- Types of heating system

- Furniture items

- Steam heating boiler in a private house

- What is steam heating?

- Advantages and disadvantages of steam heating

- Characteristics and scheme of arrangement of steam heating

- Design of a steam heating system

- Gravity system calculation

- The principle of operation of closed CO

- Underfloor heating system

Types of heating system

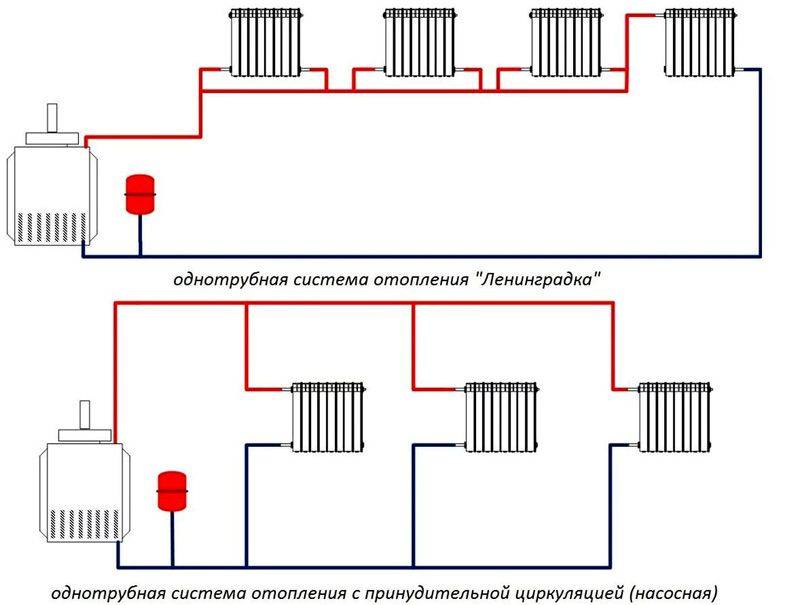

In practice, you can find a fairly large number of variations of steam heating. By the number of pipes, one and two-pipe types of steam systems are distinguished. In the first case, the steam moves through the pipe continuously.

In the first part of its journey, it gives off heat to the batteries and gradually turns into a liquid state. Then it moves like condensate. To avoid obstacles in the path of the coolant, the diameter of the pipe must be large enough.

It happens that the steam does not partially condense and breaks into the condensate line. In order to prevent its penetration into the branch intended for condensate drainage, it is recommended to install condensate traps after each radiator or group of heating devices.

A significant disadvantage of a single-pipe system is the difference in heating of radiators. Those located closer to the boiler heat up more. The ones that are further away are smaller. But this difference will be noticeable only in large buildings.In two-pipe systems, steam moves through one pipe, condensate leaves through the other. Thus, it is possible to make the temperature in all radiators equal.

But this significantly increases the consumption of pipes. Like water, steam heating can be one or two-circuit. In the first case, the system is used only for space heating, in the second - also for heating water for domestic needs. The distribution of heating is also different.

There are three options available:

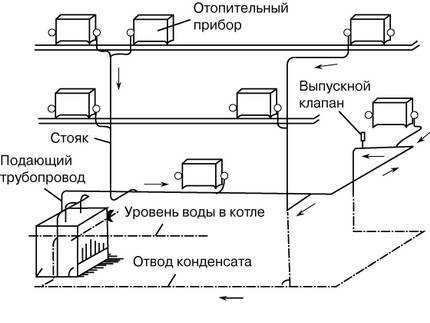

- With top wiring. The main steam pipeline is laid above the heating devices, pipes are lowered from it to the radiators. Even lower, near the floor, a condensate pipeline is laid. The system is the most stable and easy to implement.

- With bottom wiring. The line is located below the steam heating devices. As a result, steam moves in one direction and condensate moves in the opposite direction through the same pipe, which should be slightly larger than usual in diameter. This provokes water hammer and depressurization of the structure.

- With mixed wiring. The steam pipe is mounted slightly above the level of the radiators. Everything else is the same as in the system with the top wiring, thanks to which it is possible to retain all its advantages. The main disadvantage is a high injury risk due to easy access to hot pipes.

When arranging a scheme with natural coercion, it must be remembered that the steam pipeline is mounted with a slight slope in the direction of steam movement, and the condensate pipeline - condensate.

The slope should be 0.01 - 0.005, i.e. for each running meter of a horizontal branch, there should be 1.0 - 0.5 cm of slope. The inclined position of the steam and condensate pipelines will eliminate the noise of steam passing through the pipes and ensure the free flow of condensate.

Steam heating systems are built according to a single-pipe and two-pipe scheme. Among single-pipe options with horizontal connection to heating devices prevail. In the case of constructing a circuit with a vertical connection of devices, it is better to choose a two-pipe version

Steam heating systems are built according to a single-pipe and two-pipe scheme. Among single-pipe options with horizontal connection to heating devices prevail. In the case of constructing a circuit with a vertical connection of devices, it is better to choose a two-pipe version

According to the level of internal pressure of the system, two main varieties are distinguished:

- Vacuum. It is assumed that the system is completely sealed, inside which a special pump is installed that creates a vacuum. As a result, the steam condenses at lower temperatures, making such a system relatively safe.

- Atmospheric. The pressure inside the circuit exceeds the atmospheric pressure by several times. In the event of an accident, this is extremely dangerous. In addition, radiators operating in such a system are heated to very high temperatures.

There are many options for arranging steam heating, so everyone can choose the best option for their home, taking into account all the features of the building.

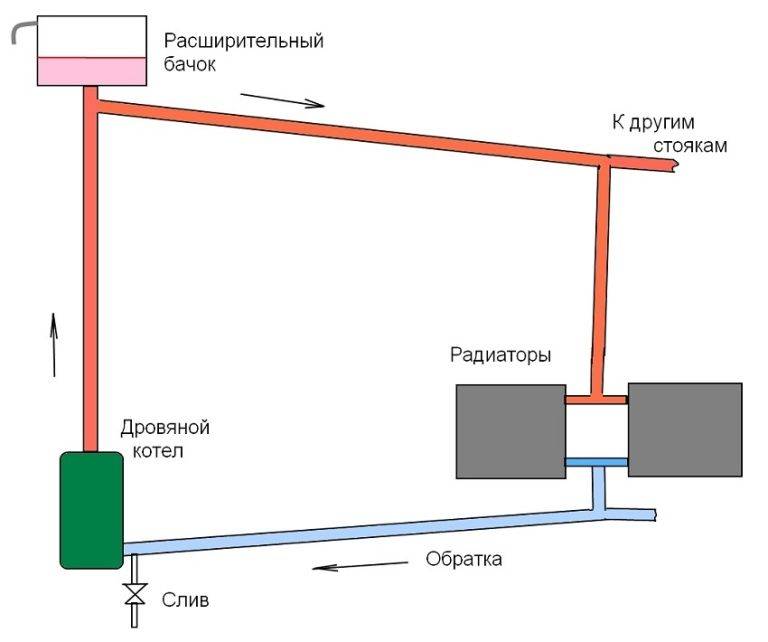

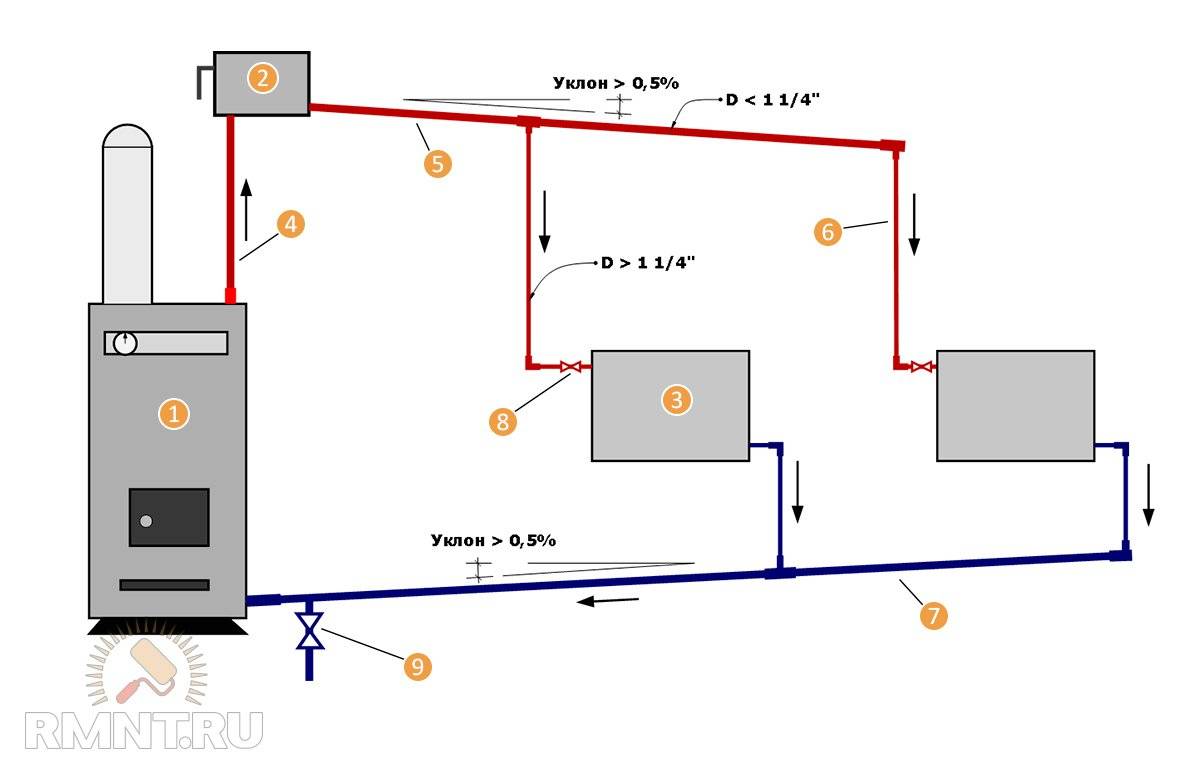

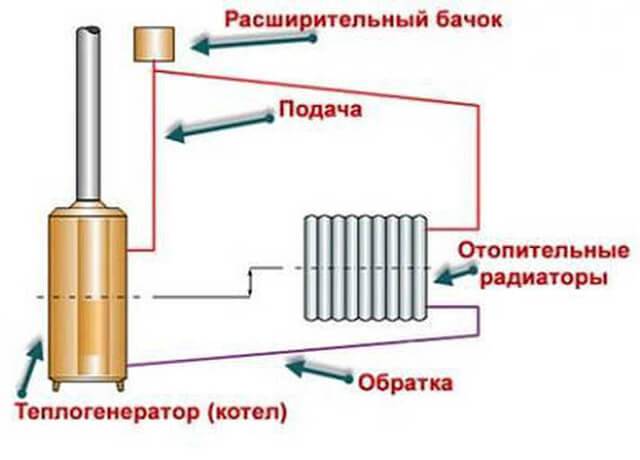

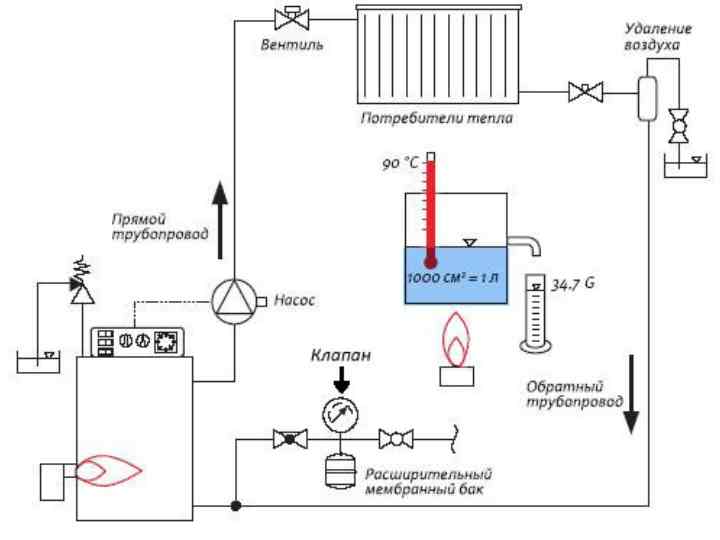

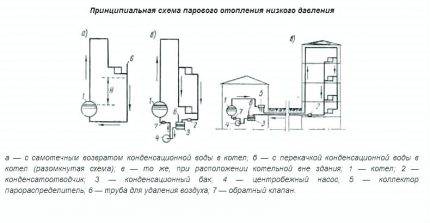

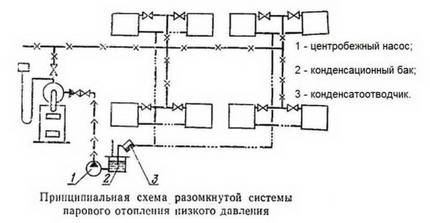

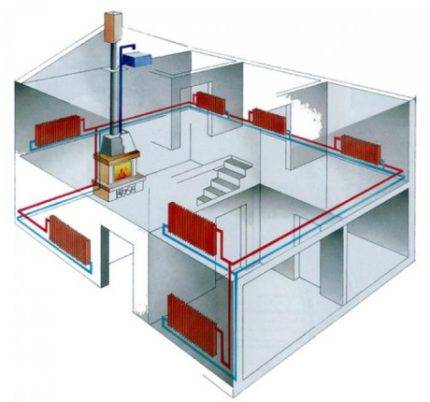

The figure shows a diagram of an open-loop steam heating system

The figure shows a diagram of an open-loop steam heating system

Furniture items

A few examples of furnishing a kitchen combined with a living room:

- 1. Sofa. It becomes an object that zones the space. The sofa is placed with its back to the place where food is prepared. In small rooms (less than 20 sq m) they put a corner, which is located against a wall installed perpendicular or parallel to the kitchen.

- 2. Headset. According to the designers, minimalist models without elaborate details look modern. The service, vases or glasses are placed on an open shelf. You can buy a fashion showcase for them. Furniture is placed near the wall. If the space is large (20 sq m, 25 sq m or 30 sq m), then in the central part you can install an island, which also has departments for kitchen appliances.

- 3.Furniture set. Style should be combined with the design of both rooms. In small rooms, a compact table and chairs made of transparent material or painted in light colors look good. In the interior of the living room, you can put a table with a round top. In spacious rooms, the kit is installed near the wall or in the central part. An elongated rectangular dining table will look good here.

Steam heating boiler in a private house

A steam boiler is an alternative type of heating for private houses and cottages. Water heating of buildings is incorrectly called “steam” - such a confusion in the names is associated with the principle of heating apartment buildings, where an external coolant under pressure flows from a CHP to individual houses and transfers its heat to an internal carrier (water), which circulates in a closed system.

Steam heating in a private house is used much less frequently than other methods of space heating. It is economically justified to use the boiler in a country house or a country house, when year-round living is not provided, and the main role in heating is played by the speed of heating the premises and the ease of preparing the system for conservation.

The possibility of installing such equipment in addition to the existing one, for example, a furnace, is another advantage of using steam as a heat carrier.

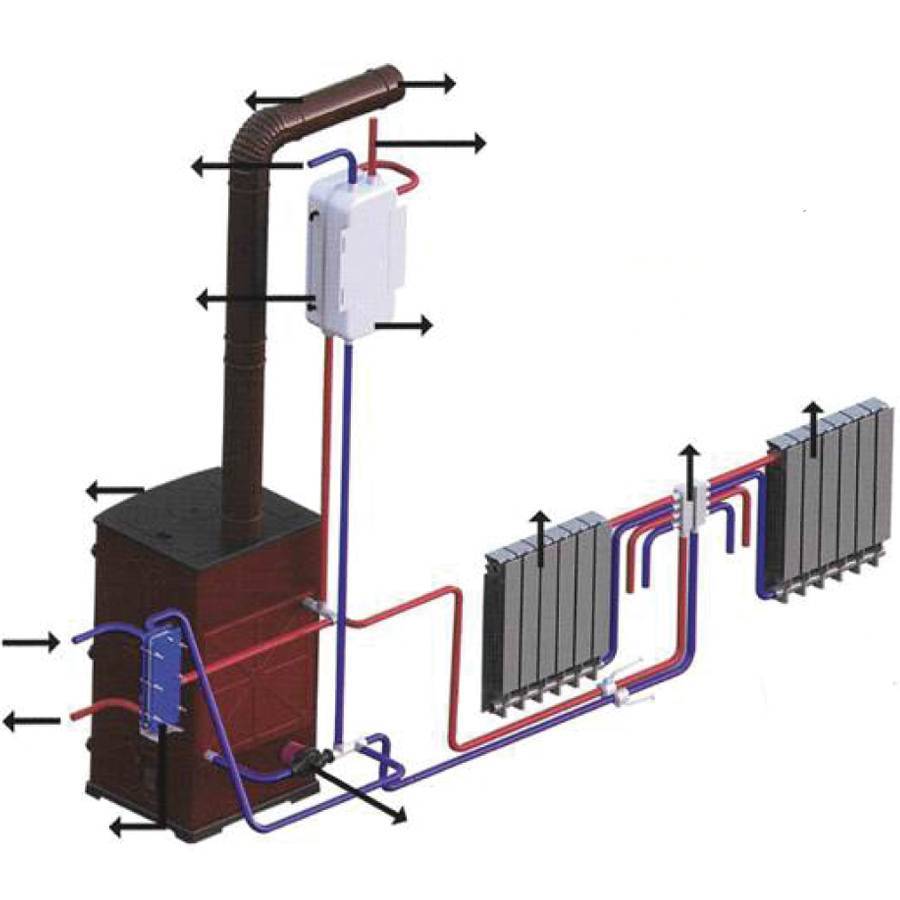

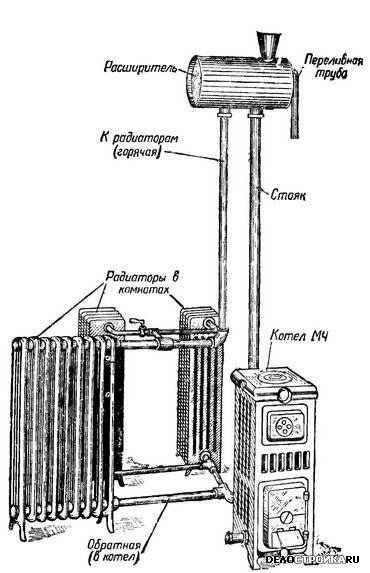

As a result of water boiling in the boiler unit (steam generator), steam is formed, which is supplied to the system of pipelines and radiators. In the process of condensation, it gives off heat, providing rapid heating of the air in the room, and then returns in a liquid state in a vicious circle to the boiler.In a private house, this type of heating can be implemented in the form of a single- or double-circuit scheme (heating and hot water for domestic needs).

According to the wiring method, the system can be single-pipe (serial connection of all radiators, the pipeline runs horizontally and vertically) or two-pipe (parallel connection of radiators). Condensate can be returned to the steam generator by gravity (closed circuit) or forcibly by means of a circulation pump (open circuit).

The scheme of steam heating of the house includes:

- boiler;

- boiler (for a two-circuit system);

- radiators;

- pump;

- expansion tank;

- shut-off and safety fittings.

Description of steam heating boiler

The key element of space heating is the steam generator, the design of which includes:

- furnace (fuel combustion chamber);

- evaporator pipes;

- economizer (heat exchanger for heating water due to exhaust gases);

- drum (separator for separating the steam-water mixture).

Boilers can operate on various types of fuel, but it is better for private houses to use a household steam boiler with the ability to switch from one type to another (combined).

The efficiency and safety of such space heating depends on a competent approach to choosing a steam generator. The power of the boiler unit must be commensurate with its tasks. For example, to create an optimal microclimate in a house with an area of 60-200m 2, you need to buy a boiler with a capacity of 25 kW or more. For domestic purposes, it is effective to use water-tube units, which are more modern and reliable.

Self-installation of equipment

Work is carried out in stages, in a certain order:

one.Drawing up a project taking into account all the details and technical solutions (length and number of pipes, type of steam generator and its installation location, location of radiators, expansion tank and shutoff valves). This document must be agreed with the state control authorities.

2. Installation of the boiler (made below the level of the radiators to ensure steam advances upwards).

3. Piping and installation of radiators. When laying, a slope of about 5 mm should be set for each meter. Installation of radiators is carried out using a threaded connection or welding. In reviews of a steam heating system, experienced users recommend installing taps to eliminate problems when air locks occur and facilitate subsequent operation.

4. Installation of the expansion tank is carried out 3 meters above the level of the steam generator.

5. The piping of the boiler unit must be carried out only with metal pipes of the same diameter with outlets from the boiler (adapters must not be used). The heating circuit is closed in the unit, it is desirable to install a filter and a circulation pump. A drain unit must be installed at the lowest point of the system so that the pipeline can be easily emptied for repair work or conservation of the structure. Necessary sensors that control the process and ensure safety are necessarily mounted on the boiler unit.

6. Testing a steam heating system is best done in the presence of specialists who can not only perform all procedures in accordance with applicable norms and standards, but also eliminate any shortcomings and inaccuracies in the installation scheme with their own hands.

What is steam heating?

Steam networks are called networks in which not water circulates, but steam.The system works like this - from heating in the boiler, water boils, goes into a vapor state, and in this form is transported through pipelines to radiators. In the process of moving, the substance cools down, condensate settles on the internal tunnels of pipes, radiators, giving off all the heat - thanks to this property, steam heating in a private house is considered one of the most heat-efficient. After settling, the condensate flows down from the walls, then goes to the boiler, where the heating cycle is repeated.

Advantages and disadvantages of steam heating

The advantages of the method include:

- Increased performance. Due to the huge heat transfer, it will not be necessary to form many batteries; in the case of external arrangement of pipelines, the owner has enough heat coming from these elements.

- Minimum inertia. Room heating is carried out within 10 minutes after the start of the network.

- Profitability. Steam does not give off heat to other elements, heating only pipes and radiators, so the user gets the opportunity to save on fuel and network maintenance.

- Ease of installation. To form a highway, you do not need much experience, work is within the power of a home master.

There are also disadvantages:

- high thermal efficiency increases the risk of burns in contact with batteries, pipelines;

- there is no way to adjust the smooth supply of heat;

- restriction on the choice of material - it is unacceptable to use plastic pipes, only metal ones will do;

- difficulties when connecting the taps to a working network - the elements warm up to +100 C, therefore, to repair or renew parts, you need to turn off the main line and wait for it to cool.

All requirements for the formation of the network, including the selection of materials, are observed exactly.Violations increase the risk of a pipe break, hot steam (+100 C) will escape into the room, severely burn.

Experts recommend equipping steam pipelines with an automatic control system to connect the network to work when the air cools. To regulate each circuit, it is more practical to install automation on a separate branch - it is more convenient to start heating through networks.

Characteristics and scheme of arrangement of steam heating

The principle of operation of the network is to transfer thermal energy from water heated to a vapor state to devices. High thermal efficiency is achieved by the physical property of the liquid - steam is converted into water only with a significant loss of heat, which is spent on heating the house.

Characteristics depend on the type of network:

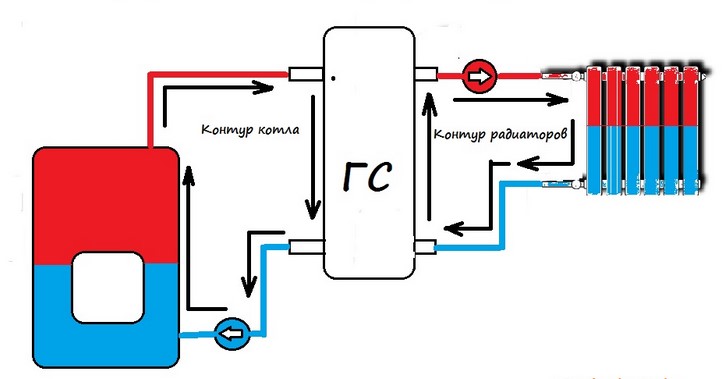

- A closed system is a scheme in which the settled condensate returns to the boiler by gravity under the influence of the difference in temperature and pressure in the network devices. When choosing a boiler for a closed circuit, it is necessary to take into account the parameters of heating (temperature) and pressure.

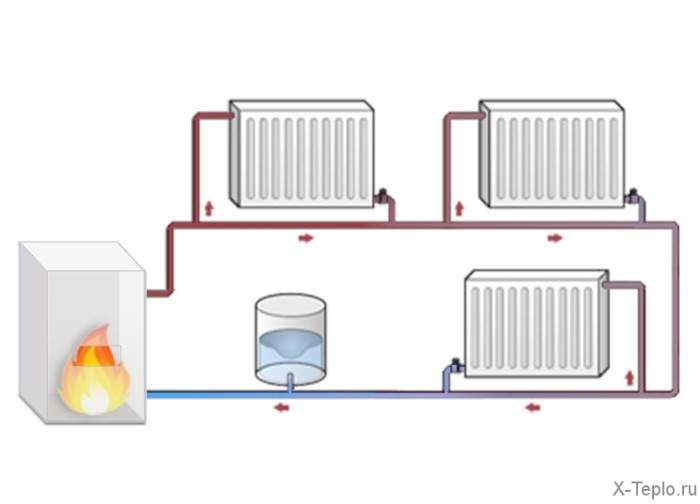

- Open system. The scheme provides for a tie-in storage tank, where condensate enters, and then moves to a thermal station. For transportation, a pump or pump is used. An important point is to install the tank at the lowest point of the circuit so that the condensate drains without residue.

Networks also differ in terms of steam pressure. So, an open circuit can be of 4 types: subatmospheric, vacuum-steam, with reduced or increased pressure. Steam heating threshold +130 C, in systems with vacuum-steam, subatmospheric pressure no more than +100 C.

The advantages of steam heating include a minimum set of equipment. A steam pipeline will be required, a condensate pipeline is two pipes through which the coolant is supplied and recirculated. A condensate drain tank is installed in open circuits. According to the type of system, pipelines for condensate are selected, they can be gravity and pressure. The former are designed for arbitrary drainage of liquid, the latter for pumping through a pump or pump.

Design of a steam heating system

Even for a small room, it is best to draw up a project. A system made on the “maybe” with a high degree of probability will soon require rework, and a diagram drawn up on paper will immediately identify weaknesses and correct them.

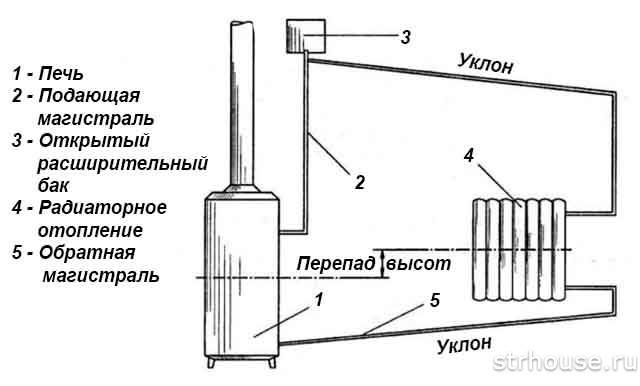

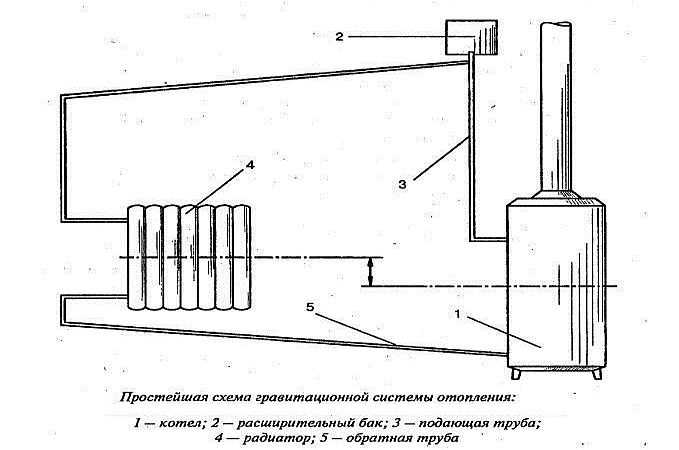

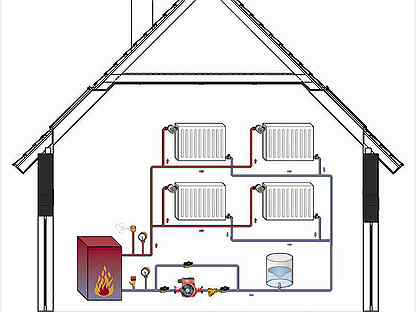

For example, in order to create a system with natural circulation of the coolant, the heat exchanger, and, accordingly, the heating device, should be located at the lowest point of the house.

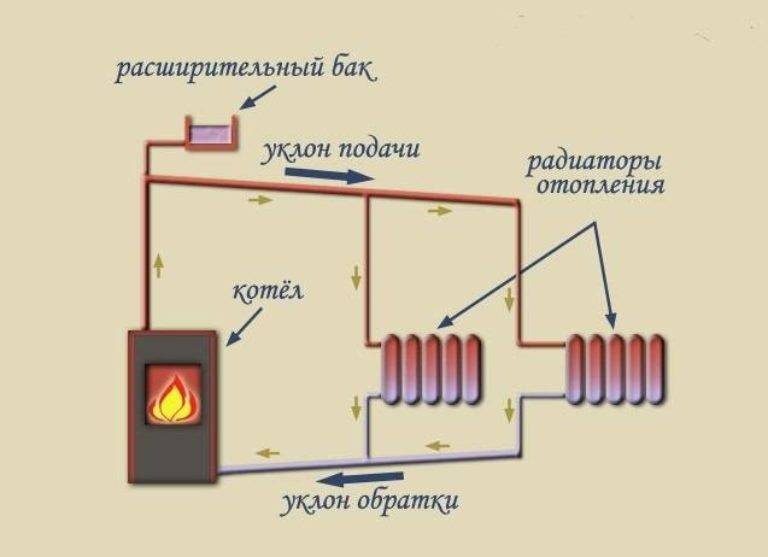

The steam pipeline and condensate pipeline of heating systems with a natural type of movement of the coolant are arranged with a slope in the direction of its movement (+)

This means that the stove or boiler must be below all radiators, as well as pipes that are not vertical, but horizontal or at an angle to the vertical.

If it is not possible to place the heater in this way (there is no basement in the house, the basement is used for other purposes, etc.), forced circulation heating should be preferred.

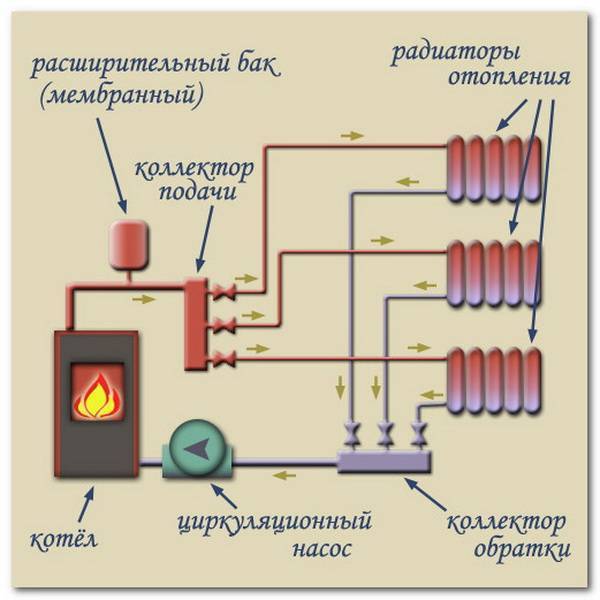

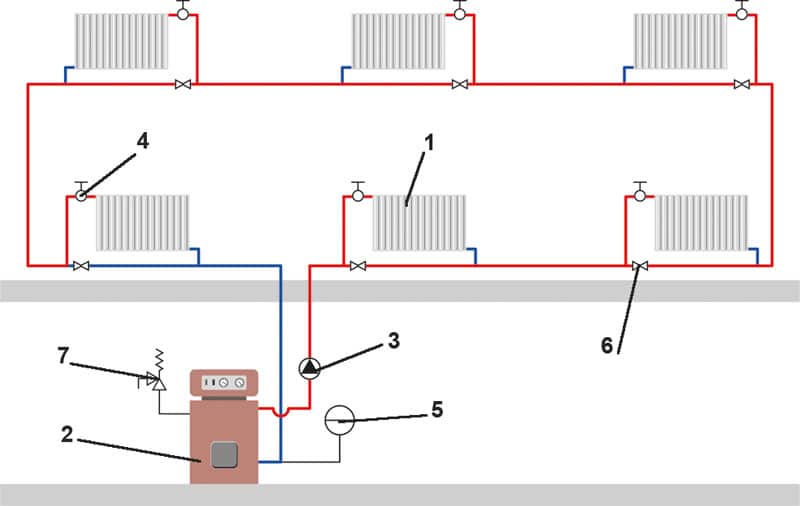

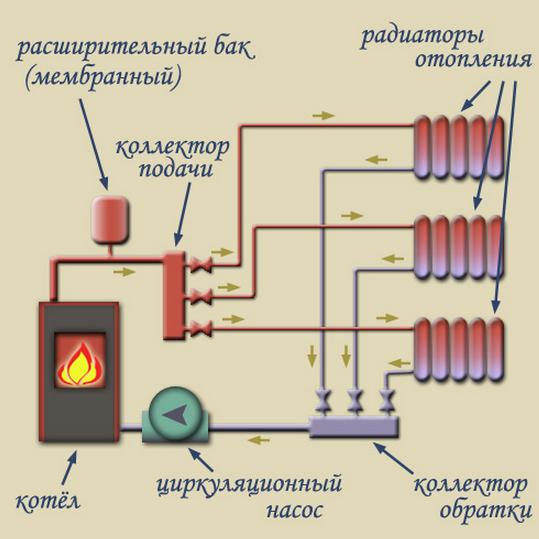

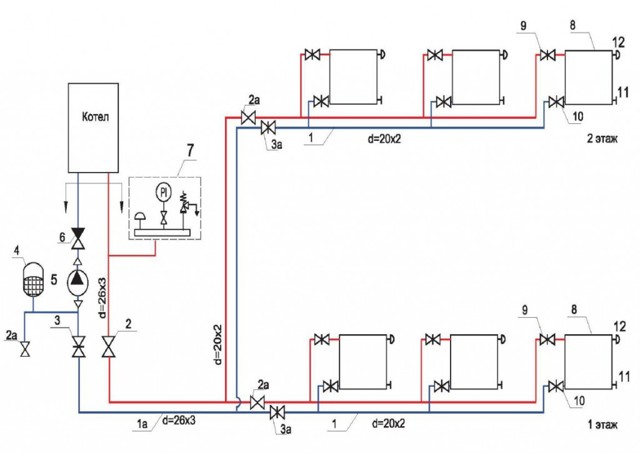

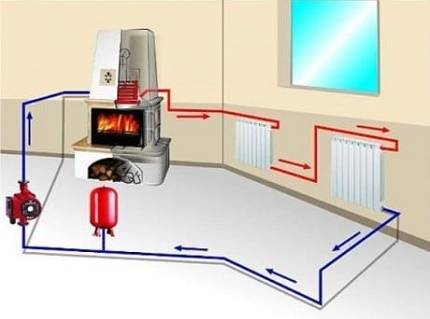

The diagram shows a heating system with forced circulation. For its installation you will need a circulation pump and a storage tank

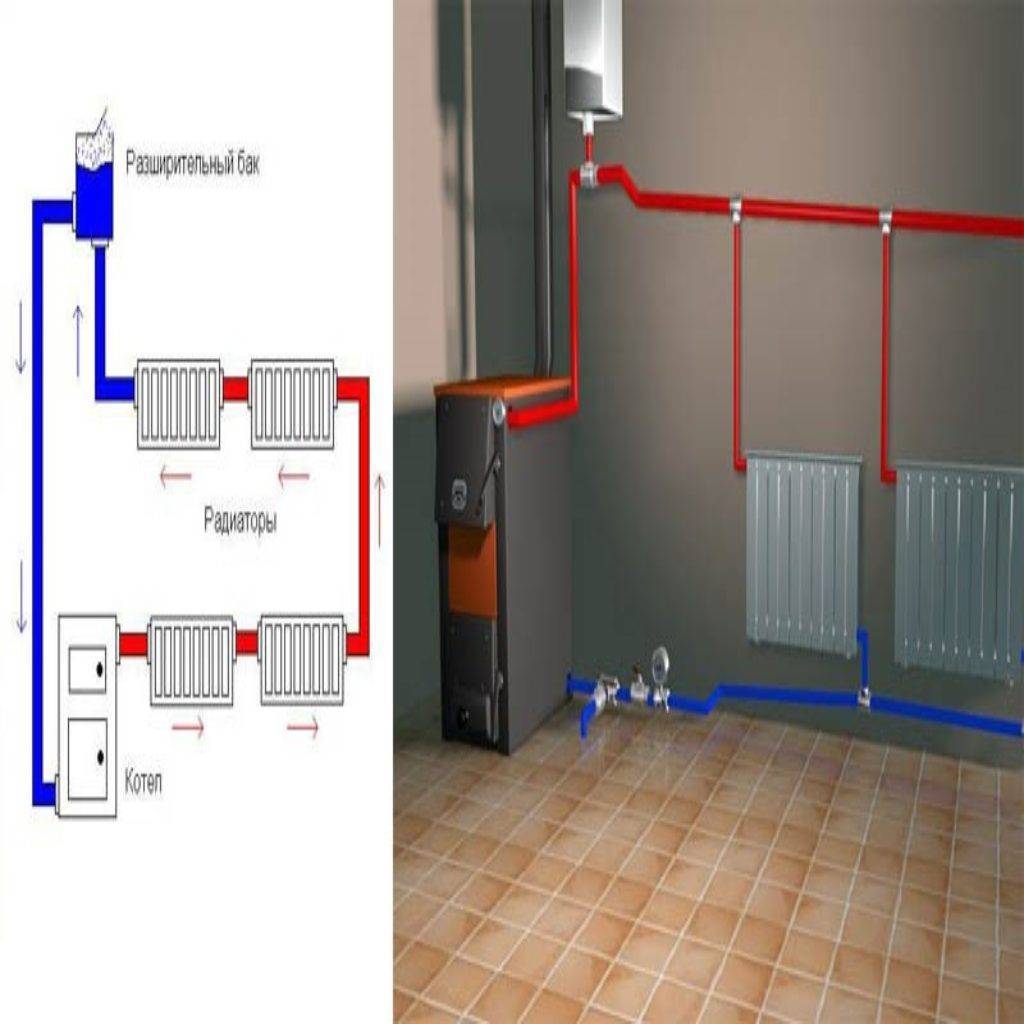

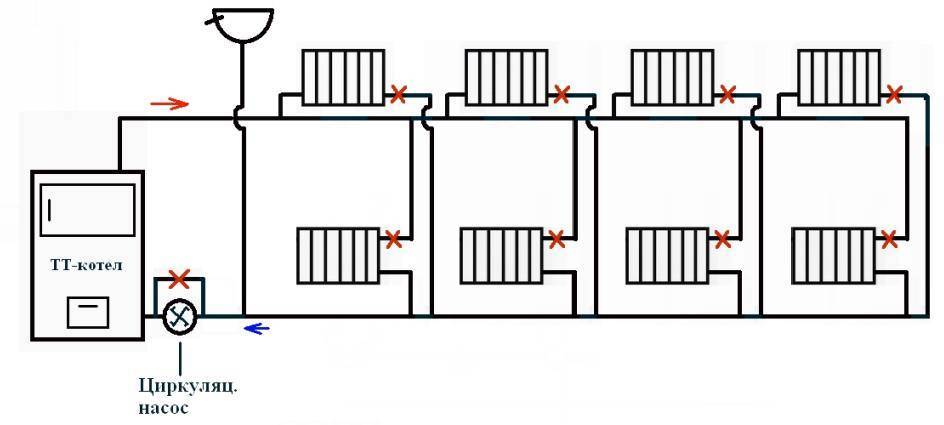

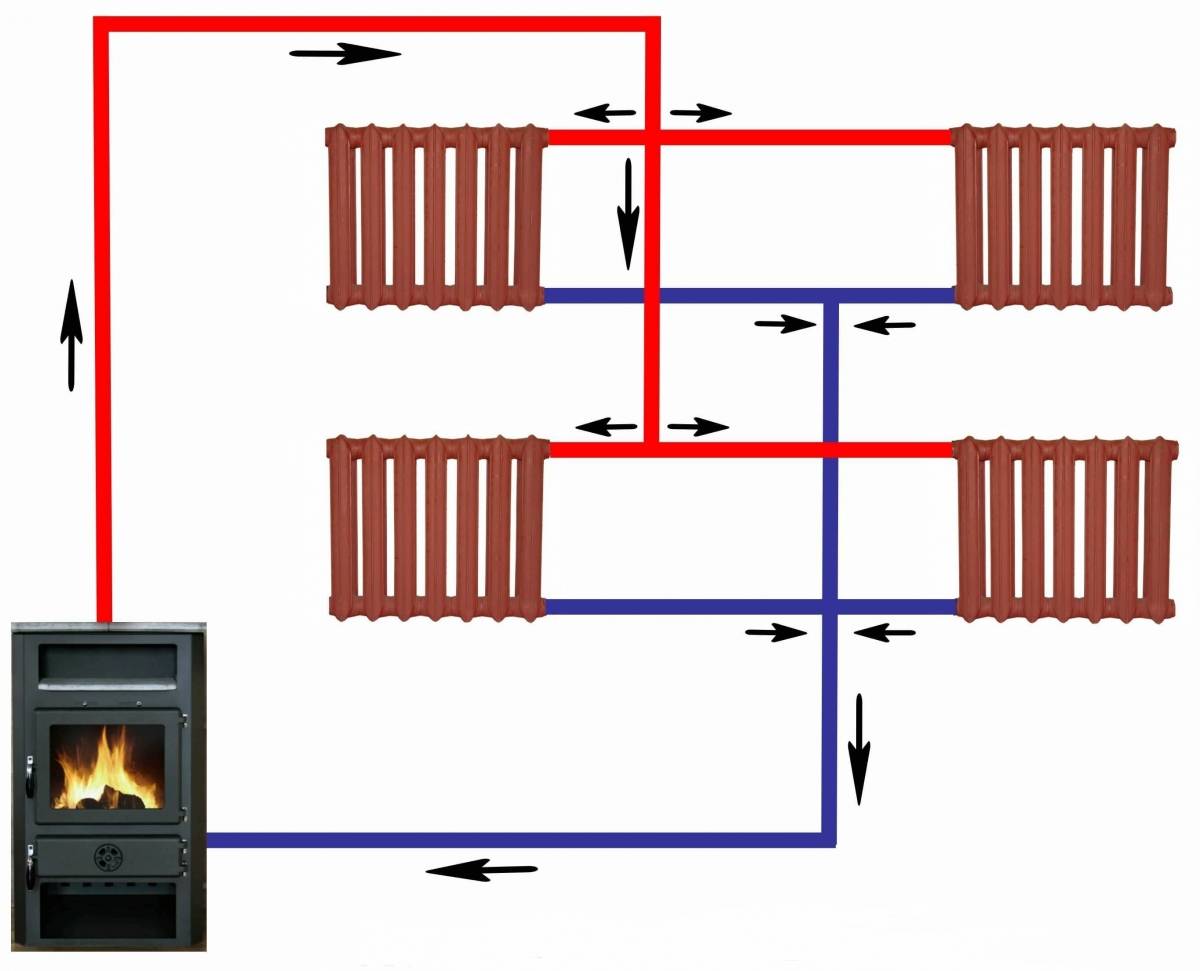

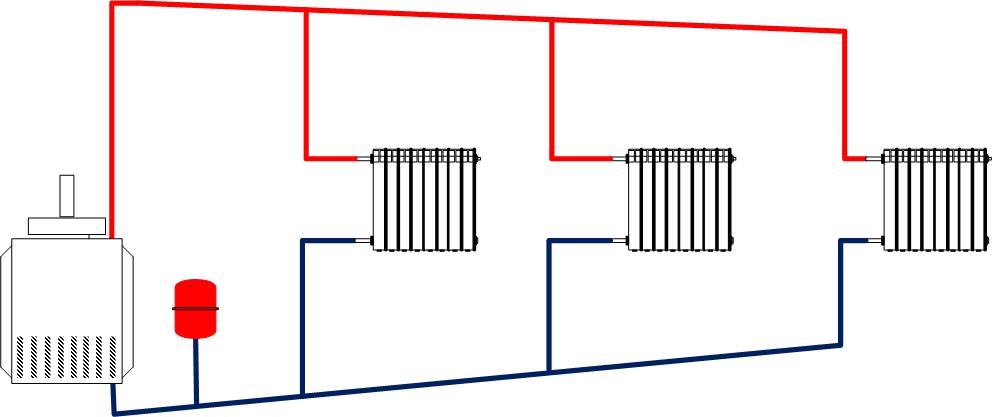

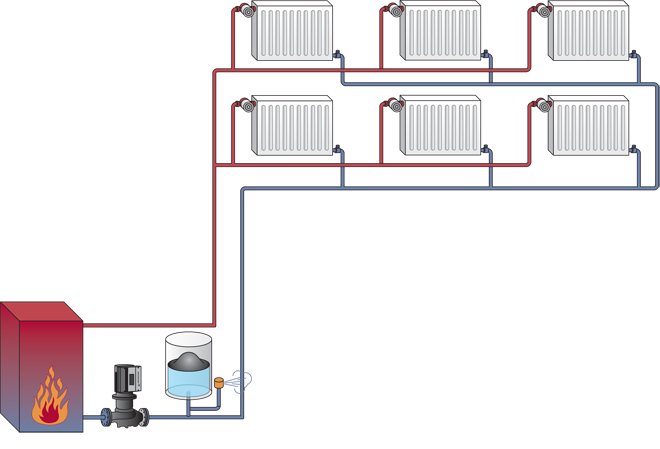

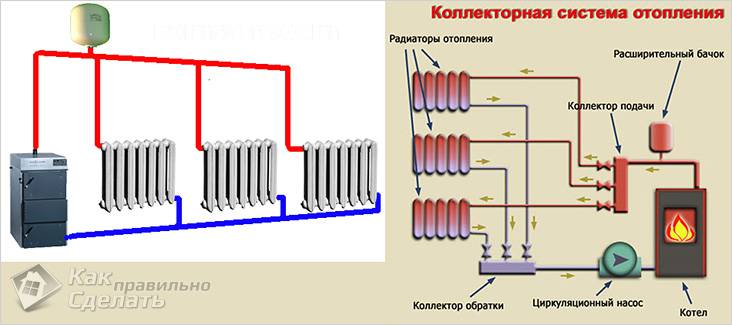

Therefore, it is necessary to include a pump in the steam heating circuit, which will pump water into the heat exchanger.An important point in the design of the heating system is the order in which radiators are connected. Serial connection or the so-called one-pipe system involves the connection of all radiators in order.

As a result, the coolant will sequentially move through the system, gradually cooling down. This is an economical connection option, which is easier to install and cheaper.

But the uniformity of heating with this method will suffer, since the first radiator will be the hottest, and the last coolant will enter in an already half-cooled state.

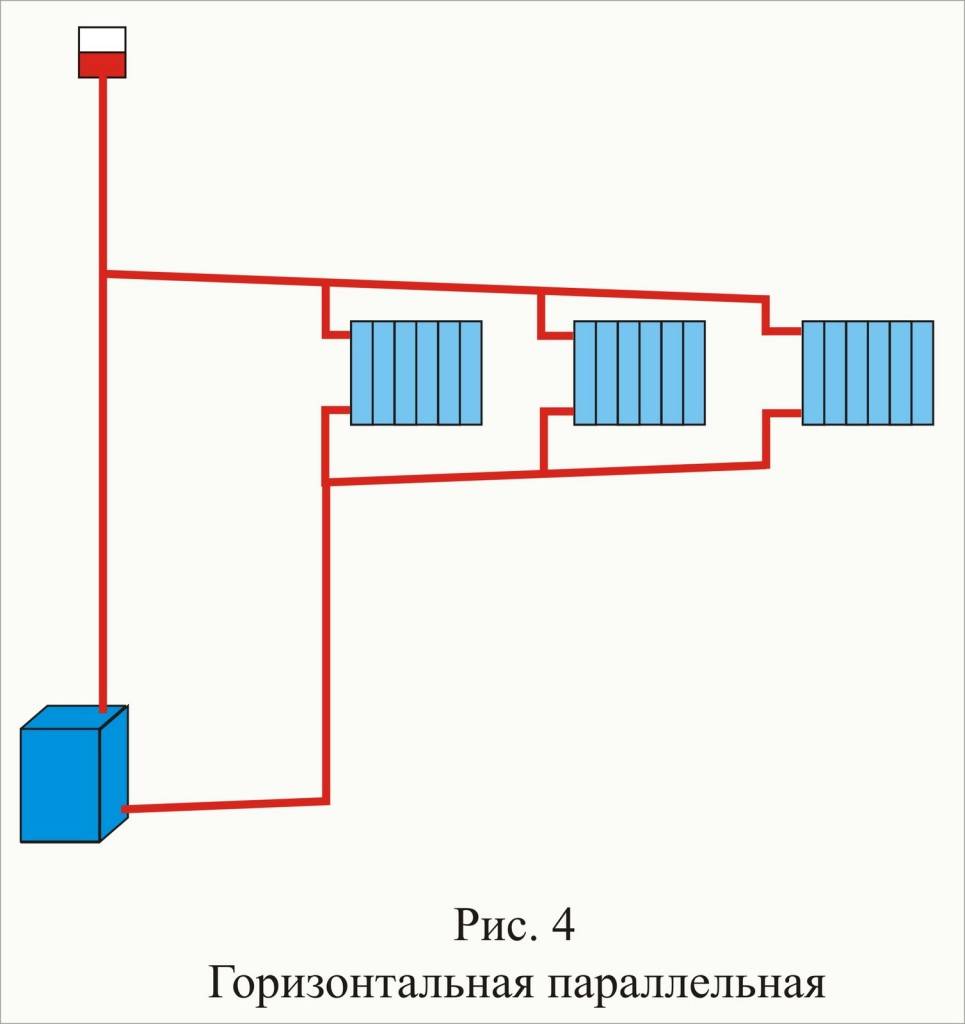

One-pipe connection of radiators, as can be seen from this diagram, involves a series installation. The coolant enters the last radiator already cooled down

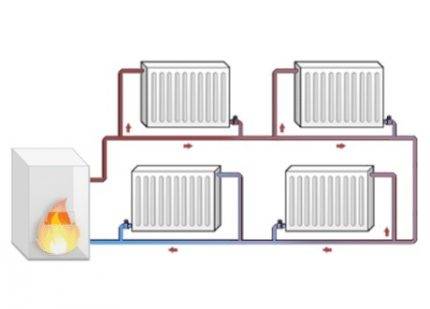

A one-pipe solution can only be acceptable when connecting steam heating in a country house or in a small house, on an area of \u200b\u200bless than 80 square meters. m. And for a spacious cottage or a two-story building, a two-pipe system is more suitable, in which radiators are connected in parallel.

The scheme with one pipe provides a simultaneous, rather than sequential flow of coolant into each radiator, and the heating of the premises is carried out more evenly. But with a two-pipe circuit, two pipes will have to be connected to each radiator: a straight line and a “return”.

Such a system is more difficult to implement, and it will cost a little more than when installing a single-pipe system. However, the vast majority of water heating systems are made according to a two-pipe scheme, despite the difficulties, and they function quite successfully.

This diagram shows a two-pipe system for mounting steam heating radiators.Each radiator is connected to a common riser and has a return pipe, which ensures uniform distribution of the coolant

If a wood-burning stove is supposed to be used as a heat source, then a special heat exchanger should be immediately calculated and designed. It looks like a coil welded from metal pipes. This element is built directly into the design of the furnace, and is not installed separately.

Therefore, the design of a new furnace should also be considered at the design stage. You can also use an existing furnace, but it will have to be partially disassembled in order to mount the heat exchanger inside.

To obtain 9 kW of heat, a heat exchanger with a surface area of about one square meter is needed. The larger the area to be heated, the larger the heat exchanger should be.

If it is supposed to heat the room with the help of a boiler, then everything is a little simpler: you need to buy and install it. Usually, for steam heating in a house, it is recommended to take a water-tube boiler model, as the most efficient one.

Although fire tube, smoke tube or combined fire tube and fire tube models can also be quite an acceptable option.

Sometimes a home-made boiler is used to organize steam heating, in which used engine oil is burned. But this option is considered suitable for use in utility rooms, for example, in a garage. For a residential building, this option is not very good.

Gravity system calculation

To calculate and design heating with natural circulation, proceed in this order:

- Find out the amount of heat needed to heat each room. Use our instructions for this.

- Choose a non-volatile boiler - gas or solid fuel.

- Develop a scheme based on one of the options suggested here. Divide the wiring into 2 shoulders - then the highways will not cross the front door of the house.

- Determine the coolant flow rate for each room and calculate the pipe diameters.

We note right away that it will not be possible to split the "Leningradka" into 2 branches. This means that the annular pipeline will necessarily pass under the threshold of the front door. To withstand all the slopes, the boiler will have to be placed in a pit.

The calculation of the diameter of the pipes in all sections of the gravity two-pipe system is done as follows:

- We take the heat loss of the entire building (Q, W) and determine the mass flow rate of the coolant (G, kg / h) in the main line using the formula below. The temperature difference between supply and "return" Δt is taken equal to 25 °C. Then we convert kg / h to other units - tons per hour.

- Using the following formula, we find the cross-sectional area (F, m²) of the main riser by substituting the value of the natural circulation velocity ʋ = 0.1 m/s. We recalculate the area of the circle in diameter, we get the size of the main pipe suitable for the boiler.

- We consider the heat load on each branch, repeat the calculations and find out the diameters of these highways.

- We pass to the next rooms, again we determine the diameters of the sections according to the heat costs.

- We select standard pipe sizes, rounding the resulting numbers up.

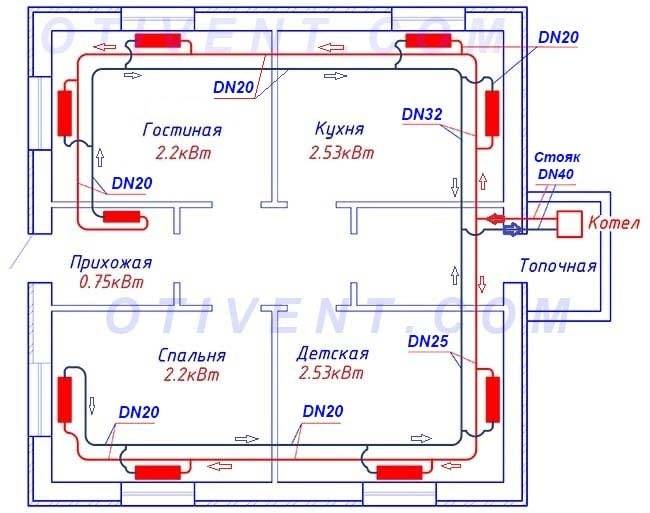

Let's give an example of calculating a gravity system in a one-story house of 100 sq.m. On the layout below, heating radiators are already applied and heat losses are indicated. We start from the main collector of the boiler and move towards the last rooms:

- The value of heat loss at home Q = 10.2 kW = 10200 W.Coolant consumption in the main riser G = 0.86 x 10200 W / 25 °C = 350.88 kg/h or 0.351 t/h.

- Cross-sectional area of the supply pipe F = 0.351 t/h / 3600 x 0.1 m/s = 0.00098 m², diameter d = 35 mm.

- The load on the right and left branches is 5480 and 4730 W, respectively. Heat carrier quantity: G1 = 0.86 x 5480/25 = 188.5 kg/h or 0.189 t/h, G2 = 0.86 x 4730/25 = 162.7 kg/h or 0.163 t/h.

- The cross section of the right branch F1 = 0.189 / 3600 x 0.1 = 0.00053 m², the diameter will be 26 mm. Left branch: F2 = 0.163 / 3600 x 0.1 = 0.00045 m², d2 = 24 mm.

- Lines DN32 and DN25 mm will come to the nursery and kitchen (rounded up). Now we consider the dimensions of the collectors for the bedroom and living room + corridor with heat losses of 2.2 and 2.95 kW, respectively. We get both diameters DN20 mm.

To connect small batteries, you can use DN15 piping (outer d = 20 mm), the plan shows the dimensions DN20

It remains to pick up the pipes. If you cook heating from steel, Ø48 x 3.5 will go to the boiler riser, branches - Ø42 x 3 and 32 x 2.8 mm. The remaining wiring, including battery connections, is done with a 26 x 2.5 mm pipeline. The first digit of the size indicates the outer diameter, the second - the wall thickness (range of water and gas steel pipes).

The principle of operation of closed CO

A closed (otherwise - closed) heating system is a network of pipelines and heating devices in which the coolant is completely isolated from the atmosphere and moves forcibly - from the circulation pump. Any SSO must include the following elements:

- heating unit - gas, solid fuel or electric boiler;

- safety group consisting of a pressure gauge, safety and air valve;

- heating devices - radiators or contours of underfloor heating;

- connecting pipelines;

- a pump that pumps water or non-freezing liquid through pipes and batteries;

- coarse mesh filter (mud collector);

- closed expansion tank equipped with a membrane (rubber "pear");

- stopcocks, balancing valves.

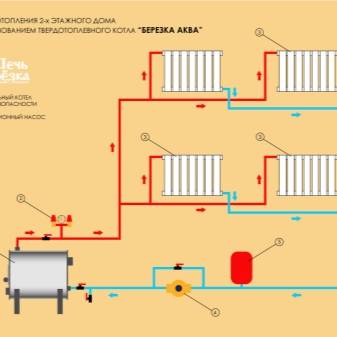

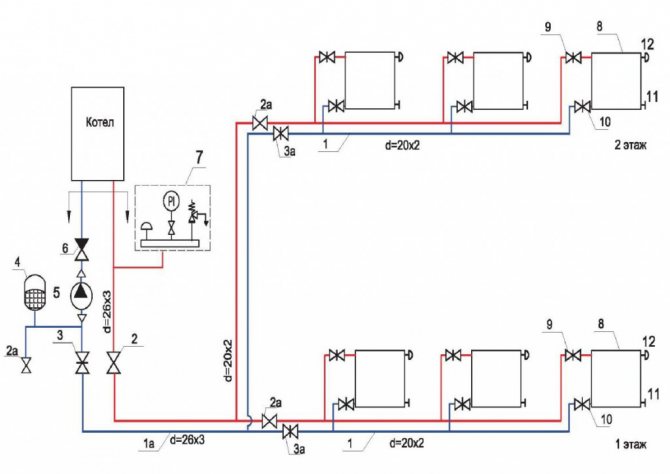

Typical diagram of a closed heating network of a two-story house

The algorithm of operation of a closed-type system with forced circulation looks like this:

- After assembly and pressure testing, the pipeline network is filled with water until the pressure gauge shows a minimum pressure of 1 bar.

- The automatic air vent of the safety group releases air from the system during filling. He is also engaged in the removal of gases that accumulate in pipes during operation.

- The next step is to turn on the pump, start the boiler and warm up the coolant.

- As a result of heating, the pressure inside the SSS increases to 1.5–2 bar.

- The increase in the volume of hot water is compensated by a membrane expansion tank.

- If the pressure rises above the critical point (usually 3 bar), the safety valve will release excess fluid.

- Once every 1-2 years, the system must undergo a procedure for emptying and flushing.

The principle of operation of the ZSO of an apartment building is absolutely identical - the movement of the coolant through pipes and radiators is provided by network pumps located in an industrial boiler room. There are also expansion tanks, the temperature is controlled by a mixing or elevator unit.

How a closed heating system works is explained in the video:

Underfloor heating system

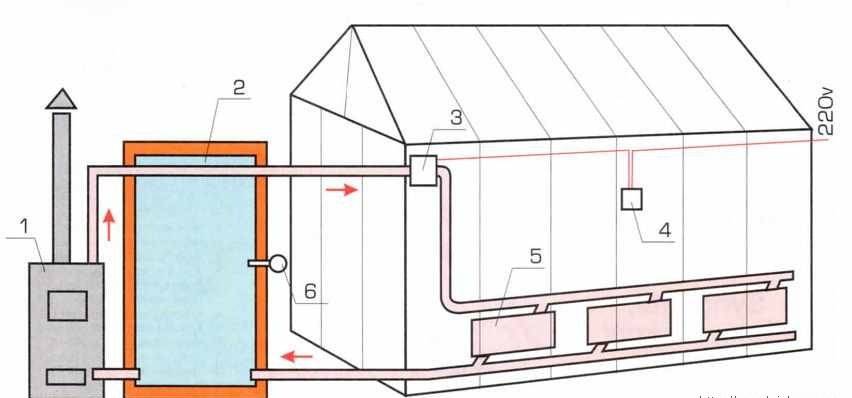

An excellent way to insulate private property would be an insulated floor system.

The main convenience is that you do not need a lot of equipment, different equipment.

Flexible, but high-strength hoses are laid out on the base, through which hot water or steam will pass. From above, the layout is poured with cement mortar, performing a floor screed. Due to the thermal conductivity of concrete, the surface warms up evenly.

Always warm floors do not allow the premises to cool down.

In a temperate climate, this measure is enough to create comfort.

Some homeowners successfully combine steam heating with an insulated base system, which is very important for residents of the cold regions of the country.

Example of combined heating

Example of combined heating

The main thing is that the installation is safe, and then it fits the requirements of the selection. Next - calculations taking into account the correction factors in order to buy the right equipment.

Calculations and drawing up a diagram are the most important stages in laying heating lines, so it is better to order them from professionals.

The principle of laying underfloor heating is clearly shown in the following video:

average rating

ratings over 0

Share link