- Steam heating scheme

- 5 Installation of heating - is it really easy?

- Heat management

- Single pipe scheme

- Types of heating system

- What should be guided

- gas boilers

- Electric boilers

- Solid fuel boilers

- Oil boilers

- Wood-burning brick oven

- 3 Benefits of stove heating

- Steam heating installation: an overview of the arrangement process

- First scheme: open single-pipe version

- Second scheme: closed two-pipe version

- Life time

- Some Helpful Tips

- Conclusion

Steam heating scheme

By and large, the schemes of heating systems for steam and water are almost the same. Only in the case of steam, the connection to the boiler becomes more complicated, an additional storage tank for condensate (receiver) and water treatment devices appear, which is shown in the diagram:

Regardless of whether you are going to install heating with your own hands, or hire specialists, we will present 5 arguments why it should not be steam:

- steam heating is traumatic: radiators and pipes heated to 130 ºС are a source of burns for you and your children;

- lack of savings: it is almost impossible to control the temperature in rooms heated by steam;

- the purchase and installation of steam boilers, as well as special fittings, is much more expensive than traditional water systems;

- the commissioning of steam generating equipment requires permission from the relevant control authorities;

- steam generation equipment is a source of increased danger. Its scope is industrial production.

5 Installation of heating - is it really easy?

When installing steam heating with your own hands, consider the size of the heated area, the number and location of radiators, shut-off and control equipment, filters and other elements necessary to ensure the normal functioning of the system. The circulation pump and steam fans must be selected so as to ensure efficient circulation of the coolant

It is important to take into account where the equipment will be located and how far the steam boiler will be located.

Steam heating installation

To make steam heating yourself, you need to prepare the following equipment and materials:

- steam generator (boiler);

- pipes for laying the highway;

- radiators;

- instrumentation;

- shut-off and control valves.

The project documentation should indicate the length of the pipes, their number and diameter, as well as the radiators or other heating elements used. All this must be put on paper in the form of a diagram with a detailed description of all the nuances. When the project and the scheme are ready, we proceed to the installation. The system is mounted strictly according to the scheme.

- 1. At the first step, we prepare the surfaces to which the equipment will be attached. On the walls we mount the fasteners on which the radiators will be held. Then we fix the heating devices on the walls.They should be placed under the windows in order to exclude the appearance of cold drafts: the air flows coming from the outside will immediately heat up. In addition, this will prevent windows from fogging up and shift the dew point.

- 2. Next, install the boiler (steam generator) on a concrete base. The floor is insulated with fireproof material. It is better to place it in the basement, as the vapors rise up (or in the garage). If you plan to install underfloor heating, then it is better to buy a double-circuit boiler that will separate work for the house and floors. In this case, the steam generator is located above the floor surface.

- 3. We install the expansion tank using special fasteners at the highest point of the heating system, it must be included in the line between the steam generator and radiators. According to the recommendations of experts, an open tank should be installed at the closest distance to the heating boiler.

- 4. At the next stage, we mount the pipeline. We will start the wiring with the steam generator. We bring the pipe from it to the first heater, if necessary, cut it off if it is too long. Then we connect all the inputs and outputs. Similarly, we connect the pipe to the next device until we connect all the heating parts into a single line. Pipes are mounted with a slope of 3 mm per meter for natural circulation.

- 5. We equip each battery with a Mayevsky crane so that air pockets that have formed that will interfere with the efficient operation of the system can be removed.

- 6. We install a storage tank in front of the steam generator, in which condensate will collect, and then, under a natural slope, water will flow into the heating boiler.

- 7.We close the main on the heating boiler, thus creating a closed circuit. We install a filter on the boiler, it will trap dirt particles contained in the water, and, if possible, a circulation pump. The pipe leading from the pump to the boiler must be smaller in diameter than the rest of the pipes.

- 8. At the outlet of the boiler, we install instrumentation: a pressure gauge and a relief valve.

- 9. We include a drain / fill unit in the system to pump out the coolant from the system at the end of the heating season or during repairs.

- 10. After the installation is completed, we check the system for operability and the presence of a leak. We fix all found problems.

The use of steam heating is cheaper than water heating, but it is not recommended to install it in residential premises because of the risk of an emergency in the event of a rush.

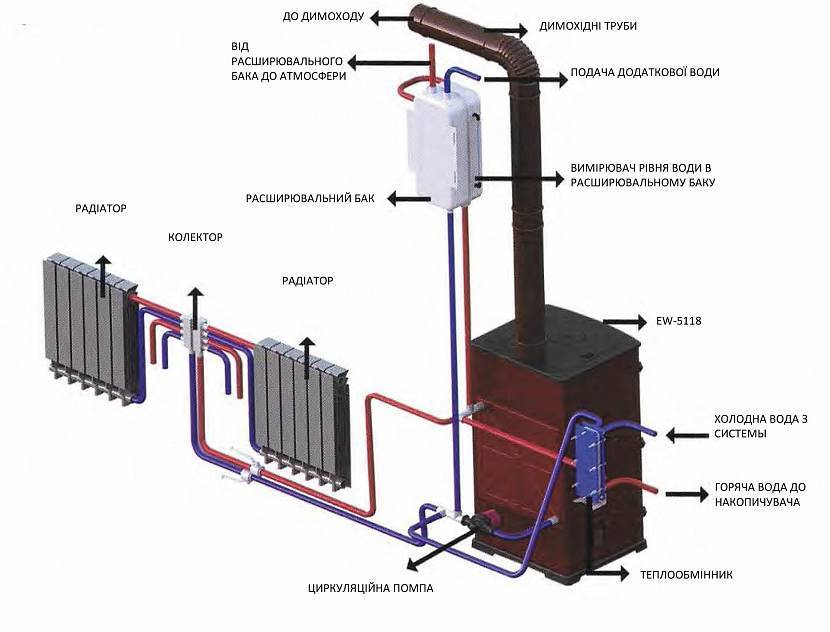

Heat management

An important role in the absorption of heat is played by the presence of a buffer tank (heat accumulator) in the system. This device allows you to smooth out the peak heat during intense combustion of the fuel. All the heat absorbed by it returns to the heating system after the bookmark burns out. One of the important advantages of a boiler in conjunction with a heat accumulator is that this process can be automated. The hydraulic separator (hydraulic arrow) allows you to separate the boiler circuit from the heating circuit and supply exactly as much heat to the latter as is necessary to maintain a comfortable temperature in the premises. Of course, this causes some rise in the cost of the heating system.

Furnaces also have temperature control capabilities, only they are much more modest. Heat dissipation can be regulated in much smaller ranges and only manually.Many stoves have a long burning function, when the firewood smolders for several hours. However, the next laying should be burned intensively so that soot and tar deposits do not accumulate in the chimney. In any case, the combustion of fuel in the furnace will be accompanied by temperature fluctuations in the premises. And each owner of the furnace will have to develop a fuel loading schedule, empirically determine the optimal positions of the dampers. Although production models are the same, the volumetric calorific value of firewood can vary greatly.

Thus, the boiler provides a more balanced microclimate in the house.

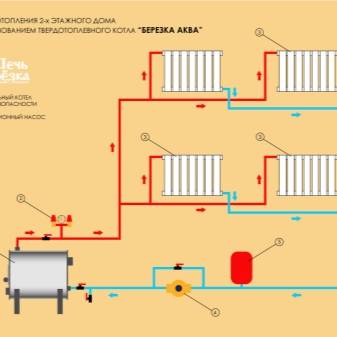

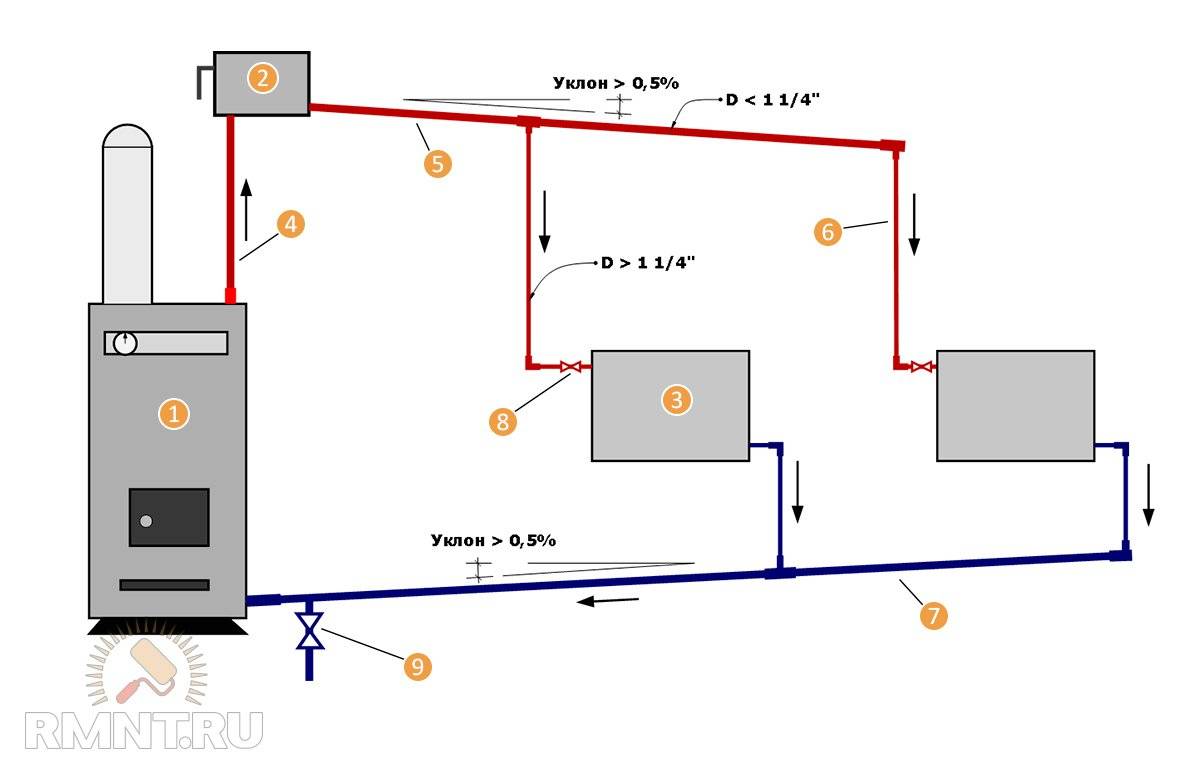

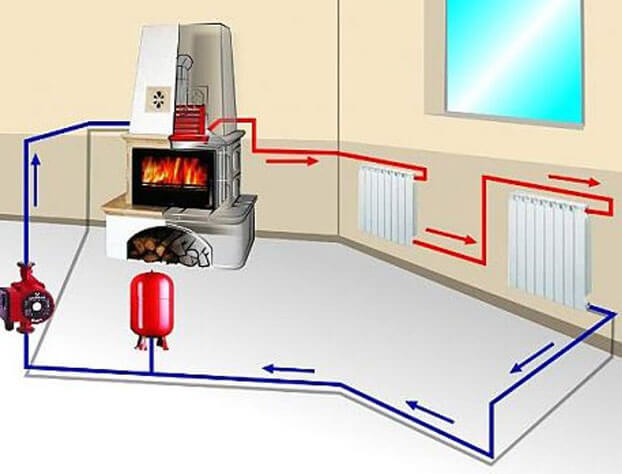

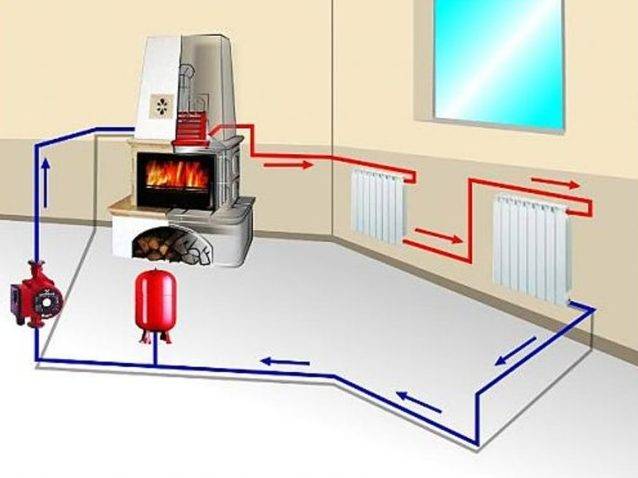

Single pipe scheme

If the house in the country is small, less than 100 m2, then it is more economical to make one-pipe heating for heating. The coolant and condensate in this case will be in the same pipe. Mounting scheme:

- the boiler in which the steam generator is located;

- steam pipeline;

- radiators;

- condensate pipeline;

- highway is closed.

For an area of 100 m2, a boiler of no more than 10 kW is required. This power will be enough for normal heating of the house. In order for the water in the boiler to heat up quickly, gas, electric boilers, diesel fuel or waste oil stoves are used.

A brick wood-burning stove or fireplace looks attractive, but it takes a long time to heat up. The advantage of wood heating is that it is completely autonomous. If the house is connected to a gas main, then they use a gas stove, but choose equipment with piezo ignition, which will make the heating independent, independent of electricity.

To make the connection of individual sections of the system, galvanized fittings are used. Tow is used as a sealant.Radiators are also purchased from galvanized steel. If the rooms in the house are small, then heating devices are not installed. A pipe is run around the perimeter of the room. She will act as a heater.

Always remember that steam comes out under a pressure of 170 kg/m2. Its temperature is 150 0С, the speed is 30 m/s. If the pipes are connected poorly, the line will break, which will be accompanied by a powerful steam flow. Before starting work, it is necessary to make a pressure test of the system in order to identify the places where air passes from the pipes.

Where does the installation of the heating system begin? First, the entire scheme is transferred to a sheet of paper. The drawing indicates the location of all elements of the system, the length of the pipeline in individual sections.

- Install the boiler. For a wood-burning stove, it is necessary to equip a separate area. The walls are protected from high temperatures with asbestos sheets. The stove is located away from interior items. The gas boiler is fixed on the wall. For heating units, a chimney is equipped. It should come out of the furnace at an angle to increase draft.

- Install radiators if necessary. They are fixed to the wall on brackets. Distance from the floor 10 cm, from the window sill 10 cm, from the wall 5 cm.

- Pipes of the appropriate diameter are brought to the radiators. To create a slope, the pipe is raised: 0.5 cm by 1 m towards the boiler. Fittings are used for connection. Connect all heaters one by one.

- A pipe is removed from the last radiator: a loop is installed. It is necessary to make the condensate line slope towards the boiler by 0.5 cm/m.

- The main is closed: the pipes are connected to the boiler.

- If a high power boiler is used, it is recommended to install an expansion tank to remove excess steam. The tank is installed in the attic. A steam pipeline from the boiler leads to it and a pipe descends to the radiator.

To be able to remove the radiator without affecting the main line. Bypasses and ball valves are installed on the sides in the lower corners. If it becomes necessary to change or repair the device, then the taps block the access of steam, the radiator cools down: it is ready for repair work.

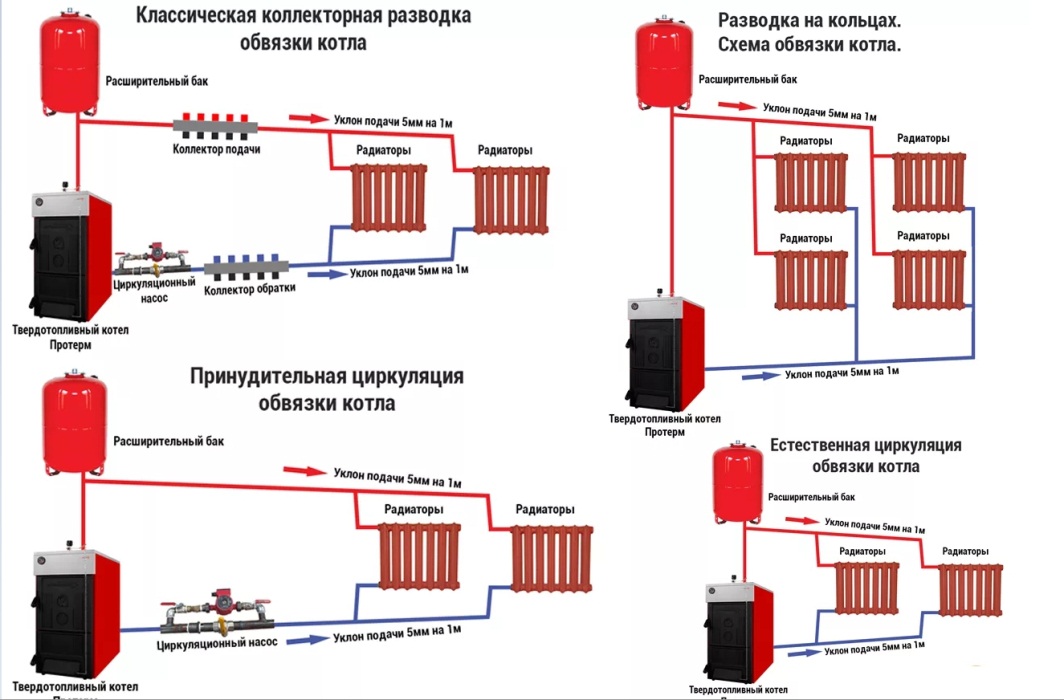

Types of heating system

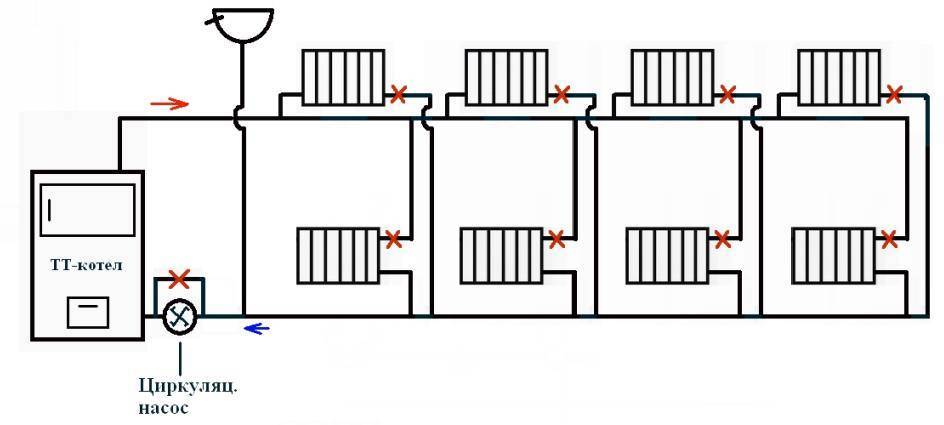

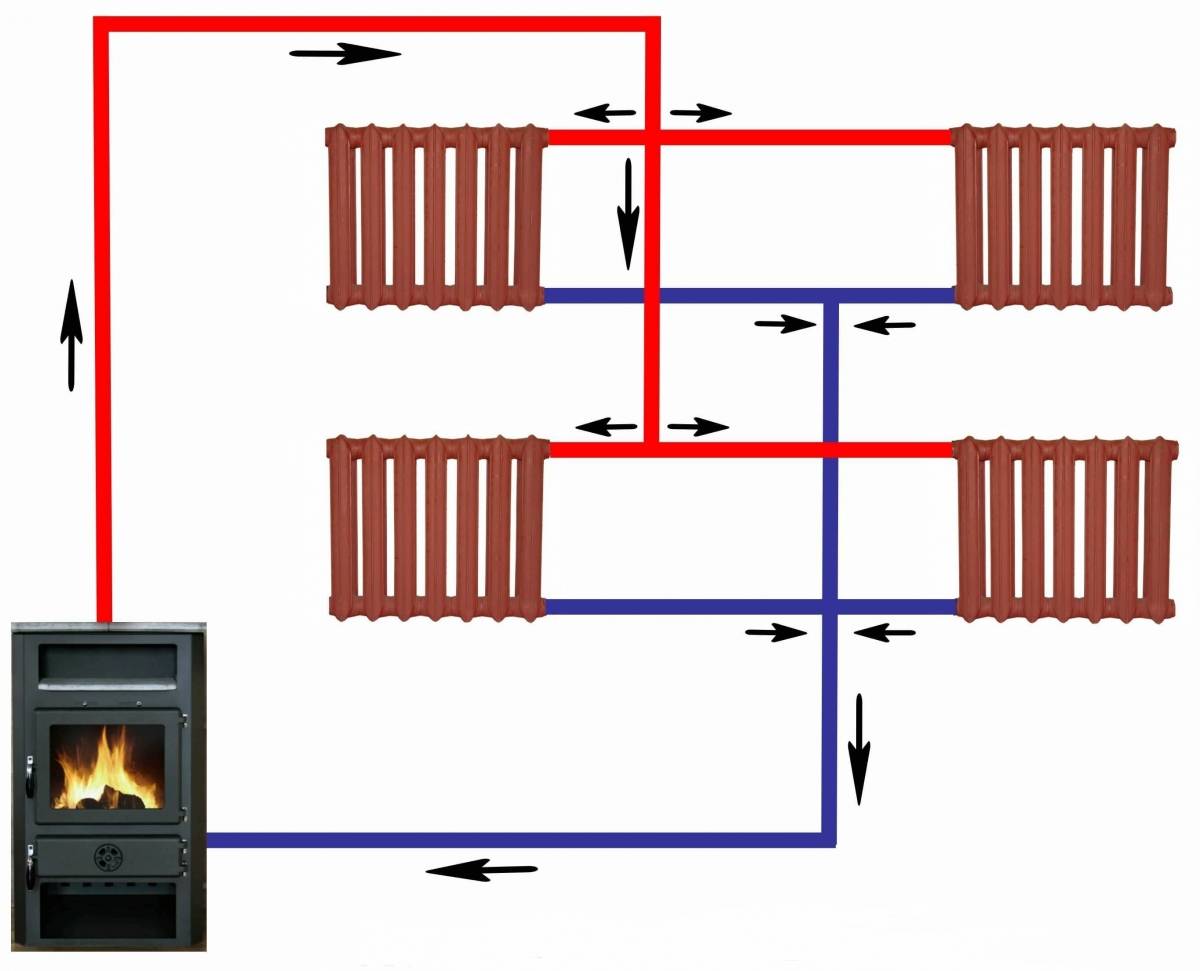

In practice, you can find a fairly large number of variations of steam heating. By the number of pipes, one and two-pipe types of steam systems are distinguished. In the first case, the steam moves through the pipe continuously.

In the first part of its journey, it gives off heat to the batteries and gradually turns into a liquid state. Then it moves like condensate. To avoid obstacles in the path of the coolant, the diameter of the pipe must be large enough.

It happens that the steam does not partially condense and breaks into the condensate line. In order to prevent its penetration into the branch intended for condensate drainage, it is recommended to install condensate traps after each radiator or group of heating devices.

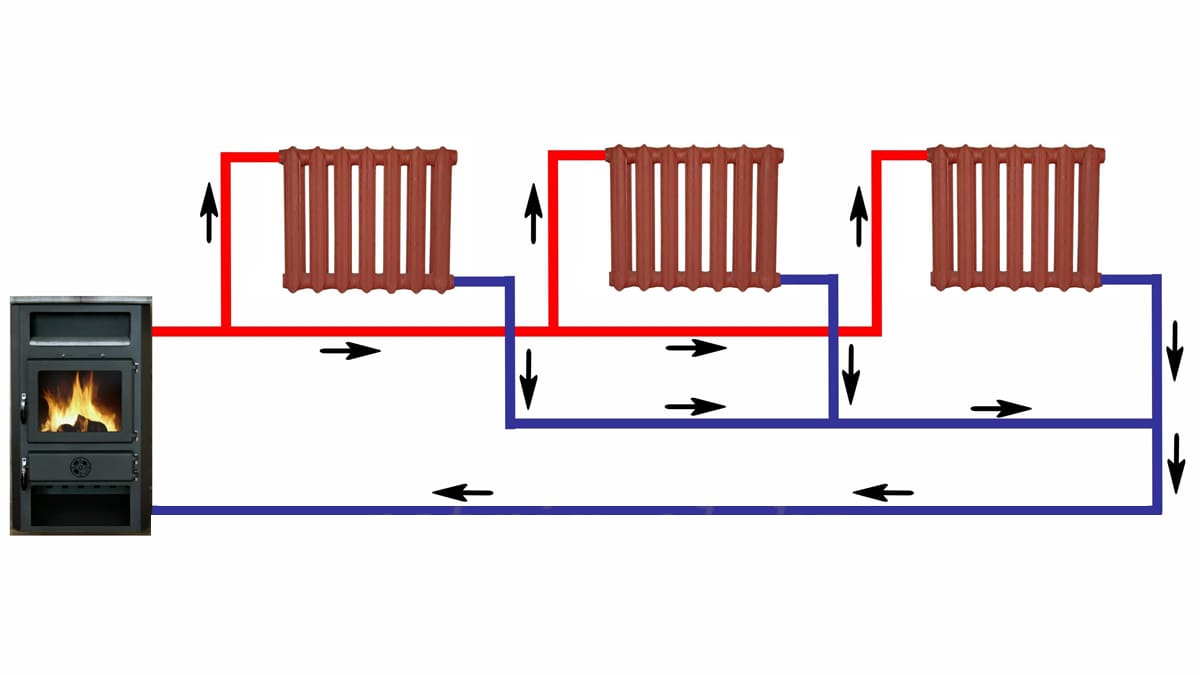

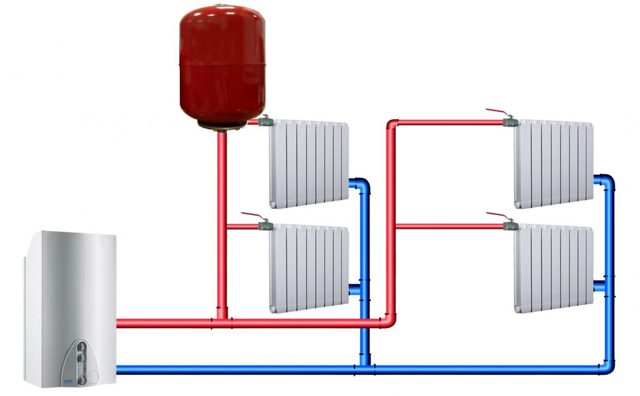

A significant disadvantage of a single-pipe system is the difference in heating of radiators. Those located closer to the boiler heat up more. The ones that are further away are smaller. But this difference will be noticeable only in large buildings. In two-pipe systems, steam moves through one pipe, condensate leaves through the other. Thus, it is possible to make the temperature in all radiators equal.

But this significantly increases the consumption of pipes.Like water, steam heating can be one or two-circuit. In the first case, the system is used only for space heating, in the second - also for heating water for domestic needs. The distribution of heating is also different.

There are three options available:

- With top wiring. The main steam pipeline is laid above the heating devices, pipes are lowered from it to the radiators. Even lower, near the floor, a condensate pipeline is laid. The system is the most stable and easy to implement.

- With bottom wiring. The line is located below the steam heating devices. As a result, steam moves in one direction and condensate moves in the opposite direction through the same pipe, which should be slightly larger than usual in diameter. This provokes water hammer and depressurization of the structure.

- With mixed wiring. The steam pipe is mounted slightly above the level of the radiators. Everything else is the same as in the system with the top wiring, thanks to which it is possible to retain all its advantages. The main disadvantage is a high injury risk due to easy access to hot pipes.

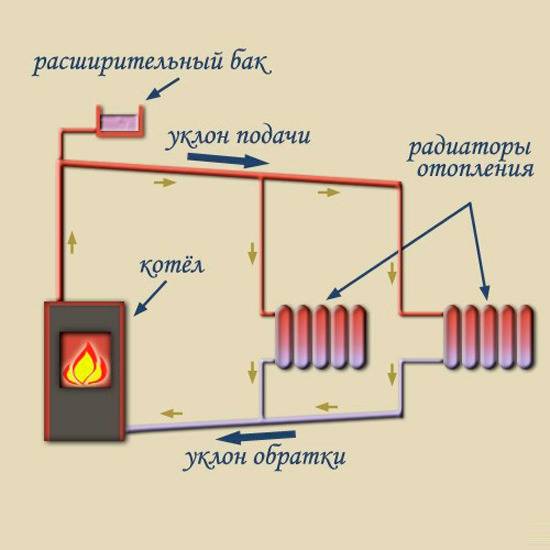

When arranging a scheme with natural coercion, it must be remembered that the steam pipeline is mounted with a slight slope in the direction of steam movement, and the condensate pipeline - condensate.

The slope should be 0.01 - 0.005, i.e. for each running meter of a horizontal branch, there should be 1.0 - 0.5 cm of slope. The inclined position of the steam and condensate pipelines will eliminate the noise of steam passing through the pipes and ensure the free flow of condensate.

Steam heating systems are built according to a single-pipe and two-pipe scheme. Among single-pipe options with horizontal connection to heating devices prevail.In the case of constructing a circuit with a vertical connection of devices, it is better to choose a two-pipe version

According to the level of internal pressure of the system, two main varieties are distinguished:

- Vacuum. It is assumed that the system is completely sealed, inside which a special pump is installed that creates a vacuum. As a result, the steam condenses at lower temperatures, making such a system relatively safe.

- Atmospheric. The pressure inside the circuit exceeds the atmospheric pressure by several times. In the event of an accident, this is extremely dangerous. In addition, radiators operating in such a system are heated to very high temperatures.

There are many options for arranging steam heating, so everyone can choose the best option for their home, taking into account all the features of the building.

The figure shows a diagram of an open-loop steam heating system

What should be guided

When asked how to choose a heating boiler, they often answer that the main criterion is the availability of a particular fuel. In this context, we distinguish several types of boilers.

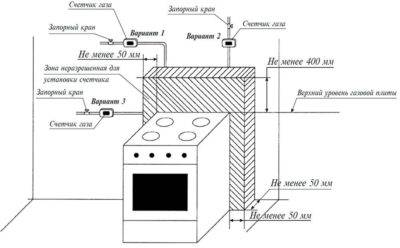

gas boilers

Gas boilers are the most common types of heating equipment. This is due to the fact that fuel for such boilers is not very expensive, it is available to a wide range of consumers. What are gas heating boilers? They differ from each other depending on what type of burner - atmospheric or inflatable. In the first case, the exhaust gas goes through the chimney, and in the second, all combustion products leave through a special pipe with the help of a fan. Of course, the second version will be a little more expensive, but it will not require smoke removal.

Wall mounted gas boiler

As for the method of placing the boilers, the choice of a heating boiler assumes the presence of floor and wall models. Which heating boiler is better in this case - there is no answer. After all, everything will depend on what goals you are pursuing. If, in addition to heating, you need to conduct hot water, then you can install modern wall-mounted heating boilers. So you will not need to install a boiler for heating water, and this is a financial savings. Also, in the case of wall-mounted models, combustion products can be removed directly to the street. And the small size of such devices will allow them to fit perfectly into the interior.

The disadvantage of wall models is their dependence on electrical energy.

Electric boilers

Next, consider electric heating boilers. If there is no mains gas in your area, an electric boiler can save you. Such types of heating boilers are small in size, so they can be used in small houses, as well as in cottages from 100 sq.m. All combustion products will be harmless from an environmental point of view. And the installation of such a boiler does not require special skills. It is worth noting that electric boilers are not very common. After all, fuel is expensive, and prices for it are rising and rising. If you are asking which heating boilers are better in terms of economy, then this is not an option in this case. Very often, electric boilers serve as spare appliances for heating.

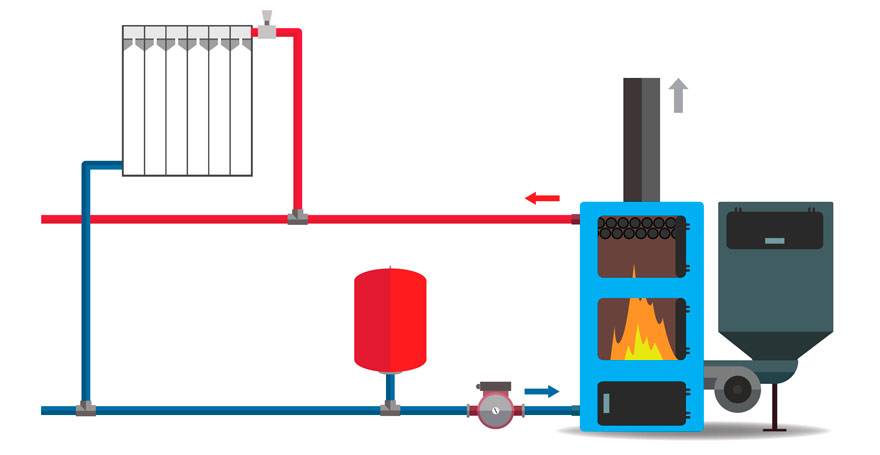

Solid fuel boilers

Now it's time to consider what solid fuel heating boilers are. Such boilers are considered the most ancient, such a system has been used for space heating for a long time.And the reason for this is simple - fuel for such devices is available, it can be firewood, coke, peat, coal, etc. The only drawback is that such boilers are not able to work offline.

Gas generating solid fuel boiler

Modification of such boilers are gas generating devices. Such a boiler differs in that it is possible to control the combustion process, and the performance is regulated within 30-100 percent. When you think about how to choose a heating boiler, you should know that the fuel used by such boilers is firewood, their humidity should not be less than 30%. Gas-fired boilers depend on the supply of electrical energy. But they also have advantages in comparison with solid propellant ones. They have a high efficiency, which is twice as high as solid fuel appliances. And from the point of view of environmental pollution, they are environmentally friendly, since the combustion products will not enter the chimney, but will serve to form gas.

The rating of heating boilers shows that single-circuit gas-generating boilers cannot be used to heat water. And if we consider automation, then it is great. You can often find programmers on such devices - they regulate the temperature of the heat carrier and give signals if there is an emergency danger.

Gas-fired boilers in a private house are an expensive pleasure. After all, the cost of a heating boiler is high.

Oil boilers

Now let's look at liquid fuel boilers. As a working resource, such devices use diesel fuel. For the operation of such boilers, additional components will be needed - fuel tanks and a room specifically for the boiler.If you are thinking about which boiler to choose for heating, then we note that liquid fuel boilers have a very expensive burner, which can sometimes cost as much as a gas boiler with an atmospheric burner. But such a device has different power levels, which is why it is profitable to use it from an economic point of view.

In addition to diesel fuel, liquid fuel boilers can also use gas. For this, replaceable burners or special burners are used, which are capable of operating on two types of fuel.

Oil boiler

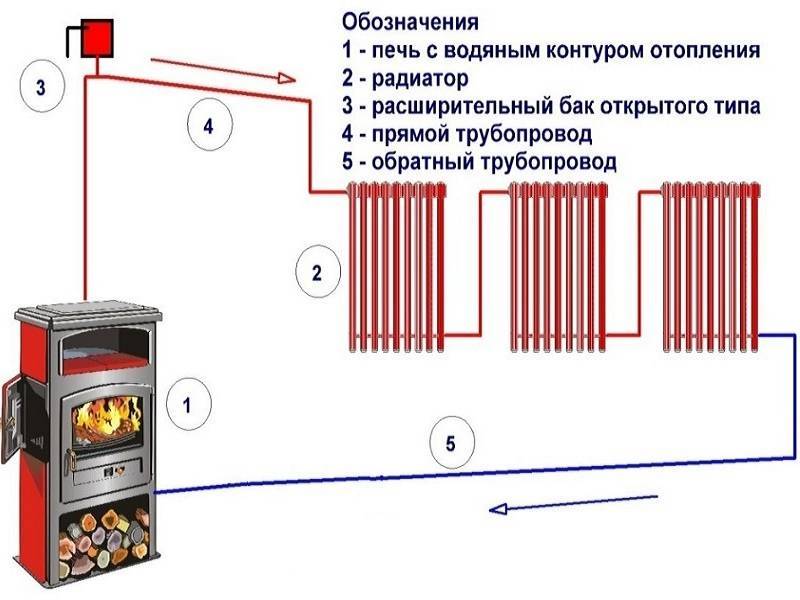

Wood-burning brick oven

If furnace heating is used as heating for heating a home, then the main question that needs to be decided is where to install a heat exchanger or steam generator. There are several options. The generator may be a coil or a boiler.

In order for the water in the generator to heat up quickly, it can be installed directly into the furnace. The water will boil quickly, but the equipment will soon become unusable. It will be under constant fire.

The coil is built into the brick walls of the furnace, pouring it with mortar. This design will last a long time. The water will absorb the heat that is transferred through the brick walls. She will boil quickly. This design option has some disadvantages. If there is a breakdown in the coil, then it will be impossible to eliminate it. You will have to disassemble the furnace wall and install a new heat exchanger.

It is not recommended to install the steam generator close to the wall. Soot and dirt can get into the niche. It should be possible to clean the surface of the coil and the niche itself. The steam pipeline can be connected to a boiler or direct steam to the radiators or to the "warm floor" system.

The system must be equipped with control devices to regulate the temperature and pressure of the steam. The optimum outlet temperature is 150 0С. The pressure at the exit to the steam pipeline is 170 kg/m2. When installing the line, it is not recommended to use fittings. Connect the pipes with welding seams.

3 Benefits of stove heating

In Russian homes, the stove occupied a special place and was considered a kind of "heart" of the house. The structure was made of bricks and clay (iron products are also sold today) and was always placed in the central part of the building, and all everyday life was in full swing near it. Food was cooked in the oven, and in winter it performed the function of heating the room.

At the same time, people knew how to properly heat the stove so that even after the fire went out, it continued to give warmth and comfort to the household. And since there was a lot of fuel for such a system, stove systems were present in almost every home. Trying to arrange a brick hot water oven, you should carefully consider the advantages of this design:

- 1. The unit is able to function autonomously without being connected to gas or electric mains. Wood is used as fuel. In most regions of Russia, firewood is very cheap or even free.

- 2. The operation of the furnace implies the implementation of the most comfortable radiant heating, in which the massive walls of the furnace evenly transfer heat to the surrounding objects and the air as a whole.

- 3. The furnace installation can perform several tasks at once: heat the building, be used for cooking, heat water.

- 4. The ability to monitor an open fire in a fireplace, which is a common type of stove, creates an atmosphere of coziness and comfort.

- 5.During the cold period, the massive structure accumulates impressive amounts of heat, which will be constantly distributed to the surrounding space. In the summer, the stove can act as an air conditioner, because if it is installed on a separate foundation, then a significant part of the excess heat energy will be “discharged” into the ground.

- 6. Well, the main advantage of the furnace heating system is complete safety for the environment. When using natural fuel, no harmful emissions into the atmosphere occur.

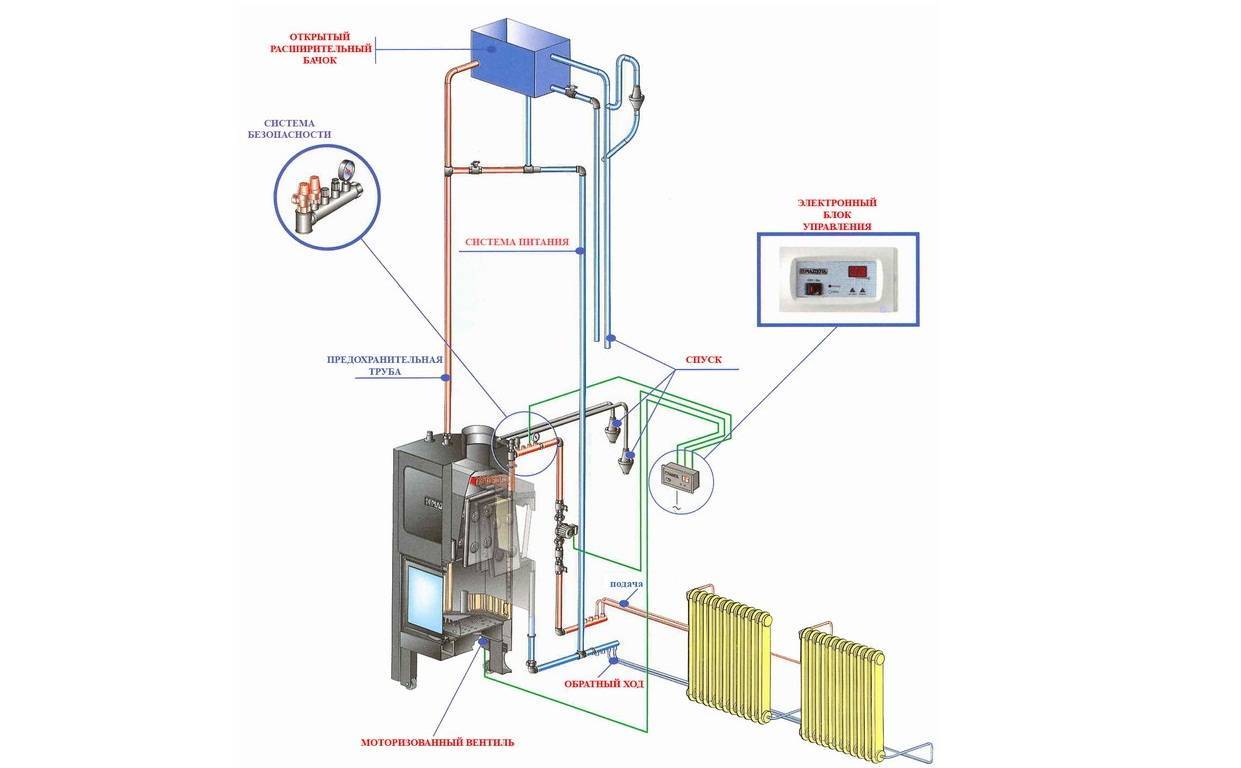

Steam heating installation: an overview of the arrangement process

In the review of the process of arranging steam heating, we will move from simple to complex. Therefore, the first option will be considered with a closed single-pipe type wiring, designed for natural circulation. And the last is an open version with two-pipe wiring, designed for forced circulation of the coolant. So, let's begin.

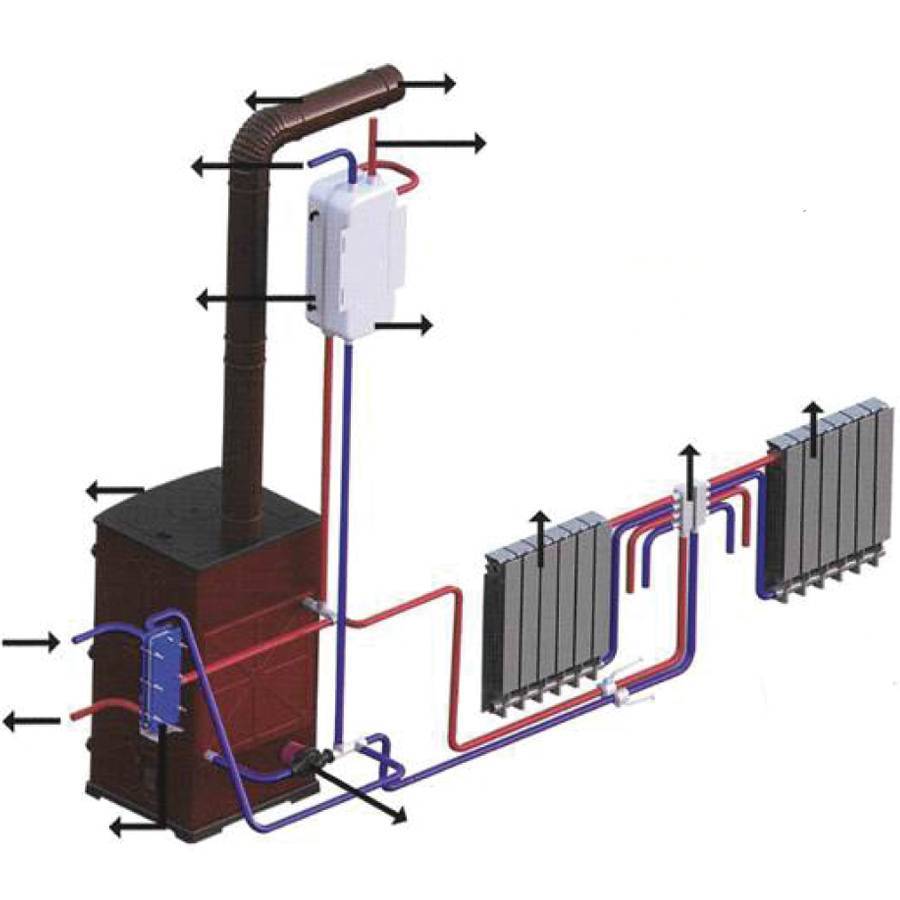

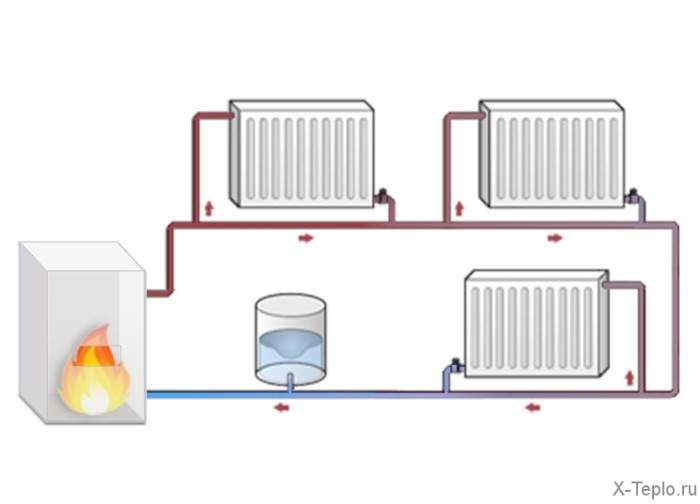

First scheme: open single-pipe version

In this case, a steam heating furnace will not be useful to us: after all, an open loop on gravity only functions if the steam generator is located below the capacitor banks.

That is, the installation of the system begins with the installation of a special solid fuel or gas steam generator, to the outlet of which a tee is mounted to connect a pressure gauge and primary section of the steam pipeline.

The primary section is raised to the level of the ceiling and directed along the perimeter of the walls, at a slope of 1.5-2 centimeters per linear meter of pipe to the first battery.Moreover, the input to the battery is designed as a vertical outlet connected to the right lower radiator fitting.

Next, you need to connect the upper left fitting of the first battery and the upper right fitting of the second radiator. The same operation is done with the lower inputs. And in a similar way connect all the batteries - from the first to the last. Moreover, each battery should be located slightly lower than the previous one, taking into account a 2-centimeter slope for each linear meter of the pipeline connecting the radiators. Otherwise, there will be no self-flow.

The condensate line, in fact, is the lower branch connecting adjacent radiator fittings. Moreover, a separate condensate pipeline departs from the last battery, connected to the evaporator tank. Of course, the last section must be mounted with the same slope.

As a result, if you do not take into account a slight difficulty with the positioning of the steam generator, or rather the evaporator tank of this element, then this wiring method is the most accessible installation scheme for steam heating. Moreover, the assembly of components is carried out on threaded or crimp couplings. And the main material for the construction of a steam pipeline and a condensate pipeline is a copper pipe.

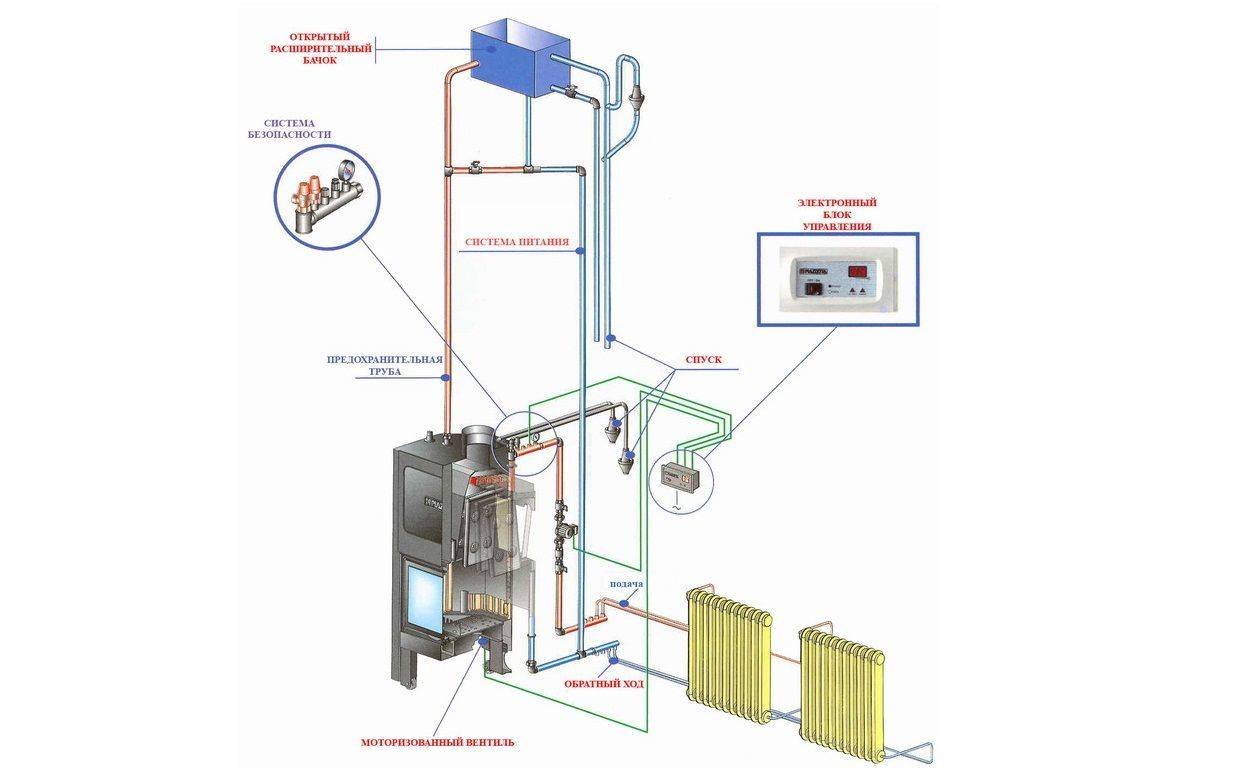

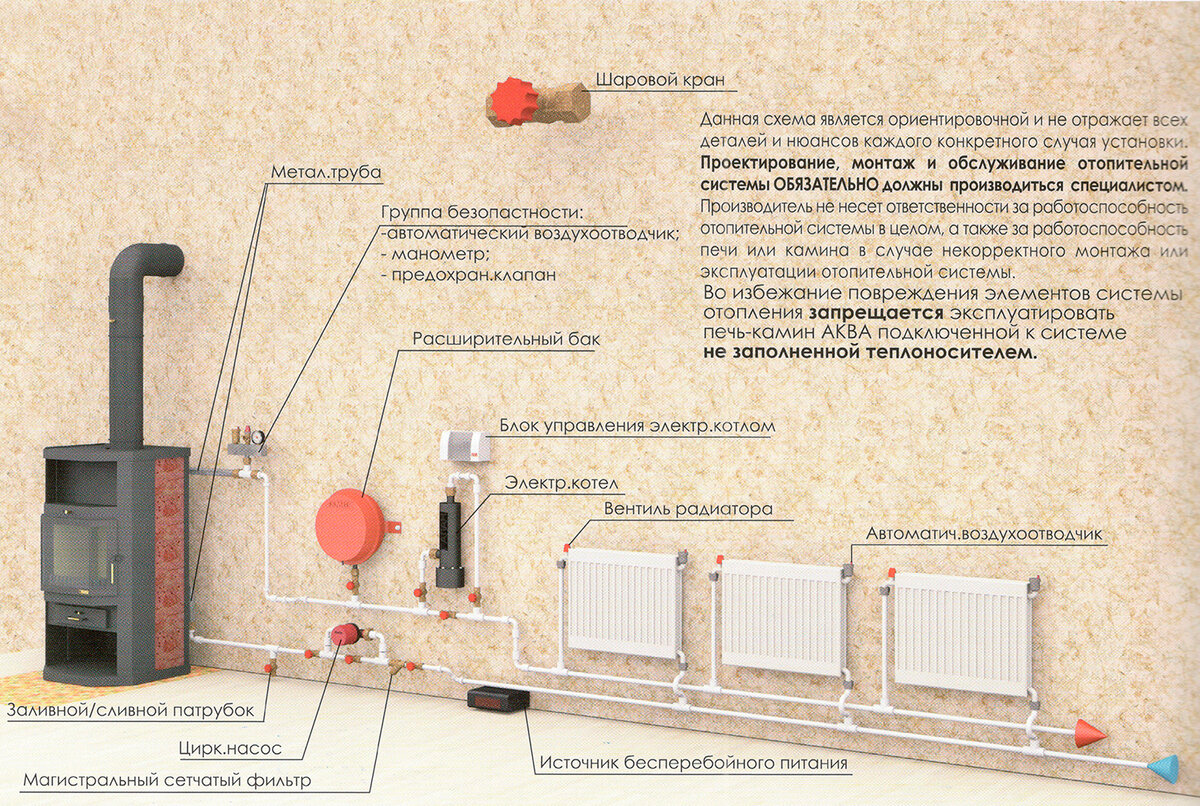

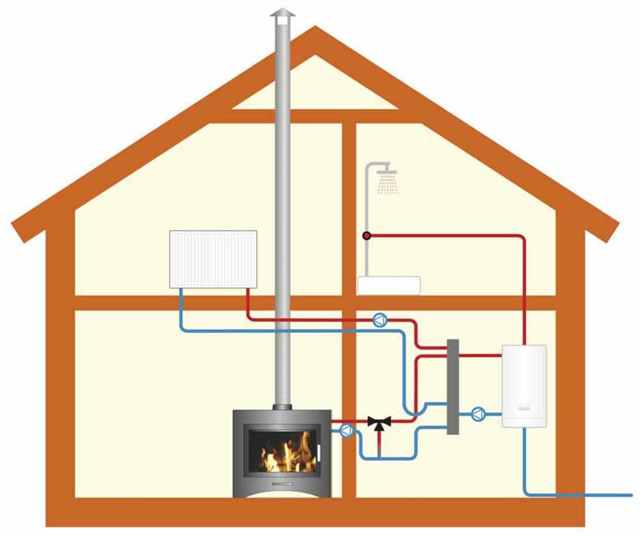

Second scheme: closed two-pipe version

In this case, you can use the most budgetary version of the generator - a stove - for steam heating a house, the energy emitted by burning wood, peat or coal is quite enough, and the location of the evaporator tank with open wiring can be anything.

Installation of the system begins in a similar way.That is, the first (vertical) section of the steam pipeline is connected to the outlet valve of the evaporator tank, which passes into the horizontal, which is laid under the very ceiling along the entire perimeter of the dwelling.

Batteries-capacitors are mounted in the right places, connecting them to the horizontal section of the steam pipeline with vertical outlets.

A horizontal condensate pipeline is mounted at the floor level, into which the condensed steam collected from the batteries is discharged through small vertical outlets connected to the lower branch pipes.

The condensate line is connected to an open or closed storage tank. Moreover, a closed tank allows you to increase the pressure in the system up to 5-7 atmospheres, which, of course, affects the effectiveness of the heat exchange process between the evaporator and condensers.

From the storage tank to the evaporator is a regular plumbing with very hot water. And it is customary to mount the circulation pump in this area.

As a result, in terms of complexity, this scheme does not exceed single-pipe wiring. True, the two-pipe version with its expansion tanks, circulation pumps and two branches of the wiring (steam line and condensate line) requires a lot of effort at the assembly stage. But all the effort expended is compensated by the increased efficiency of the heating system. At the same time, the wiring assembly technology and the main type of pipe moldings are similar to a single-pipe system.

Life time

The durability of steam heating operation depends on compliance with safety requirements

The service life of steam type heating depends on compliance with safety requirements. Usually, with the correct setup and sealing of the system, the design lasts for more than a dozen years.However, with pressure surges inside the pipes, malfunctions in the operation of the boiler and its components are possible.

When using steel pipes for a heater, it is worth remembering that they will not last long. Hot and humid steam will circulate in the carrier. These are the optimal conditions for the development of corrosion and the appearance of rust. Often this problem occurs precisely at the seams.

Some Helpful Tips

When installing a steam heating system, it should be remembered that all its elements must withstand high temperatures, more than 100 degrees. For example, a conventional membrane expander will not work as a storage tank, because its maximum is 85 degrees.

The chimney of the stove, in which the heat exchanger is built, will become dirty faster than that of a conventional stove. Therefore, cleaning the chimney must be planned and performed more often.

An oven with a heat exchanger, if desired, can also be used for cooking, but this is not very convenient. In the summer, when heating is not needed, this stove cannot be lit. Will have to look for an alternative. It is easier if a separate comfortable stove is arranged for the kitchen in the house.

Conclusion

It is possible to say unequivocally which is better - a furnace or a boiler (solid fuel, gas or electric) only in relation to specific operating conditions. Here we can only summarize the general points. It is preferable to install furnaces in buildings of a small area with irregular residence. They quickly warm up the room and do not require supervision after stopping. They can also be used as an additional or backup source of heating.

Boilers are more often used in large houses with permanent residence. The water heating system effectively heats two-story buildings, gives good heat distribution along the height.And with a properly configured circulation, the temperature in the room does not depend on its distance from the boiler room.

We recorded a video in which we clearly examined a number of important points in our opinion in choosing between a stove and a heating boiler. And if you have any questions, you can ask them to us on the official website of the Fornax company or by phone.