- Criteria for choosing a gas oven

- fire safety requirements

- Design features and principle of operation

- How does a gas stove work?

- What are the benefits of using gas sauna stoves?

- Prices for gas ovens

- Where can I use a gas oven

- Types and features of gas furnaces

- Calculation of power for a bath

- Gas oven in the bath

- Foundation for a gas furnace

- Construction of a gas oven for a bath

- Using a gas stove in a bath

- Where to install the stove

- Brick gas ovens

- Metal gas furnaces

- The principle of operation of the gas furnace

- Required materials

- Furnace installation

- Criteria for choosing a sauna stove

- Wood and gas stoves

- Choice of combined design

- Advantages and disadvantages of bath gasification

- Advantages of using blue fuel

- Cons noticed by owners and professionals

- Classification

- Wiring requirements for an electric furnace in a bath

- Selection principles

- Advantages and disadvantages

- Popular models and prices

- What are gas appliances?

- Stone and brick stoves

- Metal stoves

Criteria for choosing a gas oven

The power of the furnace is the main criterion on which you need to focus. But there are other nuances that will help you choose the right and reliable device:

- Furnace dimensions - so that the furnace does not “eat up” space, it should not be large. It is better to choose one in which the remote fuel channel is extended;

- Gas consumption - the lower the gas consumption, the better the furnace works (these data are indicated in the equipment passport);

- Permissible type of gas - some stoves work only on natural network gas, while other models allow you to reconfigure the gearbox;

- Versatility of models - some stoves can work both with gas and with wood. This option is convenient only if gas has not yet been connected to the bath, but it is planned. In other cases, it's just an overpayment of money;

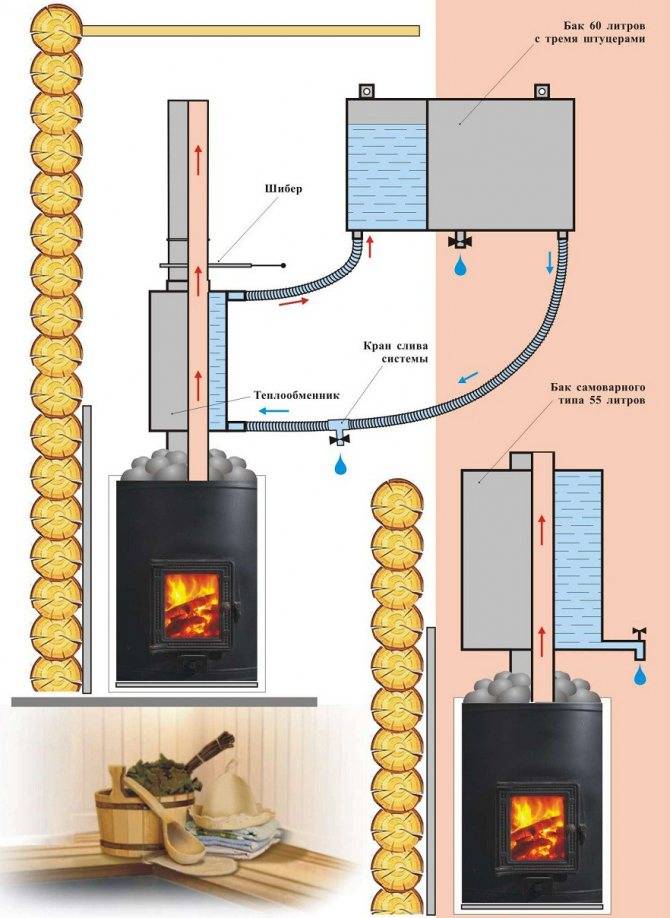

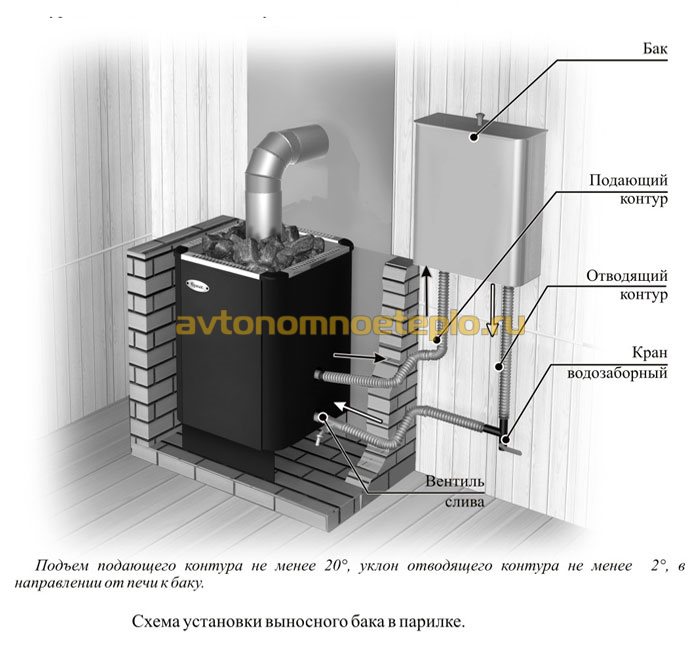

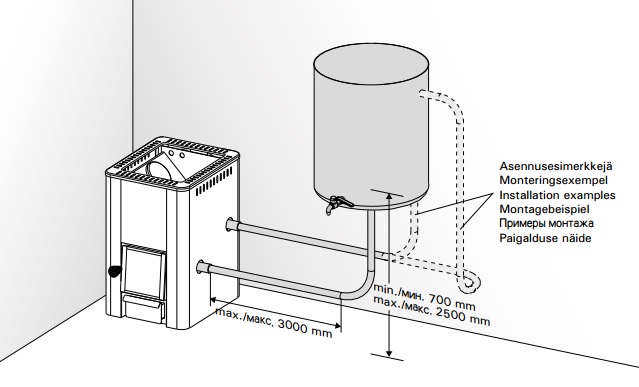

- If the equipment for the bath is sold with a water tank, then you do not need to bother with an additional purchase of a tank. But, if there is no water tank, then you should think in advance how the water will heat up.

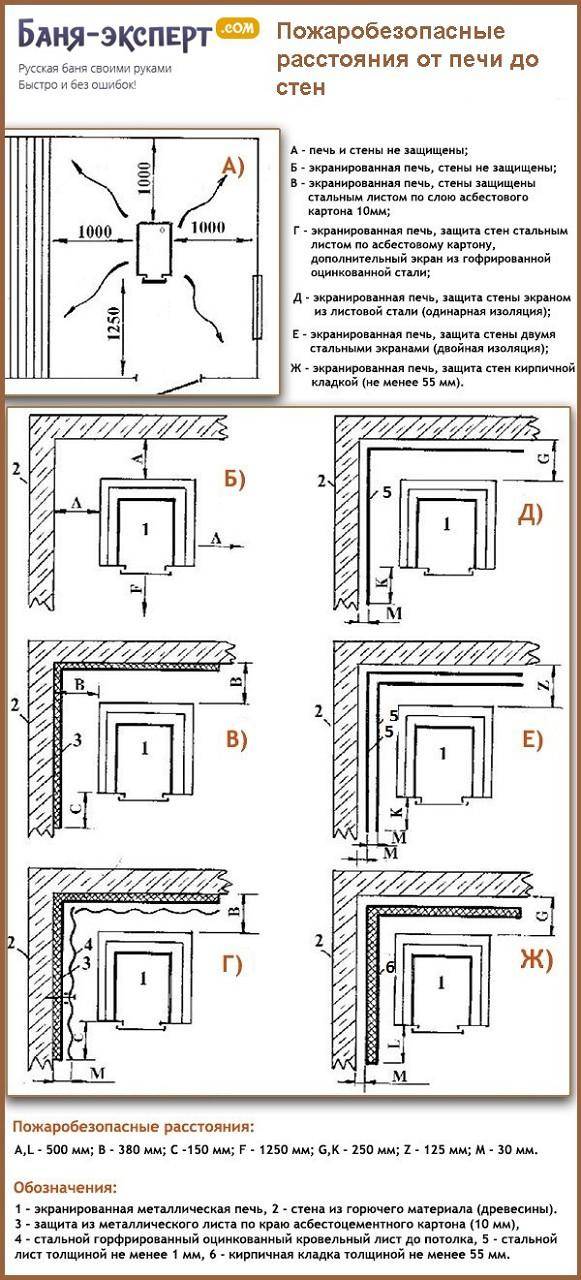

fire safety requirements

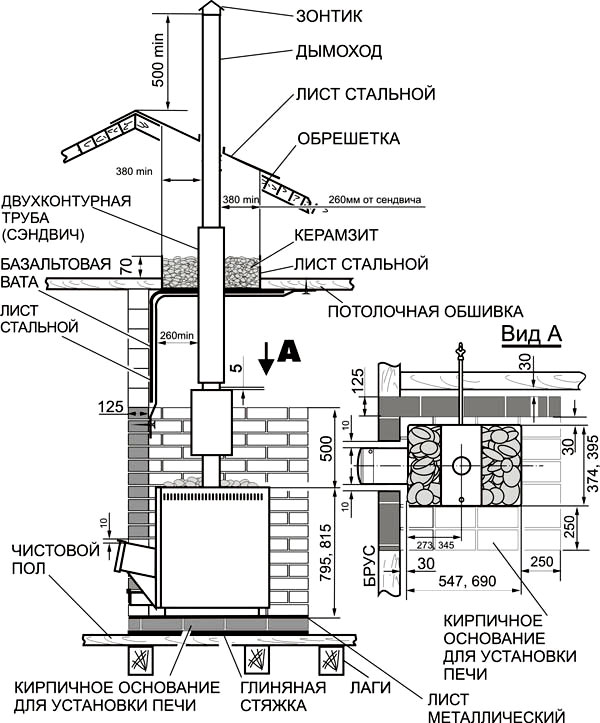

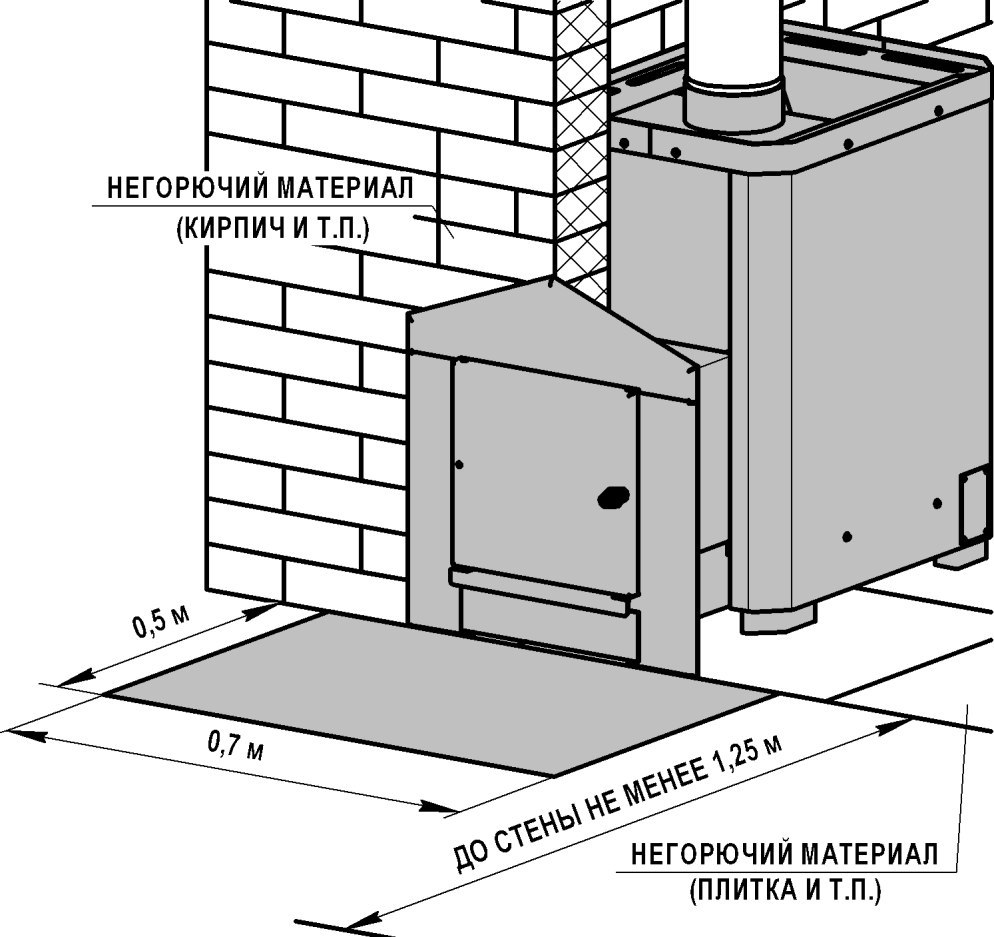

When installing any sauna stove, fire safety requirements must be strictly observed, since the walls of the device during its operation are heated to sufficiently high temperatures. In order to ensure maximum safety and not have problems with regulatory organizations, it is recommended to install the furnace, guided by the provisions prescribed in SNiP 41-01-2003 (chapter 6.6).

- The first thing to do is to equip a reliable foundation for the main structure of the furnace, which will adjoin the wall separating the room. The foundation must be covered with a heat-resistant material and then with a metal sheet. Asbestos sheets were previously used as heat-resistant insulation.Today on sale you can find panels of pressed mineral wool, which is less dangerous from an environmental point of view, sheets of foam glass or EZhKAH (heat-resistant structural mica).

- It is also necessary to provide a metal flooring in front of the furnace door, which will prevent the fire of the wooden floor and simplify garbage collection. The size of the pre-furnace sheet must be at least 400 × 800 mm.

- If the partition between the steam room and the dressing room is wooden, then the opening through which the fuel channel will pass must be separated from the wood with brick or masonry. The distance between the stove and wooden walls should be 400÷450 mm.

In the shown embodiment, the owner preferred to lay the opening with a brick

- Provided that on the end part of the wall of the opening through which the combustion channel will pass, gaskets made of heat-insulating material (mineral basalt wool or cement-fiber sheet) with a thickness of 40 ÷ 50 mm, the distance between the part of the wall erected from combustible material and the outer wall oven can be shortened to 250 mm. If thicker thermal insulation material is installed, the safety distance can be 125 mm.

- Between the ceiling of the bath and the surface of the furnace, the distance should not be less than 1200 mm.

- The distance from the edge of the furnace door to the nearest door must be at least 1250 mm.

- If a non-factory-made oven is purchased, or the device is independently made of sheet metal, then it is best to overlay it with bricks. Thus, it is possible to protect the structure of the bath from a fire, and people taking water procedures from burns.Factory products, as a rule, are made with double walls, between which heat-insulating material is laid or convection channels pass.

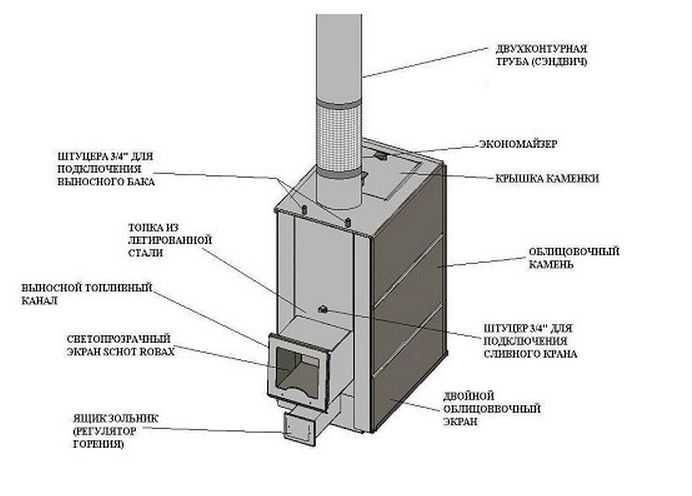

Design features and principle of operation

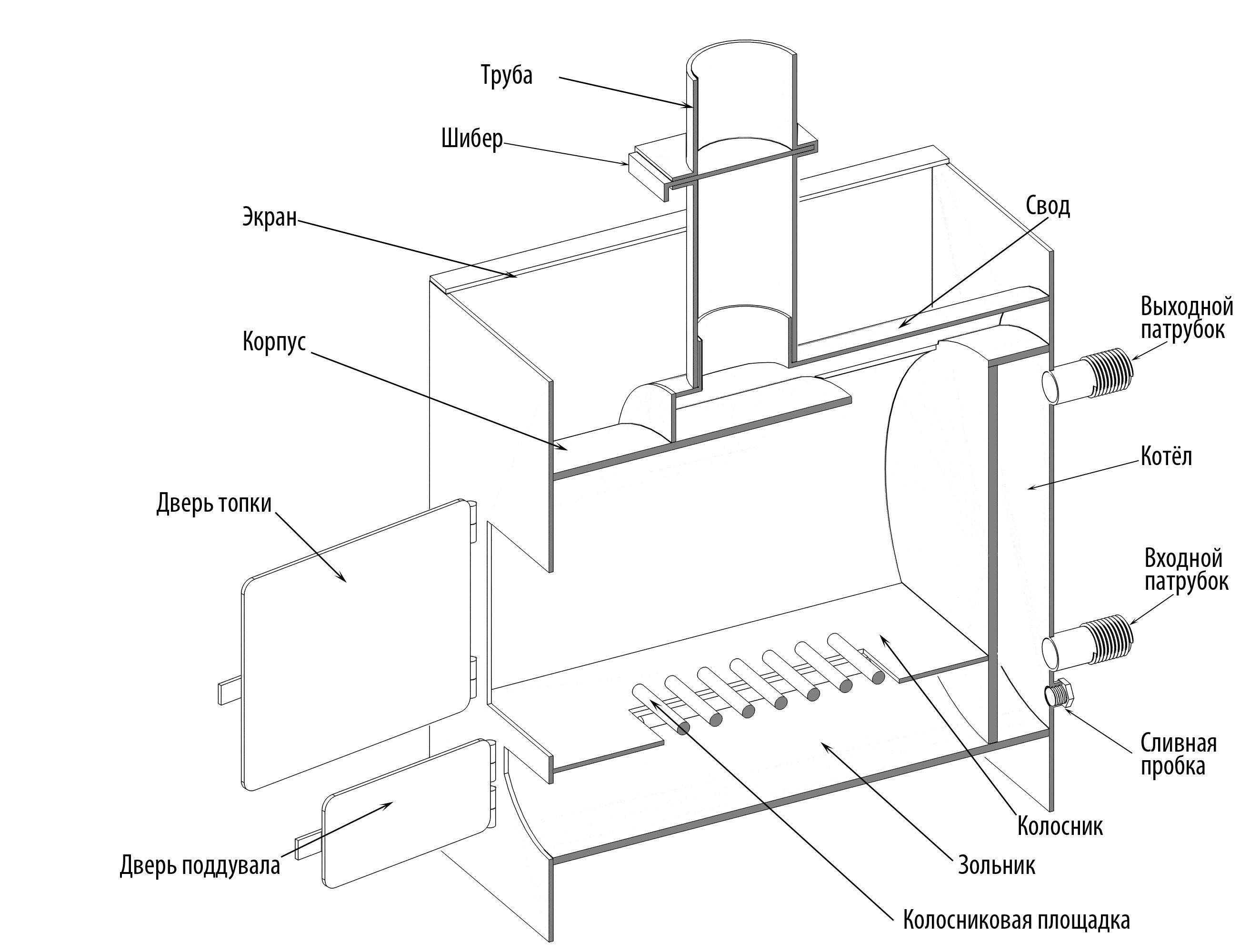

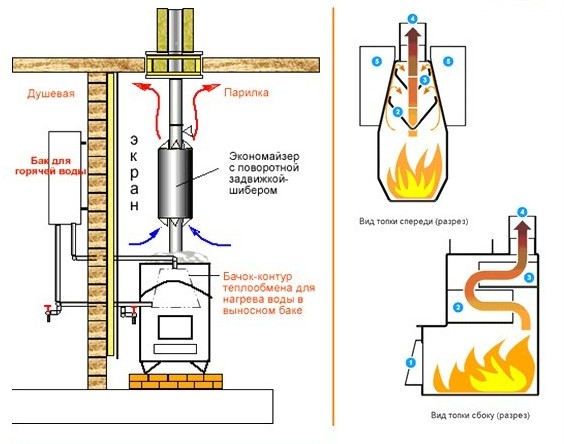

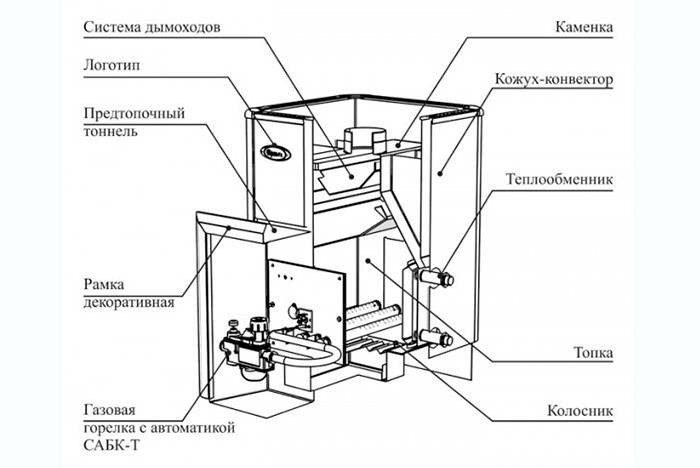

Structurally, gas heating equipment for a bath is a housing with a built-in burner-nozzle. The device is provided with shut-off and relief valves, a fuse, filters, a compartment for mixing gas with air. Here are the control mechanisms that regulate the mode of fuel supply. With the help of a burner, the air in the furnace chamber is heated, then the thermal energy is transferred to the generator body with a stone tray. The functionality of the equipment, the efficiency of the device and safety depend on the characteristics of the gas nozzle.

How does a gas stove work?

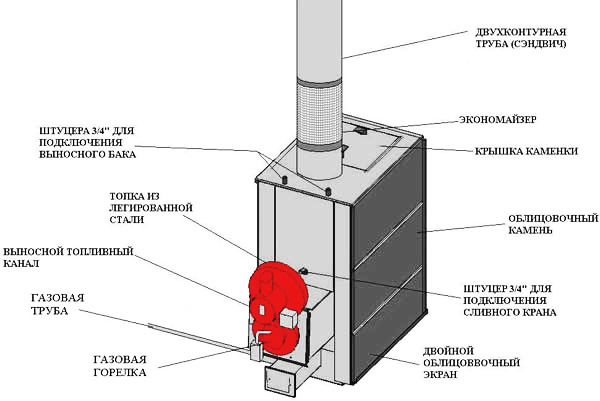

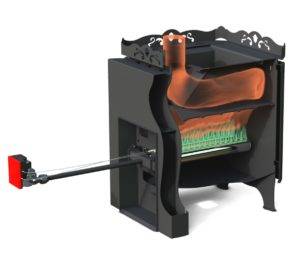

A gas stove for a steam room, regardless of model, is similar to stoves that are fired with logs. The only difference is that gas is used for kindling, not wood, so instead of a window for wood, gas stoves have a special socket into which a gas burner is mounted.

The gas mixes with air and produces heat at the outlet, which can be regulated by opening the door located at the bottom of the stove. A gas burner in a sauna stove can be installed together with a firebox for firewood, such models are considered universal and make it possible to use both gas and firewood for kindling.

What are the benefits of using gas sauna stoves?

Compared to their wood-burning counterparts, gas sauna stoves have a number of significant advantages:

Almost all models have a thermostatic control system.And this means that in the process of taking bath procedures there is no need to be distracted by maintaining the required temperature - laying firewood, changing the position of the blower window, etc. It is enough to set in advance the required level of heating in the steam room - the rest will be taken care of by the automatic operation control system.

The thermostatic control system for gas burners allows you to set the desired temperature - and no longer be distracted by this business while taking bath procedures

- Modern gas ovens are extremely easy to operate. They are equipped with all the necessary levels of control and security.

- Wood stoves have to be cleaned of accumulated ash literally after each kindling. There is no such problem in gas installations. Prevention is certainly necessary, but its frequency, as a rule, does not exceed two times a year. By the way, this also applies to the chimney for a bath - there are incomparably more solid products of combustion in the smoke from wood than when burning gas.

- When using natural network gas, there are no issues with the organization of fuel storage, with its delivery to the bathhouse. It is enough to open the tap - and you can kindle the heater. If liquefied gas is used in cylinders, then this is a little more complicated. But for cylinders, too, you can once organize a compact gear cabinet at the outer wall of the bath, stretch the hoses on an ongoing basis, and not experience any serious problems in the future.

If you plan to use bottled gas, then you can mount a special cabinet near the wall of the bath.

- In terms of heating speed, gas-fired steam ovens are in no way inferior to wood-burning or electric ones, but at the same time, their operation will be much cheaper, thanks to the quite affordable cost of “blue fuel”.

- Modern models of gas sauna stoves are distinguished by enviable durability, and the manufacturer gives them a very good factory warranty.

- Many models of gas stoves for a bath have already been given an appropriate appearance in advance, which does not require any modifications. However, there are those that require obligatory bricking or complete closure on all sides with a heater.

- It is also important for the traditionally cramped bath conditions that gas stoves are usually compact.

Prices for gas ovens

gas oven

Only one thing can be called a significant drawback of such furnaces. As with any other gas equipment, they require the approval of the installation by the relevant organization and the laying of the line. This means that you will have to order the drafting of the project, and then deal with its approval by authorities, which is always accompanied by a loss of time, nerves, and additional material costs. But the advantages of gas ovens still outweigh this "minus".

Where can I use a gas oven

The gas heating system is universal, it is used:

- for heating baths and saunas;

- as heating boilers when laying heat communications in the room;

- as part of boiler structures to provide apartments with hot water in the summer;

- if we consider household gas stoves, they are very popular with housewives.Thanks to an open fire, dishes on this design are cooked much faster.

Types and features of gas furnaces

Before you build a gas stove for a bath with your own hands, you need to understand the main design features of these structures and their types.

All gas structures are classified:

- heating;

- household;

- heating.

If we consider a stove for a bath or sauna, then it is worth stopping at a heating gas structure.

Heating furnaces are used in autonomous heating systems and hot water supply of private buildings. It should be borne in mind that with high humidity, these structures are practically useless, since they cannot maintain high temperatures.

Gas ovens have different qualifications for:

- the type of burner that is installed in the boiler;

- method of heating the coolant;

- material for the manufacture of the furnace frame;

- type of fuel to be used.

There are many varieties of gas stoves, there is another type of qualification - by the type of gas burner:

- atmospheric;

- supercharged.

The most affordable on the market are atmospheric burners. They are easy to install - no need to supply electricity and mount special automation. In this case, injection is involved, under the influence of which air enters the zonal chamber or a special pipe installed by analogy with self-made structures.

It should be understood that this is why the efficiency of the furnace will depend on the supply of oxygen. If the blowing is weak, then the efficiency of the furnace will greatly decrease - gas combustion will be sluggish.

The most complex and expensive design is inflatable type burners, which are directly dependent on electricity.The design feature of this unit is a special fan that blows air into the combustion chamber. The efficiency of the structures is high, its use is universal, since they can be installed in combined furnaces. Atmospheric units can only be installed in gas ovens.

The body material can be different:

- stone;

- brick;

- metal.

Calculation of power for a bath

The described equipment can produce different power during operation, and therefore, when choosing a suitable stove, this is the most important criterion.

The required power is determined based on such parameters as the total area of the bath (including the steam room, and the dressing room and other rooms, if any). The larger the heating area, the more power the stove should have.

It is extremely important to make accurate measurements of all the parameters of the bath, this is its height, and width, and the diameter of the chimney.

Power is calculated according to the following principle:

Power is calculated according to the following principle:

- Multiply the width, length and height of the bath. For example, if a bath is 3x2 in size and 2.2 meters high, then its volume will be 13.2 cubic meters.

- Next, heat loss through a door, window, brickwork or other partitions is calculated. Each square meter of the listed surfaces absorbs heat. To make a calculation, taking into account this factor, you need to multiply the area of \u200b\u200bthe bath by a factor of 1.2. If the steam room has a window with a size of 0.3 * 1.0m = 0.3 square meters, and a door with a size of 1.8 * 0.8 m = 1.44 square meters, then the total heat loss will be (0.3 square meters + 1.44 square meters) * 1.2 = 2.088 cubic meters.

- The next step is to add the resulting total area of the bath with the heat loss area. For example: 2 + 2.088 = 15.288 cubic meters.

Based on the data obtained, it is possible to select a furnace of the required power, since manufacturers indicate in the technical data sheet of the equipment what area the furnace power is designed for. It is better to give preference to equipment whose power is in the range of 25kW.

Gas oven in the bath

Foundation for a gas furnace

The foundation of the gas furnace We build baths in the following sequence:

- We swarm a pit with a depth of 70 cm, given that the bottom of the pit should be slightly wider than the base.

- We fill the bottom of the pit with sand 15 cm thick, fill it with water and wait until the water is absorbed.

- After the water has been absorbed, about 20 cm thick we pour pieces of brick and stone.

- Let's cover it all with rubble.

- We make formwork and create a reinforced frame.

- We fill it with concrete and wait until it sets a little, then we remove the formwork.

- We cover the surface in several layers with tar.

- We cover the place where the formwork was with a mixture of sand and fine gravel.

- We put moisture insulation - and the foundation is ready for the construction of a gas furnace.

Construction of a gas oven for a bath

The procedure for making a gas stove for a bath looks like this:

- We prepare a solution of sand and clay in a ratio of 1: 1. Mix all this with water until a homogeneous mass without lumps is formed.

- Soak bricks in water for 10 minutes before laying.

- We put the first layer of brick on the bitumen, which we previously placed on the foundation. After laying the first row of bricks on the mortar, let it rest for a couple of minutes.

- The second and subsequent rows are laid so that each brick lies on the joint between two bricks of the previous row. Make sure that the seams have a thickness of no more than 5 mm.

- In the process of laying the third row, you can make a door for the blower.Use strips of steel or galvanized wire to secure the door.

- In the fourth row we create a hole for ash one centimeter in size.

- In the sixth row we finish with the installation of a blower, and in the seventh we install the door for the firebox and the grate.

- Eighth row - we make a partition for the chimney and continue to lay bricks until the channels are placed in the 14th row.

- We install a water tank on the channels, so that it is located on the front wall, and the side walls support it vertically.

- The fifteenth row is the basis for a separate wall, so we put it in half a brick. We also put the next three rows.

- We put the door for releasing steam in the nineteenth row.

- Between 20 and 21 rows we put strips of steel, then we put a tank for hot water.

- The chimney is installed starting from the 23rd row. Remember that the pipe should rise half a meter above the roof, and the thickness of the pipe itself should be half a brick.

When the work with the laying of the furnace is completed, we proceed to the plaster. We clean the walls of the furnace from excess mortar and plaster with a mixture of sand, clay, gypsum and alabaster.

Using a gas stove in a bath

- We recommend burying a bottle of liquefied gas on the street near the bathhouse.

- Be sure to install an automation system that will regulate the fuel supply and when to turn it off.

- After the stove is ready, let it dry for at least two weeks, and after the first kindling, do not immediately bring it to high temperatures.

- Make sure that the refractory base under the stove extends 100 mm beyond the boundaries of the stove.

- The gas pipeline to the stove must be made of steel or copper.

Where to install the stove

You can’t just put the stove in the middle of the steam room, it is important to take into account the location of the air ducts, correctly calculate the distances from the walls, think about protecting the walls of the bath from heat. If you look at the “Appendix to SNiP 41-01-2003”, you can find lines where it is clearly stated that if the walls of the bath are not combustible, that is, they have a fire resistance limit of 60 minutes or more, then a metal stove is allowed to be installed at any distance, but it is better when more than 380 mm of free space remains between the steel furnace and the wall

If you look at the “Appendix to SNiP 41-01-2003”, you can find lines where it is clearly stated that if the walls of the bath are not combustible, that is, they have a fire resistance limit of 60 minutes or more, then a metal stove is allowed to be installed at any distance, but it is better when more than 380 mm of free space remains between the steel furnace and the wall.

It is quite difficult to meet completely brick or concrete walls in a bath without sheathing, often the finish is done with easily combustible wooden clapboard.

Another thing is if the material of the walls is wood. In this case, you should follow these rules:

- when purchasing a factory oven, ask for instructions for it and carry out the installation strictly according to the manufacturer's diagrams. This rule is spelled out in SNiP 41-01-2010, namely in paragraph 6.6.2.19 (Individual stove heating);

- from the hot walls of the unit to the walls not protected by screens, there should be more than half a meter;

- the wall or partition through which the fuel channel is led must be made of non-combustible material from the floor itself to a mark of 25 centimeters above the furnace door;

- the thickness of the non-combustible wall through which the fuel channel is led should be 12.5 cm;

- if the ceiling in the steam room is thermally insulated and protected with plaster on a metal mesh or similar, then the distance from the top of the metal stove to the ceiling should be more than 80 cm;

- in the case when the ceiling is not protected by refractory materials, the distance from it to the furnace must be more than 1.2 m;

- from the furnace door to the opposite wall should be more than 125 centimeters;

- leave 3 cm between the wall and the front wall of the furnace with an external firebox.

Fireproof distances from the furnace to the walls

When choosing the best location for your own stove, take into account the location of elements such as external heat exchangers, hung heaters, hot water tanks, pipelines for remote tanks. These elements must be freely accessible for repair and maintenance.

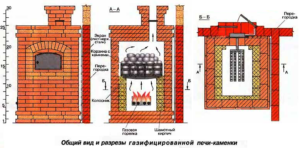

Brick gas ovens

Furnaces of this design warm up for a long time, but they keep heat well. Therefore, it is worth starting to warm up early.

Appearance is not much different from the most ordinary wood-burning stove. It will look great in a bath, decorated in a traditional style. The furnace door serves to access the heater, which is located inside the structure. It is heated by the currents of warm air, which rise due to the combustion of gas.

Here, directly above the burner, there is a heater, which has special requirements. Stones for heating are located in a trough made of metal, which has a side along the entire perimeter (this does not allow poured water to the fire).

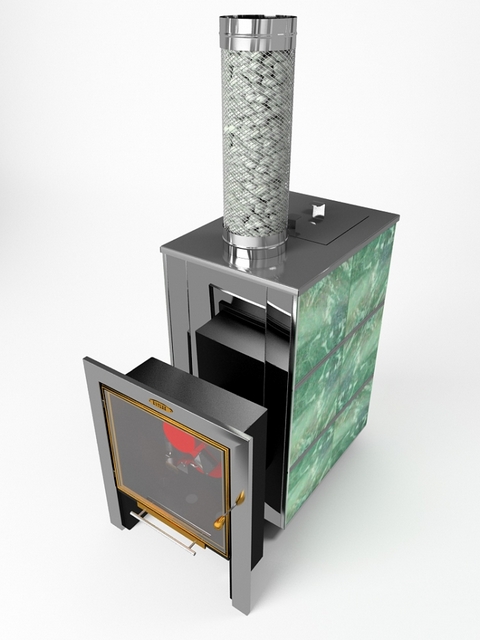

Metal gas furnaces

A gas stove for a do-it-yourself bath made of metal is distinguished by a relatively small thickness of the walls of the body and a small number of stones in the heater. Such a model warms up quickly, but also cools down quickly too. Models of this type are quite compact, they can equip a bath of almost any area.

This design is cheap in cost. If you have a small set of tools, you can make it yourself in the shortest possible time. Here we will describe the manufacture of a gas oven that is powered by a gas cylinder. Many speak positively about such a design, which has a very simple device.

The principle of operation of the gas furnace

In a separate chamber, which is located in front of the burner, the gas is mixed with oxygen. Air enters the furnace and ensures normal combustion. To ensure air supply and the possibility of cleaning the burner, a door is mounted in the lower part of the furnace. Gas is supplied through a tube.

If bottled gas is used for the stove, this should be taken quite seriously. Such a cylinder should be placed outside the bathhouse. Some install cylinders in the ground, a few meters from the bath. Keep in mind that the propane mixture is more efficient for the operation of the furnace.

Required materials

Materials must be prepared in advance.

This will allow you not to break away while working:

Many write that you can use any old gas cylinder to ensure the operation of the furnace.

- Any brake disc, most importantly, without cracks, it will serve as the basis for the heater.

- Buy two gas pipes with a diameter of 50 mm (they will provide gas and air supply to the chamber) and one with a diameter of 100 mm (a chimney will be made from it).

- Gas burner (better than atmospheric type).

- Connections for connections.

In no case do not take connections made of silumin. They are cheap, but when heated or a small impact immediately burst. You should buy made of copper or bronze.

Furnace installation

To begin with, we trim the cylinder using a grinder and a cutting wheel. The diameter of the cutting base must match the radius of the brake disc so that it can be fixed without problems. When fastening, it is best to use welding, after which metal streaks should be cleaned with a grinder and a cleaning wheel.

- To supply air to the system, we prepare a pipe with a radius of 50 mm. We make about 10 holes in it with a diameter of about 5 mm.

- We make a hole slightly larger than the diameter of the pipe at the bottom of the cylinder. We install the pipe so that the whole end enters 20 cm from the cylinder. We weld the joint.

Cut out the door

- According to such a system, a gas supply pipe is fastened.

- To connect to the gas, we install an adapter for gas installation. The joint is treated with a sealant.

- We fix the chimney in the upper part of the pipe.

- Cut out a hole for the door. Curtains are attached to the cut piece of metal and attached to the body.

When installing the furnace, it is extremely important to protect the wall from overheating and fire. For this, a expanded clay sheet is mounted between the furnace and the wall. This insulation is done in two layers.

Finally, a reflective stainless steel screen should be used. It is possible to equip the furnace with an indirect heat exchanger

This insulation is done in two layers. Finally, a reflective stainless steel screen should be used. It is possible to equip the furnace with an indirect heating heat exchanger.

Properly selected gas stoves for a bath and high-quality installation work will provide you with a comfortable and safe stay.

Criteria for choosing a sauna stove

In order to choose the most suitable model of a gas device, the following factors are taken into account:

The area of the steam room - the power of the device directly depends on the size of the room (one kilowatt of power per cubic meter of air).

The quality of the thermal insulation of the steam room, the presence of windows that cause heat loss and, accordingly, require an increase in the power of the heating apparatus are taken into account.

- The heat capacity of the stove is an important factor that allows you to warm up the room better, as well as effectively dry the steam room with the help of residual heat. Brick models have the highest heat capacity, in the case of making a device from metal, the presence of a screen, the location and length of the nozzle, and the type of heater are of great importance.

- Fuel consumption - depends mainly on the power of the furnace, the average figures for a small steam room and a device with a power of 10 kW: 1.5–4 cubic meters / hour. When the task is to heat a fairly large room for several people, more powerful stoves with two or three burners are usually used, and gas consumption increases significantly. Increasing the heat capacity of the furnace helps to reduce losses.

To increase safety and save space in the steam room, it is recommended to choose a model with an external fuel channel that allows you to place part of the equipment behind the wall. It will also provide more convenient control of fuel supply, carrying out the necessary actions for servicing the device.

Wood and gas stoves

Very often, a combined version of the furnace is installed, usually equipped with two fireboxes.

This provides the possibility of both the traditional method of heating - by burning wood, pieces of peat and other solid fuels, and heating with a gas burner.

Often such a universal model is obtained when re-equipping an existing sauna stove, usually a brick one - its design almost does not have to be changed, only a gas channel is supplied for additional heating and a burner is installed.

Reference! Burning wood, especially when using a brick oven, gives a softer heat that is beneficial to health and creates a special comfortable atmosphere in the steam room. Therefore, when building a bath, many do not want to abandon this method of heating, although the use of gas is much more profitable.

The installation of a combined stove is very convenient when there is no gas main on the site and heating is provided by imported liquefied gas from cylinders. Then the ability to heat the bathhouse with firewood will insure in the event of interruptions in the supply of fuel.

The design of a metal gas-wood stove is almost the same as a conventional mono-fuel stove. The difference lies in the ability to remove a block with a gas panel, which turns a gas firebox into a regular wood one. An even easier-to-use option with the installation of an additional fuel receiver is common.

Choice of combined design

As in the case of a monopropellant apparatus, the following conditions are taken into account when choosing:

Steam room area - depending on the size of the room, the power of the stove is calculated for each type of fuel.

If the wooden or tiled walls of the steam room do not have surface thermal insulation, the stove power is selected one and a half times more in order to warm them up qualitatively and create the right microclimate.

- Heat capacity - combined stoves are often built of brick, which increases their ability to retain heat, and therefore save on fuel. When choosing a metal model with two fireboxes, it is recommended to lay out a brick lining.

- Fuel consumption - for wood-burning stoves, on average, about 4 kg of firewood is required per hour, if the area of the steam room does not exceed 20 sq.m. To reduce fuel consumption, increase the heat capacity of the furnace - this will increase the heating time, but reduce heat loss.

Due to their versatility and versatility, combined stoves do not lose popularity in baths in suburban areas. When choosing this option, it is recommended to calculate in advance where the fuel for the stove will be stored (you will need space for both gas equipment and firewood).

Advantages and disadvantages of bath gasification

Before deciding to conduct gas to the bath, the owners of suburban areas try to take into account all the features of this method.

The cost of operation, environmental friendliness, complexity of care, efficiency are taken into account.

Advantages of using blue fuel

In addition to significant savings, the advantages of this method include the hygiene of gas - there are no smells, soot, soot during combustion. In addition, a gasified bath heats up almost twice as fast.

Firewood is inferior to gas in many respects: they need to be stored somewhere, to monitor the timely delivery and condition. However, they are still the most popular firebox material. And even used in combined gas-wood stoves

Firewood is inferior to gas in many respects: they need to be stored somewhere, to monitor the timely delivery and condition. However, they are still the most popular firebox material. And even used in combined gas-wood stoves

A big plus is the automation of the process. Kindling requires a minimum of labor on the part of the owner.Together with the cheapness of gas, this advantage makes the gasification of the baths especially attractive.

Cons noticed by owners and professionals

According to the owners, the main drawback is the difficulty in obtaining permission: with the slightest inaccuracy, the commission prohibits the use of gas to heat the bath.

Professional gas workers note a high level of danger if the installation rules are not followed, there are no safety devices and the vigilance of the owners

Professional gas workers note a high level of danger if the installation rules are not followed, there are no safety devices and the vigilance of the owners

Other disadvantages include:

- the need to pay for the work of installation specialists;

- high cost of equipment;

- restrictions on the choice of sauna design.

Another subjective observation concerns the lack of smell. Many appreciate the aroma that spreads throughout a heated room when wood is burned. Gas equipment eliminates this possibility.

Classification

There are two types of burners:

- Forced burners. The design has a fan with which air is injected. The design itself is efficient in operation, but energy-consuming.

- atmospheric burners. This is a device with a simple design. Air supply is carried out using special tubes. The efficiency of atmospheric burners depends on the strength of the air flow supplied to the combustion chamber.

According to the material, two more types of furnaces are distinguished:

- Brick structures. This material heats up slowly, but retains heat for a long time. The disadvantages of brick ovens are a large mass, high price. Advantages - durability, reliability.

- Metal constructions. They heat up and cool down quickly. They are cheaper than brick ovens, but less durable and reliable. Rust can appear on metal surfaces, which over time will lead to the destruction of the walls.

Wiring requirements for an electric furnace in a bath

Consider the following points:

- For a single-phase network, use a three-core cable, for a three-phase network, use a five-core cable.

- A prerequisite for wires is the presence of a ground wire.

- Attach the wires to the wall using conventional cable channels.

- The cable between the control panel and the oven must be in special rubber insulation. Sometimes such a cable is supplied with the oven.

- Wires with reinforced insulation are expensive, so it is recommended to reduce their length. To do this, near the stove (not closer than 1 m), on the wall, install a metal mounting box. Run regular vinyl-insulated wires between the box and the remote control, and reinforced wires from the box to the oven. Pull heat-resistant wires through a metal hose or pipe, which is grounded.

- Under high temperature conditions, the strands of copper and aluminum wires oxidize, so all wires in the building must be copper.

Selection principles

When choosing, you need to consider a number of factors:

Furnace dimensions. Its dimensions should not interfere with free movement around the bath rooms.

It is recommended to choose a design with a remote combustion chamber.

Fuel consumption.

If there is no warm water in the bath, you need to choose a model with a water tank.

If you want to buy a universal model, it is recommended to pay attention to units powered by gas, solid fuels. A special mechanism is installed inside the structure, which divides the combustion chamber into two parts for different types of fuel.

The volume of the water tank depends on its location. If it is built-in, the capacity will be small. If it is external, the volume will be larger.

Furnace selection

Furnace selection

Advantages and disadvantages

Advantages:

- Small size.The design does not have a large combustion chamber as in furnaces that run on solid fuel.

- Furnace equipment allows you to set different temperature conditions. Thanks to this, you can set the optimum temperature, maintain it for a long time.

- If you do not need to heat the bath, you can simply heat the water in a mounted or built-in tank.

- Fast heating.

- You can connect gas cylinders if it is not possible to connect a pipe with a central gas supply.

- Fuel economy.

- In universal models, 2-3 types of fuel can be used.

Flaws:

- The risk of explosion is higher than for equipment operating on other types of fuel.

- It is necessary to constantly change gas cylinders or connect the furnace to the central gas supply system.

If there are no problems with the gas supply, the minuses become less.

Popular models and prices

Popular Models:

- Furnace "P-20GT". Power - 20 kW. Suitable for heating steam rooms up to 22 m3. There are mounts for installing a water tank.

- KUTKIN Standard G-2.0. Model for space heating up to 16 m3.

- Thermofor Taimyr INOX. Suitable for heating steam rooms up to 18 m3. The design has two heaters - internal and external.

- Termofor Urengoy Carbon. Made from high strength steel. Suitable for heating rooms up to 12 m3.

- Heat-Malyutkagaz. Equipment power - 16 kW. Designed for heating steam rooms up to 12 m3.

The average price of gas stoves is 16,000 rubles.

Types of ovens

Types of ovens

What are gas appliances?

There are several types of gas stoves, they are classified according to the following principle:

- What type of burner is used;

- What material is the case made of?

- What device is installed for heating water;

- Power options.

Depending on these criteria, there are a lot of models of gas furnaces, which complicates the selection task. Therefore, before buying equipment, you should study all the important nuances.

Stone and brick stoves

A stove for a bath with a gas burner, which is made of brick or stone, is an analogue of a Russian stove with a firebox for logs. The layout of the bath with gas stoves will not suffer in any way due to the material in which the device body is made. Stone or brick structures fit into any interior.

The only drawback of this material is the duration of heating. Stone conducts heat better than brick, so it will heat up faster. In models made of brick and stone, there is a heater behind the firebox door, which heats up due to the radiation of energy from the combustible fuel.

The heater is located above the gas burner. A gas stove for a sauna with a closed heater does not require an additional ventilated mode of operation, unlike an open heater. In many models, the heater is open, so if this issue is fundamental, this nuance should be taken into account.

Metal stoves

Metal stoves are cheaper than brick and stone stoves, and they are easier to install. The compact design of the metal device allows it to be installed even in baths with a small area. Other benefits include:

- Fast heating as the metal construction is very thin;

- The ability to select the furnace of the required power, so you can save on energy resources.

The presence of a metal structure implies the presence of mandatory thermal insulation. It is necessary to make the thermal insulation of the equipment case from the floor covering (for example, with a brick layer), thermal insulation from the walls and the chimney.If this is not done, then there is a high chance of a fire.

If the bath is planned to be melted from time to time, and not constantly, then it is better to choose a metal structure, its minimum weight is 45 kg, while a brick or stone structure weighs from 750 kg.