- The device and features of combustion

- Advantages and disadvantages of the Canadian stove

- Principle of operation

- Design features and principle of operation

- Is it possible to put buleryan in a residential building?

- Advantages and disadvantages of the Canadian stove

- General instruction

- What kind of wood to heat?

- Can other fuels be used?

- How to lay firewood correctly?

- How to reduce consumption?

- Optimum temperature

- General fire safety rules

- The principle of operation of the furnace

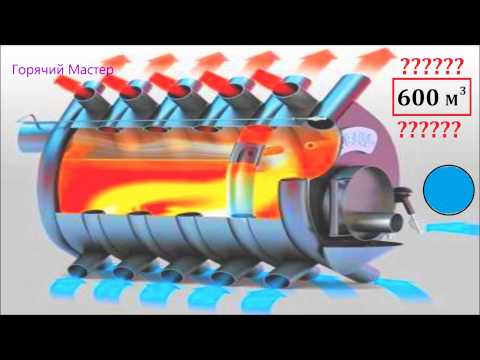

- Video: Buleryan power calculation

- Proper operation and maintenance of the oven

- The design and operation of the heating system (video)

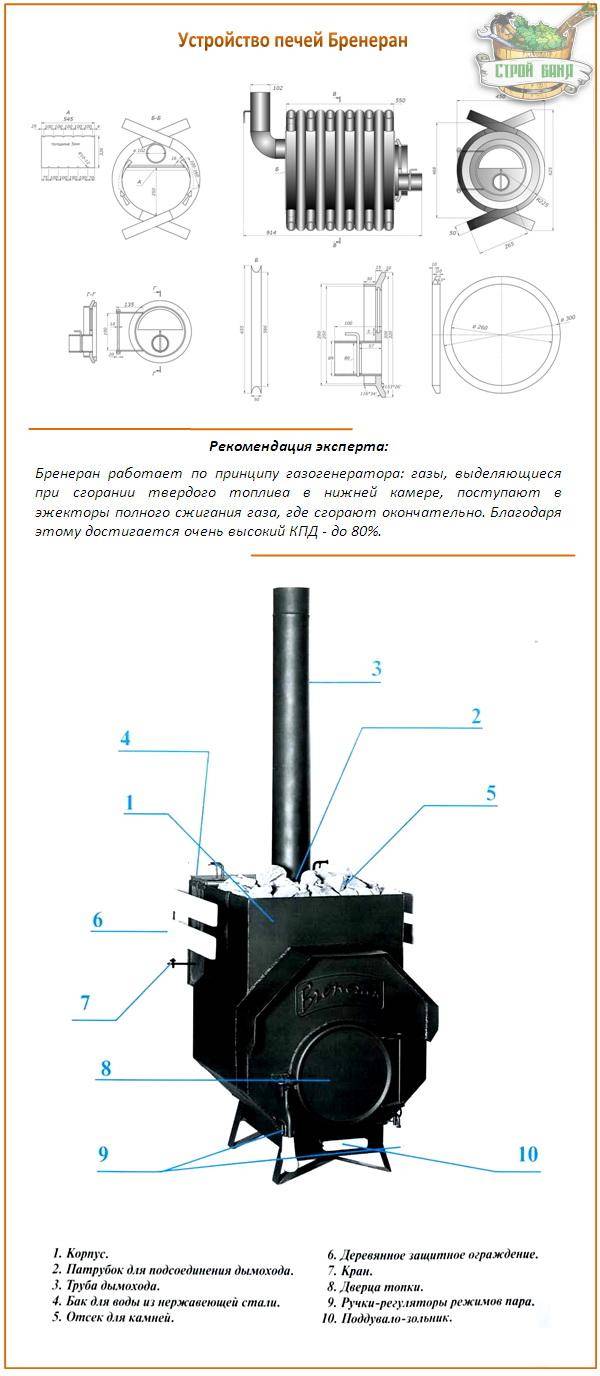

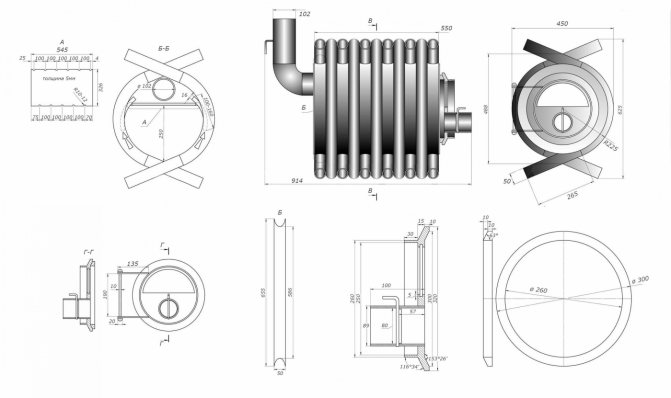

- Unit device

- We make buleryan ourselves!

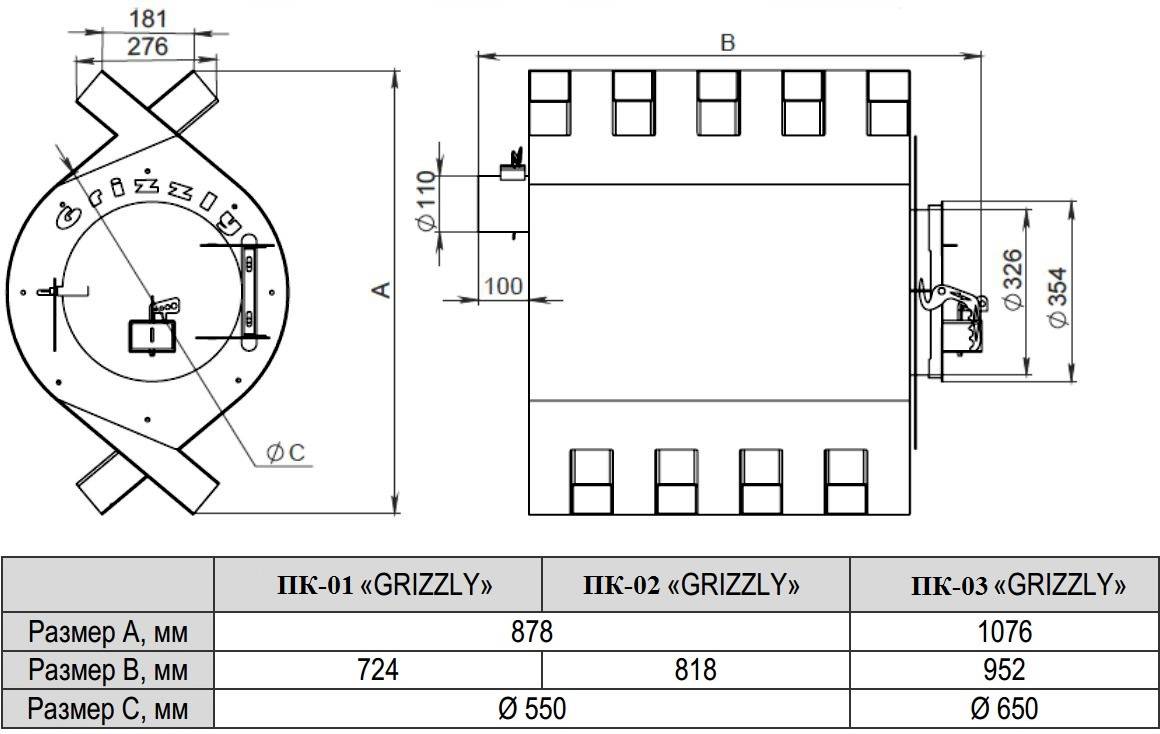

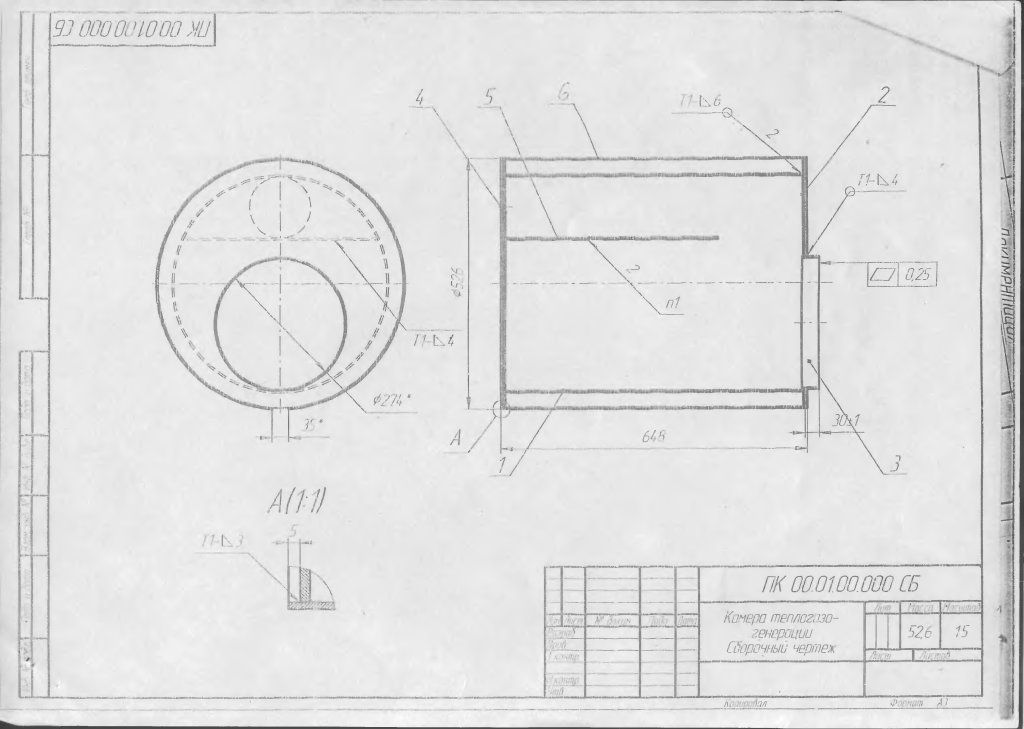

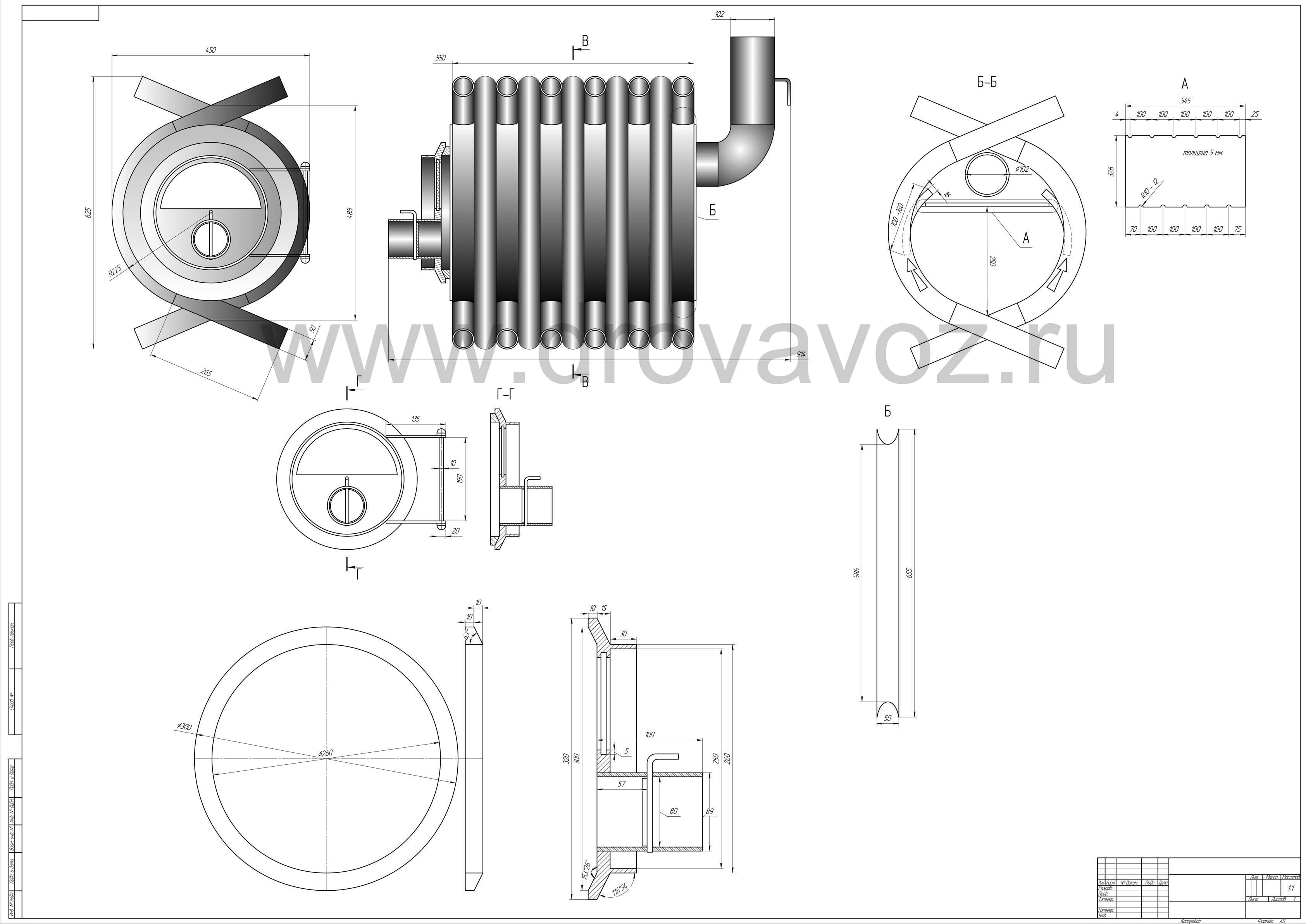

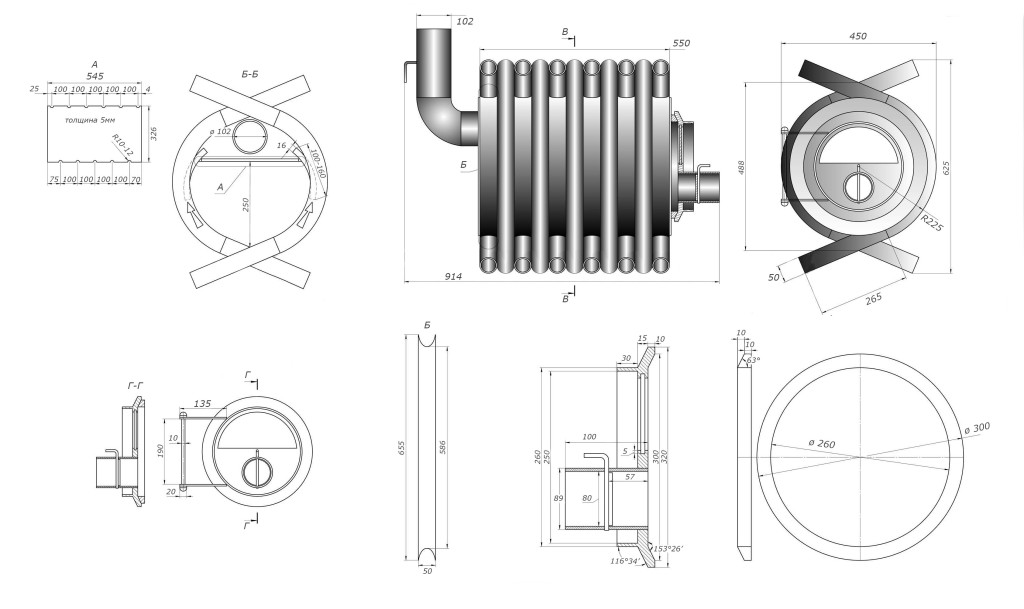

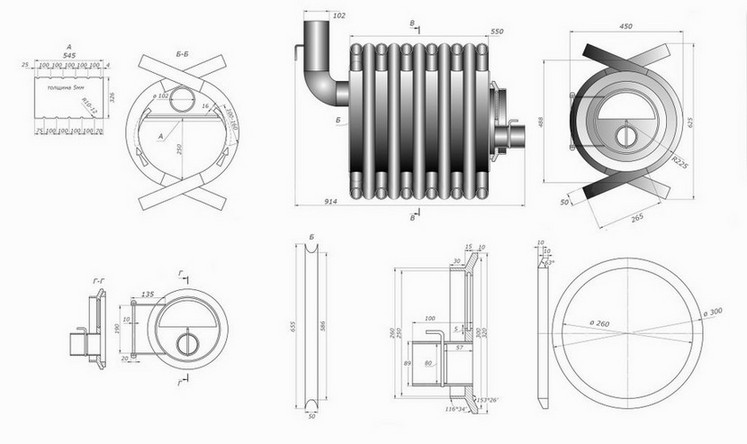

- Buleryan do-it-yourself drawings and photographs.

- The device of the future stove

- Manufacturing instructions

- Principle of operation

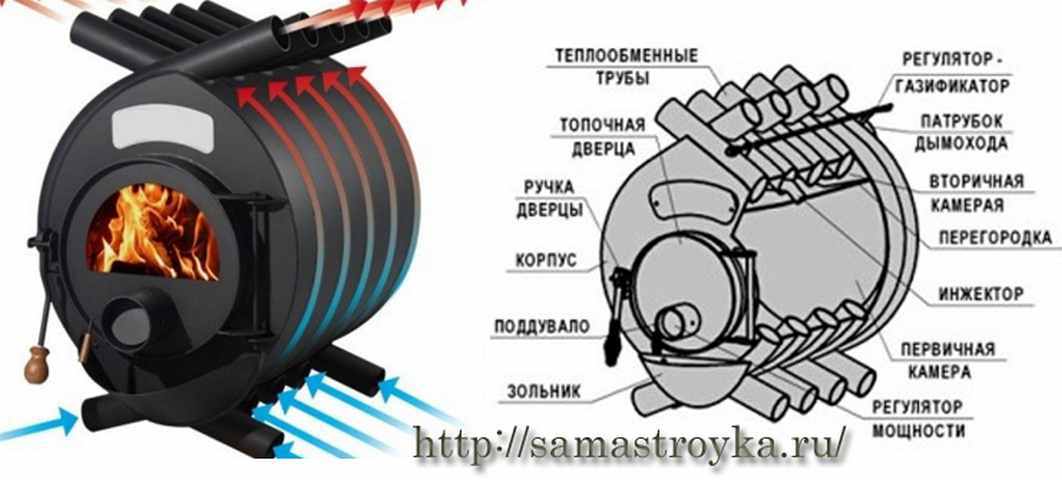

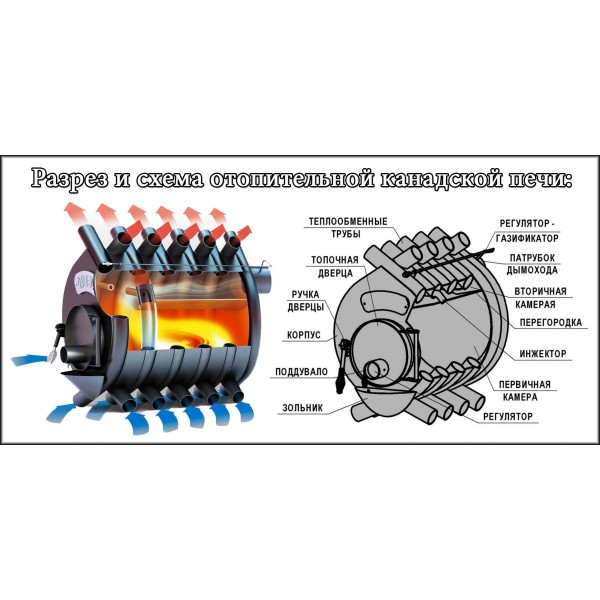

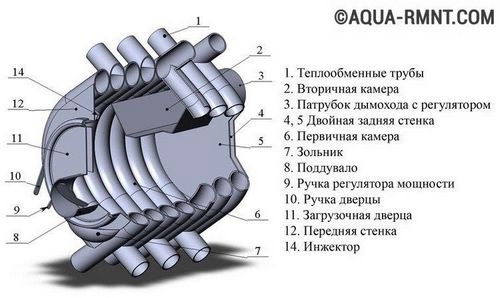

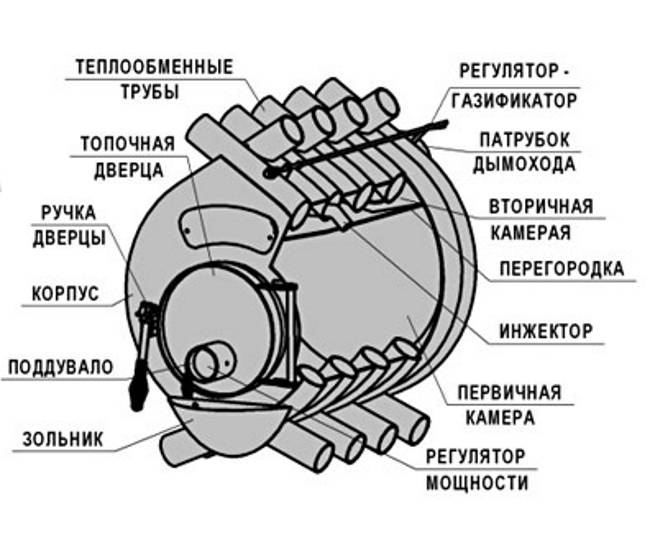

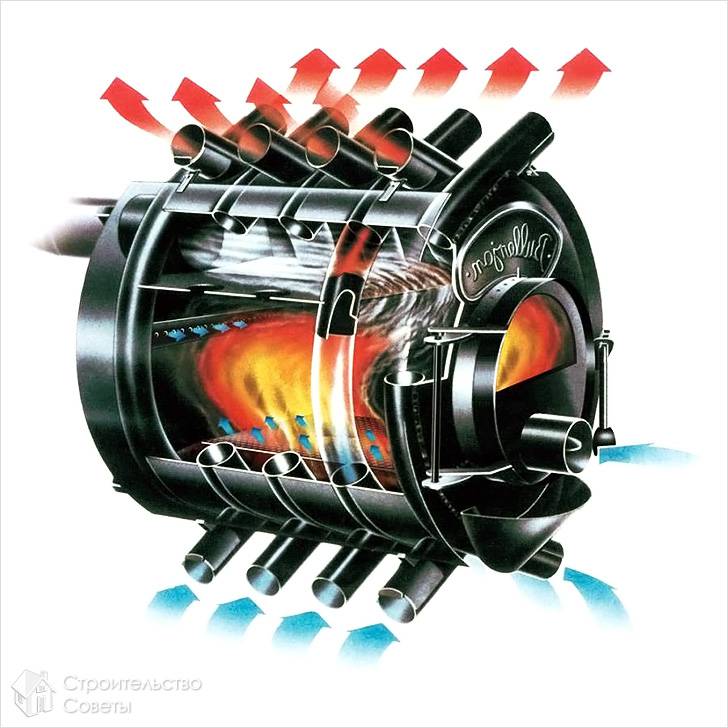

The device and features of combustion

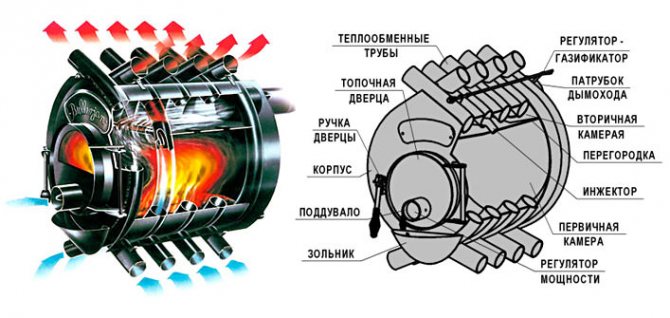

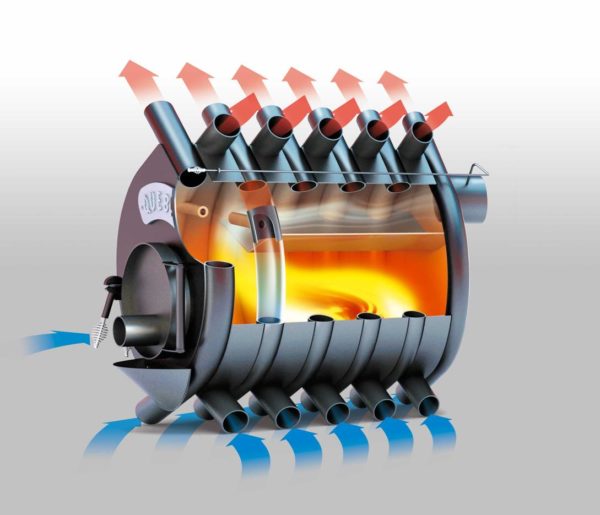

In fact, the Buleryan furnace is a seriously modernized convection-pipe air boiler. Its principle of operation lies in the conventional heating of air circulating through curved pipes built into the housing. To do this, sinusoidally curved pipes are mounted in its cylindrical body, protruding from the body by a third of its length. During operation, an air flow circulates through them: heated air goes up, and cold air mass is sucked into the pipes from below.

In the process of burning, 4-6 cubic meters of air passes through the pipes per minute, which heats up to 110-130 degrees.

The combustion chamber is divided into two chambers placed one above the other. In the main chamber, fuel burns out, from which carbon monoxide is released under the influence of high temperature. The latter burns out in the upper chamber, separated from the middle chamber by a cast-iron chariot or a steel grate. Oxygen for the combustion of carbon monoxide comes from a partition located above the oven door.

But in the upper part, carbon monoxide does not burn out completely, its complete combustion occurs in a horizontal section of a meter-long chimney, where it comes from the furnace. This is a mandatory design feature of all Buleryan furnaces. Here, the mode of afterburning of gases slows down a little due to their cooling.

After the chimney turns up, where the original Bullerian stoves have an economizer in which the carbon monoxide finally burns out. Thanks to the economizer, the efficiency of Buleryanov increases to 80%.

Advantages and disadvantages of the Canadian stove

In fact, being the same "potbelly stove", Buleryan has a special charm and charm, doesn't it?

The specifics of using the Buleryan furnace initially implied compliance with several mandatory requirements, which subsequently made the unit known throughout the world. The design of the heater should provide:

- Mobility. Since cutting down trees involves constant movement through the forest, the woodcutters' stove is constantly transported from one place to another, and is carried from transport to the premises by hand.

- Compactness. The unit must have a configuration and dimensions that make it possible to install the device in small temporary buildings.

- Safety. Since the operation of the buleryan provides for the installation of a heater directly in the residential area, its design should exclude the possibility of leakage of carbon monoxide. It was possible to make this possible due to the hermetic working chamber and the decision in favor of a single-door scheme. It is also important that the configuration of the body prevents accidental contact with the hot metal of the furnace body.

- Performance. The use of forced convection makes it possible to warm up the room in record time. This condition is met thanks to a system of channels that accelerate air exchange.

- Possibility of long work. The configuration of the working area and the design of the blower allows the buleryan to work for several hours from a single load of fuel, and firewood, bark, wood chips, shavings, etc. can be used as fuel. case overheats and deforms. As a result, the geometry of the device is distorted, the furnace door does not close, cracks in the places of welded joints.

- Simplicity and reliability. When developing the design of a solid fuel unit, the engineers took into account that it would be operated in places remote from civilization. For the manufacture or repair of a Canadian potbelly stove, special equipment or expensive materials are not required, and for a beginner to operate the stove, a little instruction is enough.

As you can see, the advantages of buleryan were incorporated into the design at the design stage. Perhaps the developers did not even suspect that their brainchild would become so popular and be used both in everyday life and in production.Of course, like any other design, a convection oven of this type is not without some drawbacks. First of all, the unit achieves the declared performance only when using absolutely dry firewood. When the moisture content of the fuel is more than 10%, the released water vapor prevents the flow of air and reduces the intensity of combustion, which leads to a decrease in efficiency. In addition, like any potbelly stove, Buleryan does not keep heat at all - it is enough for the fuel to burn out, as the temperature in the room begins to drop.

The model range of Buleryan type furnaces contains many types that differ in power and configuration

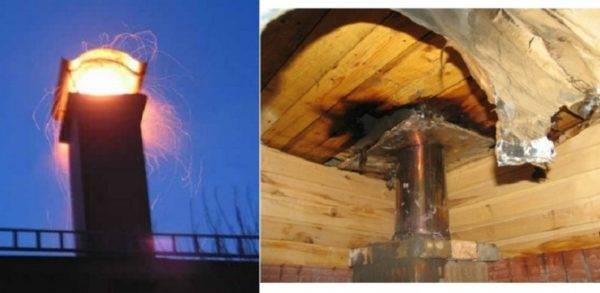

The disadvantages of the design include the fact that the operation of the furnace involves a gas-generating mode of operation, in which firewood smolders more than burns. This process is accompanied by increased smoke formation, which leads to the emission of harmful substances and tar deposits in the smoke channel. Often, the outer part of the chimney and nearby sections of the roof are covered with an oily substance, which does not add any attractiveness to the picture.

It is also important that when installing the stove, additional requirements are put forward for thermal insulation and the height of the chimney, otherwise its efficiency will be reduced.

As you can see, the unit is not without flaws, which are honestly pointed out by both the developers themselves and the owners. Nevertheless, the numerous advantages of buleryan made this heater one of the most popular units on the market for compact solid fuel equipment.

Principle of operation

The modern potbelly stove Buleryan is used in different areas - for heating a house, industrial or gardening buildings.Buleryan's well-thought-out device makes it possible to obtain maximum heat output from solid fuel. The Buleryan wood-burning stove works according to the following principle:

- The required amount of firewood is loaded into the firebox (you can add a little paper or ignition mixture to facilitate the process of engulfing in flames).

- After the fire flares up confidently, it is necessary to limit the flow of air.

- The process of pyrolysis occurs - ignition under the influence of a secondary air inflow.

Schematic representation of the principle of operation

The heat generated during the active process of smoldering and residual combustion of wood fuel, pyrolysis products, then enters the air heat exchanger. To ensure the complete tightness of the combustion chamber, the pipes at the base of the heat exchanger, if the furnace is assembled by hand, must be welded together with sheet iron.

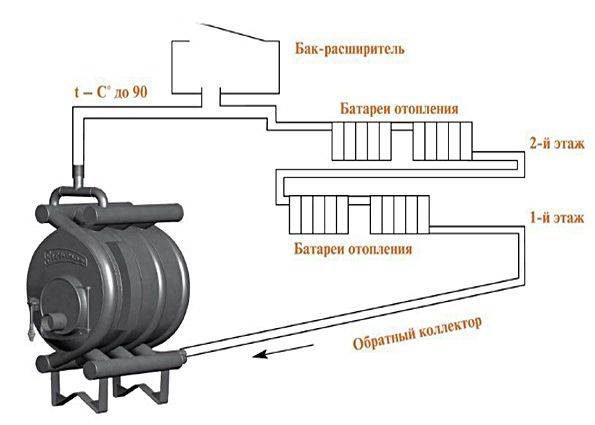

Important! The amount of heat generated by the unit is sufficient to create a fully functioning piping that heats other rooms or premises.

Incandescent gases under the action of fire give off thermal energy (up to 90%) into the curved pipes of the structure. If you correctly calculate the power of the furnace and the area of \u200b\u200bthe room heated by it, then you will need to add fuel 2-3 times a day.

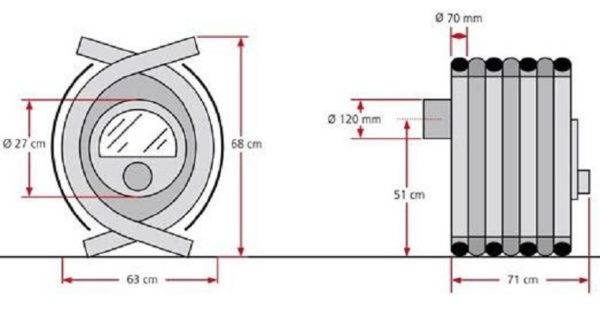

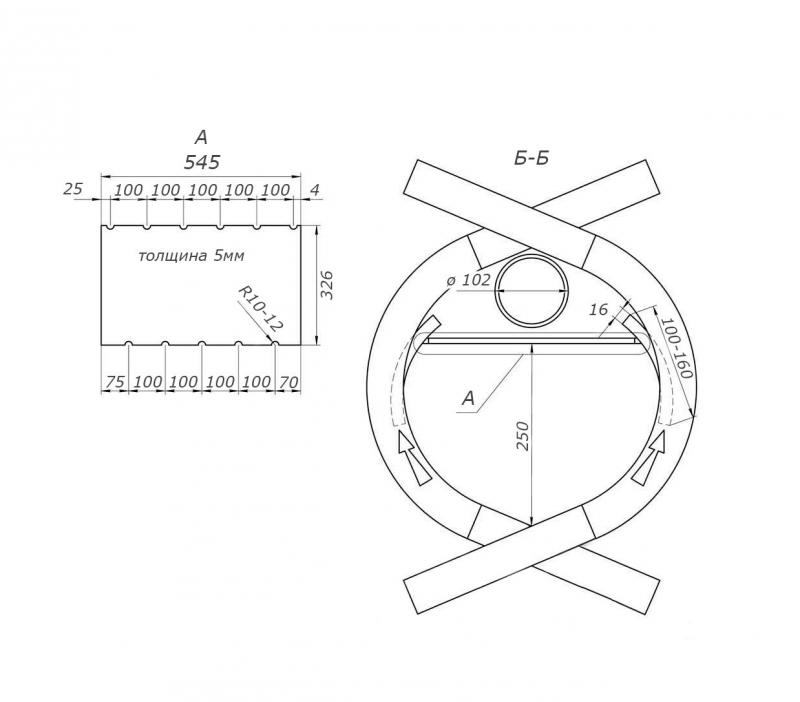

Design features and principle of operation

When developing Brenaran, Canadian specialists used the long-known design of a long-burning convection boiler, called a calorific oven. Due to the increase in the furnace door, it became possible to load not only chopped logs, but also parts of rhizomes, as well as large logs.The new form of the blower - in the form of a pipe cut into the loading hatch, made it possible to abandon the two-door scheme. To adjust the amount of air required for fuel combustion, a throttle was installed inside the blower - a round rotary damper. The throttle control lever brought out to the outside allows, if necessary, to reduce or increase the air flow, thereby controlling the power of the buleryan.

Buleryan construction

The furnace of the heating unit is a metal cylinder, on both sides of which tubular metal heat exchangers are cut in at regular intervals, bent in the form of knees. Due to the fact that two thirds of the diameter of the pipes are recessed into the body of the furnace and are in the combustion zone, the air receives up to 70% of the heat that is released during the combustion of firewood. The remaining kilocalories heat the body of the stove and are subsequently also spent on heating the room. Due to this distribution, the buleryan body usually heats up to only 60-65 ° C, while the air that leaves the convection channels has a temperature of more than 100 ° C. I must say that it is the high heating rate that ensures the active suction of cold air masses in the lower part of the tubular heat exchangers and their ejection from the upper openings of the heater.

The furnace space inside the device is divided into three chambers. In the lower part of the furnace at a height of up to ¼ of the diameter of the body, a metal hearth or a removable grate is installed. You can do without these elements, but with them it will be easier to light the stove and remove the ash.Under the vault of the firebox, at the same distance from the body as under, a perforated metal sheet is welded in, which does not reach the loading hatch for a quarter of the length of the buleryan. The upper chamber is designed for afterburning volatile compounds that are released during the operation of the unit in the gas generator mode.

Rapid air heating is provided by convection heat exchangers that make up the core of the furnace

The removal of combustion products occurs through the hole, which is located in the afterburner chamber, from the side of the rear wall of the unit. At the beginning of the smoke channel, a damper with a cut out 90-degree sector is mounted. In addition, around the gate (a metal plate that regulates the chimney draft) there is a gap of at least 10–15% of the chimney diameter. This design makes it possible to set the correct draft and at the same time does not allow carbon monoxide to enter the room, even if the smoke channel is completely blocked during intensive gas formation.

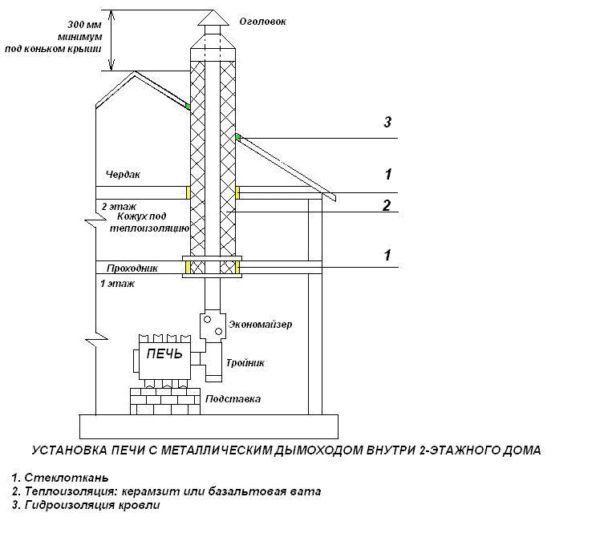

Increased requirements are placed on the buller's chimney

A horizontal section of the chimney extends from the outlet opening, designed to reduce the temperature of the combustion products, and then an elbow is installed that directs the pipe vertically. Here, at the "real" units manufactured by Bulerjan, a device for pyrolysis combustion of gases, called an economizer, is installed. The chimney must be high enough to obtain high-quality traction and insulated to prevent the combustion products from cooling down excessively.If this requirement is not met, as well as when using fuel with a high moisture content, the temperature in the afterburner will be reduced, as a result of which the content of tar and other unsafe carbon compounds in the flue gases will increase.

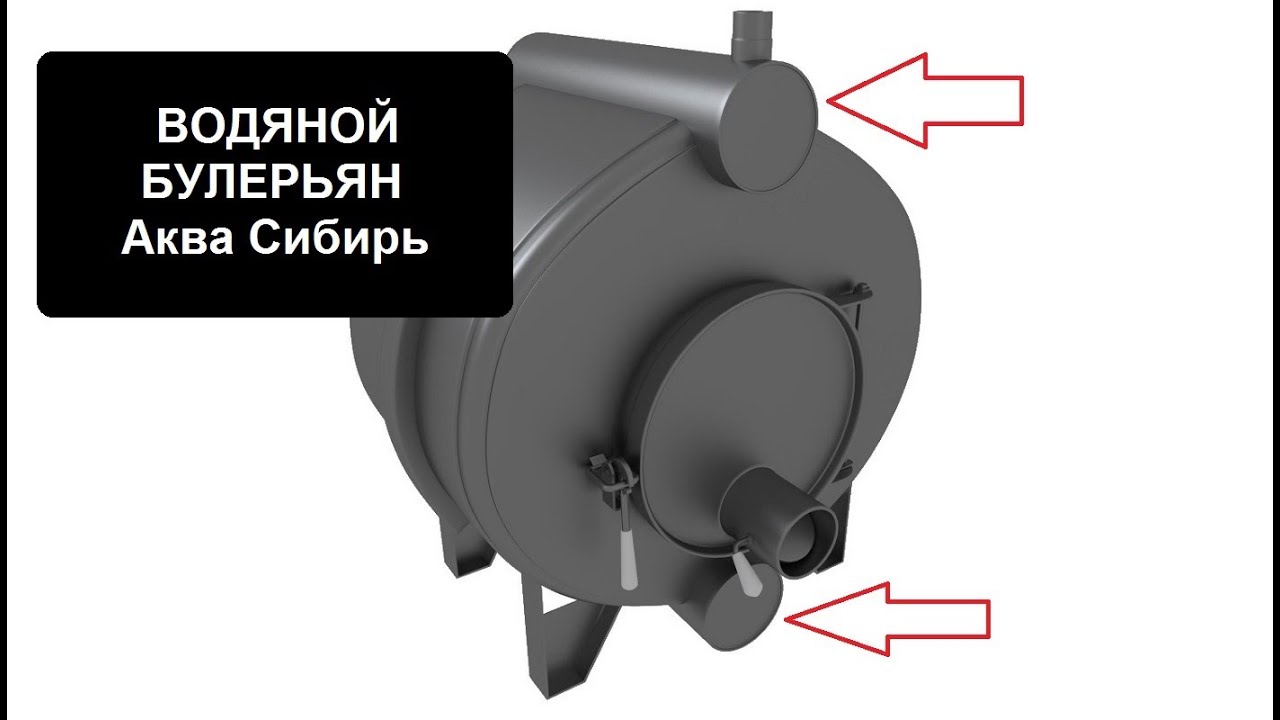

Is it possible to put buleryan in a residential building?

The technology of the pyrolysis process and the convection oven found its way into low-rise individual construction. Subject to all fire regulations and proper installation, buleryan is safe even for wooden cottages.

Such systems have existed for a long time, but initially they were used more for heating non-residential premises. Modern manufacturers have implemented solutions suitable for use in residential buildings.

Buleryan does an excellent job of heating a room in which there are no internal walls. The heat transfer indicators are significantly superior to traditional stove heating. Long combustion allows you to reduce the amount of fuel consumed. The efficiency is about 80%. This indicator is facilitated by the process of pyrolysis and convection heating.

The appearance of the stove is more in line with an industrial hangar. A non-standard interior solution will help. In the hands of a skilled designer in a residential building, such a stove can look very organic:

Modern manufacturers offer boilers of different capacities. Minimum - easily heats up to 100 m3. Exist systems for heating multi-apartment at home.

Advantages and disadvantages of the Canadian stove

The presented type of furnace has a huge number of advantages.

It is important to comply with the mandatory requirements and rules of operation. The following advantages can be distinguished:

- Mobility. When cutting trees, you need to constantly move through the forest.The stove can be easily transported, it is effortlessly transferred from transport to the room.

- Compact dimensions. The design has a different configuration, parameters and sizes. Thanks to this, the stove is installed even in small buildings, rooms.

- Safe operation. The device works in a residential area and a zone. The design must be airtight so that carbon monoxide gases do not leak through the gap. To prevent leakage, it is recommended to use a one-door scheme. The body is configured in such a way that a person cannot get burned.

- High level of performance. When used, the principle of forced convection is activated. The space warms up within a short period of time. All channels that are located inside must be carefully thought out. They help speed up the movement of air.

- Long burning. The working area has an optimal configuration, there is a blower, so the stove will work for 3-4 hours from one load. Wood shavings, chips, bark or firewood are suitable for the firebox.

It tends to overheat the metal surface, so the case begins to deform, burn out. As a result, the geometry is distorted, the furnace door warps and stops closing tightly. At the junctions seams by welding holes appear.

Experts have come up with a way to help use coal during the furnace. To do this, the furnace is additionally equipped with a collector, which is installed at the bottom, and the air supply is regulated by a blower. Thanks to such modifications, the temperature inside the furnace is reduced to a safe level. The design of the furnace is simple and reliable in operation.To carry out repairs or self-manufacturing of the furnace does not require large financial investments.

Appearance of the oven

Appearance of the oven

Before operating Buleryan, it is important to familiarize yourself with the shortcomings. The performance of the stove is significantly reduced if damp or wet wood is used for the firebox.

As a result of ignoring this requirement, water vapor is released, which worsens the intensity of heat release. The efficiency of the stove decreases and the room heats up slowly.

The design has a gas generating mode of operation. Firewood does not burn, but smolder after laying. As a result, a lot of smoke is formed, so harmful substances begin to be released. During installation and installation of the stove, it is necessary to ensure sufficient height of the chimney and its thermal insulation. Otherwise, the efficiency of functioning will decrease several times.

General instruction

Scheme of kindling Buleryan:

- Open the chimney gasifier.

- Open the blower damper.

- First put in wood chips or medium/large firewood, add some crumpled paper/newspaper;

- Light firewood, check combustion and close the stove door;

- Check for traction after 15-20 minutes;

- Approximately every 5 minutes, you need to cover the damper a little, but you cannot close it completely;

- During the kindling, do not leave the stove;

- When the temperature decreases, you can add the next batch of firewood (use only large dry firewood);

You can also watch a detailed video instruction for kindling Buleryan:

After some time of use, you will gain the necessary experience and melting buleryan will become an easy task.

Furnace fired up

What kind of wood to heat?

Before using the stove, you should figure out how to properly heat Buleryan with firewood, because not everyone can fit for this goals. For melting, any firewood of deciduous trees is suitable.

It is not recommended to use coniferous varieties, because of them the chimney quickly clogs. If you heat the stove with apple, pear, cherry, etc., little heat will be released.

The best fuel for buleryan will be oak or acacia due to its hardness.

An important condition is that the firewood should not be too wet.

Can other fuels be used?

- Coal. Buleryan stoves are accompanied by special operating and fire safety instructions. If you strictly follow this instruction, then it is forbidden to heat the furnace with coal alone, a large amount of heat from burning coal can fuse the metal. You can use brown coal, but only with firewood. Many sources on the Internet describe many ways to heat buleryan with coal, but you should not rely on them, these methods may not be safe.

- Working off. According to the instructions, mining cannot be fuel. Its use will lead to the burning of pipes and the failure of the furnace.

- Briquettes. Peat briquettes are an ideal type of fuel, they have good heat transfer and do not impair the performance of the furnace. Briquettes are difficult to purchase in a store, they are usually ordered on the Internet, but suppliers mostly sell only in large quantities, which is inconvenient for personal use.

- Sawdust, wood chips and tree bark. Kindling with sawdust, wood chips and tree bark is not prohibited - this is a good way to save money, allowing you to reduce the use of good firewood.In order to use this type of fuel, you must first kindle the stove with wood, and then add wood waste.

- Pellets. The method of melting with pellets is similar to that used for melting with sawdust, wood chips and bark. Since pellets are made from wood, they are also suitable for buleryan, but before that a special mesh is installed.

How to lay firewood correctly?

First of all, chips are laid for kindling. You can set it on fire using various means of ignition. After that, firewood is laid. The furnace operates in normal mode or in gas generation mode. Continuous operation in normal mode reduces the life of the boiler

It is important not to use damp firewood, as this will damage the chimney over time.

For a longer service life of the furnace, it is necessary to periodically clean it, for this it is enough to burn special briquettes if the chimney begins to clog.

How to reduce consumption?

- Use dry wood.

- Regularly clean the chimney.

- To heat the stove with firewood from acacia, oak and aspen - they are the hardest.

- Insulate the chimney.

Optimum temperature

Before purchasing a buleryan oven, you need to decide on its size. This affects how much area the boiler can heat. The period between laying firewood is large - 8-12 hours. To always maintain a comfortable temperature, it is enough to periodically add firewood.

The optimum temperature depends on the size, power of the furnace and the volume of the firebox. The principle of operation is similar to a conventional potbelly stove, but the efficiency is higher, so bulleryan will quickly warm up a large room.

General fire safety rules

- Do not lay too much firewood.

- During melting, do not leave the oven, constantly check the presence of traction.

- Do not use only coal as fuel, as this may melt the metal and spread the fire.

- Keep a close eye on the stove while burning.

- Clean your chimney regularly.

- Read the instructions carefully before use.

The principle of operation of the furnace

It is worth knowing what is interesting about Buleryan, the principle of which we will now consider. You might think that this is just a metal barrel with built-in pipes.

The Buller, or bullerjan, uses the newly popular fuel economy technology. Namely, pyrolysis.

True, how correctly it will be called a buller - pyrolysis, one can argue. Often, the buller is called pyrolysis, although this is only partly true. As in pyrolysis boilers, primary air usually passes through the fuel, from top to bottom. The thrust is forced and, accordingly, the design and equipment is different. In itself, this is the process of decomposition of wood under the influence of temperature. Volatile hydrocarbons, carbon monoxide and charcoal.

Video: Buleryan power calculation

Watch this video on YouTube

Watch this video on YouTube

Pyrolysis devices can be considered devices that burn pyrolysis gas in the secondary chamber. An isothermal process takes place in the primary chamber, with the release of heat and gases. Here we have similar processes, albeit not in perfect execution. Therefore, I might have called our experimental one a pyrolysis boiler, but I did not vouch for one hundred percent and did not argue. Since combustion processes, similar to those occurring in a buller, partly occur in simple furnaces. It is located in the middle, between a potbelly stove and absolutely pyrolysis-oriented devices.The air is heated thanks to an impressive battery of convector pipes. In which the air warms up quickly and circulates. Moreover, the air of the room is well mixed, due to the speed with which it breaks out of the exchangers.

Proper operation and maintenance of the oven

For quick kindling of the stove, finely chopped dry firewood is used, under which paper or cardboard is placed. After the ignition of the wood, the main portion of the fuel is placed in the buleryan. I must say that thick logs up to 40 cm long are ideal for this unit - they will give off heat for several hours. You should not warm up the furnace for more than 20-30 minutes with the damper fully open - the branderan is designed for smoldering fuel, so a large fire will simply carry away the lion's share of thermal energy into the pipe. In addition, a red-hot oven can warp or one of the welds will open.

After the firewood is completely flared up, the stove is switched to gasification mode, for which the gate and throttle are covered. The operation of the unit in the gas generator mode is evidenced by a small flame under the roof of the fuel chamber, which accompanies the process of combustion of the released gases.

The efficiency of the unit depends on how dry the wood is. Therefore, it is recommended to dry the fuel before laying. By the way, for this you can use the heat of the melted stove itself, if you lay another armful of firewood on the heat exchange pipes.

The versatility of the buller is manifested even when drying firewood

The smoke that fills the room when the potbelly stove is melted indicates one of the following errors:

- insufficient height of the chimney.Excellent traction characteristics will be provided by a pipe with a height of at least 5 m, while its upper cut must necessarily be located above the roof;

- the slide gate is closed;

- deposits of condensate and soot narrowed the smoke channel so much that the normal removal of combustion products became impossible. They need to be removed.

Pollution of the furnace during operation is manifested not only in the deterioration of traction. Deposits on the gate prevent its normal closing, and a layer of soot on the inner surfaces of the heating unit significantly impairs heat transfer.

In order to clean the buleryan, several methods are used, one of which involves burning resins and soot. Experts do not recommend burning the unit, as this is associated with heating the furnace and chimney to too high a temperature. In addition, the process is often accompanied by uncontrolled ignition and the release of burning residues onto the roof.

Cleaning by burning soot threatens with big trouble

It is best to clean the buller and chimney using the old methods, using metal brushes and scrapers. Dirt and oily deposits from the chimney are removed by first removing the flange in its lower part. The inner surface of the combustion chamber can be brought into proper shape with a small paint spatula or chisel.

The design and operation of the heating system (video)

Difficulties in the manufacture of the Buleryan furnace may arise not due to the structural complexity of the unit, but due to the lack of necessary skills when working with welding and metalwork equipment. Nevertheless, do not despair prematurely - part of the work can be done independently, and the most complex and responsible stages can be entrusted to professionals.Even despite the additional costs, the cost of a hand-made heater can be reduced by two or more times compared to factory products.

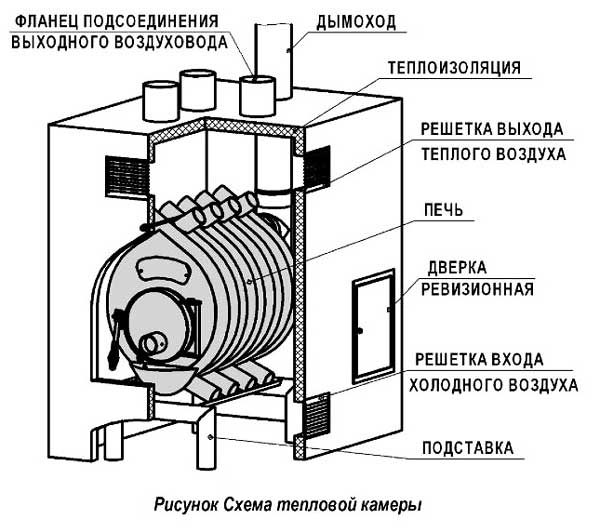

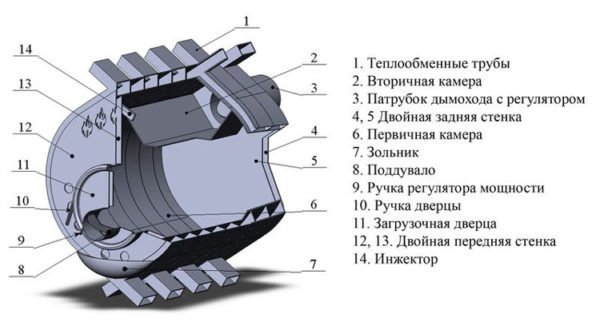

Unit device

Device diagram

The basis of the product is a scheme of a steel convection-pipe slow-burning air boiler. Sometimes it is called a furnace-heater type device.

Buleryan consists of the following parts:

- Fireboxes. Heat exchangers are deepened into its walls by 2/3 of the diameter. At the same time, 70% of the heat released in the furnace during smoldering is transferred from the air to the tubes. And 10% is distributed over the furnace and heats the air.

- Doors that close tightly.

- Blower type pipe.

- Throttle. With it, you can adjust the power of the device, and when it overlaps, the stove goes out.

- Grids made of cast iron. When the product is being installed, they are placed at the bottom at a level slightly more than half of the furnace.

- Partitions located horizontally. It is welded from the top by a quarter of the height of the firebox and at the same time reaches the front side by a fifth of the entire size of the firebox. This jumper has holes with a total area of 7%.

We make buleryan ourselves!

Buleryan do-it-yourself drawings and photographs.

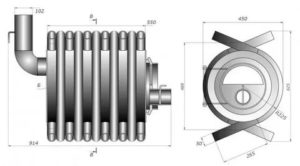

Profile pipes 60/40 mm 3 mm thick were taken as the basis, round ones could be used, but there was no pipe bender at hand and I wanted originality.

Long burning wood stove

The dimensions of the profile pipes were not chosen by chance, the area of the profile pipes 60 mm on 40 mm, is equal to the area of a round pipe with a diameter of 80 mm, namely, such pipes are used by the Buleryan brand furnace.

If the pipes are larger in diameter, the draft will be smaller and the room will warm up longer, but we need the room to heat up quickly with a minimum amount of firewood and there should be air circulation in the room.

Do-it-yourself wood burning stove

I welded the pipes to each other according to the pattern, on the floor in the garage I screwed two boards with a distance between them of 360 mm, so that all my workpieces were the same width.

Potbelly stove in the garage

Homemade potbelly stove of long burning

after I welded seven such blanks, I began to weld them together

it is best to do this on a flat surface, avoiding distortions. Be sure to watch so that nothing goes astray and everything is welded together neatly.

Long burning furnaces

after we welded all the pipes together, we get the skeleton of our future stove, here you can go in two directions to weld iron from the outside of the skeleton or from the inside, in our case, the iron was welded onto the skeleton of a home-made buleryan so that the cold air warms up quickly and once again does not burn on our stove.

Buleryan do it yourself

Do-it-yourself buleryan oven

In addition, the appearance is much more pleasant when the skeleton of the Buleryan stove is not visible.

5 mm steel was used for plating the skeleton, in order to bend the steel sheet without using the strength of the hero, it is necessary to make an incision on the fold line

Garage stove

Heating in the garage

garage oven

What is Buleryan famous for? the fact that this is a long-burning furnace, it can work in smoldering mode. The smoldering mode of fuel (firewood) is regulated by a damper on the front of the stove.

How to make a potbelly stove buleryan with high efficiency? Everything is very simple, do not let your heat and firewood fly out into the chimney, you need a partition in front of the chimney

Do-it-yourself garage oven

in this way we get two combustion chambers and before the smoke, unburned particles go outside, we need to overcome our partition.

Here the fun begins, everyone asks the question how to make a stove with high efficiency and low fuel consumption? On this partition, which serves as a division of the combustion chamber into 2 sections, we install a pipe with air suction

Do-it-yourself buleryan furnace drawings

all the particles that we did not burn out in our potbelly stove before flying out into the chimney, they burn out in the second combustion chamber when an additional air channel is supplied there. The air supply is carried out from below the pipes, but it is best to provide for manual adjustment of the air supply for complete combustion of particles.

This adjustment was made by welding nuts onto our tube, if a lot of air enters and the particles that remain do not ignite and do not burn out, but fly out into the pipe, the air supply should be reduced by tightening the bolts into them.

Do-it-yourself long-burning stove

The bottom of our homemade buleryan was also made from a 5 mm steel sheet, cutting it out under our pipes, then scalding it around the pipes.

Then you need to make a damper for air suction, it was made from a pipe, a huge bun with a diameter the same as the pipe and a nail to open and close the damper. With this damper, you can control the smoldering mode in the furnace. When the damper is open, the oven operates normally.

Homemade damper for air suction and air supply adjustment.

In order for the door to the stoves from high temperatures not to lead, it is necessary to weld a protective screen. The heat-resistant screen was made of 5mm steel.

Heat-resistant screen for Buleryan oven

Heat-resistant screen for Buleryan oven

The chimney must be made from a 120mm pipe, no less! This is necessary for good traction.

IMPORTANT to remember for better air circulation through the buleryan it needs to be installed at least 14 cm from the floor, then the air intake will be the best, forming good traction from profile pipes

The device of the future stove

The Buleryan furnace, also called the Breneran furnace, is a solid fuel heating system that is simple to implement: it can be assembled by anyone who is friends with metal material and knows its basic properties. Of course, working with iron requires a certain accuracy, unlike wood and concrete materials.

This type of furnace assumes a gas-generating type of wood combustion, that is, combustion products emit pyrolysis, which is sent to the afterburner and, together with secondary air, completely burns out. The final product of combustion is sent through the chimney to the open air, leaving behind condensate.

The design of the Buleryan furnace consists of several parts:

- The combustion chamber is the most spacious part of the stove, it works as the main combustion chamber for firewood, which is stacked on convection pipes;

- Afterburner - a sheet of iron that separates the upper quarter from the common chamber, in this part the combustion products burn out;

- A pipe convector is a part of a device made of several curved pipes that are in direct contact with combustion products (wood, coal, gases);

- Solid fuel loading door - with the help of this part of the structure it is possible to load firewood, it is also a regulator of the amount of oxygen supplied into the system;

- Chimney - a part of the furnace responsible for collecting condensate and exiting the final combustion products outside the system.

- Injectors - tubes responsible for supplying secondary air;

Such a simple device of this heating system made the Buleryan stove very popular among fans of making various designs with their own hands. The simple principle of operation, ease of manufacture and efficiency of the system also contributed to the wide distribution of this furnace.

Manufacturing instructions

First, a design drawing of the heating system is being prepared, which can now be found and freely downloaded on the Internet.

The algorithm for making buleryana using available metal processing methods consists of the following steps:

- The basis for the future stove is being prepared.

- An iron pipe for the chimney is welded, and it must be borne in mind that the size of the minimum diameter of the duct must be at least sixty millimeters. This is due to the ratio of heat capacity to air viscosity.

- A mount is prepared for the exhaust pipe, which is fixed with anchors to the wall.

- The rear wall is welded onto a prepared wide iron pipe;

- A soot chamber is welded in the form of a metal corner as in the drawing;

- Two round holes are made for the pipe, for exhaust from the main large pipe into the soot chamber.

- A draft regulator is created in a pipe intended for exhaust. To do this, two small holes are cut out in it, into which a piece of reinforcement is inserted. An iron valve in the shape of a crescent is welded to it.Outside the “body” of the buleryana, the outgoing reinforcing pipe must be bent, and made into the shape of a handle.

- The heating oil grate inside is welded from the eighteenth armature.

- A gas chamber is being made; for this, two afterburner nozzles are assembled. The upper part of the main chamber must be separated with a sheet of metal from the lower part, leaving an indent of two centimeters in front. We weld two nozzles into this gap along the edges of the iron sheet, which will also serve as the legs of the boiler.

- The front part of the boiler base is welded with the same metal sheet as the back.

- From above, around the main body of the future buller, iron sheets are welded in a semicircle. They will serve as side convection guns.

- At the next stage, the deflectors of the rear gun are welded.

- The front bearing frame of the future door is being welded.

- Windows are cut from the profile pipe.

- The door is made of a heat-reflecting plate with a heat-resistant seal so that the door does not lead during direct operation.

- The door handle must be welded in the center.

- A blower regulator is welded into the ash drawer. It will be controlled by opening the door.

On this, in principle, we can consider the stove ready for work.

Principle of operation

The furnace is a one-piece body, consisting of a barrel-shaped steel structure. A two-level firebox and a set of pipes are integrated into it, the latter are placed in the direction from bottom to top towards the stove. At the bottom, a cooled air intake is formed, and at the top, hot air enters the room. This design eliminates the main problem, which is air injection, since there is a temperature difference between the outlet and inlet.

Based on these facts, this stove is a truly reliable and efficient firebox. Buleryan is especially popular in workshops or garages up to 40 m2. With a ceiling height of 2.5 m, such a unit is able to warm the air to a comfortable temperature in just 25 minutes. It seems that it is no longer necessary to argue in favor of buying a buleryan oven. This unit can become a reliable assistant in heating both small and large rooms.

Buleryan, in fact, combines the practicality of a potbelly stove and a wood-burning stove. As mentioned above, the operating principle is based on a forced convention. At the bottom of the furnace there are special holes through which a cold stream passes from the room. As it moves through the pipes, it quickly heats up, as it comes into contact with the firebox. Warm air comes out. One of the features of the stove is that the product of burning wood does not immediately come out. It enters another chamber, where re-combustion takes place, but only at a higher temperature.

The high temperature of convection air allows heating rooms of almost any size. If you have a heating system with a liquid heat carrier, then the Buleryan stove can be combined with it

But for this it is important to make accurate calculations and properly install twin heating system