- Principle of operation

- Advantages and disadvantages of the Canadian stove

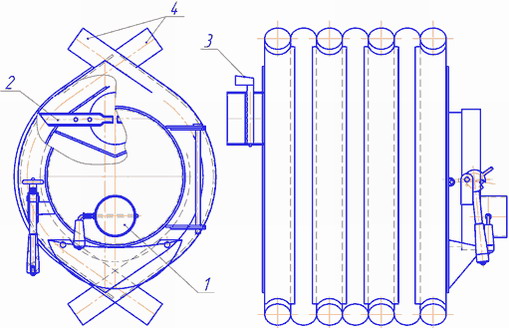

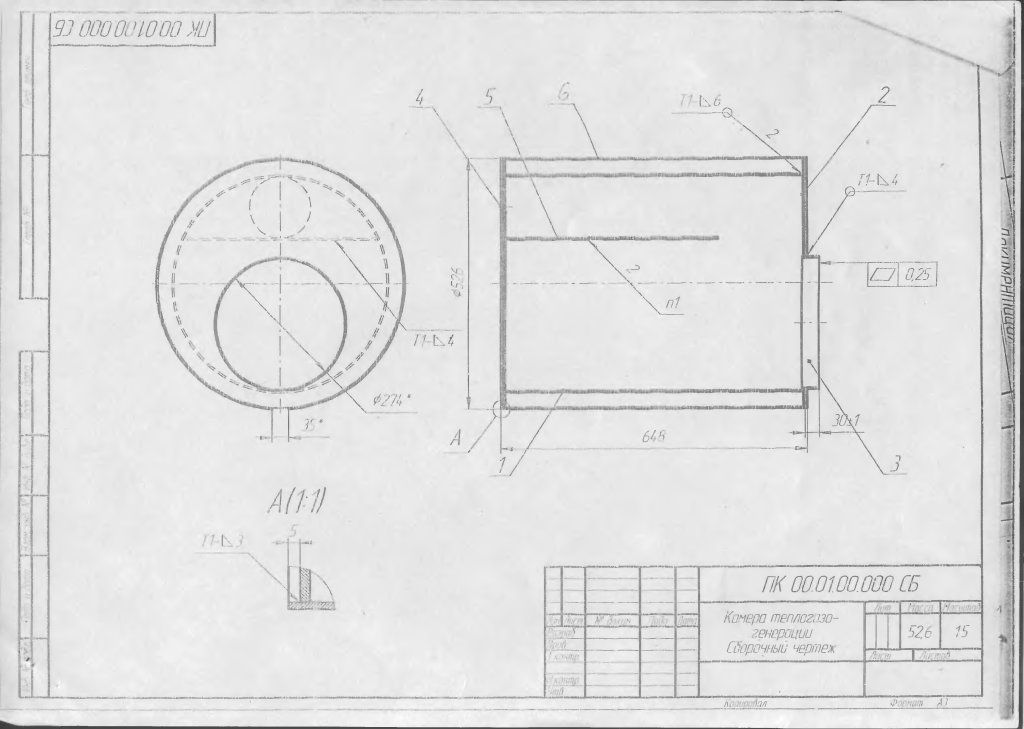

- The device of the furnace Buleryan

- Dimensions

- We determine the size of the buleryana stove

- Do-it-yourself Buleryan oven. Step-by-step instruction

- How to properly drown buleryan

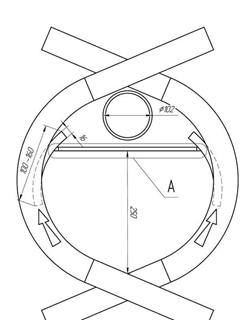

- Furnace Buleryan scheme of convection of air flows

- Positive and negative sides of the device

- Design cons

- Design features and principle of operation

- Refinement and modernization

- Distribution of heat in the rooms of the house

- Appearance improvement

- Alteration of a potbelly stove for liquid fuel

- Water circuit installation

- The device and principle of operation of the furnace

Principle of operation

The design is considered safe, since access is limited to the heated surface. The circuit with a liquid heat carrier can be combined with Buleryan furnaces.

Cold air creeps along the bottom of the room and, thanks to the furnace tubes located below, capture it and pass it through. The tubes are in contact with the firebox, as a result of which the air heats up and comes out already hot. Forced convection occurs.

From the firewood that enters the stove, the combustion products do not evaporate instantly into the street, but undergo secondary combustion in the next chamber, where a very high temperature is observed. Having gone through the entire process of afterburning the air-gas composition, heat transfer increases up to 80%.

The air temperature in the pipes reaches 120 degrees Celsius after 15 minutes. Therefore, we can say that the fuel will be consumed slowly and economically. For a full day, you will need two or three bookmarks of firewood.

Heat, thanks to the regulators on the chimney and the door, can be stored. When only heat remains from the firewood, they can be covered, and all the heat will linger in the room. All wood waste, peat briquettes, cardboard products, wood are suitable for heating. The only thing that cannot be used is coal.

Advantages and disadvantages of the Canadian stove

In fact, being the same "potbelly stove", Buleryan has a special charm and charm, doesn't it?

The specifics of using the Buleryan furnace initially implied compliance with several mandatory requirements, which subsequently made the unit known throughout the world. The design of the heater should provide:

- Mobility. Since cutting down trees involves constant movement through the forest, the woodcutters' stove is constantly transported from one place to another, and is carried from transport to the premises by hand.

- Compactness. The unit must have a configuration and dimensions that make it possible to install the device in small temporary buildings.

- Safety. Since the operation of the buleryan provides for the installation of a heater directly in the residential area, its design should exclude the possibility of leakage of carbon monoxide. It was possible to make this possible due to the hermetic working chamber and the decision in favor of a single-door scheme. It is also important that the configuration of the body prevents accidental contact with the hot metal of the furnace body.

- Performance.The use of forced convection makes it possible to warm up the room in record time. This condition is met thanks to a system of channels that accelerate air exchange.

- Possibility of long work. The configuration of the working area and the design of the blower allows the buleryan to work for several hours from a single load of fuel, and firewood, bark, wood chips, shavings, etc. can be used as fuel. case overheats and deforms. As a result, the geometry of the device is distorted, the furnace door does not close, cracks in the places of welded joints.

- Simplicity and reliability. When developing the design of a solid fuel unit, the engineers took into account that it would be operated in places remote from civilization. For the manufacture or repair of a Canadian potbelly stove, special equipment or expensive materials are not required, and for a beginner to operate the stove, a little instruction is enough.

As you can see, the advantages of buleryan were incorporated into the design at the design stage. Perhaps the developers did not even suspect that their brainchild would become so popular and be used both in everyday life and in production. Of course, like any other design, a convection oven of this type is not without some drawbacks. First of all, the unit achieves the declared performance only when using absolutely dry firewood. When the moisture content of the fuel is more than 10%, the released water vapor prevents the flow of air and reduces the intensity of combustion, which leads to a decrease in efficiency.In addition, like any potbelly stove, Buleryan does not keep heat at all - it is enough for the fuel to burn out, as the temperature in the room begins to drop.

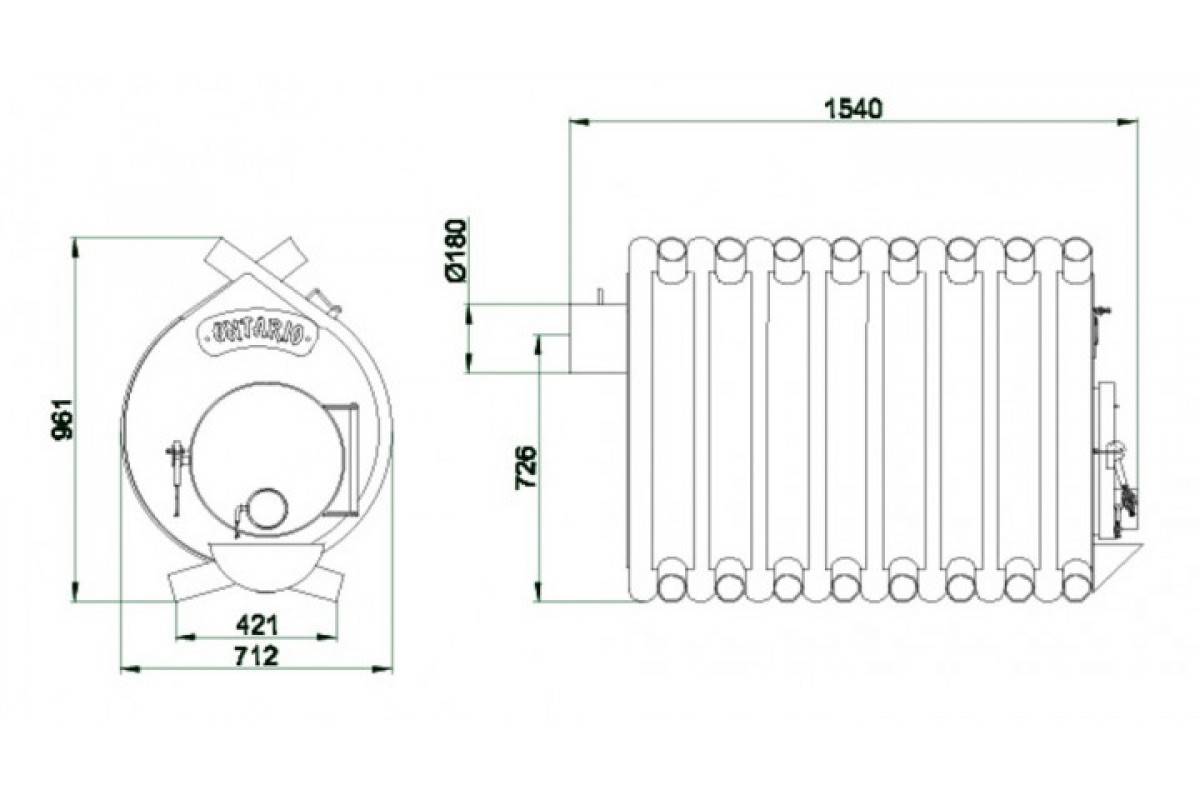

The model range of Buleryan type furnaces contains many types that differ in power and configuration

The disadvantages of the design include the fact that the operation of the furnace involves a gas-generating mode of operation, in which firewood smolders more than burns. This process is accompanied by increased smoke formation, which leads to the emission of harmful substances and tar deposits in the smoke channel. Often, the outer part of the chimney and nearby sections of the roof are covered with an oily substance, which does not add any attractiveness to the picture.

It is also important that when installing the stove, additional requirements are put forward for thermal insulation and the height of the chimney, otherwise its efficiency will be reduced.

As you can see, the unit is not without flaws, which are honestly pointed out by both the developers themselves and the owners. Nevertheless, the numerous advantages of buleryan made this heater one of the most popular units on the market for compact solid fuel equipment.

The device of the furnace Buleryan

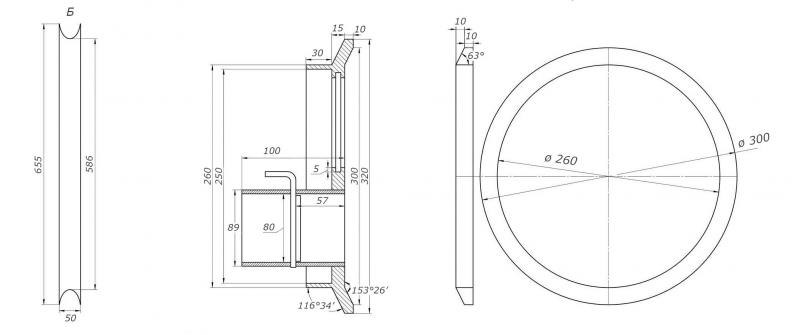

The oven is made of metal. Buleryan's device includes a convector made of large diameter pipes, a hatch for loading fuel, injection pipes and dampers.

The convector is a metal pipe, curved in the form of arcs. They are installed vertically and are interconnected at the intersection. Thus, a furnace is formed between the inner surfaces of the pipes. The air mass comes from the bottom of the convector. When heated, the air moves up.

How the stove is set up

There is a partition inside the firebox.It is necessary to form a secondary chamber into which air enters through the injection tubes.

In it, afterburning of the products formed as a result of pyrolysis takes place. Such design of a fire chamber increases efficiency of the furnace. The hatch for loading firewood is equipped with heat-resistant glass. This makes it possible to monitor the combustion process. At the bottom of the door is a blower.

The boiler itself can be placed in the casing. Photo source: ecoteplo.pro

It is equipped with a damper to regulate the air flow supplied to the furnace. A snug fit of the hatch to the Buleryan body provides a locking mechanism. The back of the furnace is equipped with a chimney. It is necessary for the removal of combustion products into the atmosphere. The chimney is equipped with a draft regulating damper.

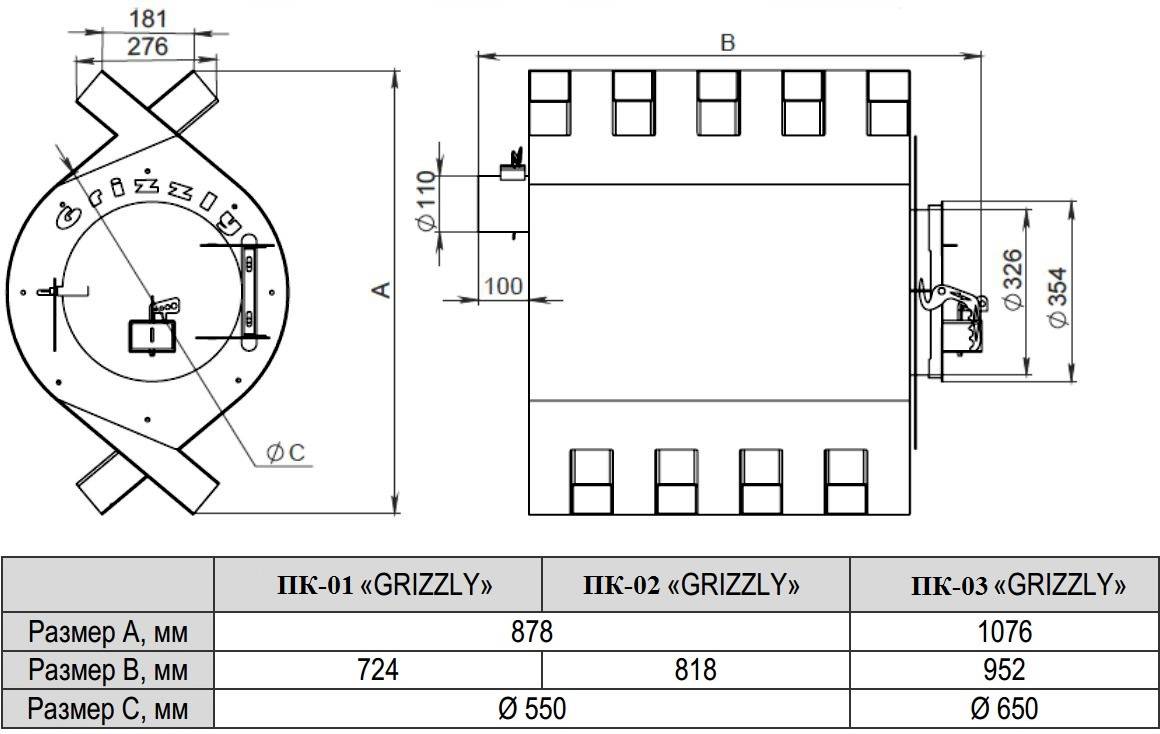

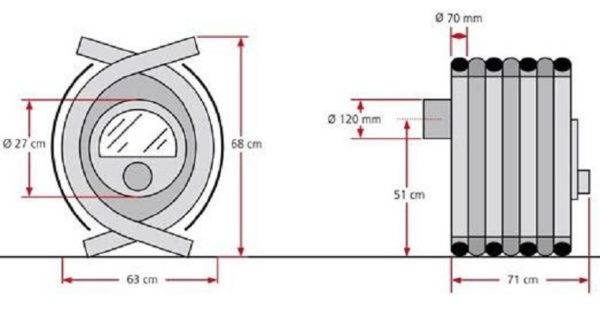

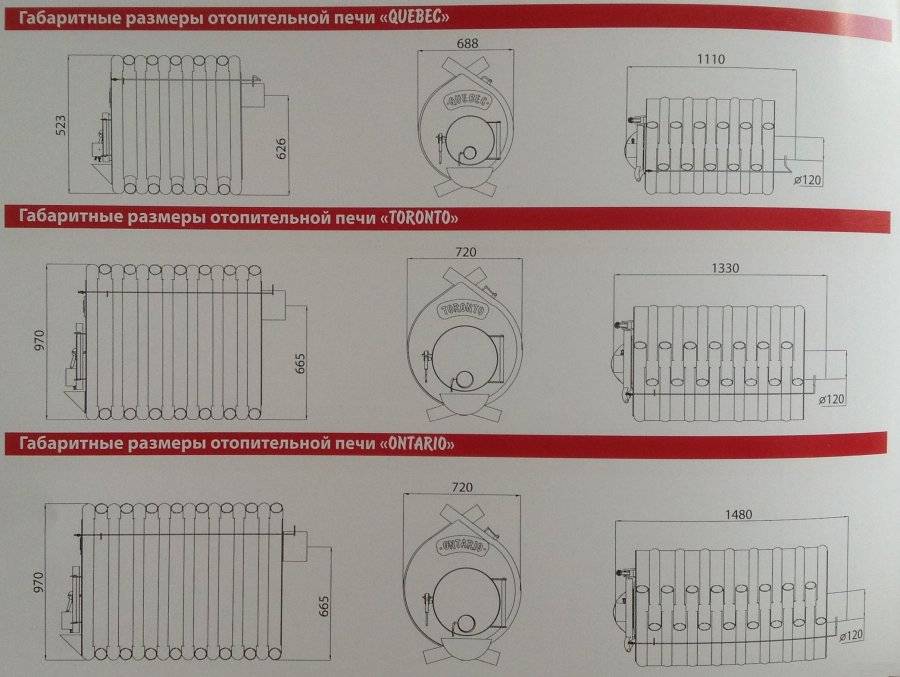

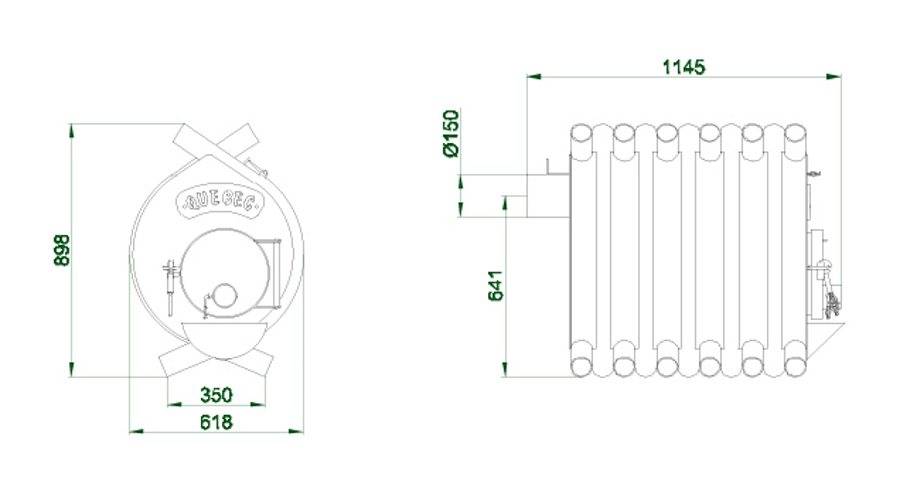

Dimensions

The Russian-made boiler is manufactured under license from a German company. The principle of operation of the Buleryan and Breneran furnaces is no different. On some models of domestic production, the fuel loading hatch is made without a viewing window. The Buleryan solid fuel boiler can be equipped with a protective screen. It eliminates the risk of burns when touching the oven.

We determine the size of the buleryana stove

The dimensions of the oven are of great importance. In the shortest, smallest buleryan (with a length of 455 mm, a width of 620 mm, a height of 555 mm), respectively, the firebox is small, so there is not much room for firewood.

Fuel burns in such a miniature boiler from two to six hours. It depends on the type of wood, the quality of firewood, the thickness of the cut.Accordingly, the area of \u200b\u200bthe heated room will be small - this must be taken into account when the size of the future buleryana is selected.

Of course, for rooms with an area of more than twenty square meters, long-burning stoves with larger dimensions are designed. The average dimensions of buleryana are: length - 835 mm, width - 436 mm, height - 640 mm. A large oven has the following parameters: 950 mm by 676 mm with a height of 1505 mm.

The frame of a homemade oven Buleryan

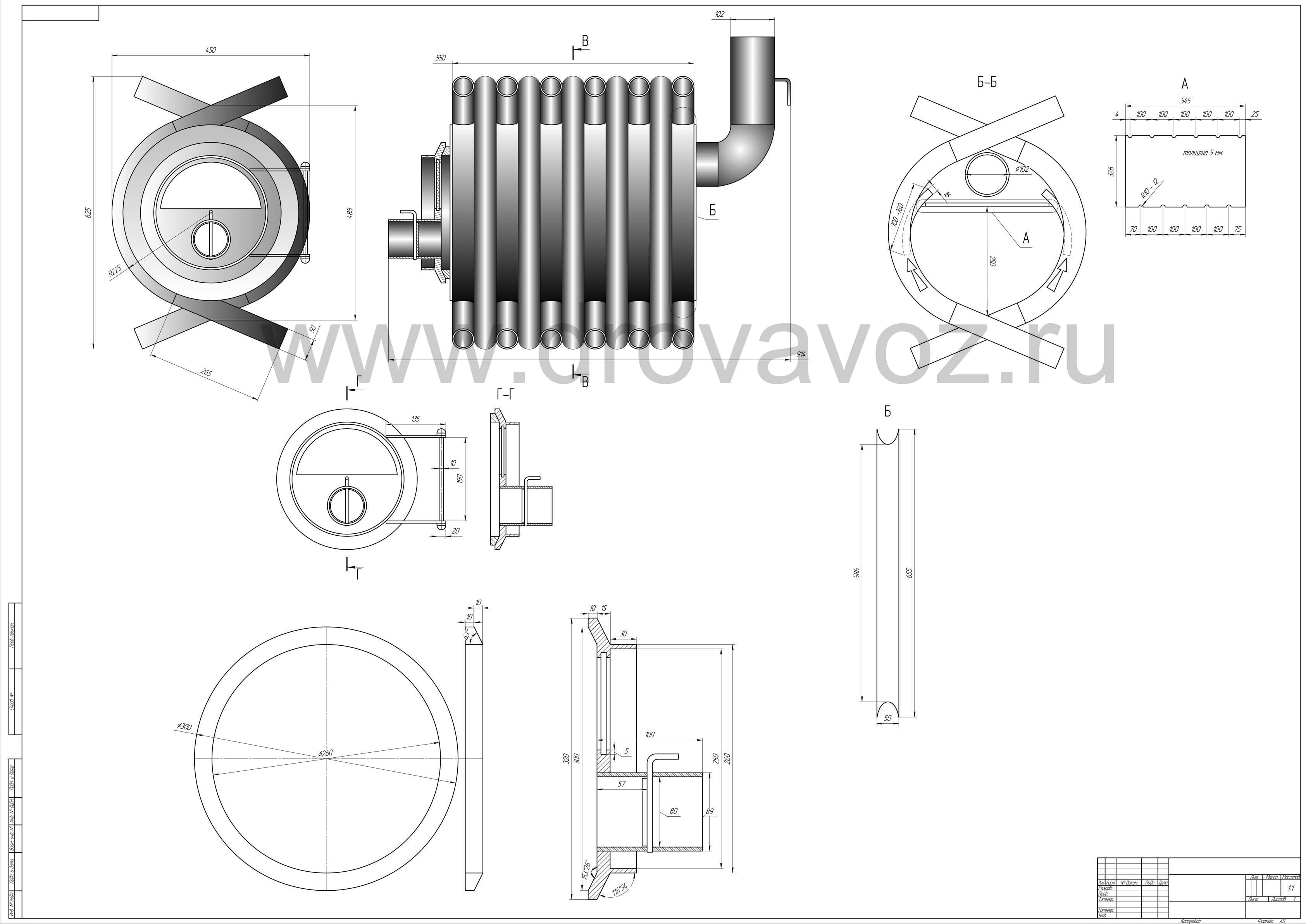

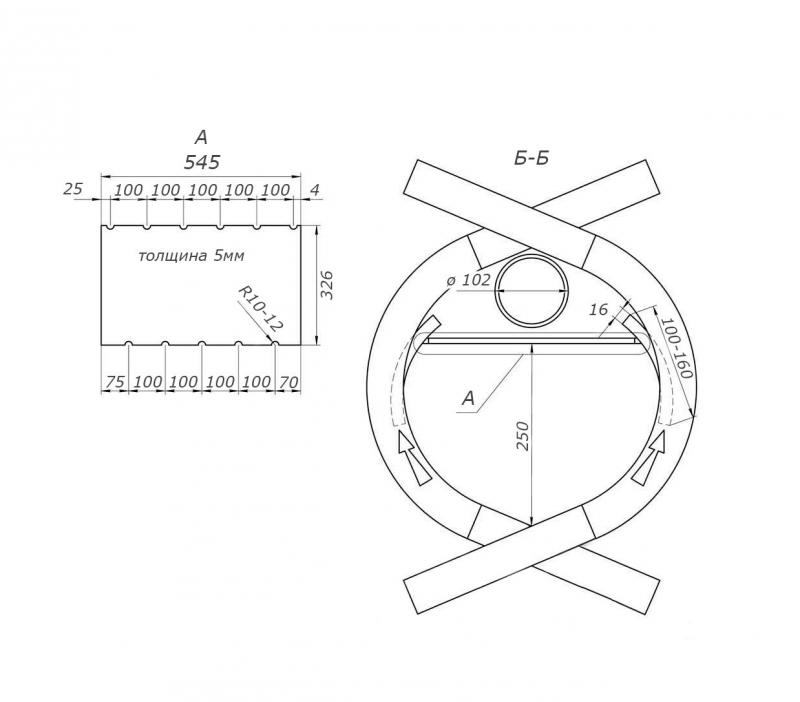

Do-it-yourself Buleryan oven. Step-by-step instruction

To do bake Buleryan with your own hands, you should purchase metal pipes, the diameter of each of which will be from 50 to 60 millimeters. You also need to buy metal in sheets. Remember that the combustion temperature in the furnace is quite high, which means that the thickness of the sheets must be appropriate (about 5-6 millimeters). To perform this work, you will need a pipe bender, a welding machine and the most standard set of tools.

Next, follow these steps:

- Bend pipe sections.

- To manufacture devices designed to collect condensate and remove smoke.

- Make dampers for the outlet and blower.

- Make doors for the furnace chamber.

- Trim sheets of metal in the space located between the pipes.

- Install door and lock.

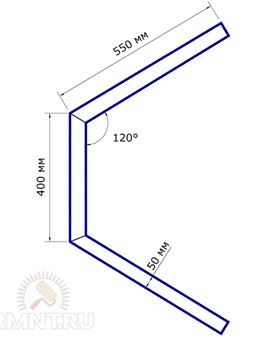

- Make and trim the legs, which are also made of metal.

It is necessary to make identical segments from the pipe, the length of each of which will be 1.2 meters. Using a pipe bender, they need to be bent to a radius of 225 millimeters. The resulting pipes should be installed in a checkerboard pattern.

In order to get rid of condensate, as well as excess smoke, it is necessary to build a special T-shaped device, thanks to which moisture will flow down, and smoke, on the contrary, will go up. There is also a special valve for removing moisture, which must be closed immediately after its excess has flowed out.

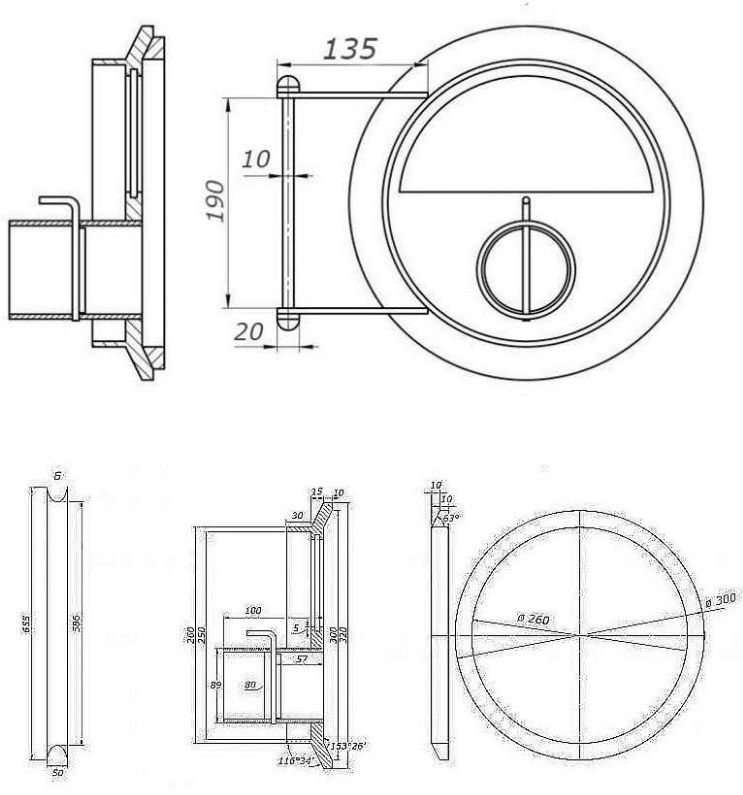

Well, in order to remove smoke from the pipe, a special damper should be made. By the way, with it, you can also adjust the traction force. At the same time, a blank damper is installed on the blower located on the front door.

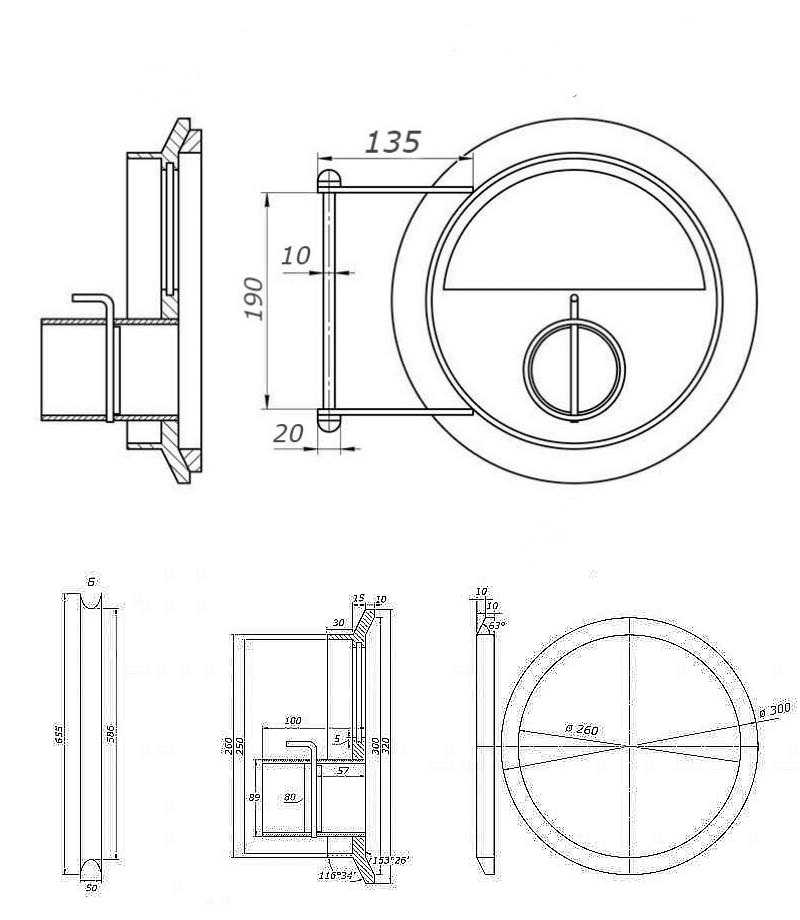

The most difficult element of this furnace is considered to be the front door, which must be made practically airtight. Remember that the tighter the door fits the unit, the higher the efficiency of its operation.

From a large diameter pipe, two rings should be made that fit tightly into each other. To do this, pieces of 4 centimeters should be cut from a pipe with a diameter of 35 centimeters, one of which is cut and unfolded. Further, using the ring, the diameter of which turned out to be smaller, the front side of the furnace is made. And the second ring is welded to a circle cut out of a sheet of metal and used during the installation of the door.

Then another ring is welded to the resulting structure, the diameter of which will be slightly smaller than that of what was welded earlier. Thus, a gap is formed between the rings on the door. It is in it that it is necessary to lay the asbestos cord and do the installation of the damper.

And now it's time to return to the pipes that were bent at the beginning of work. We take two pipes, make holes in them, to which we weld the injection tubes.This element is a 150 mm pipe with a diameter of 15 mm. It is necessary in order to connect other convection elements to the firebox.

Of all eight pipes, the frame should be welded, placing a partition between them. For her, it is best to use a sheet of metal with a thickness of at least 6 mm. With the help of strips cut from sheet metal, we close all the gaps between the pipes. For this, welding is used. Thanks to such actions, we create the body of the furnace itself. Tip: in order to cut out the partitions between the pipes as accurately as possible, it is best to use patterns made of cardboard or any other bending material.

It will be just fine if you are not too lazy and install a special lock on the oven door. It should be made in the form of an eccentric, fixing the loop, which is previously fixed on the oven door. If you continue to scroll the device further, the door will fit tighter and tighter with each turn. Unfortunately, it is impossible to make such a lock at home, since a lathe is required. In this regard, for its manufacture, you need to contact a specialist. The only thing left to do is to make hinges, mount the door and, of course, attach the legs to the stove. The latter, by the way, can easily be made from a square pipe.

As you can see, the process of making Buleryan is quite laborious and requires certain skills, as well as special tools. However, with a strong desire to make it at home is quite realistic. And the installation of the unit will not cause any difficulties even for a beginner.

How to properly drown buleryan

Well, now that almost everything is known, briefly about how to properly drown buleryan. First, it is advisable to put dry fuel into the furnace, in the amount necessary to heat the chimney and form coals. Moreover, it is advisable not to clean out the old coals and ash at all, leaving a layer that will slightly cover the metal, protecting it from burning out. Open the chimney damper completely, and blew, based on the required ignition speed and other factors, dry firewood, windy weather.

When the first "dose" burns through about two-thirds, enough heat is generated. You can make the main bookmark, large, but I highly recommend - dry firewood

It is important to understand that slow burning or smoldering occurs within 500 - 650 degrees. This means that raw firewood, resinous wood, waste containing chemicals and adhesives, all this will leave deposits and moisture on the walls of the chimney at an accelerated pace.

Also, do not use coal or coke. The air, which acts as a coolant, will not have time to remove all the energy from the surfaces of the exchanger. And most of it will fly into the chimney. Moreover, the increased temperature of the gases in the chimney will increase the risk of soot catching fire, and the furnace metal will burn through.

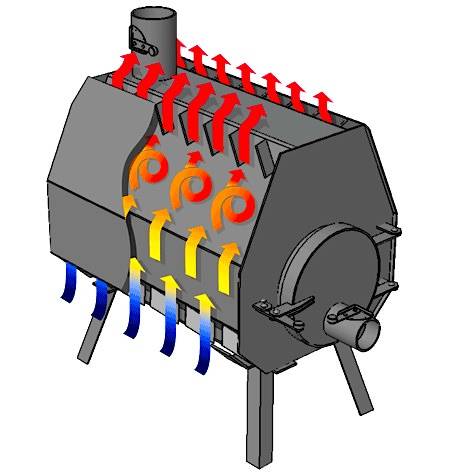

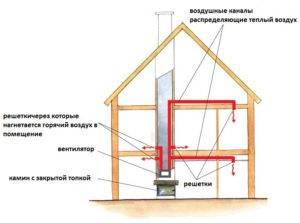

Furnace Buleryan scheme of convection of air flows

So, further the heated chimney will provide ignition and further combustion, in the desired mode. And this is most likely the economy mode. As economically as possible, the buller works with the blower and damper closed. In the combustion process, the effect of afterburning pyrolysis gases will begin to turn on.If we reduce the access of air through the blower, the gases formed with a lack of oxygen in the main furnace will additionally burn out in the upper chamber, separated by a partition. At the inlet, hot air is sucked in through the injectors.

With its help, the gases will give off more energy during the slow smoldering of firewood. Below, under the stove, colder air is picked up by the draft created by the already heated flow in the convector pipes and “shoots” upwards. Convection processes make the air masses circulate in the room, which ensures a high heating rate, which is why buller is valuable. It should be noted that due to its special design, the temperature of the outer surfaces of the furnace remains quite low. This reduces the risk of fire and burns are much less likely. To do this, you need to “look” for a hotter place.

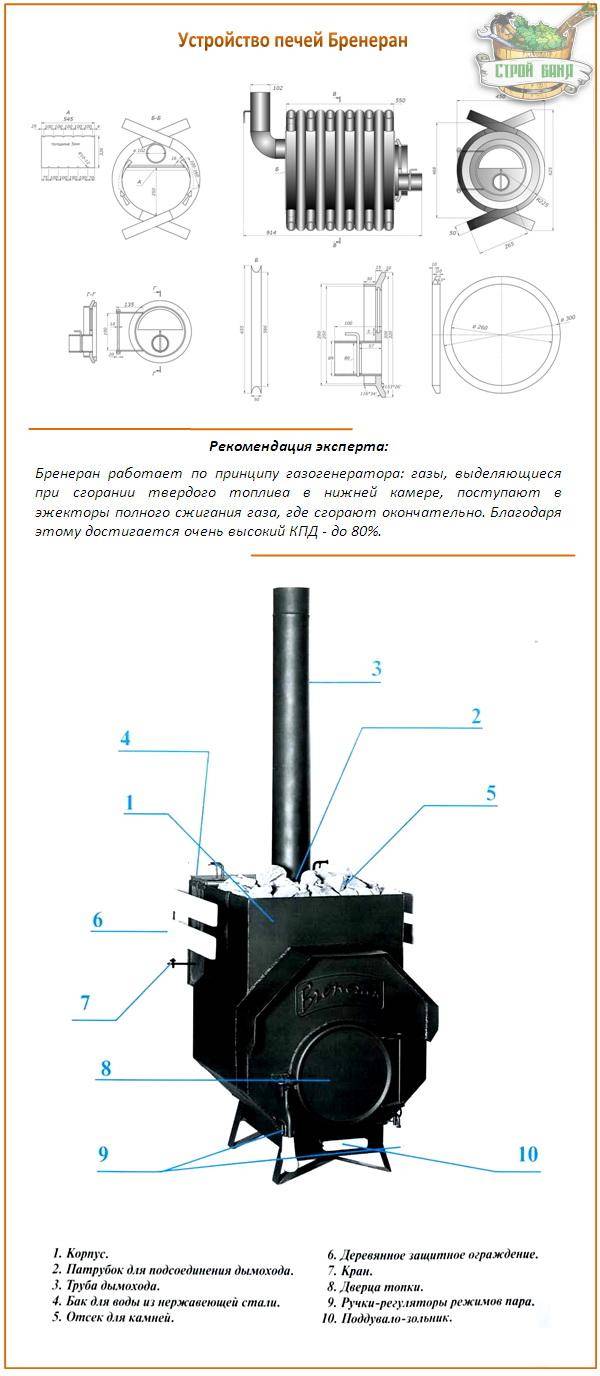

Positive and negative sides of the device

Breneran is a successful design that runs on solid fuel. It has many advantages:

- The housing serves as a forced convector through which all the oxygen in the room passes. At the same time, air exchange is carried out in a natural way - due to the different densities of heated and cool air.

- You can heat with peat briquettes, logs, waste paper and woodworking industries.

- High efficiency of the stove - it reaches 80%.

- The drawings of this heating device are widely distributed, and they can be found without much difficulty on the World Wide Web.

- The materials and equipment for mounting the product are quite simple and not very expensive. You will need a welding machine, a pipe bender, metal sheets and stainless steel heat exchangers.

- The installation of the equipment itself is quite simple, as well as the principle of its operation.

Design cons

Buleryan has no visible negative sides. These devices are called “furnaces without flaws”. But if you understand the design well, you can still find negative points:

- Burning hard coal in a stove may damage the device. The use of flammable liquids and gases is also not allowed.

- The principle of operation is based on the combustion of firewood and paper. In this case, reaction water is released, which is formed during the decay of the molecules of living organisms.

Modern design

Sellers, advertising breneran, say that when burning, the tree does not form ash, but it is present in the wood from the very beginning. Therefore, ash particles fly into the chimney pipe.

During the decomposition of organic matter, hydrocarbon radicals are released, which reduce the efficiency of the stove by 6%. This is a small figure, but for heating appliances in everyday life, radicals are quite dangerous.

The resulting water after the reaction precipitates in the form of condensate. Moreover, this is not just a contaminated liquid, but a mixture of ash particles and a thinnest film rolled into a ball. The resulting toxins, which have an unpleasant odor, fall into the sump. This “water” constantly needs to be taken out somewhere, because it cannot be poured into the garden - otherwise the soil will be poisoned. In connection with this not very pleasant phenomenon, a heating device is often used in greenhouses, where the soil must be renewed annually.

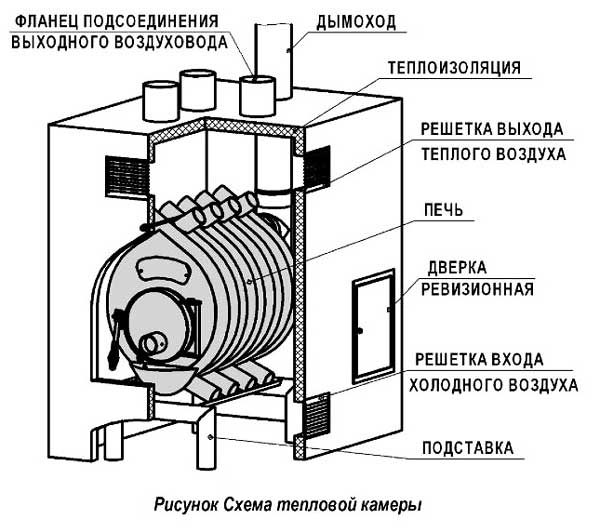

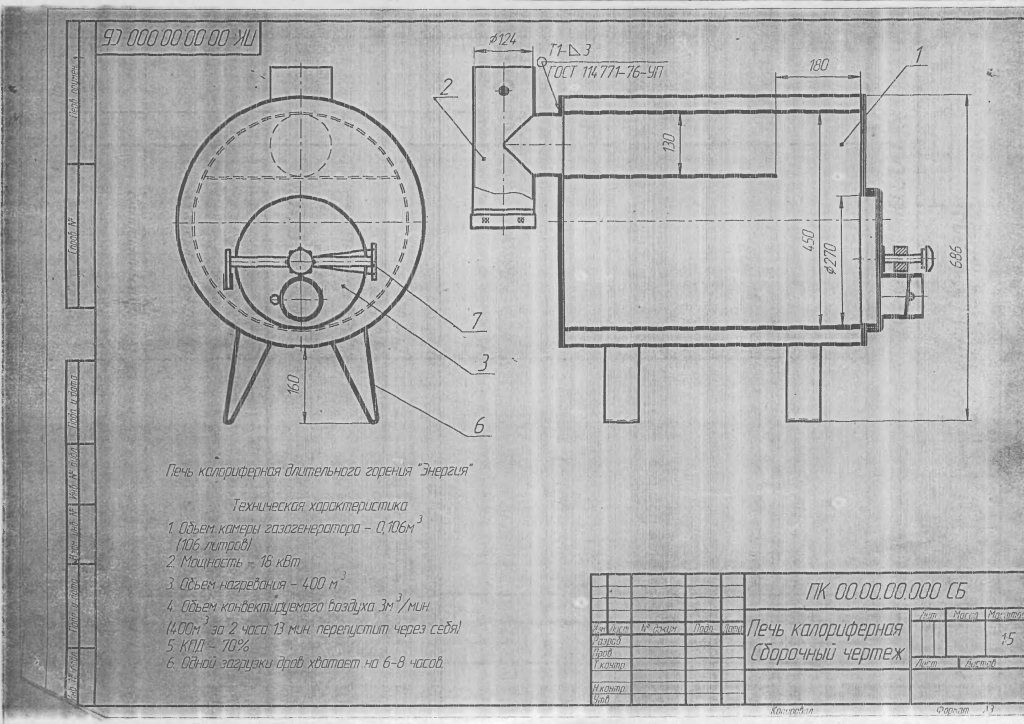

Design features and principle of operation

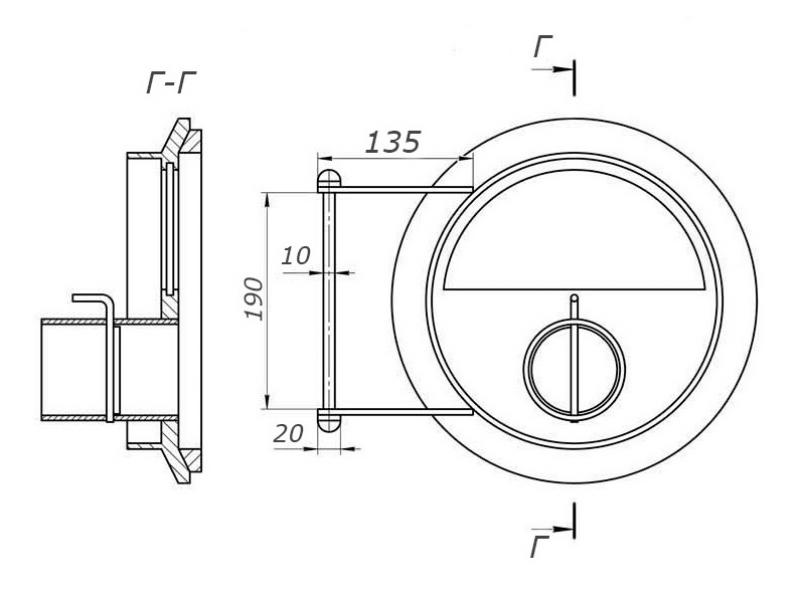

When developing Brenaran, Canadian specialists used the long-known design of a long-burning convection boiler, called a calorific oven.Due to the increase in the furnace door, it became possible to load not only chopped logs, but also parts of rhizomes, as well as large logs. The new form of the blower - in the form of a pipe cut into the loading hatch, made it possible to abandon the two-door scheme. To adjust the amount of air required for fuel combustion, a throttle was installed inside the blower - a round rotary damper. The throttle control lever brought out to the outside allows, if necessary, to reduce or increase the air flow, thereby controlling the power of the buleryan.

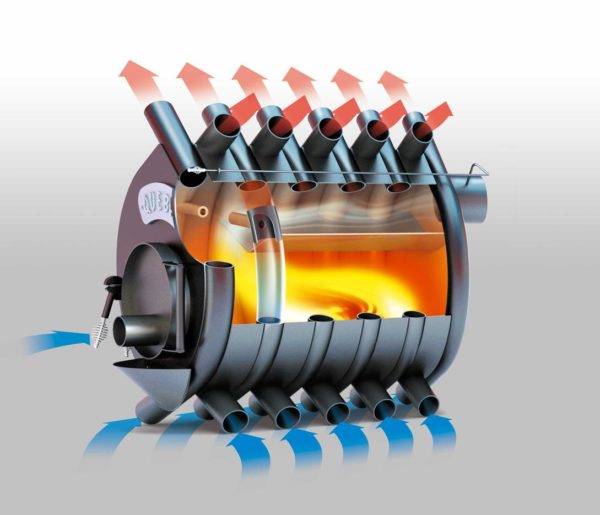

Buleryan construction

The furnace of the heating unit is a metal cylinder, on both sides of which tubular metal heat exchangers are cut in at regular intervals, bent in the form of knees. Due to the fact that two thirds of the diameter of the pipes are recessed into the body of the furnace and are in the combustion zone, the air receives up to 70% of the heat that is released during the combustion of firewood. The remaining kilocalories heat the body of the stove and are subsequently also spent on heating the room. Due to this distribution, the buleryan body usually heats up to only 60-65 ° C, while the air that leaves the convection channels has a temperature of more than 100 ° C. I must say that it is the high heating rate that ensures the active suction of cold air masses in the lower part of the tubular heat exchangers and their ejection from the upper openings of the heater.

The furnace space inside the device is divided into three chambers. In the lower part of the furnace at a height of up to ¼ of the diameter of the body, a metal hearth or a removable grate is installed. You can do without these elements, but with them it will be easier to light the stove and remove the ash.Under the vault of the firebox, at the same distance from the body as under, a perforated metal sheet is welded in, which does not reach the loading hatch for a quarter of the length of the buleryan. The upper chamber is designed for afterburning volatile compounds that are released during the operation of the unit in the gas generator mode.

Rapid air heating is provided by convection heat exchangers that make up the core of the furnace

The removal of combustion products occurs through the hole, which is located in the afterburner chamber, from the side of the rear wall of the unit. At the beginning of the smoke channel, a damper with a cut out 90-degree sector is mounted. In addition, around the gate (a metal plate that regulates the chimney draft) there is a gap of at least 10–15% of the chimney diameter. This design makes it possible to set the correct draft and at the same time does not allow carbon monoxide to enter the room, even if the smoke channel is completely blocked during intensive gas formation.

Increased requirements are placed on the buller's chimney

A horizontal section of the chimney extends from the outlet opening, designed to reduce the temperature of the combustion products, and then an elbow is installed that directs the pipe vertically. Here, at the "real" units manufactured by Bulerjan, a device for pyrolysis combustion of gases, called an economizer, is installed. The chimney must be high enough to obtain high-quality traction and insulated to prevent the combustion products from cooling down excessively.If this requirement is not met, as well as when using fuel with a high moisture content, the temperature in the afterburner will be reduced, as a result of which the content of tar and other unsafe carbon compounds in the flue gases will increase.

Refinement and modernization

Homemade Buleryan has an unattractive appearance, so it can ruin the atmosphere in the room by itself. Often, in order to correct this problem, the design is ennobled and modernized by welding design details or various forged elements onto the skeleton.

The main thing to understand is that high-quality air circulation is very important in the operation of this system, so all openings must be opened:

If the heating system is installed in a garage or greenhouse, then it is not necessary to ennoble it, it will not spoil the aesthetic appearance, and efficiency can be lost if the stove is overmodernized.

Distribution of heat in the rooms of the house

The use of Buleryan in multi-room buildings is ineffective, because it is not able to heat large areas. Most often, such systems are used in greenhouses, garages and sheds. But some owners install this stove in their dachas, using for this the distribution of warm air in several rooms in the house. In this case, the same wiring system is used as when installing the fireplace:

It should be remembered about the quality of ventilation in this case, it is best for a specialist in this field to handle the installation of warm air distribution.

Appearance improvement

By far the best way to improve and give an aesthetic appearance to Buleryan stoves is brick or stone masonry. The main thing is to leave all the holes open, both for the entry of cold and for the exit of hot air.

All oven channels are hidden

You can decorate the interior using bricks and a stove without embedding the structure itself inside the masonry, as they did in this solution:

Brick wall

In European countries, this stove is used as a decorative element, which can also be done in the case of a home-made structure by embedding it in a fireplace or overlaying the heating system with brickwork, as in the photo below:

Buleryan under the fireplace

Alteration of a potbelly stove for liquid fuel

Breneran is a converted potbelly stove, a stove with pipes welded on top to heat the air in the room. The alteration takes place in the same way as the manufacture of Buleryan, which is described in this article above.

Water circuit installation

In order to increase the efficiency of the heating system, a water cone is welded inside the solid fuel stove, which, when the water is heated inside, allows heating the batteries installed in the room. Such a firebox is very popular in rural areas, as they are solid fuel boilers for long burning. The disadvantage of such boilers is that the pipes inside which the water liquid is heated take some of the energy and reduce the efficiency of the furnace, but if you need to heat a large number of rooms, then this will be a more effective solution to the problem than heating them with warm air.

In order to properly install the water circuit, it is best to call a specialist or buy a ready-made system, into which you then install the water heating system yourself.Since the proper functioning of this type of heating requires a structure made taking into account certain inclination factors, the installation of a pump and a condensate outlet is necessary, it is best to entrust the installation of the water circuit to a professional.

But if you nevertheless decide to implement this heating system yourself, then the correct scheme of the water heating circuit is proposed below:

The device and principle of operation of the furnace

In the diagram, the device of the Buleryan furnace is as follows:

The device of the furnace is quite simple. Outwardly, it is a steel cylinder, from which curved pipes come out, square or round. The device itself is similar to a stove - a heater, on the basis of which the stove was originally made.

The entire operation of the Buleryan furnace is based on the principle of convection of air flows. The body of the structure is made of steel in the form of a boiler, for which some call the furnace a boiler. Thickness from 4 to 10 mm and covered with heat-resistant paint. The pipes are bent to 2/3 into the body, forming part of the main mechanism of the furnace. Inside the case there is a two-tier firebox, which is not protected by anything and its volume directly depends on the volume of the main cylinder. The combustion chamber is divided into two tiers by a perforated steel sheet: lower and upper.

The total area of the chamber, about 8%, is occupied by the upper section, in which the burning of volatile compounds coming from the lower chamber (furnace) is carried out.

The door for the combustion chamber, like the body itself, is made of durable steel, and in some models there is a heat-resistant glass insert in the door.The door itself is large in size, which allows you to put large firewood into the stove, and also closes tightly and has a reliable lock that will not allow the door to open during the fire. The air supply regulator with a movable throttle (smoke damper) located on the door allows you to adjust the traction force and select the appropriate operating mode for the stove, of which there are two in this model:

- Kindling mode.

- Slow burning mode.

The first mode allows you to quickly heat up the oven. The temperature is set in the combustion chamber, and the generated heat is evenly distributed over the entire heated area.

In the second mode, the chamber is filled with a large amount of firewood, which smolders as a result of setting the smoke damper to the minimum air supply. In this mode, one bookmark can smolder for 10-12 hours and at the same time heat the room.

The principle of operation of the Canadian stove is as follows: when kindling, the body of the stove heats up and provokes the drying of cold air through the pipes of the buller. Passing through the pipes, the air is heated to a high temperature and exits upwards through the exhaust outlets, due to which the room is quickly heated.

Scheme of the principle of operation of the Buleryan furnace

The cooled air again settles on the floor and again enters the pipes. In simple terms, the air circulation occurs constantly and, thereby, completely warming up the air in the room.

The movement of air masses occurs due to natural convention and does not come into contact with fire, passing through pipes, thereby maintaining oxygen saturation and comfortable humidity.