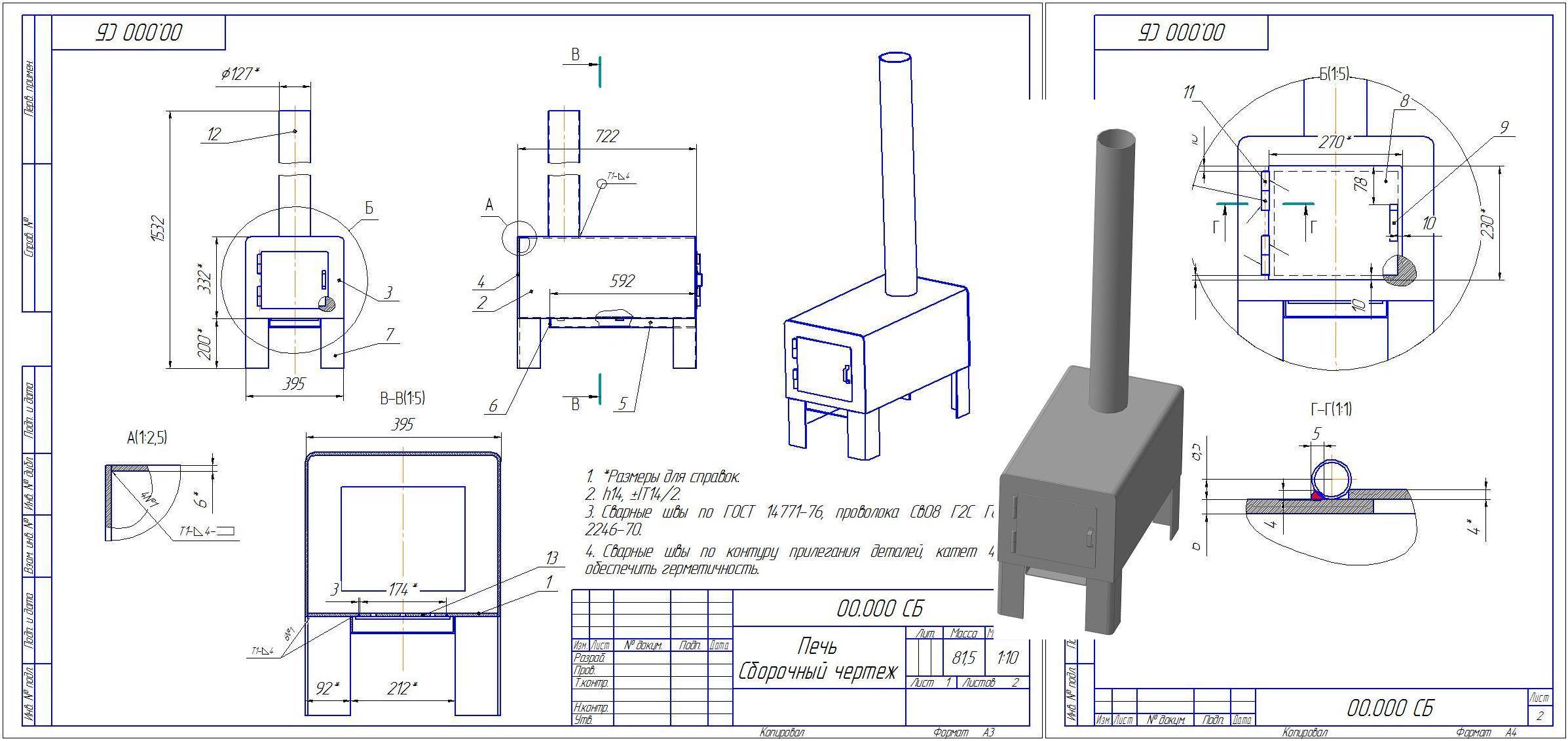

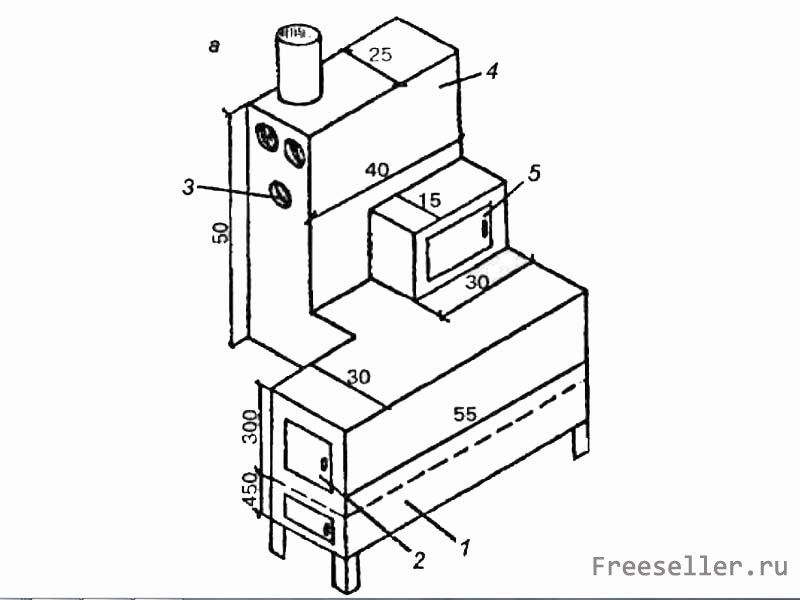

If you need to heat a house in the country and cook food, you should definitely know how to weld a potbelly stove yourself from sheet steel. This design will not require a lot of fuel. This is achieved through the installation of partitions in the furnace, reliable fastening of the doors and the ability to adjust the air flow. To make such a device with your own hands, you will need to prepare the following elements:

- metal sheet with a thickness of 4 mm or more;

- metal with a thickness of 8-12 mm, from which partitions will be made;

- lattice;

- chimney;

- corners from which the legs will be built;

- welding device.

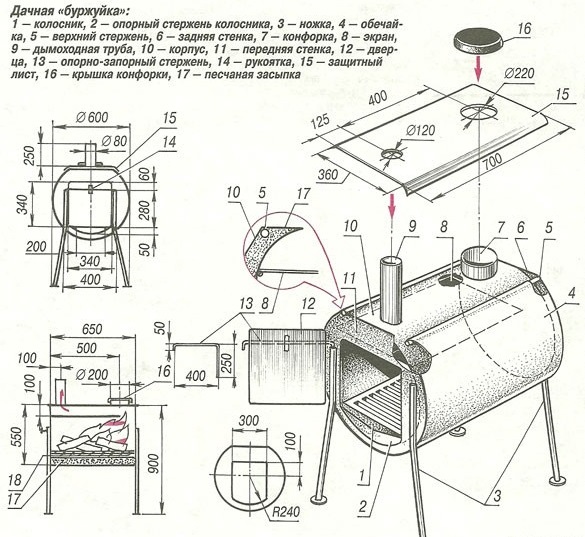

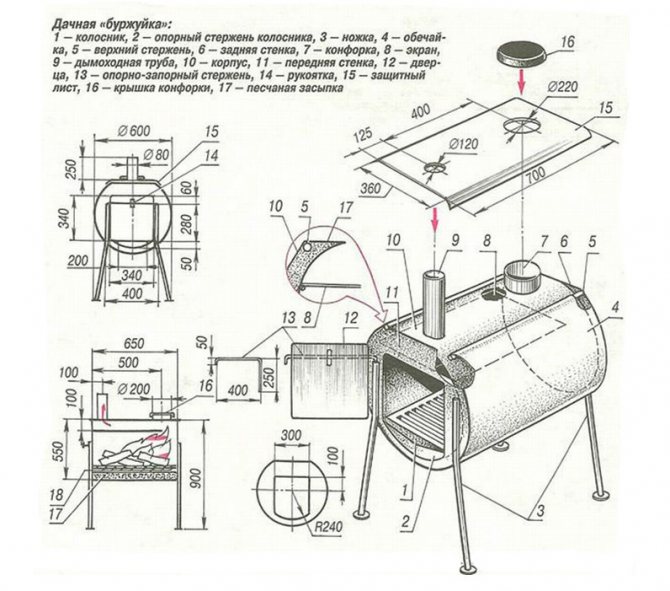

Manufacturing sequence

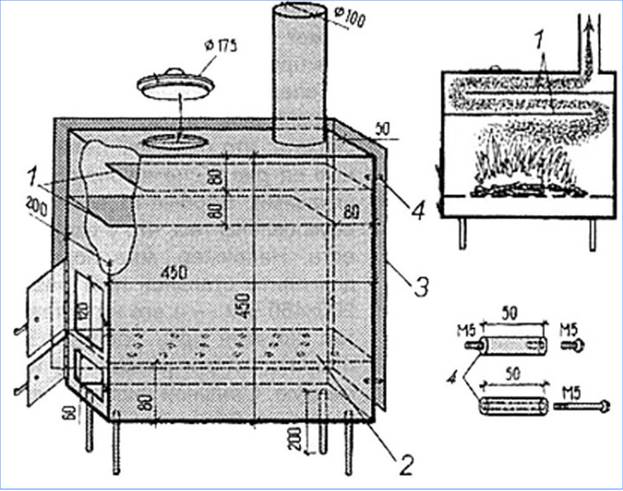

From the steel sheet, the first step is to cut out the elements for the body and several partitions that will be mounted on the top of the firebox. They will be able to make a labyrinth for the smoke, as a result of which the efficiency of the stove will increase. In the upper part, you can make a recess for the chimney structure. The recommended recess diameter is 100 mm. Next, you will need to make a recess for the hob with a diameter of 140 mm.

Stove potbelly stove made of sheet steel.

Using a welding device, you need to attach the side elements to the bottom of the structure. To the side walls you will need to attach strips of metal of great thickness. As a result, it will be possible to attach the grate. It can be a sheet of metal with recesses with a diameter of about 20 mm. The lattice can be made of reinforcing bars. At the next stage, supporting elements from a metal strip must be attached to the side walls. After that, the installation of partitions is carried out.

Doors for the firebox and ash pan should be cut out of metal. They can be installed on ordinary hinges. However, a more reliable option is to use curtains made of steel pipes and rods. They can be fixed on wedge hecks. The elements are cut from a stainless steel sheet, after which they are fixed with bolts. In order to be able to adjust the intensity of fuel combustion, on the door that closes the ash pan, it is necessary to make a recess for mounting the damper.

To the recess for the chimney structure, you need to attach a sleeve 200 mm high, on which the pipe will be mounted. A damper in the tube will help keep the heat in. For her, it will be necessary to cut a circle from a metal sheet. One extreme part of the steel rod must be bent. After that, several parallel holes will need to be made in the tube. Next, a rod is mounted, after which a round damper is welded to it.

Diagram of a brick fence for a potbelly stove.

The flue pipe must be installed at an angle of 45°. If it passes through a recess in the wall, in this place the part must be wrapped with fiberglass, and then fixed with a cement mixture.

To prevent the occurrence of burns from touching a red-hot stove, it will be necessary to build a steel protection screen from several sides and place it at a distance of 50 mm. If there is a desire to increase the heat transfer coefficient, the structure can be overlaid with bricks. After the firebox is finished, the brick will heat the house for some time. Laying should be carried out at a distance of 12 cm from the metal body.

The air cushion can become heat protection.

For its implementation, holes for ventilation must be made in the masonry above and below.

What metal to use

In anticipation of the manufacture of the furnace, it is imperative to inspect the metal for defects - corrosion, cracks, bulges. If they are, they must be processed by grinding, welding, stamping.

The reliability and durability of the furnace is given by the material from which it is assembled. Suitable metals for the thematic task can be considered:

- Ordinary steel;

- heat resistant steel;

- Cast iron.

If the stove is made from a finished container, then sometimes a can or a fire extinguisher acts as the latter. The strongest material is steel. But this indicator (strength) also depends on the thickness. If it is 10-18 mm, then the oven will last a long time.

If there is a large amount of cast iron, you will have to make a heavy furnace with walls 6-25 mm thick. Despite their enormous weight, the corresponding structures heat up quickly and retain heat for a long time. In other words, cast iron stoves have good efficiency.

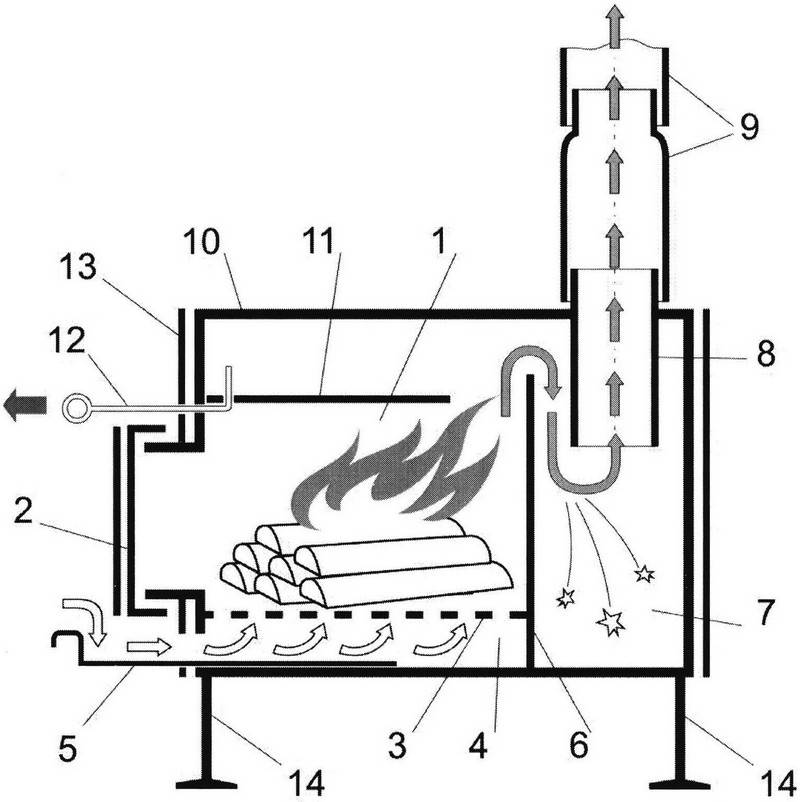

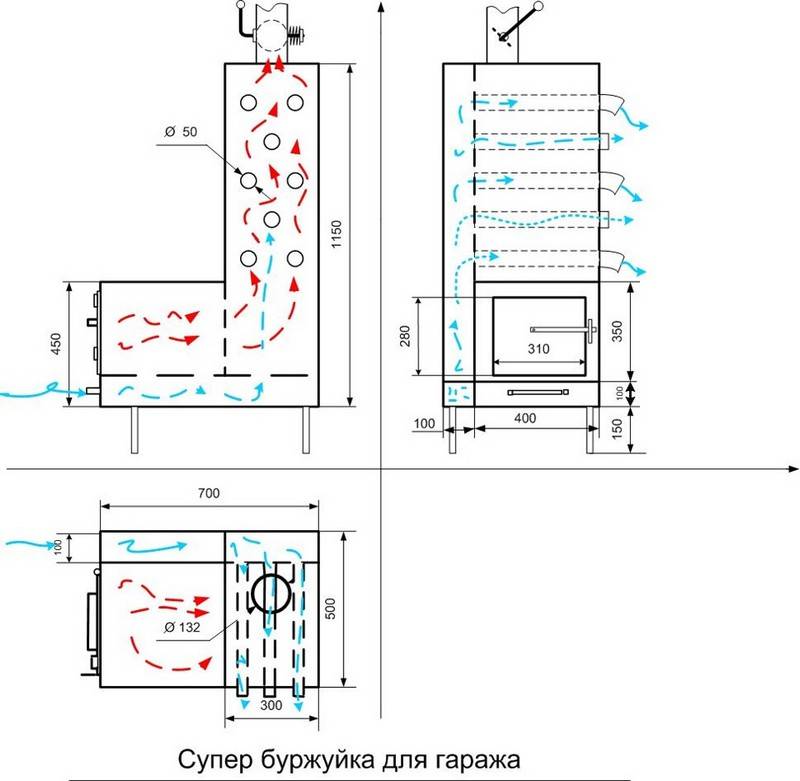

We make a potbelly stove at work

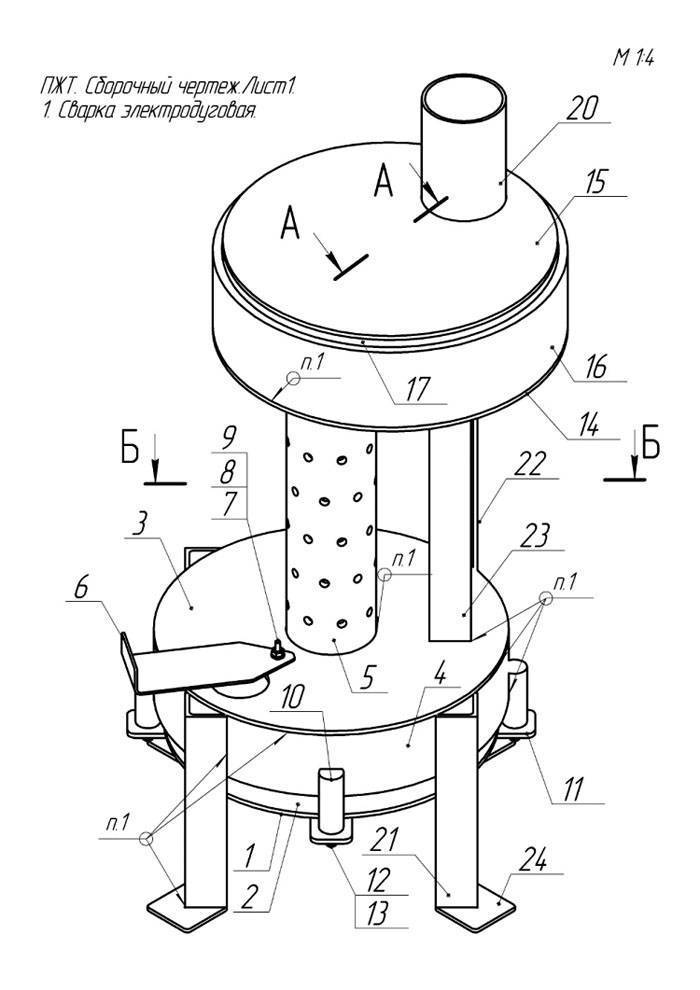

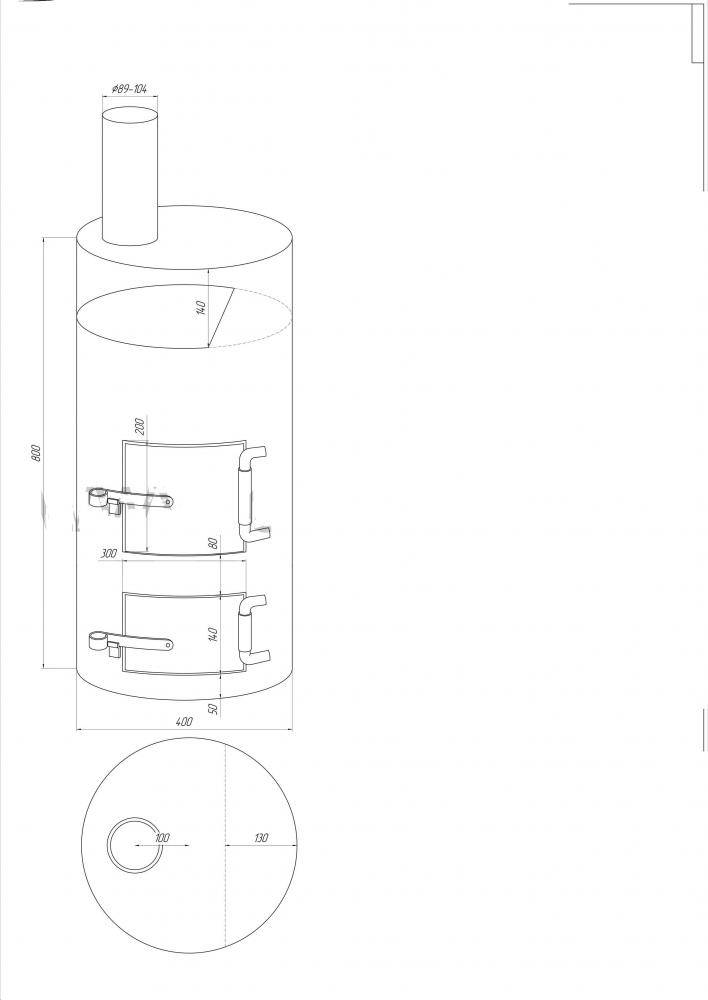

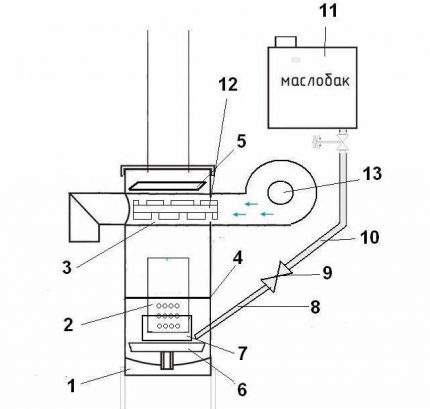

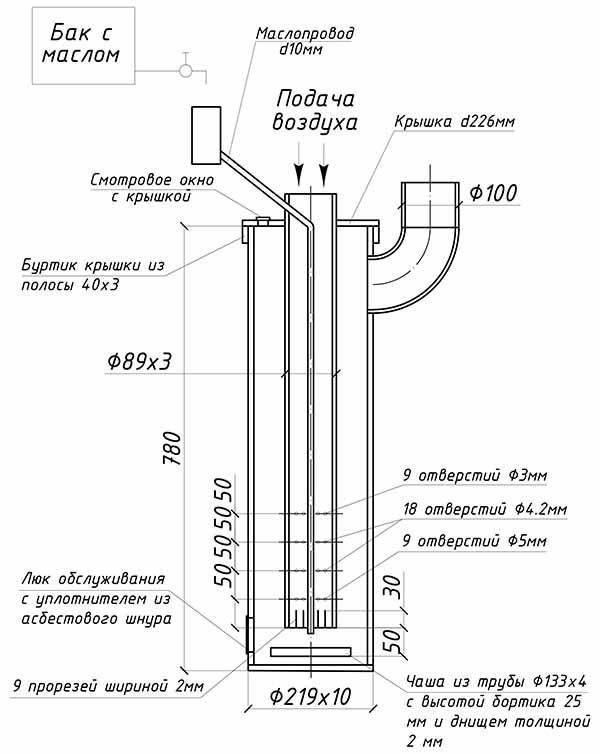

Diesel fuel and used engine oil are very high-calorie fuels. If you get it inexpensively, then it makes no sense to mess with firewood and coal, it’s easier to make a reliable furnace - a dropper. Its principle of operation is to burn mining, dripping into a red-hot bowl. Moreover, along the way, liquid fuel has time to warm up, as it passes through the oil pipeline built into the pipe - the afterburner. The drip-type potbelly stove device is shown in detail in the drawing.

For efficient combustion of oil, air is forced into the stove using a fan, and mining flows naturally from a tank suspended from the wall next to the heater.Another option is the forced supply of fuel by pressurizing the fuel tank (for example, with a hand pump).

Both a pipe Ø219 mm and a propane cylinder with a diameter of 30 cm can act as a furnace body. Making an oil potbelly stove with your own hands is a simple task, the main thing is to make holes and slots in the afterburner correctly and lay the fuel pipe to the bowl installed at the bottom. A complete assembly guide is provided in our other article. You can get a closer look at the operation of the heater from the video:

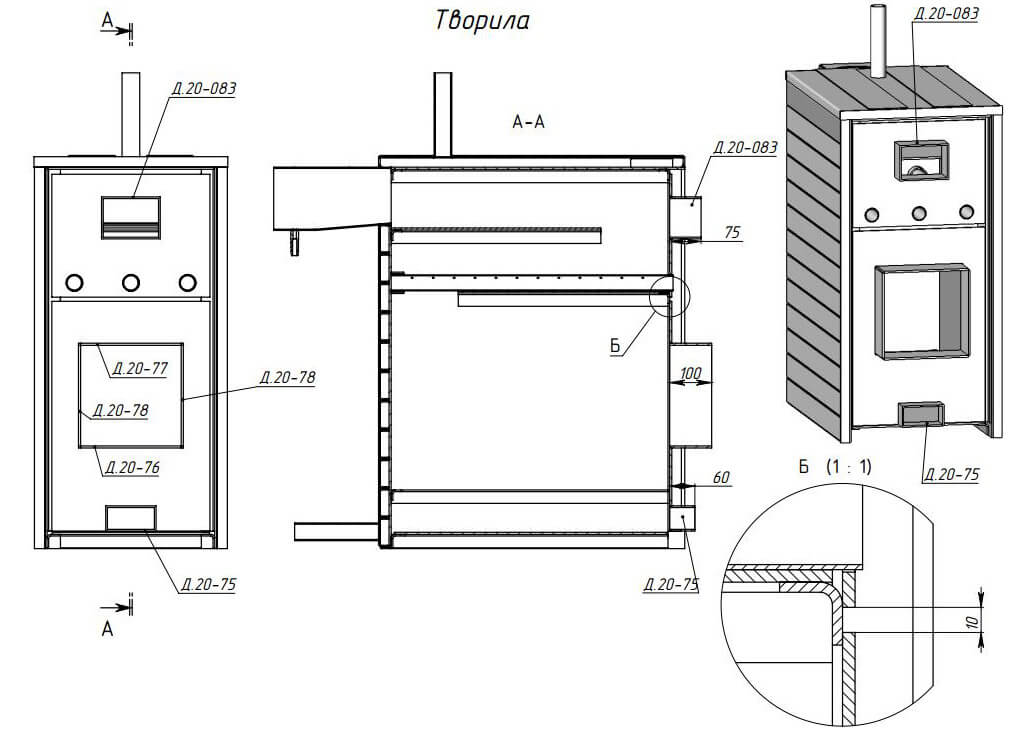

warm brick

A potbelly stove on wood, coal and other types of fuel can significantly increase its efficiency. To do this, it is enough to build a screen of baked clay bricks around it with your own hands. If you look closely at the drawings of such a mini-building, you can see that the bricks are laid at a short distance from the walls of the stove (about 10-15 cm), and if desired, around the chimney.

Bricks need a foundation. Do you want the masonry to last a long time? Then pour the base at a time to form a monolith. The material for the foundation is better to take concrete, which should be reinforced with steel reinforcement with your own hands. It is desirable to make a reinforcement layer at a distance of approximately 5 cm from the surface of the concrete pad.

Ventilation holes are made at the bottom and top of the brickwork, which will ensure the movement of air (heated masses will go up, cold air flows from below). Ventilation also prolongs the life of the metal walls of the potbelly stove, postponing the moment of their burnout due to cooling by circulating air.

Bricks laid around the stove accumulate heat, and then give it away for a long time, warming the air in the room even after the potbelly stove goes out. In addition, brickwork additionally protects the objects surrounding the stove from fire.

If desired, the stove can be completely laid out of brick. Such a structure is beneficial in that it will last for many years without additional effort on the part of the owner. However, there are also certain disadvantages. The disadvantages of this option include the following:

- the process of laying out such a stove is quite laborious and is suitable only for those people who have experience in masonry with their own hands;

- a brick potbelly stove is quite expensive, as it requires the use of refractory materials, including fireclay bricks and special clay for mortar.

In order to get a small potbelly stove on wood, it is enough to lay out a cone measuring 2 by 2.5 bricks, 9 bricks high. In the combustion chamber, 2-4 rows are laid out from fireclay bricks. Ordinary clay baked brick is suitable for a chimney, into which you must remember to insert a stainless steel sleeve.

Whatever the method of making a miniature stove or a potbelly stove with your own hands, you make them according to a drawing or by eye, the main thing is that at the output you get an effective heater, and in an expanded configuration also a hob for cooking. Look around for suitable materials (barrels, sheet metal, etc.) and go to your own homemade stove or even a potbelly fireplace!

How to make a wood splitter with your own hands? How to install a sandwich chimney with your own hands It is not difficult to build a chimney for a boiler with your own hands Do-it-yourself metal stove How to make a smokehouse yourself at home or in the country

Garage stoves and their varieties

Before we tell you how to make a do-it-yourself stove for a town, let's try to consider the main types of stoves and the types of fuel available to us. To heat garages we can use:

- Diesel fuel;

- The most common firewood;

- Coal;

- Petrol;

- Working off.

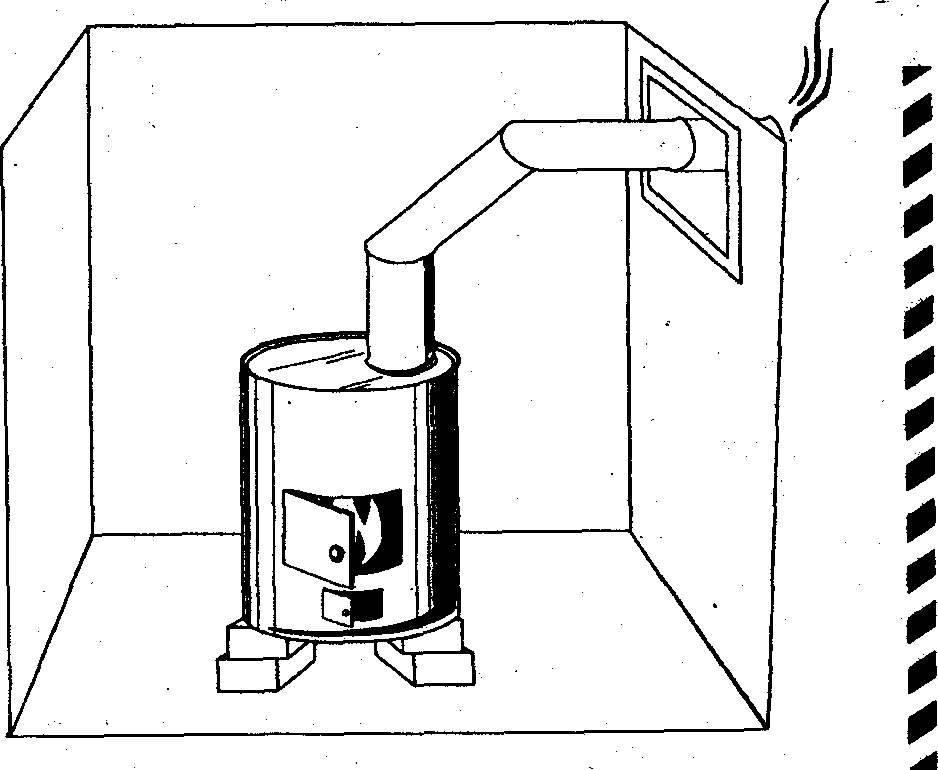

A shop diesel oven works without a chimney and takes up little space.

A purchased diesel stove for a garage is an excellent and aesthetic solution. It will allow you to completely warm up the garage, working on a simple diesel fuel. Such a stove quickly ignites and enters the operating mode, does not require a chimney. But you need to remember that you will always be haunted by the smell of diesel fuel, which is simply impossible to get rid of. In addition, you will need to buy diesel fuel somewhere, spending large sums on heating.

There is practically no high-quality diesel fuel, which will give a minimum of an unpleasant odor, on sale.

With the help of a gasoline stove for the garage, the design of which we will describe in our review, you can quickly warm up the working room. The main thing is to get cheap gasoline from somewhere. A gasoline-powered barrel garage oven will delight you with its ease of manufacture. Also, such a unit can be used for heating any other premises, for example, country houses.

The main feature of our stove will be the absence of a strong unpleasant odor during its operation.

If you have a solid fuel stove, you will have to find a place to store firewood.

Solid fuel stoves on wood and coal please with simplicity and affordability. Fuel for them is cheap, and in some cases free. The wood-burning garage stove has a simple design, does not produce an unpleasant smell of petroleum products, and can operate on various types of solid fuels. Only now the owner of the garage will have to constantly remove the ashes from it, but it can be used as fertilizer in your garden or vegetable garden.

An oil stove (aka a working out stove) will please you with the simplicity of its manufacture. A do-it-yourself device installed in a garage will provide people with warmth. And if your activity is connected with frequent oil changes, then you will have at your disposal an inexhaustible and free source of fuel. Let's see how to make a garage oven and what you need for this.

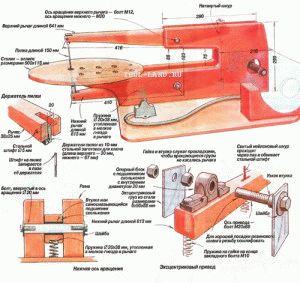

DIY jigsaw

A steel square with a bolt soldered into it is made by hand as a file holder block.

The improved block is soldered to the old saw holder.

Focus on the desktop. Plywood is chosen as the base

The narrow area of \u200b\u200bthe table in size repeats the parameters of the jigsaw.

Furniture legs are mounted in the front plane of the table, a small wooden stand is fixed to the back plane of the working area.

To create a lever, use only hardwoods.

The lever hole must be created a little larger than the diameter of the stud (regulates the spring tension).

The described home-made craft should stand on a "sole" that will not interfere with the workflow. If necessary, a corner is cut in the area of the base plate.

Pros and cons

Like any heating device, a wood stove has its advantages and disadvantages.

Let's look at some of the benefits:

- Relatively low fuel cost.

- The versatility of the device during operation. You can use the heater for space heating, cooking and heating food.

- Installation and installation of a garage oven is very simple and does not require high costs.

- For the manufacture of the unit, improvised materials can be used.

- During operation, the use of additional installations and devices is not required.

- The small overall dimensions of the unit make it versatile when used in garages.

- The operation of such a device does not require the use of an additional type of energy (electricity).

The disadvantages of this design include:

- Such furnaces have a large heat transfer, as a result of which they heat up quickly and cool down quickly.

- To maintain a high temperature in the oven, it is necessary to periodically add firewood.

- Constant monitoring of the heating process is necessary to ensure safety.

Metal ovens

Metal stoves are the most popular garage heating option. This is because these units have many advantages:

- Compactness;

- Light weight;

- High heating level;

- Easy to install (does not require foundation preparation);

- Suitability for cooking.

Potbelly stoves are also distinguished by their simplicity of design:

- Firebox for laying firewood;

- Grids (grid for creating traction);

- Ash pan for collecting ashes;

- Chimney to remove smoke.

Such an oven for a garage on do-it-yourself firewood will have to be made from tin or cast-iron worn out structures.However, the market offers ready-made and used potbelly stoves at attractive prices.

The only drawback of the potbelly stove is its heating due to solid fuel. The latter is not always easy to get, it quickly burns out and forms an exhaust.

Advantages

A self-built oven in the garage will please the motorist with a number of positive qualities:

- the ability to create optimal temperature conditions indoors, which will avoid the risk of unpleasant odors, mold, fungus. By adjusting the dampers, blowing a person is able to reduce the rate of combustion of firewood, coal. If you throw firewood into the firebox, the air temperature will rise rapidly. It will be much more pleasant to work inside a warm room, the risk of catching a cold will decrease when repairing a car in the winter season;

- long cooling period. A well-built brick stove is superior in this parameter to structures made of cast iron and steel. After throwing fuel into the furnace for a long time, the space will be warm;

- the larger the brick structure, the more powerful it will be in terms of heating the surrounding air. However, even a tiny structure, if properly erected, can make a small garage warm;

- the cost of purchasing coal and firewood is significantly lower than in the case of using main gas.