- Error related to water and dirt on the connected products

- PVC soldering secrets and safety measures

- Connection of pipes by soldering with reinforcement

- Drawing a wiring diagram

- Welding instruction

- Training

- Heat

- Welding

- Cleanup

- Important additions

- Stages of work welding process

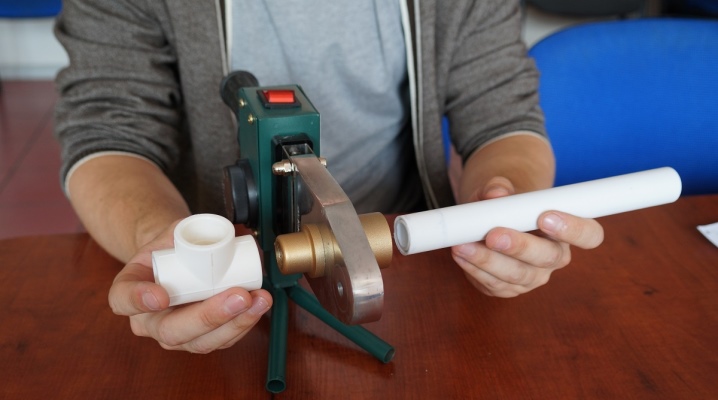

- Preparing the Welding Machine

- What is the welding process?

- Common questions and answers for soldering polypropylene

- Effect of errors on welding quality

Error related to water and dirt on the connected products

A professional installer must wipe down all parts to be fastened before starting work to remove surface contaminants. You should also thoroughly wash the floor in the room where the welding is performed, because the pipes are placed on the floor, and dirt can again get on them. When dismantling a broken pipe, you can often find a clear trace of dirt along the entire length of the connection.

The rest of the liquid in the pipe can be fatal for the connection. A few drops during heating turn into steam, the material is deformed and loses its reliability. To remove liquid from the pipe, it is necessary to stuff crumpled bread crumb into it or push ordinary salt. After completion of work, the pipe must be thoroughly rinsed.A connection made with such flaws can remain reliable even during pressure testing, but after a certain period of time (often even a whole year), a leak will appear anyway. This error occurs when brazing stabilized pipes if the foil was carelessly removed from the intermediate layer. Even a tiny piece of foil at the point where the individual parts are fastened together will significantly degrade the quality of the installation.

Not only products, but also a soldering iron should be clean. The master needs to remove particles of molten polypropylene from the heating elements of the equipment in a timely manner, otherwise they may get to the next section of the structure.

PVC soldering secrets and safety measures

Soldering work should be carried out in a room with positive temperature. It must be taken into account that the colder it is, the longer the elements will warm up. However, there are a number of other rules that must be observed.

Features of soldering PVC pipes:

- The power of the iron should be 1200 watts.

- The manual device is used for pipes with a diameter of up to 32 mm. For large sizes, professional equipment is used.

- Before starting work, the device must be warmed up for 5-10 minutes. This is necessary for the device with nozzles to reach the desired parameters.

- After soldering, it is forbidden to scroll the connection. Otherwise, it may violate the integrity of the seam. You can only straighten the distortions so that the connection does not leak.

- No need to apply a lot of force to compress the parts. Otherwise, the gap will be filled with hot plastic and disrupt the patency.

- No gaps between the pipe joint and the inside of the fitting are allowed. Otherwise, leaks will occur under pressure.

- The soldered area must be completely cool before use.

- After completion of work, the iron is cleaned of plastic. So on the device there will be no carbon deposits, and the elements for soldering will not be damaged.

Use a flat wooden stick for cleaning. So the teflon will not be damaged. Metal objects can scratch the surface and make the nozzle unusable, because the plastic will begin to stick to the coating.

The soldering machine should be placed in such a way that it is stable.

When working with power tools, it is important to observe safety precautions. Otherwise, you may get burned or injured. Work with protective gloves

The room must be clean and dust-free. Otherwise, the particles will settle on the plastic and disrupt the quality of the soldering.

You need to work with protective gloves. The room must be clean and dust-free. Otherwise, the particles will settle on the plastic and disrupt the quality of the soldering.

The soldering iron is placed horizontally on the surface. During operation, it is forbidden to turn off the equipment. Work begins when the iron is fully heated. In modern models, this is indicated by an indicator. For old-style options, wait 20 minutes.

The soldering of polyethylene pipes does not have a complex technology. Welding may have features if you solder reinforced products

However, it is important to take precautions. Soldering pipes correctly will help the basic secrets and rules. It also follows with accuracy follow instructions

Also, follow the instructions exactly.

Also, follow the instructions exactly.

Connection of pipes by soldering with reinforcement

Consider, how to solder reinforced polypropylene pipes. Here it is mandatory to remove the protective material.The presence of a reinforced layer (aluminum foil) in the pipe structure requires additional heating. But that's not the point.

Usually such products have an increased diameter and do not fit standard soldering iron nozzles. They need to be cleaned before the soldering process. The exception is pipes reinforced with fiberglass. They solder as standard.

Given the variety of technologies for reinforcing polypropylene pipes, various processing methods are used before soldering. Traditionally, a seamstress is used for stripping.

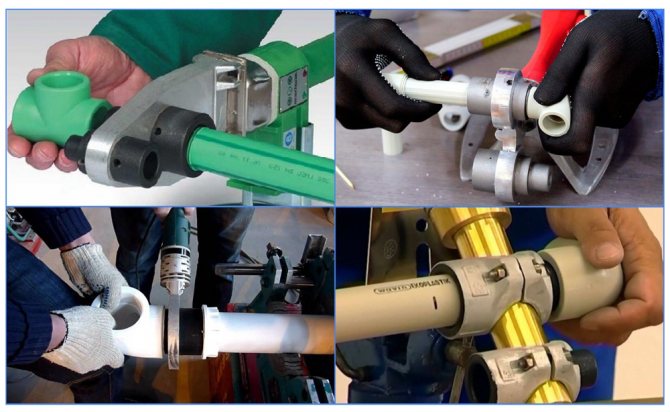

Image gallery

Photo from

Schweier - a tool for the preparation of reinforced PP pipes

Removing the two outer layers

Polypropylene pipe prepared for soldering

Processing before soldering non-reinforced PP pipe

This name has a special device in the form of a metal sleeve with knives. The porter is put on the end part of the pipe to be soldered, and with rotational movements around the axis of the pipe, the reinforced layer is scraped off to clean plastic.

If the reinforced layer is located in the middle part of the plastic pipe wall, it is more reasonable to use another tool for processing - a plastic pipe trimmer.

Another device is a trimmer, which is necessary for welding reinforced pipes. As a rule, the facer is used on pipes, the wall structure of which contains a reinforced layer in the central area.

The fixture is not much different from a doorman, with the exception of the placement and design of the cutting elements. After processing with a trimmer, the end part of the pipe is aligned along the end, plus a part of the reinforced layer is cut out to a depth of 2 mm around the entire circumference. This treatment allows soldering without defects.

This is interesting: Gas welding work - step by step instructions for replacement of heating batteries

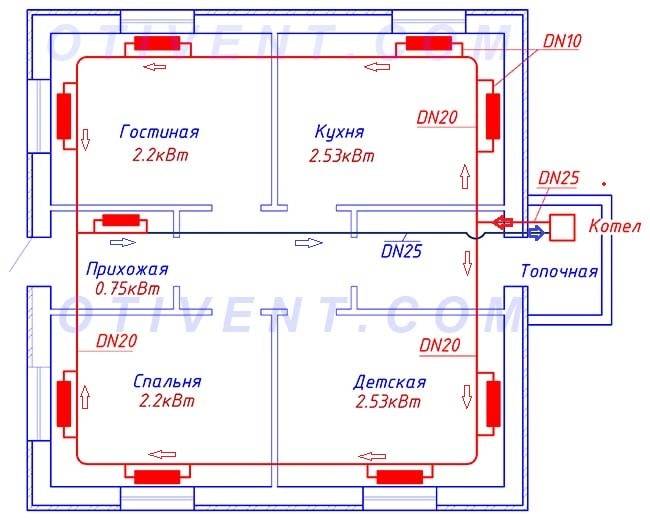

Drawing a wiring diagram

At the stage of laying pipelines and connecting plumbing equipment, you need to have a heating and plumbing project on hand. If the wiring diagram has not yet been developed and the diameters of the mains have not been determined, we recommend that you first familiarize yourself with selection guide heating system of a private house.

Before purchasing and welding polypropylene elements, transfer the circuit to real conditions:

- Mark the contours of the radiators or install all heaters in advance.

- Mark with a pencil or marker on the inner surfaces of the walls the mounting points for water outlets, taps, distribution manifolds and other fittings.

- Using a long rail and a building level, connect the marked points with lines along which pipes are planned to be laid.

- By branching and turning pipelines, find out the need for fittings - tees, couplings and bends.

After drawing projections on the walls, it is easy to calculate how much plumbing materials will be needed - just measure the length of the lines with a tape measure. Don't forget the plastic clips for attaching the pipes.

When purchasing fittings and pipes, take note of a number of recommendations:

- plastic pipes are soldered by immersing each end inside the shaped element to a depth of 14-22 mm (depending on the diameter), which means that the length of each straight section increases by 3-5 cm;

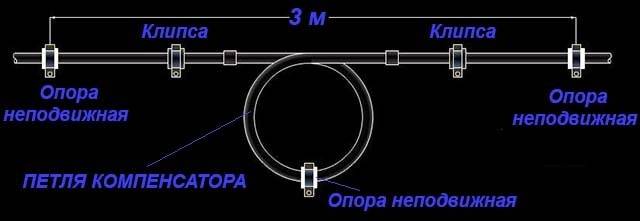

- in the heating and hot water system, polypropylene lengthens due to heating, therefore, in order to avoid bends in the lines, you need to purchase special fittings - compensating loops;

- to cross other pipelines, use bypass elements made of PPR;

- for hot water supply and coolant supply, take pipes reinforced with aluminum foil, basalt and fiberglass.

Compensation loops are placed on long lines or risers fixed by a fixed support (for example, they connect 2 metal pipes of neighboring apartments). Without elongation compensation, the PPR pipe will in both cases bend like a saber as a result of the heat.

Welding instruction

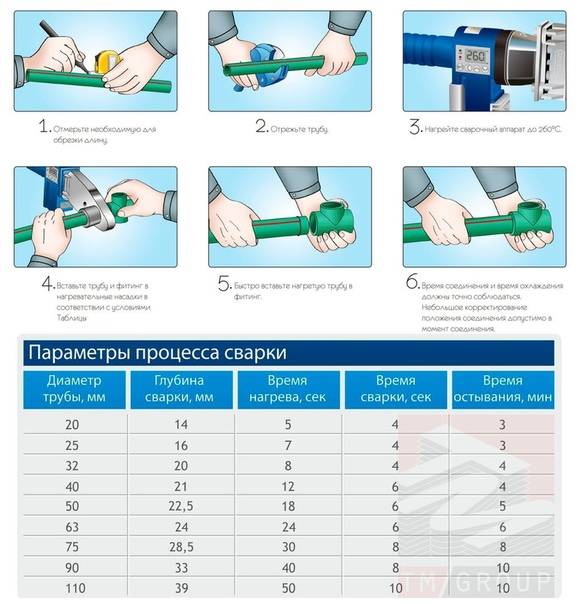

In domestic conditions, the soldering of polypropylene fittings and pipes into a single structure is most often performed by the thermal polyfusion method. After heating with a special device, the pipes are quickly connected. Works, in accordance with the technology, are carried out in stages.

Training

At the preparatory stage, design documentation is developed, in which the selected pipeline scheme is necessarily indicated. The places of fixing the system to the walls are correctly determined, and, if necessary, the required number of mounting holes is punched with a construction tool.

It is necessary to mark and then cut polypropylene pipes into individual elements in strict accordance with a pre-prepared scheme, as well as full-scale measurements. Such a simple event will allow you to verify the accuracy of the markup.

Pipe sections laid out on the most even surface should repeat the correct sequence of connections. The foil parts are removed from the ends with a trimmer, after which the depth of entry into the fitting is marked with a marker at the selected ends.

Heat

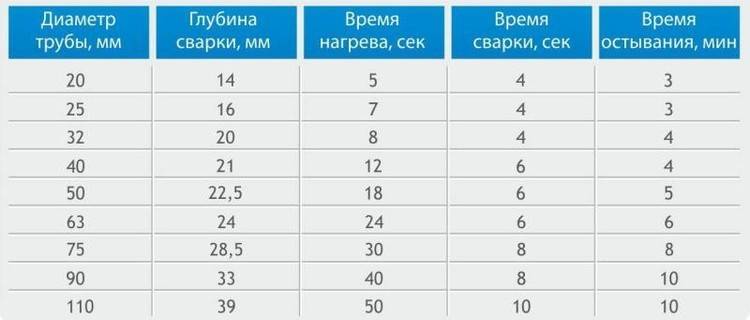

The operating temperature of the heater on the soldering device must be selected depending on the technical characteristics of the pipes.The process of brazing pipelines with aluminum reinforcement should be carried out at nozzle temperatures in the range of 260-300 ° C.

The soldering equipment used in the work must reach the temperature of the desired value before welding, so the thermostat is set to the appropriate position, and the plug of the device itself is plugged into the electrical outlet.

The readiness of the welding machine for welding polypropylene is signaled by switching on the device of a special backlight. On different models of equipment, the options for alarm notifications are different. In order not to be mistaken in the rules for operating the device, you need to carefully study the instructions supplied by the manufacturer.

Welding

Proper operation is the simultaneous heating of the end of the polypropylene pipe and fitting with a soldering device. In this case, the fitting used is located on a special nozzle mandrel, and the pipe is inserted into the sleeve with little physical effort. The depth of entry must be monitored without fail in accordance with the marker marking applied to the PPR pipe.

| Diameter (mm) | Welding depth (mm.) |

| 20 | 14,0 |

| 25 | 16,0 |

| 32 | 20,0 |

| 40 | 21,0 |

| 50 | 22,5 |

| 63 | 24,0 |

| 75 | 28,5 |

| 90 | 33,0 |

| 110 | 39,0 |

The standard heating time of all connected elements is selected depending on their diameter. It is necessary to combine polypropylene pipes and fittings quickly enough, thereby preventing temperature losses of the heated material. Docking of elements is carried out by means of an even translational movement without rotation.

The connected structure of the pipeline section should be securely fixed until the moment when the joined polymer elements reach the maximum strength indicators. As practice shows, the system seizes within 10-20 seconds (depending on the D of the pipe).The ideal option is to maintain a fixed position until the joint area has completely cooled.

| Diameter (mm) | Cool down time (sec.) |

| 20 | 3 |

| 25 | 3 |

| 32 | 4 |

| 40 | 4 |

| 50 | 5 |

| 63 | 6 |

| 75 | 8 |

| 90 | 10 |

| 110 | 10 |

Cleanup

After all welding work is completed, and the material in the joints has completely cooled down, the joining areas are carefully cleaned from natural plastic sagging. Such an event allows you to give welded structures a neat and aesthetic appearance.

A sharp knife can be used for this purpose, but stripping must be done very carefully. It should be remembered that an excessive amount of polymer material may well prevent a tight fit of the pipeline elements into the fastening clips.

Important additions

Of course, only special devices should be used for welding polypropylene pipes, and in domestic conditions, simple hand-held equipment with a minimum number of standard nozzles will be the best option.

Some manufacturers install two heaters in one device at once, which are equipped with separate switches. There is no need to use both heaters at the same time, because the plastic can overheat and overload the electrical network.

Today, the best, well-established brands of devices for welding polypropylene pipes (according to experts and users) include: Candan Сm-03, Elitech SPT-1000 and Elitech SPT-800, Wester DWM-1500, Prorab 6405-K, BRIMA TG-171 and Gerat Weld 75-110.

Read also:

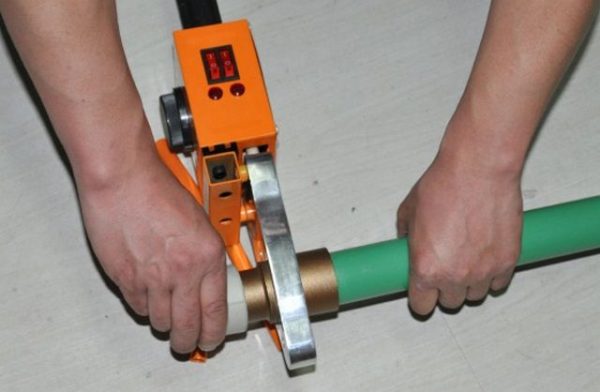

Stages of work welding process

Having measured the required length of the pipe, make a mark on it with a marker. With a pipe cutter or scissors, cut the product at an angle of 90º to the axis.The tool must be sharp enough so that the pipe does not deform.

The pipe is cut at an angle of 90º to the axis

The edge of the reinforced product must be cleaned, getting rid of the top layer and foil. Without this stage, the aluminum foil, which is part of the pipes, will come into contact with the liquid during operation. As a result, corrosion of the reinforced layer will lead to a violation of the integrity of the seam. Such a connection will leak over time.

The edge of reinforced pipes is cleaned

For non-reinforced products at the end of the pipe, the depth of welding is indicated, focusing on the length of the fitting sleeve. Another important point in preparing pipes for welding is degreasing the surface. Treatment of the junction with alcohol will provide more reliable contact of the parts.

Preparing the Welding Machine

Before welding plastic pipes, it is necessary to prepare the welding machine. The handheld device is fixed on a flat surface. Machine parts must be clean and free of defects. Clean them with a cloth soaked in alcohol. The heating elements are put on when the tool is off. A mandrel is used to fuse a fitting, a sleeve is used to fuse a pipe.

The heating time of parts for welding is determined according to the table

Then the device is connected to the network. At the same time, the indicators located on the unit body should light up. One of them signals that the device is connected to the network. The second, after reaching the required heating temperature, should go out. After the indicator goes out, it is desirable that five minutes pass and only then begin the welding process. This time depends on the ambient temperature and lasts from 10 minutes to half an hour.

What is the welding process?

After heating the apparatus, put the fitting on the mandrel, and insert the pipe into the sleeve. This is done at the same time and with little effort.

After heating the device, put the fitting on the mandrel, and insert the pipe into the sleeve

In order to know how to properly weld polypropylene pipes, it is necessary to take into account the heating time. The correct period will allow the parts to warm up to the required temperature and not melt. It depends on the diameter of the pipe.

After the required period of time, the parts are removed from the apparatus and connected. In this case, the pipe must enter the fitting strictly up to the mark. During this process, it is forbidden to rotate the parts along the axis.

In the process of connecting parts, it is prohibited to rotate products along the axis

After joining the parts, mechanical impact on the seam is not allowed until it has completely cooled down. Subject to technology, the result should be a strong and tight seam.

The article gives the necessary recommendations on how to properly weld pipes, with a detailed description of each stage. By putting these tips into practice, you can independently conduct a pipeline for water supply or heating. The main thing is to choose the right pipes and follow the process technology. Only then the polypropylene pipeline will serve for a long time and uninterruptedly.

Cast iron has not been used in modern water supply and heating systems for a long time. It was replaced by light, easy-to-install and non-corrosive plastic. Today we will talk about welding polypropylene pipes with our own hands for beginners - the main stages of this process and its intricacies.

Common questions and answers for soldering polypropylene

Is it possible to solder pipes of one manufacturer, and fittings of another? Of course it is possible, but I want to warn you that both couplings and pipes should be of good quality. Not

it is worth using parts from unnamed manufacturers. In non-professional stores, pipes of different companies are often sold, and the fittings are the same, from an unnamed manufacturer. I don't

I recommend using this link. In general, nothing prevents soldering pipes and fittings from different manufacturers, with or without different reinforcement on opposite sides of the coupling.

Can polypropylene pipes be bent? You can not bend them, neither during installation, nor after. If there is a need to bend the pipe during installation, then you should use bypasses or

corner combinations. In fairness, it should be noted that the weak point of the pipeline for bending is the junction of the pipe and fitting. This conjugation point breaks off at some

breaking force. To verify this, it is enough to solder a trial construction from a corner and two pieces of pipe 50 cm each, and try to break this “poker” with your hands.

Sometimes there is a need to solder a knot with a non-standard angle. Let me remind you that only two types of PP corners are printed: 90 and 45 degrees, at least they are different for me

did not meet. But what if you need to turn the pipe of a different degree? There are two methods that I know of:

With the help of two 45 ° corners, you can make any angle by changing the angle of rotation of the corners relative to each other. The disadvantage of this method is that due to non-standard

rotation, the connection will not be in the same plane.

The second way is to misalign the pipe and fitting at multiple connections.Do not forget that the straightness at the junction of the pipe and fitting should not deviate

more than 5°.

How to solder pipes if the crane does not hold? It is strictly forbidden to weld if water is present in the area to be soldered. If, for any reason, it is completely blocked

water fails, you need to stop it for the duration of welding. On the Internet, it is advised to plug the pipe with a bread crumb, but the problem is that the crumb immediately squeezes out the newly created

pressure in the pipe. Therefore, the method will work only when it is possible to open the area to the place of soldering for air to escape. And when the pipes are soldered, the crumb is easy

pops up when pressure is applied.

Tip: if during welding you could hear the hiss of water on the nozzle, it is better to cut the knot and redo it! It is better to spend extra time during installation than to correct and eliminate

flow in the future, with a bunch of crawled out problems!

In this photo, you can see that the plug is unscrewed at the filter and excess water flows down the rag from there. And in the place of soldering, a bread crumb is plugged.

Thanks to the open filter, we had a little over a minute to complete the soldering before the water squeezed out the crumb.

Actually on this I propose to end the presentation of information. I plan to expand the list of common questions about soldering polypropylene pipes over time.

Rate this post:

- Currently 3.86

Rating: 3.9 (22 votes)

Effect of errors on welding quality

Slow, carefully thought-out actions are a guarantee against mistakes that can nullify all the work. All the details of soldering technology should be taken into account and not deviate from them even a step.

Common mistakes, as a result of which defective nodes of the installed propylene water supply network appear:

- The pipe surface has not been cleaned of grease.

- The cutting angle of the mating parts is different from 90º.

- Loose fit of the end of the pipe inside the fitting.

- Insufficient or excessive heating of the parts to be soldered.

- Incomplete removal of the reinforced layer from the pipe.

- Correction of the position of parts after setting of the polymer.

Sometimes on high quality materials, excessive heating does not give visible external defects. However, internal deformation is noted when the molten polypropylene closes the internal passage of the pipe. In the future, such a node loses its efficiency - it quickly becomes clogged and blocks the flow of water.

An example of a soldering defect resulting from erroneous actions. The master overheated the plastic pipe, which, in turn, was deformed from the inside

If the cut angle of the end parts differs from 90º, at the moment of joining the parts, the ends of the pipes lie in a beveled plane. Misalignment of parts is formed, which becomes noticeable when a line several meters long has already been mounted.

Often, for this reason, you have to redo the entire assembly again. Especially when laying pipes in strobes.

Poor degreasing of the articulating surfaces contributes to the formation of "rejection islands". At such points, polyfusion welding does not occur at all or occurs partially.

For some time, pipes with a similar defect work, but at any moment a rush can form. Also common are errors associated with a loose fit of the pipe inside the fitting.

A common mistake when soldering polypropylene pipes is the loose entry of the end of the pipe into the socket. The pipe must enter to the border of the rim or marking line

A similar result is shown by joints made with incomplete cleaning of the reinforcing layer. As a rule, a pipe with reinforcement is placed on high pressure lines. Residual aluminum foil creates a non-contact zone in the soldering area. This is where leaks often occur.

The grossest mistake is an attempt to correct soldered elements with scrolling around the axis relative to each other. Such actions sharply reduce the effect of polyfusion welding.

However, at some points, a spike is formed, and the so-called "tack" is obtained. With a small force to break, the "tack" holds the connection. However, one has only to put the connection under pressure, the soldering will immediately fall apart.