- Features of homemade gas ovens

- Operating rules

- The best steel electric sauna stoves

- EOS Filius 7.5 kW – premium heater

- SAWO Scandia SCA 90 NB-Z - with large stone compartment

- Polytech Classic 10 – with an innovative heating element

- Harvia Cilindro PC70E - compact model for small steam rooms

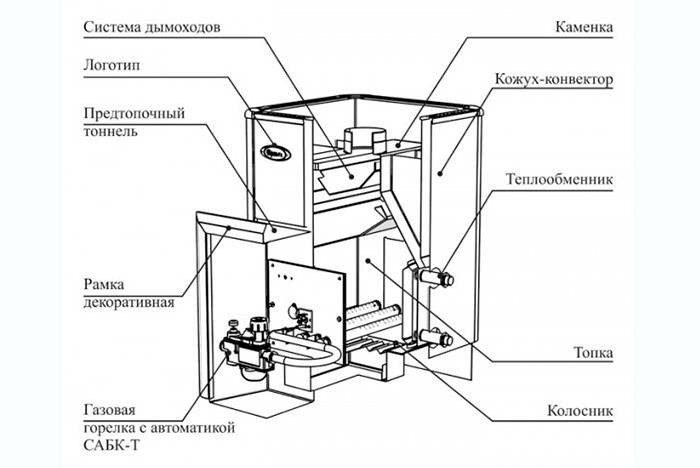

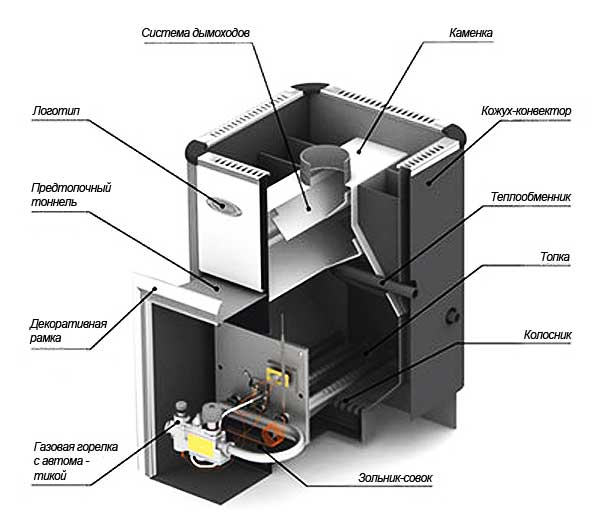

- Classification of a modern gas unit

- conclusions

- Criteria for choosing a gas oven

- Stove-heater

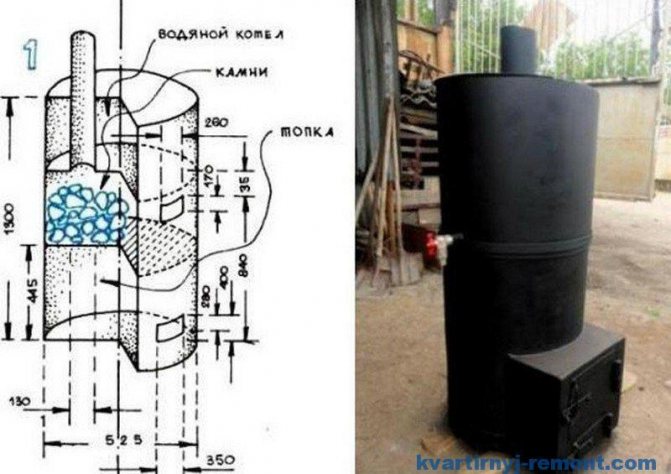

- Option 1

- Option 2

- Option 3

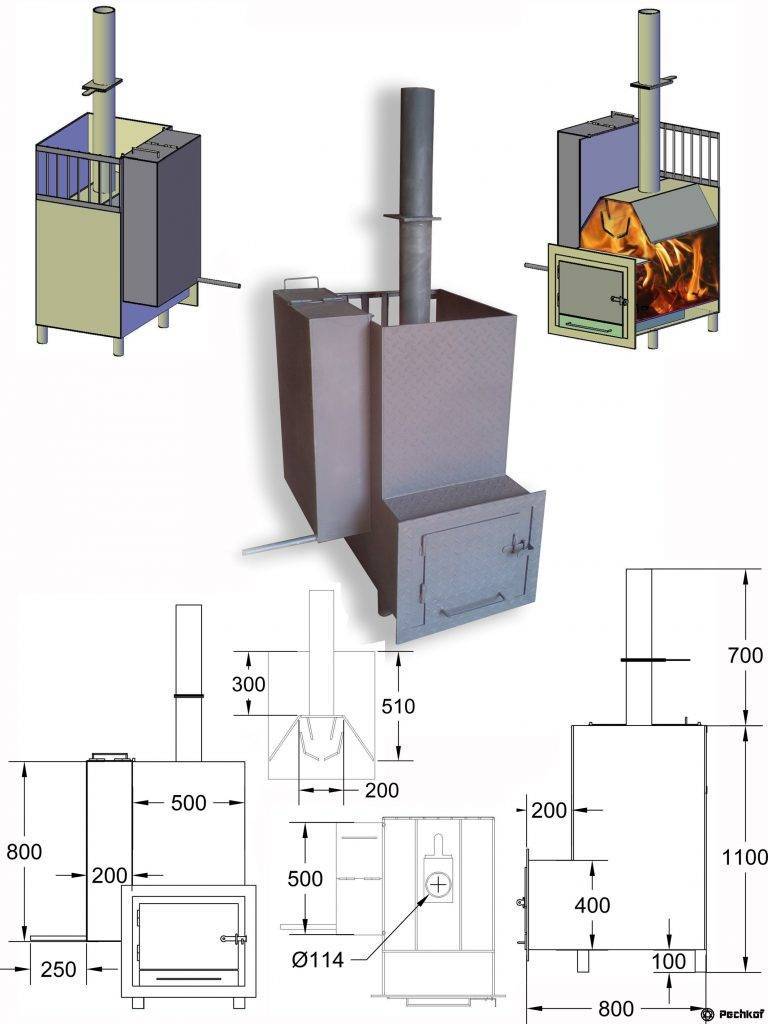

- Stove-potbelly stove of long burning

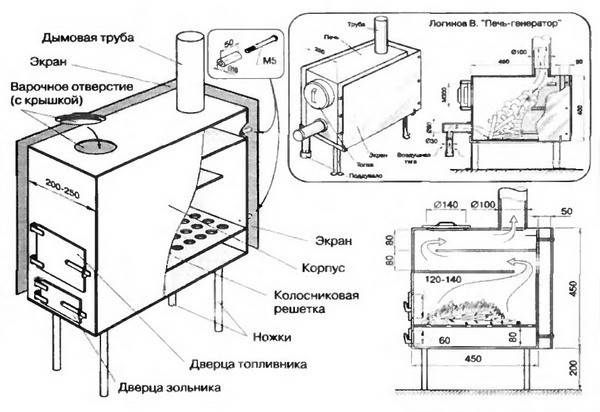

- Main scheme

- How to make a door

- Homemade secondary gas afterburning system

- Criterias of choice

- Gas cylinder stove

- Cylinder selection

- Tools and materials

- Wall preparation

- Manufacturing process

- Each steam room has its own oven!

- Types of brick heaters

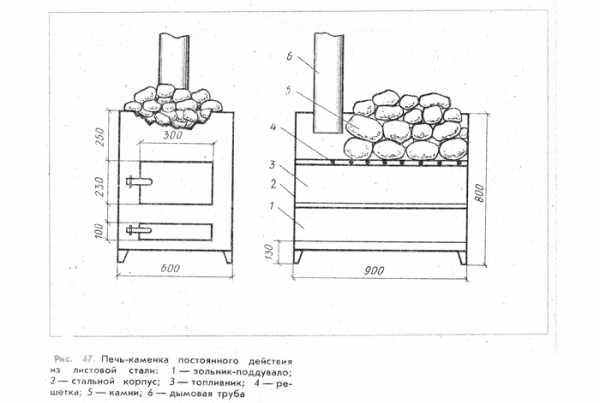

- permanent action

- periodic action

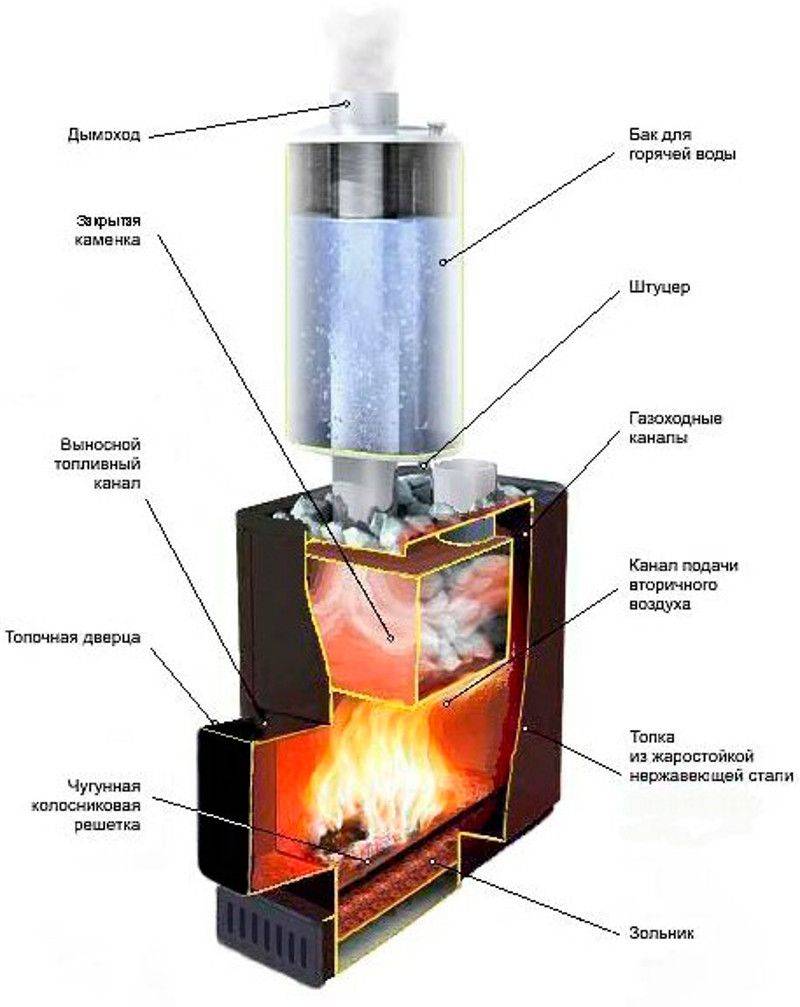

- For solid fuel

- Compact (small)

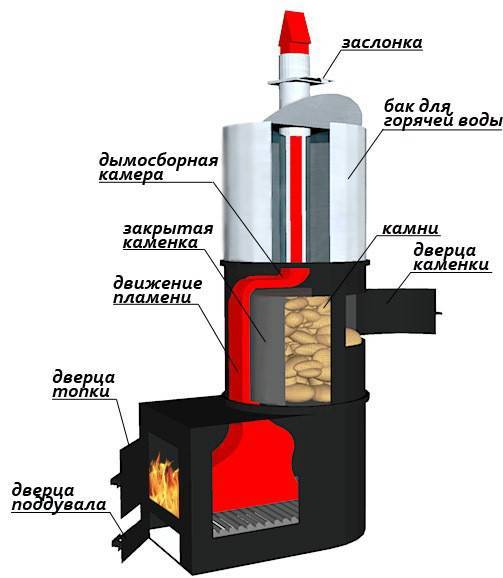

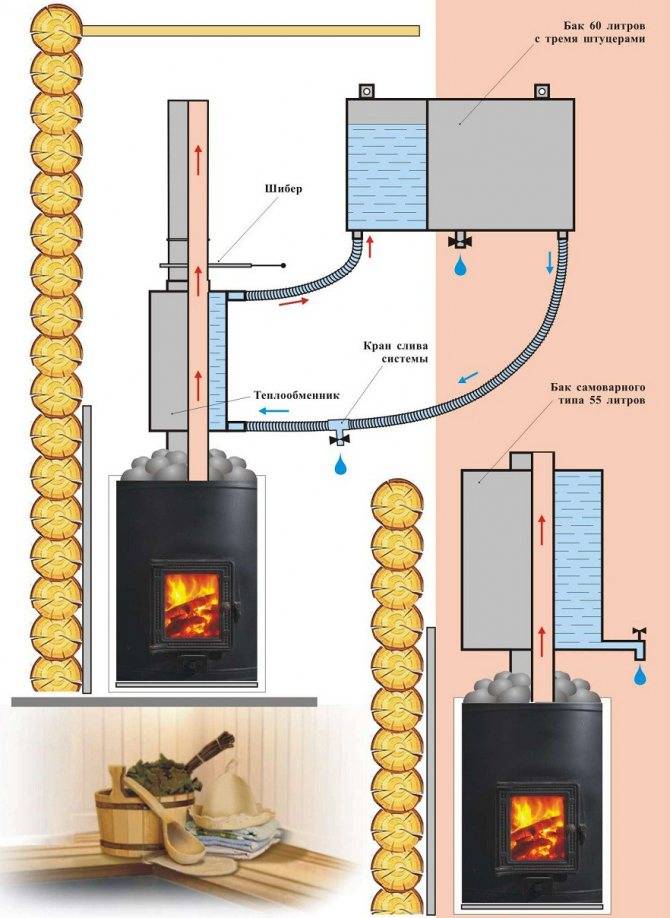

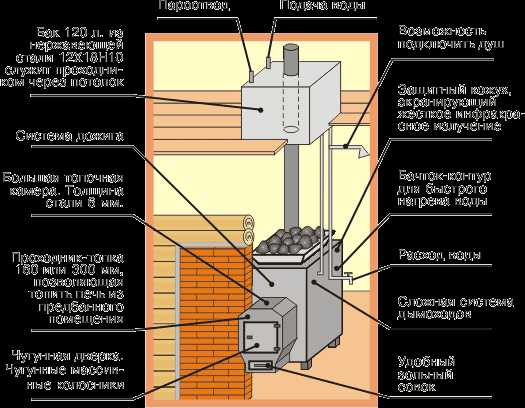

- With integrated water tank

- Above

- Bottom

- Types of gas ovens

Features of homemade gas ovens

A gas stove differs from a wood stove in that it uses gas for kindling. Therefore, in such a device, instead of a window for laying firewood, a cavity for the burner is mounted. However, you can also make a gas-fired oven with your own hands.

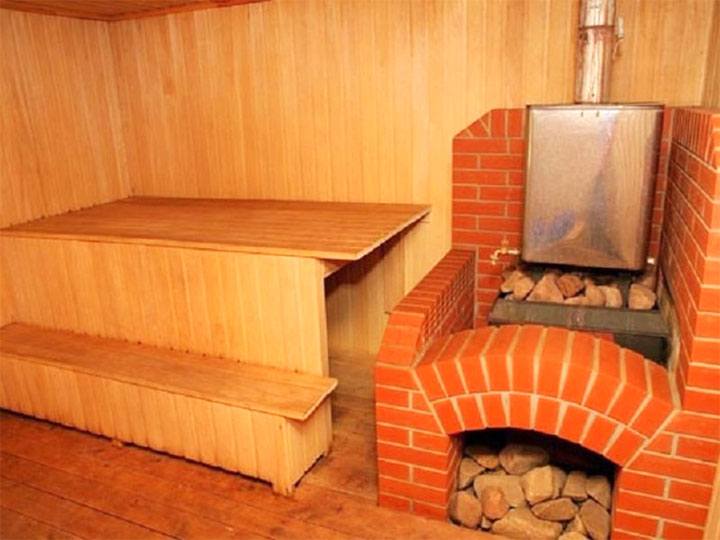

A metal bath stove is often lined with bricks. The lining is made in order to increase heat transfer.In addition, a metal structure with a brick casing cools down much more slowly.

Most gas ovens have the following design. A pressurized or atmospheric gas burner is mounted in the body of the device. Fuel supply is carried out through a hermetically attached gas hose or pipe.

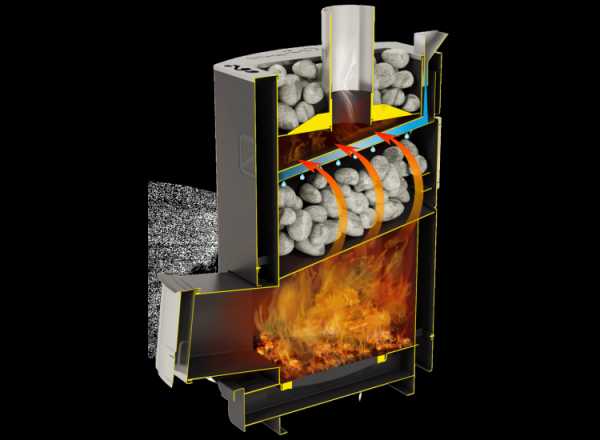

At the top of a homemade gas stove there is a closed heater or an open pan with stones that are heated by a burner, as well as a device that removes combustion products.

When self-assembling, be sure to take care of installing a thermostat and a fuse that cuts off the gas supply if the burner goes out. The gas chamber containing the combustible gas is usually located under the stone tray.

The advantages of homemade gas stoves for a bath include:

- compact size, because gas stoves do not have a firebox and an ash pan;

- rapid heating to the required temperatures;

- economical resource consumption;

- there is no need for constant maintenance of the device;

- when installing a water tank, you can also heat water.

The disadvantages include the need for a source of gas. For example, if the bathhouse is located outside the city in a non-gasified area, some owners will have to buy gas cylinders or install a mini-gas tank. However, there is a plus in this - there is no need to obtain permits.

It is worth remembering that when working with gas, you must always follow safety precautions.

When choosing a gas burner for a sauna stove, it should be borne in mind that the efficiency of atmospheric burners does not exceed 90%, and the efficiency of pressurized burners is more than 95%. However, the first option wins in terms of independence from electricity.

When installing an open-burning stove, it is necessary to design and install a ventilation system and a chimney. Also, when oxygen is burned, the air becomes drier, so you need to take care of air humidification.

Operating rules

When operating combined heating equipment, a number of rules must be observed:

- It is forbidden to let small children near the stove.

- Do not turn on the gas burner if any of the elements fail.

- After the end of the bath procedures, you need to check the gas taps. Do not cover them.

- We must not forget to regularly clean the chimney, combustion chamber from soot, ash.

- It is forbidden to fill the flame in the firebox with water.

- You can use liquefied gas, natural gas or any kind of firewood.

Gas-fired stoves have become very popular due to the ability to use different types of fuel to heat bath rooms. A complex device requires accuracy in performing installation work, taking into account the features of operation, but the result will please with its economy and versatility.

The best steel electric sauna stoves

Electric furnaces made of alloy steel can be an excellent replacement for cast-iron wood-burning models.

Such devices are characterized by relatively low weight, affordable cost and fast heating. Their only drawback is the need to connect to a separate power supply line.

EOS Filius 7.5 kW – premium heater

5.0

★★★★★

editorial score

100%

buyers recommend this product

Suspended stove-heater for baths and saunas from a well-known German manufacturer. The main feature of this model is the multi-layer construction of the back wall of the case.

This technical solution eliminates the possibility of overheating in this area, which allows you to mount the unit in close proximity to the wall. The stove is controlled from the remote control. The price of the furnace is 65 thousand rubles.

Advantages:

- Reliable design;

- fire safety;

- Rapid heating of the sauna room;

- Excellent build quality.

Flaws:

High price.

This model will become a real decoration of a small sauna, organized in an apartment or a private house.

SAWO Scandia SCA 90 NB-Z - with large stone compartment

5.0

★★★★★

editorial score

100%

buyers recommend this product

A powerful sauna stove of a closed type, which is capable of heating a small steam room to the desired temperature in 8-10 minutes.

The well-thought-out design of the steel convector body quickly warms up the air in the room, and the stones serve to maintain the temperature and generate steam.

The main feature of this model is the ability to control the operation of the device from the remote control. The average cost is about 20 thousand.

Advantages:

- Excellent power for the declared volume;

- Quick heating of the steam room;

- Simple and convenient control with a remote control;

- High quality materials, components and assembly.

Flaws:

Large power consumption.

A great option for organizing a small sauna.

Polytech Classic 10 – with an innovative heating element

4.9

★★★★★

editorial score

93%

buyers recommend this product

The floor bath electric furnace is made of stainless steel and has quite modern appearance.

The main feature of this unit is the use of a tape heater with an increased heat transfer surface.

At a relatively low temperature, the tape element creates a powerful convection air flow that quickly warms up the room. The stones located above it serve to generate steam and maintain the temperature in the steam room.

The unit is controlled by means of a remote control, which itself, after a certain period of time, will disconnect the device from the network for security purposes. The average cost of a Polytech belt oven is 17.5 thousand.

Advantages:

- High performance;

- Rapid heating of the room;

- Increased area of the heating element;

- Auto power off.

Flaws:

The need to lay a separate cable and connect to a 380 V network.

An inexpensive and easy-to-use model with excellent technical characteristics for connoisseurs of hot saunas and dry steam.

Harvia Cilindro PC70E - compact model for small steam rooms

4.8

★★★★★

editorial score

87%

buyers recommend this product

See review

One of the most compact floor-standing electric sauna heaters from the legendary Finnish manufacturer differs from competitors in its vertical orientation, which allows you to place the unit even in a tiny space.

The main feature of this model is the large volume of stones placed in the lattice of the case. The switches are located on the front solid wall. The price of this model is about 16.5 thousand.

Advantages:

- Compactness;

- Excellent build quality;

- Rapid heating of the sauna;

- Possibility of producing "light" and "heavy" steam;

- Remote control.

Flaws:

Not very convenient location of controls.

A good and inexpensive model for a small sauna.

Classification of a modern gas unit

To date, a fairly large number of modifications of gas-powered units have been manufactured. In order to make the right choice, you need to decide on the parameters that you want to get in the end.

Here it is important to determine the place you have where a gas oven can be or is breaded.

Gas boilers are divided into three options. Firstly, these are heating boilers, they are designed for the heating process, therefore they are often found on the territory of private houses. Secondly, these are heating boilers that regularly provide hot water to their owner. Thirdly, household boilers, they are responsible for the heat of a room with a large area. The photo shows all models of boilers according to their professional purpose.

As for the bath room, it is best to use heating heating systems, which can differ not only in the cladding option (brick, metal or cast iron), but also in the type of burner, as well as the method and technology of heating the water in the bath.

conclusions

All these parameters, with proper choice and further use, will allow your bath to become not only warm, multifunctional, but also comfortable.

We also draw your attention to the fact that any gas system has detailed instructions that will allow you to safely perform all the necessary work yourself.

A gas stove is the most popular unit, designed not only to provide warmth and comfort, it is also a unique system that will serve you and your home or bath for quite a long time.

Criteria for choosing a gas oven

The power of the furnace is the main criterion on which you need to focus. But there are other nuances that will help you choose the right and reliable device:

- Furnace dimensions - so that the furnace does not “eat up” space, it should not be large. It is better to choose one in which the remote fuel channel is extended;

- Gas consumption - the lower the gas consumption, the better the furnace works (these data are indicated in the equipment passport);

- Permissible type of gas - some stoves work only on natural network gas, while other models allow you to reconfigure the gearbox;

- Versatility of models - some stoves can work both with gas and with wood. This option is convenient only if gas has not yet been connected to the bath, but it is planned. In other cases, it's just an overpayment of money;

- If the equipment for the bath is sold with a water tank, then you do not need to bother with an additional purchase of a tank. But, if there is no water tank, then you should think in advance how the water will heat up.

Stove-heater

This simple variety has several ways to create.

Option 1

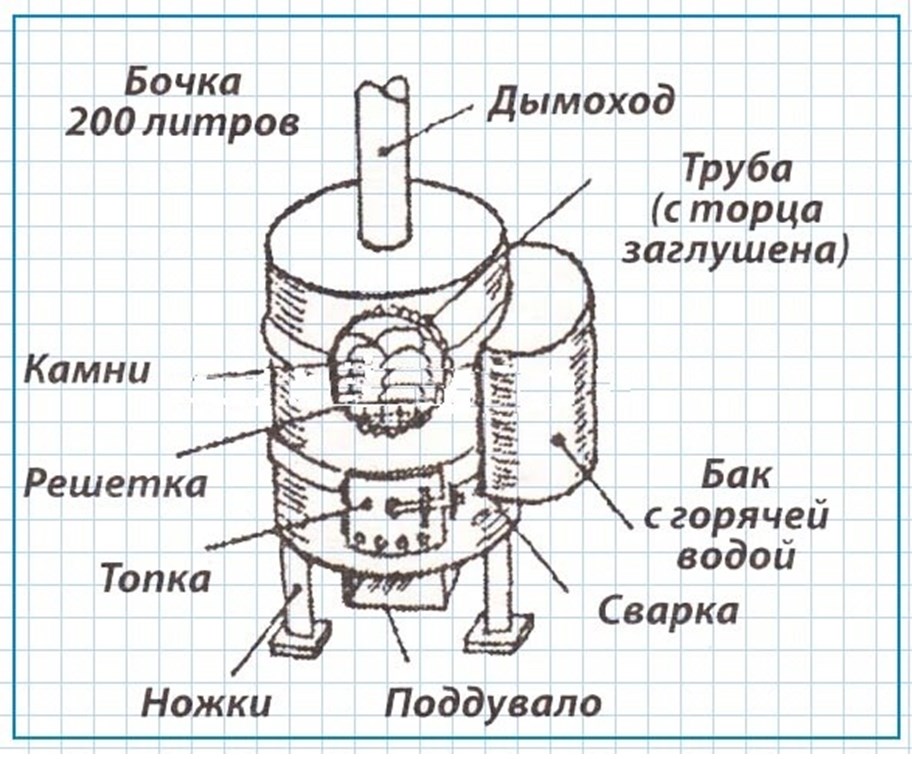

Using an iron barrel without a bottom and top. The resulting container is half filled with bricks laid on edge and a grate laid on top. Stones are placed in the remaining 2/3 of the space, a chimney is installed. At the end, such a home-made stove in the bath is covered with a lid made of steel sheets.

Option 2

Bricks are not used for the construction of the stove. Sequence of work:

- Prepare diagrams and necessary tools.

- In a long pipe, cut a hole for the blower with dimensions of 5x20 cm. Fix the mount for the grate above it inside the pipe.

- For the firebox, form a hole 25x20 cm.Above it, mount fasteners for rods, the size of which is about 1 cm.

- On the other side of the furnace, create a hole into which liquid will be supplied. Place stones in the stone.

- Make a hole for the chimney. Install a valve at the bottom of the pipe.

- Form a lid on the heating tank with a slot for the chimney, a loop and a handle.

Option 3

This oven has 2 heaters. It is made by analogy with the previous ones. The difference is that 4 plates are used to connect two heaters.

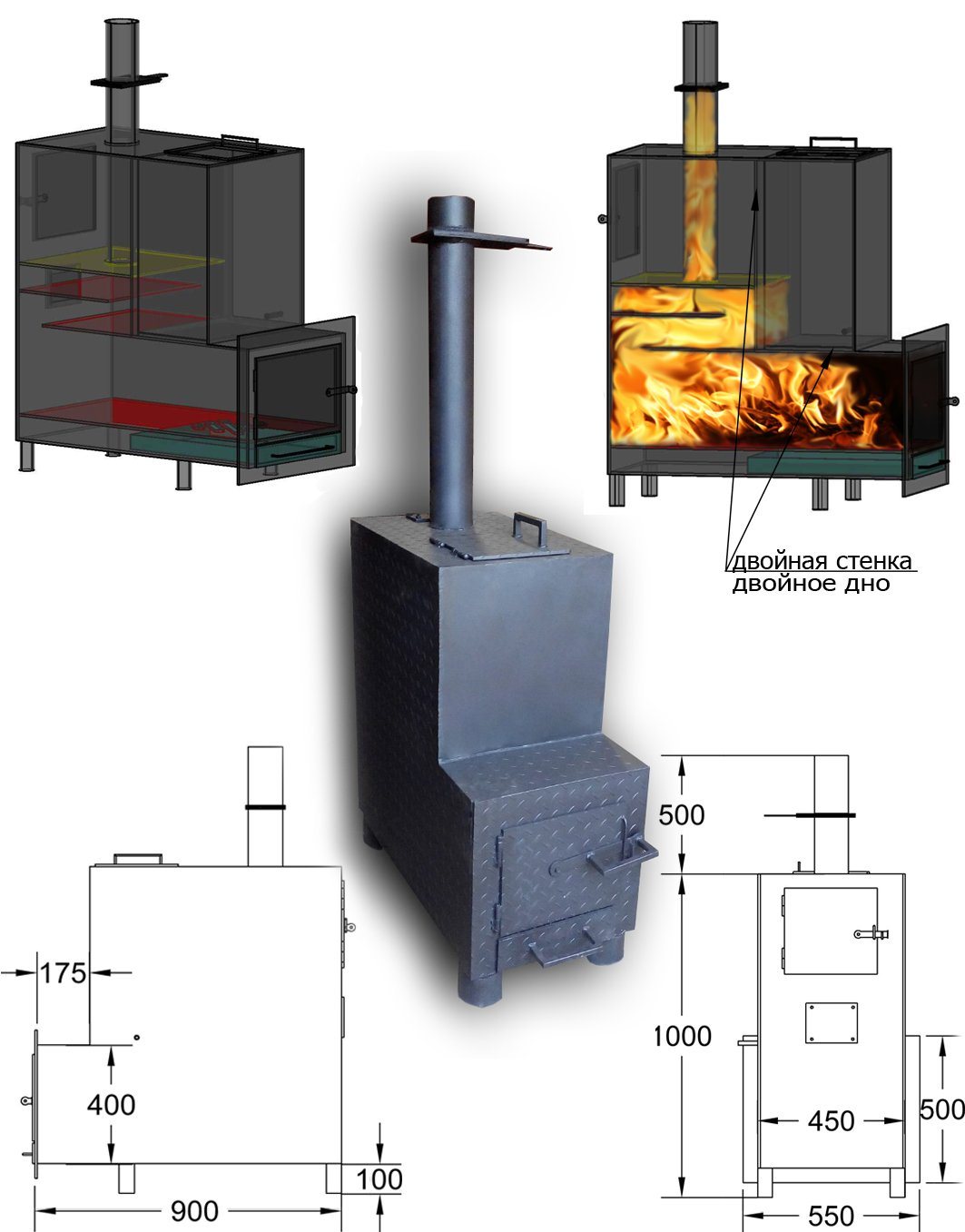

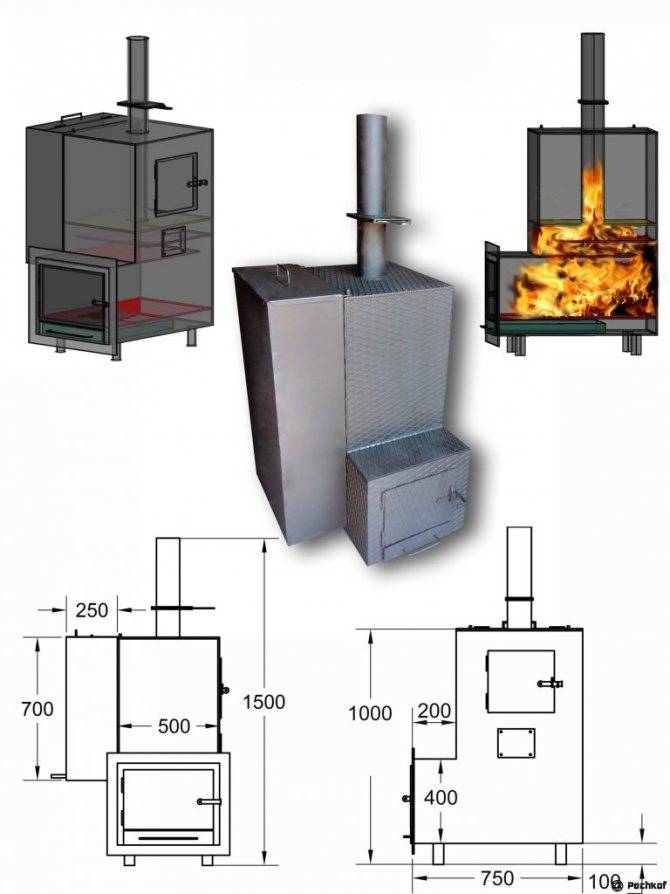

Stove-potbelly stove of long burning

The potbelly stove has become a real symbol of Russia since the times of the Revolution and the Civil War.

The potbelly stove has become a real symbol of Russia since the times of the Revolution and the Civil War.

So they called the simplest iron stove of a cylindrical or cubic shape. Its advantage was that the smoke channel - an ordinary iron pipe - could be taken anywhere - through a wall or roof, through a window.

Taking simplicity and practicality from the potbelly stove, you can make a small stove that embodies some simple ideas that significantly increase its efficiency, safety and environmental friendliness.

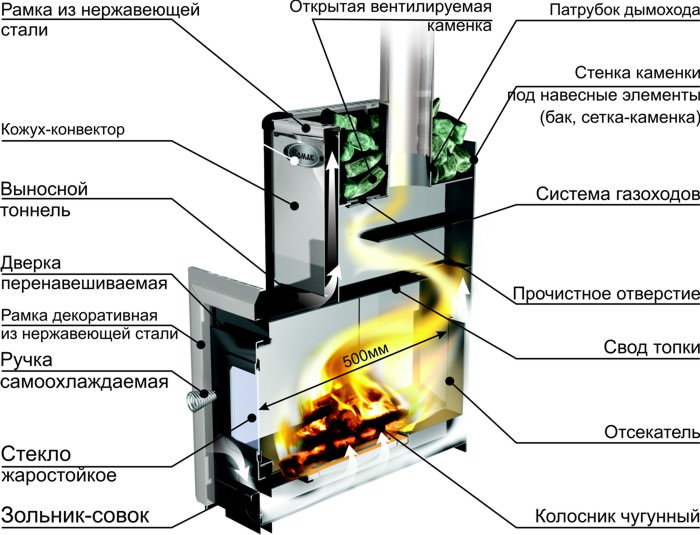

Main scheme

The classic potbelly stove has a cylindrical design. However, it is difficult to do this when making it yourself, so you need to take a cube or a parallelepiped as a basis.

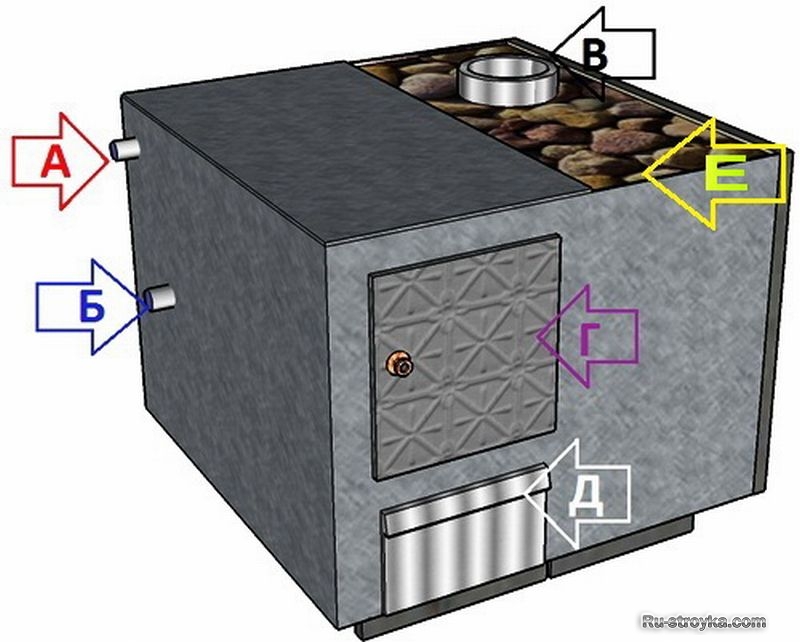

Contains the following structural elements:

Contains the following structural elements:

- Firebox. This is the chamber in which the combustion of fuel takes place, most often firewood. The walls and bottom of the firebox should be thick, since it is on them that the main temperature load falls. For laying firewood in the firebox, there is a door in front, if desired, it can even be equipped with heat-resistant glass.

- Ashpit (blew). The compartment under the firebox is separated from it by a grate. The ash pan is also equipped with a door, only smaller.It serves to remove ashes and ashes. which fall through the grate from burnt firewood. But the meaning of the ash pan is not only this - air is sucked in through the blower door and passes through the fuel layer from below, ensuring the best combustion.

- Smoke channel. For its arrangement, a round hole is cut out in the upper part of the stove, a piece of steel pipe is inserted into it and scalded. In the future, you can attach other sections of the pipe here or use the factory sandwich chimney with special locks.

Expert opinion

Levin Dmitry Konstantinovich

Some manufacturers of homemade stoves believe that the design with a blower and a grate is not suitable for a sauna stove - too much draft is created, which prevents the firewood from completely burning. Instead, it is proposed to lay firewood directly on the bottom of the stove, and ensure the air supply by drilling several round holes in the lower part of the furnace door and providing them with a sliding damper.

How to make a door

The door is made of a thick sheet of metal. For fastening, you can use purchased factory hinges or make your own. An asbestos thread is used to seal the fit - it is wedged in a groove cut by a grinder.

If there is a suitable sheet of heat-resistant glass, it is inserted as follows: a window is cut in the door and the cut point is ground. Then the glass is laid, lay asbestos fiber around the perimeter invisible from the outside of the part, after which, using small tongues of steel, I make tacks on each side.

The rotary handle latch is easiest to do from the outside.

Homemade secondary gas afterburning system

The main drawback of the potbelly stove is its low efficiency.The jet of air quickly and strongly passes through the entire oven, taking with it not only unburned products, but also heat. As a result, the case does not warm up sufficiently and gives off less heat. To solve this problem, a simple but ingenious refinement was invented.

By placing two steel sheets above the firebox, the smoke passage can significantly increase the length of the path that the burnt gases pass before exiting through the chimney:

- The first horizontal sheet is welded directly above the firebox so that a channel for the passage of gases remains in the back of the furnace.

- The next sheet is cooked higher, offset so that the passage is now at the front of the oven. It turns out that smoke, gases and heat, having got into this labyrinth, snake along it to the very chimney. Along the way, they give all the accumulated heat to the sheets, side walls and the top plate of the furnace.

If several holes are drilled at the back from the bottom and closed with a steel sheet screen, then at the top point, when fresh, but already warmed up by the screen wall, the air meets unburned gases, the afterburning process of secondary gases will occur in the channel, which will lead to significant increase the efficiency of the furnace.

Criterias of choice

When choosing a gas nozzle, the following items are taken into account:

- The specifics of the model - power, efficiency level, efficiency, economy, safety,

- Features of operation. When arranging a small bath, atmospheric models are most often preferred. Powerful automatic burners for a blow-type sauna stove are recommended for use in large rooms.

- type of heating equipment.

- Features of fuel supply - from the main, gas tank or cylinder.

- Purpose of the product.

Models of nozzles of certain categories provide for installation in certain types of heat generators. For example, some proposals of domestic manufacturers are designed for operation exclusively in boilers with a long channel for the fuel mixture.

Gas cylinder stove

Having determined that metal stoves show high efficiency in small farms, and, therefore, will become the choice of the majority, it is necessary to consider the available examples.

Such a heating element is economical, since improvised means are used in the manufacture.

Cylinder selection

For the manufacture of the furnace, a cylinder is chosen without visible damage and holes in the metal. The presence of paint is not a mandatory factor. During use, the coating will burn. It is desirable that the tap be removed in advance and the gas released.

Advice! Don't buy a new container. You can contact the nearest scrap metal collection points or friends. The money saved is better spent on the purchase of other materials, the services of metal and welding craftsmen, or personal goals.

Tools and materials

To complete the work you will need:

- gas cylinder;

- metal sheet 3 mm thick;

- fittings for the manufacture of grate and handles;

- metal corners or the remains of a profile pipe for legs;

- chimney pipe with a diameter of 120 mm and a length of 400 mm or more;

- metal rods or fittings for the heater;

- bricks for the foundation and lining of the furnace location;

- welding machine and protective equipment;

- electrodes for welding metal parts;

- grinder and a set of trimming and cleaning discs;

- set of locksmith tools.

Wall preparation

Small furnaces are lightweight, so making a special foundation for them does not make practical sense. But the walls must be protected.

When fuel burns, a large amount of heat is released. The temperature easily damages wood and fusible surfaces. To protect against damage, wall cladding is also covered with foil. The metal reflects the temperature into the room, reduces the load on the wall and increases the efficiency of the stove.

Note! Brick lining is carried out throughout the part, the furnace is in contact with the wall.

Manufacturing process

Begin assembling the furnace from a gas cylinder after preparing all the necessary items. This will save time. After studying the step-by-step instructions with drawings and photos, you will learn how to build the most efficient sauna stove with your own hands.

Procedure:

- Prepare the gas cylinder. If the valve has not been removed, remove and drain the remaining gas.

- The container is filled with water to prevent ignition while working with the grinder.

- Cut off the top. To do this, draw a line along the rounded part. This section will serve as a door.

- On the cut top, the tap hole is closed and the handle, lock and hinges are welded on the outside.

- The balloon is placed horizontally. A hole 100 mm wide is cut out in the lower part, stepping back 200 mm from the back. This is the hole for the ash to fall out. For the sides of the ash pan, a metal strip 70 mm wide is welded to the edges. The bottom of the ash pan is made from the cut off bottom of the cylinder or a metal sheet. The front part of the ash pan is closed with a door, hinges, handles and a latch are attached.

- Legs are mounted along the edges of the cylinder from the bottom and the stability of the structure is checked. If the oven stands still and does not wobble, the job has been done correctly.

- A hole for the chimney is cut out in the back of the container, a piece of pipe is installed and welded.

- Install the oven door by attaching the hinges to the body. Also mount the locking mechanism. Check the tightness of the closure and seal if necessary.

- To ensure that only ash gets into the ash pan, a grate is made along the entire length of the furnace.

- Install a hot water tank. The boiler is made independently of metal or purchased ready-made. In the side part, a cutout is made for connection with a cylinder along the diameter of the container. All joints are carefully boiled so that the tank does not let water through. The roof for the water tank is made removable. This will make it easier to operate. A faucet is mounted at the bottom for convenient water draining.

- A heater is made from the remnants of reinforcement and rods. The design is made in the form of a grid and welded to the top of the furnace. The distance between the rods is chosen less than the size of the stones used.

After the final assembly, the stove is installed in the bath and the chimney system is adjusted.

Note! Before the first use, a test run is carried out. The purpose of such an audit is to identify existing shortcomings in the work

It is important to bring the water to a boil. During the test, paint and oil residue will burn, so all doors and windows are opened for ventilation.

The video shows how to make a simple mobile oven from a gas cylinder.

Each steam room has its own oven!

When choosing a gas-powered sauna stove, as in other cases, they are guided by power characteristics. First, the area of \u200b\u200bthe steam room is calculated so that it is clear which model you need to purchase

It is also important to decide on the variation of the control unit, which is almost always purchased separately. Few models on the market already come with built-in control systems

The advice of specialists and managers of the sales department will help you decide.

Some gas sauna stoves come with built-in water tanks. It is very comfortable. When planning the purchase of such a device, you can not rack your brains over the location of hot water storage. At the same time, the masters advise purchasing devices with a tank located on the pipe. They are practical and do not take up much space.

There are differences in the degree of functionality. Some models run on natural gas, others on LPG. There are devices of combined action. When purchasing models that operate on all types of fuel, check the availability of circuit injectors and their mounting options.

Examine the furnace layout. The kit may include a deflector for the chimney. If not, then be sure to purchase the device. Manufacturers always supply with combined models spare adapters and couplings necessary for mounting and changing nozzles. If they are not included in the kit, purchase devices that are adaptive specifically to your model of gas oven in advance.

Types of brick heaters

According to the frequency of use, they are divided into two types.

permanent action

Heating equipment has thin walls and a small layer of stones. Heating of stones is maintained at the level of 300-350 degrees. Temperature stability is achieved by a connected automatic control system.

The main types of fuel are electricity and gas.

In electric heaters, heating can be reduced (increased) by changing the current strength, in gas heaters - by adjusting the amount of fuel supplied.

Both types are equipped with protective automatics, which, when the desired temperature limit is reached, turn off the power or, on the contrary, increase it when the fire begins to go out.

Installation and operation of devices occurs only with the permission of the fire inspectorate.

The stove is heated until the stones are sufficiently heated and steam is generated.

It looks like a closed electric oven, on top of it is a metal box with stacked stones. Heating is performed by heating elements - they enter from below through a layer of stones.

Advanced models have a soft heating system. The layout of the stones does not come into contact with the ventilation air, they are heated in a separate way.

It is important to pay attention to the fact that with an increase in the layer of stones, the production of heat and, accordingly, steam increases. In factory models, it is allowed to change the volume of stones from 5 to 60 kg

To obtain dry steam in saunas, stones are needed minimally.

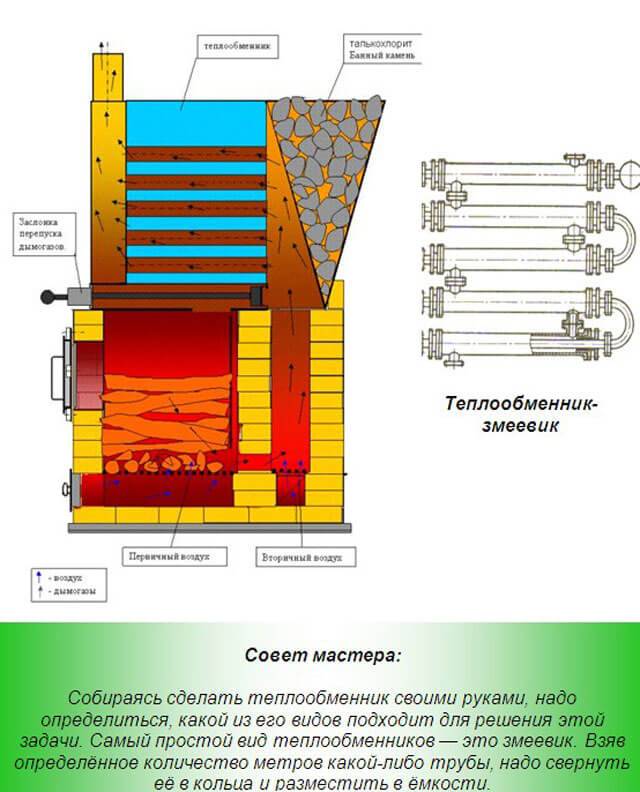

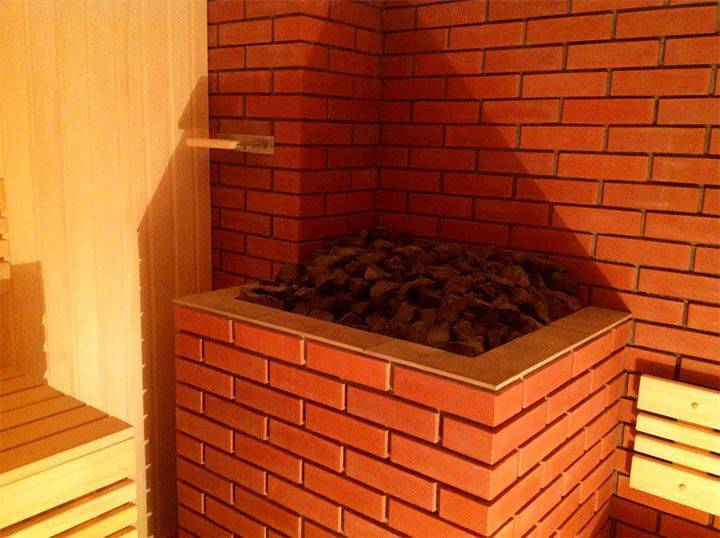

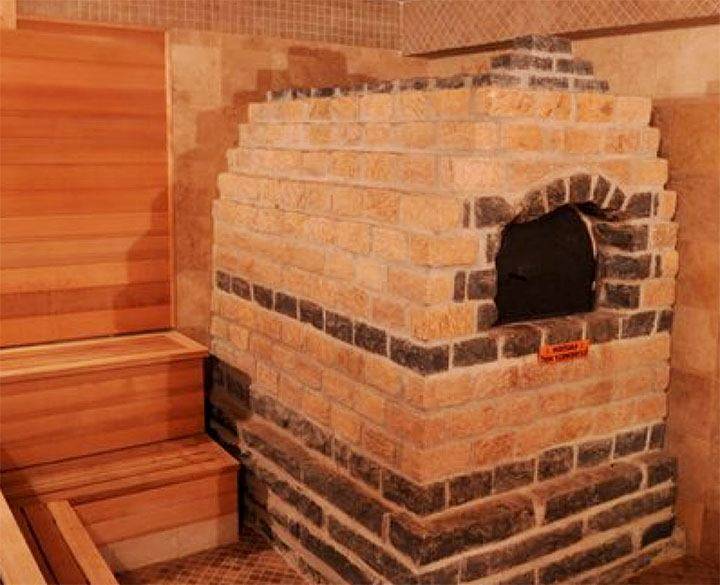

periodic action

It is customary to lay out such furnaces with thickened brickwork. The amount of stones used is large. Strong brickwork protects the outer wall from overheating, allows you to retain heat for a long time, keeping the temperature at the proper level inside the room.

A reinforced firebox heats the stones at the bottom to 1100 degrees, the top layer - up to 600 degrees (they become crimson). Soot, dust are burned out completely.

For solid fuel

In such heaters, the firebox and smoke circulations are separated from the stones by a cast-iron stove or a wall. The partition prevents combustion products from getting into the bath, soot does not settle on the stones. The average heater is able to heat a steam room up to 10 cubic meters.m, maintaining the temperature in the room up to 140 degrees. A device with double side walls, through their slots, air is exchanged and heated.

Compact (small)

A home-made version of a small-sized one is easy to get from a laundry oven. Only instead of water, stones are placed in the tank. And water, when necessary, is heated in a bucket, placing it on top of the stones.

Minus small size - thin walls of the furnace. The solution is to overlay with brickwork, leaving gaps for air exchange.

It is recommended to assemble with your own hands from steel sheets 3–5 mm thick.

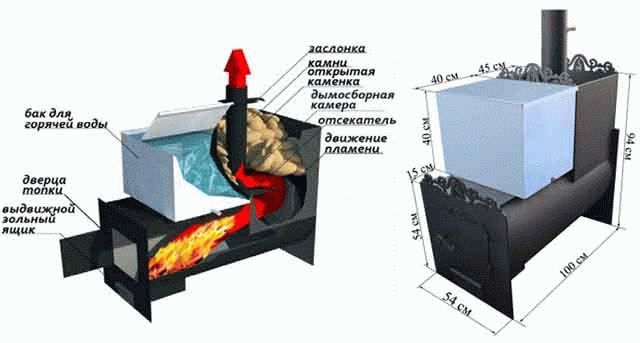

With integrated water tank

Double-walled ovens are considered the most efficient. The gap between the walls is used to heat water. In addition, an additional water tank can be placed next to the stove.

It is located above or below the structure.

Above

To enhance the heating rate of stones, it is allowed to add scrap iron to the lower layer. The plate can be installed as a solid one, or as a team. The recommended plate thickness is from 10 mm. In order for the furnace to warm up faster from below, it is necessary to make smoke turns along the back of the brickwork. For this, steel plates are taken, they divide the internal cavity into two channels: lowering and lifting. Insert them into the gap between the bricks. On the 8th row, the plate must be bent so that it can be imperceptibly sealed between the bricks.

At the top of the furnace, stones protrude, so the lifting channel is designed in the form of a zigzag. Due to this shape, heat transfer is increased. A damper is placed at the top of the channel. A tank of water, stones are covered with a small steel or iron lid.

Bottom

In such a device, the dimensions of the furnace are increased. More and the volume of the chamber for stones - 50 liters. For the convenience of kindling, there is a damper at the bottom.

Since the end of the tank goes to the firebox, on the sides, at the bottom it comes into contact with hot gases, the heating of water is accelerated at times.

To lay the upper bricks, the container is closed from above for most of the length. A steel plate will suffice.

When the lower damper is open, the flue gases immediately exit into the chimney without entering the chimneys. Therefore, as soon as the furnace has reached the desired temperature and a stable combustion process has been established, the damper is closed from below. Stones with a tank are covered with hinged lids.

The partition is easier to make from a cast-iron boiler. Its surface will be washed by flue gases, so the stones located inside will quickly heat up. The firebox is lined with refractory bricks, so that coal can be used as fuel.

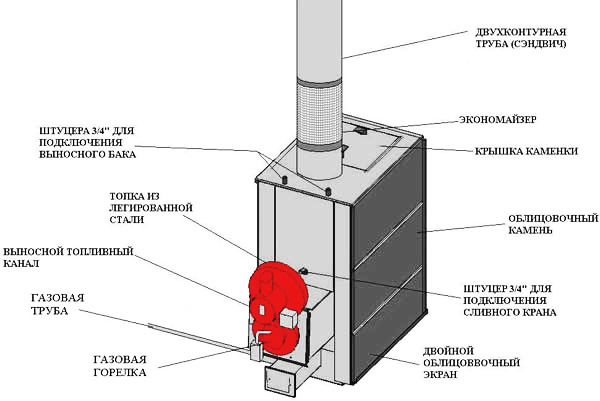

Types of gas ovens

According to the nature of the internal structure, gas furnaces are divided into several types:

- by application - a conventional convection installation, which is the optimal solution for a sauna. The consumer receives dry steam at an air temperature regime exceeding ninety degrees. Such furnaces are made of metal, the heater is closed. The peculiarity is that wet steam is supplied. Stones covered with a metal case are able to retain heat longer, and the steam room does not immediately cool down after the gas is turned off;

- according to the working principle - the steam room is heated by the convection method. Modern furnace designs are equipped with complex heat exchangers; it is possible to connect a heating circuit. When such a furnace is operating, the steam room and adjacent rooms are simultaneously heated, while the gas consumption does not increase significantly;

- for water heating - there are several models that heat water with different levels of efficiency:

- a stove with an external water tank is a classic option. The storage tank is mounted on the chimney, water is heated by accumulating heat from heated smoke, the temperature regime of which reaches one hundred or more degrees, which is quite enough;

- a heat exchanger is installed in the furnace body, which maintains a certain temperature regime for water. While the oven is heating, the water remains hot. Heating principle - flowing;

- gas stoves with built-in water tanks are considered convenient for small steam rooms. For example, a tank with a capacity of forty to eighty liters will provide water for washing one to three people.

What does a gas stove for a bath look like