- How to get started as a beginner welder

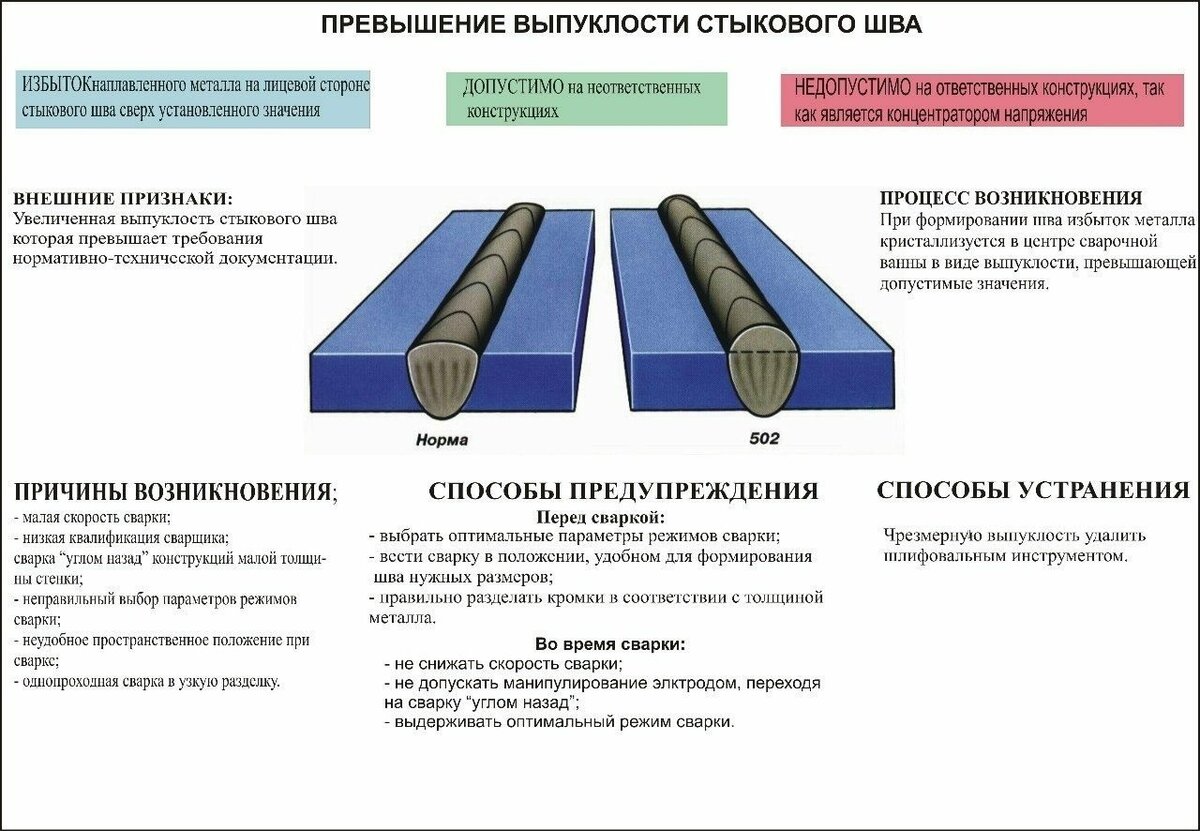

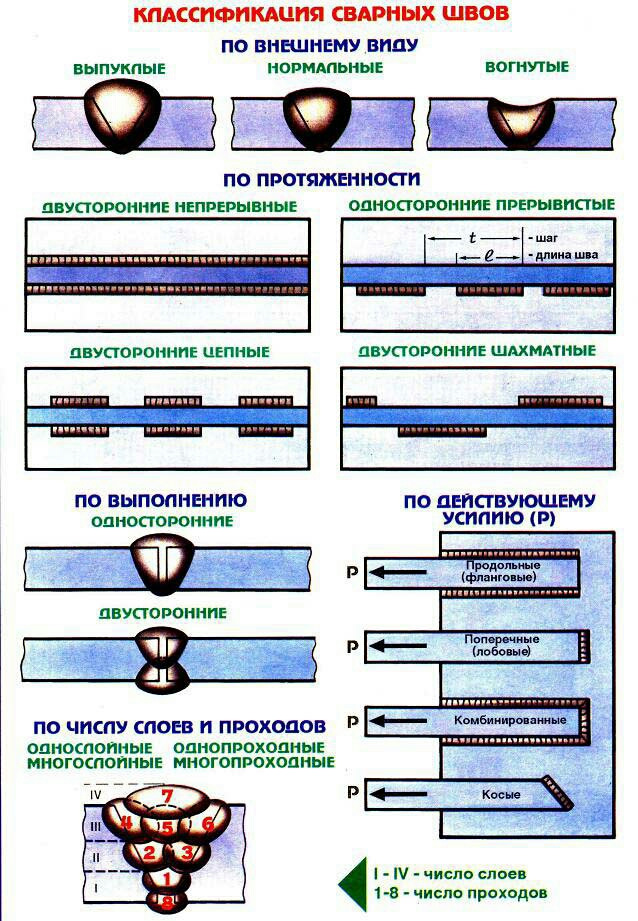

- Possible defects in welding joints and seams

- Electric welding technology

- How to light an arc

- Welding speed

- Welding methods

- Tip six

- What do you need for welding at home?

- What else do you need to have

- Welding elements

- The basics of electric welding

- Types of electric welding

- Welding technology

- Step-by-step instructions for welding with an inverter

- Tools and equipment

- Equipment types

- Tools and equipment

- Welding technology

How to get started as a beginner welder

Here is finally a welding inverter, a welder's mask and electrodes in front of you. This is not all that an experienced welder will need, but it is enough for a beginner to start. learn to cook with electric welding.

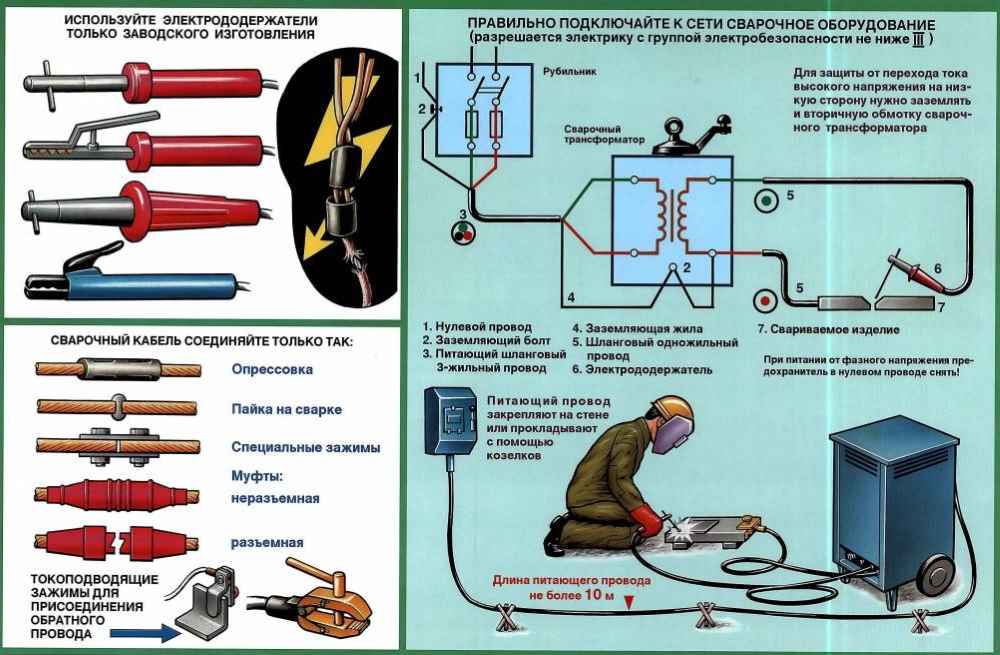

First of all, you will need to connect two cables to the inverter. One cable with an electrode holder, and the second with a ground terminal

Where it is better to connect which cable to the plus or minus of the inverter is not yet so important. You can learn more about direct and reverse polarity, gradually learning the basics of welding

Therefore, boldly, we connect the electrode holder to the plus of the inverter, and the clamp with ground to the negative connector, insert the electrode into the holder and try to cook. In this case, before igniting the electrode, properly adjust the welding current on the inverter.Just use the table with the parameters of the electrodes and welding current (see above), and then select the most appropriate value.

So, first you need to learn how to light an arc. This is done by lightly tapping the electrode on the metal or by slightly moving its tip over the metal. For beginners, it is preferable to use the second option.

It is not necessary to stick the electrode too hard into the metal, since it will definitely stick to the surface. As soon as the welding arc lights up, you need to keep it constantly burning while welding is in progress. In this case, the distance between the electrode and the metal surface should be about 2-3 mm (short arc).

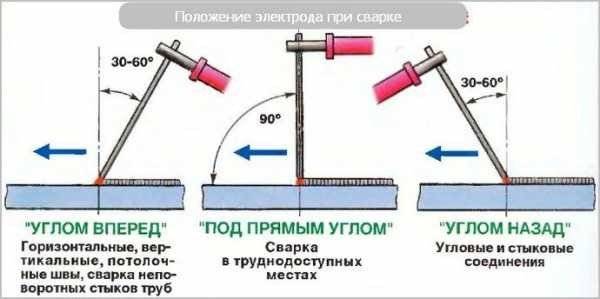

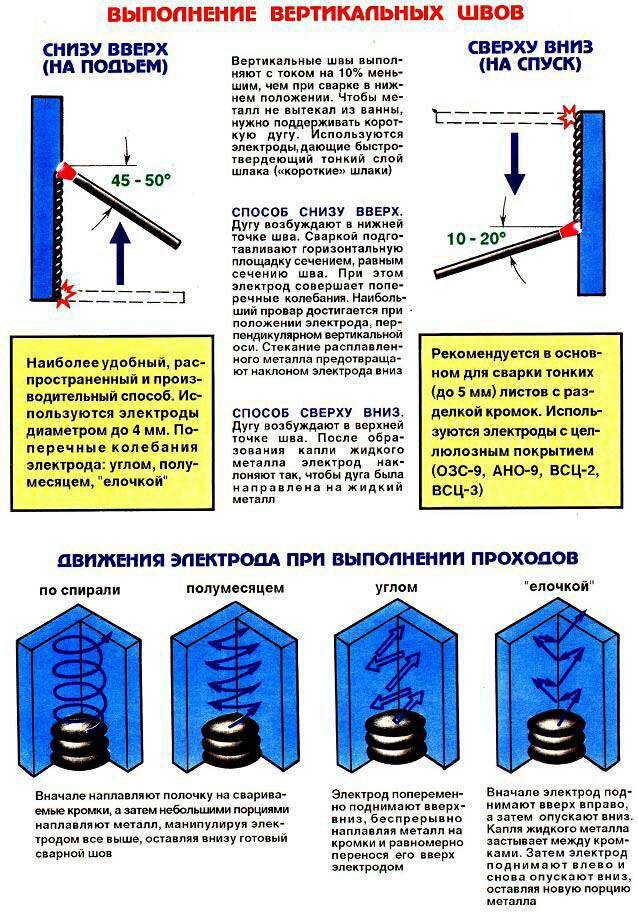

If everything worked out for you and the arc burns, you can try to weld the workpiece. To do this, tilt the electrode to the side and hold it at an angle of 40-60 degrees. Gently start moving the electrode from side to side along the joint. You can lead the electrode in various ways, but it is simply impossible to master everything at once.

Possible defects in welding joints and seams

Electric welding is a complex process and not always everything goes smoothly.

As a result of errors in work, seams and joints may have various defects, including:

- Craters. Small indentations in the weld bead. May appear as a result of an arc break or an error in the execution of the final fragment of the seam.

- Pores. The welding seam becomes porous as a result of the contamination of the edges of the parts with rust, oil, etc. In addition, porosity can appear when the seam is cooled too quickly, at high welding speeds and when working with wet electrodes.

- Undercuts. They look like small indentations on both sides of the seam bead.They appear when the electrodes are displaced in the direction of the vertical wall when welding corner joints. In addition, undercuts are formed when working with a long arc or if the welding current values are too high.

- Slag inclusions. There are pieces of slag inside the welding bead. This can happen if the edges are dirty, the welding speed is high, or if the welding current is too low.

These are the most common weld defects, but there may be others.

Electric welding technology

Electric welding is a process that occurs under the influence of high temperatures, above the melting of the metal. As a result of welding, a so-called weld pool is formed on the metal surface, which is filled with a molten electrode, thus forming a weld.

Therefore, the main conditions for the implementation of electric welding are to ignite the electrode arc, melt the metal on the workpieces to be welded and fill the weld pool with it. It would seem, in all simplicity, it is very difficult for an unprepared person to do this. First, you need to understand how quickly the electrode burns, and this depends on its diameter and current strength, and also be able to distinguish slag during metal welding.

In addition, it is necessary to maintain a uniform speed and the correct movement of the electrode during welding (from side to side), so that the weld is smooth and reliable, able to withstand rupture loads.

How to light an arc

Beginning the development of electric welding should be with the correct ignition of the arc. Training is best done on an unnecessary piece of metal, but it should not be rusty, as this will seriously complicate the task and may confuse a novice welder.

There are two simple ways to start an arc:

- By quickly touching the electrode on the surface of the workpiece and then pulling it up to a distance of 2-3 mm. If you lift the electrode from the metal above, the arc may disappear or become too unstable;

- Striking the electrode on the surface of the workpiece to be welded, as if you were lighting a match. It is necessary to touch the metal with the tip of the electrode, and draw it 2-3 cm along the surface (towards the welding site) until the arc ignites.

The second method of arc ignition is best suited for beginner electric welders, as it is the simplest. Also, short-term guidance on metal warms up the electrode, and then it becomes much easier to cook with it.

After ignition of the arc, it should be kept as close as possible to the surface of the workpiece, at a distance of no more than 0.5 cm. In addition, this distance must be kept approximately the same all the time, otherwise the weld will be ugly and uneven.

Welding speed

The speed of the electrode depends on the thickness of the metal being welded. Accordingly, the thinner it is, the faster the welding speed is, and vice versa. Experience in this will come with time, when you learn how to light an arc and begin to cook more or less. The pictures below show illustrative examples by which you can understand at what speed the welding was carried out.

If slowly, then the welding seam turns out to be thick, and its edges are strongly melted. If, on the contrary, the electrode is driven too fast, then the seam is weak and thin, as well as uneven. At the correct welding speed, the metal completely fills the weld pool.

In addition, when practicing welding, you need to monitor the correct angle of the electrode in relation to the metal surface.The angle should be approximately 70 degrees and can be changed if necessary. During the formation of the weld, the movement of the electrode can be longitudinal, translational and oscillatory, from side to side.

Each of these electrode leading techniques allows you to achieve the desired seam, reduce or increase its width, and also change some other parameters.

Welding methods

At the moment, there are many methods used for welding. They are divided according to various criteria. This information will be useful for a beginner, so you should definitely read it.

Depending on the heating, the edges of the product may completely melt or be in a plastic state. The first method also requires applying certain forces to the parts to be joined - pressure welding.

In the second, the connection is formed as a result of the formation of a weld pool, in which there is molten metal and an electrode.

There are other welding methods in which the product does not heat up at all - cold welding, or not brought to a plastic state - connection using ultrasound.

Methods and types of welding.

Other types of welding are listed below:

- Blacksmith.

In this method, the ends of the products to be joined are heated in a furnace and then forged. This method is one of the most ancient and is currently practically not used. - Gas press.

The edges of the products are heated by an oxygen-acetylene tribe over the entire plane and brought to a plastic state, after which they are subjected to compression.This method is highly efficient and productive. It is used in the construction of gas pipelines, railways, mechanical engineering. - Contact.

The parts are included in the electrical circuit of the welding equipment and current is passed through them. A short circuit occurs at the contact point of the parts, as a result of which a large amount of heat is released at the junction. It is enough to melt and connect the metal. - Butt, spot and seam - varieties of the contact method of fastening the product.

- Roller.

It is used in the connection of sheet structures that require high-quality and reliable seams. - Thermite.

The metal is held together by burning thermite, a mixture of iron scale powder and pure aluminum. - Atomic water.

The edges of the product are melted by the action of an arc burning between two tungsten electrodes. The electrodes are connected to special holders through which hydrogen is supplied. As a result, the arc and the liquid metal of the weld pool are protected by hydrogen from the harmful effects of atmospheric gases such as oxygen and nitrogen. - Gas.

The essence of the method is to use a flame to heat and melt parts. The flame is obtained by burning combustible gas in an oxygen atmosphere. The gas-oxygen mixture is obtained using special burners.

The gas welding method refers to fusion welding. The gaps between the products are filled with filler wire. This method is widely used in various areas of human life. Most often found when connecting thin-walled products, non-ferrous metals, cast iron.

When working with an inverter apparatus, the polarity of the electrodes is of no small importance.Depending on the scheme, the heating intensity of the part changes, which allows you to create different welding conditions

Tip six

Drunken sea knee-deep. Never weld while under the influence of alcohol. It is better to leave work than to do welding "drinking". This advice is relevant for Ukraine. I had to watch how a welder of the fourth category did a marriage after he was welding while drunk. The next day he couldn't believe his eyes. He denied that it was his job. If the design is responsible, then everything is much worse. In one construction firm, a welder, unable to perform a vertical seam, was sent to the site, where his tasks included the installation and installation of balconies and railings on them. Now imagine that most of the time he did this job while drunk. By the way, these skyscrapers are already inhabited by people, and the construction company has not existed for a long time.

What do you need for welding at home?

To carry out the work, you will need, first of all, a welding machine. There are several varieties of it.

Let's decide which one to prefer.

- welding generator. A distinctive feature is the ability to generate electrical energy and use it to create an arc. It will be useful where there is no power source. It has impressive dimensions, so it is not very convenient to use.

- welding transformer. The device converts the alternating voltage supplied from the mains into an alternating voltage of a different frequency, which is necessary for welding. The devices are easy to operate, but have significant dimensions and react negatively to possible power surges.

- Welding rectifier.A device that converts the voltage supplied from the mains into direct current, which is necessary for the formation of an electric arc. Differ in compactness and high efficiency of work.

For home use, an inverter type rectifier is preferred. They are usually referred to simply as inverters. The equipment is very compact. When working, it is hung on the shoulder. The principle of operation of the device is quite simple.

It converts high frequency current into direct current. Working with this type of current provides the highest quality weld.

The welding generator can work in the absence of a network. It generates electricity on its own. The system is very bulky, it is quite difficult to work with it.

Inverters are economical, they work from a household network. In addition, it is better to work with them for a beginner. They are extremely easy to operate and provide a stable arc.

The disadvantages of inverters include a higher cost than other devices, sensitivity to dust, moisture and power surges.

When choosing an inverter for home welding, pay attention to the range of welding current values. Minimum value - 160-200 A

Additional equipment features can make the job easier for a novice.

Of these pleasant "bonuses" it is worth noting:

- Hot Start - which means an increase in the initial current supplied at the moment the welding arc is ignited. Thanks to this, the arc is much easier to activate.

- Anti-Stick - automatically reduces the welding current if the electrode rod is stuck. This makes it easier to take it off.

- Arc Force - increases the welding current if the electrode is brought to the workpiece too quickly. In this case, sticking does not occur.

In addition to a welding machine of any type, electrodes will be needed. Their brand is best chosen according to a special table, which indicates the type of material to be welded.

You will also need a welding mask. The best thing is the one that is worn on the head. Models that you want to hold in your hand are extremely uncomfortable.

It is necessary to work with welding only in a protective suit. A special mask will protect your eyes from ultraviolet radiation and splashes, a tight suit and canvas gloves will prevent burns

The mask can be a simple tinted glass or the so-called "chameleon". The latter option is preferable, since when an arc appears, the glass is automatically darkened.

It is necessary to work only in special clothing that protects against splashes and ultraviolet radiation. It can be thick cotton overalls, boots or high boots, canvas or rubberized gloves.

What else do you need to have

A welding machine without electrodes is a completely useless unit. Electrodes are consumables, they are also different: consumable and non-consumable, metallic (made of steel, copper and other metals) and non-metallic, in the form of a wire or a rigid rod, with different protective coatings, etc.

For those who wondered how to properly weld with electrodes, it is best to start with steel universal rods 3 mm or 4 mm thick. The diameter is indicated on the package, it will not be difficult to choose the right ones. Having mastered the work with them, it will be possible to switch to other types, but they are unlikely to be in demand in everyday life.

Electrodes for inverter

In addition to consumables for welding, you will definitely need a welder's mask.It is absolutely impossible to work without it, otherwise you can quickly get a burn of the cornea of \u200b\u200bthe eyes and many other vision problems. The best are masks with chameleon glass. Or rather, with an automatic light filter that reacts to changes in illumination and protects the eyes from harmful radiation.

It is also advisable to get suitable clothing, shoes and gloves that are not burned by sparks and, in which case, can protect against electric shock.

From the tools you will need a hammer to knock the scale off the seam, as well as all kinds of vise, clamps and magnetic corners, with which you can fix the parts to be welded in the desired position.

Minimum set for a beginner welder

Welding elements

Having confidently mastered the basics of the welding process, you can proceed to connecting the elements into a single structure. And here, too, there are subtleties associated with the reaction of the metal to such an impact.

First of all, you need to correctly evaluate the length of the seam and ensure that it does not pull the parts to be joined at the joints. To do this, they must be fixed in a given position with the help of clamps or other methods. And to fix the fixation, they grab it with transverse seams in several places. And only then they scald.

The order of welding depends on the length of the joint. In one direction and in one run, only short seams up to 300 mm long can be welded. If this distance is greater, it is necessary to compensate for the resulting stresses by suturing in small segments.

Schemes for making seams depending on the length

Not too beautiful seams at the end of the work can be carefully cut and sanded with a grinder.

The basics of electric welding

Welded metal joints today are the most reliable: pieces or parts are fused into a single whole.This happens as a result of exposure to high temperatures. Most modern welding machines use an electric arc to melt metal. It heats the metal in the impact zone to the melting point, and this happens in a small area. Since an electric arc is used, welding is also called electric arc.

This is not quite the right way to weld)) At a minimum, you need a mask

Types of electric welding

An electric arc can be formed by both direct and alternating current. Welding transformers are welded with alternating current, inverters with direct current.

Working with a transformer is more complicated: the current is alternating, therefore the welded arc “jumps”, the apparatus itself is heavy and bulky. Still a lot of annoying noise, which emits during operation and the arc and the transformer itself. There is one more nuisance: the transformer strongly "sets" the network. Moreover, significant voltage surges are observed. This circumstance is not very happy with the neighbors, and your household appliances may suffer.

Welding technology

For an electric arc to occur, two conductive elements with opposite charges are required. One is the metal part and the other is the electrode.

When an electrode and metal of different polarity touch, an electric arc occurs. After its appearance, in the place where it is directed, the metal of the part begins to melt. At the same time, the metal of the electrode rod melts, being transferred with an electric arc to the melting zone: the weld pool.

How is a weld pool formed? Without understanding this process, you will not understand how to weld metal correctly (To increase the image size right click on it)

In the process, the protective coating also burns, partially melting, partially evaporating and releasing some hot gases. Gases surround the weld pool, protecting the metal from interaction with oxygen. Their composition depends on the type of protective coating. The molten slag also coats the metal, helping to maintain its temperature. In order to properly weld by welding, it is necessary to ensure that the slag covers the weld pool.

The weld is obtained by moving the bath. And it moves when the electrode moves. This is the whole secret of welding: you need to move the electrode at a certain speed

It is also important, depending on the required type of connection, to correctly select its angle of inclination and current parameters.

As the metal cools, a slag crust is formed on it - the result of the burning of protective gases. It also protects the metal from contact with the oxygen contained in the air. After cooling, it is beaten with a hammer. In this case, hot fragments scatter, therefore eye protection is required (wear special glasses).

You can read about how to make a brazier from a balloon or barrel here. Just get used to it.

Step-by-step instructions for welding with an inverter

First of all, for welding, it is necessary to have protective elements:

- coarse cloth gloves;

- welding mask with a special filter protecting the eyes;

- a rough jacket and trousers made of a material that does not ignite from sparks that appear during welding;

- closed shoes with thick soles.

The position of the electrode during welding.

Before you start welding with a welding inverter, you must take the necessary measures aimed at creating safe working conditions.

Proper preparation of the workplace is:

- providing the necessary free space on the table, all unnecessary items should be removed, but which can get splashed;

- creating high-quality lighting;

- it is necessary to carry out welding work while standing on a wooden deck that protects against electric shock.

Then the current is adjusted depending on the thickness of the parts and the electrodes are selected. The latter must be prepared. If they were only bought in a distribution network and their quality is beyond doubt, then this action can be skipped.

After preparing the electrodes, the mass terminal is connected to the product.

To obtain a high-quality and reliable metal connection, it must be prepared:

- rust is completely removed from the edges of the product;

- with the help of solvents, various contaminants are cleaned;

- at the last stage, the edges are checked for cleanliness, the presence of grease, paintwork and other contaminants is unacceptable.

Next, you need to connect the welding inverter. Training is best done on a thick metal sheet, forming a seam in the form of a roller. Make the first connection on the metal lying horizontally on the table. On it, draw a straight line with chalk along which the seam will go.

The electrical circuit of the inverter.

In the process, training on such an object can significantly improve the welding technique.

The welding process begins with the ignition of the arc.

There are two ways to perform this action:

- scratching on metal;

- tapping on metal.

The choice of method depends on the preferences of the person, the main thing when kindling is not to leave traces of welding outside the joint area.

After ignition of the arc, an arc is ignited from contact with the metal, the welder removes the electrode from the surface of the part for a short distance corresponding to the length of the arc and begins welding.

As a result, a welding seam is formed at the junction of two metal parts. It will be covered with scale - scale on the surface. It must be removed. This is very easy to do by tapping with a small hammer on the seam.

Tools and equipment

The technique of manual arc welding is relatively simple and is performed using specialized equipment and electrodes. You will also need auxiliary tools and protective equipment.

Equipment types

There are three types of devices that can be used for do-it-yourself arc welding:

- transformers. The principle of operation of such devices is based on alternating current. It should be noted that they are quite heavy, capable of causing sudden changes in voltage in the general electrical network and are very noisy. It is quite difficult to make an even seam on a transformer; only experienced welders can do it. But if novice craftsmen are trained in arc welding with the use of a transformer, then it will be much easier to work with other equipment;

- rectifiers. The operation of the devices is provided by semiconductor diodes. Units of this type turn alternating current into direct current. These are versatile devices. Almost all electrodes are suitable for them and welding can be carried out on different metals. Compared with a transformer, the welding process is much easier and the arc stability is maintained;

- inverters. They work almost silently. Easy to use due to compactness and automatic settings system.During operation, the device produces a high power direct current by converting the alternating current.

Among all devices, inverters are considered the best. They create a stable arc even during power surges and are multifunctional.

Tools and equipment

Before welding with electric arc welding, you must first prepare personal protective equipment and tools:

- apparatus for welding and electrodes to it. Those who are just learning welding skills should prepare more electrodes;

- auxiliary tools. The arc welding technique involves the removal of the slag that has arisen during welding, and for this you need a hammer and a brush for metal;

- protective outfit. Do not start welding without a special mask, gloves and protective clothing made of dense materials. It is not worth neglecting such means, since human safety depends on them.

If you are working with the device for the first time and want to learn how to properly weld by manual arc welding, it is recommended to pre-prepare training metal elements.

Welding technology

To date, the following types of electric arc welding are known:

-

Welding with a non-consumable electrode.

The tungsten (or graphite) rod used as an electrode does not melt, but maintains an electric arc. The weld metal is supplied in the form of wire or rod. This type of welding can also work without filler material, in the soldering iron mode.

-

Submerged arc welding.

An electrode that creates an electric arc is fed into the flux layer that covers the part.Thus, conditions are created for an ideal connection of metals, not subject to the destructive influence of air.

-

Semi-automatic arc welding.

The role of the electrode is performed by a metal wire to which an electric current is supplied. As it melts, an automatic feed occurs (so that the length of the arc is kept constant). At the same time, a shielding gas - carbon dioxide or argon - is injected to the welding site. As a result, the quality of the weld is significantly improved.

At home, these types of welding are practically not used. Therefore, let's move on to the consideration of the fourth type of welding - manual arc welding.

Manual arc welding is based on the use of a special electrode in the coating

Electric welding machines for manual welding are divided into two types - AC and DC. The use of alternating current makes it possible to design devices of high performance and power. The advantage of direct current, due to the lack of polarity reversal, is a smoother seam with less metal spatter.

Subsea pipeline repair

The operation of the welding machine is based on the creation of an electric arc at the point of contact between two metal parts. High temperature (up to 7000o C) melts the material to a liquid state and diffusion occurs - mixing at the molecular level.

The fundamental difference between welding and gluing is the absence of auxiliary materials - the parts to be joined turn into a monolithic structure.

Therefore, it must be clearly understood that only homogeneous metals can be used for the correct application of welding. You can't weld aluminum to iron or copper to stainless steel.The melting point of different materials is different, and the creation of alloys is not included in the range of possibilities of welding equipment.

For welding iron structures, there are various welded machines.

-

Transformers. They are used to convert mains current with a voltage of 220 V into a current with the parameters necessary to create a high-temperature electric arc. This happens due to a decrease in voltage (no more than 70 V) and an increase in current strength (up to thousands of amperes). Today, such devices are gradually becoming a thing of the past, as they are too bulky for domestic use and consume a large amount of electricity. In addition, the operation of the transformer is not stable and negatively affects the state of the network as a whole - when turned on, voltage drops are created, sensitive household appliances suffer. There are one and three phase.

-

Rectifiers.

They convert the alternating current of the consumer network into direct current. The principle of operation of such devices is based on the use of rectifying silicon diodes, which are also called valves. A characteristic difference between a DC welding machine and an AC welding machine is the strong heating of the electrode at the positive pole. This makes it possible to control the welding process: to carry out “gentle welding”, by manipulating the settings, significantly save electrodes when cutting metal.

-

Inverters.

For quite a long time (until 2000) they were not available for widespread use in everyday life due to their high cost. But later they gained great popularity. The principle of operation of the inverter is to convert mains alternating current into direct current, and then again into alternating, but already high-frequency current.The difference between this scheme and transformer welding is that the arc obtained from the converted direct current is more stable.

The main advantage of inverter welding is the improvement in the dynamics of the electric arc, as well as a significant reduction in the weight and dimensions of the installation (compared to direct transformers). In addition, it became possible to smoothly adjust the output current, which significantly increased the efficiency of the unit and ensured the ease of ignition of the arc during operation.

But there are also disadvantages:

- temporary restrictions in use, which is associated with heating of the electronic conversion circuit;

- creation of electromagnetic "noise", high-frequency interference;

- the negative influence of air humidity, which leads to the formation of condensate inside the device.

a good article for a welder really liked a lot of useful things said.