- Peculiarities

- Differences from water heating

- Pros and cons

- Device

- What are the disadvantages

- The principle of operation of steam heating

- What are the types of steam heating

- How to choose a heating boiler

- Steam heating installation: an overview of the arrangement process

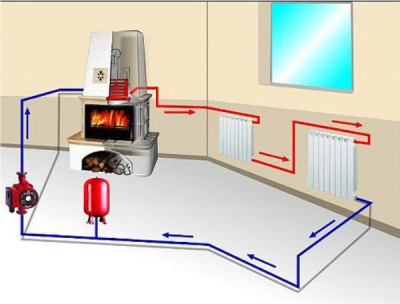

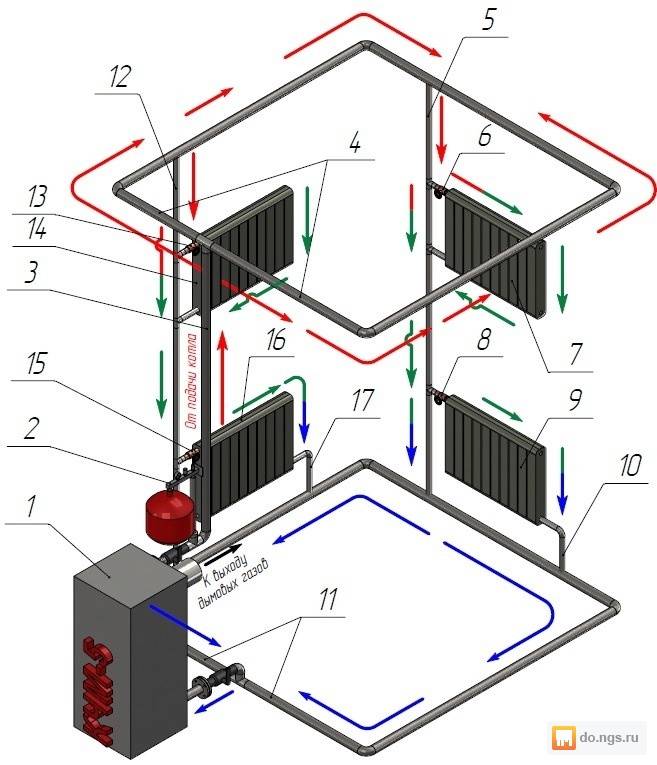

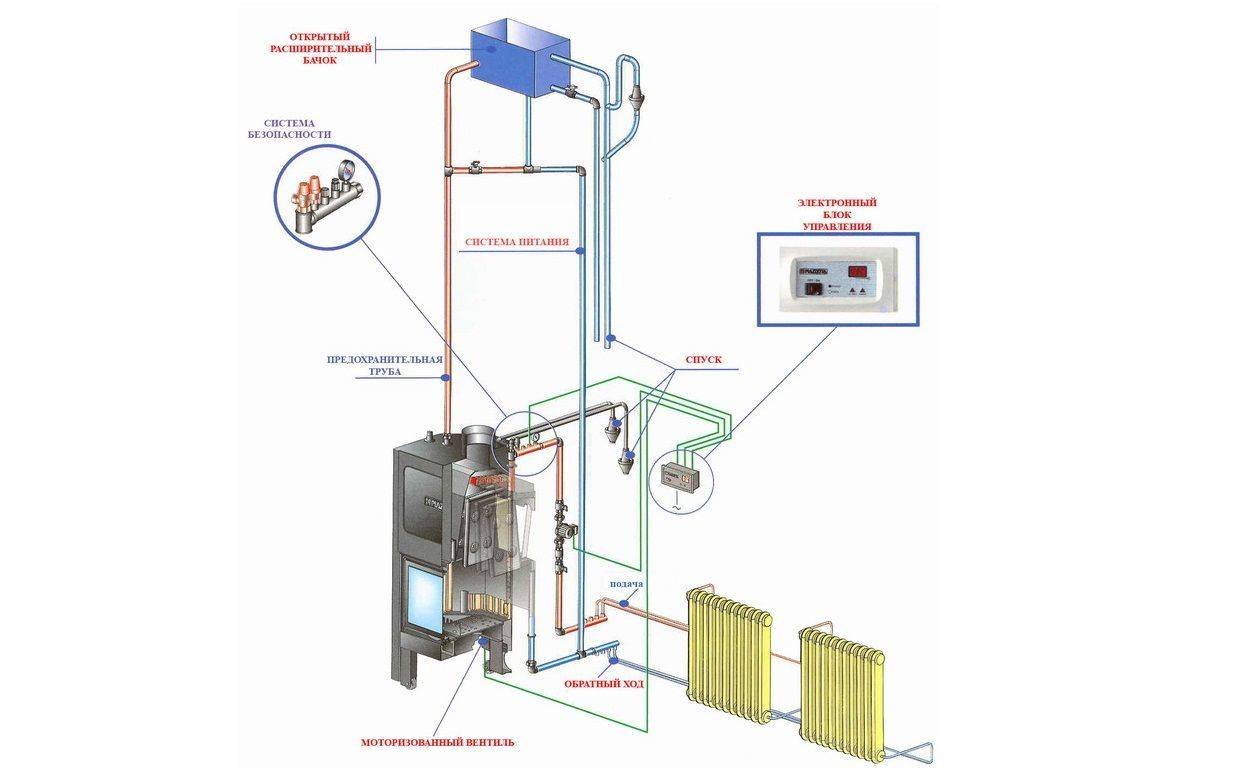

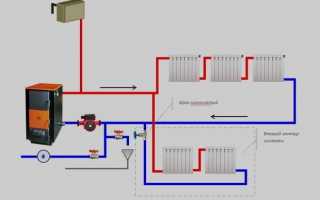

- First scheme: open single-pipe version

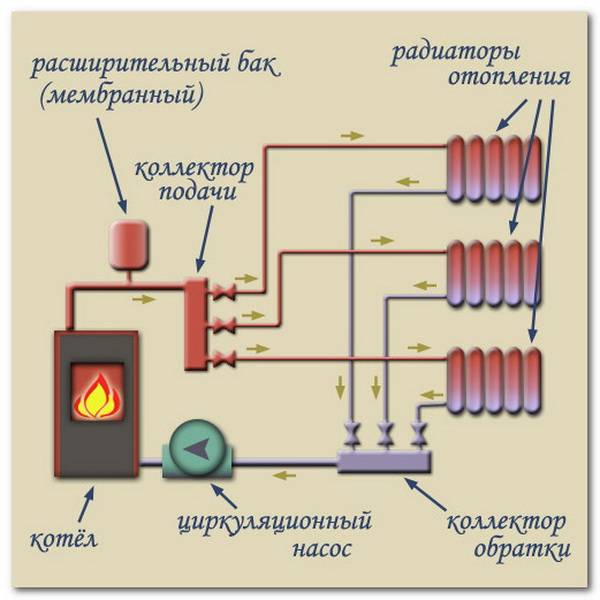

- Second scheme: closed two-pipe version

- Do-it-yourself steam heating

- Stage 1. System design

- Boiler

- Heating scheme

- Pipes

- Issue price

- Stage 2. Installation work

- Tiered floor

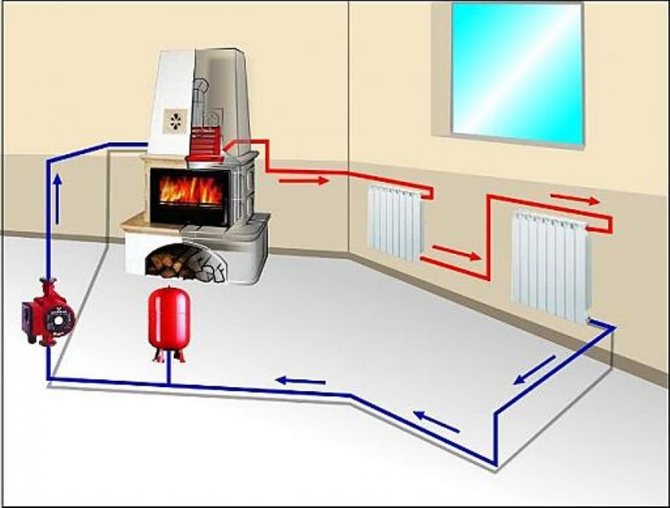

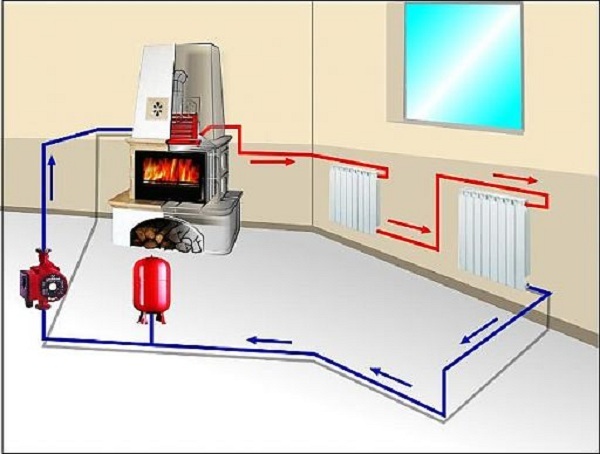

- How is the distribution of steam heating from the furnace

- We also recommend seeing:

- Various schemes for the implementation of steam heating

- Closed and open piping

- Two-pipe or one-pipe system?

- We focus on system pressure

- 5 Installation of heating - is it really easy?

Peculiarities

This type of heating is a system with a coolant in the form of heated water vapor. This is not an innovative invention, since this method was widely used for heating residential premises in the 19th century. And only then they decided to replace the steam with water. Water and steam heating are different from each other, so do not confuse them.

Replacement was necessary due to the fact that the efficiency of heat transfer with steam is extremely high.This resulted in excessive heating of the equipment. Its temperature could rise above 100 ° C. Any contact with steam heating equipment could lead to burns of varying degrees. That is why this option for heating a private house or cottage is quite dangerous.

Today, steam heating in its original form is forbidden to be used in residential and public buildings. However, this restriction does not apply to private property. Therefore, having carefully studied all the features of the steam system, you will be able to install it in your home.

Differences from water heating

Steam heating, in comparison with water heating, has a higher heat transfer and ergonomics. Thanks to steam heating, the room heats up 3 times faster than with water.

Also, such a system requires small-sized equipment, so heating as a whole is cheaper. Steam heating works not only from a wood-burning stove, but from boilers that use waste oil. True, this heating option is not entirely environmentally friendly, so it is used for garages or utility rooms.

Pros and cons

It is possible to single out the main advantages due to which this type of heating has become widespread:

- small price;

- coolant resistance to low temperatures;

- high efficiency due to convection and radiation;

- small size of the system;

- the ability of steam to penetrate anywhere in the system without lowering the temperature;

- ensuring rapid heating of the room;

- minimal (practically zero) heat loss;

- underfloor heating compatibility.

At the same time, the steam system has certain disadvantages:

- loud noise during operation;

- excessive heating of the equipment, which can lead to burns or accidents;

- inconvenient temperature control;

- relatively short service life due to instability to corrosion.

However, these shortcomings can be corrected. To prevent excessive heating of appliances from causing harm to people and animals, it is necessary to fence off radiators and pipes with a special protective screen. Noise during operation can be reduced by installing anti-noise brackets or by mounting the steam generator in a separate remote room.

Device

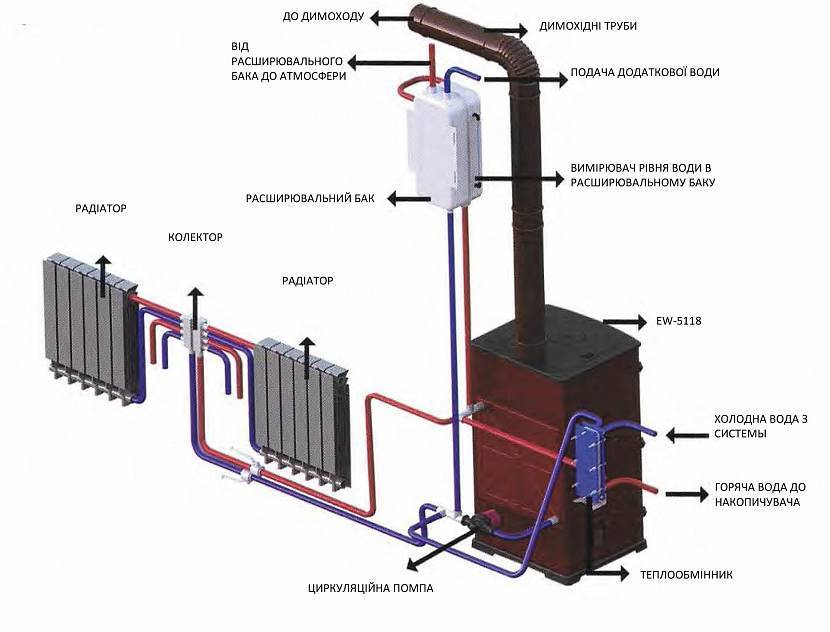

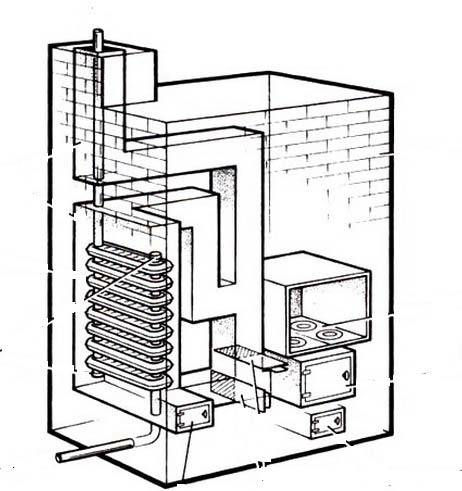

The steam heating device includes several elements. These are: firebox, burner, ash pan, and also a pressure gauge for pressure measurement. The main component of the system is a drum with control and measuring units and a pipeline. Sometimes home-made furnace steam boilers are used for private houses. However, this option is less efficient, since in this case the oven is only a steam boiler, it is impossible to cook on it.

What are the disadvantages

Not everyone is suitable for steam heating due to imperfections.

The hot steam heats up the batteries so much that you can get burned if you touch them.

When steam is mixed with water, rust forms inside the pipes, gradually clogging the space, and the likelihood of sudden depressurization increases.

If the joints are broken, a steam stream breaks out, capable of causing severe burns.

If the homeowner is allergic to dust, such heating is not advised, due to the acceleration of air circulation.

The air space inside the room dries up very much, which can cause frequent colds, a cough that does not go away for a long time.

The choice of pipes, building materials for finishing is very limited, since not every type of raw material tolerates a high degree of heat.

A simple connection scheme eliminates temperature control. Separate inclusion or deactivation of parts of the circuit is allowed.

The problem may be the noisy operation of the boiler.

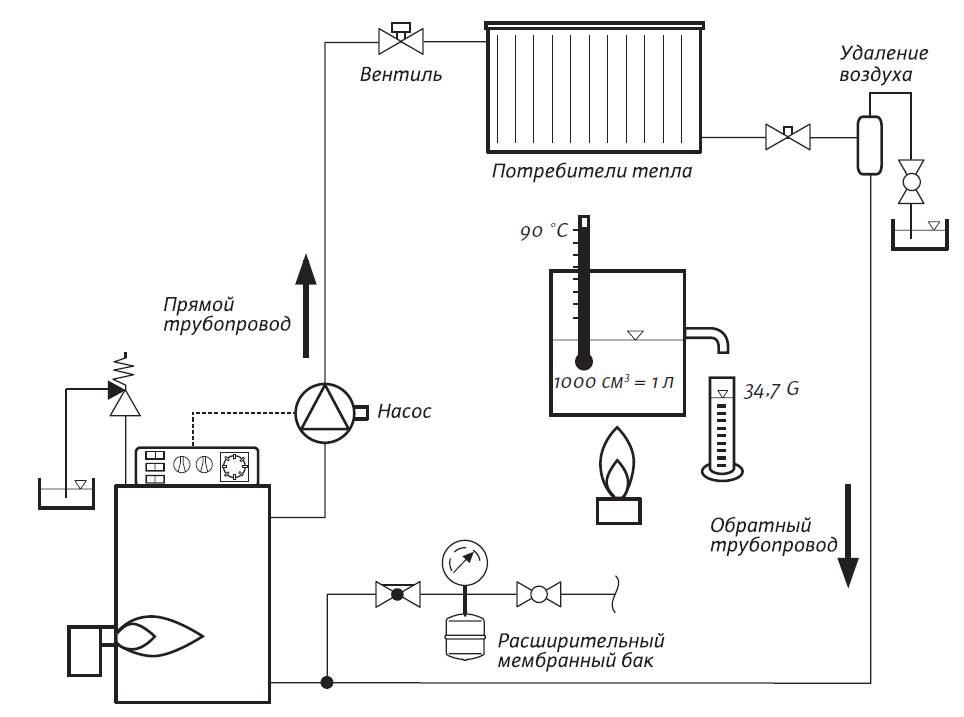

The principle of operation of steam heating

The operation of such a heating system can be described something like this: there is a special boiler in which water under high pressure heated to boiling point. As a result, steam is formed, which enters through the lines directly into the heating radiators. When it completely gives off heat, it returns back in the form of condensate. It is worth noting that in such a system hot steam squeezes out air. The temperature of the radiators can reach 100o C, and this is not the limit.

Main advantages.

Consider the advantages of steam heating:

- No heat is lost in the heat exchanger. Steam accumulates heat, so small pipes are needed for such a system.

- With the help of such heating, you can heat the building you need in record time, as there is a small inertia.

- The steam boiler used in the system accumulates steam.

This is all, of course, good, but the steam heating system also has some disadvantages. So, its service life is quite short. Moreover, the heat-releasing surface during operation is heated to a high temperature.

Touching it can cause severe burns.

What are the types of steam heating

There are several classifications of heating, which depend on a number of principles and aspects of the application. So, according to the method of returning condensate back to the boiler, heating systems are:

- Closed, in which condensate is immediately sent to the heating boiler.

- Open, where it first accumulates in a special tank.

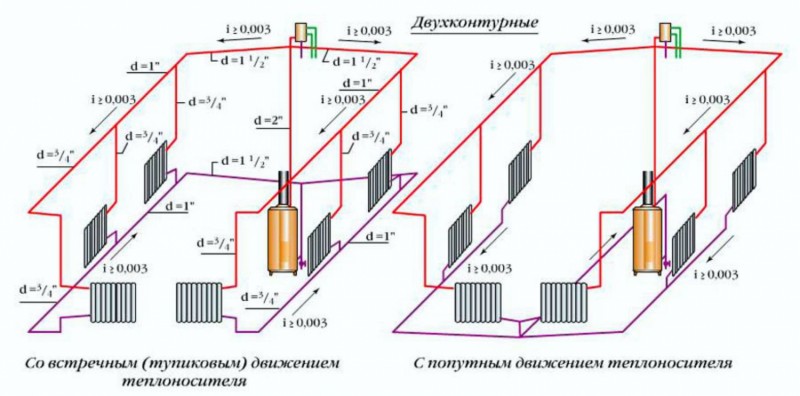

Move on. Depending on the number of circuits, heating can be:

- Single-circuit, designed exclusively for heating the building.

- Double-circuit, capable, in addition, to provide heating of water for household needs.

Finally, steam systems can differ in the way they are wired, which can be:

- Lower.

- Upper.

The wiring itself is selected based on the functional features of the structure and the type of pipes used.

How to choose a heating boiler

The boiler is the basis of the system, its core. It will function properly only when it is selected in accordance with the characteristics of the heated room. In other words, the heating boiler must have sufficient power to heat the desired room. To help with this, we have provided the following indicators:

- For a building with an area of up to three hundred meters, the required power is 30 kilowatts.

- Up to six hundred meters - 60 kilowatts.

- Up to one thousand two hundred meters - 80-100 kilowatts.

In addition, steam heating in a private house can be powered by various types of fuel:

- Solid.

- liquid.

- Combinations.

- Gaza.

The most important role in the device of the heating boiler is assigned to the drum, to which all the relevant sensors, pipelines and so on are attached. In addition, the boiler can be water-tube and gas-tube.

Which pipes suit us best.

In this case, everything will depend mainly on your desires and preferences.Classify such pipes depending on the material used for manufacturing.

- Steel pipeline. When installing it, you will need welding equipment. It is distinguished by good stability and strength, but at the same time it has a significant disadvantage - over time, its surface becomes corroded.

- Copper pipeline. It is also quite reliable, it showed itself perfectly in such pipelines, where the coolant circulates under high pressure and high temperature. In order to mount such a system, you will need to use the soldering method. She also has disadvantages. So, it will be very expensive to equip a house with a copper pipeline, which is why it is found mainly in expensive luxurious mansions.

- Galvanized and stainless pipeline.

Unlike the first option, this highway system is extremely resistant to rust. The connection is made with a thread. The only disadvantage, as in the case of copper, can be considered the high cost of working materials.

Installation features.

If you are planning to install a heating system, then first of all you must decide on the material from which the pipes will be made. Moreover, for the most successful installation, it is necessary to take into account the following aspects:

- Number of available adapters.

- The total length of the pipeline.

Actually, here we have examined what steam heating is in a private house.

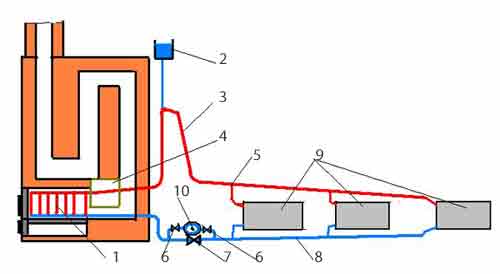

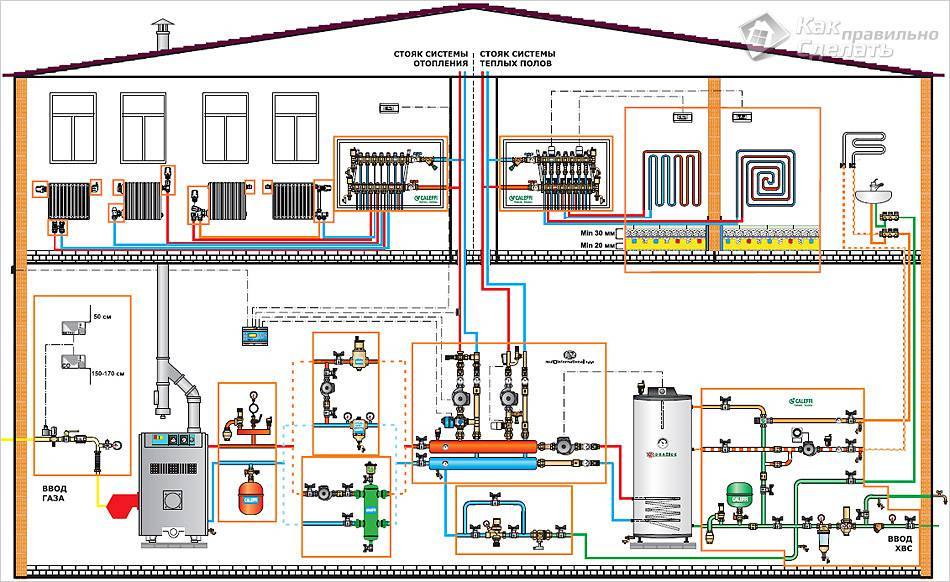

Steam heating installation: an overview of the arrangement process

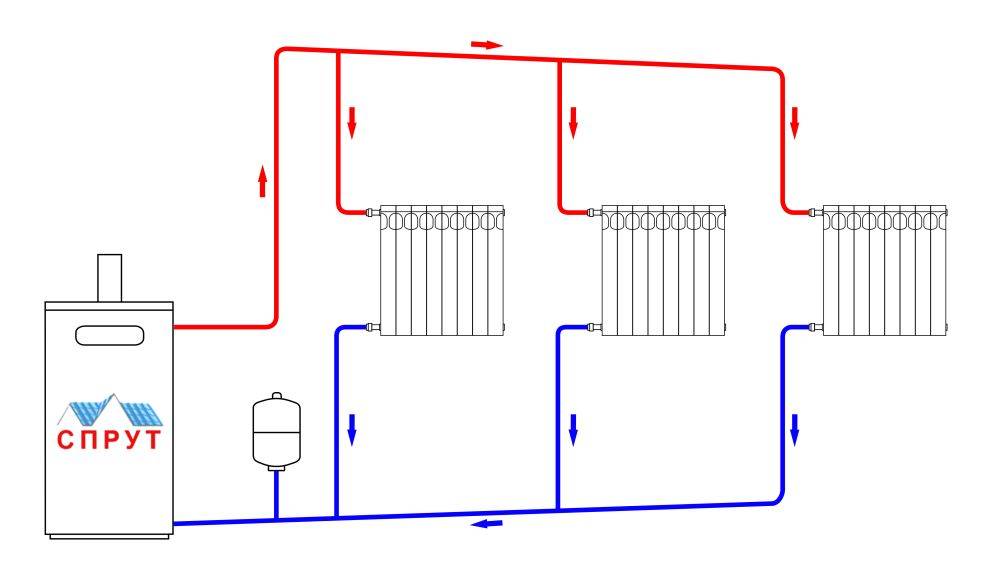

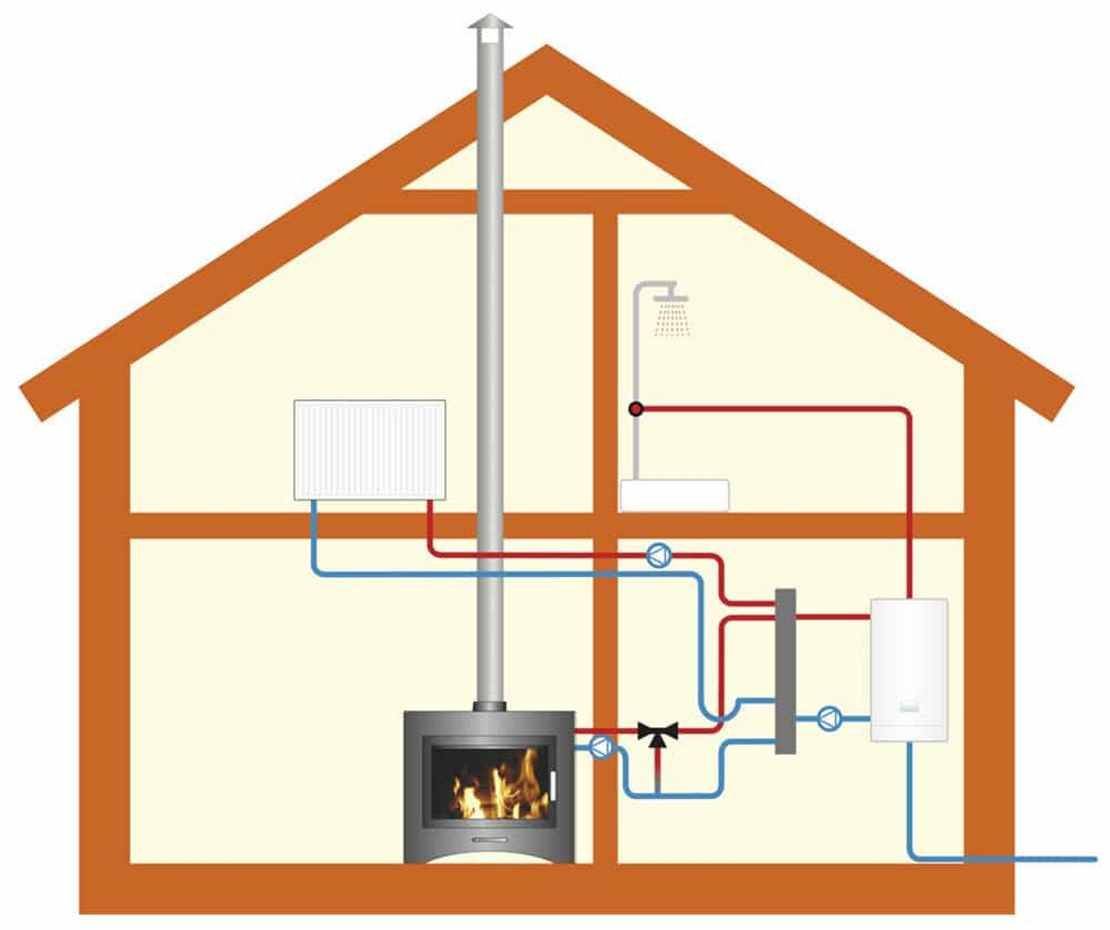

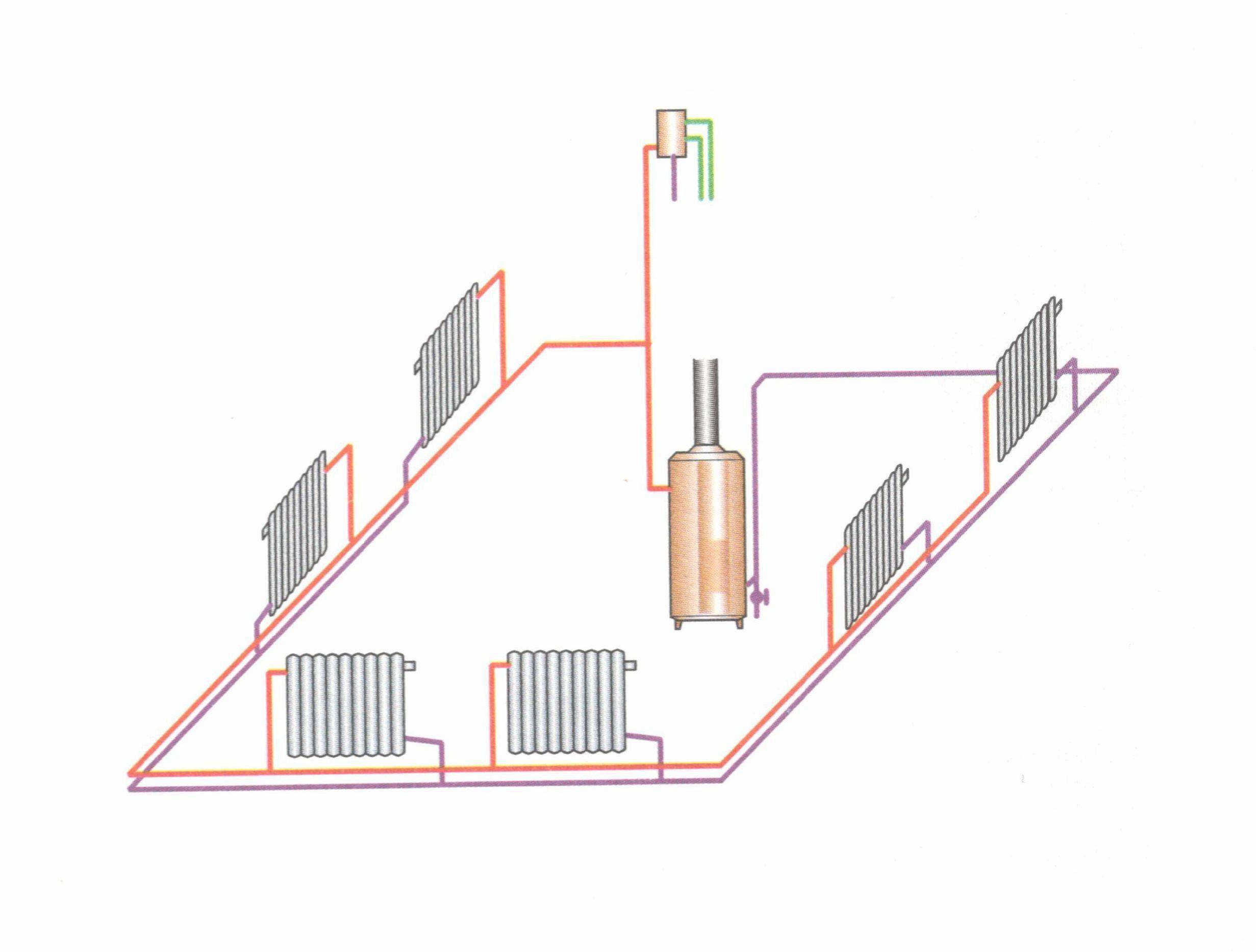

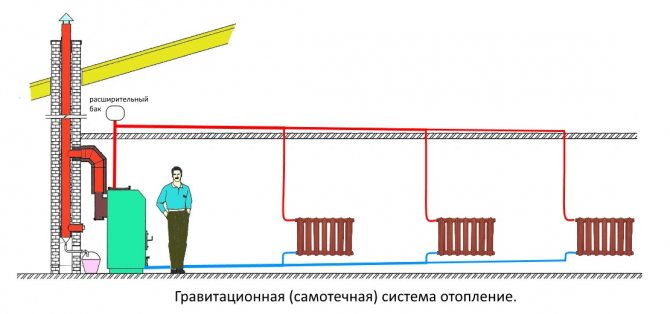

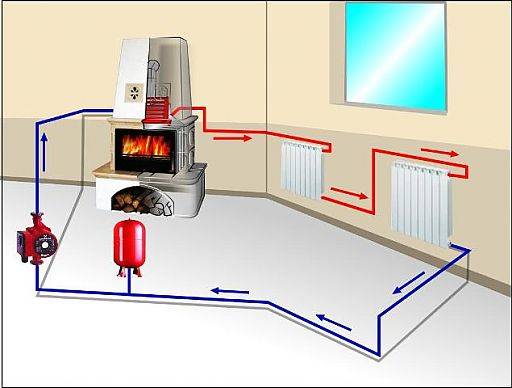

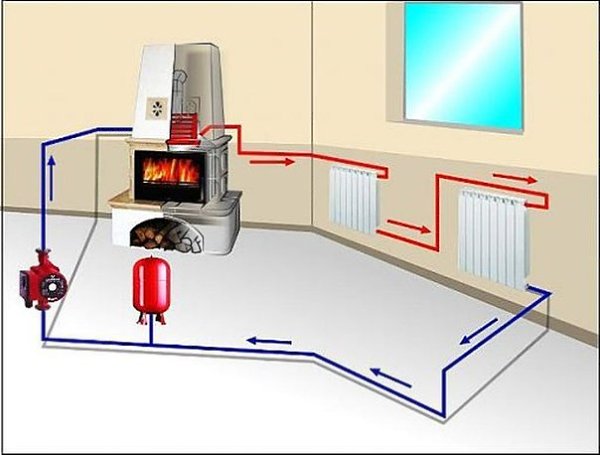

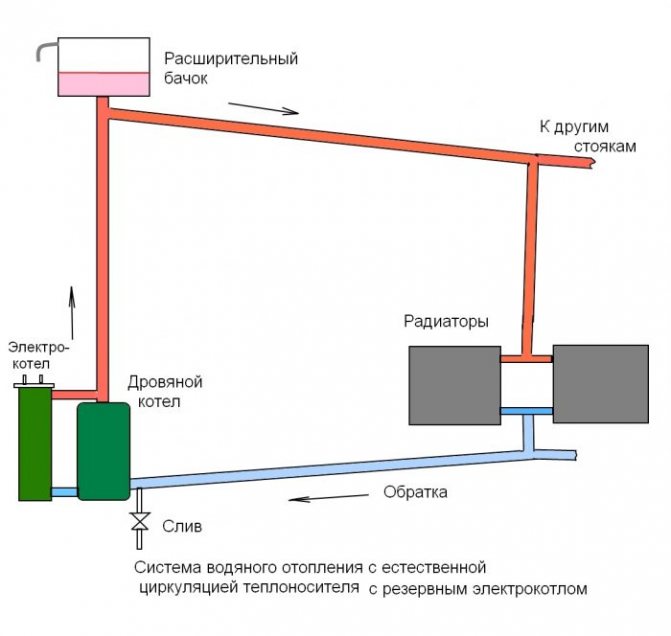

In the review of the process of arranging steam heating, we will move from simple to complex. Therefore, the first option will be considered with a closed single-pipe type wiring, designed for natural circulation.And the last is an open version with two-pipe wiring, designed for forced circulation of the coolant. So, let's begin.

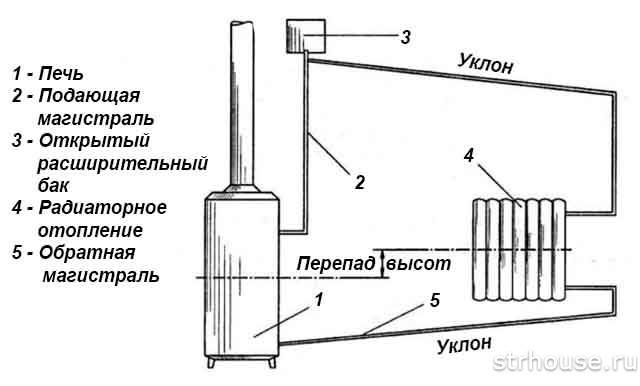

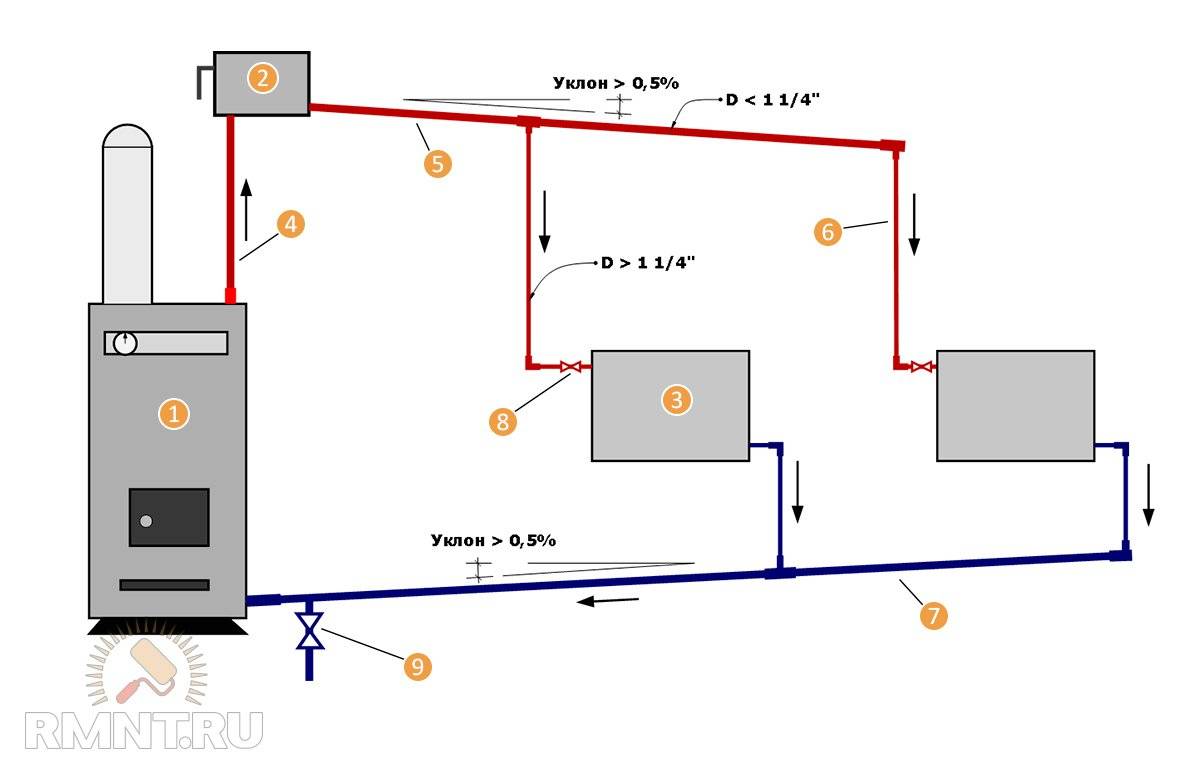

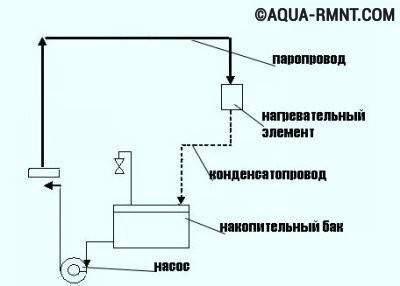

First scheme: open single-pipe version

In this case, a steam heating furnace will not be useful to us: after all, an open loop on gravity only functions if the steam generator is located below the capacitor banks.

That is, the installation of the system begins with the installation of a special solid fuel or gas steam generator, to the outlet of which a tee is mounted to connect a pressure gauge and the primary section of the steam pipeline.

That is, the installation of the system begins with the installation of a special solid fuel or gas steam generator, to the outlet of which a tee is mounted to connect a pressure gauge and the primary section of the steam pipeline.

The primary section is raised to the level of the ceiling and directed along the perimeter of the walls, at a slope of 1.5-2 centimeters per linear meter of pipe to the first battery. Moreover, the input to the battery is designed as a vertical outlet connected to the right lower radiator fitting.

Next, you need to connect the upper left fitting of the first battery and the upper right fitting of the second radiator. The same operation is done with the lower inputs. And in a similar way connect all the batteries - from the first to the last. Moreover, each battery should be located slightly lower than the previous one, taking into account a 2-centimeter slope for each linear meter of the pipeline connecting the radiators. Otherwise, there will be no self-flow.

The condensate line, in fact, is the lower branch connecting adjacent radiator fittings. Moreover, a separate condensate pipeline departs from the last battery, connected to the evaporator tank. Of course, the last section must be mounted with the same slope.

As a result, if you do not take into account a slight difficulty with the positioning of the steam generator, or rather the evaporator tank of this element, then this wiring method is the most accessible installation scheme for steam heating. Moreover, the assembly of components is carried out on threaded or crimp couplings. And the main material for the construction of a steam pipeline and a condensate pipeline is a copper pipe.

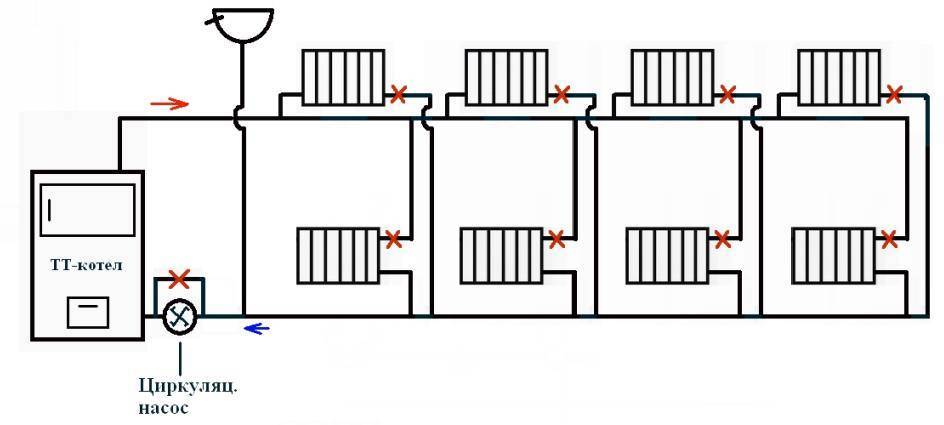

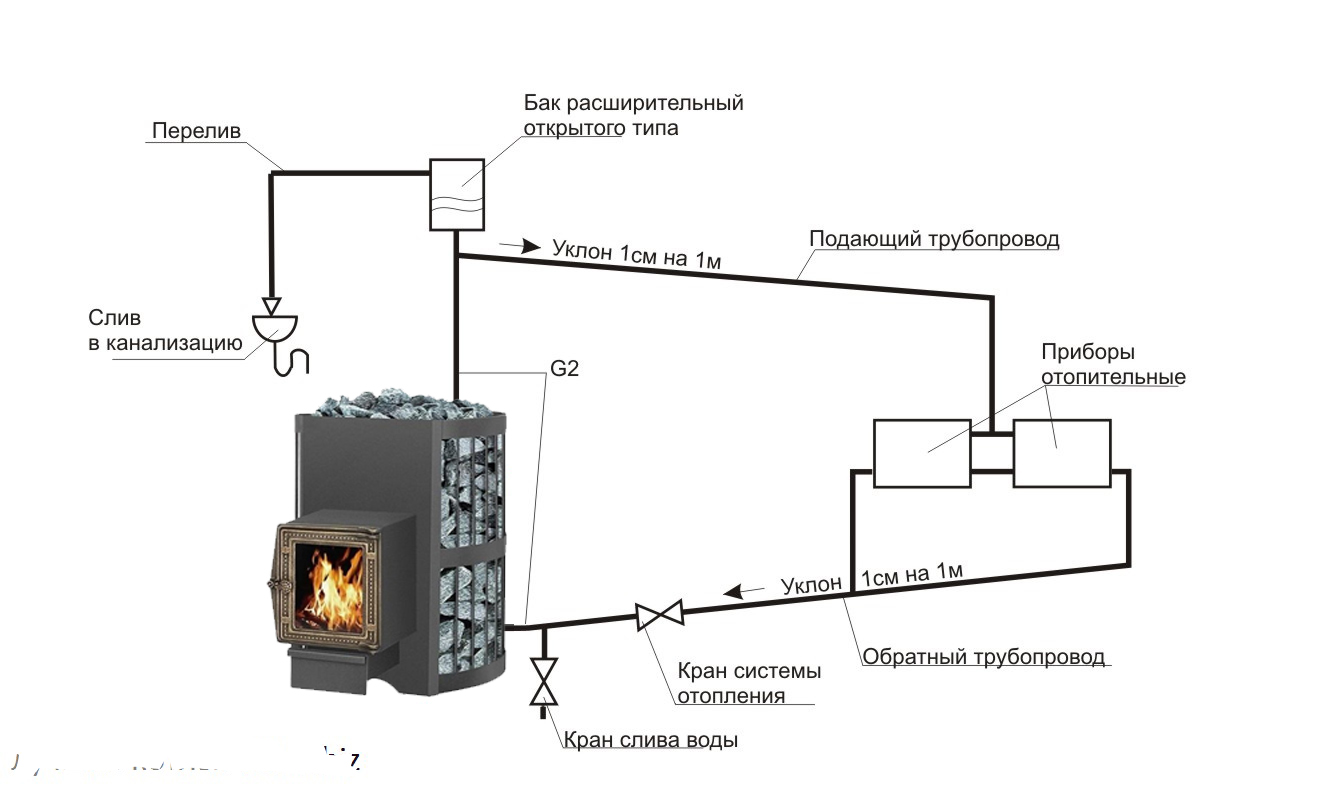

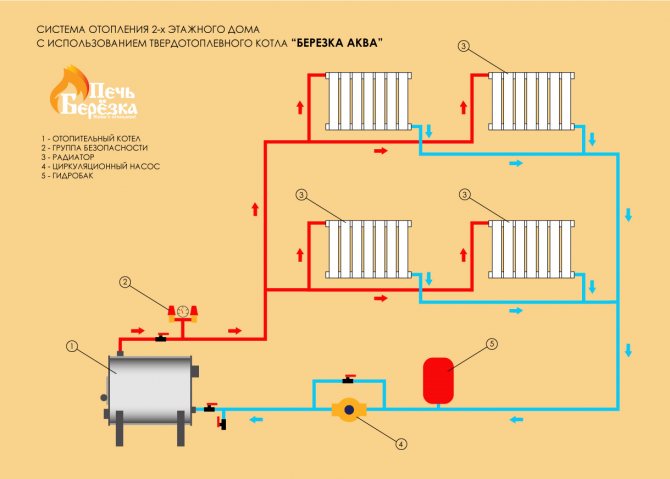

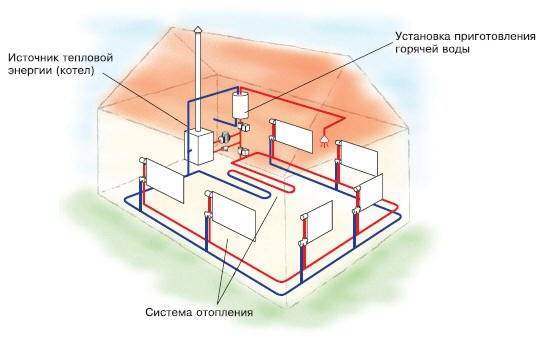

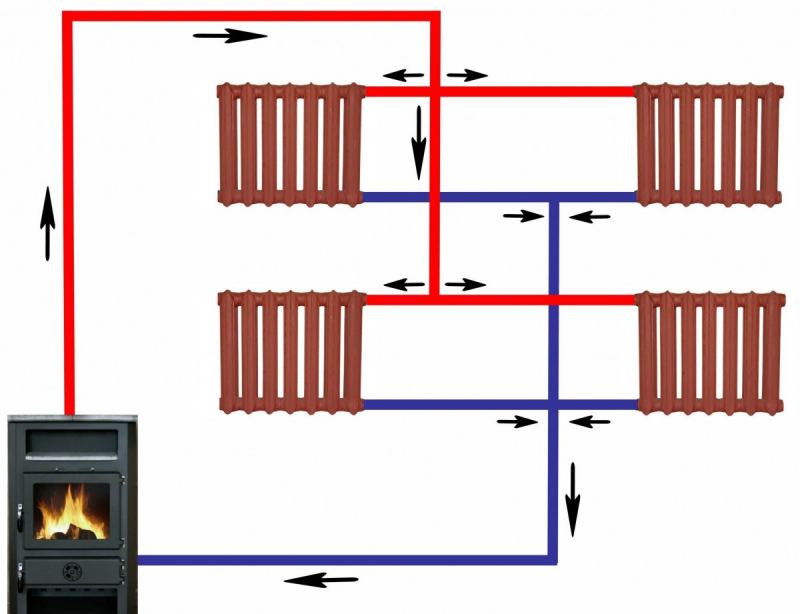

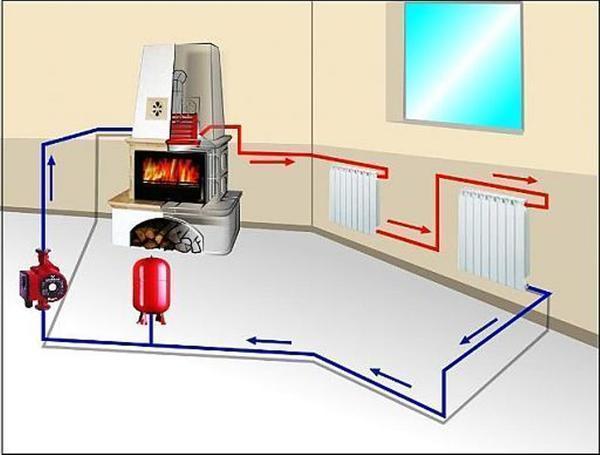

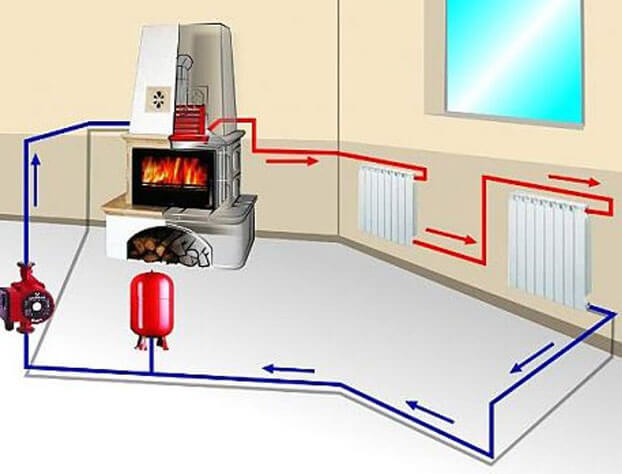

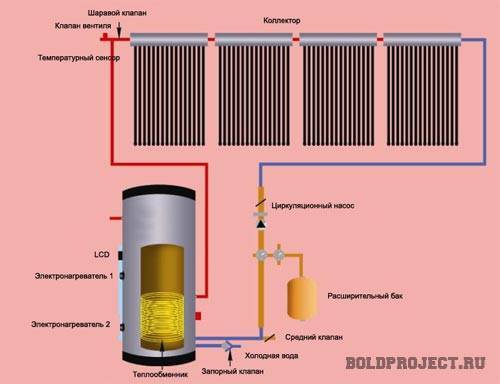

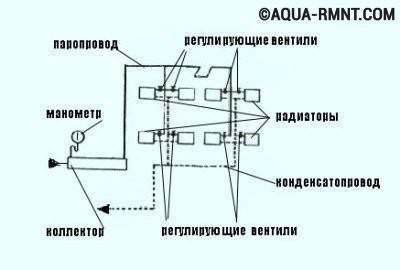

Second scheme: closed two-pipe version

In this case, you can use the most budgetary version of the generator - a stove - for steam heating a house, the energy emitted by burning wood, peat or coal is quite enough, and the location of the evaporator tank with open wiring can be anything.

Installation of the system begins in a similar way. That is, the first (vertical) section of the steam pipeline is connected to the outlet valve of the evaporator tank, which passes into the horizontal, which is laid under the very ceiling along the entire perimeter of the dwelling.

Installation of the system begins in a similar way. That is, the first (vertical) section of the steam pipeline is connected to the outlet valve of the evaporator tank, which passes into the horizontal, which is laid under the very ceiling along the entire perimeter of the dwelling.

Batteries-capacitors are mounted in the right places, connecting them to the horizontal section of the steam pipeline with vertical outlets.

A horizontal condensate pipeline is mounted at the floor level, into which the condensed steam collected from the batteries is discharged through small vertical outlets connected to the lower branch pipes.

The condensate line is connected to storage tank open or closed type. Moreover, a closed tank allows you to increase the pressure in the system up to 5-7 atmospheres, which, of course, affects the effectiveness of the heat exchange process between the evaporator and condensers.

From the storage tank to the evaporator is a regular plumbing with very hot water. And it is customary to mount the circulation pump in this area.

As a result, in terms of complexity, this scheme does not exceed single-pipe wiring. True, the two-pipe version with its expansion tanks, circulation pumps and two branches of the wiring (steam line and condensate line) requires a lot of effort at the assembly stage. But all the effort expended is compensated by the increased efficiency of the heating system. At the same time, the wiring assembly technology and the main type of pipe moldings are similar to a single-pipe system.

Do-it-yourself steam heating

The arrangement of steam heating consists of two stages - design and actual installation.

Stage 1. System design

System design

Once again, we remind you of the peculiarities of using steam as a heat carrier - this is a high temperature of the pipeline and radiators, as well as an increased accident rate. When all the pros and cons are weighed, work can begin. First, a project of the future system is created.

Boiler

wood burning boiler

First, the required power of the heat generator is determined. This takes into account the area of \u200b\u200bthe house - if it does not exceed 200 m², then a device with a power of 25 kW is enough, but if it fluctuates between 200 m² and 300 m², then a minimum of 30 kW will be required. Based on this information, a boiler is selected. When buying, consider the following factors:

- the type of fuel to be used;

- the possibility of heating water for domestic needs.

Heating scheme

Two-wire top-wired system

Single wire system with bottom wiring

Scheme of an open heating system

The scheme also needs to be decided in advance.The choice of one or the other depends on:

- boiler location;

- the area of the heated room;

- conditions for the installation of heating devices;

- the required number of these devices.

In a word, this is a rather difficult choice, in which the video below will help.

Pipes

For steam heating, the use of conventional plumbing pipes is unacceptable due to the high temperature of the entire system.

For this reason, the choice of pipes should be given great attention, even if it is small.

-

Copper pipes are characterized by excellent thermal conductivity and high cost. Installation is carried out by soldering.

Copper pipes

-

The advantage of steel pipes is resistance to aggressive media and mechanical stress, the disadvantage is susceptibility to corrosion. They require a welding machine to install.

Steel pipes

-

Galvanized products combine the positive qualities of the previous ones - they do not rust and are relatively inexpensive. Docking of pipes is carried out by a threaded connection.

Galvanized products

In order to facilitate installation work at the design stage, it is necessary to determine:

- location of radiators;

- pipeline length;

- installation sites for distributors, branch lines, adapters, etc.

Issue price

After drawing up the project, future costs are determined. It is difficult to say how much the equipment of such a system will cost, without reference to heating devices, scope of work and specific conditions. We only note that, according to experts, steam heating in any case will cost less than conventional water heating.

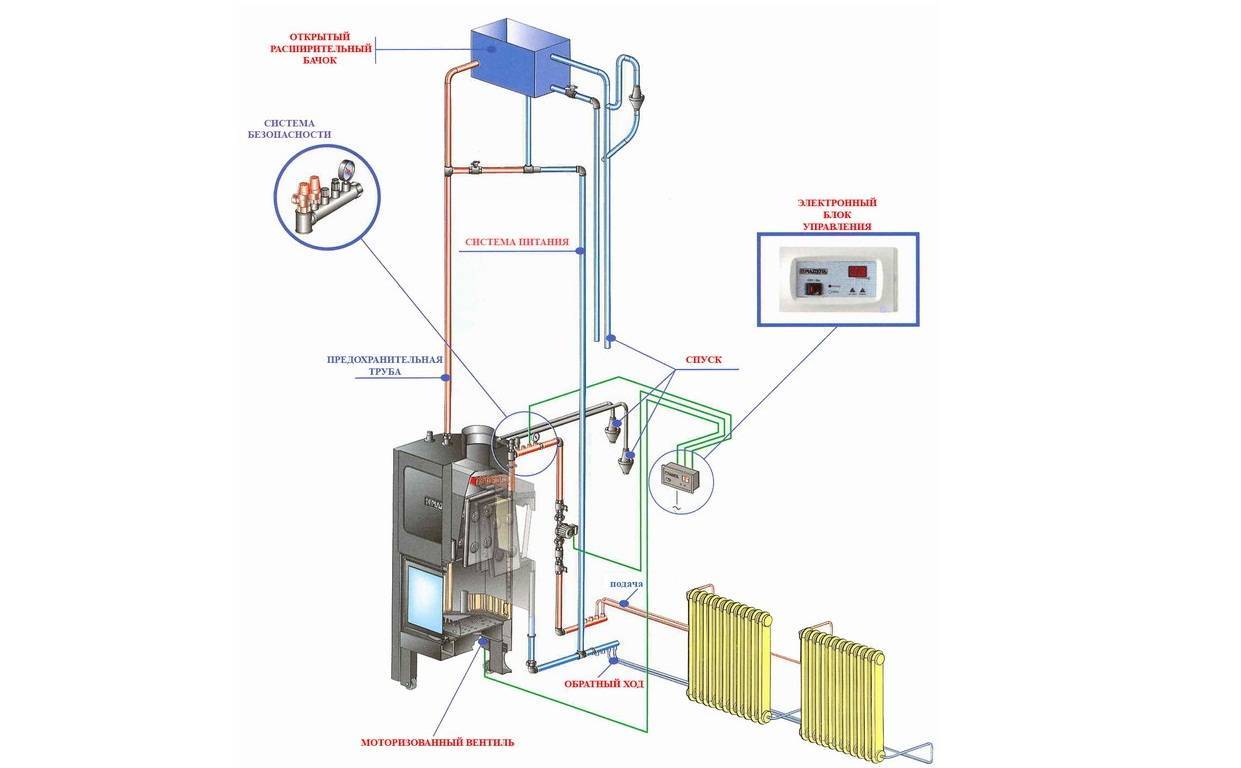

Stage 2. Installation work

Step 1. First, an exact wiring diagram is drawn based on the sketch.

Heating wiring diagram

Step 2Next, radiators are installed. They are recommended to be placed under the windows - this will not only heat the glass, but also prevent fogging and, as a result, the displacement of the "dew point".

Connecting a multi-section radiator

Installing a heating radiator

Installing a heating radiator

Radiators are installed next.

Step 3 An expansion tank is attached. It must be connected to the pipeline leading from the heat generator to the radiators. Another important point: the tank must be installed at the highest point of the heating system.

Expansion tank mount

Expansion tank mount

It can be closed and open, with or without overflow.

Step 4. Pipelines are being installed. This happens as follows: the pipe is brought to the radiator, cut off if necessary, after which the outputs and inputs are connected. Then the pipe is similarly connected from the first radiator to the second, then from the second to the third, and so on.

Step 5. The circuit closes, that is, it is brought to the beginning - the heat generator

It is important that the boiler is equipped with a filter and (if necessary) a circulation pump.

Vortex heat generator

Step 6 Next, you need to install the boiler itself. Quite often, car garages adjoin country houses. The heater can be installed in one of these garages.

Installation of a heating boiler

In this case, the installation of a heat generator is no different from a similar procedure in a residential area. At the same time, the bay / drain unit can be equipped on any section of the highway. This unit is necessary to drain the coolant at the end of the heating season or before repairing the system.

Step 7. All heating devices are tested.If they are new, then it is advisable to invite a specialist for a trial run.

Tiered floor

For zoning the space, the craftsmen mount the floors at different levels. They advise installing a podium to distinguish between the kitchen and the dining room. This option is considered one of the most practical, because, among other things, the owners have an additional free space where you can hide something.

It is convenient to use boxes or boxes for this. Wicker baskets will look good. But such a space can remain free.

However, such a design should not be done if the family has small children, since the podium can become an obstacle for him. In addition, various floor coverings can be used.

They will zone the space between the living room and the kitchen and protect the podium from damage. For example, tiles are laid in the kitchen area, and laminate flooring is laid in the dining room. The main thing is to choose colors and textures, to correctly combine the finish.

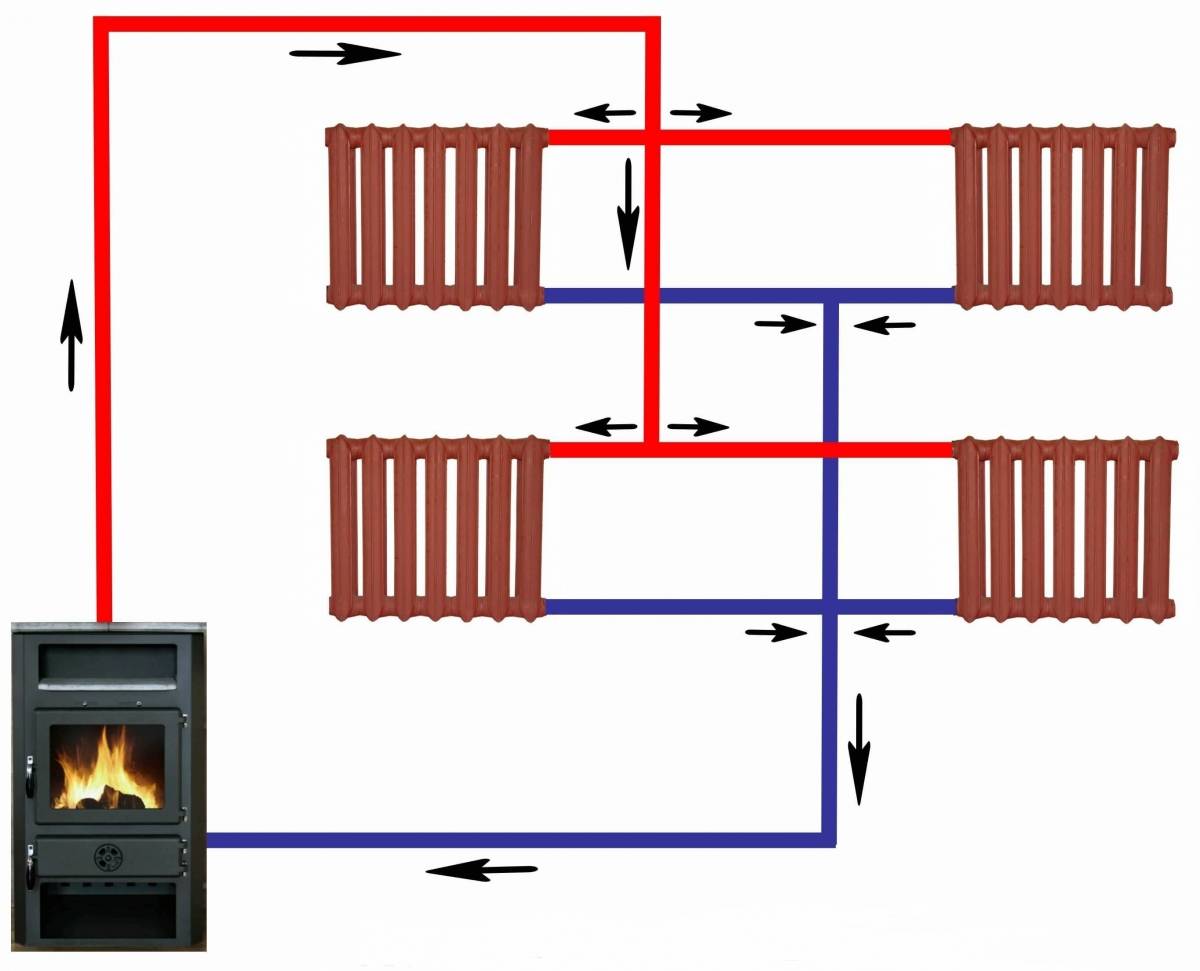

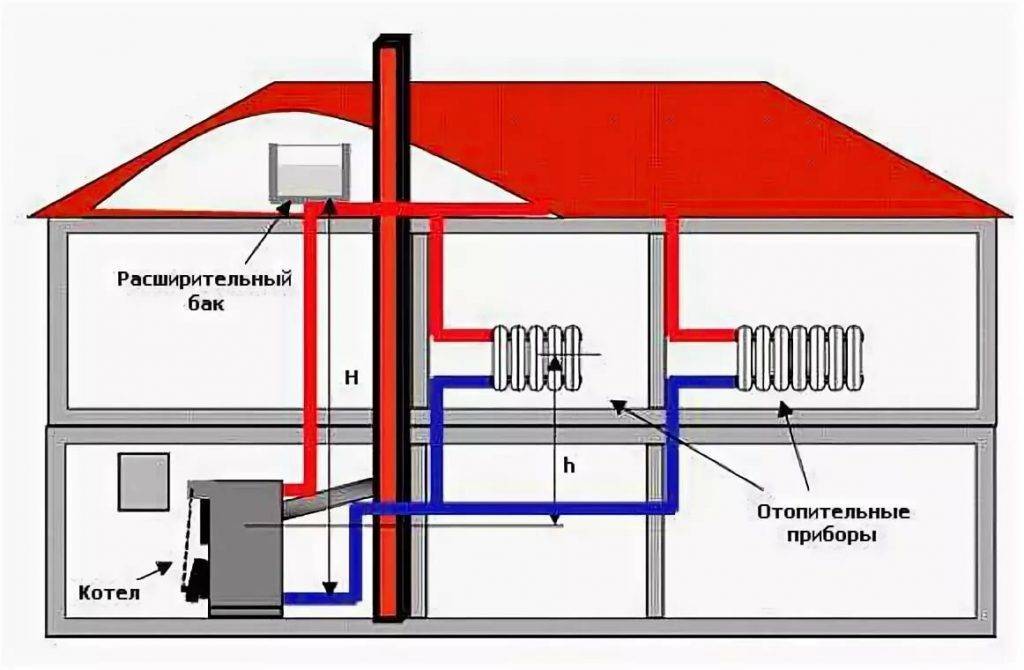

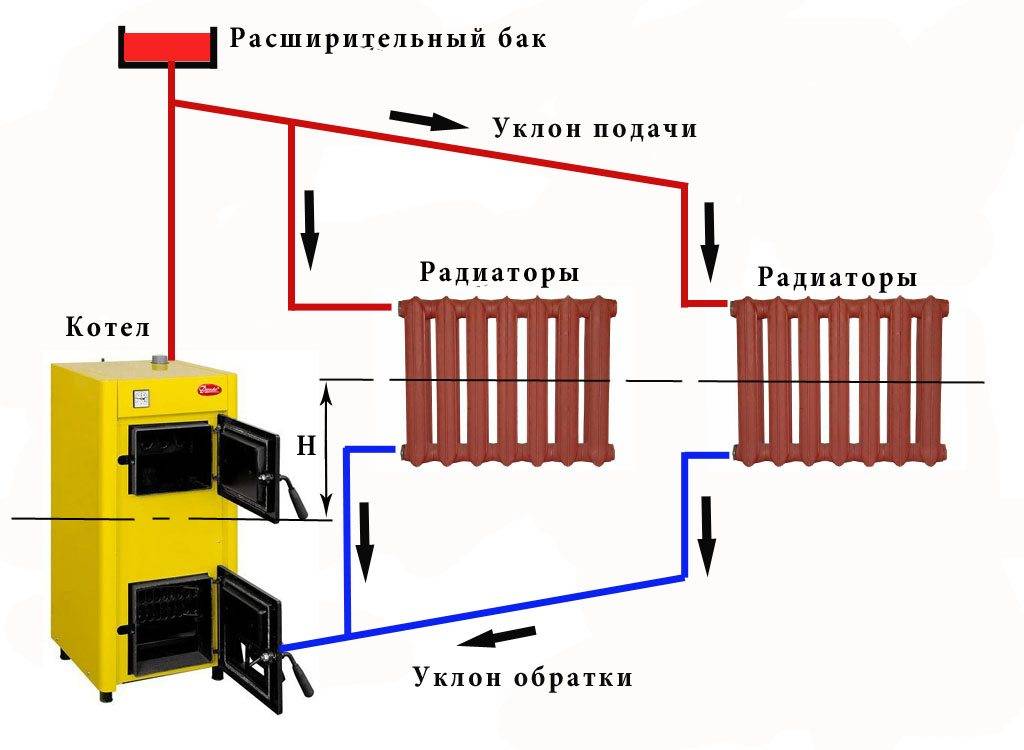

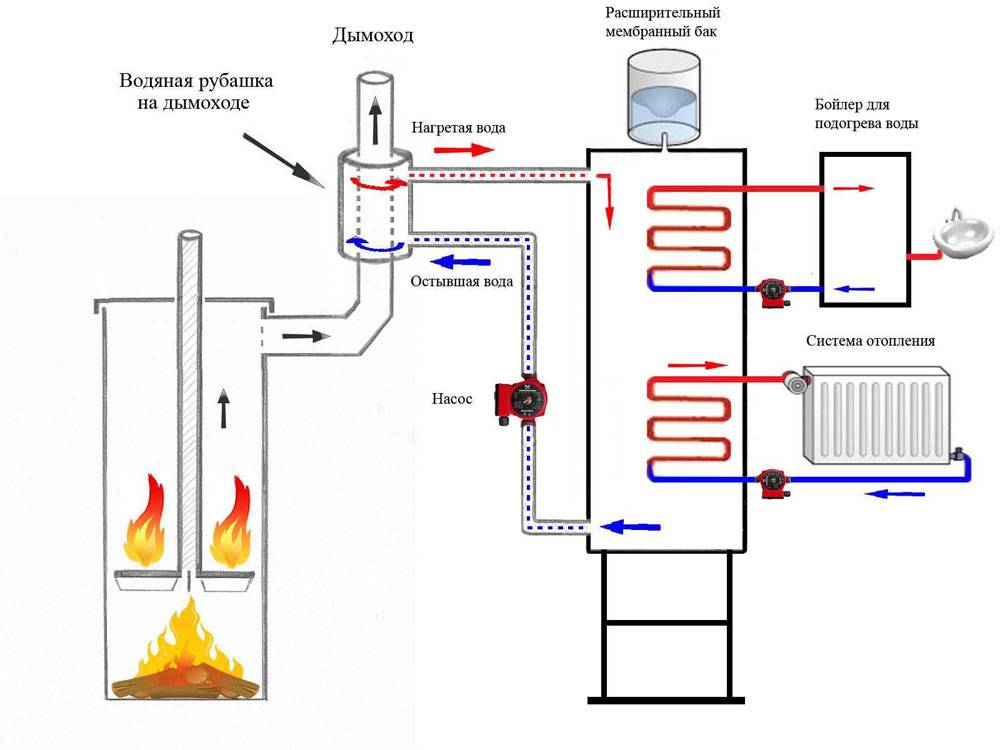

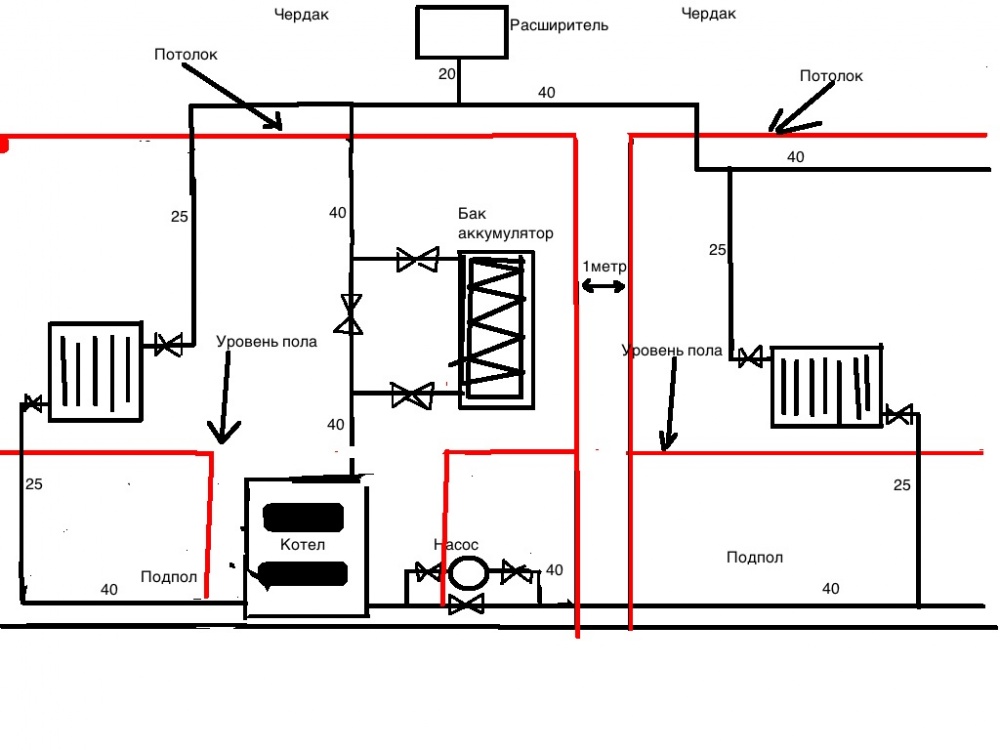

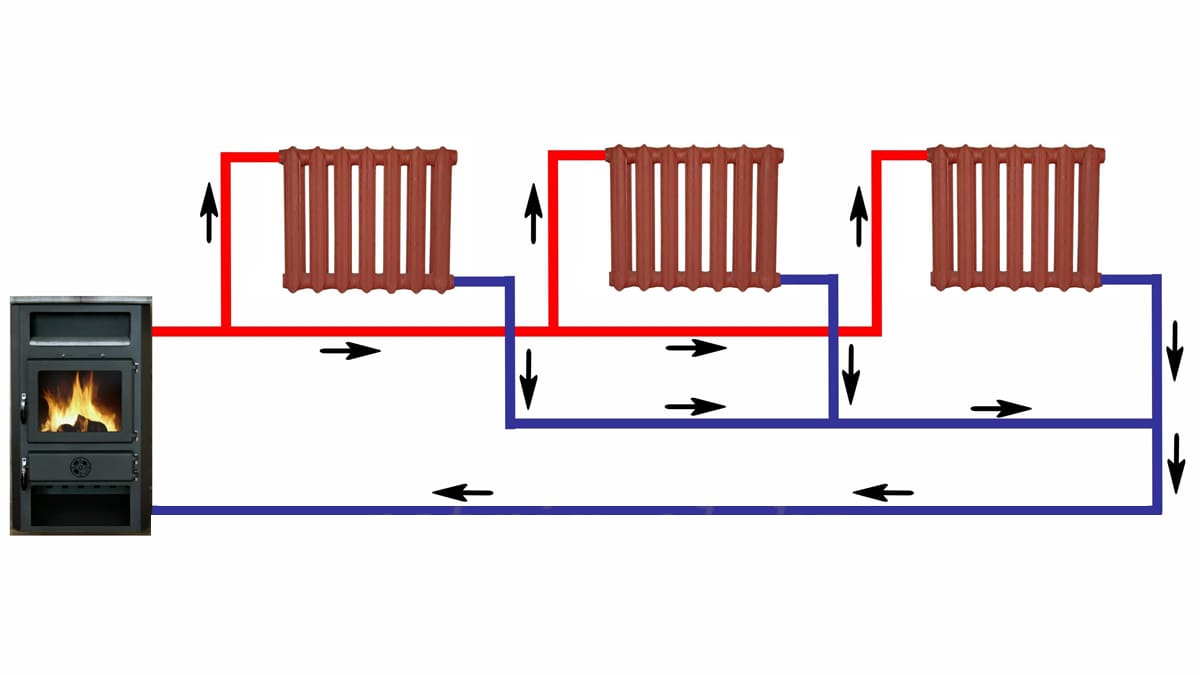

How is the distribution of steam heating from the furnace

In this case, most experts recommend a single-circuit wiring option.

Such a scheme of steam heating from the furnace is equipped as follows:

- A vertical branch of the pipeline rises from the pressure pipe of the heat exchanger, turning into a horizontal one at the very ceiling.

- At the junction of the vertical and horizontal branches of the pressure pipe, a tee cuts in, which is used to connect an open expansion tank. This drive is located behind the ceiling - in the attic.

- The horizontal branch of the pressure pipe stretches to the first battery, at a slope of 2 centimeters per 1 meter of pipeline.Moreover, above the radiator, the horizontal again turns into a vertical, which ends at the upper battery fitting.

- From the upper fitting of the first battery to the corresponding "connector" of the next radiator, a connecting pipe is thrown, the diameter of which matches the dimensions of the pressure branch of the wiring.

- The lower "connectors" of the first and second radiators are "connected" with the same pipe. At the same time, a plug is screwed into the free branch pipe (under the pressure pipe inlet).

- The second battery is connected to the third according to the same principle, stretching a double line from radiator to radiator to the extreme position.

- The last (before the furnace) radiator "accepts" the upper and lower pipes from the penultimate one from one edge. On the other hand, a tube is screwed into the lower branch pipe of the last battery, connecting it to the return pipe of the heat exchanger in the furnace. A Mayevsky tap is screwed into the free upper pipe of the extreme battery - with its help, air is bled from the wiring.

- Pressure equipment is mounted between the furnace and the extreme battery - in the return line of the wiring, using a standard bypass for pumps.

The wiring arranged in this way supports both forced and natural circulation of the coolant. Simply put: your stove will heat your house with radiators even if there is no electricity in the outlet. That is, by acting in this way, you will achieve complete energy autonomy of the home heating system.

We also recommend seeing:

- Glass doors for stoves and fireplaces

- Fireproof Heat Resistant Glass for Fireplace

- What is the optimal pressure in the heating system of a multi-storey building?

- Stainless steel chimney pipe insulation

Various schemes for the implementation of steam heating

To do steam heating with your own hands, you need to know what options can be implemented.

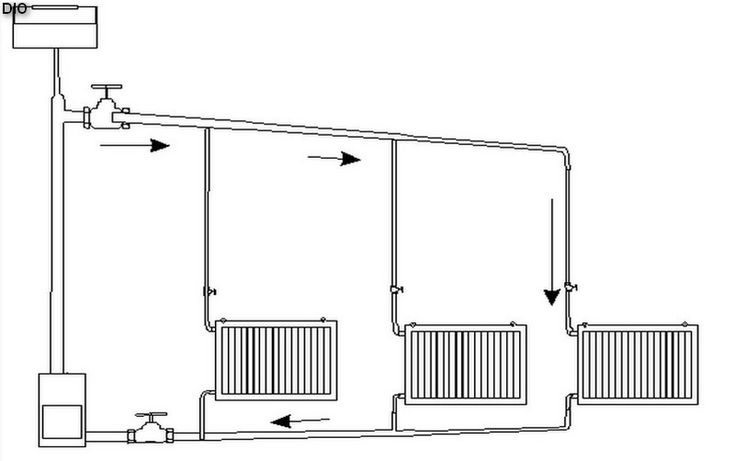

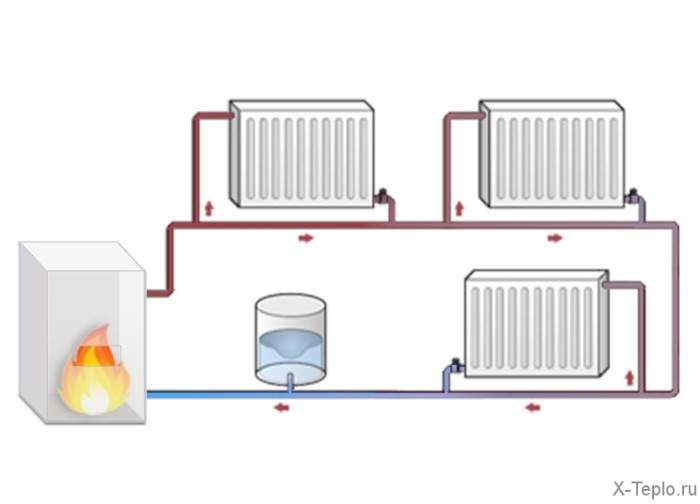

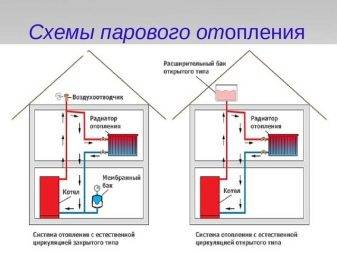

Closed and open piping

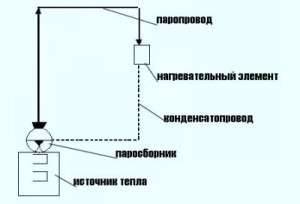

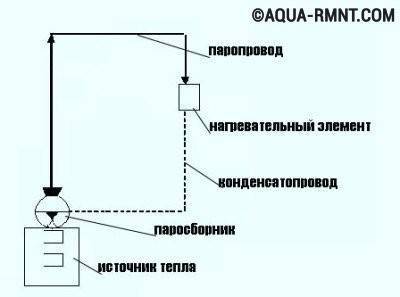

Depending on the method of returning condensate to the heat source, there are two options for steam heating: closed and open.

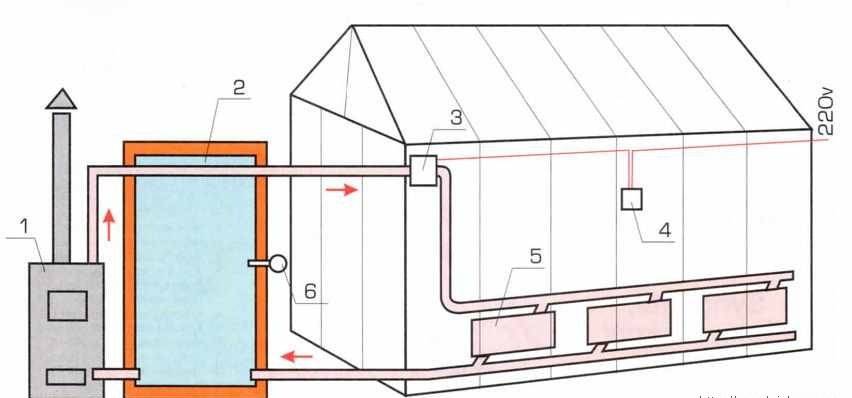

In a closed system, condensate from the heating elements is returned to the heat source under the action of a pressure difference. For the efficient operation of such a system, it is necessary that the steam collector be placed low enough in relation to the heating elements.

In order for steam heating with a closed system to work with full efficiency, the steam collector must be placed so that it is below the heating elements

An open system assumes the gravity flow of condensate into the storage tank. From where periodically there is a transfer to the heat source using a pump. Such a system must be ensured by the free flow of condensate from the last heating element into the storage tank.

In an open-loop steam heating system, the condensate line leaving the last heating element must be inclined in relation to the storage tank

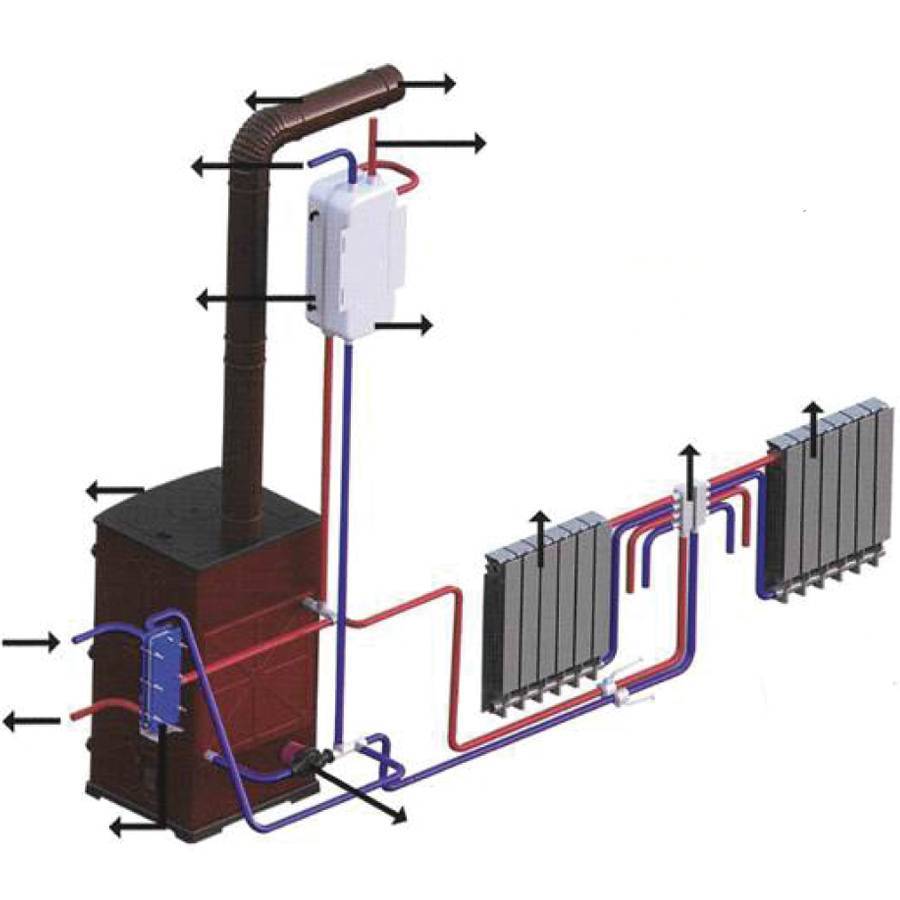

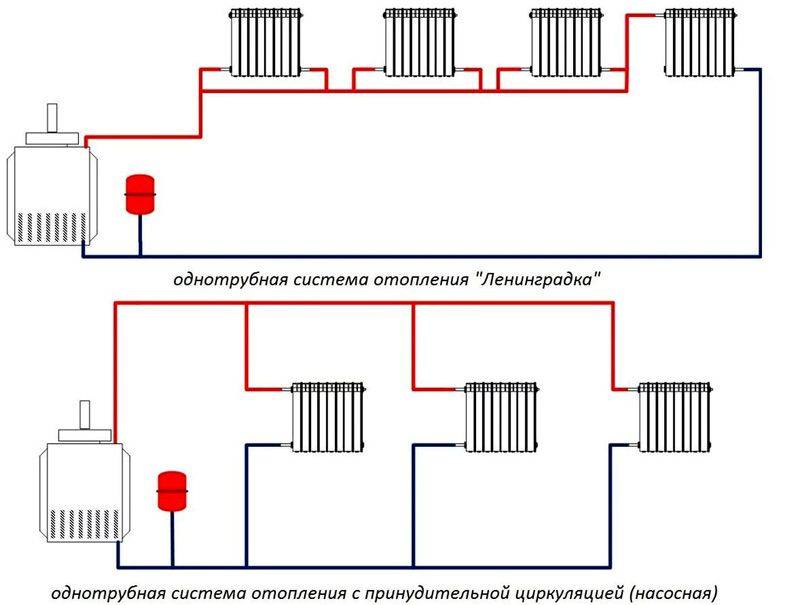

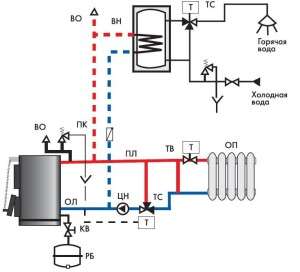

Two-pipe or one-pipe system?

Depending on the method of supplying pipes to the devices, steam heating is divided into one-pipe and two-pipe. Due to the difficulty of controlling the heat flow, a single-pipe steam heating system is rarely used. For control, you have to purchase special devices, which increases the cost of work. It is much easier to regulate a two-pipe heating system.A control valve is installed at the steam inlet to the heater. At the condensate outlet there are thermostatic condensate traps. Due to this, a two-pipe system is less noisy than a single-pipe system.

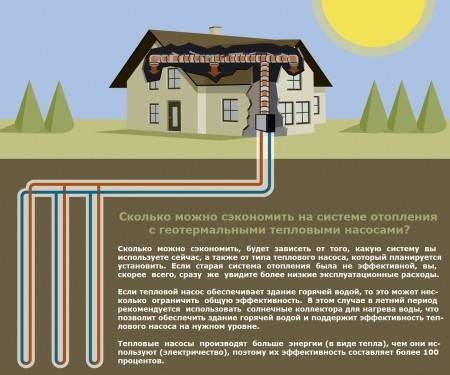

We focus on system pressure

Steam Heating Division in pressure dependent:

- low pressure, there are closed and open;

- high pressure;

- vacuum steam.

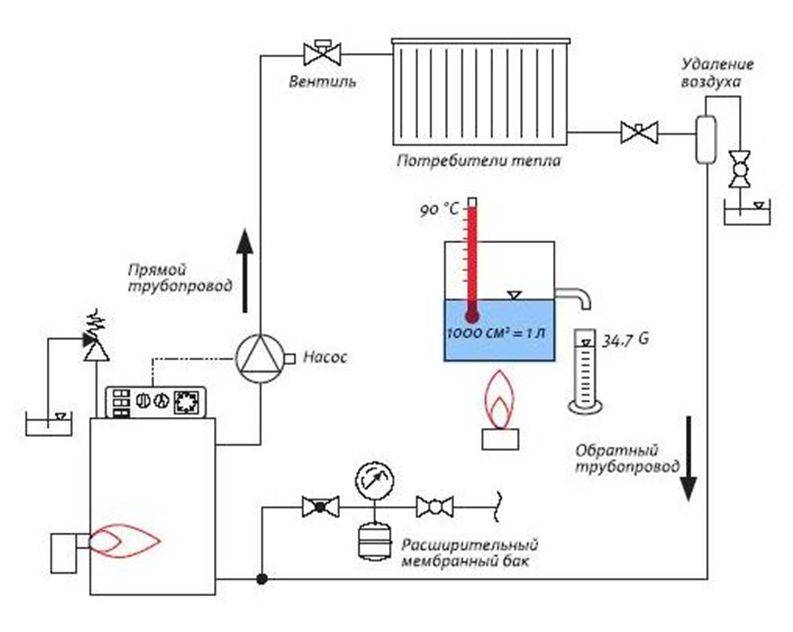

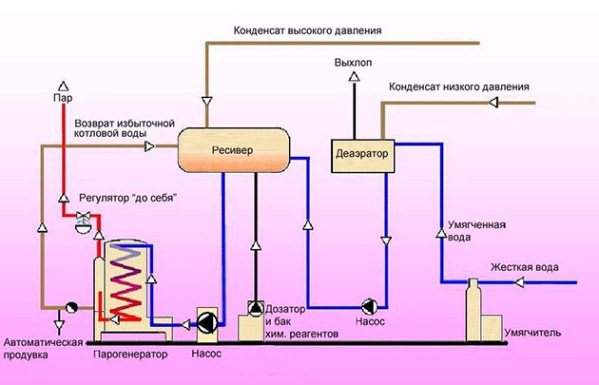

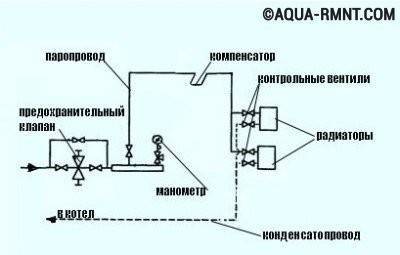

Various schemes of steam systems differ in the method of connecting radiators, the location of steam lines and condensate lines. Let's consider a variant of the low pressure system. The pressure arising in the boiler contributes to the movement of steam, which enters the riser, and then into the distributing steam pipeline. Risers leading to the heating elements depart from it. Steam connections with control valves are connected to the radiators. Steam enters the heating elements, cools from contact with the walls of the device, giving off heat. In the process, condensate is released, which is sent back to the boiler through the condensate pipelines.

Low pressure steam heating systems are equipped with pressure gauges that help control the pressure in the system. The boiler must have a fuse

High pressure systems at the starting point of the steam pipeline have a steam pressure above 0.7 kgf / cm². They are only available in closed loop. Consider one of the options for implementing such a system. The generated steam is reduced and sent to the distribution comb. A safety valve is also installed here, which controls the pressure within the set limit. To repair it, a bypass is installed.

Further, the steam is directed through the risers to the heating elements.The pressure in the system must be sufficient to remove the condensate, since its temperature is almost equal to the temperature of the steam. The steam line at the inlet and the condensate line at the outlet of the radiators are equipped with valves. A pressure gauge is installed to control the pressure. To compensate for temperature elongations, compensators are provided on the pipeline.

Heating elements must be equipped with control valves at the inlet of the steam line to the radiator. Temperature-controlled steam traps are installed at the outlet to the condensate pipeline

Vacuum-steam systems work with the help of a pump. It contributes to the creation of low pressure in the boiler and the movement of steam, and subsequently condensate, through the system.

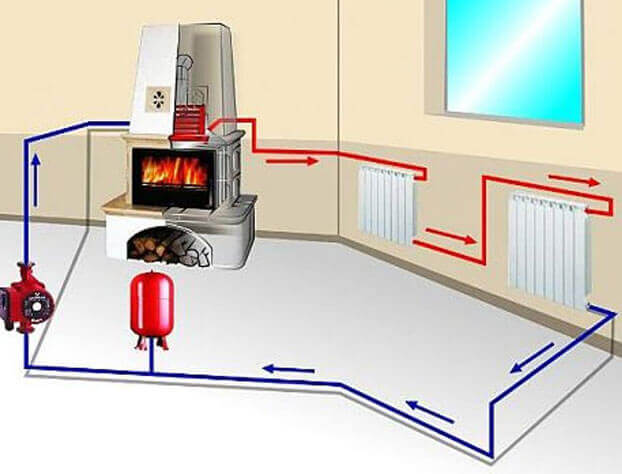

5 Installation of heating - is it really easy?

When installing steam heating with your own hands, consider the size of the heated area, the number and location of radiators, shut-off and control equipment, filters and other elements necessary to ensure the normal functioning of the system. The circulation pump and steam fans must be selected so as to ensure efficient circulation of the coolant

It is important to take into account where the equipment will be located and how far the steam boiler will be located.

Steam heating installation

To make steam heating yourself, you need to prepare the following equipment and materials:

- steam generator (boiler);

- pipes for laying the highway;

- radiators;

- instrumentation;

- shut-off and control valves.

The project documentation should indicate the length of the pipes, their number and diameter, as well as the radiators or other heating elements used. All this must be put on paper in the form of a diagram with a detailed description of all the nuances.When the project and the scheme are ready, we proceed to the installation. The system is mounted strictly according to the scheme.

- 1. At the first step, we prepare the surfaces to which the equipment will be attached. On the walls we mount the fasteners on which the radiators will be held. Then we fix the heating devices on the walls. They should be placed under the windows in order to exclude the appearance of cold drafts: the air flows coming from the outside will immediately heat up. In addition, this will prevent windows from fogging up and shift the dew point.

- 2. Next, install the boiler (steam generator) on a concrete base. The floor is insulated with fireproof material. It is better to place it in the basement, as the vapors rise up (or in the garage). If you plan to install underfloor heating, then it is better to buy a double-circuit boiler that will separate work for the house and floors. In this case, the steam generator is located above the floor surface.

- 3. We install the expansion tank using special fasteners at the highest point of the heating system, it must be included in the line between the steam generator and radiators. According to the recommendations of experts, an open tank should be installed at the closest distance to the heating boiler.

- 4. At the next stage, we mount the pipeline. We will start the wiring with the steam generator. We bring the pipe from it to the first heater, if necessary, cut it off if it is too long. Then we connect all the inputs and outputs. Similarly, we connect the pipe to the next device until we connect all the heating parts into a single line. Pipes are mounted with a slope of 3 mm per meter for natural circulation.

- 5.We equip each battery with a Mayevsky crane so that air pockets that have formed that will interfere with the efficient operation of the system can be removed.

- 6. We install a storage tank in front of the steam generator, in which condensate will collect, and then, under a natural slope, water will flow into the heating boiler.

- 7. We close the main on the heating boiler, thus creating a closed circuit. We install a filter on the boiler, it will trap dirt particles contained in the water, and, if possible, a circulation pump. The pipe leading from the pump to the boiler must be smaller in diameter than the rest of the pipes.

- 8. At the outlet of the boiler, we install instrumentation: a pressure gauge and a relief valve.

- 9. We include a drain / fill unit in the system to pump out the coolant from the system at the end of the heating season or during repairs.

- 10. After the installation is completed, we check the system for operability and the presence of a leak. We fix all found problems.

The use of steam heating is cheaper than water heating, but it is not recommended to install it in residential premises because of the risk of an emergency in the event of a rush.