- Design and main characteristics of the parapet boiler

- Installation Features

- Installation Requirements

- Installation conditions

- Features of mounting a wall-mounted boiler

- Types and prices

- Strengths of parapet heating boilers

- Equipment Features and Available Models

- Gas boiler Volcano AOGV 10 E

- Gas boiler Volcano AOGV 12 BE

- Gas boiler Volcano AOGV 9 VPE

- Gas boiler Volcano AOGV 16 VPE

- Mounting Features

- Service

- Do-it-yourself installation of a parapet gas boiler

- Installation conditions

- Boiler installation

- Models and their characteristics

- KSG-7AT

- KNG 24

- KSG-11

- KSTG-16

- KSG 10-AT

- KSG-7 E

- What are parapet gas boilers

- The device and principle of operation of the equipment

- Under what conditions is it most appropriate to use such boilers?

- The possibility of installing a parapet boiler in a wooden house

- Other Tips

- Rating of the best manufacturers

Design and main characteristics of the parapet boiler

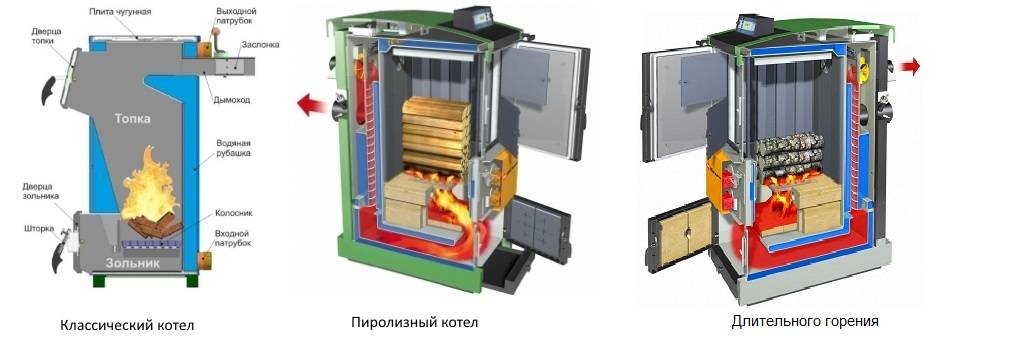

There are several types of parapet boilers, the following classification will help you choose the right model:

- according to the installation method: floor and wall, left- and right-handed;

- by the number of circuits: single and double circuit;

- by the presence of automation: energy-dependent or not.

A few words about the second classification.Single-circuit boilers perform only one function - space heating; double-circuit, in addition, heat the water. The body of the device has special convection holes that allow you to maintain heat in the room without installing additional radiators.

The parapet boiler can operate both using a portable cylinder and from a conventional gas pipeline. The case of the device is made of steel; the minimum thickness is 3 mm, and a special powder coating prevents rust, even if the boiler is located in the kitchen, where there is usually high humidity.

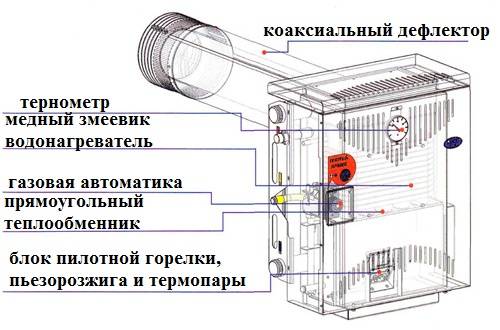

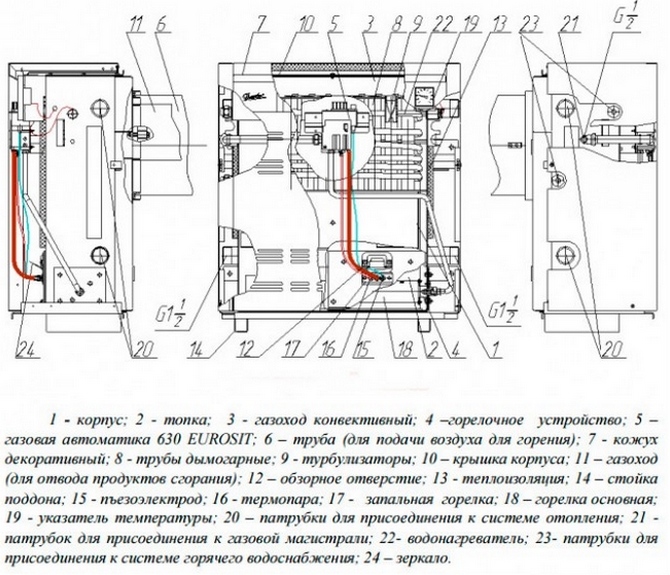

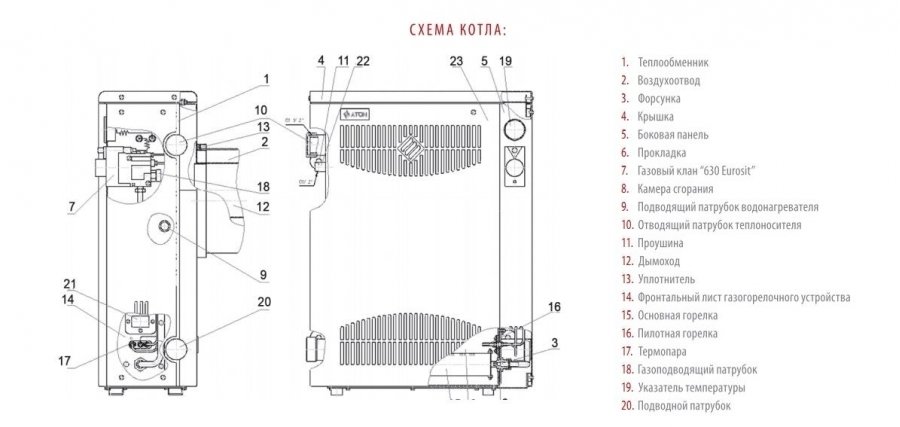

The parapet boiler consists of the following parts:

- steel cases;

- closed combustion chamber;

- pilot burner unit, piezo ignition and thermocouple;

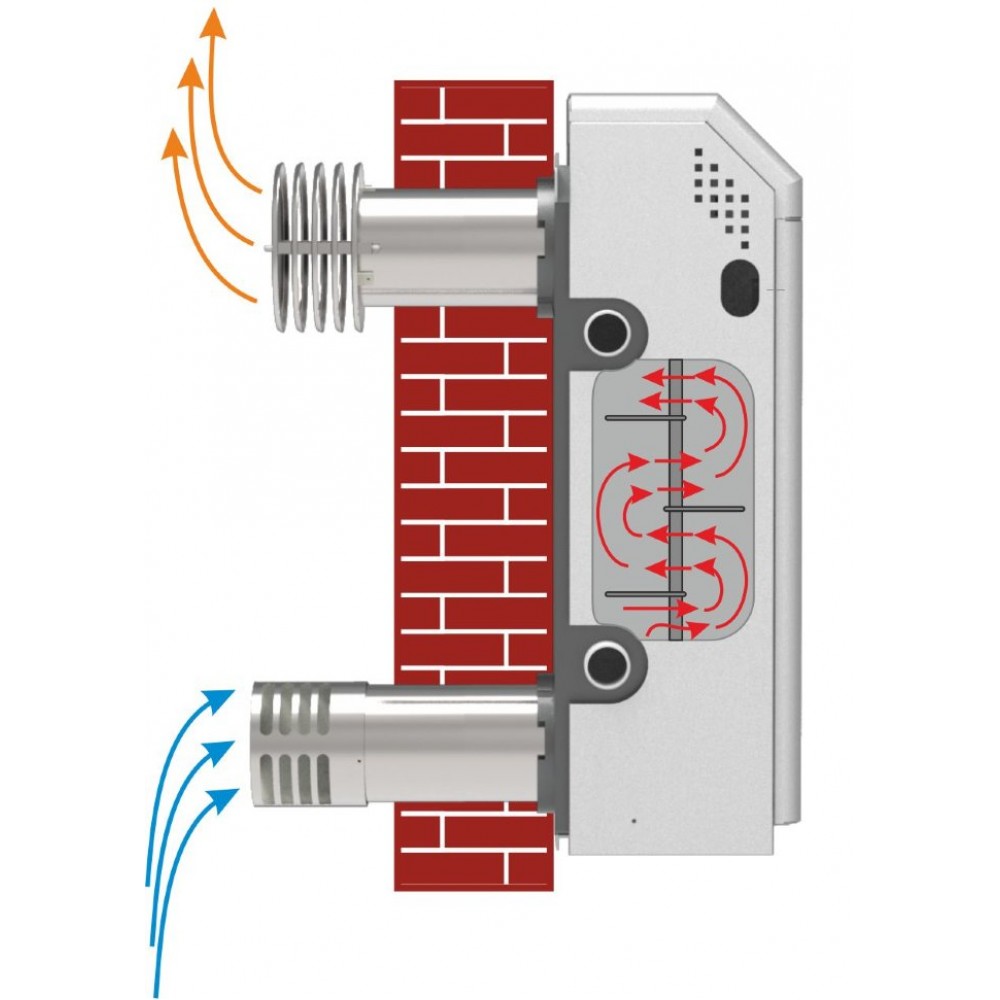

- exhaust systems in the form of a coaxial chimney facing the street;

- heat exchanger;

- electrical sensors that control the operation of the device.

The chimney allows you to collect air for combustion not from the room, but from the street. Combustion products, on the contrary, are emitted from the apartment. Safety is ensured by the operation of the following components: thermometer, thermocouple and draft sensor.

Installation Features

Many owners are trying to find out how to install a Thermo gas parapet boiler? To do this, you should familiarize yourself with the requirements that are prescribed in state regulations regarding the connection of such equipment. In order not to waste time studying the rules for "Gas distribution systems" and "Gas supply", it is better to coordinate this with Gorgaz, a service that specializes in connection features and requirements for equipment and premises.

It is important for you to read the technical specifications, which will describe the connection features in your home. To do this, write an application to the city gas supply service and indicate the required amount of fuel per hour

After the application is considered and satisfied, you can begin to study the technical conditions for installing the boiler and the entire system.

You should not install the boiler yourself, as this is not only unsafe, but also illegal. As a result of your actions, many people can suffer, especially if you live in an apartment.

After all the instructions have been studied, you can proceed to the design of the heating system and the Gas Supply project, which indicates the location of the boiler and the scheme for laying a gas pipeline to it. After development, the project is submitted to the service for approval along with the following documents:

- technical passport for the boiler;

- boiler operation manual;

- certificates certifying compliance with technical requirements and sanitary and hygienic standards;

- expert opinion on the compliance of the boiler with mandatory requirements.

Only after permission from Gorgaz can you proceed to the installation.

Installation Requirements

- do not install the boiler on combustible materials;

- can not be placed in the corridors, bathroom, basement, balcony;

- it is forbidden to install the boiler in a poorly ventilated room or a room without vents;

- you can not put a boiler in the hostel.

Installation conditions

The first step is to choose the right room parameters for installing the Thermobar gas boiler.

The square of the room where the boiler will be must be at least 4 sq. m.

The width of the front door should not be less than 80 cm.

Good lighting and high ceilings are a must.

The presence of a ground loop and a cold water pipeline.

The chimney must meet the requirements that depend on the power of the equipment, so it is important to choose the Kolvi parapet gas boiler according to the parameters.

The walls of the room should be even.

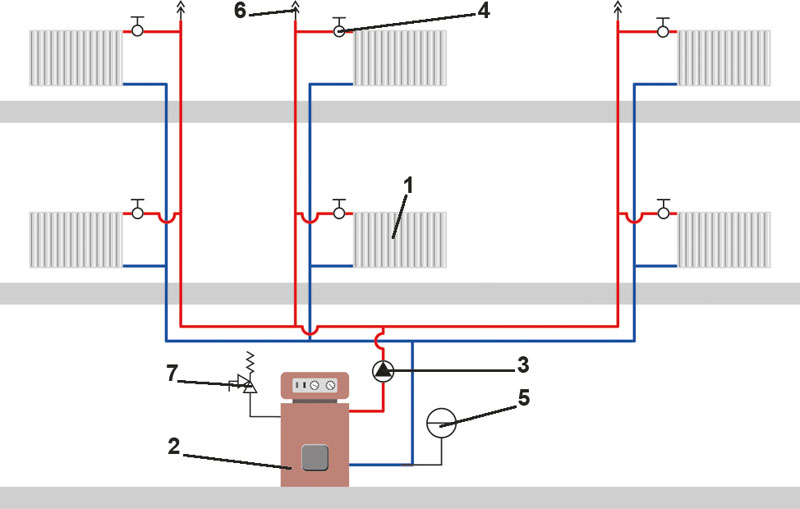

Following these requirements, dual-circuit models are best placed in the kitchen near the gas stove. If the boiler is floor-standing, then it requires a separate room.

Features of mounting a wall-mounted boiler

IMPORTANT: It is forbidden to independently install the boiler and other equipment. First, it is necessary to carry out preparatory work, which includes the availability of specialists with a license to carry out such work and compliance with the temperature regime of 15–25 degrees Celsius

First, it is necessary to carry out preparatory work, which includes the availability of specialists with a license to carry out such work and compliance with the temperature regime of 15-25 degrees Celsius.

We fix the boiler bracket.

We connect water

If the model is dual-circuit, it is important not to forget about the need for a strainer.

We connect the equipment to the gas valve.

With the help of a three-wire wire, we connect electricity.

A coaxial pipe should be connected to the boiler, which is led through the wall to the street. Before starting the equipment, fill the system with water

This is followed by a check for gas or water leaks.

If the boiler is very powerful, then natural draft may not be enough to remove combustion products. In this case, a forced exhaust is required, which is built in the passage between the floors or the roof. To do this, install a pipe with a hatch, which can be easily cleaned.

Types and prices

The advantage of such boilers is a large selection of models with different fixtures: floor and wall. When choosing a boiler, the actual connection conditions are taken into account.

Boiler equipment from European factories, Russia, the CIS countries and China is quite widely represented on the construction market. It is clear that the quality of equipment from the EU is higher than that of boilers from China, but the price is much higher.

Popular parapet boilers:

- TERMOMAX-C are non-volatile compact boilers for individual heat supply of one-story and multi-storey buildings, equipped with a flue gas emission system through a coaxial duct, horizontally built into the outer wall.

Structurally, they are carried out both as one and in a double-circuit version with the marking E and EB and a thermal power of 7 to 16 kW. For heating systems with high hydraulic resistance, a circulation pump is provided. Control, protection and start-up are carried out through the EuroSit 630 gas valve. The burner is started using a piezo ignition. TermoMax C 16EV has an efficiency of 90% and is able to heat rooms of 120 m2 in size, the cost of the unit is 20,100 rubles.

- Another Russian parapet boiler model is Lemax Patriot 20 with a closed firebox. Steel heat exchanger treated with an inhibitory composition and covered with an enamel coating to resist corrosion processes. By type of installation - wall. Line of heat load of Lemax boilers from 6 to 20 kW. Gas burner equipment from the Italian concern "SIT" with an injection flare burner "POLIDORO". There are special holes on the front panel to create a convection effect and increase heat transfer in the room.Features include: removable lining elements, igniter, coaxial smoke exhaust system, non-volatile installation option. The cost of the unit is 25820 rubles.

- The double-circuit boiler "Slim 2.300 Fi" is produced by the Baxi brand with a heat load of 14.9 to 29.7 kW, capable of heating objects with a size of 140 -160 m2. The boiler is made of quality materials, with a price of 120.0 to 140.0 thousand rubles.

- EcoCompact VSC D INT 306/4-5 190L, the boiler of the German brand Vaillant is a highly efficient unit, it can heat 160-180 m2, the price is 240.0 thousand rubles.

- The Danko parapet boiler, with a power of 7 to 18 kW, is equipped with a cast-iron boiler with a wall thickness of 3 mm and a closed combustion chamber. The universal design allows for two-way connection of engineering networks, the control unit is located on the operating panel of the boiler. The units are equipped with Honeywell gas automation, piezoelectric ignition and a microtorch burner, the heating area is up to 160 m2, the price is 21 thousand rubles.

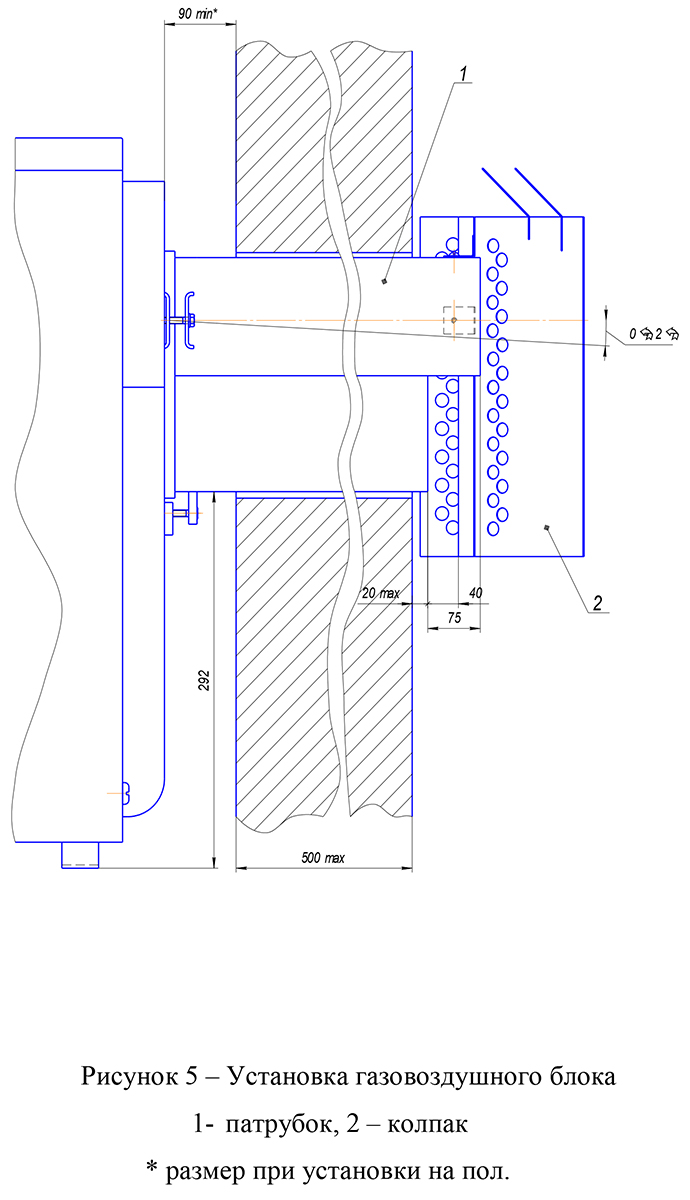

- Eurotherm KT TSY (P2) for individual heat supply in systems with natural and forced circulation of the heating circuit, with a water heating temperature of up to 90 C, heat output 10 kW, gas flow 1.13 m3/h, efficiency 92%, weight 59 kg, warranty period 24 month, heating area 100 m2, price - 24 thousand rubles. rub. Steel boilers are equipped with a copper recovery system with a bypass channel. A copper coil of a special design is placed in a water cavity to generate hot water. Design features: heat recovery system with a receiving tank, housing, control and protection unit, air duct, gas duct, wind protection cover. The design allows you to install the unit at floor level near the wall.DHW loop connecting pipelines are made on one side. The air intake duct passes through the outer wall with a thickness of 200 - 500 mm. It is not allowed to mount on the walls in a wooden house, without fire protection measures.

Strengths of parapet heating boilers

Parapet gas boilers have the following advantages:

- Compact dimensions. This allows you to easily solve the problem of how to install a parapet gas boiler inside a small apartment, the owners of which decided to acquire an individual heating system. Equipment of this type can even be installed under the kitchen table or in a niche near the window. The main thing is that the distribution of gas pipes gets there.

- Good smoke extraction. This is ensured by the use of coaxial pipes, which can be laid at any convenient angle.

- Ease of installation. This is especially true for wall-mounted parapet boilers. Before you install a floor-standing parapet boiler, you will have to equip a separate room (boiler room), in accordance with the recommendations of the gas service. A prerequisite for the use of floor gas boilers is a chimney and a wide front door (from 80 cm). The boiler room must be equipped with a window for regular ventilation. The chimney must be equipped with a series of small ventilation holes. Parapet boilers do not have similar installation requirements.

- Possibility of connection on any part of the heating circuit. Some boilers have only a right-hand or left-hand installation principle, however, this restriction does not apply to parapet devices.Thanks to this, the installation of a parapet gas boiler can be carried out in a place convenient for it.

- Aesthetics. Parapet models are distinguished by external attractiveness. Most often they are tinted in a light color, which allows them to harmoniously fit into any modern design. For painting devices, a very high-quality material is used that retains its original decorative qualities over a long period of operation. Such a surface is not afraid of sunlight and frequent wet cleaning.

- Ease of management. The package of gas parapet boilers includes a modern control unit. Thanks to the automatic control system, the state of the coolant is constantly monitored. If its temperature goes beyond the pre-set parameters, the sensors immediately send a signal to the main console, which turns on the heating or cooling system. The control over the level of pressure inside the pipes is built in a similar way. Thanks to automation, it is possible to select the most optimal operating mode of the device, which makes it possible to save energy resources.

- The presence of piezoelectric ignition. This allows a single or double-circuit parapet gas boiler not to depend on the presence of electrical energy in the room. This is especially convenient outside the city, where power outages often occur.

- Full set. The device is already equipped with all the necessary elements, which are compactly located under a beautiful body. A parapet boiler hung on the wall will not be hung on the sides with additional equipment that spoils the overall interior.

- Ability to reconfigure to another fuel.When switching to another type of fuel (electricity, liquefied gas), you do not need to buy new boilers: parapet models can be reconfigured and nozzles can be changed in them.

In the room where there is a single-circuit type gas parapet boiler, heating batteries can not be installed. The fact is that the body of the device is equipped with many convection holes through which heat enters the room.

Outcome

A parapet boiler is an excellent opportunity to solve the issue of organizing heating in any dwelling (private house or apartment). When investigating the question of which parapet boiler is better, it is necessary to take into account a number of factors. For example, if in addition to heating it is also required to provide heating of water for domestic use, two-circuit parapet boilers of imported production are on sale. Some of them do not require a chimney connection at all. In situations where the dwelling already has a single-circuit heater of low power, the organization of the DHW system can be carried out using a boiler

Equipment Features and Available Models

Boilers Volcano are two lines of modern floor heating equipment for heating residential buildings and buildings for other purposes. Features and benefits of these units:

- Long service life - the average is at least 14 years.

- High efficiency - it is up to 92%.

- Stable performance in all conditions.

- Durable stainless steel burners.

- Complete energy independence.

- Open combustion chambers.

- Heated area - up to 300 sq. m.

Besides, gas boilers Volcano are divided into models of parapet type and models with traditional chimneys.

The undoubted advantage of these boilers is the lack of dependence on the electrical network.Thanks to this, they will be able to work in settlements where there is no gas supply. The presented models are made in a floor form factor, they do not take up much space and have a good, albeit strict appearance. Let's see what we can find for sale.

Gas boiler Volcano AOGV 10 E

Before us is a typical model, made according to a single-circuit scheme using a traditional chimney. It is intended for operation in heating systems with forced or natural circulation of water and other types of heat carriers. There is no secondary circuit; for the preparation of hot water, connected "indirect" small volume boilers are used. In order not to create excessive load and not waste heat, you can install an electric storage water heater in the house.

The boiler Vulkan AOGV 10 E is connected to a gas main, but can also be operated from liquefied gas. The control system here is mechanical, with a similar protection system. The heat exchanger is made of steel with additional protection against corrosion. The manufacturer of the burners is the Italian company Polidoro. The thermal power of the unit is 10 kW, gas consumption is up to 1.4 cubic meters. m/hour.

Gas boiler Volcano AOGV 12 BE

This model is suitable for heating households and buildings for other purposes up to 120 square meters. m. Its power is 12 kW, therefore, taking into account the necessary margin, it is better to heat a maximum of 100 square meters. The boiler is built according to a scheme with two circuits, Italian automation controls the switching, as is customary in similar units from alternative brands. A traditional chimney is used to remove combustion products.

The boiler is connected to the gas main, consuming up to 1.56 cubic meters from it at maximum load. The efficiency is 90%, which is quite a high figure. The operating temperature of the coolant is from +50 to +90 degrees, the volume of boiler water is 19.3 liters.

Gas boiler Volcano AOGV 9 VPE

We turn to parapet models. They differ from traditional Vulkan boilers in that traditional chimneys are not needed for their operation. Instead, double chimneys of the "pipe in pipe" (coaxial) system are used, coming from the back and leaving the wall. The presented model is dual-circuit and non-volatile. It is suitable for installation in new households, where ordinary chimneys are built extremely rarely. The unit is no different in appearance from its counterparts with open combustion chambers.

The boiler Vulkan AOGV 9 VPE operates from a gas main with a maximum consumption of up to 1.4 cubic meters. m/hour. Its heat exchanger is made of durable steel, protected from corrosion by a special coating. Italian mechanical automation is responsible for temperature control in the pipes and the secondary circuit. Ignition is carried out from a piezoelectric fuse. The boiler does not require connection to a socket, and a two-way connection to the heating circuit ensures ease of installation.

Gas boiler Volcano AOGV 16 VPE

Before us is one of the most powerful parapet-type boilers. It is equipped with a closed combustion chamber, the combustion products emitted by it are sent outside through a coaxial chimney. Through it, air is taken in for the operation of the burner. The power of the device is 16 kW, which is enough to heat rooms up to 160 square meters.As in all other models, the heat exchanger here is steel, with additional anti-corrosion treatment.

Control system - mechanical type, made in Italy. It provides switching between circuits and maintaining the set temperature in the heating system. Ignition is carried out by a piezoelectric igniter. Connection to the mains is not required, thanks to which the boiler Vulkan AOGV 16 VPE can be operated in buildings that are not connected to gas mains.

Mounting Features

Proper installation of the boiler is the key to a productive heating system and fire safety. The requirements for the installation site of a floor-standing boiler are:

- installation is carried out on a flat surface, protected from freezing;

- there should be a power outlet with grounding nearby;

- a safe distance from furniture and other interior elements;

- equipped boiler room.

As a rule, a medium-sized apartment requires a boiler with a capacity of 6-20 kW. If you choose a model with automatics, this will save up to 12% of fuel consumption, which is an indisputable advantage.

If difficulties arise, our manager will consult by phone on the characteristics of the equipment and help you make the right choice.

Service

Some malfunctions identified during operation can be eliminated independently:

- Thrust sensor problems. It can cause an emergency shutdown with excellent traction. False alarm occurs due to oxidation of the contacts - they need to be cleaned. If the sensor is completely broken, it is easy to replace it with a new one.

- Igniter problems. Ignition does not occur due to weak burning of the wick.How to fix the situation? Set the desired flame power. You can read about this in detail in the instructions. Also attached to the equipment is a connection diagram and a technical passport.

In almost any specialized store you can buy components and parts to be replaced. Repairs may only be carried out by an authorized worker.

Do-it-yourself installation of a parapet gas boiler

It is necessary to begin the installation of heating equipment with a thorough study of the instructions, the safety rules described in it. It must also be remembered that the commissioning of the boiler is coordinated by the gas services. If you installed the boiler yourself, then consult with specialists to complete the correct installation.

The process takes place in several stages.

Installation conditions

First, choose the optimal place for installing the boiler that meets existing standards.

The equipment is installed only in premises that are non-residential (kitchen, hall, utility rooms).

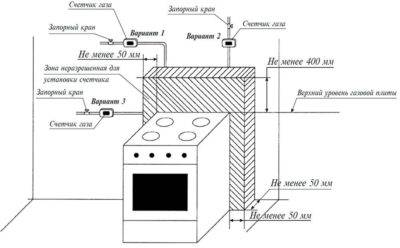

The outlet of the chimney pipe must be located on an external surface that is resistant to fire. Included with it, in most models, is a metal casing. It is attached directly around the diameter of the pipe outlet to the outer wall. If there are elements on the chimney outlet wall that can ignite when heated, then the distance to them should be at least 20-35 cm.

It is strictly forbidden to bring the chimney to balconies and loggias, to passage arches, especially to the entrance. It must be remembered that toxic products of combustion are removed.

It is forbidden to install an outlet chimney near the supply ventilation fences (distance from 60 cm - for low-power boilers; up to 1.5 meters - for equipment with a power of more than 7 W). With a close location of the inlet ventilation and the chimney, it is possible for exhaust gases to enter the supply ventilation ducts.

Periodically, the chimney will need to be cleaned, so it would be more correct to place it in the place of access to it, for example, under the window.

For the first floors, a hinged installation of the boiler is preferable, approximately at a height of 2-2.2 meters.

Indoors, flammable surfaces must not be placed around the boiler closer than 30 cm (upholstered furniture, curtains, tulle).

There must be access to the system from all sides, at least one meter.

Boiler installation

You will need the following tools: a diamond drill for punching a hole in the wall, boiler fasteners, level, caps (stop valve), adjustable wrench.

Installing a parapet boiler with your own hands requires certain practical skills.

Sequencing:

- First, a hole is punched in the wall, according to the size of the outer diameter of the chimney. To do this, use special diamond drills with a diameter of 240-270 mm.

- Then the outer contour of the coaxial pipe is mounted. The chimney is installed at an inclination of 4-5 mm so that condensate drains.

- Next, fasten the fasteners for the mounted boiler, mark the floor section.

- Install plumbing system, gas outlet.

- The inner chimney pipe is fixed.

- Install the boiler, connect to it the water and gas outlets, pipes of the heating system.

The last step will be the control start of the boiler. It is better to carry it out in the presence of a specialist.Make sure that the flame is even, there is a special viewing window for this. Check if gas has been etched or water is leaking at the joints.

Models and their characteristics

We note the technical characteristics of the most popular models of gas boilers Ochag.

KSG-7AT

This volatile single-circuit unit has an affordable price. The approximate cost is 10,000 rubles. The material used for manufacturing is steel. It is produced in the floor version, the device is very simple and convenient to use.

Gas boiler Ochag KSG-7 AT

This gas boiler Hearth consumes fuel economically, the device is able to effectively heat a room of 80 m². Specifications:

- power is 7 kW;

- high efficiency - 85%;

- water pressure - 0.1 MPa.

The unit functions without failures and malfunctions even at the minimum pressure in the pipeline. The package includes a gas block, a built-in pressure and draft stabilizer, a compact steel heat exchanger. The burner is made of heat-resistant stainless steel. It is simple and convenient to maintain - the lining can be easily removed, the gas is connected on both sides. There is a device that collects condensate.

Users note that this model has good characteristics. If you replace the burner jets, then liquefied gas can be used as fuel.

KNG 24

Hearth KNG-24

The approximate price for such equipment is 25,000 rubles. It is double-circuit, wall-mounted, small in size. Features a stylish design.

In operation, the device is absolutely silent - you can mount it right in the room, it will not create discomfort.

On the front panel there is a liquid crystal screen that shows the current parameters. The boiler can be used for heating rooms that are equipped with a water heating system, as well as for heating water.

Technical indicators:

- high performance, efficiency reaches 90%;

- effectively heats rooms up to 220 m²;

- the maximum heating power is 24 kW;

- there is auto ignition;

- gas consumption is 2.6 m³/h.

Such units can be connected to a floor heating system. The combustion chamber is closed, it can run on natural or liquefied gas. There are several levels of automatic protection. The mass of the boiler Ochag KNG 24 is 36 kg.

KSG-11

KSG-11 is a floor-standing gas boiler Hearth, designed for heating rooms for various purposes.

Installation is simple and convenient, because gas can be connected from any side. The door can be mounted on any side convenient for the user.

There is a device for collecting condensate, the heat exchanger is made of steel, the thermal insulation is 30 mm. The type of combustion is low-flame, the device does not emit any noise during operation.

Technical specifications:

- heating capacity is 11 kW;

- the maximum area that the unit can heat is 125 m²;

- Efficiency - 85-90%;

- gas consumption is - 1.34 m³ / hour;

- weight - 48 kg.

KSTG-16

Combined single-circuit boiler, maximum power is 16 kW. The device operates on gas and coal. Designed to supply heat to rooms up to 160 m². Installation of floor type, without auto-ignition and flame modulation. Efficiency - 75%.

KSG 10-AT

The unit is floor-standing, the heating capacity is 10 kW, it heats a room up to 100 m².

Gas boiler Ochag KSG-7 AT

Fuel consumption is 1.11 m³/h. The cost of the device is 11,000 rubles.

If you replace the burner jets, then liquefied gas can be used as fuel. The unit has a compact size, dimensions - 25x47x75 cm. Weight - 48 kg. Tank capacity - 18 liters.

KSG-7 E

Floor single-circuit gas boiler Hearth KSG-7 E, which is characterized by stable operation at reduced pressure in the gas supply pipes. It is small in size, has an attractive design, consumes fuel economically, efficiently heats houses up to 80 m² in size. The mass of the device is 37 kg.

The combustion chamber is open, there is no auto-ignition, and there is also no flame modulation. This model is inexpensive, but its functionality is very narrow.

Summing up all of the above, it is worth noting that Ochag gas boilers occupy a worthy place in the domestic market among the variety of heating appliances. A wide selection of models in terms of technical characteristics, appearance and price allows each user to choose the most optimal option. Owner reviews of Ochag boilers are mostly positive. Their effectiveness and ease of use are noted.

You can also pay attention to German, Japanese, Korean, Czech and Ukrainian gas boilers

What are parapet gas boilers

A parapet gas boiler is a compact boiler unit used for heating (single-circuit) and supplying objects with hot water (double-circuit).

In general, initially such models were developed as a non-volatile alternative to wall-mounted appliances, but unlike the latter, they are universal when choosing a place for installation, that is, they can be placed both on the wall and on the floor. The only condition is that it must be fixed to the outer wall of the room, preferably below the line of window sills.

The device and principle of operation of the equipment

In terms of functionality, parapet gas boilers are something between a classic atmospheric heat generator and an air convector.

This combination is achieved by modifying standard nodes:

- closed combustion chamber - completely isolated from the living space, which excludes any influence of smoke products on the internal microclimate;

- primary heat exchanger - has dissipating turbulators, which increase the passage time of air flows and prevent heat from escaping;

- air intake and smoke exhaust system - implemented through a short (from 25 cm to 53 cm) coaxial pipe, without complex elbows, wiring and insulation;

- sealed steel case - equipped with a viewing window for direct visibility of the flame of the burners, as well as convection holes, the so-called. ribs.

Schematic representation of the design and principle of operation of parapet models.

Schematic representation of the design and principle of operation of parapet models.

The principle of operation of parapet boilers is not quite typical: despite the closed combustion chamber, they function according to the natural air exchange (draught) scheme - street oxygen is supplied through the outer part of the pipe from below to the burner that heats the heat exchanger, after which the smoke is removed through the core of the pipe.

Under what conditions is it most appropriate to use such boilers?

Parapet models are used to organize a heating and hot water supply (DHW) system in buildings whose design does not involve the construction of a full-fledged chimney, as well as problems in power supply and other aspects: stable pressure, soft water and high-quality fuel.

However, it is necessary to take into account the power limitation in the range from 4 to 46 kW, i.e., according to similar indicators, “parapets” are seriously inferior to both wall-mounted and, moreover, floor-standing units. This means that it is reasonable to install them only in relatively small rooms (from 30 to 250 m2), such as private and country houses, trading floors, offices in the shopping center and, of course, high-rise apartments, in which they fit perfectly into the niche under the window sill in the kitchen.

The possibility of installing a parapet boiler in a wooden house

Almost any wooden house is allowed to be equipped with a parapet boiler: the exception is barracks and other old-style apartment buildings.

Installation is carried out according to the current rules of SNiP 42-101-2003:

- the unit is placed on an external wall, while an empty gap must remain outside - from 0.3 to 3.1 m (depending on power), without facade elements;

- the chimney outlet must not be carried out near or directly in enclosed spaces (hallways, attics, porches, balconies, loggias, etc.);

- the mounting wall is sheathed with fire-resistant material and covered with a sheet of steel so that there is a distance of 10–25 cm to difficult and easily combustible areas;

- porous wood, in order to increase fire safety, is prepared in advance for overlapping, treated with special mastics and impregnations in 2-3 layers.

Many companies still use asbestos to protect walls from fire, although today it is officially recognized as a material hazardous to health. Replace it with ceramic or silicate brick, GWP-plate, mineral wool, basalt insulation, foam, aerated concrete panel and even gypsum plaster.

Other Tips

The living room with the kitchen can be combined and decorated with various shortcomings.

It is important to calculate and anticipate everything in advance.

Designers and craftsmen share tips that will help you avoid problems during repairs and arrangements:

The result depends on how detailed the project will be. Oddly enough, it is worth considering the growth of loved ones and relatives. It is also advised to calculate the approximate number of possible guests.

You can get rid of the smell of food if you install a strong hood or ventilation system.

Small models are more suitable for housewives who cook little.

If a sleeping place is planned in the living room, then it is important that the ringing of appliances and other kitchen utensils is not heard. Silent dishwashers and other appliances will come in handy.

In addition, you can install a sliding door and install a soundproof partition. If there is sensitivity to ultraviolet light, the owners hang thick curtains made of opaque fabric.

If household appliances do not fit the direction of the interior, they are hidden behind furniture or put away in kitchen cabinets.

When installing fixtures and lamps are guided by several criteria

It is important that the light falls evenly throughout the space. Particularly bright lighting is preferred in the kitchen area and where the dining table is installed

In the living room, designers create a subdued atmosphere using wall lights and table lamps.Multi-level stretch ceilings with LED strip also look good in this room.

Moisture-resistant finishing materials are more durable and easy to clean. Thus, they retain their appearance for a long time.

The kitchen, combined with the living room, combines:

- personal tastes of the owners;

- reliable finishing materials;

- current design ideas;

- convenience;

- trends. The best photos of living room kitchen design

Rating of the best manufacturers

Gas double-circuit parapet boiler, which manufacturer is better, what to focus on. It is necessary to analyze the rating of parapet gas boilers, read reviews.

Imported parapet gas boilers. Among them, it is worth highlighting equipment with cast-iron heat exchangers, their advantage in reliability, power from 12 to 60 watts. They will be able to heat houses and apartments of a larger area. A distinctive feature of this kind of heat exchangers is their resistance to temperature extremes, mechanical deformation. So, the Electrolux company produces equipment that can withstand critical temperatures above 90 degrees.

It should be noted the quality products of such companies: Italian - Fondital, Beretta; Slovak - Alphatherm Beta, Attack; Hungarian - Alphatherm Delta.

Russian parapet gas boilers. Domestic manufacturers for the manufacture of equipment often use components from the CIS countries, the EU. These are cast-iron heat exchangers, sensors, controllers. Thus, while maintaining the quality characteristics, the final cost is reduced, up to about 15%.

Such products include: boilers "Titan N" (Ryazan company CJSC "Gaztekhprom"); "Lemax Leader GGU-ch" (Taganrog); Siberia KCHGO (CJSC Rostovgazoapparat).These models are distinguished by a wide range of equipment power. Manufacturers offer single-circuit, double-circuit boilers of various types.

It is worth noting the quality products of Russian companies Helios, Danko, Conord.

It can be concluded that parapet gas boilers are universal equipment for heating a house, which combines high quality indicators (efficiency of 93-95%) and optimal prices. They compare favorably with chimney models with an open gas chamber in that they do not require a separate room for the boiler room. At the same time, in comparison with turbocharged models, it is easier to operate. The advantageous side of this type of equipment is its autonomy from the power supply system. This makes it possible to install the boiler in an area where there is a risk of power outages.