- Tips

- How to connect a metal-plastic pipe with a polypropylene

- Installation steps and soldering features

- Manual welding technology for polypropylene pipes

- How to weld a pipe from polypropylene using a welding machine

- The specifics of soldering polypropylene pipes

- General description of technology

- Soldering Machines for Pipe Welding

- Polypropylene Welding Procedure

- Stage two. Welding of polypropylene pipes

- Welding Machine Manufacturing

- Accessories for polypropylene pipes

- How to choose a soldering iron for welding plastic pipes?

- SAFETY REQUIREMENTS DURING WORK

- Formula for calculating pipe diameters

- Butt welding of polypropylene pipes

- Socket welding of polypropylene pipes

- About cold welding technology

Tips

It’s not enough not to make mistakes, you also need to take into account the welding tricks that professional installers have developed over the years. Conventionally, they can be divided into "life hacks" for the choice of materials and tools, and useful tips for work.

How to choose pipes:

- Make it a rule that thin-walled pipes can only be used for cold water and decorative items. To work with hot water, you should choose only reinforced thick-walled ones. For ventilation, pipes marked with PHP are needed.

- Products with fiberglass as a reinforcing layer are universal.They are suitable for beginners who are just learning how to use a soldering iron and last up to 50 years. You should not be led by consultants' stories about the best quality of aluminum pipes.

- The appearance of the pipes can also say a lot. If the product has a uniform color, an even round cut and smooth walls inside and out, it is of high quality. If the coloring is spotted, the cut is not round, and the walls are rough, the product will fail during operation.

- The tube needs to be sniffed. Only pipes made from low-grade raw materials have a characteristic pungent smell of plastic. The product made of high-quality propylene almost does not smell.

- The pipe must enter the fitting tightly and only when it is hot. If there is a gap between the walls of at least a millimeter, this is a marriage.

- All components must be purchased from the same manufacturer.

There are many more tricks of welding and installation. They come with experience, and each master has his own techniques. But there are some general tips.

So, every master knows that soldering iron nozzles are processed with a special solution in production. It protects the tool from negative environmental influences before use. The protective layer evaporates when you first turn on the soldering iron with nozzles. Evaporation produces a characteristic odor and light soot. Therefore, you need to run the device on the street for the first time and let it warm up until it completely evaporates. Only then start soldering.

The second secret concerns the treatment of pipes and a soldering iron with a degreaser. It is better to choose pure alcohol. It evaporates quickly and leaves no odor inside the pipes, unlike acetone and thinner.

If the ambient temperature is close to zero, it is necessary to slow down the cooling of the joint.To do this, use napkins made of warm fabric.

Wipe the parts with a lint-free cloth. Inside the soldering iron nozzle, it will smolder.

For a double pipe circuit (hot water and cold), it is preferable to place the hot circuit above the cold one. This will prevent condensation from forming on the pipes. It is possible to connect parts at the transition points from horizontal to vertical only at an angle of 90 degrees.

If you follow these recommendations, the installation will be successful, and communications from polypropylene pipes will last for several decades.

How to solder polypropylene pipes, see the following video.

How to connect a metal-plastic pipe with a polypropylene

Due to various circumstances, it happens that it is necessary to connect various types of pipes, for example, PPR and steel, metal-plastic with polypropylene, and so on. Such situations happen in apartments where it is difficult to change the section of the common water supply or heating riser, laid with a steel or metal-plastic pipe, but you need to connect to it. This is not a big problem, you just need to consider that all such connections are made through threaded fittings.

Since the connection of metal-plastic pipes can be carried out with press and collapsible fittings, it is more convenient to take a detachable fitting with an external thread for joining with polypropylene. In turn, a fitting with an external thread is soldered to the end of the polypropylene pipe, after which the connection is twisted in the traditional way, with flax or fum tape winding.

Split fitting for connecting pipes

When you need to crash into metal-plastic pipes, then it is most convenient to put a tee with a threaded outlet, where you can later screw the fitting, and then solder the polypropylene pipe to it. True, you will have to tinker with the installation of the tee: you need to turn off the water or empty the heating system, and then cut the metal-plastic and install it.

Installation steps and soldering features

Strict observance of all stages of creating a pipeline is necessary; this is the only way to get a reliable system.

Before installing pipes, it is necessary to calculate and mark places for fastenings and designate complex nodes

The procedure is as follows:

A high-quality tool has heat regulation, and a stable stand

It is convenient to weld pipes with such a soldering iron, and with minimal care it is safe

Long industrial pipelines, technological systems, and heating systems that use large diameter pipes are usually connected to each other using special equipment necessary for uniform heating of the connected segments. This is how polypropylene pipes are welded, the machine controls the heating temperature automatically.

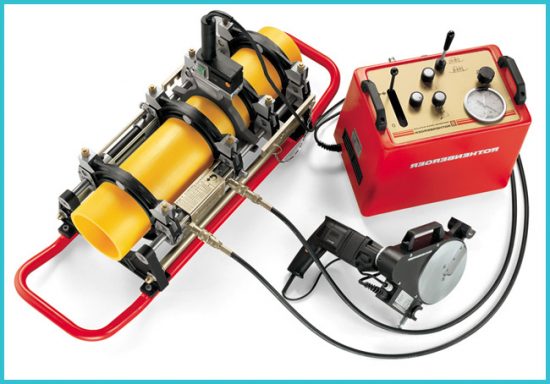

A special machine is used for welding pipes of large diameters using the "butt" method.

It is customary to weld the pipeline line end-to-end, and in the presence of a mechanical welded complex, the connection is very strong.

Components of a stationary automatic welding complex:

- support frame on which all components are mounted;

- mechanical saw for trimming pipes;

- automatic grippers for pp pipes;

- internal self-leveling liners for secure fixation of pipes;

- electronic temperature control unit;

- heating element.

Manual welding technology for polypropylene pipes

In order to weld PP pipes, it is necessary to stock up on the necessary equipment and components. First of all, a detailed project is drawn up, an assembly option is determined, and a decision is made on how to weld a polypropylene pipe with fittings and the counterpart of the pipeline. Based on the configuration and geometric shape of the future pipeline, welding for a polypropylene pipe is also determined, which is better suited for a particular project and will not entail an increase in the construction estimate. The number of swivel fittings, branch tees and couplings and the installation procedure are calculated, it is also the order of welding polypropylene pipes.

During installation, it is possible to adjust the pipe layout, but due to the ease of connection, this does not cause any particular problems.

Manual welding of polypropylene pipes does not require a large supply of tools and special skills. Exact adherence to the assembly sequence makes it possible to create a reliable plumbing or heating system that is sealed throughout.

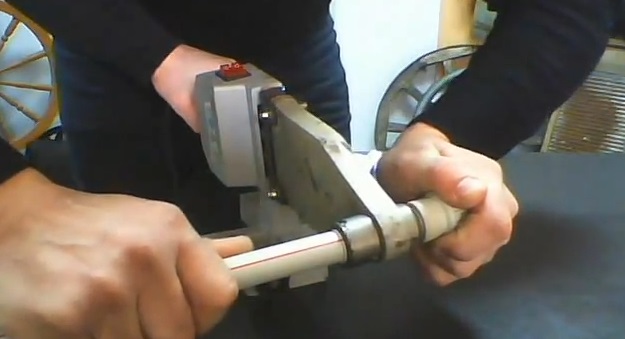

Manual pipe welding is carried out using a compact heating device

Tools and equipment:

- scissors or cutter for plastic pipes. Preferably guillotine-type scissors, with a powerful blade and a toothed force transmission unit;

- tool for stripping reinforced pipes made of PP. It is a special cutter, and in its primitive form - a durable knife with a comfortable handle and a short blade;

- it is advisable to use alcohol components for degreasing the surface. As a rule, ethyl (isobutyl) alcohol is used.Acetone, which is very common as a degreaser for paints and varnishes, is not suitable for PP pipes - it simply destroys the surface, makes it loose and fragile;

- a soldering iron for polypropylene pipes is a surface heated to a selected temperature (at least 260 degrees Celsius) - a mandrel - on which nozzles for pipes and fittings are attached. Soldering irons are tubular and in the form of an elongated hammer. It is more convenient to weld pipes in hard-to-reach places with a tubular soldering iron;

- an ordinary construction tape measure will help to avoid overspending of materials. Correctly measured length of the site will minimize the number of undercuts and fittings;

- a template in the form of a short piece of pipe of a larger diameter. The length of the template must exactly correspond to the depth of the pipe entering the fitting. It is better and more convenient to use a template with a bottom. Butt welding does not require the use of templates.

If the technology for welding a polypropylene pipe for heating is correctly observed, then after the weld has cooled down, an even, neat bead is formed, which is the same in height along its entire length.

How to weld a pipe from polypropylene using a welding machine

The sequence of actions when working with a mechanical welding machine is slightly different from working with a manual soldering iron. The technology for welding polypropylene pipes in automatic mode is similar to manual soldering, except that the stripping (trimming) of the pipe occurs with a mechanical saw, and mechanical clamps provide clamping of the pipes at the soldering point. The process is called butt welding of polypropylene pipes.

Control of the heating temperature level when welding polypropylene pipes and automatic shutdown of the heating element is provided by the control system unit.

Butt welding of a polypropylene pipe using an automatic unit takes a minimum of time, and is of high quality seam joints. Accurate polypropylene welding temperature pipes - another advantage of the automatic system

For heating systems, this is important, but the cost of professional equipment is quite high. But this problem is solved simply: you can rent the necessary devices

The specifics of soldering polypropylene pipes

PPR is made of polymeric material. It is thermoplastic, easy to melt at a temperature of 149 ° C, and retains its properties when cooled. Due to this, when heated, polypropylene pipes are easily joined, forming monolithic nodes of a single complex of communication systems. They are widely used in the construction of sewerage, drainage systems, and are also suitable for heating and water supply.

General description of technology

The soldering of polypropylene pipes is based on the principle of simultaneous melting with the help of a welding machine, the upper part of the pipe and the inner part of the coupling. After removing the heated parts from the heater of the soldering machine, they are joined to each other by compression.

At the confluence of the heated surfaces of the joined parts, an interpenetrating bond of molten masses occurs, forming a single monolithic unit during cooling. This method is called the coupling connection.

The method of welding PPR of one diameter is called direct (butt).It is based on the same principle of melting the edges of the pipes with their subsequent joining and fixing in a fixed position until it cools completely. The quality of direct welding depends on the exact alignment of the axes of the joined PPR.

The process of soldering polypropylene pipes with your own hands.

Soldering Machines for Pipe Welding

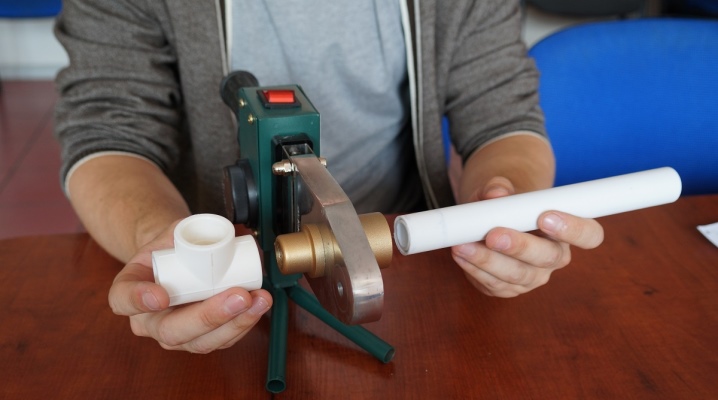

There are many varieties of soldering machines for PPR welding. Their technical design and dimensions depend on the diameters of the PPR with which they interact and the availability of auxiliary equipment.

Soldering machines are divided into:

- machine tools (with guides for centering the axis);

- bell-shaped ("Iron");

- butt.

For carrying out welding and installation work during the construction of a pipeline from PPR, you will also need:

- pipe cutter or scissors for polypropylene pipes;

- metalwork corner;

- pencil or marker;

- roulette;

- doorman;

- trimmer;

- alcohol-based surface cleaner (avoid acetone, solvents and products that leave a greasy, oily residue);

- work gloves.

Complete set for welding of polypropylene pipes.

Polypropylene Welding Procedure

When performing PPR welding, it is necessary to observe the duration of heating of the parts. The wall of the part should not be strongly heated, but underheating also has a bad effect on the quality of the joints. The table reflects the amount of time sufficient to warm up the parts. The recommended soldering temperature is 260°C.

| Pipe section diameter, mm | Welding depth, mm | Heating duration, sec | fixation, sec | Cooling period, min |

| 20 | 13 | 7 | 8 | 2 |

| 25 | 15 | 10 | 10 | 3 |

| 32 | 18 | 12 | 12 | 4 |

| 40 | 21 | 18 | 20 | 5 |

| 50 | 27 | 24 | 27 | 6 |

For soldering pipes you need:

- Install nozzles on the soldering machine heater.

- Install the soldering machine in a place convenient for work, fix it with fasteners (if any), set the temperature controller to the required level and turn on the power.

- Prepare parts for welding.

- Treat the surfaces of the parts to be welded with a cleaning, degreasing agent.

- Measure the welding depth from the edge of the pipe and mark with a pencil. After putting the parts on the heater nozzles and keep the time indicated in the table.

During heating, do not allow the part to rotate around its axis, rotation worsens the tightness of the connection of the brazed parts. The heated parts must be removed from the heater and immediately docked by inserting one into the other.

When deepening (entering) the pipe into the coupling (fitting), it is impossible to turn it along the axis and cross the welding depth level marked with a pencil. It is necessary to fix the achieved position of the parts and not move them during the time necessary for the reverse polymerization.

To achieve the desired position when joining a pipe with a corner bend, both parts should be marked in advance by drawing a guide with a pencil at the junction. This will avoid rotation of the bend and achieve the required angle relative to the pipe axis without correction.

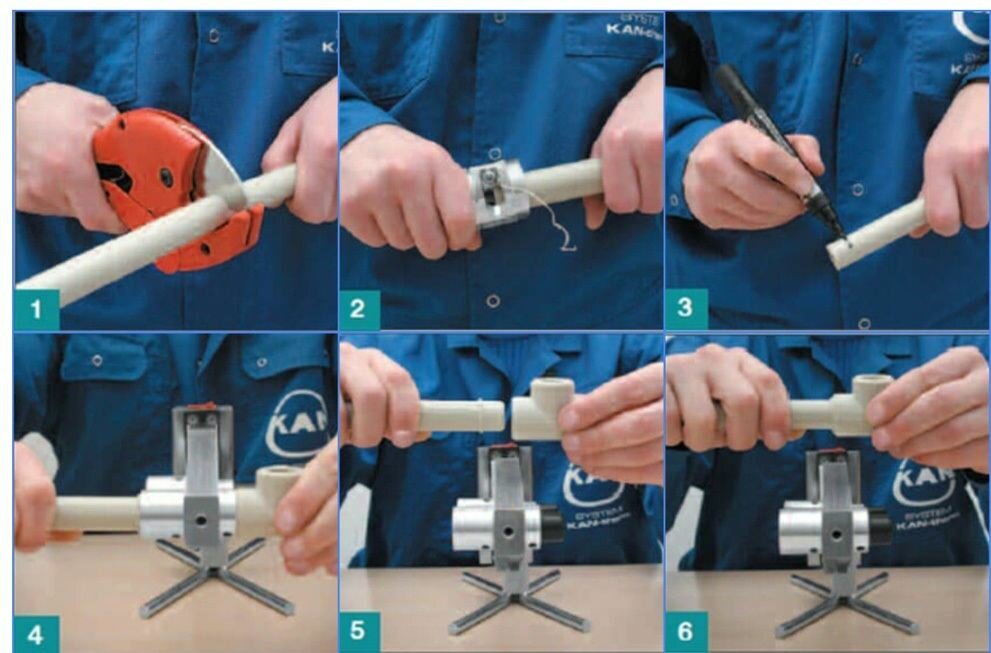

Stage two. Welding of polypropylene pipes

Welding of polypropylene pipes

This procedure will require an electric jigsaw (cutting polypropylene) and special welding equipment.

Welding machine

Step one. While the apparatus is warming up, the necessary measurements are taken, the pipes are marked and cut.

Scissors for cutting polypropylene pipes

Step two. The ends of the products that are planned to be interconnected are carefully cleaned and degreased.

Step three.Using a pencil, the depth of entry of each product into the sleeve is marked. It is characteristic that at the same time there should be at least a millimeter gap, so the pipes do not abut against the coupling of the fitting.

Errors when welding polypropylene pipes butt

Step four. A PP pipe with a fitting is put on the sleeve in accordance with the marks made, and the heating of all elements must occur simultaneously.

The duration of heating depends not only on the diameter of the products, but also on the depth of welding (this can be found in the table below).

Technological pause table

Step five. After a certain period of time, the products are removed and connected, with little effort, sitting on each other. It is forbidden to rotate the elements along the axial line.

The process of welding polypropylene pipes

Step six. Within a few seconds after the connection, the primary adjustment is performed, then the elements are finally fixed.

Welding of polypropylene pipesWelding of polypropylene pipes

If there are no gaps left at the junction, then it (the connection) can be considered of high quality.

Welding Machine Manufacturing

Since more or less good welding machine costs over a thousand rubles, it is cheaper to rent it or do it yourself. If the latter was chosen, then for work you should prepare:

- thermal paste for computers;

- iron of the old model;

- bolt, washer to it;

- electric drill;

- sleeve (nozzle) of the desired diameter.

The sequence of actions should be as follows.

Step one.In order to improve heat transfer, the sole of the iron is treated with thermal paste, then a Teflon sleeve is fixed. The location of the latter is determined in advance - the wide part up or down.

Step two. A sharp “nose” is sawn off for more convenient work near the walls.

Step three. The heating of the iron is carried out until the device switches off a second time.

Step four. It is good if the iron is equipped with a temperature sensor - this will allow you to accurately determine the heating temperature. But there is an easier way - through lead. This metal melts at 230ᵒС and higher, which approximately coincides with the temperature required for welding.

Further soldering technology is identical to that described above.

Accessories for polypropylene pipes

For the installation of water pipes from plastic pipes, various components are used. Their assortment is very extensive and amounts to dozens of positions in the price lists of manufacturers. Details differ in shape, size and purpose. Consider the most common types of such elements.

A large number of components are available for polypropylene pipes.

When buying them, it is important to choose parts from the same manufacturer as the pipes. Couplings

The simplest connecting piece. The shape resembles a small barrel, the inner diameter of the hole of which exactly matches the cross section of the connected pipes. The element is designed to connect two pipe sections

Couplings. The simplest connecting piece. The shape resembles a small barrel, the inner diameter of the hole of which exactly matches the cross section of the connected pipes. The element is designed to connect two pipe sections.

Adapters. These parts are designed to connect pipes of different diameters.Outwardly, they are very similar to couplings, but their main difference is that the inner diameter of the two opposite ends of the element is different.

Adapters are selected according to the diameter of the pipes to be connected and come in various sizes. Parts are produced with internal or external threads, designed to switch to threaded connections.

corners. As you know, polypropylene pipes cannot be bent. Therefore, in order to perform the rotations required during installation, the manufacturer produces special connecting parts bent at an angle of 90° and 45°.

Corners can end with holes for pipes or have threads, both internal and external. For example, such parts are used for mounting a mixer. Moreover, they can be both double and single.

Some home craftsmen argue that there is no need to complicate and use corners. After all, polypropylene is plastic and can be bent. They heat the pipe to softening temperature and bend it the way they want.

Indeed, it is very easy to bend a part, but you need to understand that unpleasant changes occur in it: the wall on the outside of the bend becomes thinner. This will significantly reduce the life of the pipe and lead to its breakthrough.

The shut-off ball valve made of polypropylene is installed in the water supply system by soldering

Crosses and tees. This is the name of the elements designed to connect three or four pipes at the same time, which is often required for the installation of a water supply system. They are produced in a variety of variations: with different hole diameters, with fittings for pipes of other types, for example, for metal-plastic or copper, with internal and external threads of various sizes.

Contours.This is the name of specially molded bends that are used to circle the pipe around some small obstacle. At the same time, it is desirable that the distance from the pipeline to the wall be minimal. The bypass is welded into the gap in the section of the water supply so that the pipe sections lying before and after it are straight.

In addition to these components, other items are also available. Among them are plugs used to block unnecessary branches of the water supply system, special ball valves for polypropylene pipelines.

To fix the pipes to the wall, special clips are used, which are selected according to the diameter of the part. Can be single or double. Experts advise choosing pipes and components from the same manufacturer. So there will be fewer problems during installation, and the system will turn out to be of better quality.

For PP pipes of all sizes, a wide range of fittings is produced, allowing you to quickly install a plastic circuit and, if necessary, connect it to metal branches

How to choose a soldering iron for welding plastic pipes?

All devices for mounting polymer pipelines are divided into mechanical and manual types. Mechanical - designed for soldering ends with a diameter of more than 50 mm or used in situations where you need to make an effort to tightly fit the ends. This is a support frame, supplemented with an instrument block and a hydraulic unit, with half-ring grips on the sides.

In the middle of the grips, special inserts are installed, corresponding to the outer circumferences of the elements to be welded, which help to better center the inserted pipes and distribute the pressure on them. Mechanical soldering irons are equipped with rotating disks to align the ends.Heating of pipes is carried out by a metal disk.

Mechanical soldering iron for welding polypropylene pipes

Mechanical soldering iron for welding polypropylene pipes

A hand soldering iron for connecting plastic pipes resembles small household electrical appliances. The most common option was the iron for welding. Its design includes: a heating plate, a thermostat and an ergonomic holder. The plate has holes for welding elements of different diameters, into which the ends of the pipes are inserted. Hand soldering irons are designed for pipes less than 50 mm.

Hand soldering iron for welding polypropylene pipes

Hand soldering iron for welding polypropylene pipes

SAFETY REQUIREMENTS DURING WORK

3.1. Obey the rules of the internal labor regulations, other documents regulating the issues of labor discipline. 3.2. Perform only the work for which training has been completed, instruction has been received on labor protection and to which is admitted by the person responsible for the safe performance of work. 3.3. Do not allow untrained and unauthorized persons to work. 3.4. Work in the established overalls, safety shoes, properly use personal protective equipment. 3.5. Use serviceable equipment, tools, use them only for the work for which they are intended. 3.6. Keep the workplace clean and free from clutter. 3.7. When performing work, observe the accepted technology for soldering products. 3.8. During the welding of polypropylene pipes, it is forbidden: - to move the parts in the direction of the axis, to try to correct their position immediately after connection, because this leads to a decrease in the flow area at the welding site; - during cooling, change the shape of the pipe by bending it. 3.9. Use correct tools and fixtures. 3.10. Use centralizers, monitor their serviceability. 3.11.Use certified pipes and fittings. 3.12. A ladder should be used to lower a worker with a soldering iron for polypropylene pipes into a trench or pit. 3.13. Welding installations must be disconnected from the mains while moving to a new workplace. 3.14. It is forbidden to repair cables without disconnecting from the mains. 3.15. Do not weld outdoors in snowy or rainy weather. 3.16. Do not leave welding equipment unattended during operation. 3.17. The tie-in of the gas pipeline is carried out using a saddle outlet with a built-in cutter. 3.18. Do not touch heating elements, moving or rotating parts of accessories. 3.19

During thermistor welding, pay special attention to the integrity of the embedded heating element in order to avoid the explosion of the fitting. 3.20

During welding, it is forbidden to be directly near the fitting. 3.21. When performing work on existing polyethylene gas pipelines, it is necessary to ground strands of cotton fiber soaked with water, as well as abundantly moisten the surface of pipes and the soil near grounding with water in order to avoid the occurrence of a charge of static electricity. 3.22. At workplaces, install a soldering iron for polypropylene pipes on fire-retardant stands that prevent it from falling. 3.23. Products and technological equipment heated during operation should be placed in places equipped with exhaust ventilation. 3.24. Products for soldering with a soldering iron for polypropylene pipes are laid in such a way that they are in a stable position. 3.25.Keep foreign objects and tools at a distance from moving mechanisms. 3.26. It is forbidden to smoke at the workplace, eat at the workplace. 3.27. Do not use random objects (boxes, boxes, etc.), equipment and fixtures for sitting. 3.28. Comply with the rules of conduct on the territory of the enterprise, in production, auxiliary and amenity premises. 3.29. If you feel unwell, stop work, notify your supervisor and consult a doctor.

Formula for calculating pipe diameters

Products are classified according to their patency. The diameter inside determines how much water the pipe can pass in a certain period. The outer diameter does not matter for calculating the patency, but it and the thickness of the walls determine the reliability and ability to contain fluid pressure. For a rough calculation of the required diameter inside, a simple formula has been developed: Qcommon = PI x V.

In some cases, it is better to solder the pipes first, and then bring them to where they will be installed.

In it:

- Qcommon – the amount of peak water consumption;

- The number of PIs is 3.14;

- V is the speed of movement of the liquid through the pipeline.

The value of V is taken for a large, thick element of one and a half to two meters per second, for a thin one - 0.7-1.2. The difference is that a smaller setting corresponds to a larger surface/clearance ratio. In a thin pipe, most of the transported liquid will slow down against the walls. Plastic pipes with a diameter of 10-25 mm are selected according to a small value of speed, with a diameter of 32 mm or more - according to a larger value of V.

With regard to the plumbing system, this means a minimum loss of fluid friction against the walls of the pipeline.An accurate calculation of the ratio of diameter and patency is important when a project is being created for the entire water supply system of a high-rise building. If you apply a diameter less than required, then in the evening, during rush hour, the upper floors will sit without water. Of course, you always want to play it safe and take a pipe wider, more than the calculated diameter. However, we should not forget about savings: the larger the diameter, the higher the price. The cost of the finished project is always calculated individually.

Soldering plastic pipes is not a particularly complicated process, but if you don’t have the skills to work with a soldering iron, it’s better to turn to the masters.

Butt welding of polypropylene pipes

When soldering products from PP end-to-end, the ends of the parts are heated with a hot tool until they are melted. Then the elements are pressed with force until the seam cools. This technology is distinguished by its simplicity.

In this case, there is no need to use additional devices. If everything is done correctly, a fairly reliable seam is obtained, not inferior to the strength of the pipe. The technological operation is performed in a certain sequence:

For all its simplicity, butt welding only seems so accessible. In practice, this requires solving several problems, which is almost impossible to do at home.

The pipes must be exactly aligned along their axis, while a deviation from the wall thickness of only 10% is allowed. The pressure on the parts that press the cylindrical products to the plane of the heating mirror when exposed to high temperature should only be applied for a certain time. This is the only way to get a quality connection.When performing trimming, it is necessary that the end face has a perfect perpendicularity.

The conditions listed above are quite difficult to follow without an additional device - a special centralizer. It is equipped with an electric drive that creates a certain compression force. In addition, this device is equipped with a trimmer.

In other words, in order to butt weld small diameter polypropylene pipes, you will need more special equipment than the previous connection method. Considering the fact that when welding a socket, a better joint is obtained due to the locking connection, home craftsmen prefer to use this particular method of combining pipes.

Butt welding of PP products is mainly used in production, when it is necessary to connect large-section structures during the installation of a straight section of an engineering structure from cylindrical products.

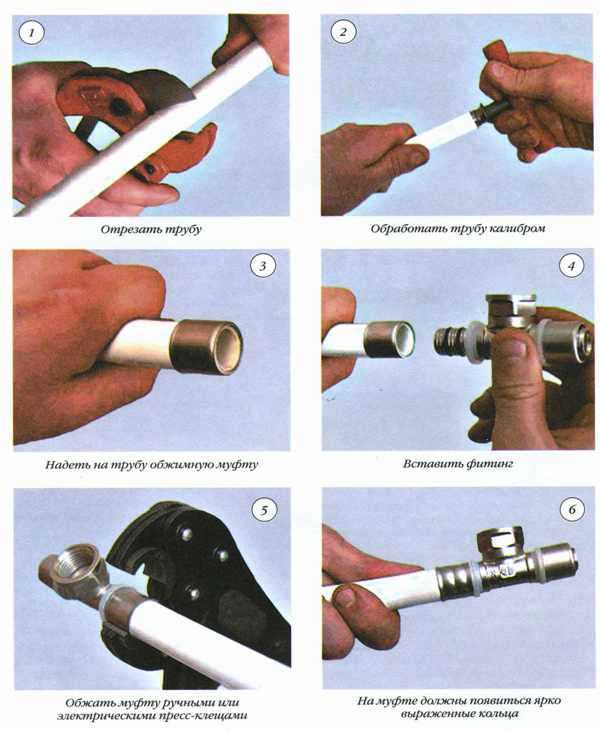

Socket welding of polypropylene pipes

The main method of mounting plastic, when you need to connect small cylindrical products of different sections, is the use of a socket. When welding a PP structure, additional parts are required:

- corners;

- tees;

- taps.

All of them are made from the same material from which the pipes were made. The use of additional elements to create a high-quality connection is not considered a disadvantage of this method. The details under consideration, in addition to the connecting function, help to change the direction of the pipeline.

This process consists of several operations:

- the mating surfaces are melted: the outer wall of the cylindrical product with the inner part of the fitting;

- special heating parts are used;

- cooling of the assembled elements takes place.

According to professionals, the socket joint is considered much more reliable than butt welding. Due to the fact that when combined, the pipe enters the fitting with force, high strength is created. In this case, the alignment does not require the use of a special tool. Even a beginner can combine cylindrical structures in this way.

About cold welding technology

This welding method involves the use of so-called aggressive glue. It is simpler than the previous one. Almost all work is done independently, without assistants.

- Pipes and fittings must be prepared as if it would be necessary to carry out work for reinforced polypropylene products. First, we apply a mark on the surface of the structure corresponding to the correct arrangement of the elements.

- Glue is applied to the parts involved in the connection process. They need to be pressed against each other very quickly and quite strongly. The coupling is processed in the same way.

- In the desired position, we fix the pipes with our own hands for literally fifteen seconds.

- You need to turn on the water one hour after the end of the process. Until the specified time has passed, the system must remain absolutely motionless. Video tutorials presented on our website will add clarity to the explanations.

Video 5. Soldering a PVC pipeline with a minimum set of tools