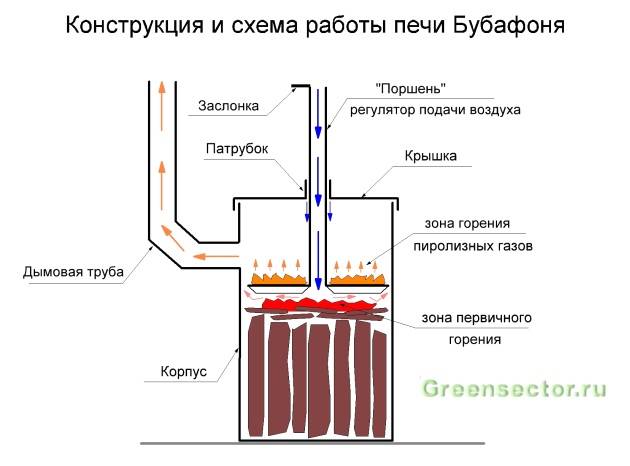

- The principle of operation of the Bubafonya furnace "on the fingers"

- Potbelly stove features - pros and cons

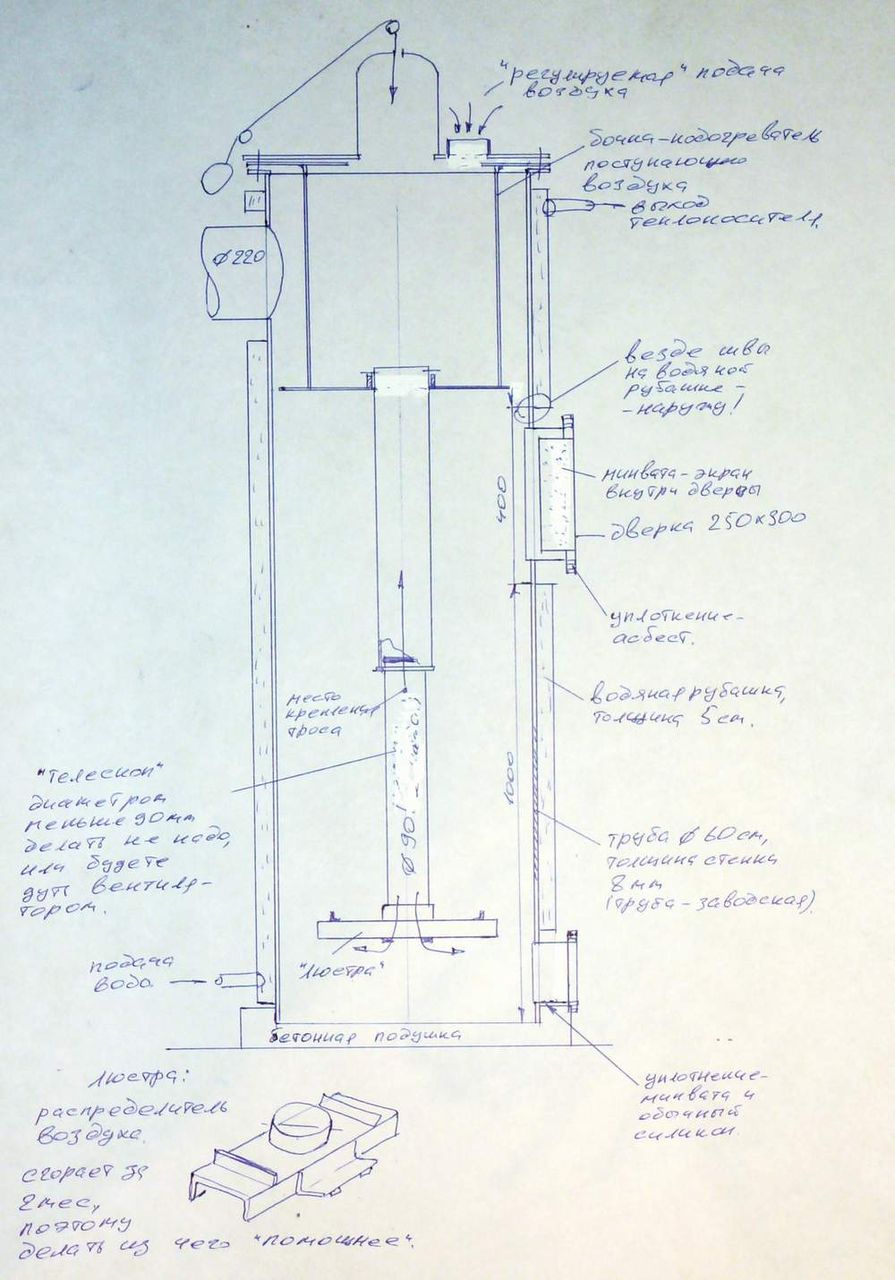

- How to make a do-it-yourself oven

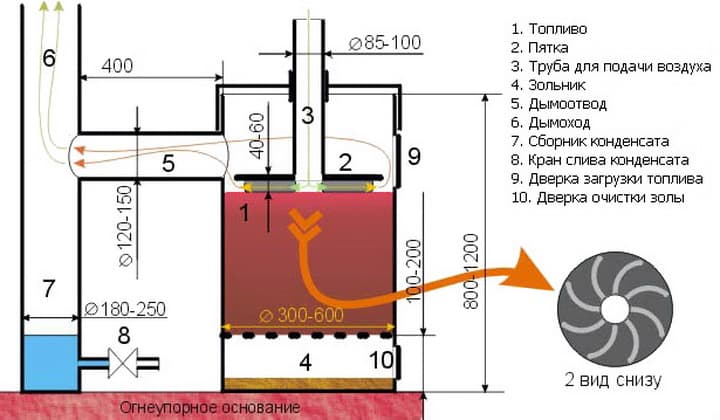

- Varieties of Bubafonya stoves

- What can the Bubafonya boiler be made of?

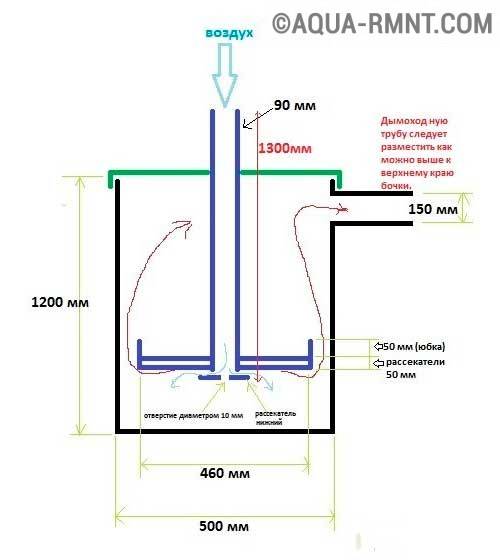

- One of the simplest barrel designs

- Cylinders and pipes

- Furnace manufacturing

- Step by step description

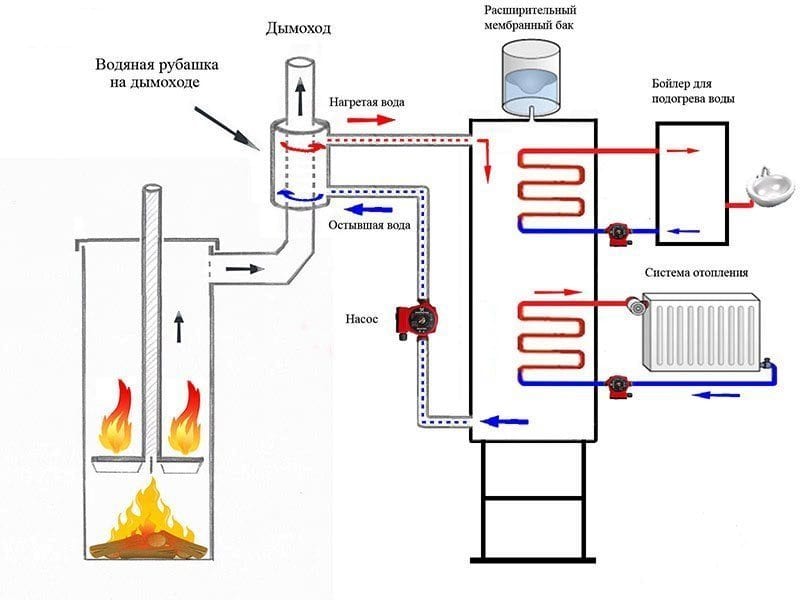

- Water jacket

- Ignition of the stove "Bubafonya"

- Advantages and disadvantages

- Top-loading furnace - "Bubafonya"

- Oven "Bubafonya", why is it called that?

- How to assemble the stove

The principle of operation of the Bubafonya furnace "on the fingers"

You can talk for a long time about the theory explaining the operation of this heating installation and operate in terms that are understandable only to a heating engineer. Our task is to help home craftsmen make the Bubafonya oven with their own hands.

Therefore, we briefly list its most important features:

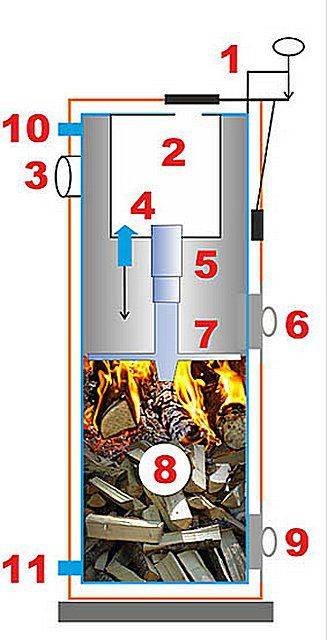

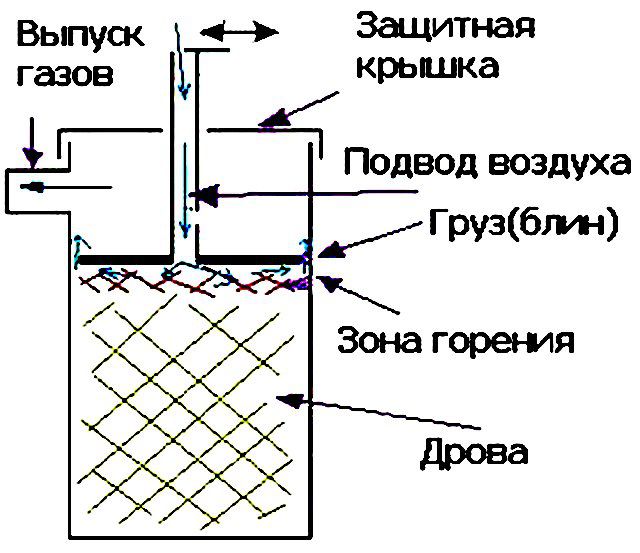

- The process of burning fuel goes from top to bottom (like a wax candle), and not from bottom to top, like a conventional stove. Firewood is laid in a vertical position, and chips, sawdust and kindling paper are poured on top of them.

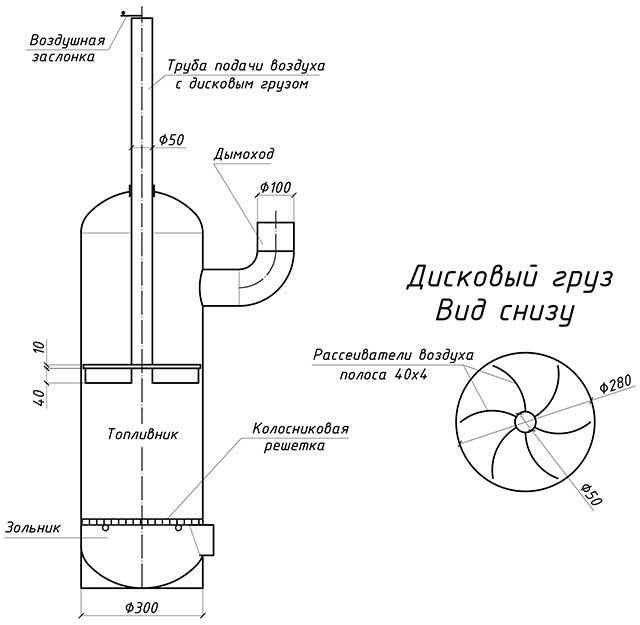

- For post-combustion of pyrolysis gases, an air distributor is used - a steel “pancake” with blades and a hole in the middle. Air enters the combustion zone through a pipe welded to the "pancake". For external similarity, this design is sometimes called a "piston".

- The fuel is ignited from above (with the air distributor removed).After the flame has ignited, a “pancake” with blades is placed on the fuel array, and a lid is put on top of the furnace body. Some users light the stove directly through the air pipe by pouring some kerosene into it.

- The process of thermal decomposition of wood occurs under the "piston". Under its weight, the burning fuel is compacted, the temperature rises and thermal decomposition occurs with the release of combustible gases. As the firewood burns, the “piston” goes down, preventing the fuel from loosening and losing the temperature necessary for pyrolysis.

- The combustible gas emitted by the fuel burns over the surface of the air distributor, increasing the efficiency of the furnace by 20-30%.

The draft of the furnace is regulated by means of a valve mounted on the “piston” pipe. The oxygen necessary for the combustion of the pyrolysis gas enters the upper chamber through the gap between the "piston" and the cover. Since the thrust of such a stove is quite powerful, there is no exit of flue gases through the gap between the cover and the body, as well as the piston and the cover. The height of the chimney, according to the owners, should be at least 4 meters.

Potbelly stove features - pros and cons

A good master will calmly make the Bubafonya oven in one day, this is a significant plus. The maximum that you have to buy is a cylinder and pipes for scrap metal. Other advantages of the potbelly stove:

- duration of burning on 1 load 6…10 hours;

- omnivorous - wood waste, garbage, sawdust, freshly cut branches are laid in the furnace;

- ease of repair, any burned-out part is easily changed.

On the left in the photo - the manufacture of a boiler shirt from bent steel sheet, on the right - the boiler assembly

Cons "Bubafoni" is much more unpleasant:

- The stove is hard to control.When working on high-quality dry wood, the damper helps to choose the optimal mode. If you heat with garbage and damp wood, the air duct must be opened completely.

- The omnivorous potbelly stove is a double-edged sword. From burning low-quality fuel, the chimney is clogged with soot in just a day.

- Without good draft, the stove will smoke into the room. Hence the requirement for a chimney height - at least 4 m, counting from the grate, pipe turns 90 ° - no more than two.

- It is impossible to throw logs “on the go”, except to pour a handful of sawdust through the air channel. So, we learn how to properly dose the amount of fuel.

- A potbelly stove from an iron barrel of 200 liters is very bulky and inconvenient in terms of operation. The piston is too large and heavy, thin metal quickly burns out. Fortunately, the case is easy to replace.

What is the danger of "Bubafonya": a well-heated firebox cannot be extinguished with a damper. Air seeps through the cracks, the smoldering of wood continues. The heater must not be left unattended or act radically - lift the lid and pour out a bucket of water. Is there a smoke screen in the room?

How to make a do-it-yourself oven

Making a do-it-yourself oven

Making a do-it-yourself oven

For the manufacture of the furnace, water and gas pipes of large diameter, gas cylinders, and old steel barrels are used. The pipe wall thickness must be at least 2.5 mm. For assembly work, the following materials and equipment will be needed:

- Welding machine, electrodes, shield;

- angle grinder (Bulgarian);

- A hammer;

- Hacksaw for metal;

- Electric drill and others.

In addition to the tool, the presence of welder skills is a prerequisite. A number of operations are conveniently carried out using a gas cutter.

The simplest method is to make a stove from a cylinder or an old thick-walled barrel. In fact, the firebox is already ready. At the gas cylinder, the upper spherical part is cut off (with a grinder along the existing joint). Then a steel strip is welded along the perimeter of the cut, which will be a skirt. The diameter of the skirt should be slightly larger than the diameter of the balloon. A hole is cut in the center of the cover corresponding to the outer size of the duct pipe. For ease of maintenance, handles made of bent metal are welded onto the lid. The lid is ready.

At the next stage, the piston assembly is made. A circle is cut out of a sheet of calculated thickness. An air duct pipe is welded to the circle in the center. After that, a hole is cut in the center corresponding to the inner diameter of the pipe. Elements of air channels are mounted on the lower plane - corners, channels, bent strips. A chipper with a hole is installed over the strips. The outer dimension of the fender should slightly exceed the diameter of the duct. A hole is drilled in the bumper in the center. A control damper is attached to the upper end of the duct. The mechanism is ready to use.

Making bubafoni from a barrel has a similar algorithm. The lid is made in a different way. A grinder cuts off the lid of the barrel around the circumference with a section of the body. The side walls of the lid are unbent with a hammer for expansion. The edge of the barrel is folded inward. Handles are welded, a hole is cut - the lid is ready.

It is worth noting that barrels are rarely used to create stoves. They have a small wall thickness, when welding they are strongly led. The ratio of diameter and height of the barrels is not optimal for proper combustion.The service life of such furnaces is short.

In the case of using a pipe as a base, its bottom is welded end-to-end with a sheet of metal. The cover is also made of steel of increased thickness.

At the last stage, the chimney pipe is mounted. A hole is cut out in the side surface and a branch pipe of the calculated diameter is welded. The length of the pipe is taken 400 - 500 mm.

The main structural elements are ready. In addition to them, additional elements are made - body fencing, furnace legs, ash pan. The ash pan is made of metal - a circle is cut out slightly smaller than the diameter of the firebox. A steel strip edge is mounted around the perimeter. Reinforcement is welded to the circle or small diameter pipe. The ash pan is installed under the piston, the fittings pass through the duct. After removing the piston, the ash pan is lifted by the armature (pipe). Some craftsmen mount a door at the bottom instead of an ash pan.

The furnace foundation for bubafoni is poured in a tape type (into a monolith). A pit is torn off with a depth of 40 - 50 cm, poured with concrete mortar. After hardening, a platform of refractory bricks is laid out on the foundation. The bottom of the kiln is hot and the simple concrete foundation will gradually collapse.

Varieties of Bubafonya stoves

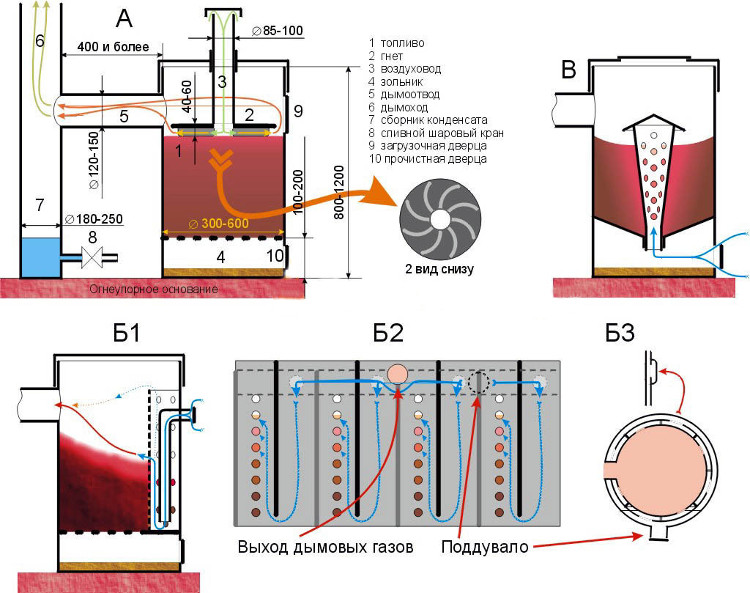

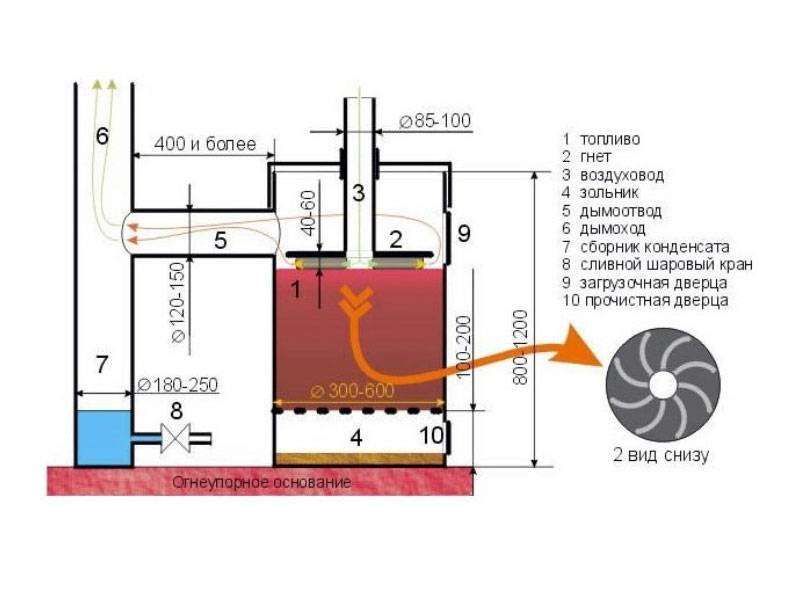

The Bubafonya stove, made by hand, will allow you to forget about the frequent laying of firewood. And its modifications will make heating more efficient. Today, three schemes are used to assemble it:

- Traditional Bubafonya stove - heats the air directly, dissipating heat through its body;

- A boiler from a gas cylinder with a water jacket (or from a barrel, but the cylinder is better in this case, since it has thicker metal) - a home-made heating unit for heating multi-room houses and buildings with many rooms;

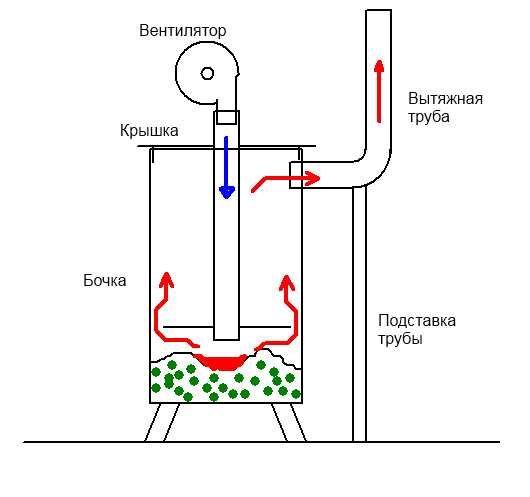

- Bubafonya potbelly stove with a convector - for this, the stove is wrapped in a sheet of soft metal so that an air gap remains between it and the body, forming a convection zone. Sucking in air from below, the stove will heat it up, removing it through the top.

Which oven to choose depends on the specific task being solved. If the task is to warm up a multi-room building, feel free to choose a boiler. In other cases, we recommend Bubafonya with a convector.

Another advantage of the convector is that it protects users from burns - the body of the stove is very hot, it is easy to get burned on it.

What can the Bubafonya boiler be made of?

Half of the whole structure is a boiler, which can be made of any material, suitable shape and characteristics. These could be the following items.

- Do-it-yourself bubafonya stove from gas cylinders. Welding cylinders are the best basis for a boiler. It is enough to fit it in size and you can already use it. Since the gas is under pressure, it is held back by the thick walls of the metal, which will prevent burnout in the stove.

- Old fire extinguisher. Large volume industrial fire extinguishers are convenient for making boilers. Despite the fact that their diameter is smaller, they are able to withstand thermal loads.

- Metal barrel. The manufacturing instructions are similar to the previous options. To prepare, you need to cut the top and use it as an air vent.

- Pipe. A wide sewer pipe with wide walls is suitable for the boiler.But for this you need to independently cut two circles from sheet steel and weld them as a bottom and a cover.

- Homemade case made of sheet steel. The boiler can be made independently from a steel sheet by rolling it into a cylinder and welding.

One of the simplest barrel designs

One of the easiest assembly methods is from a tin barrel. It has thin walls, which contributes to a decrease in efficiency and low heat transfer. The advantage of the method is a large amount of downloads and on one tab it can work for more than twelve hours. Barrels standardized size. In the event of a burn-out of the walls, it will not be difficult to replace it with a new one.

You need to remove the weld that secures the cover. The best way to do this is with an angle grinder. to prevent burr formation. To make the seam perfectly even, you can use a diamond-coated disc. The edges of the barrel are knocked out with a mallet or hammer. On the lid, on the contrary, they flare. As a result, the lid should fit tightly on the barrel. A hole is drilled in the center for the installation of a chimney. The distributor will require a lid from a similar barrel. In her absence, parts can be made from sheet steel. Air outlets are welded to the bottom. They can be made from sections of a U-shaped profile or channel. This is necessary to improve the performance of the stove. If you need low efficiency for a small room, you can not do this. A damper is attached to the axle on top of the hot air pipe. To increase ease of use, it is better to provide for a lamb fastening method. A hole is made on the body for the chimney pipe

It is important that the seam is sealed

For added convenience, a solid sheet metal screen can be installed.

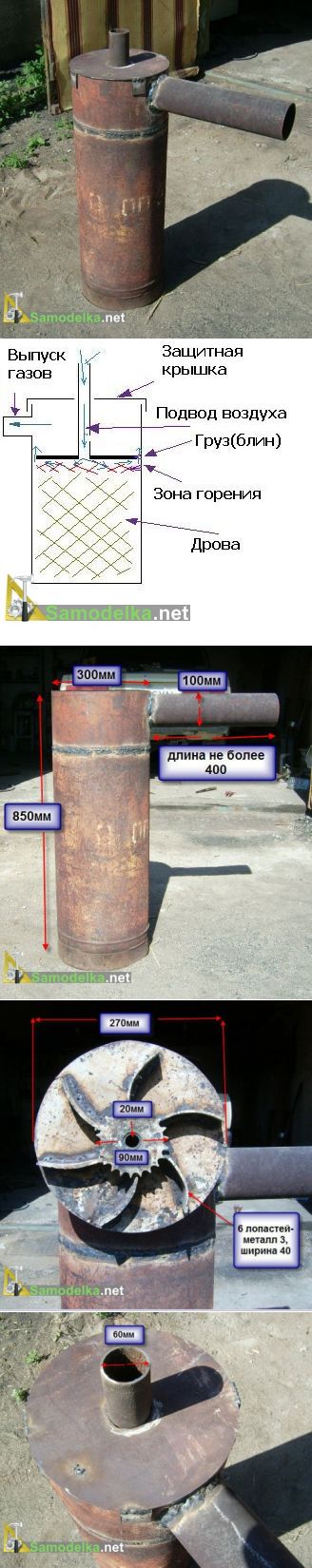

Cylinders and pipes

Furnace bubafonya from a gas bottle do-it-yourself - relevant. The principle of manufacturing from a cylinder and a pipe is similar. The main difference is that the pipe will need to be prepared. Two circles in diameter are cut out of a sheet of steel and the bottom is welded.

It is necessary to cut several steel disks according to the diameter of the cylinder. In each and they need to cut a small segment to get more than a semicircle. Inside they are installed by welding

It is important to weld them so that they are mirrored to each other. It turns out a multi-stage system for lifting air

At the level of the first floor, you need to make several holes in the wall with a diameter of 5 millimeters. The end of the channel is connected to the outlet of the branch pipe. In the middle of the wall, a rectangular firebox door is made. A grate is mounted below the door.

Furnace manufacturing

Let's move on to the step-by-step technology for creating bubafoni. As a base, you can use either an old LPG bottle or a metal barrel. In the first case, the standard capacity is 40 liters, so the stove turns out to be quite small - her working time on one bookmark of firewood will be about eight hours.

If you need more powerful equipment, then take a barrel of about 200 liters as a basis. Of course, it looks less presentable, but it can work without interruption for up to two days, without needing your participation.In addition, if the appearance of the structure is very important to you, you can overlay it with some heat-intensive material at the end of production - for example, beautiful stones. Or, alternatively, arrange brickwork around the stove. Both design options are also good because they reduce the likelihood of burns. Moreover, the heat transfer will be longer, softer and better.

Step by step description

After this operation, the balloon is ready for further achievements. Do not try to neglect cleaning, as in this case the slightest spark can cause a fire.

We take on the main work.

- Cut off the top segment of the balloon. Don't throw it away as it will later turn into a lid.

- Along the perimeter of the cut on the body, weld a strip cut from a steel sheet. Such a side will help to securely hold the lid on the main part, preventing it from moving.

- We make a piston. Take a steel sheet, the thickness of which should be 3-4 millimeters. Cut out a circle from this material so that its diameter is slightly smaller than the inner diameter of the stove body. Make a hole in the center of the part, the diameter of which should be about 10 centimeters. Attach the duct pipe to it using a welding machine. It should be of such length that it rises 20 centimeters above the upper edge of the stove.

- Now, on the bottom of the steel circle, weld six blades, also made of metal. This is necessary for the future uniform burning of the fuel.

- We figured out the “piston”, let's move on to the main part of the furnace. Cut a rectangular hole in the lower segment of the case, where the door will then be installed. The work is done with the help of a Bulgarian saw.

- Now make the door itself.Actually, for this you can take the same piece that has just been cut out, sheathe it around the perimeter with an asbestos cord for a snug fit to the body, weld the hinges and the hinge for the valve.

- Weld the finished door with hinges to the body in the appropriate place. Install the valve on the opposite side.

- Next, we work with the lid. Make a hole in it, necessary for the removal of combustion products. The diameter should be from 10 to 15 centimeters. The same indicator should be for the pipe, which is installed in this hole and welded. Another segment is connected to it at an angle of 90 degrees. Thus, you get a chimney elbow.

- Now put everything together: install the "piston" inside the structure and attach the cover. This is what the finished oven looks like. After that, you can do the kindling as described above.

Water jacket

Creating a water jacket is not particularly difficult. You will need a metal container, the diameter of which is larger than the diameter of the finished oven. Place the bubaphone in this cylinder. Weld open areas, and make holes on the sides for connecting the inlet and outlet heating pipes.

Then the corresponding pipes are welded there. In principle, such a water jacket can be placed not only on the body, but also on the chimney, since there the heating will go just as intensively. The principle of operation of the design is extremely simple. Water will be supplied to the “jacket”, where it will immediately heat up from the stove and exit into the heating main.

Actually, on this, the manufacture of bubafoni can be considered complete. When installing the oven, do not forget about fire safety.If you plan to place the equipment in a wooden building, then it must first be prepared.

To do this, take a few asbestos sheets and cover the walls with them, as well as furnishings that will be located in the immediate vicinity of the stove. As for the floor, you can fill it with a concrete screed or simply put a thick metal sheet on the place where the bubafon will stand. If the aesthetic aspect is important to you, then you can finish these areas with ceramic tiles - they look quite decent and can withstand high temperatures.

Ignition of the stove "Bubafonya"

We take out the piston-feeder with a welded air duct from the inside, having previously removed the cap from the cylinder.

We put wooden logs inside. They must be placed horizontally butt to each other. Vertical placement of firewood can have rather unpleasant consequences if an unburned log standing on an edge prevents the piston from moving. This will lead to the fact that instead of smoldering, a full-fledged fire will flare up in the primary chamber. As a result, the correct mode of operation of the stove will be violated, the firewood will burn faster and, in addition to everything, it may begin to smoke through the duct. Logs must not be laid above the location of the chimney.

Laying firewood in the pyrolysis oven

Pour chips with sawdust or small branches on top of the wood bookmark. Soak a piece of old fabric in a kindling liquid (kerosene is also fine) and place it on a layer of wood chips. Paper can serve as an alternative to a rag.

Processing the top layer of the bookmark with kerosene

We press the bookmark with a piston and put the furnace cover back on.

Installing a piston with a cover

We set fire to firewood by throwing a piece of lit rag or paper inside through the duct-duct. A bubafoni match is not suitable, because it has time to go out before it falls down.

Ignition of the furnace

After 15-25 minutes, after the bookmark flares up well, it is necessary to close the valve on the air duct. This will restrict the air supply to the primary combustion chamber and cause the logs to smolder, releasing pyrolysis gases. Thus, the bubaphone will switch to its main operating mode.

Advantages and disadvantages

Bubafonya solid fuel stoves are simple and have good characteristics. They save users from unnecessary trouble with firewood, providing a long-term supply of heat to the premises. Let's take a look at their main features:

The fuel in Bubafon burns for a long time, warming up the room well, however, as soon as the burning stops, the stove cools down very quickly.

- Long burning - from 6 to 20-24 hours (and even more). It all depends on the size of the unit used and the quality of the fuel used;

- The simplest design - allows you to easily assemble the Bubafonya oven with your own hands, using improvised tools;

- Minimum adjustment - the only regulator is a small slide valve in the air supply pipe;

- Does not require electricity - the Bubafonya stove can work in buildings without electrification;

- Reliability - if we look at the scheme of this stove, we will find that there is practically nothing to break in it;

- The ability to work on any type of solid fuel - up to anthracite, characterized by maximum heat release.

There are also some disadvantages:

- The rapid loss of temperature during the attenuation of firewood - there is simply nowhere for heat to accumulate;

- Not the most beautiful design - to the greatest extent this applies to home-made units, which are often assembled from old gas cylinders and barrels;

- Difficulties in care - loading firewood requires removing the pressure plate and thoroughly cleaning the bottom of the stove from ash and coals;

- Care must be taken to remove soot and condensate - soot is most often formed when coal is burned;

- Too intense burning of the Bubafonya stove can lead to overheating of the air or coolant (when using a water jacket) - therefore, the most minimal control is still necessary;

- The possibility of smoke entering the room - this happens due to the back draft effect when the smoke exits through the air supply pipe.

Some of the cons are quite serious, but you have to put up with them. For example, for easier removal of condensate, it is recommended to work on the chimney, and in order to give the draft the right direction, it is necessary to install a blower in the system variable speed fan rotation.

The easiest way to collect condensate is to make a chimney with a vertical downward outlet. The smoke will go to the upper part, and the condensate will be collected in the lower part, equipped with a drain cock.

This is interesting: impregnated wood

Top-loading furnace - "Bubafonya"

Before using a top-loading oven, you should find out their advantages. In this article, we will describe in detail how they differ from conventional counterparts, and why is it better to use exactly them.Specialists identify the following design advantages: · These furnaces have a compact combustion chamber, which is convenient to use. · It is possible to use gravity in the operation of the furnace; · Fuel is consumed in minimum quantities, i.е. A top-loading stove helps save firewood. · The above structure has a low discharge temperature. Those. you do not need to isolate the chimney using additional technologies. · Smokeless emission will not pollute the atmosphere. A distinctive feature of top-loading furnaces is that the fuel is gradually burned. And this means that the heat in the room will be distributed evenly, i.e. the body will have time to get used to the increase in temperature. As for the bourgeoisie and the like, the fuel immediately flares up. The most popular are "Bubafonya" and "Rocket"

Oven "Bubafonya", why is it called that?

The stove got its name from its creator. The peculiarity of this type of PDH (long-burning furnace) is that there is a constant piston pressure. The heel of this piston keeps the optimum temperature in the room for a long time. As a result, certain parts of the room will not overheat, and some will not be too cold.

How to assemble the stove

To assemble the furnace, you must follow the instructions below: Initially, we need a barrel. We cut off the upper part of it (it can be used in the future as a furnace cover). If you used a gas cylinder instead of a barrel, you should cut off the upper part along the soldering border. Do not forget that the balloon is a flammable structure. Therefore, you should make sure that there is no gas left in it.To do this, pour water into it, and after that you can already use it without fear. · Slightly lower from the cut part, it is necessary to place a hole for the chimney. Then we weld the channel from the pipe, the diameter of which should be about 120 millimeters. Let's start with the construction of the air duct. The inner diameter of the duct must be 75 mm. Length - about 30 millimeters. We spend a sheet (6 millimeters) on the heel. We cut out the structure in the form of a circle, the diameter of which should be 4 centimeters less than the combustion chamber. Next, in the center of the heel, we cut a special hole about 3 millimeters. · Then it is necessary to weld on the working surface of the heel corners 30x30 or 40x40 in the form of rays from the center.