- Self assembly

- From steel pipe

- From an old cast iron battery

- Instructions for self-assembly

- Battery based droplet heater

- Homemade steam-and-drop heating from a steel pipe

- Assembly and modernization processes

- Pros and cons of vapor-drop batteries

- Features of the tubeless system

- Comparative characteristics of heat sources

- Principle of operation

- Common models

- Used oil potbelly stove

- Gas heating

- Self-manufacturing of PKN

- Safety

- DIY steam heater

- Principle of operation

- Conclusion

Self assembly

To equip vapor-drop heating with your own hands, you need to have some knowledge and skills of similar work. A self-made heater should be as similar as possible to the one that is produced in the factory.

From steel pipe

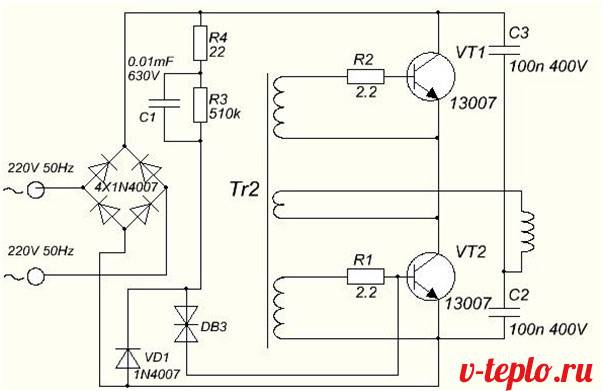

Before starting the manufacture of a vapor-drop heater, it is necessary to find a ready-made scheme and carefully study it.

In addition, it is important to ensure maximum safety, since the slightest inaccuracy can lead to electric shock.

For self-production of a vapor-drop battery, you will need the following materials and tools:

- a piece of pipe made of metal that is resistant to corrosion (aluminum, copper, and others);

- a tube of small diameter, made of a similar material, and a cover for it;

- water valve;

- a piece of stainless steel wire;

- welding machine.

The work of assembling the heater is simple, but requires the ability to work with welding and electricity. If you are not sure that you can cope with such a task, then it is better to seek help from a specialist or abandon a home-made device.

Video about the heater on electricity:

The assembly of the heater is carried out in a few simple steps:

- A pre-prepared piece of metal pipe is carefully welded on one side. In this case, the seam should be tight and as even as possible.

- A cover is attached to the opposite edge.

- A tube of small diameter is mounted to it, which will serve to fill the apparatus with coolant.

- A water valve is connected to it. Thanks to him, you can not only control the flow of liquid into the device, but also monitor the accumulating vapors. The valve must be made of an alloy compatible with the material of the pipe on which it is to be installed.

- According to the selected scheme, the electrical part of the device is assembled. It must be provided with a stainless wire wick.

From an old cast iron battery

The simplest homemade heater is considered to be a device made on the basis of an old cast-iron battery. To do this, you need to somehow build into it a heating element powered by the mains, and fill it with water. In this case, the device must be made as airtight and safe for humans as possible.

The cast-iron battery heater heats up for a long time, but it remains hot for a very long time after turning off

The cast-iron battery heater heats up for a long time, but it remains hot for a very long time after turning off

Pour so much water into a homemade heater so that it completely covers the installed heating element.

At the same time, it is important to observe the measure: a battery filled to the brim will burst when the liquid freezes

To make a homemade airborne device from an ordinary battery, it is necessary to provide a thermoregulation system. Thanks to it, it will be possible to maintain the desired level of heating and monitor possible deviations. The best option would be to buy the simplest and cheapest mechanical room thermostat. It will work efficiently and monitor temperature indicators.

Instructions for self-assembly

Do-it-yourself vapor-drop heaters will be no less effective than their factory-assembled relatives. With the right components and materials, assembly takes a minimum of time. There is also an economic effect - a home-made heater will cost less. Moreover, you only need to buy a heating element with a thermostat (or find an old unnecessary heating element).

Battery based droplet heater

There are quite interesting schemes for the manufacture of this equipment. For example, a simple droplet heater can be made from an old cast iron battery. The task here is simple - you need to build a heating element into it and fill it with water so that it covers the heating element. The design should be as tight as possible.

A home-made heater from a heating battery will upset you with a long heating, but it will please you with long-term heat retention even after turning off the device. The vapor-drop principle of operation will avoid an increase in pressure when water is heated and a rupture of the resulting apparatus during freezing.That is, if you fill the battery with water to capacity, it will burst when it freezes.

A battery-based vapor-drop heater will become relevant for a country house, which is often left without tenants and can freeze through in winter.

The task of the vapor-drop heater designer is to embed the heating element inside the old radiator. But we need to solve another problem - to build a thermoregulation system. The easiest way is to purchase a heating element with a built-in thermostat. But it will monitor the temperature of the water, and we do not need it. Therefore, we choose the second option - we buy the simplest mechanical room thermostat.

The room thermostat monitors the room temperature. Being equipped with a contact group, it will ensure that the heating element is turned off. You can also implement manual temperature control - using an ordinary switch

Please note that thermostats and switches must withstand the voltage and current in the electrical circuit.

Homemade steam-and-drop heating from a steel pipe

A simple vapor-drop heater can be made with your own hands from a pair of pipe segments. There are no detailed drawings, so we will act according to the simplest drawing. We will need:

- Metal pipes of different diameters, inserted into each other (and tightly). You can also get by with one pipe.

- TEN - it is welded into the lower part of the heater.

- A small tube with a ball valve - water will be poured through it.

- Stand - since our vapor-drop heater must stand at an angle of 20-25 degrees, its upper part must be supported with a stand.

The most important thing is to properly embed the heating element.It is necessary to ensure reliable sealing, since during the heating process the pressure inside the pipe will increase. Our task is not to lose a single drop of coolant.

It is recommended to use distilled water as a coolant - it is sold in car dealerships. It does not contain salts, which will restrain the formation of corrosion in a closed environment. To completely protect against corrosion, it is recommended to use a stainless steel pipe to assemble the vapor-drop heater.

Assembly and modernization processes

To assemble a vapor-drop heater, you will need a grinder and a welding machine. We cut off the main pipe (we will use one pipe), set it at a given angle. We align the lower part vertically and weld it - the heating element will crash here. We also weld the upper part, but do not forget to weld a tube with a ball valve to it. Better yet, two taps - through one the water will be poured, and through the second the air displaced by it will come out.

You can also pour water into the heater immediately after the bottom part has been welded and the heating element has been inserted. Make sure that the coolant closes the heating element completely, otherwise it will fail. That is why a do-it-yourself device must turn out to be airtight in order to prevent loss of coolant and exposure of the heating element.

We place the finished structure in a heated room near the window. We proceed to the tests - we connect the heater to the mains. After a few minutes, the water will boil, the release of steam will begin, which will condense in the upper cold part of the pipe and flow back along the inclined wall.The vapor-drop principle of operation will ensure a quick warm-up of the device with minimal losses.

Pros and cons of vapor-drop batteries

We have already listed the main advantages of vapor-drop systems, but it is worth noting a few more advantages:

- The radiator contains a minimum amount of coolant, which ensures its rapid heating.

- A small amount of water will not damage the appliance when it freezes. The heater can be left switched off in a cold room: after connecting to the network, the ice will melt and it will work normally.

- Since there is no oxygen inside the circuit, there is no corrosion on the surface.

- The service life is about 30 years.

- The device does not require installation, it can be moved to another room at any time.

Only a power outlet is required to install a vapor drip heater

Other disadvantages include the high price of vapor-drip heating and the control unit, as well as the complexity of the repair.

Features of the tubeless system

PKN developers emphasize that the system is energy-saving and environmentally friendly. They make a whole list features of a pipeless installation scheme:

- Simplification of the preparation of sites for construction. For heating to work, it is enough to connect to the mains.

- Automatic adjustment and maintenance of the set temperature in each room.

- Reducing the cost of maintaining boiler rooms and maintenance personnel.

- Fuel economy in dual-circuit systems. The first circuit (gas, solid fuel or fuel oil) provides the minimum temperature in the entire building, the second (vapor-drop) - supplies additional heat to the living quarters.

- Extending the life of radiators.

- Possibility of use in any climatic zones.

industrial model

Comparative characteristics of heat sources

Pipeless systems can be used as a replacement for centralized or autonomous heating. The advantages of such a scheme are presented in the table:

| Natural resources (coal, gas, oil products) | Electricity | PKN systems | |||

| Capital investment in the construction and maintenance of systems. Expense items | Centralized boiler houses | Autonomous boiler rooms with the arrangement of the ventilation system. Gas line connection. Office space equipment. | Installation of a heating element boiler, reinforced grounding. Office space equipment. | Installation of an electrode boiler, reinforced grounding. Home preparation. | Mounted at the heat connection points. Do not require preliminary preparation of the premises. Can be used as temporary heating |

| Cleaning the coolant, flushing the system | Regular | If necessary | If necessary | Regular | Not required |

| Arrangement of forced circulation, installation and maintenance of pumping equipment | Necessary | Necessary | Necessary | Necessary | Not necessary |

| electrical safety | Very dangerous | moderately dangerous | Increased danger level | Increased danger level | Safely |

| Explosion proof | Increased danger level | Increased danger level | moderately dangerous | moderately dangerous | Safely |

| Environmental friendliness | Low level | Low level | Average level | Average level | High level |

| Need for service | periodic | periodic | periodic | periodic | Complete computerization of control |

| Accountability to oversight bodies | Yes | Yes | Yes | Yes | Not |

| efficiency | 70% | 90% | 90% at the beginning of the operation process, up to 45% - after burning out the filaments | Up to 98% | |

| Project development and approval | Wanted | Wanted | Wanted | Wanted | Not required |

Vapor drop batteries have been tested in several hundred government agencies. Separate PKN can be used as heat stabilizers or full-fledged heating, industrial accordion models in anti-vandal design effectively cope with heating large areas.

Principle of operation

A vapor-drop heater is the latest heat exchanger capable of heating residential and public premises by raising the temperature in them to 24 degrees. It consists of the following elements:

- Sealed heat exchanger, isolated inside the device.

- An electric heating element located at the bottom of the machine.

- News block with control system.

When the heater is turned on, work is going on inside it to turn air into steam:

- Eating from the electrical network, the heating element heats the water.

- Water turns into steam.

- Rising, the steam heats the body, turns into condensate and gives off its heat to the surrounding space.

- Water in the form of condensate again rolls down to the heating element, and the procedure is repeated.

In terms of size, a vapor-drop heater is no larger than a standard battery, but several times larger than systems based on fuel combustion. The steam heater works without pipes. He only needs electricity. Even with a sharp power outage, it is able to generate heat for some time.

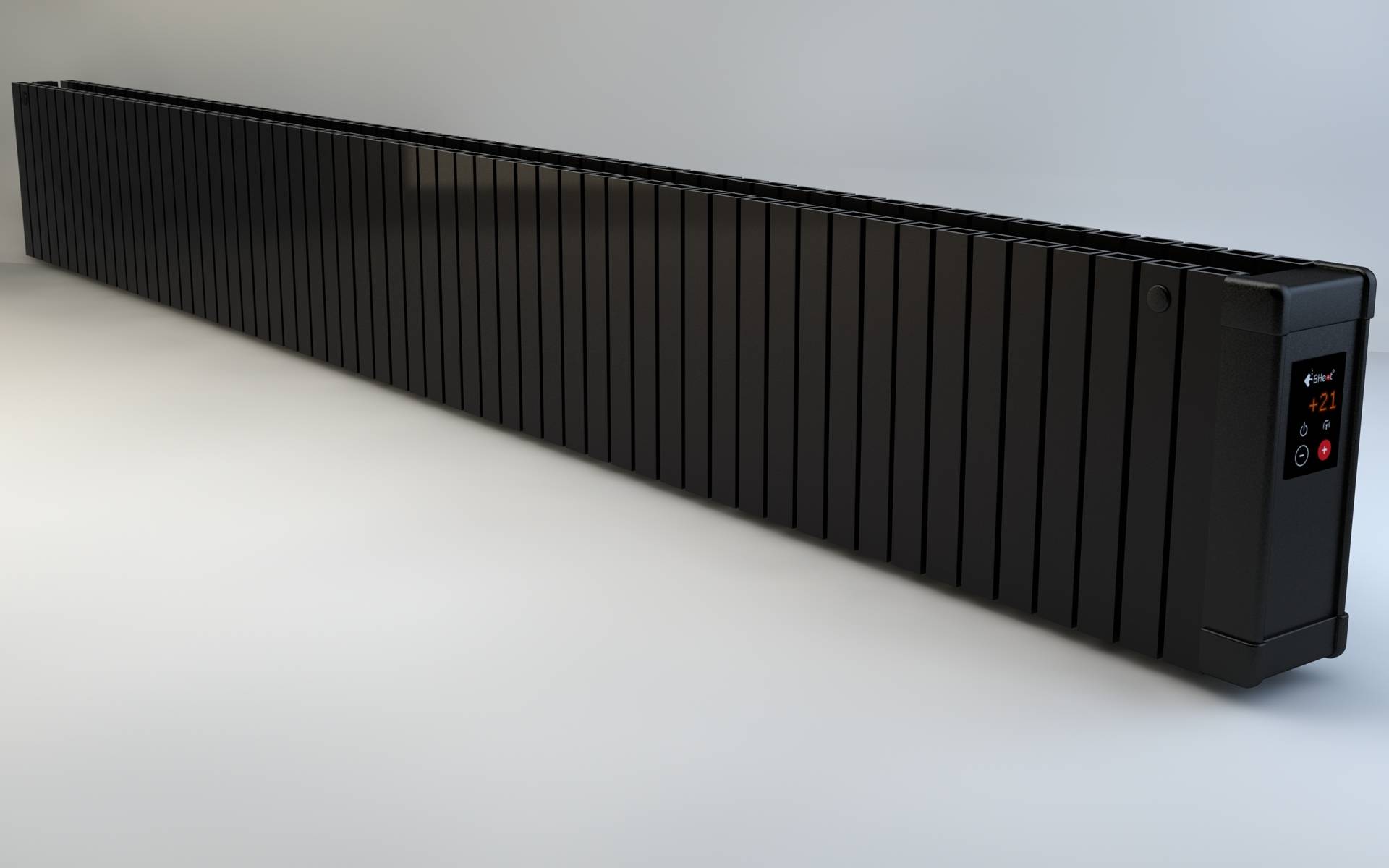

Common models

Among the equipment that can be purchased in our country, there are several popular designs. Among them, it is worth noting the following technique:

- BHeat Air-4 with a power of 0.7 kW. Power consumption is 280 watts.With a small weight (5.7 kg) and dimensions (375x90x580 mm), it heats a room with an area of 7-21 m². This comfortable device is liked by buyers for its economy.

- The kilowatt heater BHeat Air-6 is larger, heavier and consumes more power (400W). But the dimensions of the serviced premises are also larger - from 10 to 30 m².

- The power of the BHeat Air 2000 unit is 1 thousand watts, dimensions - 890x106x245 mm, weight - 12 kilograms. The heated area approaches 20 m². This model has a function of maintaining a given temperature regime, which allows saving resources, as well as an electronic control system. The device is protected against overheating and freezing.

- About 30 squares will be served by the BHeat Air 3000 product with dimensions of 1310x106x245 mm and a weight of 18 kg. Its power is 1500 watts. It has modes for maintaining parameters and saving the last settings.

- The thirty-kilogram unit BHeat Air 5000 is designed for 2.5 kilowatts and an area of up to 50 m². He weighs 30 kg. It is distinguished by simple installation and the ability to control via radio.

- The compact heater PKN-3−0.5−4 will qualitatively heat up to 17 m² of area.

- Up to 20 m², this indicator will increase for the PKN-3−0.6−6 model by 0.6 kilowatts. Its size is 550x600x80 mm, weight - 8 kilograms.

- The PKN-3-1.2-12 device has a power of 1.2 kW, a weight of 15 kg and dimensions of 1000x600x80 mm. The heated room can be up to 40 m².

A vapor-drop type heater will provide comfortable conditions in the house and significantly save finances due to energy efficiency. The absence of expensive repairs and service will reduce the family's expenses, and the long service life will not necessitate the purchase of a new device.All this speaks in favor of convenient and efficient devices of the new generation.

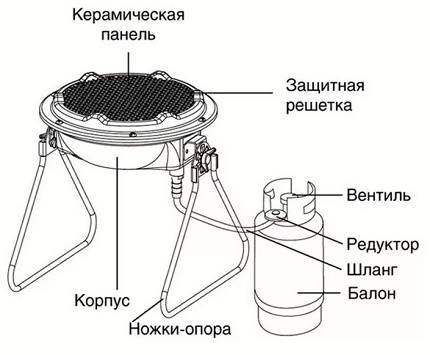

Used oil potbelly stove

Furnaces that operate on used engine or transmission engine oil are widely popular. The advantages of such furnaces are reliability, efficiency in terms of consumption and uselessness of used oil. The drip oven is considered the most economical due to the peculiarities of the fuel supply, but it is difficult to make it on your own.

Stove-dropper

The drip stove works due to the fact that the ignited exhaust in the first tank emits combustible gases, which are mixed with air in the second tank and re-ignite, reaching very high temperatures (about 800 ° C).

It is best to purchase a ready-made design. But if there is a desire to try your hand at such a thing, then photo 2 shows a drawing according to which the assembly is carried out. Instead of a 180x180x6 pipe, a gas cylinder is often used (before cutting the cylinder, fill it with water or slowly drill a hole in the bottom and pour out the contents).

To automate the process and create a drip system, you need to filter the waste by driving it through a hose, at the end of which a complete filtration car filter is installed.

You also need to choose a fuel pump that will supply the right amount of fuel. You can use a piece of hose from a dropper with a regulator, put it on the bottom fitting and control the fuel supply.

A drip oven can also be used to heat water if a heat exchanger with a removable tank is arranged in the upper part.Such a drip oven can also be used for space heating, if you connect the house's water heating system to it and equip it with a pump to circulate water through the system.

It is worth mentioning such a heater as a diesel oven. It is often used in homes where it is impossible to implement another type of heating. According to the characteristics, a diesel fuel stove is similar to a gas boiler. It has a high efficiency and can be converted to gas consumption. True, it requires timely maintenance and the availability of high quality fuel. A diesel fuel stove is more expensive and harder to build, so the above designs are good alternatives to it. published

Gas heating

Gas heating is an old and proven solution for heating a house, but it has a number of significant disadvantages:

- Extremely expensive to purchase and install. Despite the modest figures in the calculations of gas supply organizations, the actual total cost of introducing gas heating (including a gasification project, supplying gas to the border of the site, laying pipes for the heating system and installing batteries, arranging a heating unit with a boiler, meters and other related equipment) fluctuates around 1 one million rubles or more.

- Requires approval of a large amount of documentation, technical specifications and a boiler installation project.

- Requires the involvement of a specialized organization in the installation of equipment and subsequent control of the correct connection of the equipment.

- In addition, many people forget that in addition to payments for gas, it is also necessary to pay monthly for the monitoring and maintenance of the gas heating system by the gas supply organization.

- Do not forget that gas is far from being available everywhere, and even where the pipe runs nearby, the promises of gas workers “we will connect soon” often remain unfulfilled for years.

It should be borne in mind that the use of a close alternative - liquid or solid fuel boilers also requires the ability to handle equipment, compliance with fire safety and requirements for chimney systems in order to avoid poisoning by combustion products.

Self-manufacturing of PKN

The high price of steam-condensate heaters, with the apparent simplicity of the principle of operation, gives rise to the temptation to make such an apparatus on our own, bearing in mind the modern availability of materials, parts and tools.

In fact, today vapor-drop heaters are often made with their own hands - materials and components for their assembly can be easily found on sale. But to make such units at home only after reading the instructions and advice is not real - there are a lot of designs of these devices, and the production technology of each has characteristic features. At the same time, it is necessary to have not only general skills in installation and welding work, but also functional experience in the manufacture of PKN.

Moreover, the assembly of a low-power vapor-drop heater is not practical - there are many other types of inexpensive heaters, moreover, industrial-made ones that can cope with home heating better and safer. And a hand-made high-performance device is not very aesthetic to use it for heating a home.

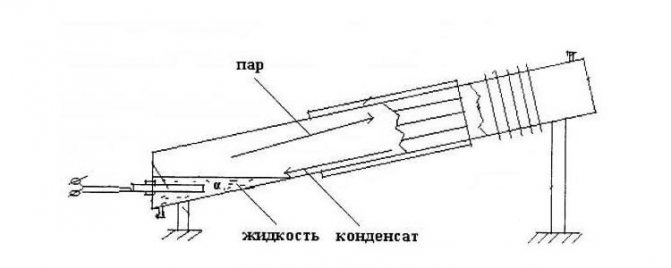

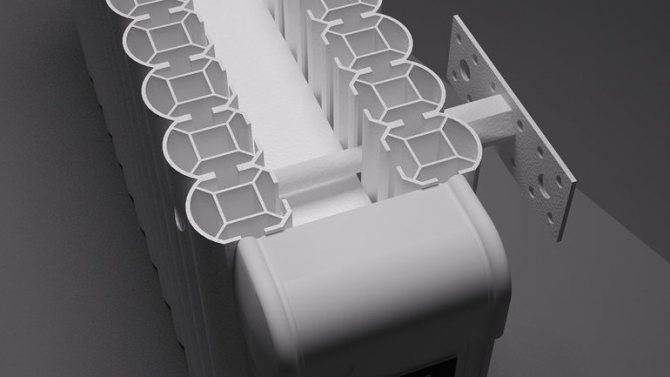

Handmade PKN from a steel pipe with a 500 W tubular heater

The heating register shown above, operating according to the vapor-drop type, will serve as a visual aid to the questions of how to perform the PKN yourself.

The device is assembled from four parts - "streams" made of a steel pipe with a diameter of 50 mm and plugs-plates made of steel based on a sheet. A tubular heating element is built into the lower "stream", equipped with a pipe section. At the top of the register there is a plug with a valve through which a mixture of water and antifreeze was poured into the heater and air was bled under pressure when the device was first turned on.

Schematic representation of the PKN device in section

The lower "stream" is filled with a heat carrier, which erodes when heated. Steam fills all the empty space of the “streams”, gives off heat to the walls of the heater and condenses on them, then flowing back down to the Tubular heater.

The design of the PKN can be quite simple, but this does not negate the need for certain professional skills.

PKN of handicraft production of a single-strand design from a pipe from steel

Important! The lack of vacuum in a homemade radiator causes the heat carrier to boil, accompanied by a certain noise during operation of the unit

Safety

Any home-made or factory-made device, especially powered by electric current, poses a threat to human life and health. Therefore, in its manufacture, it is necessary to foresee all possible emergency situations and try to reduce the risk of their occurrence.

To protect yourself from unpleasant situations, you must follow the safety rules

To protect yourself from unpleasant situations, you must follow the safety rules

The main safety measures for the operation of vapor-drop batteries:

Before turning on the device, it is necessary to study in detail the principle of its operation.

It is forbidden to use the heater at voltages that do not correspond to the technical characteristics of the device.

It is not recommended to cover or block the device with any object.

Such carelessness can cause overheating and damage.

Do not place a vapor drop heater next to furniture. High temperatures can harm them and ruin their appearance.

It is strictly forbidden to use the device in rooms where paints, fuels and other flammable materials are stored

Failure to follow this rule may result in fire and all the serious consequences associated with it.

Do not touch the device with your hands during operation. Otherwise, there is a high probability of getting burned from a hot surface.

If you need to move the device to another place, then you must first disconnect it from the mains and cool it to room temperature.

Do not dry clothes on a heater.

Avoid getting any foreign objects into the inside of the device.

The heater can only be used away from water. In addition, even the slightest exposure to moisture should be prevented. In case of accidental contact with water, the device must be immediately de-energized, and only then remove the liquid.

Do not plug in a steam heater with a damaged cord or plug. Otherwise, there is a risk of electric shock.

Extension cords are not recommended.

More about the steam drop heater:

>Vapour-drop heater is a useful and necessary device in the household. With its help, you can quickly heat the room and make your stay in it as comfortable as possible. In addition, you can make such a device with your own hands. This will not only save money, but also allow you to gain experience in similar work that you may need in the future.

DIY steam heater

The simplest vapor-drop heater is made by hand according to the drawings. To assemble the device at home, you will need a locksmith tool and spare parts. Homemade installation has high efficiency and low cost.

The simplest type of steam heater is a cast iron or steel battery. Do-it-yourself assembly of a vapor-drop heater is performed in the following order:

- Holes are drilled at the bottom of the end of the battery.

- The electrodes of the heating element are inserted into the holes made.

- Holes are carefully sealed.

- The outer ends of the heating element are connected by wires to the network through a thermostat.

- A hole with a diameter of 3-5 mm is drilled in the upper part.

- The coolant is poured through the hole made.

- A thread is cut into the hole and a bolt is inserted.

- After pouring the coolant, the bolt is tightened until it stops.

- Check the correct connection of the electrical circuit.

- Connect the device to the mains.

- Using the thermostat knob, set the optimal operating mode of the device.

If any deviations in operation are detected, disconnect the device from the power supply. They resume work only after the elimination of all identified violations.

Principle of operation

Typically, a device of typical dimensions is produced with a conventional household battery, however, their efficiency is much higher relative to the amount of heat generated.

This type of device can be briefly described as a heat accumulator. The principle of its operation is pulsed, however, this does not affect the level of temperature that has been set, and it must be maintained in the room. The device switches to the shutdown mode at some intervals, but half of the heat accumulated during the shutdown period continues to be released to the environment. Some models of imported manufacturers can heat up to a temperature threshold of 350 Co.

A vapor-drop heater is classified as an advanced device that has a heat exchange system at the heart of its work. But this particular type of heater has significant differences from other similar equipment. The general principle of operation of the device can be divided into several processes:

- water is heated by electricity;

- a process is characteristic in which the coolant changes its state of aggregation to the level of steam and simultaneously releases thermal energy;

- due to the condensation process, the entire volume of the coolant is returned back to the system;

- the sequence of processes has cyclic repetitions.

The operation of a vapor-drop heater mainly depends on a heat pipe. Its functions and characteristics can be described as follows:

- This element of the device is a conductor and transfers heat from the zone in which heating occurs (heating zone) to the one that is not yet heated (heating zone).

- It has a high level of thermal conductivity, exceeding silver and copper in this parameter.

- Transfers about 90% of the heat energy to the condensation zone thanks to the previous feature.

- Due to the fact that the tube has a capillary effect, used in modern elements, the movement of liquid condensate occurs through a capillary network inside the device.

- The cavity of the tube contains porous materials such as a wick or loosened pottery.

- As a coolant, modern designs contain water, ethanol, methanol or ammonia.

- As for the efficiency of the heating element, it depends on the size and shape of the element, its properties and the value of the heat transfer coefficient.

The vapor-drop type of heaters is classified as pipeless heating systems. In addition, the owner of such a system is given the opportunity to regulate the operating mode of the device and set the required temperature regime, which can be selected for each individual case. It also allows you to control costs and be independent of the central heating system and their requirements.

In a closed system with an infinite number of cycles, electrical energy is converted into heat.

If we describe the principle of operation of a vapor-drop heater in more detail, then it will look like this:

| Start/End Cycle | Due to the action of the batteries, the water is heated in the system to the required set temperature. |

| Second phase | Boiled water forms steam, which is completely sealed in the cavity of the heating element. |

| Third stage | Thermal energy is generated and released into the environment. |

| End / start of cycle | During the release of heat during condensation of steam, it begins to flow back into the heating element along the surface from the inside of the device, after which, according to a similar cycle, it begins the process of converting again into steam. |

It is worth considering the fact that a distinctive advantageous feature of the vapor-drop heater system is that, thanks to the tube, it can transfer a much larger amount of thermal energy. In this regard, the small size of the installation of a vapor-drop heater makes it possible to produce a much larger amount of heat for space heating than similar converter-type devices.

Conclusion

You must definitely study the device of a vapor-drop heater if you plan to manufacture it. This will make it clear that the slope of the heating chamber should be at an angle of 20 degrees, but no more. Its position should be such that it faces the end wall of the housing. This effect can be achieved if the support posts are made of different heights. They should be located at different ends of the body. Vapor-drop heaters, the owners' reviews of which were presented above, must have an electric heating element, which is fixed using gaskets, a fitting or union nut and a nipple.