- How the Buleryan oven works

- Video - Overview of the Buleryan furnace

- Proper operation and maintenance of the oven

- The design and operation of the heating system (video)

- Do-it-yourself buleryan oven: sequence of actions

- The specifics of the installation of the furnace in the bath room

- How to make a stove stand

- Major faults and repairs

- Safety

- Advantages and disadvantages of the Buleryan oven

- How is buleryan arranged?

- The principle of operation of the furnace

- Video: Buleryan power calculation

- Helpful Hints for Operation

- Design features and principle of operation of the Buleryan furnace

- Manufacturing instructions

- We prepare tools and materials for work

- Advantages and disadvantages of the furnace

- The structure of the Buleryan furnace and the principles of operation

- Advantages and disadvantages of the heating system

- Do it yourself?

How the Buleryan oven works

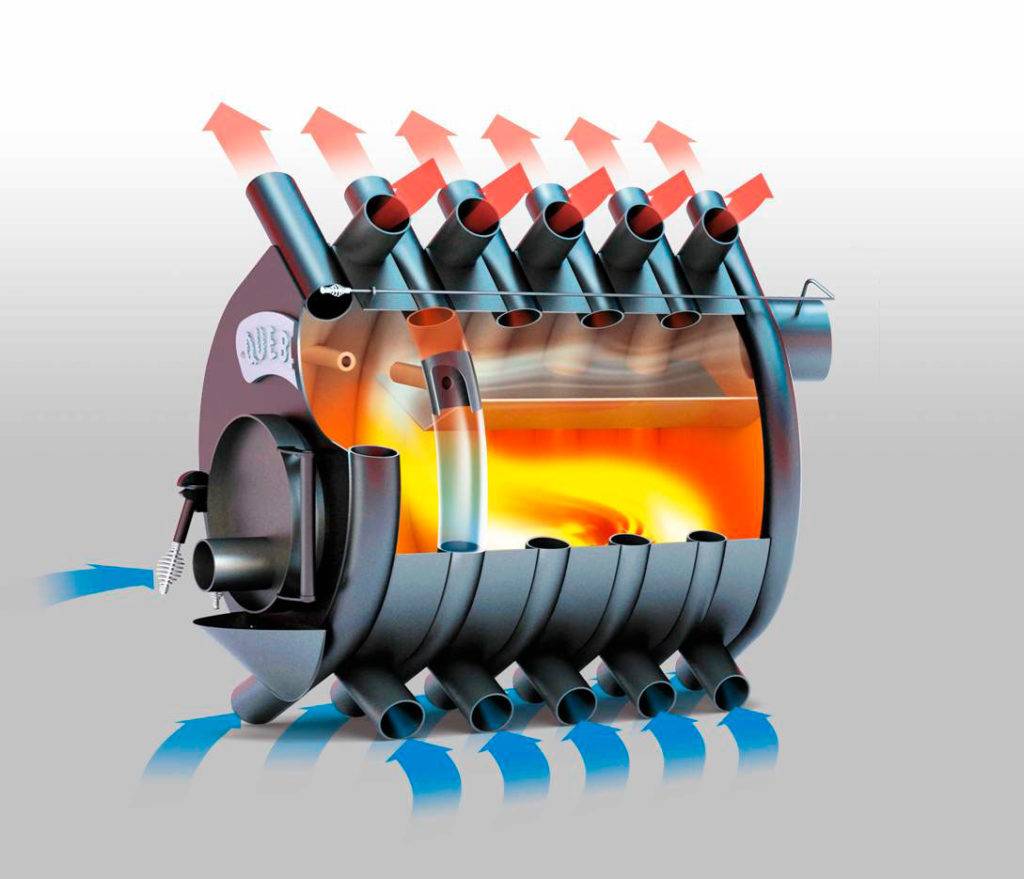

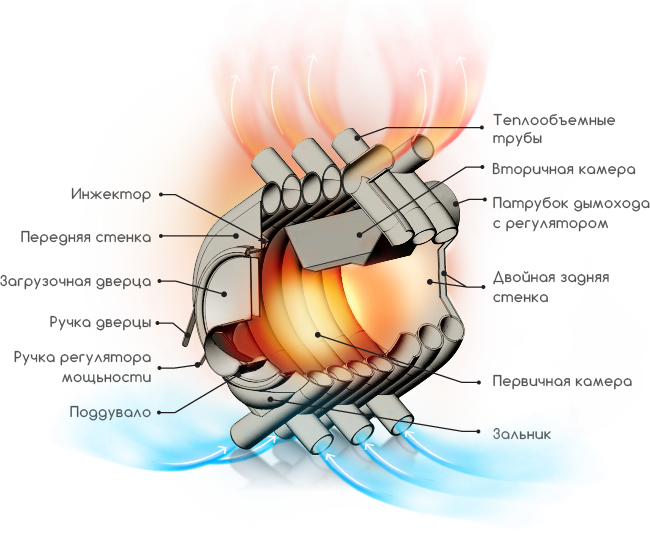

The functioning of the furnace unit in such a design is remotely similar to the operation of a gas boiler. The furnace consists of a pair of chambers. In the first chamber, fuel slowly smolders, forming completely unburned gases. They burn out already in the next chamber, which provides forced air supply through installed nozzles.

How to make buleryan

Thanks to the “double” combustion, there is almost no waste left, and the efficiency exceeds 80%.

There are three possible methods for adjusting the temperature:

- using a gate (regulator) installed on the door;

- by means of a gate fixed on the chimney;

- a combination of the two previous methods, which allows you to comprehensively control the air supply.

How the Buleryan oven works

As already noted at the beginning of the article, one of the design features of the Buleryan can be called special tubes recessed into the combustion chamber by two-thirds of its diameter. This ensures rapid heating of the room.

Such furnaces perform two functions at once:

- quickly heat up the air to the required temperature;

- maintain this temperature for a long time.

Moreover, they do not dry the air and do not heat up during operation.

Buleryan

Video - Overview of the Buleryan furnace

Proper operation and maintenance of the oven

For quick kindling of the stove, finely chopped dry firewood is used, under which paper or cardboard is placed. After the ignition of the wood, the main portion of the fuel is placed in the buleryan. I must say that thick logs up to 40 cm long are ideal for this unit - they will give off heat for several hours. You should not warm up the furnace for more than 20-30 minutes with the damper fully open - the branderan is designed for smoldering fuel, so a large fire will simply carry away the lion's share of thermal energy into the pipe. In addition, a red-hot oven can warp or one of the welds will open.

After the firewood is completely flared up, the stove is switched to gasification mode, for which the gate and throttle are covered. The operation of the unit in the gas generator mode is evidenced by a small flame under the roof of the fuel chamber, which accompanies the process of combustion of the released gases.

The efficiency of the unit depends on how dry the wood is.Therefore, it is recommended to dry the fuel before laying. By the way, for this you can use the heat of the melted stove itself, if you lay another armful of firewood on the heat exchange pipes.

The versatility of the buller is manifested even when drying firewood

The smoke that fills the room when the potbelly stove is melted indicates one of the following errors:

- insufficient height of the chimney. Excellent traction characteristics will be provided by a pipe with a height of at least 5 m, while its upper cut must necessarily be located above the roof;

- the slide gate is closed;

- deposits of condensate and soot narrowed the smoke channel so much that the normal removal of combustion products became impossible. They need to be removed.

Pollution of the furnace during operation is manifested not only in the deterioration of traction. Deposits on the gate prevent its normal closing, and a layer of soot on the inner surfaces of the heating unit significantly impairs heat transfer.

In order to clean the buleryan, several methods are used, one of which involves burning resins and soot. Experts do not recommend burning the unit, as this is associated with heating the furnace and chimney to too high a temperature. In addition, the process is often accompanied by uncontrolled ignition and the release of burning residues onto the roof.

Cleaning by burning soot threatens with big trouble

It is best to clean the buller and chimney using the old methods, using metal brushes and scrapers. Dirt and oily deposits from the chimney are removed by first removing the flange in its lower part. The inner surface of the combustion chamber can be brought into proper shape with a small paint spatula or chisel.

The design and operation of the heating system (video)

Difficulties in the manufacture of the Buleryan furnace may arise not due to the structural complexity of the unit, but due to the lack of necessary skills when working with welding and metalwork equipment. Nevertheless, do not despair prematurely - part of the work can be done independently, and the most complex and responsible stages can be entrusted to professionals. Even despite the additional costs, the cost of a hand-made heater can be reduced by two or more times compared to factory products.

Do-it-yourself buleryan oven: sequence of actions

-

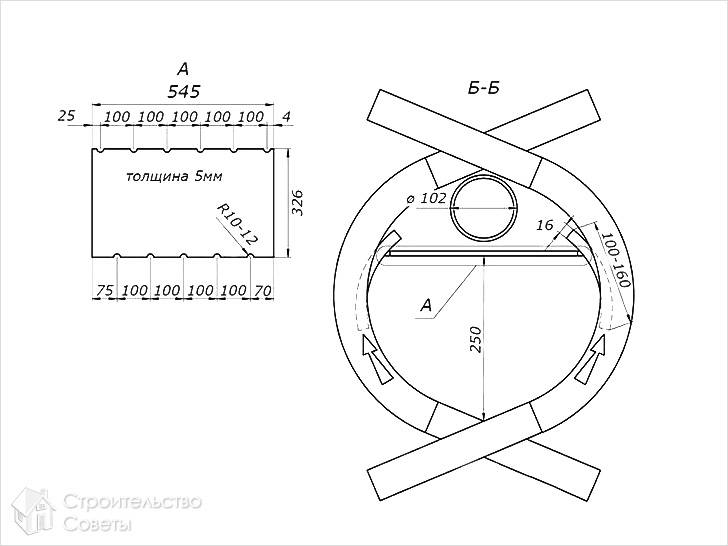

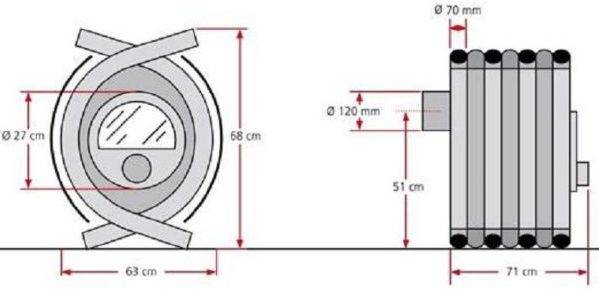

Equal segments of a metal pipe with a diameter of 45-50 mm are taken in the amount of 8 pieces and bent in the middle part with a pipe bender at an angle of approximately 80 degrees. For a medium-sized oven, pipes 1-1.5 m long are sufficient. Then, by welding, curved convection pipes are connected into a single structure. They need to be welded symmetrically, with the outlet part outward.

-

The resulting heat-removing structure will simultaneously play the role of a frame. Accordingly, strips of metal 1.5-2 mm thick are welded onto the pipes, which will become the furnace body.

-

A metal plate located horizontally should be welded inside the housing. This plate will become the floor (tray) of the furnace compartment and firewood will burn on it. Therefore, it is better to choose metal for this plate with a thickness of at least 2.5 mm. To facilitate the cleaning of the oven, it is best to weld the pallet from two halves located at a large angle to each other.To make it easier to fit the pallet of parts into place, first you need to make patterns from cardboard, and only then just start working with metal.

-

Production of the front and rear walls of the furnace. Start this stage with the preparation of a cardboard pattern based on the actual dimensions of the oven. The easiest way is to attach a sheet of cardboard to the sidewall of the oven and circle around the perimeter with a pencil. The walls of the heating device are cut directly from the sheet metal template. For the front wall, you will need to cut a window for loading fuel. The diameter of this window should be approximately half the diameter of the furnace, the center of the hole should be shifted slightly below the axis of the structure itself. Along the perimeter of the window, we weld a ring from a strip of sheet metal 40 mm wide from the outside.

- The rear wall is made in the same way, only the hole should be located in the upper part of the wall, and its diameter should correspond to the diameter of the outlet pipes. Both walls are welded to their seats.

-

Furnace door. It is made of sheet metal cut to the diameter of the window in the front wall of the stove. A narrow strip of metal is welded onto the metal circle around the perimeter, which improves the tightness of the door. In addition, it is necessary to cut a hole to the door cover and weld a blower with a valve into it.

- On the inside of the door, you will need to install a heat-reflecting screen, for which a semicircle of the appropriate diameter is cut out of metal and welded into the inside of the door on metal spacers.

-

The door is suspended on metal hinges welded to the outer wall of the furnace.You can use either industrial-made hinges, or construct them yourself from scraps of metal. The same applies to the bottom door lock.

-

Chimney. The T-shaped outlet-chimney is mounted on a hole in the rear wall of the furnace. To create it, a piece of metal pipe with a diameter of 110 mm is taken of the required length. At the height of the outlet in the rear of the furnace, a cut is made in the pipe to install a tap with a valve.

The valve itself can also be made by hand. To do this, a metal circle is cut out along the inner diameter of the branch, and a hole is drilled in the branch itself so that the valve axis can be inserted horizontally into it. After that, the whole structure is assembled and welded. Another rod is welded onto the outer part of the axis, which becomes a handle. This handle will need to be equipped with either wooden or heat-resistant plastic lining.

Now it's enough just from the leftovers pipes to make metal legs for ovens.

Feet for oven

At the same time, it is important that the body of the buleryan furnace is located at a height of at least 30 cm from the floor level. This will increase the draft in the convection pipes, which will ensure greater efficiency of the entire heater.

The specifics of the installation of the furnace in the bath room

The Buleryan stove, like any device of this type, poses a fire hazard and a danger to human health. With this in mind, the requirements for the safety of the installation must be strictly observed.

- The place for installation in the bath is selected based on the following standards: the distance to elements of flammable materials must be at least 100 cm.If the wall is covered with plaster with a thickness of 2 cm, then this limit is reduced to 80 cm.

- The floor covering in the installation area of the stove must be made of non-combustible materials, and the size of this area is at least 1.3 m. The best ways to meet the requirement are a brick base or metal sheet.

- When installing the stove between the steam room and another room, the opening in the partition must be made of non-combustible materials in such a way that the distance from the stove to combustible elements is at least 50 cm.

Special requirements are put forward for the arrangement of the chimney. Gases having a high temperature pass through it, as a result of which the walls of the pipe are noticeably heated. Combustible materials may ignite if they come into contact with them. To avoid this, a gap of at least 30 cm is maintained, and additional thermal protection is mounted at the points of passage through the ceiling and roof.

In the inner channel there should be no obstacles for smoke: protrusions, bumps. In addition, its sharp cooling in the pipe reduces traction. With this in mind, thermal insulation is applied to the chimney at the intersection of the attic.

How to make a stove stand

The stand features include:

- It improves air circulation in the room.

- Increases convenience when kindling and laying firewood.

- It will be easier to clean the ashes in the oven.

- The level of fire safety is increasing.

In addition, the stand will be required in the case when the oven will be installed indoors. With its help, it will be easier to make a chimney.

To get a stand of the required size, you need to measure the length and width of the oven and add 3 cm to these parameters. The height of the stand can be completely different.

We turn to the manufacture of the stand. The drawing shows the dimensions of the stand, which is made of pipes and corners.

With the help of a bolter and a circle for metal, we cut off pieces from a pipe of the same length 4 pieces. These will be the legs of the structure. The tops of the legs must be cut obliquely in the same way so that it is easier to weld the crossbars to them.

Next, we cut two identical trimmings for the horizontal crossbars and also cut obliquely from both ends.

Trimmings from the corners will serve as horizontal crossbars.

Now let's move on to welding the structure. All parts must be welded together with high quality and reliability.

This is the easiest and most common way to make a stand.

The stand for the oven is ready. Now it remains only to install the oven on it.

Major faults and repairs

The most serious breakdown of the Buleryan furnace is the burning of one or another part of it. You can fix such a malfunction by welding the damaged part.

There are also other errors:

- Lack or lack of traction. This malfunction is caused by clogging of the chimney, its low height or too tightly closed doors and windows of the room. It is necessary to clean the chimney, open the window. If it does not help, you will have to increase the chimney.

- The oven smokes. Also, the reason may be in closed windows or a clogged chimney. Additional air suction is also possible. To solve the problem, it is necessary to open the window, clean the chimney, seal the places through which the suction occurs.

- The pipe is rusting. If this happens, then too much condensate accumulates in the pipe. The chimney needs to be insulated.

- If the pipes smoke, you should increase the height of the chimney and insulate it.

Buleryan is an economical and efficient oven, which is equipped with two rows of pipes for additional air convection. Intensive convection allows you to quickly heat the room using a minimum amount of combustible materials.

The oven can be made independently using sheet steel and steel pipes, which are interconnected by welding. Most buleryan malfunctions are associated with insufficient height, lack of insulation or clogging of the chimney.

Safety

If it is planned to install the stove in a residential area, then the stove is located so that the distance to the walls of the house is at least 0.5 m. If you raise the stove above the floor, this will increase the draft and, accordingly, the heating rate. Usually, a small podium is made for Buleryan, how to make it is a matter of opportunities and improvised materials. It is advisable to use non-flammable materials. Ideally, the podium is also a welded structure.

Near the stove, under the firebox, you need to lay a metal sheet so that falling sparks or shooting coals do not cause a fire.

Special mention deserves the safety of children. On advertising pictures of long-burning stoves of the Buleryan type, it is often depicted that the stove is in the house in the living room or in the hall. But the oven heats up very quickly and, according to the reviews of the owners, some parts of it are heated red-hot. In this regard, a person can burn himself on the stove by making an awkward movement, and children can touch out of embarrassment, accidentally or out of curiosity. Therefore, it is better to install the stove in utility rooms that perform the functions of a stoker.

Advantages and disadvantages of the Buleryan oven

This design has certain advantages:

- air in water heats up very quickly;

- heated air through metal ducts can enter different rooms of the room;

- the design is easy to install and operate;

- with proper operation, the efficiency of the furnace reaches 80%;

- with a full bookmark of fuel, it is enough for 10 hours of burning.

Disadvantages of the Buleryan oven:

- only firewood is used as fuel;

- most of the generator gas goes into the pipe;

- the chimney must be insulated, regardless of the material;

- when installing the stove, a lot of free space is required: the distance from the wall to the stove should be at least a meter;

- dust constantly burns on the surface of the structure;

- the pipe is brought to a height of 3-5 meters from the surface so that the furnace does not smoke due to incomplete combustion of the fuel;

- during the operation of this design, condensate often occurs in the chimney, which, when heated, emits an unpleasant odor into the room.

How is buleryan arranged?

The Canadian "answer to the potbelly stove" is a steel barrel with air ducts, which differs from the classic stove precisely in the presence of pipes. Their holes are located at the bottom and top of the structure. This convection heater is not as simple as a conventional device; it uses a pyrolysis type of combustion. The generated heat immediately enters the air ducts, which provides the furnace with an efficiency of at least 80-85%.

Buleryans are very different from the usual bourgeois. They come in two forms. Those that are intended for heating rooms of a small area have the shape of a cylinder. High-capacity designs are produced teardrop-shaped. A classic buller consists of a certain number of elements, which are more than a traditional oven has.

- Primary compartment for combustion of fuel.This is the largest part of the device: the main fuel chamber occupies up to 85% of the entire structure. Primary ignition takes place in it, and pyrolysis products are generated.

- Secondary compartment designed for afterburning fuel. It "takes away" only 25% of the volume from the oven. Pyrolysis products enter the upper chamber: in it, the residues burn out, forming a flame that raises the temperature.

- Pipes made of metal. This is the "brand name" of the devices. They are 2/3 of the diameter recessed into the walls of the large chamber. These elements play the role of air ducts: cold air enters the furnace from below through them, heated masses exit from above.

- Injectors are narrow tubes connecting the primary compartment to the afterburner chamber.

- The chimney and ash pan are traditional elements that play a familiar role in the furnace.

- Throttle and damper. Their task is simple: it is the regulation of the air supply.

It cannot be said that such a design cannot be “repeated” on its own, since Buleryan is arranged quite simply. The minus of the operation is a large number of different elements that have to be connected as accurately as possible. This option can be considered if the price of purchased models seems somewhat overpriced, and the master has experience with welding equipment.

The principle of operation of the furnace

It is worth knowing what is interesting about Buleryan, the principle of which we will now consider. You might think that this is just a metal barrel with built-in pipes.

The Buller, or bullerjan, uses the newly popular fuel economy technology. Namely, pyrolysis.

True, how correctly it will be called a buller - pyrolysis, one can argue.Often, the buller is called pyrolysis, although this is only partly true. As in pyrolysis boilers, primary air usually passes through the fuel, from top to bottom. The thrust is forced and, accordingly, the design and equipment is different. In itself, this is the process of decomposition of wood under the influence of temperature. Volatile hydrocarbons, carbon monoxide and charcoal.

Video: Buleryan power calculation

Watch this video on YouTube

Pyrolysis devices can be considered devices that burn pyrolysis gas in the secondary chamber. An isothermal process takes place in the primary chamber, with the release of heat and gases. Here we have similar processes, albeit not in perfect execution. Therefore, I might have called our experimental one a pyrolysis boiler, but I did not vouch for one hundred percent and did not argue. Since combustion processes, similar to those occurring in a buller, partly occur in simple furnaces. It is located in the middle, between a potbelly stove and absolutely pyrolysis-oriented devices. The air is heated thanks to an impressive battery of convector pipes. In which the air warms up quickly and circulates. Moreover, the air of the room is well mixed, due to the speed with which it breaks out of the exchangers.

Helpful Hints for Operation

“Incorrect” installation of chimney pipes is due to the need to protect the structure from the resin that is formed as a result of the combustion of wood. If this moment is not foreseen, then the resin will flow out of the stove, and with such an installation, it will remain in the chimney and gradually burn out.

Upon completion of the assembly, the Buleryan stove is installed on a flat and fire-resistant base and connected to the chimney. At the same time, fire safety rules must be observed.

Clogging with resin for the Buleryan furnace is almost inevitable. Over time, tar layers build up and clog the device. This is expressed in a noticeable reduction in the efficiency of its work, a decrease in traction, problems with the free movement of the gate. So, it's time to clean the oven.

A lighter version of such a cleaning consists in heating the device with aspen wood. Unfortunately, the practical benefit of such a measure is small and short-lived.

The best way to eliminate resin contamination is by burning. To do this, the furnace is strongly melted with an open ash pan, in fact, all channels are calcined. As a result, resinous deposits burn out.

On the basis of the Buleryan stove, you can organize an autonomous heating system:

Image gallery

Photo from

Burelyan as the basis for autonomous heating

The basis of air heating

Connecting the air ducts of their corrugations to the furnace pipes

Water heating device

Some craftsmen use oxygen to burn the stove by bringing the cylinder nozzle to the ash pan opening. This is an extremely dangerous operation that violates fire safety regulations. Careless handling of an oxygen cylinder near an open flame can cause an explosion.

As a fuel for the Buleryan stove, you can use not only firewood, but also wood waste (chips) or special briquettes

An important condition is the low moisture content of the fuel. The less moisture, the less resin is formed inside the stove, and the less often it will have to be cleaned.

During the operation of the furnace, it is necessary to select such an operating mode in order to obtain maximum heat with minimal formation of resin. If the best option is found, cleaning will only need to be done a couple of times during the heating season.

Design features and principle of operation of the Buleryan furnace

The Buleryan furnace belongs to heat engineering devices of long burning. Its design includes a body made of metal, on which tubes are installed.

During the operation of the unit, cold air is taken from the floor level through a part of the tubes located below. When air moves through them, it is heated in the temperature range of 60-150 degrees Celsius from a heated body. As the hot air exits the pipe cavity, it moves upwards and heats the room. In this case, the well-known property of lighter warm air to rise up works.

The body of the stove is coated with a special heat-resistant paint, so during the initial ignition of the stove and 2-3 subsequent ones, an unpleasant odor should be expected. After the implementation of the first few fireboxes, this coating polymerizes and the smell disappears. This feature of the device necessitates the implementation of heating outside the premises.

To heat several rooms, pipes supplying hot air are put on metal sleeves of a special design, with the help of which the heat is distributed.

The grateless design of the Buleryan furnace suggests that the ash must be present in the furnace, located on the lower pipes. This feature of the device does not allow the pipes that are below to burn through, thereby extending the life of the entire unit. In addition, due to such a constructive solution, a normal process of fuel gasification is ensured.There is also no need for regular cleaning of the furnace from the accumulation of ash, since the combustion of fuel occurs almost without residue. The formation of ash is much slower when compared with a potbelly stove. With a significant amount of ash, it spills out of the furnace. Therefore, it is necessary to remove the layer located at the top, while the lower ones should close the pipes.

The design features of the Buleryan furnace make it possible to achieve a long combustion process and complete combustion of the fuel. As a result of combustion (smoldering), flue gases are released, which move to the upper chamber, where they are completely burned. At this stage of the process, the source of energy is not fuel, but the gas emitted by it and completely burned. The operation of the unit does not require constant laying of firewood, as in a classic potbelly stove, since the main process is the smoldering of fuel, and not its combustion. One load of fuel is enough to ensure operation for 8-12 hours.

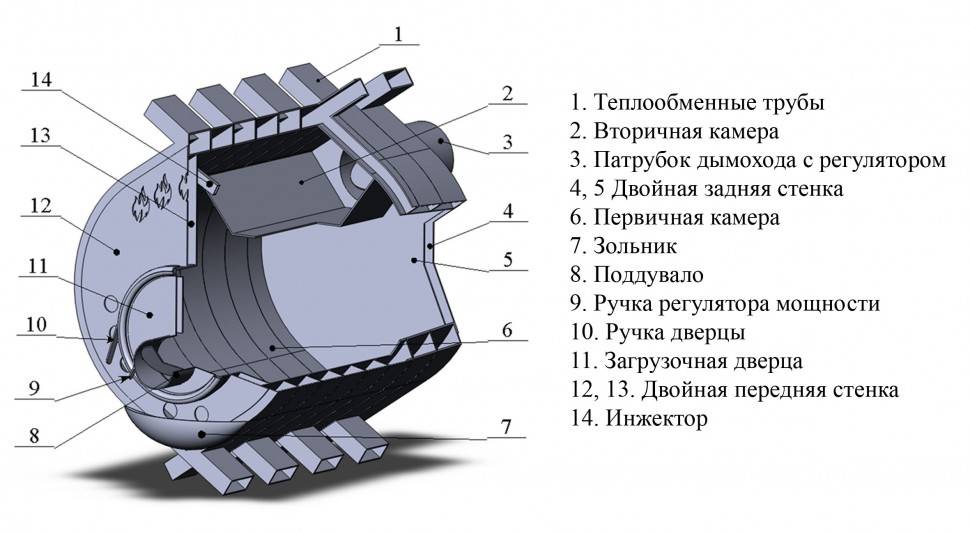

Names of parts

Names of parts

Manufacturing instructions

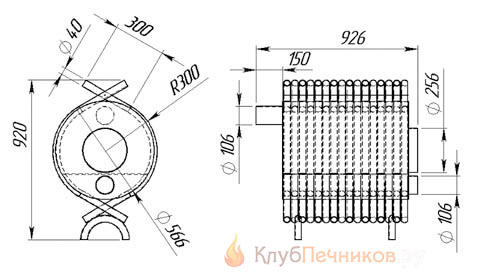

First, a design drawing of the heating system is being prepared, which can now be found and freely downloaded on the Internet.

The algorithm for making buleryana using available metal processing methods consists of the following steps:

- The basis for the future stove is being prepared.

- An iron pipe for the chimney is welded, and it must be borne in mind that the size of the minimum diameter of the duct must be at least sixty millimeters. This is due to the ratio of heat capacity to air viscosity.

- A mount is prepared for the exhaust pipe, which is fixed with anchors to the wall.

- The rear wall is welded onto a prepared wide iron pipe;

- A soot chamber is welded in the form of a metal corner as in the drawing;

- Two round holes are made for the pipe, for exhaust from the main large pipe into the soot chamber.

- A draft regulator is created in a pipe intended for exhaust. To do this, two small holes are cut out in it, into which a piece of reinforcement is inserted. An iron valve in the shape of a crescent is welded to it. Outside the “body” of the buleryana, the outgoing reinforcing pipe must be bent, and made into the shape of a handle.

- The heating oil grate inside is welded from the eighteenth armature.

- A gas chamber is being made; for this, two afterburner nozzles are assembled. The upper part of the main chamber must be separated with a sheet of metal from the lower part, leaving an indent of two centimeters in front. We weld two nozzles into this gap along the edges of the iron sheet, which will also serve as the legs of the boiler.

- The front part of the boiler base is welded with the same metal sheet as the back.

- From above, around the main body of the future buller, iron sheets are welded in a semicircle. They will serve as side convection guns.

- At the next stage, the deflectors of the rear gun are welded.

- The front bearing frame of the future door is being welded.

- Windows are cut from the profile pipe.

- The door is made of a heat-reflecting plate with a heat-resistant seal so that the door does not lead during direct operation.

- The door handle must be welded in the center.

- A blower regulator is welded into the ash drawer. It will be controlled by opening the door.

On this, in principle, we can consider the stove ready for work.

We prepare tools and materials for work

For the manufacture of a long-burning boiler, a semi-automatic welding machine, a grinder and measuring tools, metal shears, a pipe bending tool, a small hammer are required, and the following material is also required:

- In a store or at scrap metal, buy a piece of a large pipe with the following dimensions: diameter - five hundred millimeters, depth - six hundred and fifty millimeters, wall thickness - ten millimeters;

- Metal sheet for the back wall with a diameter of six hundred millimeters and a thickness of at least ten millimeters;

- Soot chamber in the form of a corner with dimensions of two hundred and fifty millimeters.

Advantages and disadvantages of the furnace

The great advantage of the stove is that the fuel for the buler is firewood, which for the most part is readily available. Thanks to the built-in gas chamber, the oven heats up really quickly. And compared to a potbelly stove in Buleryan, there is a very small consumption of firewood. Approximately three loads of firewood are produced per day, which is very economical.

Another plus of buleryana is the principle of operation and heating of the room with internal heated air emanating from it. This leads to a greater efficiency in comparison with stoves that heat the housing by heat transfer from the entire surface. In addition, the stove has a compact size and a convenient door for laying firewood.

You can list some more obvious advantages of the buller - this is a large heated area of \u200b\u200bthe room, and its uniform heating, while there is no soot with smoke in the residential area.

The disadvantages of using buleryana are as follows.Often, on the websites of manufacturers of long-burning stoves, they are silent about the fact that in order to quickly warm up a cold room (that is, to raise the temperature, for example, from five degrees to twenty degrees Celsius), a large amount of fuel is consumed quite quickly in buleryans, and the firebox can burn out in thirty minutes with intensive combustion.

Another disadvantage is that a fan must be placed behind the buleryana to disperse the hot air accumulating above it. Another disadvantage is the burning of dust from the boiler itself.

The Buleryan stove has a compact size and a convenient door for laying firewood.

The structure of the Buleryan furnace and the principles of operation

The stove has an original design, in which everything is subordinated to the main task: to quickly heat the air in the room, and then maintain the temperature.

The body of the furnace consists of parabola-shaped pipes, between which strips of metal are welded. The pipes are mostly located inside the firebox, protruding only 1/3 of their diameter. Such a system is a highly efficient heat exchanger, in which air acts as a heat carrier. As soon as the furnace is ignited, air is sucked into the lower ends of the pipes, which takes away most of the thermal energy from the heated metal. This stream is very intense. With active combustion, 4-6 cubes of air pass through six pipes per minute, and its outlet temperature exceeds 120 ° C (up to 150 ° C).

Active combustion is not the main mode of operation of this furnace. Most of the time the fuel smolders. Then the air in the pipes is no longer burning “only” 60-70 ° C, but the body temperature is around 50 ° C (of course, not immediately after the “buildup”).

Cold air is sucked into the lower pipes, and heated air comes out from above.

The firebox inside is divided into three parts: the bottom ¼ part is separated by a grate, the top ¼ is also allocated for the afterburner. The grate is either a standard cast-iron grate or a steel grate made of steel at least 4 mm thick. The upper partition does not reach the door by about a quarter of its length. And this is not a solid sheet, but with holes. Through these openings, air from the furnace enters the fenced-off afterburning zone to maintain the combustion of gases. The area of the holes is about 7% of the total area of the partition.

In the upper part of the rear wall there is an outlet for venting gases. A damper / gate is installed here, which has a smaller diameter (a gap of about 10-15% of the chimney diameter). Additionally, a 90o sector is cut out in the damper. This device allows you to adjust the draft, but the existing gaps will not allow carbon monoxide gases to go into the room at any position of the gate. This will not happen even with the door open. Then, however, the room will dry out completely, but safety is above all.

Further in "Buleryany" from the pipe there is not a chimney pointing upwards, but a horizontal section of the pipe in which the unburned pyrolysis gases cool down a little (this is intentional). Then the chimney bends up. Here, the “branded” Bulerjan has an economizer. This is a heavily insulated section of the pipe, in which pyrolysis gases from the furnace are periodically burned out. Read more about pyrolysis boilers here.

"Buleryan" factory-made with an economizer

Here's how it works. Partially cooled gases pass into the section of the insulated pipe. A certain amount of thermal energy has already accumulated here. The gases heat up again and flare up. Due to the rise in temperature, they expand, and since they have nowhere to go in the pipe, they clog the chimney.A gas plug is formed (this phenomenon is known to stove-makers and owners of their unsuccessful creations). Gases burn out and cool down, the cork dissolves. For some time, the oven works like a conventional oven until the required amount of heat is accumulated in the economizer. This process is spontaneous. The frequency and duration depend on the characteristics of the firewood and the position of the shutters.

To regulate the intensity of fuel combustion, there is a throttle in the stove door that blocks the air flow. The door itself is usually round and large in size so that large logs can be laid - this is the best option for the smoldering mode. But that's not the most important thing

It is important to ensure a tight fit of the door: combustion products should not leak through it. This is also the difficulty of making pyrolysis ovens with your own hands.

With the design and principle of operation, it seems, they figured it out. Now you can start assembling parts and accessories.

Advantages and disadvantages of the heating system

There are many modifications of the furnace. In the photo of the Buleryan furnace, you can see the design features and typical equipment. Moreover, additional equipment is possible, which will increase the efficiency of use.

But even without it, the unit has many advantages:

- rapid heating of premises due to the convective effect;

- the possibility of selecting a model for the parameters of the room;

- economy in fuel consumption;

- ease of installation and operation;

- high level of efficiency, reaching 80% or more;

- safety;

- the ability to adjust the intensity due to the mechanism on the door.

Buleryan type stoves can be used for heating residential and non-residential premises. Application in greenhouses and workshops, in warehouses is possible.

Due to the volumetric principle of operation, heat does not accumulate directly near the unit, but moves over the entire area.

At the same time, during operation, you should pay attention to several points:

- the need for pipe insulation;

- the need for a spacious place for the unit;

- the possibility of burning dust;

- the need to bring the chimney to a considerable height - more than 3-4 m;

- the possibility of condensation in the pipe and the appearance of smell inside the house.

Do it yourself?

Properly made homemade buller

Before moving on to the features of the installation and operation of buleryans, their improvements and varieties, we need to dwell on the question: is it worth making a buller with your own hands? The reason is, first of all, the sale price of ready-made factory ones. Bullers are very technologically advanced: the zero cycle of their production is reduced to the manufacture of a couple of bending templates and welding jigs. The material of the product is even scrap metal.

A very good buleryan for 10-15 kW can be purchased for $200-250. At the same time, equipment that is common for a camping repair shop is not kept at home, in a garage or in a summer cottage, if only because of the lack of suitable space. And ordering individually bent rather large parts made of thick metal will cost much more.

Perhaps the only exception is if the home-made master works in a provincial provincial factory, where most of the technological equipment is idle anyway. And the “Soviet-style” leadership will allow him to use the machine park in his spare time, and even allow him to rummage through the landfill, pick up blanks. Although at current prices for scrap metal, this is unlikely.

In such a case, we will give advice: do not be tempted for batteries by narrow water pipes. The minimum diameter of air ducts is 60 mm; it is determined by the ratio of heat capacity and viscosity of air. Buller with a "palisade" is unlikely to be more economical than any other slow-burning stove, but it is more difficult to make it. A drawing of an unsuccessful design in this respect is shown in Fig. below, and an example of a properly executed homemade buller is in fig. right at the beginning of the section.

Drawing of an erroneously designed buller