- Furnace manufacturing

- Step by step description

- Water jacket

- Making the oven yourself

- Parameters and dimensions

- Required materials and tools for work

- Foundation laying

- Installation and assembly of the structure. Chimney installation

- How to kindle a bubafonya

- What materials are needed?

- Manufacturing sequence

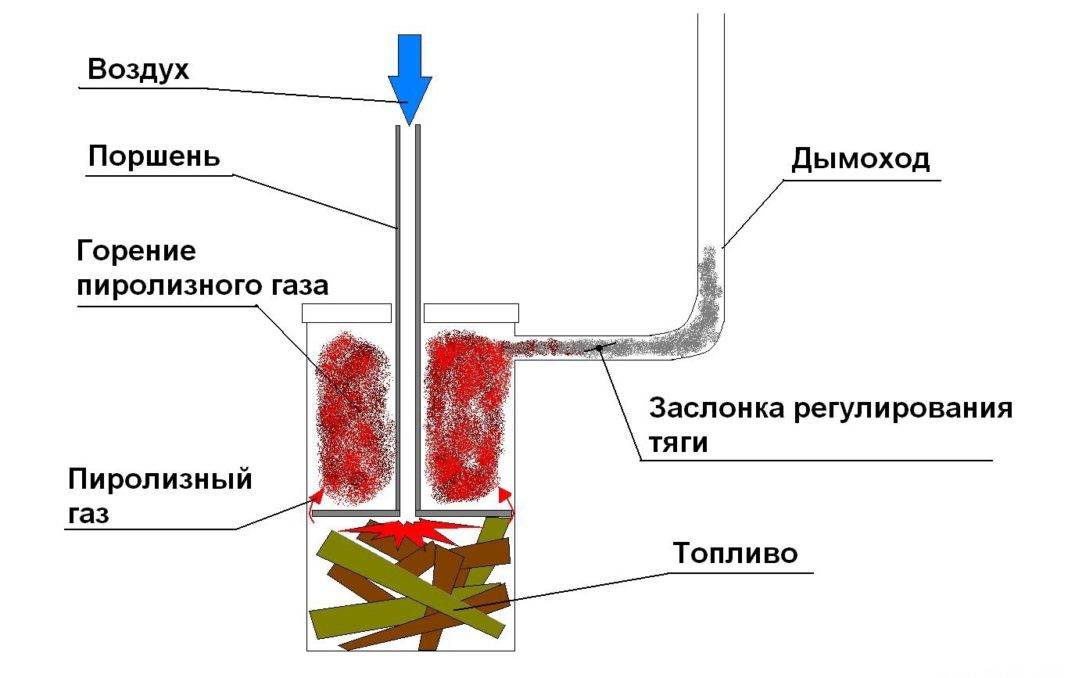

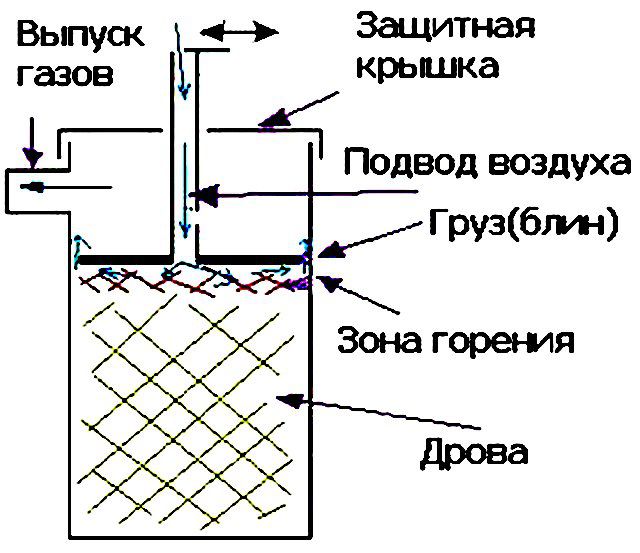

- The principle of operation of the Bubafonya furnace "on the fingers"

- Long-burning stoves "Bubafonya"

- Application area

- Advantages and disadvantages of a thermal unit

- Furnace device

- What is a long burning stove? On what principle is its work based?

- Preparatory work for the installation of a stove from a gas cylinder

- Mounting

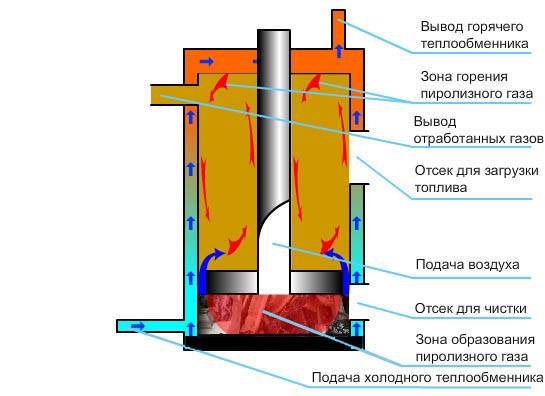

- Bubafonya with a water jacket

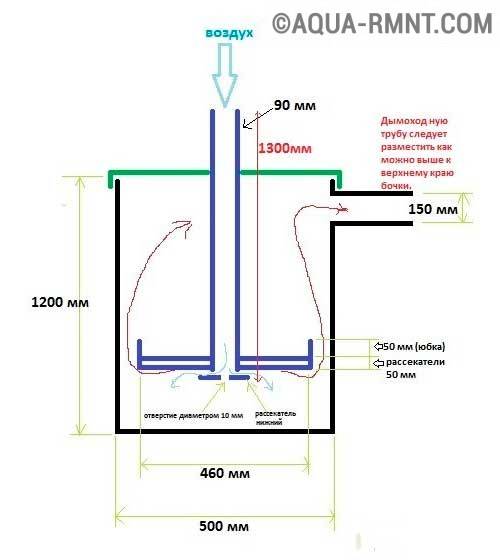

- Design Options

- How to make a do-it-yourself oven

- Who invented the oven?

- What is the Bubafonya oven

- Design advantages

- Furnace Disadvantages

- Stages of building a bubafoni from a balloon

- Balloon preparation

- Chimney and place for laying fuel

- Building assembly

- What is the essence of the principle of upper combustion?

- Rationalization from Afanasy Bubyakin: scheme of a new device

Furnace manufacturing

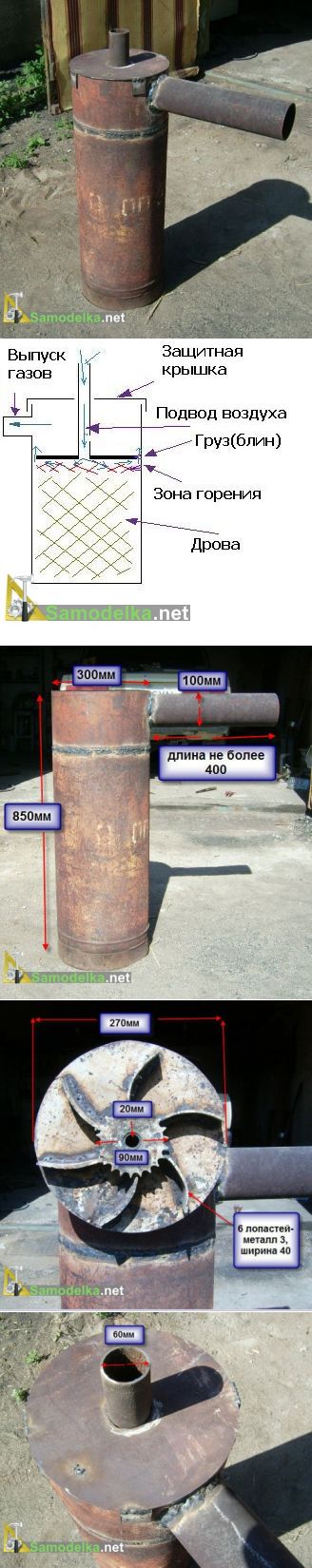

Let's move on to the step-by-step technology for creating bubafoni. As a base, you can use either an old LPG bottle or a metal barrel.In the first case, the standard capacity is 40 liters, so the stove turns out to be quite small - its operation time on one firewood tab will be about eight hours.

If you need more powerful equipment, then take a barrel of about 200 liters as a basis. Of course, it looks less presentable, but it can work without interruption for up to two days, without needing your participation. In addition, if the appearance of the structure is very important to you, you can overlay it with some heat-intensive material at the end of production - for example, beautiful stones. Or, alternatively, arrange brickwork around the stove. Both design options are also good because they reduce the likelihood of burns. Moreover, the heat transfer will be longer, softer and better.

Step by step description

After this operation, the balloon is ready for further achievements. Do not try to neglect cleaning, as in this case the slightest spark can cause a fire.

We take on the main work.

- Cut off the top segment of the balloon. Don't throw it away as it will later turn into a lid.

- Along the perimeter of the cut on the body, weld a strip cut from a steel sheet. Such a side will help to securely hold the lid on the main part, preventing it from moving.

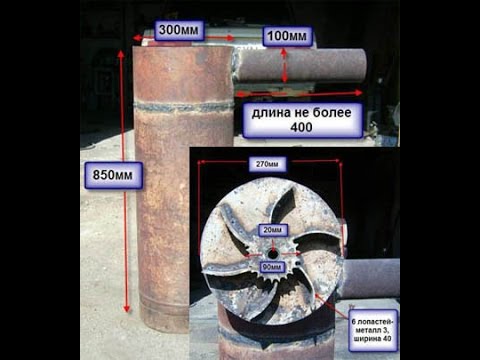

- We make a piston. Take a steel sheet, the thickness of which should be 3-4 millimeters. Cut out a circle from this material so that its diameter is slightly smaller than the inner diameter of the stove body. Make a hole in the center of the part, the diameter of which should be about 10 centimeters. Attach the duct pipe to it using a welding machine.It should be of such length that it rises 20 centimeters above the upper edge of the stove.

- Now, on the bottom of the steel circle, weld six blades, also made of metal. This is necessary for the future uniform burning of the fuel.

- We figured out the “piston”, let's move on to the main part of the furnace. Cut a rectangular hole in the lower segment of the case, where the door will then be installed. The work is done with the help of a Bulgarian saw.

- Now make the door itself. Actually, for this you can take the same piece that has just been cut out, sheathe it around the perimeter with an asbestos cord for a snug fit to the body, weld the hinges and the hinge for the valve.

- Weld the finished door with hinges to the body in the appropriate place. Install the valve on the opposite side.

- Next, we work with the lid. Make a hole in it, necessary for the removal of combustion products. The diameter should be from 10 to 15 centimeters. The same indicator should be for the pipe, which is installed in this hole and welded. Another segment is connected to it at an angle of 90 degrees. Thus, you get a chimney elbow.

- Now put everything together: install the "piston" inside the structure and attach the cover. This is what the finished oven looks like. After that, you can do the kindling as described above.

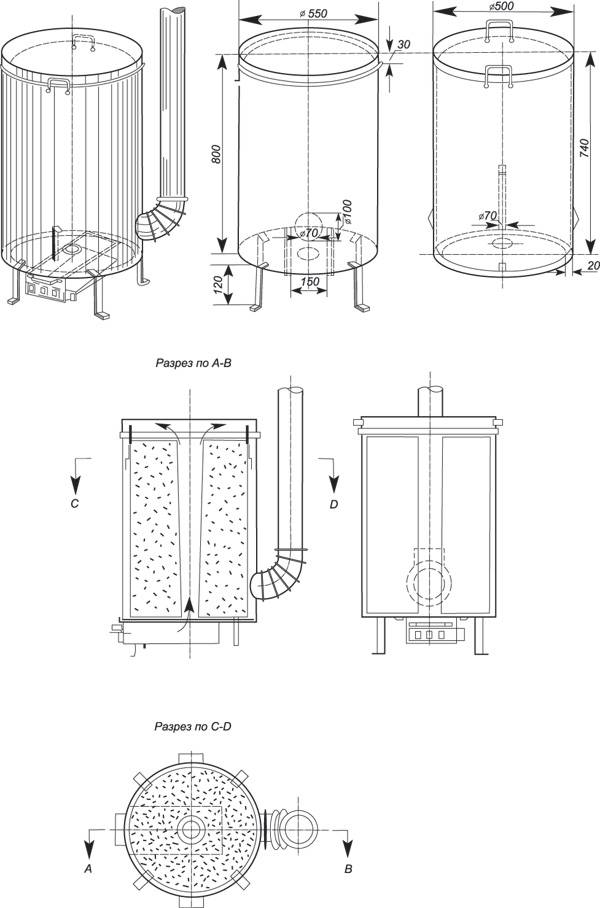

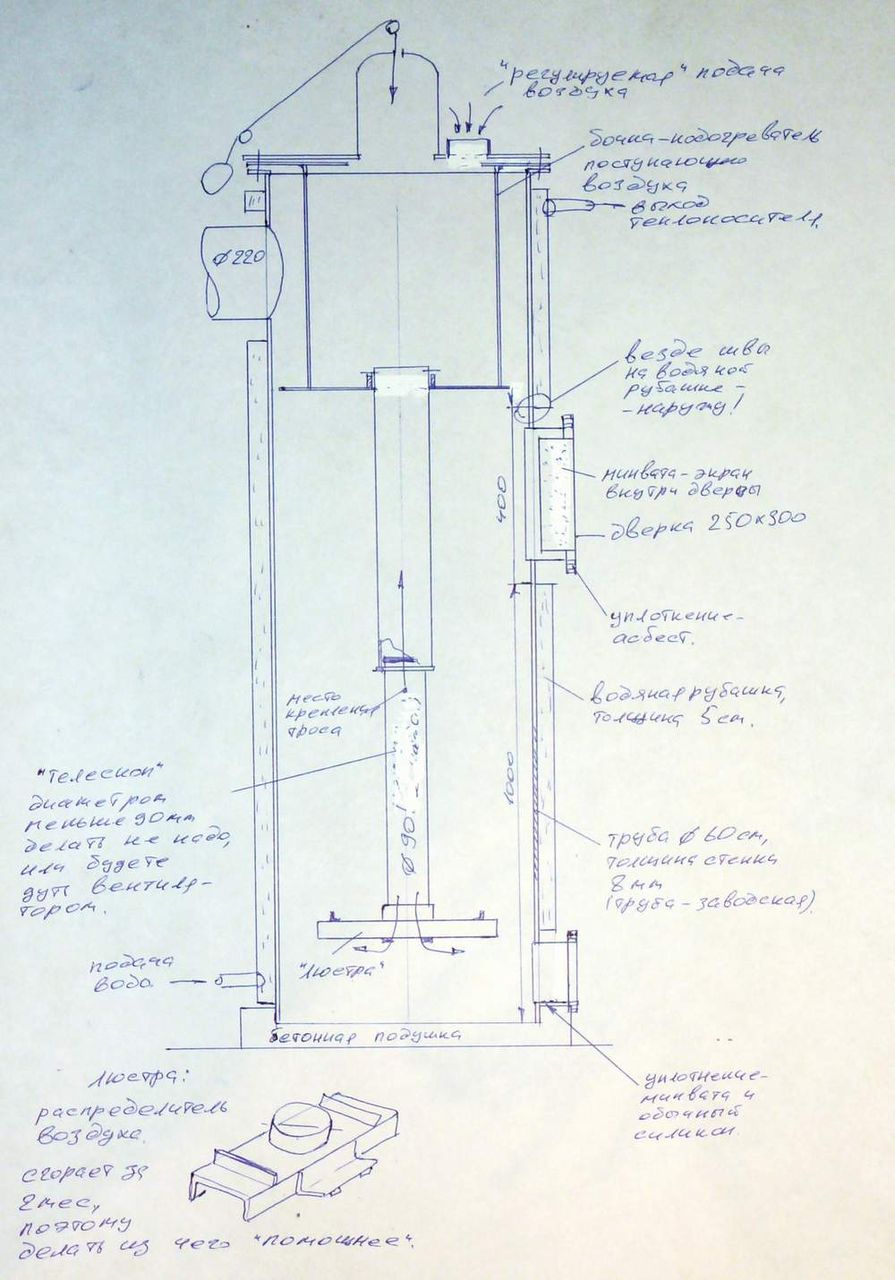

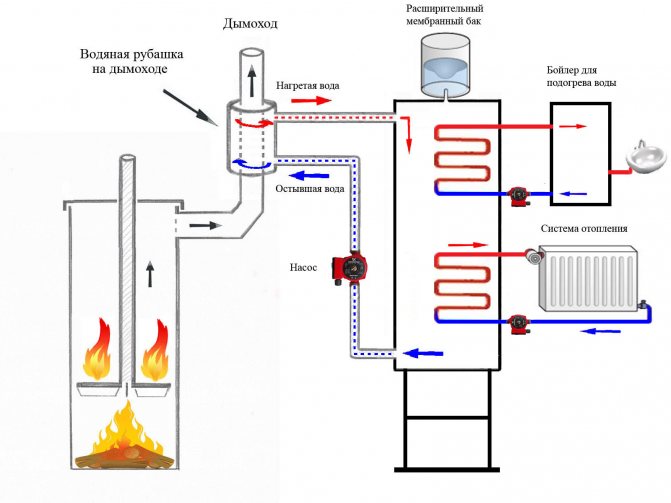

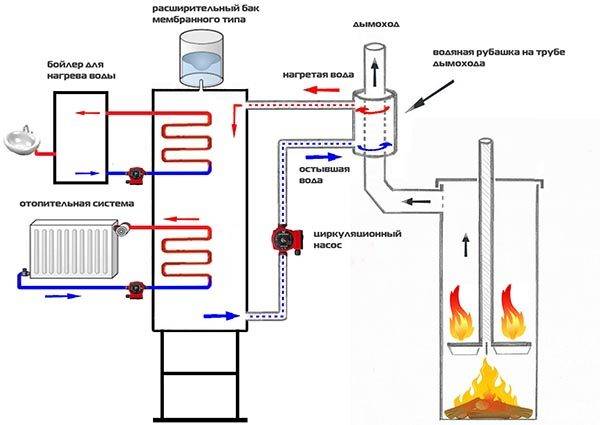

Water jacket

Creating a water jacket is not particularly difficult. You will need a metal container, the diameter of which is larger than the diameter of the finished oven. Place the bubaphone in this cylinder. Weld open areas, and make holes on the sides for connecting the inlet and outlet heating pipes.

Then the corresponding pipes are welded there.In principle, such a water jacket can be placed not only on the body, but also on the chimney, since there the heating will go just as intensively. The principle of operation of the design is extremely simple. Water will be supplied to the “jacket”, where it will immediately heat up from the stove and exit into the heating main.

Actually, on this, the manufacture of bubafoni can be considered complete. When installing the oven, do not forget about fire safety. If you plan to place the equipment in a wooden building, then it must first be prepared.

To do this, take a few asbestos sheets and cover the walls with them, as well as furnishings that will be located in the immediate vicinity of the stove. As for the floor, you can fill it with a concrete screed or simply put a thick metal sheet on the place where the bubafon will stand. If the aesthetic aspect is important to you, then you can finish these areas with ceramic tiles - they look quite decent and can withstand high temperatures.

Making the oven yourself

Do-it-yourself bubafonya stoves from a gas cylinder are made simply, but require preliminary preparation. It is necessary to prepare the tools and the room, study the drawings, pour the foundation. If necessary, lay an additional gasket.

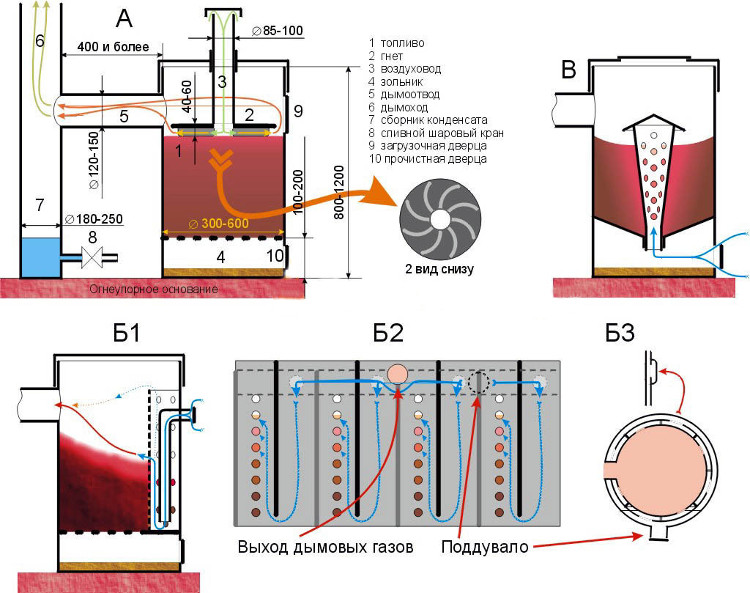

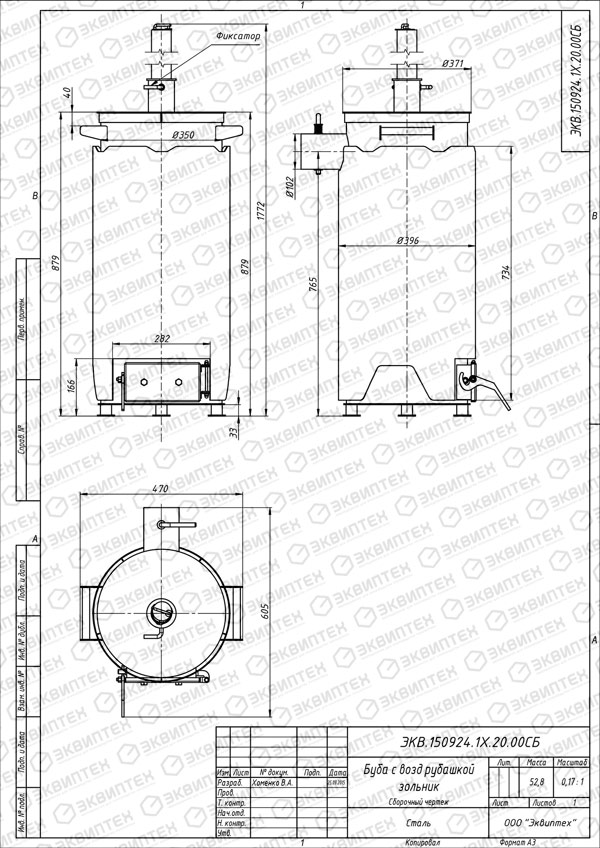

Parameters and dimensions

The ratio of width to height is important. The optimal ratio is 3 to 1

It is important that the width is at least 30 centimeters, as the air will leave too quickly without oxidizing the fuel.

In addition, consider the following options:

- Wall thickness. Optimal 4-5 mm. Thin walls burn through and require accelerated replacement.

- Gap between discs and cylinder.The calculation of this indicator is determined by the formula (0.05 x width). Making a bubafon stove from gas cylinders with our own hands with a diameter of 30 centimeters, we will get a gap of 1.5 millimeters.

- Disc thickness. The piston has a different thickness, depending on its width. It is calculated according to the table

| Width | Height |

| 30 cm | 10 mm |

| 40 cm | 8 mm |

| 60 cm | 6 mm |

| 80 cm | 4 mm |

Having developed a drawing with dimensions, you can make a heater for specific materials and premises.

Required materials and tools for work

It is impossible to make bubafonya without a welding machine. Therefore, the room must have good ventilation. In the warm season it is possible to build it on the street. Take care of uninterrupted electricity. When working, voluminous objects will be used - you need a lot of free space.

When making bubafon stoves from gas cylinders with your own hands, you need to take care of the boiler in advance. A 200 liter gallon will do. Make sure there are no signs of corrosion. For convenience, it is desirable to make support legs and carrying handles.

Additional material:

- sheet steel for the piston;

- pipe for air outlet and chimney made of stainless steel;

- channels;

- foundation mix.

Of the tools we need:

- mallet;

- Clamp;

- Shovel;

- inverter;

- Angle grinder.

Foundation laying

All work on the manufacture of the foundation is divided into three stages:

- The pit is being prepared. It is required to dig a small square pit. The depth should be 20-30 sentiments.

- Fill. Gravel is poured into the hole. Concrete is poured on top.

- After the concrete has dried, a pedestal of bricks is built on top (to increase stability).

Installation and assembly of the structure. Chimney installation

When making a do-it-yourself bubafon stove from gas cylinders, the cap is first separated. An incision is made in the upper part of the vessel. After that, you can begin to manufacture the piston.

- First of all, a circle is cut out of a steel sheet. Its diameter should be 4-5 millimeters less than the width of the balloon so that the formed gases can safely escape. In the middle we make a hole for the air outlet pipe.

- We weld the circle and the pipe.

- We weld guides from the channel onto the base of the disk, as in the photo.

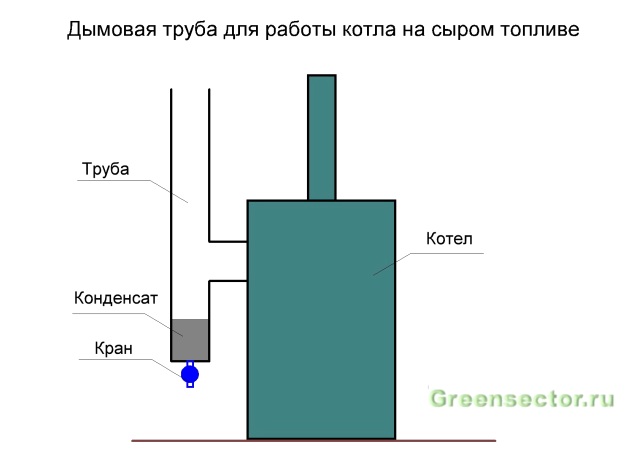

To ensure high-quality smoke removal, the chimney is made of two pipes. They are welded to each other at an angle of 90 degrees.

To make a stove with a water circuit, a pipe is laid around the chimney from the water supply system.

Below is a diagram of the installation of a water jacket.

How to kindle a bubafonya

Remove the cap and piston so that there is access to the bottom. Firewood is placed horizontally inside

This is important as standing upright will result in a fire.

Sawdust (small branches) is poured from above and we put a rag soaked in lighter fluid. We cover with a piston and throw burning paper or rags into the pipe. After twenty minutes, when the firewood flares up well, you need to close the valve. After that, smoldering and heat distribution begins. Before the fuel burns out completely, it is undesirable to open the valve, as this will lead to a sharp drop in temperature.

Bubafoni kindling video:

What materials are needed?

Do-it-yourself bubafon stove is quite simple to make. To do this, you can use an old gas cylinder of a standard volume of 40 liters or an iron barrel of 200 liters.The cylinder has less heat transfer, and it works for about 8 hours from one load. This option is used for heating small rooms.

The barrel is better in this regard. It heats the space of large volumes for 30-40 hours. Her appearance is unpresentable, but if it is finalized, lined with natural stone or brickwork, then bubafonya can be used to heat living rooms.

Carefully consider the location of the device, since during the combustion process the temperature of the stove body reaches very high temperatures, which is very fire hazard.

In addition, to create this furnace, you will need several pieces of steel pipe, a welding machine, electrodes, a grinder, a chisel, hacksaws and a chisel.

Manufacturing sequence

As an example, consider the process of making a Bubafonya stove from a gas cylinder. The first stage of work is cutting off its upper part. Later we will need it as a case cover.

Photo No. 1 Old gas cylinder - the basis of the pyrolysis furnace

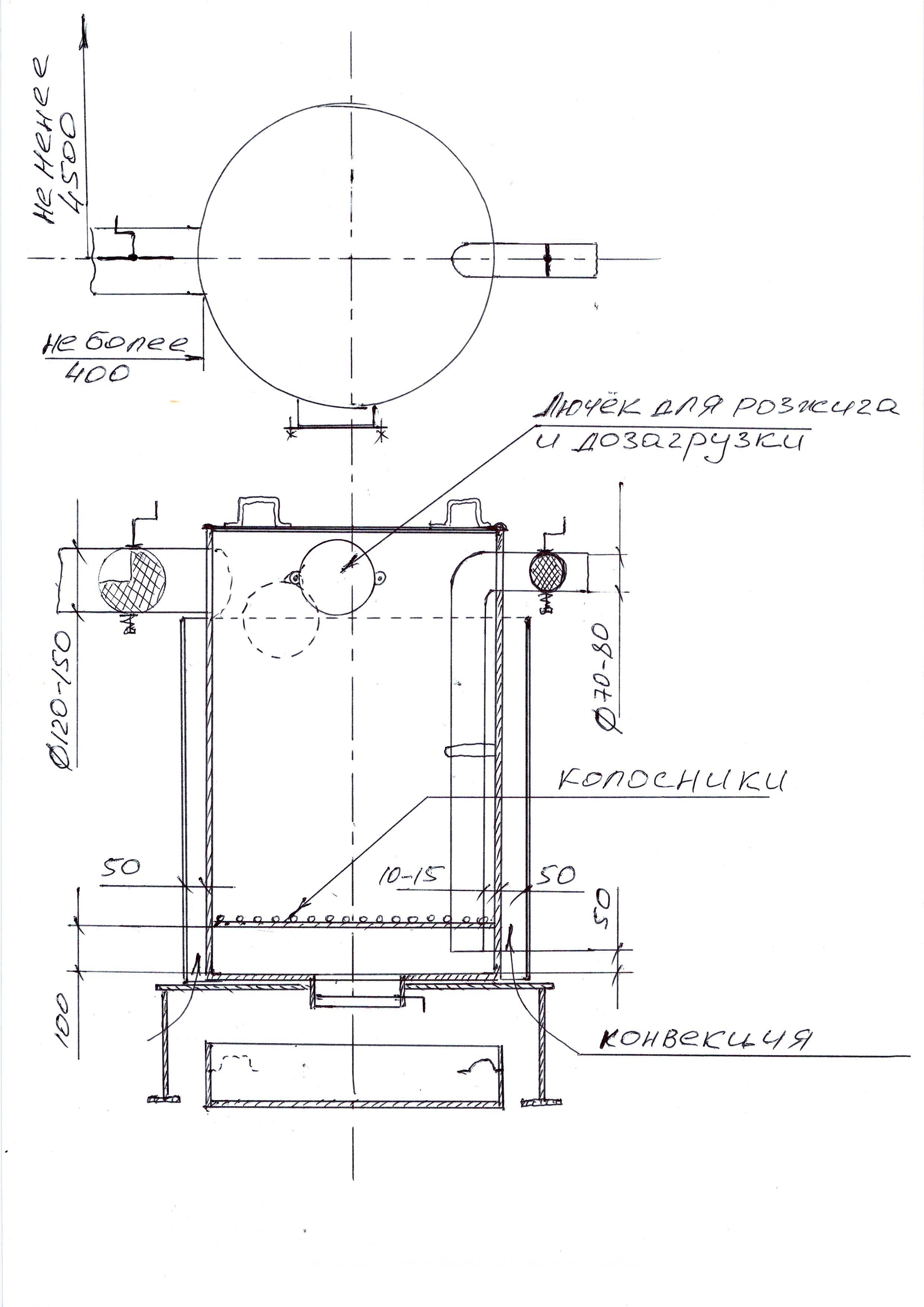

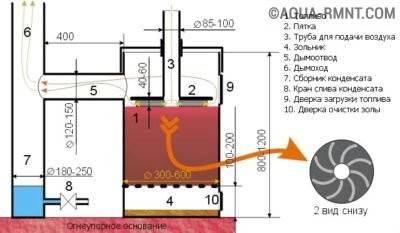

The second step is the manufacture of the knee-hood. To do this, a hole of a suitable diameter must be cut in the side of the cylinder body. The knee is welded from a corner cut of a steel pipe with a diameter of 100-120 mm. For the chimney riser, you will have to find a wider pipe - 120-150 mm. This diameter is necessary to improve the thermal efficiency of the boiler.

At the end of the hood, you need to weld an adapter for installing a chimney (Photo No. 2 and No. 3). The sealing of the “hood-riser” transition is carried out with cord asbestos on clay or fiberglass.

Photo #2

Photo No. 3 Branch from a steel pipe with an adapter

Step three. We weld two handles and an upper pipe to the lid, which will direct the movement of the “piston”.We attach a steel strip to the furnace body by welding. It will create a side that prevents the lid from shifting from the case.

We cut a hole in the cylinder cover by gas welding for installing an air pipe (outer diameter 80-90 mm).

Photo No. 4 Half of the oven is ready

The air pipe can be not only round, but also square. From this, the work of the potbelly stove will not worsen, but its assembly will become easier (photo No. 5).

Photo No. 5 Square pipe air distributor

Fourth step - a “pancake” is cut out of a thick steel sheet (3-4 mm) with a hole in the middle, with a diameter equal to the diameter of the duct pipe. The gap between the edge of the air distributor plate and the cylinder walls should be 1/20 of the "pancake" diameter.

The thickness of the metal for the plate is chosen depending on the size of the boiler body. So, for a household gas cylinder with a diameter of 30 cm, a plate with a thickness of 8-10 mm is required to make a "pancake". For a 200-liter barrel, this thickness will be less (4-6 mm).

We weld six blades to the air distributor plate from below. They are essential for uniform burning fuel in the lower chamber and complete combustion of pyrolysis gases in the upper (photo No. 6).

Photo No. 6 The main part of the furnace is the “piston” air distributor with blades

In some designs, a second smaller round plate with a small hole (3-4 cm) is attached to the center of the distribution unit. It is needed so that between the fuel and the blades there is a free space for the exit of gases, and burning coals do not clog the air supply channel. Having collected all the parts of the stove, it remains to load it with firewood, setting them vertically, and laying wood chips and ignition paper on top of them (photos No. 7 and No. 8).

Photo No. 7 The chimney is installed on the branch pipe through the seal and is ready for operation

Photo No. 8 The furnace is loaded with fuel

Photo No. 9 The air distributor is installed in the housing

Photo No. 10 A cover is put on the body and the boiler is ignited through the air duct with a small portion of kerosene

If the stove will be heated not with dry, but with raw firewood, then changes must be made to the design of the chimney. It should be extended down by making a knee to collect condensate and put a drain valve on it.

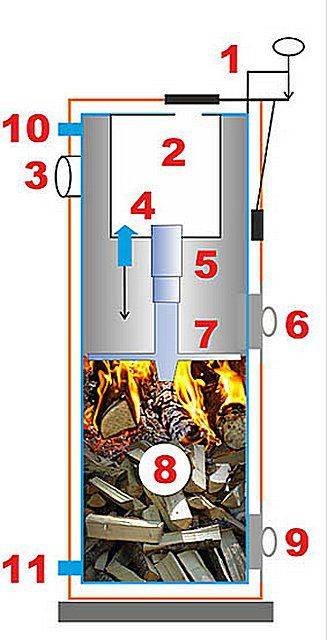

The principle of operation of the Bubafonya furnace "on the fingers"

You can talk for a long time about the theory explaining the operation of this heating installation and operate in terms that are understandable only to a heating engineer. Our task is to help home masters make a Bubafonya oven with your own hands.

Therefore, we briefly list its most important features:

- The process of burning fuel goes from top to bottom (like a wax candle), and not from bottom to top, like a conventional stove. Firewood is laid in a vertical position, and chips, sawdust and kindling paper are poured on top of them.

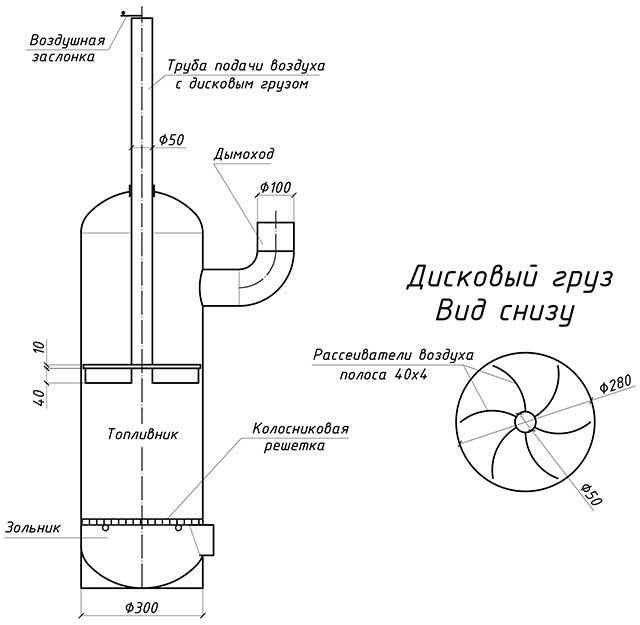

- For post-combustion of pyrolysis gases, an air distributor is used - a steel “pancake” with blades and a hole in the middle. Air enters the combustion zone through a pipe welded to the "pancake". For external similarity, this design is sometimes called a "piston".

- The fuel is ignited from above (with the air distributor removed). After the flame has ignited, a “pancake” with blades is placed on the fuel array, and a lid is put on top of the furnace body. Some users light the stove directly through the air pipe by pouring some kerosene into it.

- The process of thermal decomposition of wood occurs under the "piston".Under its weight, the burning fuel is compacted, the temperature rises and thermal decomposition occurs with the release of combustible gases. As the firewood burns, the “piston” goes down, preventing the fuel from loosening and losing the temperature necessary for pyrolysis.

- The combustible gas emitted by the fuel burns over the surface of the air distributor, increasing the efficiency of the furnace by 20-30%.

The draft of the furnace is regulated by means of a valve mounted on the “piston” pipe. The oxygen necessary for the combustion of the pyrolysis gas enters the upper chamber through the gap between the "piston" and the cover. Since the thrust of such a stove is quite powerful, there is no exit of flue gases through the gap between the cover and the body, as well as the piston and the cover. The height of the chimney, according to the owners, should be at least 4 meters.

Long-burning stoves "Bubafonya"

There are many designs of long burning stoves. The difference between their device is the dosed air supply to the furnace. Reducing its supply leads to a slowdown in oxidation and a more complete use of the fuel. The flow is adjusted through the furnace and the ash pan with special dampers, that is, from below.

Sawdust stove design option

In the bubafonya furnace, air is supplied from above through a hollow rod. In this way, the effect of gradual combustion of fuel is achieved without heating the underlying layers. When such a thermal unit warms up to a temperature of 300 degrees or more, the process of wood pyrolysis begins. Combustible furnace gases enter the upper part of the furnace and burn there with the release of a large amount of heat. That is, wood fiber burns in the lower part with the release of combustible gases that ignite on top of the piston.

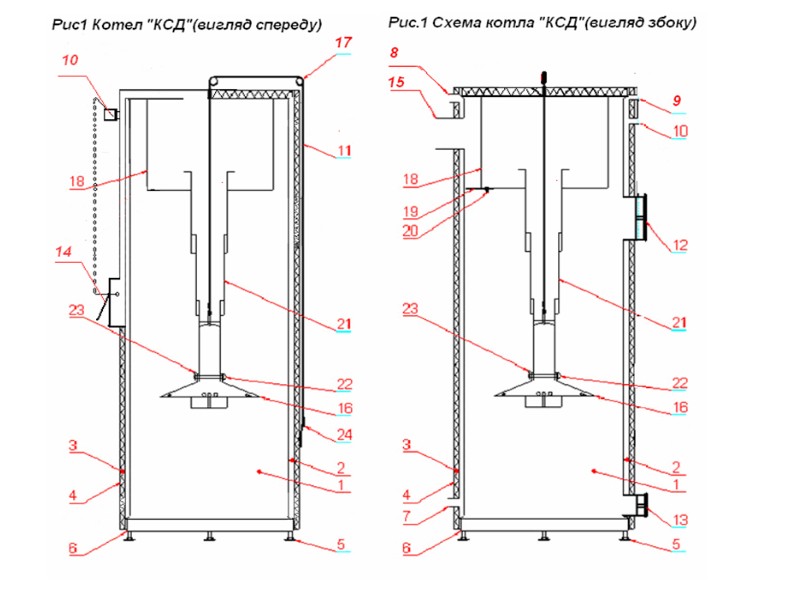

The principle of operation of the Bubafonya long-burning furnace with a water-heating jacket and an ash pan

Application area

Depending on the capacity of the furnace, the burning of one bookmark of fuel can last from 12 to 24 hours. This is convenient when used in heating systems of a country house, greenhouses, garages and industrial premises.

Advantages and disadvantages of a thermal unit

The advantages of such an oven include the following factors:

-

Simplicity of design, allowing you to make it with your own hands.

- A pyrolysis furnace of this design provides ample opportunities in choosing the type of fuel. It can successfully burn woodworking waste in the form of sawdust, wood chips, small trimmings. Such a heating unit can also work on peat briquettes, low-grade coal and fuel pellets.

- Long, up to a day work time. But it depends on the air supply rate and the volume of the combustion chamber.

However, there are a number of significant disadvantages of this design:

- Bubafonya has a low efficiency. This can be attributed to the uneven heating of the furnace body, resulting in a decrease in the degree of heat transfer of the unit. For pyrolysis furnaces of advanced designs, the efficiency can reach 90%.

- Bubafonya of classical design is inconvenient for cleaning from fuel combustion residues. They have to be removed from the top. But this disadvantage is easily eliminated by the device of the door at the bottom of the fuel tank. The door should close tightly enough to minimize the air flow through it.

- Unattractive appearance. The stove looks rough and does not decorate the interior when installed in a residential building.

Furnace device

To make a Bubafonya boiler, you need to carefully consider its design. This will create a truly productive unit that will not only heat the desired room, but also save fuel. So, Bubafonya from a gas cylinder drawing contains the following elements:

- Frame. The main element of the furnace, which often has a cylindrical shape. For construction, a barrel, a cylinder, a bulky fire extinguisher or a pipe are often used, to which the bottom is welded.

- Chimney. The element is often made of a metal pipe, which has a diameter of 11 to 25 cm. It is welded on top of the body and serves to remove combustion products.

- Delivery piston. The part is made in the form of a circle, on the lower part of which ribs are welded. An air pipe is attached to the center of the piston. The main purpose of the ribs is to create an additional layer of air between the piston and the piston. This has a positive effect on smoldering and the rate of outgassing.

- Regulating valve. Everything is pretty simple here. It serves to control the supply of oxidizer to the combustion chamber.

- Lid. A hole is made in it through which an air duct is passed. Between it and the piston, a secondary combustion chamber is formed, where vapors and gases are ignited.

These are the basic building blocks. But, if we are talking about Bubafoni with a water jacket, then the scheme will look a little different.

The unit can be used for a complete heating system

What is a long burning stove? On what principle is its work based?

To begin with, we need to understand how wood burning actually occurs.In order for wood to ignite, it must first be heated to a temperature of about one and a half hundred degrees from an external heat source. As a rule, this task is performed by paper or wood chips set on fire with a match. The tree begins to slowly char and, upon reaching a mark of about 250 degrees, decomposes into simple chemical components. The white smoke that we can observe when kindling a fire is gases and water vapor released by heated wood. And now, having stepped over a level of three hundred degrees, the gaseous substances released from the tree ignite, contributing to a further acceleration of the thermochemical reaction.

In itself, the decomposition of fossil fuels, such as, for example, wood, into simple elements is called pyrolysis. And everything would be fine, but the usual burning of wood does not fully use all the potential inherent in the energy carrier. There is a lot of waste left, which, in the end, does not contribute to savings.

Pyrolysis ovens, one of the variants of which we will consider in this article, use fuel much more efficiently. The main secret lies in the fact that the combustion of gases released during heating of wood occurs separately from the energy carrier itself. At the same time, the primary fuel slowly smolders, which makes it possible to achieve much longer work time on one log load. In furnaces of the “bubafonya” type and other pyrolysis heating devices, everything burns out almost 100%, leaving only a small amount of ash after.

How combustion occurs

This is interesting: Paint for wooden walls and ceilings: a closer look at the issue

Preparatory work for the installation of a stove from a gas cylinder

The use of welding during installation will require a room with good exhaust ventilation. If this is not available, work in the air is allowed.

The next steps might look like this:

-

Development of a preliminary design of a thermal unit with the production of drawings of parts.

- Purchase of materials.

- Parts manufacturing.

Mounting

The unit is assembled in the following order:

Carefully cut off the top of the balloon.

Make a hole in the resulting cap along its axis. Its size should be 2–2.5 mm larger than the corresponding outer size of the inlet pipe (rod).

Weld handles to the cap.

To the bottom of the cylinder, which is the furnace body, weld the legs from a metal profile 25–30 cm high.

Make a side hole for the chimney, weld the exhaust pipe.

Weld additional ribs of heat exchangers along the generatrix of the body.

Make a stock:

Weld the piston pancake to the end of the intake pipe. Control alignment.

Install a damper on its upper end to regulate the air supply.

Weld support ribs 40 mm high in the amount of 4–6 pieces to the pancake.

At the installation site of the furnace, place an asbestos sheet on the floor, lay galvanizing on top of it and fix the resulting protective layer to the floor. Install oven.

Install the chimney. For this:

Install an angle adapter on the outlet pipe.

Attach a straight pipe to it in the direction of the wall.

Install another corner adapter with a reverse slope.

After marking, make a hole of the desired diameter in the wall.

Install a straight horizontal section of the chimney through the wall

Attention! Its length should not exceed 1 meter.

Install a condensate collector at the end of the horizontal section.

From it, vertically along the wall, mount a chimney from sandwich pipes.

Install the chimney cap.

Important! The height of the chimney must be less than 5 meters from the level of the exit from the furnace

Bubafonya with a water jacket

To organize water heating of a country house, such a thermal unit can be used as a boiler. To do this, a container in the form of a water jacket is welded onto it. You can use a metal barrel by cutting a hole in the bottom for the balloon. The height of the casing must reach the outlet of the chimney. From above, the shirt is welded with an annular piece between the body and the barrel.

The outlet for the water supply is installed at the top of the shirt, the return line is at the bottom. An indispensable accessory of the heating system is an expansion tank with a membrane. Depending on the design of the thermal circuit, it can be gravity flow with natural circulation or forced circulation using a circulation pump.

Bubafonya stove with a water jacket in the heating system

By the same principle, you can arrange a shirt on the furnace body.

Design Options

Another basis for the bubafon furnace can be:

- Metal barrels of different sizes, for example, 100 and 200 liters. The smaller one serves as the body of the furnace, the larger one plays the role of a hot water boiler.

- Pipes steel of big diameter. For the furnace, you can purchase such products in the secondary market. Pipe metal is perfectly welded and is highly durable. Additional costs are associated only with the need to weld the bottom of the sheet metal.

How to make a do-it-yourself oven

Making a do-it-yourself oven

For the manufacture of the furnace, water and gas pipes of large diameter, gas cylinders, and old steel barrels are used. The pipe wall thickness must be at least 2.5 mm. For assembly work, the following materials and equipment will be needed:

- Welding machine, electrodes, shield;

- angle grinder (Bulgarian);

- A hammer;

- Hacksaw for metal;

- Electric drill and others.

In addition to the tool, the presence of welder skills is a prerequisite. A number of operations are conveniently carried out using a gas cutter.

The simplest method is to make a stove from a cylinder or an old thick-walled barrel. In fact, the firebox is already ready. At the gas cylinder, the upper spherical part is cut off (with a grinder along the existing joint). Then a steel strip is welded along the perimeter of the cut, which will be a skirt. The diameter of the skirt should be slightly larger than the diameter of the balloon. A hole is cut in the center of the cover corresponding to the outer size of the duct pipe. For ease of maintenance, handles made of bent metal are welded onto the lid. The lid is ready.

At the next stage, the piston assembly is made. A circle is cut out of a sheet of calculated thickness. An air duct pipe is welded to the circle in the center. After that, a hole is cut in the center corresponding to the inner diameter of the pipe. Elements of air channels are mounted on the lower plane - corners, channels, bent strips. A chipper with a hole is installed over the strips. The outer dimension of the fender should slightly exceed the diameter of the duct. A hole is drilled in the bumper in the center. A control damper is attached to the upper end of the duct. The mechanism is ready to use.

Making bubafoni from a barrel has a similar algorithm. The lid is made in a different way. A grinder cuts off the lid of the barrel around the circumference with a section of the body. The side walls of the lid are unbent with a hammer for expansion. The edge of the barrel is folded inward. Handles are welded, a hole is cut - the lid is ready.

It is worth noting that barrels are rarely used to create stoves. They have a small wall thickness, when welding they are strongly led. The ratio of diameter and height of the barrels is not optimal for proper combustion. The service life of such furnaces is short.

In the case of using a pipe as a base, its bottom is welded end-to-end with a sheet of metal. The cover is also made of steel of increased thickness.

At the last stage, the chimney pipe is mounted. A hole is cut out in the side surface and a branch pipe of the calculated diameter is welded. The length of the pipe is taken 400 - 500 mm.

The main structural elements are ready. In addition to them, additional elements are made - body fencing, furnace legs, ash pan. The ash pan is made of metal - a circle is cut out slightly smaller than the diameter of the firebox. A steel strip edge is mounted around the perimeter. Reinforcement or a pipe of small diameter is welded to the circle. The ash pan is installed under the piston, the fittings pass through the duct. After removing the piston, the ash pan is lifted by the armature (pipe). Some craftsmen mount a door at the bottom instead of an ash pan.

The furnace foundation for bubafoni is poured in a tape type (into a monolith). A pit is torn off with a depth of 40 - 50 cm, poured with concrete mortar. After hardening, a platform of refractory bricks is laid out on the foundation. The bottom of the kiln is hot and the simple concrete foundation will gradually collapse.

Who invented the oven?

The first furnace was designed, assembled, tested and shared with Internet users by Afanasy Bubyakin, a craftsman from the city of Kolyma. On the World Wide Web, Athanasius appeared under the pseudonym "Bubafonya" (bubafonja), thanks to which the proposed design of a long-burning heating system got its name. The designer himself admitted that he was inspired to create the furnace by the Lithuanian Stropuva boilers, which have a similar principle of operation.

What is the Bubafonya oven

The Bubafonya stove is made practically from improvised materials. The design is based on a cylindrical container or simply a metal barrel or a piece of pipe of sufficient diameter with thick walls welded at one end. The bottom of the container is sealed, and the top of the barrel is closed with a lid. A piston is installed inside with a load (welded sections of a channel or metal corners), air dividers and a supply pipe. A discharge pipe is welded to the upper part of the fuel tank (barrel) body. It is connected to the main pipeline by means of a clamp and fiberglass, which serves to reduce heat loss.

For ease of use, metal handles are welded on the lid and outer walls of the fuel tank.

Furnace Sample

Design advantages

- compactness;

- low cost of construction and fuel;

- speed and ease of assembly;

- sufficiently long operation of the furnace without additional reloading of fuel;

- the ability to assemble the structure of the required dimensions with your own hands;

- environmental friendliness;

- high efficiency;

- autonomy, that is, the ability to work without electricity;

- ease of operation (pipes from condensate are cleaned with the usual "ruff");

- the ability to quickly replace worn parts;

- the ability to regulate fuel consumption and combustion intensity;

- the possibility of modifying the furnace and connecting it to a water heating system.

Furnace Disadvantages

- formation of condensate on pipes;

- possible freezing of pipes;

- it is inconvenient to remove ash and ashes from the bottom of the fuel tank, as a result they sinter into a mass similar to asphalt and the furnace will eventually require the replacement of the fuel tank;

- sometimes "backburning" occurs when gases enter the room, which sometimes requires the installation of a blower fan;

- cools down quickly after use.

Stages of building a bubafoni from a balloon

Before manufacturing itself, you need to decide on the size of the furnace.

Balloon preparation

-

Cut the top off carefully. Save it. In the future, it will play the role of a cover.

- Weld a strip of steel to the body of the stove. This will be a side that will not allow the lid to move from the body.

-

Now you need to make a pressure circle, thanks to which the fuel will be pressed down, and oxygen will enter the furnace, ensuring long-term combustion.

- Take a thick (3-4 mm) sheet of steel and cut a circle out of it. Let's make an air distributor out of it. Its diameter should be slightly smaller than the main frame of the furnace. The gap between the edge of the air distributor and the walls of the gas cylinder is equal to 1/20 of the "pancake" diameter. Make a hole in the middle of it. In order for the traction to be effective, this hole must be at least 10 centimeters. Weld an air pipe to it. Its height should be 20 centimeters more than the body of the stove.

-

At the bottom of the air distributor plate, weld 6 metal blades.They are needed so that the fuel burns evenly in the lower chamber, and the pyrolysis gases in the upper chamber burn completely.

Chimney and place for laying fuel

-

At the bottom of the frame, make a hole in the shape of a rectangle using a grinder. Weld the curtains to it and hang the door. To ensure complete tightness, sheathe the door with asbestos cord around the edges. A little lower in the same way, you can make another door, but a little smaller. Through it it will be convenient to clean the bubafon.

- To make a chimney, it is necessary to make a hole in the lid through which the exhaust gases will exit and the necessary draft will be created. The diameter of the pipe for it should be 10-15 centimeters. Smaller sizes are not desirable.

-

Make a chimney elbow out of two pipes. Trim the edges at a 45 degree angle and weld them together to form a 90 degree angle.

- All parts of the oven are ready. Now you need to put them together and load them with fuel. Sawdust and paper can be poured on firewood for faster and more convenient ignition.

If the stove is supposed to be heated not only with dry wood, then the pipe should be extended downward and make a place to collect condensate.

Furnace drawing showing all details and dimensions

Building assembly

-

Load fuel into the furnace. Arrange the firewood vertically, sprinkle it with wood chips and lay the paper.

-

Install the air distributor or "piston".

-

The last step is to install the cover.

What is the essence of the principle of upper combustion?

In furnace and boiler equipment with top combustion, the furnace has the shape of a vertically oriented cylinder. It is obvious that the fuel bookmark under such conditions will burn longer than with the usual method of kindling from below.

At one time, Stropuva engineers improved the technology somewhat by applying the following innovations:

- Air began to be dosed and only into the combustion zone. To supply air, a telescopic duct had to be installed.

- In order for pyrolysis to occur in addition to combustion in the upper zone of the fuel filling, an air heating chamber up to 4000°C was installed.

Post-combustion of pyrolysis and flue gases - occurs in the space above the fuel bookmark. Due to the use of pyrolysis, the efficiency of the installation has been significantly increased.

Rationalization from Afanasy Bubyakin: scheme of a new device

Obviously, it is impossible to repeat the Stropuva boiler at home: in order to avoid malfunctions, the links of the telescopic duct must be made with very high accuracy. Afanasy Bubyakin proposed a simpler method for heating air and supplying it to the combustion zone. "Bubafonya" is the nickname of this builder on one of the forums where the design was published. In the future, this name was assigned to the oven.

The solution is simple:

- Place an oppression on the fuel bookmark with an air duct attached to it, which goes out through the furnace cover. As the fuel burns out, the oppression will fall under its own weight, and air will always flow to the top of the bookmark.

- On the underside of the oppression, using segments of a corner or a channel, draw hollow radial channels through which air will move to the periphery. During its journey, it just heats up to the required temperature.

Photo 1. Scheme of the internal structure of the Bubafonya furnace, indicating the dimensions of the chimney and condensate trap.

The dimensions of the oppression are selected so that between it and the walls of the furnace there is a sufficient gap for the release of pyrolysis gases.