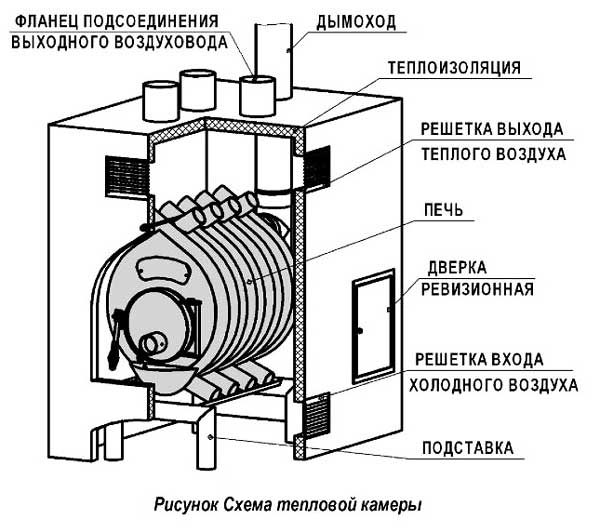

- Mounting Features

- Fire safety

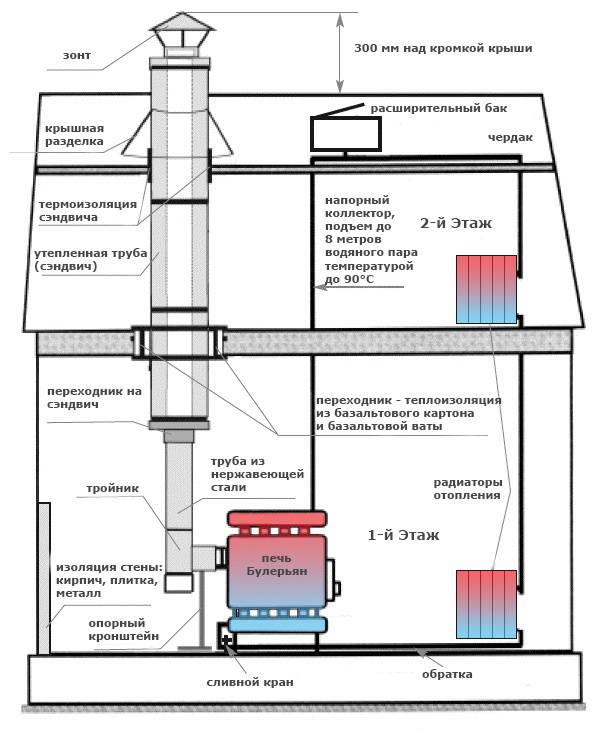

- Installing a smoke exhaust system

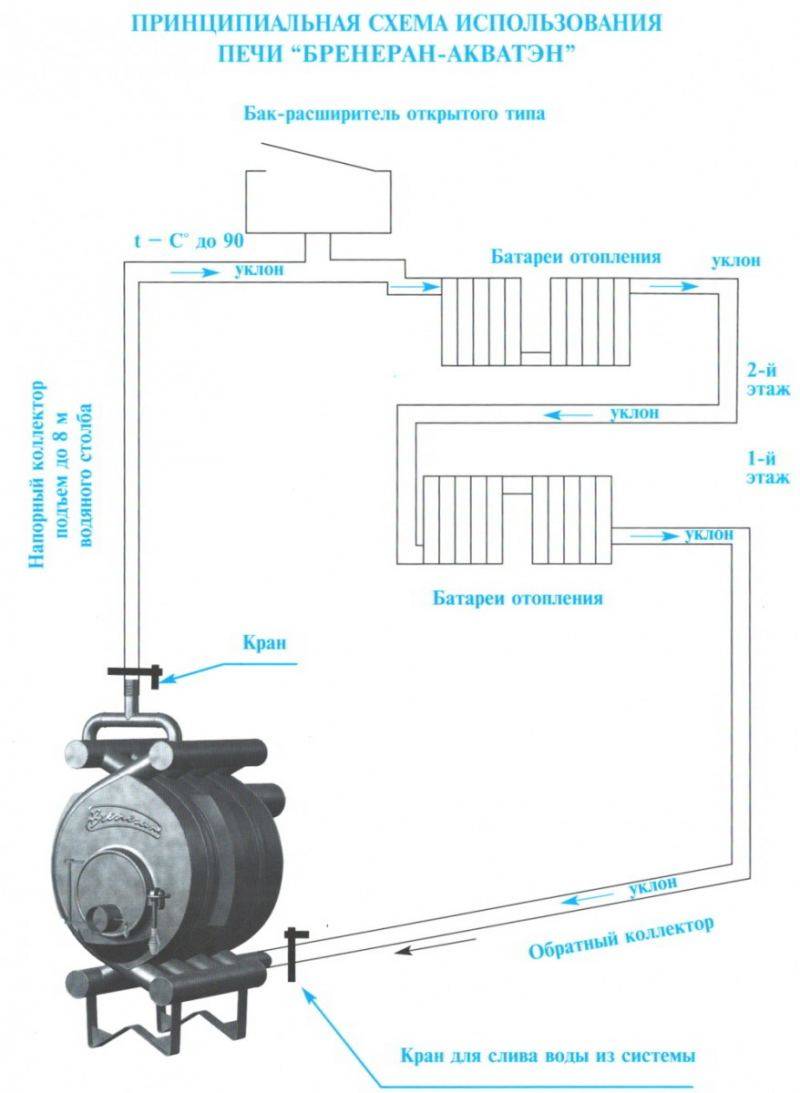

- Gravity system

- forced circulation

- Strapping pipes

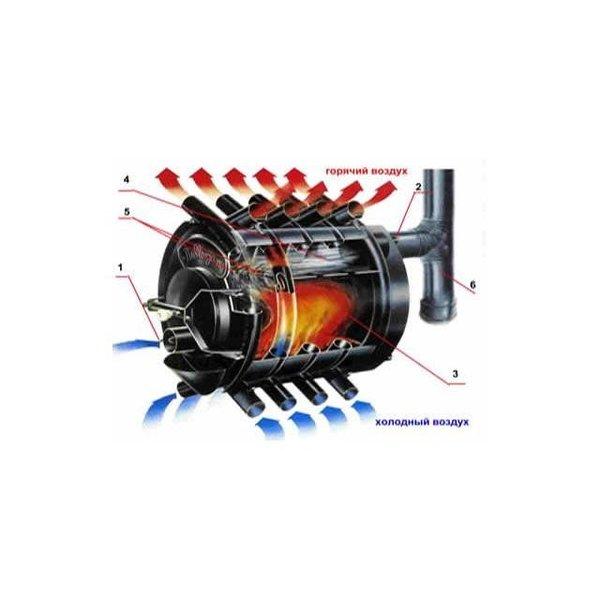

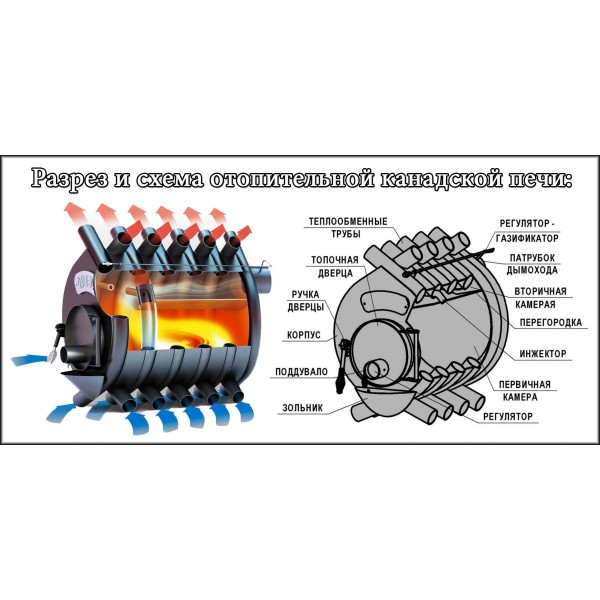

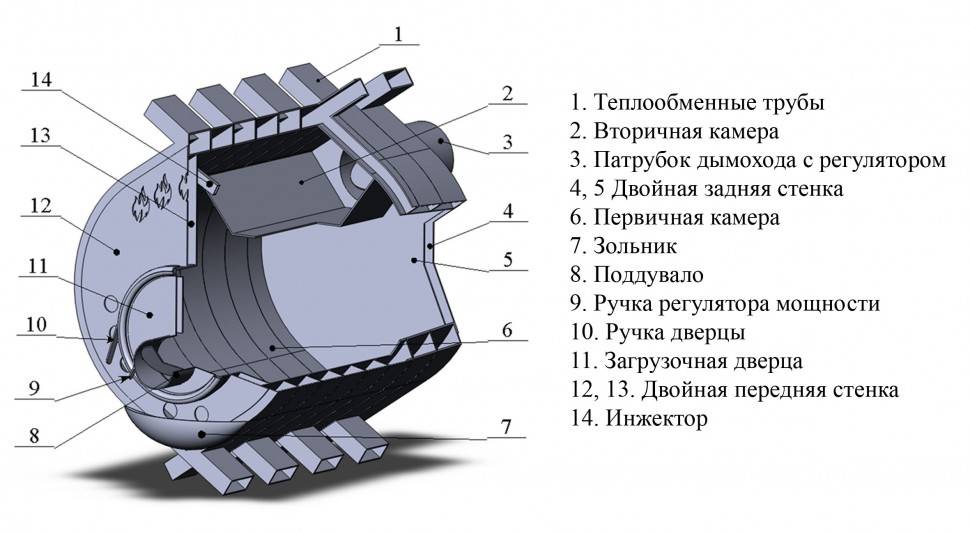

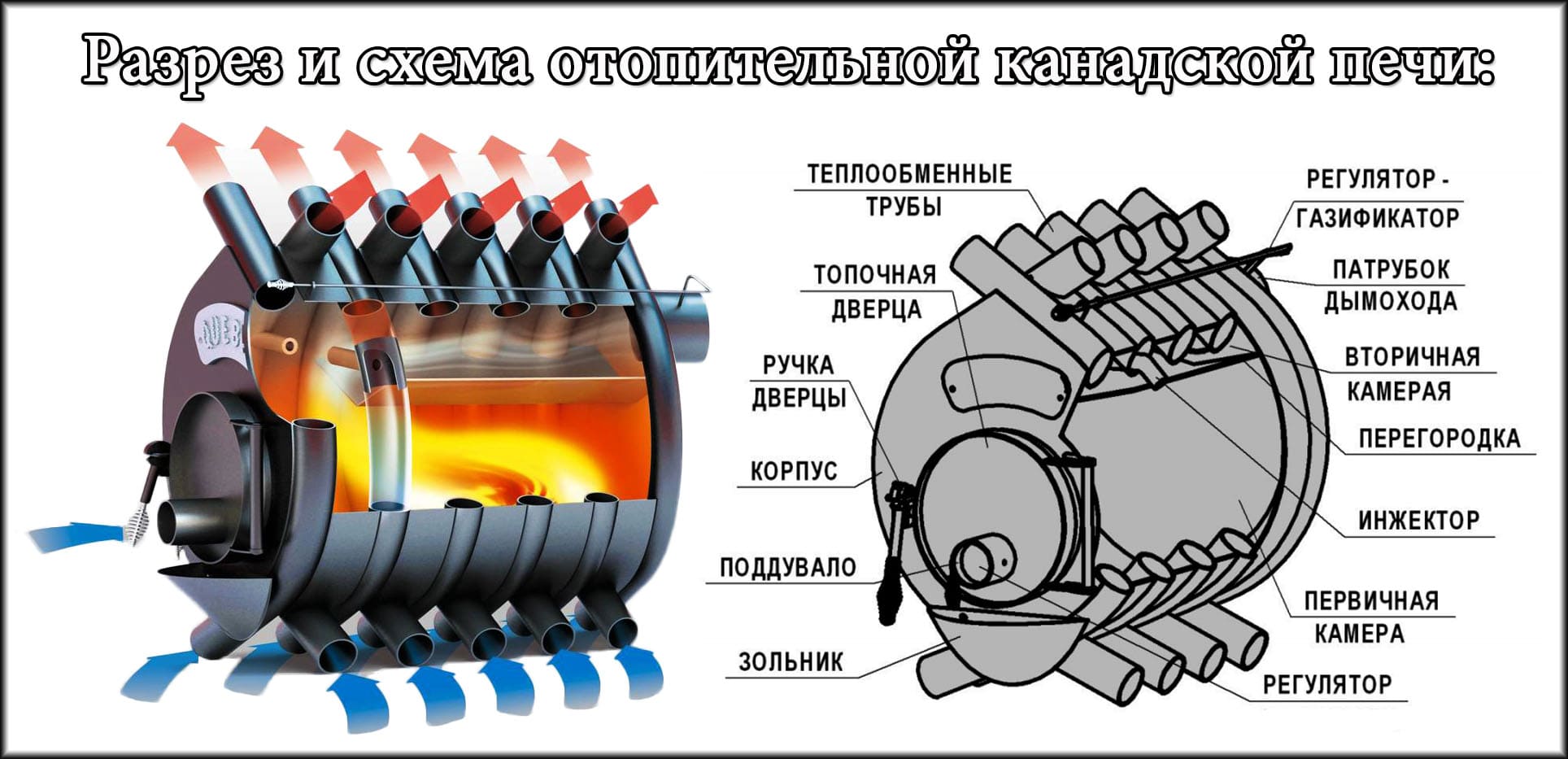

- The main features of the oven

- Buleryan oven with water circuit

- What should be considered before buying buleryan with a water circuit?

- Buleryan oven with water jacket

- How efficient is Bullerian at garage heating?

- Do-it-yourself buleryan oven: sequence of actions

- Do-it-yourself Buleryan oven. Step-by-step instruction

- Two working modes

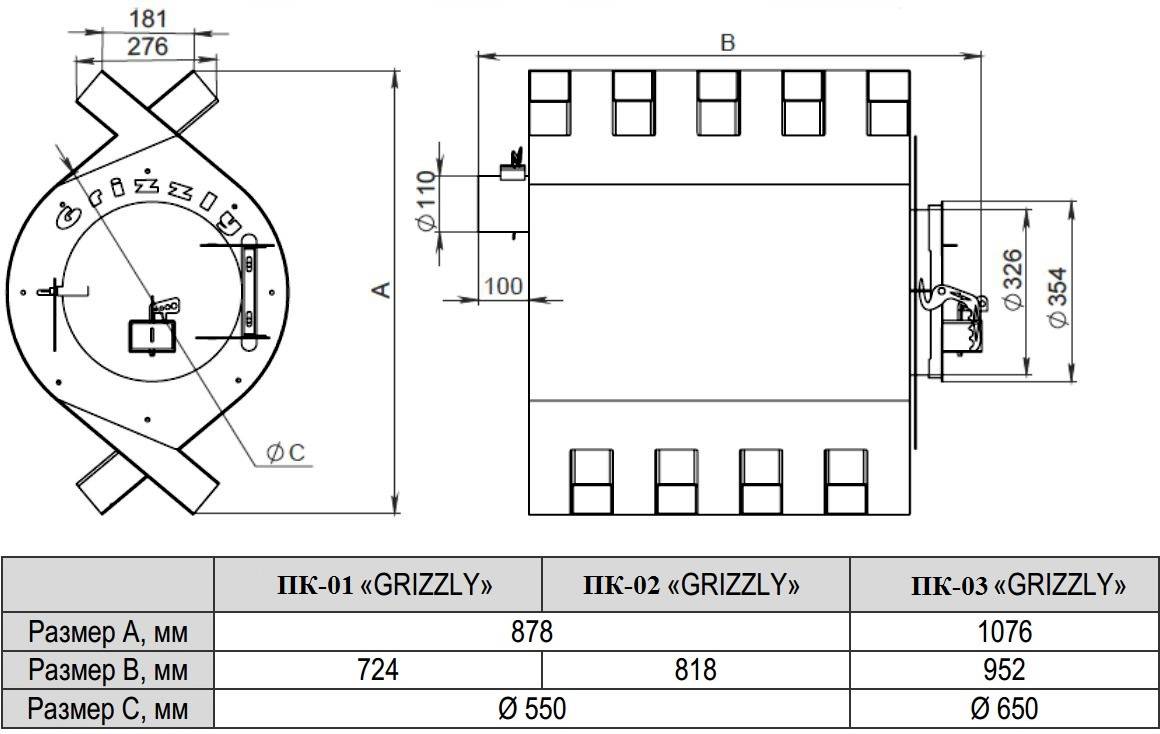

- Varieties with photos and geography of use of buleryan

- How to drown

Mounting Features

General connection diagram with description

Fire safety

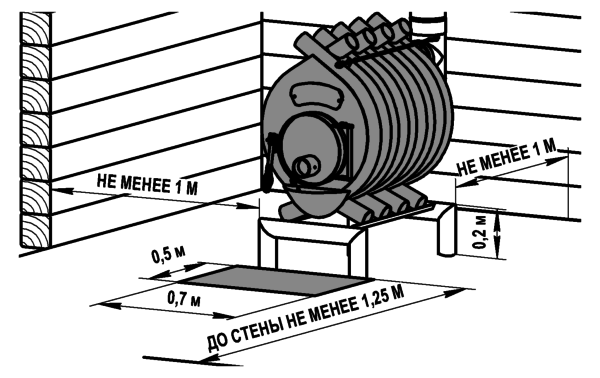

For any room where the stove will stand, it is necessary to comply with fire safety standards:

- It is possible to put the structure only on a non-combustible base; steel sheets or a concrete floor are perfect for this.

- A sheet of steel must be laid on the floor near the firebox, the length of which must be at least 1.25 m.

- The distance from the wall to the stove should not exceed 1 meter for plastered surfaces and 80 cm for surfaces with a layer of insulation.

- The stove can be installed in a room with excellent ventilation and an area of 12 sq.m. automatic machines for heating elements are placed only in adjacent rooms.

Properly installed Buleryan oven according to the rules of the PPB

Installing a smoke exhaust system

When installing a chimney, the following requirements must be met:

- materials resistant to corrosion, high temperatures, acid action are used;

- the chimney inside must be perfectly smooth;

- the pipe layer facing the street is insulated with basalt wool, the thickness of which will be at least 50 cm.

All chimneys are placed vertically, the length of the pipe outlet from the furnace to the common chimney cannot be more than 1 meter.

Gravity system

When connecting Buleryan with a water jacket to a natural heating circuit, the following recommendations must be observed:

- the wood-burning stove is placed 50 cm lower than the radiators are installed;

- pipes are mounted at an angle;

- at the highest point (usually in the attic) an expansion tank is placed;

- for unheated attics, the installation site of the expansion tank should be insulated;

- supply pipes require a special safety circuit.

forced circulation

Bake Buleryan with water circuit supplied with an additional pump. The scheme includes:

- a circulation pump is placed on the return;

- temperature sensors are used for adjustment;

- the circuit requires a closed expansion tank;

- to operate the pump, install a UPS with a voltage stabilizer.

Strapping pipes

Various pipes are used for Buleryan, but their choice should be taken responsibly, since they have a great influence on performance. Three types of pipes are recommended for tying Buleryan:

- metal-plastic, corrosion-resistant and easy to install (can be used with forced heating systems only for industrial enterprises);

- polypropylene pipes can be easily installed with your own hands, they are inexpensive, lightweight, easy to install (allowed for installation for residential buildings);

- steel pipes withstand high temperatures for a long time (can be used for any Buleryan, but requires a larger system than a circuit with plastic pipes).

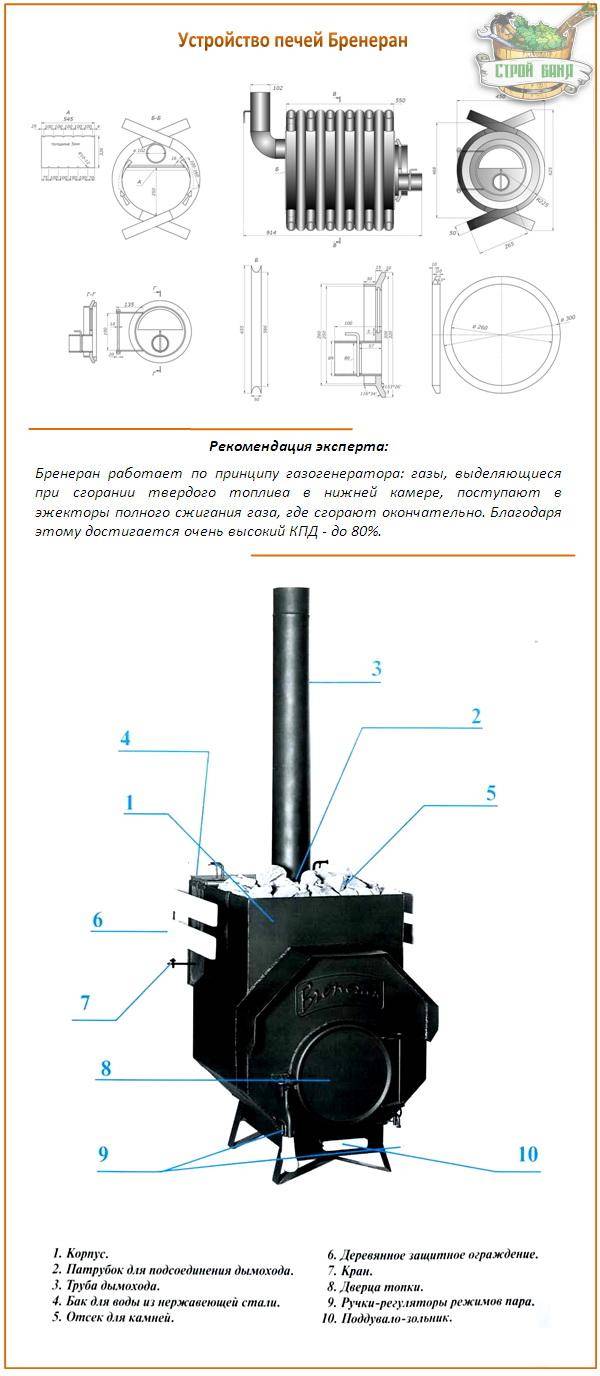

The main features of the oven

The pyrolysis used in Breneran brand furnaces allows the heat generator to work on one fuel tab for much longer than with conventional combustion.

The pyrolysis used in Breneran brand furnaces allows the heat generator to work on one fuel tab for much longer than with conventional combustion.

A conventional solid fuel boiler has to be refilled every 4 hours, while Breneran-Buleryan can work without user intervention for as long as 8 hours. Such units are called furnaces or long-burning boilers.

Note that 8 hours is far from a record. There are heaters that can work on one tab for several days. But they are much more massive than Buleryan, and, unlike him, cannot be considered mobile.

The combustion process in Buleryan brand heat generators is manually controlled by two dampers or throttles: one is installed on the front door and is used to control power, the other (gate) is in the smoke duct (switches flame / smoldering combustion modes). Thus, the oven does not need power supply and can be operated in the field for which it was originally created (by order of mobile logging teams in Canada).

The front damper handle for most models has a temperature scale (outside temperature) and a latch in the form of a movable stop.The damper has a cutout in the form of a sector, due to which the complete blocking of the chimney, leading to the ingress of carbon monoxide into the room, is impossible.

Note to the user. An obligatory element for Buleryan is a horizontal pipe section with a length of 0.8 to 1 m, through which the heat generator is connected to a vertical chimney. This detail (it is called a "bar" or "hog") slows down the burning of exhaust gases. It is behind it that the gate is installed.

The vertical section of the chimney 1.5 - 3 m long with powerful thermal insulation next to the gate is called an economizer. This is a very important element. Here, the final combustion of flue gases takes place, which flare up in the center of the gas jet when exposed to infrared radiation reflected by the walls (the “flame jump” effect).

Aqua Breneran after installation

The ignited gas expands sharply and turns into a kind of cork, slowing down combustion in the furnace. Then it cools down and leaves the chimney, and combustion resumes. Only thanks to this cunning technique, the developers managed to make the combustion regime on the verge of smoldering and flame stable at relatively low temperatures. Another positive effect: due to the operation in the self-oscillation mode, the furnace automatically adjusts in accordance with the quality of the fuel used.

Without the use of an economizer, Buleryan's efficiency drops to 65%.

The Buleryan-Breneran furnace with a water circuit is designed for wood fuel and a smoldering mode, which requires a temperature of 550 - 650 degrees. If you heat it with coal (combustion temperature - 800 - 900 degrees), then after 1 - 2 seasons the stove will burn out.

The kindling of Buleryan is carried out as follows:

- By moving both dampers to the fully open position, the furnace firebox is filled with some kind of flammable fuel (even paper or cardboard will do), which is then set on fire. For some time, the stove operates in flame mode, which allows you to quickly warm up the room. It is advisable to lay such a portion of fuel so that it completely turns into coals in 3-4 minutes before the room is completely warmed up. It is most convenient to monitor the combustion process through a transparent door made of heat-resistant glass, but if this option is not provided for in your model, you can look into the blower.

- Large logs are laid on the fuel burnt to coals. You can also use pellet pellets or peat briquettes. The chamber must be filled "to the eyeballs" - then the furnace will be able to work on one tab for the maximum period.

At the same time, the slide gate is closed completely (recall that it has a cutout), and the front throttle is closed by an amount corresponding to the required power. Buleryan will switch to smoldering mode with pyrolysis.

Buleryan oven with water circuit

Until recently, autonomous heating had a local character of heating. It distributed heat only in one room and could not be used in the bathroom, kitchen, and other small rooms. The situation changed after the buleryan furnace with a water circuit was created. When creating a furnace, you can use two options for connecting the water circuit. 1 - you can use all the air heating pipes and make the stove only for water heating. 2 - use only a part of the tubes and thereby make a combined heating of the room.You can also just draw an additional contour. Furnaces with a water circuit have the following principle of operation - they are:

- Join the water supply system;

- They take water (for these purposes it is recommended to use steel tubes with a thickness of 6 mm or more) and heat it to high temperatures;

- They pump water through the batteries, evenly distributing heat in all areas of the house.

Important - a buleryan with a water circuit can also be used in those buildings that do not have access to a central water supply. For it to work independently, you need:

- Install batteries and connect them to the oven;

- Create a source of water supply (using hoses, a pump, a well or a well);

- Ensure the pumping of water through the batteries (using a pump and other devices).

Buleryan with a water circuit is installed in the following situations:

- The house is deprived of access to the central heating system;

- The building consists of several floors or rooms that cannot be heated with a conventional stove;

- High cost of heating and low price of solid fuel in the region;

- Constant problems with central heating.

Important - the use of buleryan with a water circuit is allowed at the official level

What should be considered before buying buleryan with a water circuit?

The manufacturer always indicates the maximum power of the device. If you are offered a stove that can heat an area of 200 square meters, divide its efficiency by 2. After all, you will not load the firebox twice a day to the eyeballs. And its continuous use at maximum temperatures will accelerate equipment wear.

Remember that the high efficiency of buleryan is provided by an ash pan and a gate.Without them, the stove is simply not able to use the energy of wood gases. So - almost no different from the usual potbelly stove. You will also need to insulate the chimney, because when the stove is kindled, the gases have such a low temperature that they can settle on the surface of the chimney in the form of condensate.

Buleryan oven with water jacket

quality heating

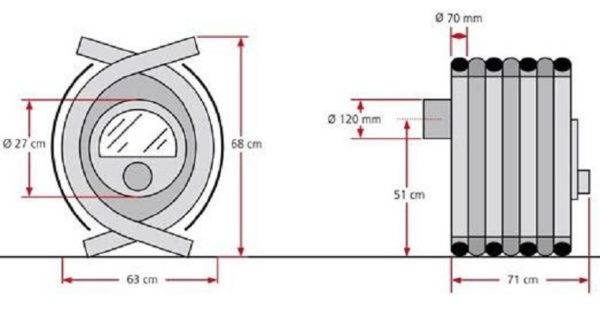

The Buleryan furnace with a water circuit is a simple and at the same time unusual device. The case is made in the form of a cylinder, consisting of two levels and resembling an ordinary barrel. The lower level - the furnace - for preliminary ignition and raising the temperature to a certain level of the combustion chamber. And the upper level is made for afterburning wood gas. The main task of the furnace on the water circuit is to heat water in a large volume. This appliance is equipped with built-in appliances that distribute approximately 10% of the energy for heating and the remaining 90% for hot water. Hot water enters the heating system or a special storage tank, thereby providing the house with a comfortable temperature.

Experts advise, in addition to distilled water, to use a low-freezing universal antifreeze coolant in the heating system in order to provide the system with the required frost protection in case of non-permanent residence in a residential building.

How efficient is Bullerian at garage heating?

Installing a Bullerian convection oven is completely justified. Air heating is carried out without a water coolant, which allows the oven to be used only as needed without fear of defrosting the system. Heating of air begins at once after a kindling of the furnace.

One Buleryan in the garage is able to warm up for 8 hours from 100 cubic meters of air.Its effectiveness also lies in the fact that, first of all, the air warms up, and already it heats the walls of the garage.

Buleryan for garage

The simple operation of furnaces is also explained by a wide range of fuel filling options. Buleryan works on wood, pellets, shavings, sawdust, wood dust and even on paper. It is forbidden to fire with coking coal and liquid fuel.

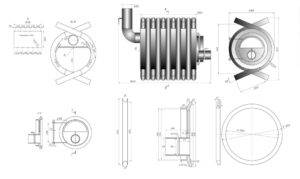

Do-it-yourself buleryan oven: sequence of actions

-

Equal segments of a metal pipe with a diameter of 45-50 mm are taken in the amount of 8 pieces and bent in the middle part with a pipe bender at an angle of approximately 80 degrees. For a medium-sized oven, pipes 1-1.5 m long are sufficient. Then, by welding, curved convection pipes are connected into a single structure. They need to be welded symmetrically, with the outlet part outward.

-

The resulting heat-removing structure will simultaneously play the role of a frame. Accordingly, strips of metal 1.5-2 mm thick are welded onto the pipes, which will become the furnace body.

-

A metal plate located horizontally should be welded inside the housing. This plate will become the floor (tray) of the furnace compartment and firewood will burn on it. Therefore, it is better to choose metal for this plate with a thickness of at least 2.5 mm. To facilitate the cleaning of the oven, it is best to weld the pallet from two halves located at a large angle to each other. To make it easier to fit the pallet of parts into place, first you need to make patterns from cardboard, and only then just start working with metal.

-

Production of the front and rear walls of the furnace. Start this stage with the preparation of a cardboard pattern based on the actual dimensions of the oven.The easiest way is to attach a sheet of cardboard to the sidewall of the oven and circle around the perimeter with a pencil. The walls of the heating device are cut directly from the sheet metal template. For the front wall, you will need to cut a window for loading fuel. The diameter of this window should be approximately half the diameter of the furnace, the center of the hole should be shifted slightly below the axis of the structure itself. Along the perimeter of the window, we weld a ring from a strip of sheet metal 40 mm wide from the outside.

- The rear wall is made in the same way, only the hole should be located in the upper part of the wall, and its diameter should correspond to the diameter of the outlet pipes. Both walls are welded to their seats.

-

Furnace door. It is made of sheet metal cut to the diameter of the window in the front wall of the stove. A narrow strip of metal is welded onto the metal circle around the perimeter, which improves the tightness of the door. In addition, it is necessary to cut a hole to the door cover and weld a blower with a valve into it.

- On the inside of the door, you will need to install a heat-reflecting screen, for which a semicircle of the appropriate diameter is cut out of metal and welded into the inside of the door on metal spacers.

-

The door is suspended on metal hinges welded to the outer wall of the furnace. You can use either industrial-made hinges, or construct them yourself from scraps of metal. The same applies to the bottom door lock.

-

Chimney. The T-shaped outlet-chimney is mounted on a hole in the rear wall of the furnace. To create it, a piece of metal pipe with a diameter of 110 mm is taken of the required length.At the height of the outlet in the rear of the furnace, a cut is made in the pipe to install a tap with a valve.

The valve itself can also be made by hand. To do this, a metal circle is cut out along the inner diameter of the branch, and a hole is drilled in the branch itself so that the valve axis can be inserted horizontally into it. After that, the whole structure is assembled and welded. Another rod is welded onto the outer part of the axis, which becomes a handle. This handle will need to be equipped with either wooden or heat-resistant plastic lining.

Now it is enough to make metal legs for the furnace from the remains of pipes.

Feet for oven

At the same time, it is important that the body of the buleryan furnace is located at a height of at least 30 cm from the floor level. This will increase the draft in the convection pipes, which will ensure greater efficiency of the entire heater.

Bake Buleryan do it yourself. Step-by-step instruction

In order to make a Buleryan oven with your own hands, you should purchase metal pipes, the diameter of each of which will be from 50 to 60 millimeters. You also need to buy metal in sheets. Remember that the combustion temperature in the furnace is quite high, which means that the thickness of the sheets must be appropriate (about 5-6 millimeters). To perform this work, you will need a pipe bender, a welding machine and the most standard set of tools.

In order to make a Buleryan oven with your own hands, you should purchase metal pipes, the diameter of each of which will be from 50 to 60 millimeters. You also need to buy metal in sheets. Remember that the combustion temperature in the furnace is quite high, which means that the thickness of the sheets must be appropriate (about 5-6 millimeters). To perform this work, you will need a pipe bender, a welding machine and the most standard set of tools.

Next, follow these steps:

- Bend pipe sections.

- To manufacture devices designed to collect condensate and remove smoke.

- Make dampers for the outlet and blower.

- Make doors for the furnace chamber.

- Trim sheets of metal in the space located between the pipes.

- Install door and lock.

- Make and trim the legs, which are also made of metal.

It is necessary to make identical segments from the pipe, the length of each of which will be 1.2 meters. Using a pipe bender, they need to be bent to a radius of 225 millimeters. The resulting pipes should be installed in a checkerboard pattern.

It is necessary to make identical segments from the pipe, the length of each of which will be 1.2 meters. Using a pipe bender, they need to be bent to a radius of 225 millimeters. The resulting pipes should be installed in a checkerboard pattern.

In order to get rid of condensate, as well as excess smoke, it is necessary to build a special T-shaped device, thanks to which moisture will flow down, and smoke, on the contrary, will go up. There is also a special valve for removing moisture, which must be closed immediately after its excess has flowed out.

Well, in order to remove smoke from the pipe, a special damper should be made. By the way, with it, you can also adjust the traction force. At the same time, a blank damper is installed on the blower located on the front door.

The most difficult element of this furnace is considered to be the front door, which must be made practically airtight. Remember that the tighter the door fits the unit, the higher the efficiency of its operation.

From a large diameter pipe, two rings should be made that fit tightly into each other. To do this, pieces of 4 centimeters should be cut from a pipe with a diameter of 35 centimeters, one of which is cut and unfolded. Further, using the ring, the diameter of which turned out to be smaller, the front side of the furnace is made. And the second ring is welded to a circle cut out of a sheet of metal and used during the installation of the door.

Then another ring is welded to the resulting structure, the diameter of which will be slightly smaller than that of what was welded earlier. Thus, a gap is formed between the rings on the door. It is in it that it is necessary to lay the asbestos cord and do the installation of the damper.

And now it's time to return to the pipes that were bent at the beginning of work. We take two pipes, make holes in them, to which we weld the injection tubes. This element is a 150 mm pipe with a diameter of 15 mm. It is necessary in order to connect other convection elements to the firebox.

Of all eight pipes, the frame should be welded, placing a partition between them. For her, it is best to use a sheet of metal with a thickness of at least 6 mm. With the help of strips cut from sheet metal, we close all the gaps between the pipes. For this, welding is used. Thanks to such actions, we create the body of the furnace itself. Tip: in order to cut out the partitions between the pipes as accurately as possible, it is best to use patterns made of cardboard or any other bending material.

Of all eight pipes, the frame should be welded, placing a partition between them. For her, it is best to use a sheet of metal with a thickness of at least 6 mm. With the help of strips cut from sheet metal, we close all the gaps between the pipes. For this, welding is used. Thanks to such actions, we create the body of the furnace itself. Tip: in order to cut out the partitions between the pipes as accurately as possible, it is best to use patterns made of cardboard or any other bending material.

It will be just fine if you are not too lazy and install a special lock on the oven door. It should be made in the form of an eccentric, fixing the loop, which is previously fixed on the oven door. If you continue to scroll the device further, the door will fit tighter and tighter with each turn. Unfortunately, it is impossible to make such a lock at home, since a lathe is required. In this regard, for its manufacture, you need to contact a specialist.The only thing left to do is to make hinges, mount the door and, of course, attach the legs to the stove. The latter, by the way, can easily be made from a square pipe.

As you can see, the process of making Buleryan is quite laborious and requires certain skills, as well as special tools. However, with a strong desire to make it at home is quite realistic. And the installation of the unit will not cause any difficulties even for a beginner.

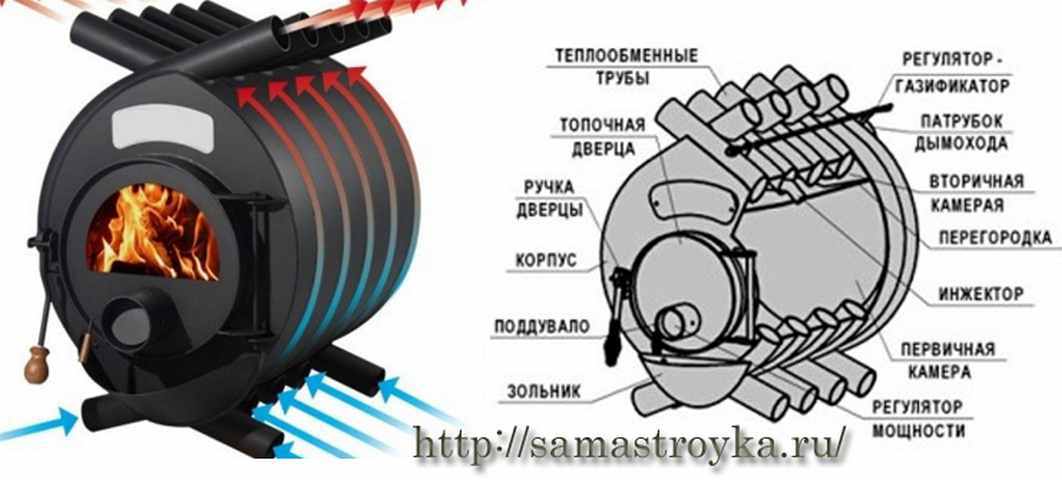

Two working modes

First, paper, cardboard, small wood are loaded into the chamber and set on fire. The door closes tightly, and the air damper swings open completely. In the process, small logs are placed so that the firebox flares up at full power. At the same time, the temperature in it reaches 700-800 degrees, and air begins to intensively pass through the heater, heated to a temperature of 130-140º. Thanks to convective draft, the Breneran stove burning in the open flame mode passes 4-6 m3 of air through its heat exchanger in 1 minute, quickly warming up the entire volume of the room.

Work in this mode is unproductive, and the efficiency is low, so the transition to the regular long-burning mode follows. To do this, logs are laid in the furnace for the entire length, and the damper is covered, limiting the access of oxygen.

Stove-makers recommend putting logs in "Buler", which is 10 cm shorter than the length of the firebox. In this case, it is better to split the log into only 2 parts. You can learn more about the firebox rules by watching the following video.

Intensive burning stops, firewood slowly smolders from the firebox door to the very end, which takes about 6-8 hours, or even more.The products of combustion rise, go around the partition and go into a horizontally located chimney. In the second chamber, formed by a partition, the gases are periodically afterburned, but this process is unstable and unregulated.

The assertion that Breneran stoves are gas generating is a myth. One of the specialized companies conducted a study with the introduction of video cameras into the upper gas duct in order to detect the process of afterburning pyrolysis gases. Only rare flashes were seen and nothing more, which means that the "Buler" is an ordinary two-pass furnace.

In normal mode, the temperature in the combustion chamber drops to 600 ºС, the air passing through the heater - up to 60-70 ºС, and the external temperature of the body becomes equal to 50-55 ºС

It turns out that in case of negligence on the unit, it is even difficult to get burned. Although manufacturers in the Breneran brand model for residential buildings install protective screens on the housing

Varieties with photos and geography of use of buleryan

In order to understand the difference between buleryan, breneran, buller, Butakov oven and other types of convection ovens, let's take a closer look at all the nuances. First of all, we note that Buleryan is a brand of the German company Bulerjan, which produces super-bourgeois. Often furnaces of this type are called the shorter word buller. Breneran - the same units, but produced by domestic factories under license. The furnace developed in Russia by Professor Butakov is very similar in principle to the original design, but has some differences:

- recessed convection heat exchangers;

- cubic body shape instead of cylindrical;

- the use of an ash pan and a grate;

- a flat platform in the upper part of the body for heating food.

In fact, the use of a grate in a gas generating unit is unnecessary, since intensive burning of firewood is expected only in the first minutes after ignition. In addition, its purpose is not clear, given that it is below the level of the blower. There are doubts about the effectiveness of the platform for installing a pot or kettle. When entering the operating mode, the temperature of Buleryan rarely reaches even 75 ° C, so it will take a lot of time to heat up food.

Butakov's stove is a modernized buleryan

Despite the fact that the heater was originally designed as a stove with an air heat exchanger, some craftsmen loop convection channels by connecting them to a water heating system. The resulting aqua buller, of course, has the right to exist, but the expediency of such a decision is doubtful. Firstly, the heat capacity of the air medium is 800 times less than that of water, so a furnace designed for convection will operate with reduced efficiency under conditions of liquid heat exchange. Secondly, even if breneran is taken as a long-term combustion unit, this is also irrational, since there are more suitable specialized designs of solid fuel boilers using pyrolysis. Despite this, aqua bullers have found their place in the line of units, which are a modernized buleryan.

A water jacket turns a convection oven into a water-heating boiler, which is called an aqua buller

Despite the fact that the calorific oven was originally developed for domestic use, currently buleryan is widely used in all areas of economic activity:

- for heating cottages and country houses, including wooden ones;

- in production shops;

- for heating utility rooms;

- in garages and workshops;

- in baths and saunas;

- to maintain the required temperature in greenhouses;

- as heating units for country cafes and restaurants;

- for heating administrative buildings in rural areas, etc.

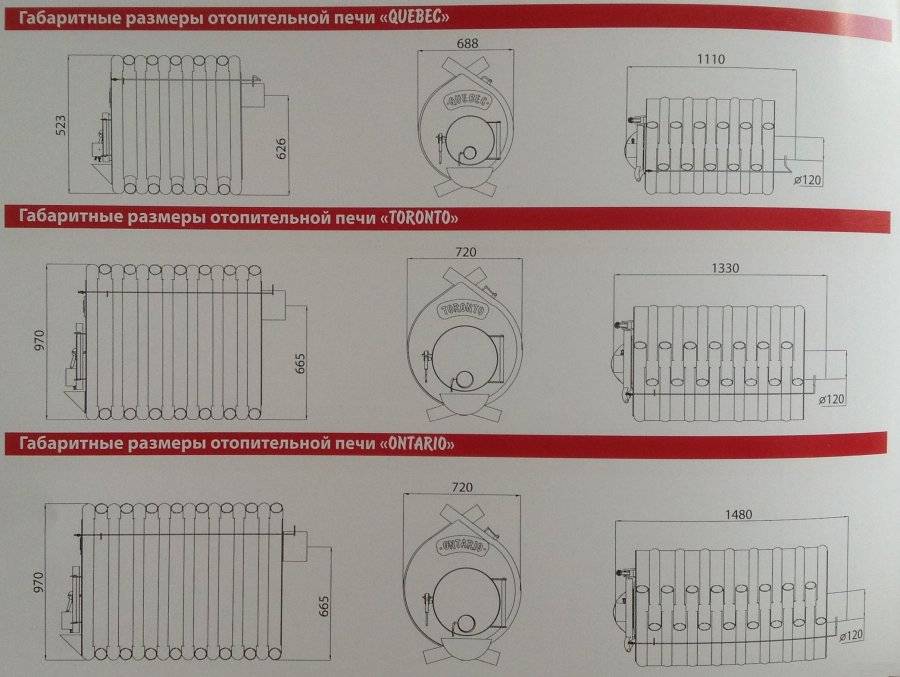

When installing a buleryan, the power and dimensions of the heating unit must be taken into account, since it depends on whether the device can evenly heat the entire room

It is equally important to choose the right place for installing the Canadian stove, equip the chimney according to all the rules and ensure its regular maintenance.

Installation diagram of the convection unit

How to drown

In order for the Canadian stove to work long and efficiently, it must be properly used and provided with periodic maintenance of the system. It is recommended to use dry firewood, lumber waste, paper, peat or wood pallets, as well as briquettes as fuel.

In no case should you pour liquid combustible materials into the furnace, pour coal or coke.

Do not forget that the device is constantly working in intensive mode. Experts advise to carry out the first firebox with open windows and doors

It is important to open both flaps beforehand for good traction.

Video: installation and launch of Buleryan

After that, paper and wood chips are lined up inside the furnace body in the shape of a triangle.

The door can be closed only when the materials flare up.With good burning, after 5-10 minutes, close the rear damper of the regulator, and the front one selects the operating mode of the buleryan.

Important! It is strictly forbidden to load fuel when the smoke damper is closed and the front regulator valve is closed.

Keep in mind that the efficiency reaches its maximum value when the rear damper is hermetically closed and the front damper is slightly ajar. You can regulate the working intensity of the stove by changing the positions of the dampers.

The operation of the buleryan includes not only the periodic laying of firewood, but also the cleaning of the firebox from ash and soot. Always open both doors fully before adding new fuel. This will intensify the burning. After loading, the regulator must be covered so that the material smolders.

Sometimes in dachas and in rooms that have been idle for a long time without heating, there is no draft when the Canadian stove is first kindled.

We advise you to read how to build a formwork for the foundation of the fence, how to choose the material for the fence, as well as how to make a fence with your own hands: from a chain-link mesh, from gabions, from a brick, a metal or wooden picket fence.

Experts advise to initially use paper rather than wood logs to solve the problem. Do not forget about the care of the chimney.

It is supposed to be cleaned of soot at least once a season through a special hatch. By the way, the lack of thrust may be the result of tar and condensate accumulated in the pipe.

Although buleryans are considered the safest stoves, it still does not hurt to follow the rules of your own safety. This is especially true for homemade units.

Important! Ash cleaning in the buleryan should be carried out when its level reaches the lower edge of the loading door.

When working with such a stove, it is strictly unacceptable:

- Leave fuel materials near the structure and in front of the firebox.

- Dry firewood, clothes, shoes and other flammable items on the surface of the cabinet.

- Use liquid fuel for ignition, as well as logs, the dimensions of which exceed the dimensions of the firebox.

- Store in the room where Buleryan stands, fuel materials that exceed the daily supply.

- Replace the chimney with ventilation and gas ducts, and also use ceramic and asbestos-cement materials for this.