- Soldering copper pipes with your own hands: how to solder copper pipes?

- Solders for soldering copper

- Gas torches for soldering

- Rules for the safe operation of equipment

- How to solder pipes

- Methods for soldering copper parts

- Features of high temperature compounds

- Brazing

- Safety precautions when soldering copper pipes

- Soft soldering instructions

- Fastening copper pipes with other materials

- Myths about copper piping

- How to choose the right solder?

- High pressure binding crimp connections

- Method #4: Push-connect connection

Soldering copper pipes with your own hands: how to solder copper pipes?

There are two types of soldering copper pipes:

- low temperature;

- high temperature.

Using the first method, as a rule, household communications are mounted. Soft solder is suitable for this method, it can be copper (with an admixture of phosphorus) wire with a cross section of 2 mm, tin or lead with additives, soft solder with silver.

Soldering yourself, with little skills, will not be difficult.

Soft solder has a lower melting point than copper, so as long as you take precautions, you can safely get to work.

First of all, you should prepare the flux, since it cleans the metal from oxides and protects the soldering site from oxygen access. Flux treats the end of the pipe and the connecting part, in this case a fitting.

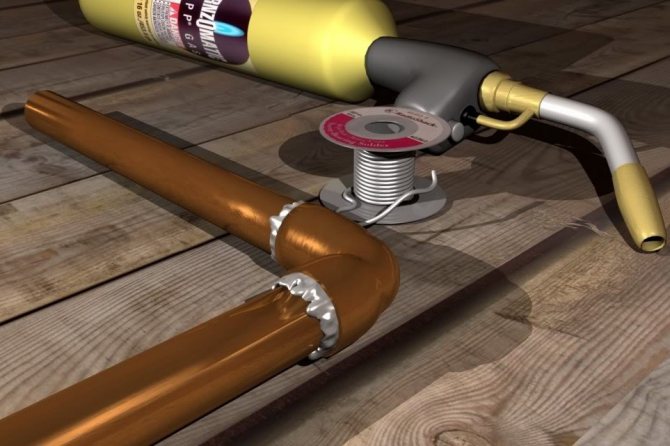

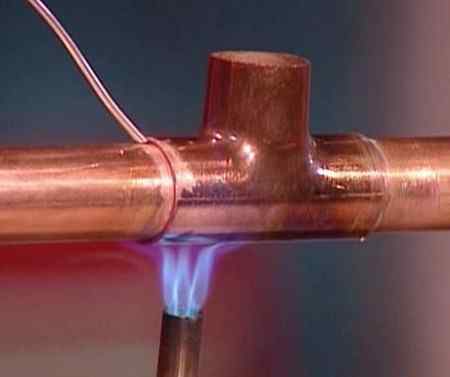

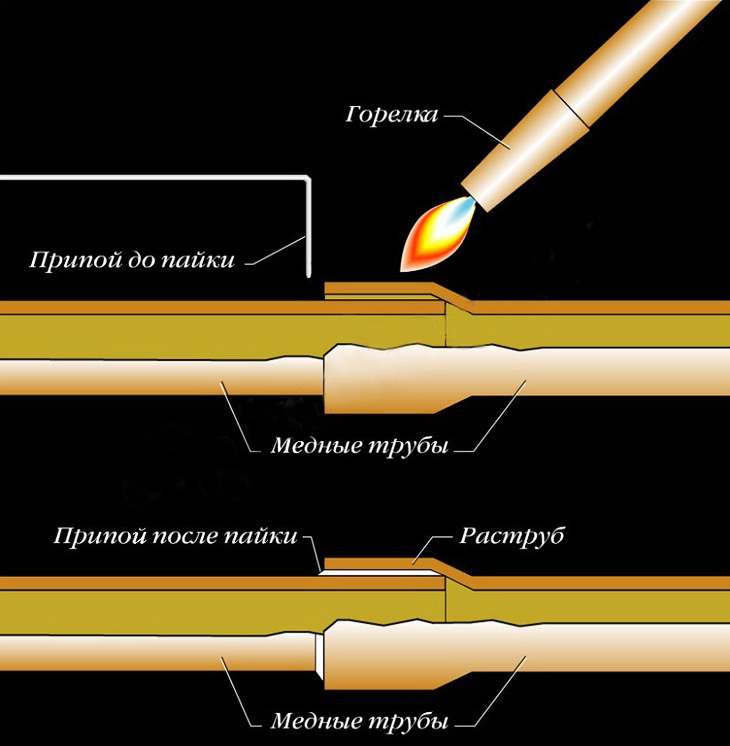

Next, the pipe is connected to the fitting, and the junction is heated with a gas burner or soldering iron. During heating, the solder melts and in a liquid state penetrates into all free cavities of the joint. The solder should be evenly distributed over the joint and the pipe with the fitting should be set aside until it cools.

Hard soldering is performed in the same sequence, but with a higher solder heating temperature.

Solders for soldering copper

The construction market offers several options solder for soldering copper pipes. There is an opinion that soft solders, consisting of tin with various additives, cannot ensure the reliability of solder joints. Despite the fact that this is not entirely true, you can play it safe and choose solder with the addition of silver.

For high-temperature soldering, hard copper-phosphorus solder is intended, which provides greater reliability of soldering. High-temperature soldering is used when joining pipes of main pipelines, where pressure drops are acceptable.

Gas torches for soldering

Starting the independent installation of the pipeline, it is necessary to choose the right tools and equipment for soldering copper pipes, paying special attention to the burner. The burner can be:

The burner can be:

- Propane (used, most often, in large volumes of work).

- With MAPP mixture (Methylacetylene-Propadien-Propane gas mixture).

- Acetylene.

- Oxygen.

Gas burners can be equipped with removable disposable cylinders or with a hose connection to a stationary cylinder.

For the installation of a small pipeline, a model with a removable gas tank is sufficient.

That's all you need to know about the features of soldering copper products. Having the necessary equipment and materials for soldering copper pipes, you can independently mount a home pipeline that will last for many years.

Rules for the safe operation of equipment

Gas cylinder equipment, if used improperly, can become a source of severe explosion or fire.

When performing welding work, be sure to use personal protective equipment: goggles, gloves, special shoes.

Before starting work, you need to carefully inspect the equipment for damage. If the equipment is dirty, be sure to remove the dirt

It is possible to work with propane cylinders only in well-ventilated areas, while the air temperature should not be below 0 ° C.

Absolutely forbidden:

- Work near open flames.

- Keep the cylinder tilted when working.

- Place vessels under the sun.

- Carry out work without a gearbox.

- Warm up the gearbox over an open flame.

In addition, if you smell gas, you must immediately stop working and close the valve on the cylinder. We also recommend that you familiarize yourself with the main causes of the explosion of gas cylinders.

Working without personal protective equipment, you can get burned, not only from open flames, but also from accidental contact with hot parts.

If the considered home-made burners are not suitable for you, we recommend that you familiarize yourself with other options for making useful home-made products discussed in our articles - a blowtorch burner and a sauna stove burner.

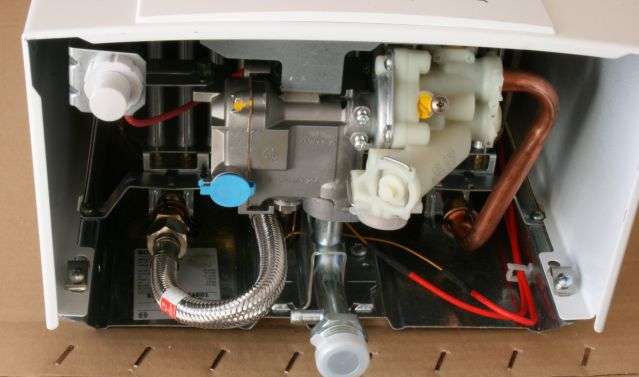

How to solder pipes

Before starting work, you need to prepare communications for exposure. Welding of pipelines is carried out on small sections of sewer systems, so you need to cut the pipe to a certain size. The place of the cut is cleaned, after which a chamfer is made there. This operation will help facilitate the connection of the heating and cooling branches to the fittings.

Photo - step by step instructions

For the installation of annealed materials, you will need to use the so-called pipe expander. This tool is required for installation on non-standard diameter fittings. There are devices of different diameters, almost up to 110 mm.

Step by step instructions how to solder copper pipes tin:

According to SNiP, the nominal diameter must always be less than the fitting;

High-temperature processing of joints begins only after they have been stripped. Fittings and pipes should be cleaned with a brush and, if necessary, rubbed with sandpaper. Depending on the storage of communications, it is also recommended to treat their joints with alcohol for degreasing;

Further, a thin layer of flux paste is applied to the place where the copper pipes will be soldered and the fittings that will be installed to connect the parts of the communication will be installed;

Now the burner turns on at the desired temperature. The solder must be carried out exactly along the edge of the joints, and the place where the fitting is joined must be heated with a torch.For welding plumbing communications, it is most convenient to work with tin, since it is absorbed into the metal and you can save time on heating the joints;

It is necessary to solder pipes no more than 20 seconds, because the maximum temperature of the burner is over 1000 degrees. Be careful, in some conditions low temperature welding is required, so it is advisable to know what type of pipes you have;

After the sewer assembly is carried out

It is very important not to immediately turn on the water in the lines, otherwise the connection will not have time to cool down and will be covered with cracks - this will negatively affect the tightness of the connection. The average cooling time for copper is from 30 minutes to two hours.

For welding copper pipes with a small diameter difference, the "capillary soldering" technology is used. It allows you to connect individual communications with a soldering iron with a difference between them up to 0.5 mm. In this case, the solder fills the space between the pipes. This allows the installation of the system without a seam. The technique uses hard solders, which have an improved protective function.

Much of the success of soldering depends on the type of solder that is used. Most often, copper pipes are welded with silver, brass and tin, which have high flow rates. Less commonly, work is done with aluminum.

You can immediately buy not only a machine for soldering copper pipes, but also a set of expanders and fittings that will be needed when wiring sewers without a professional plumber. Before starting work, we advise you to undergo training in technology, or at least watch the video.

Methods for soldering copper parts

To connect copper pipes, only two soldering methods are used.Each one is used according to the part specification and characteristics. Do-it-yourself soldering of copper pipes is divided into:

- At high temperatures, it is otherwise called "solid". The temperature indicator in this mode reaches 900 °. Refractory solder allows you to produce a seam with high strength indicators, this method is used in the manufacture of pipelines subject to high loads.

- The soft soldering process is carried out at temperatures starting from 130 °, it is used in domestic applications when working with pipes with a diameter of up to 1 cm. The technology involves joining by docking, pre-treatment with flux paste.

During work, it is important not to forget that the power of the flame given out by the burner can reach 1000 degrees. Therefore, the processing of joints must be carried out no more than 20 seconds.

When heated, the soft solder begins to melt and fill the joint.

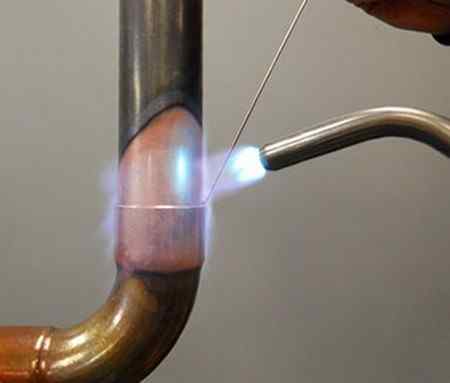

Features of high temperature compounds

In the high-temperature soldering method, the metal is fired at 700 ° C and higher, which contributes to the softening of the metal. For soldering, flame equipment is used that is capable of melting hard solders. The solder consists of their copper-phosphorus composition, is produced in the form of rods. The process of soldering copper pipes does not imply the use of flux, following the sequence of actions, it is possible to correctly fill the joint.

High temperature copper pipe connection

The process starts when the solder rod melts, the work steps are:

- after assembly, the joining seam warms up;

- a solid-state solder is supplied to the junction, the softening of which is carried out by a gas burner;

- when it is visually confirmed that the solder is being applied to the metal, the pipe must be rotated, the docking must be checked along the entire perimeter.

The main advantages of this method is the high strength of the joint of copper pipes, if necessary, it is possible to change the diameter of the connection with a smaller side. High temperatures during operation cannot destroy the seam. Hard soldering requires certain skills; overheating is possible during operation, which leads to the destruction of the metal.

Brazing

Each process requires a responsible approach to the performance of work. For heating, a propane or gasoline burner is used when using soft solder by joining copper pipes

It is important to know that a burner with piezo ignition will significantly reduce the operating time; it is not advisable to purchase expensive models without this function.

Technological process

In the process, it is important to use high-quality accessories, flux paste plays an important role in the connection. Uniform coverage of copper pipe parts is achieved using a soft brush, after application, the excess is removed with a rag

The temperature of the burner can reach 900 degrees, when soldering it is important not to overexpose the product, otherwise overheating will occur.

Safety precautions when soldering copper pipes

Copper pipes are used as fluid conductors with good anti-corrosion properties. Installation of copper pipes cannot be performed to provide potable tap water. Copper comes into contact with chlorine, which is added to purify water, and can form substances harmful to the human body.For artesian sources, wells are not dangerous to use.

Soldering copper with gloves

It is important to use high-quality tools, work with gloves and monitor the condition of the equipment. The thermal conductivity of the metal is quite high, when one of the nodes is heated and safety precautions are not observed, it is possible to get burns

A high-quality seam can be obtained in the absence of external factors in the form of loads until the joint cools completely.

Soft soldering instructions

Attention: the edge of the pipe and the pipe itself must be perfectly even and straight - the quality of fastening the parts will depend on this, therefore it is best to use a pipe cutter to cut pipes

- Using a pipe expander, increase the diameter of the fitting, using a beveler, clean the edges of the pipe.

- Polish the inside of the fitting with a brush, the outside of the pipe with a brush.

- With a brush, apply soldering paste - flux - to the fitting and pipe and immediately attach the parts, avoiding any type of contamination.

- Use a soldering torch to gently heat the joint, moving over the entire plane. The criterion for a good warm-up is a change in the color of the paste.

- Finish heating the parts to be joined, apply solder over the entire surface of the joint. The solder wire must not be touched with a burner flame: the solder must melt on the copper surface of the pipe, precisely from its temperature without the intervention of fire.

- Wait for the natural cooling of the joint - without any means of cooling.

- Be sure to remove the remaining paste from the pipes with a damp sponge. Its effect is needed only when soldering: it destroys the protective layer of the copper base.

Attention: the parts during soldering and temporarily after it must be well fixed, since copper pipes can only be soldered in a stationary position. The joint at the place of attachment of parts must be tight and even.

It will be possible to check the result only when sufficient water pressure is turned on in the pipeline, but if the soldering went well, the reliability of the connection does not decrease in any way from the water temperature, possible pressure drops or from time to time

The joint at the place of fastening of the parts must be tight and even. It will be possible to check the result only when sufficient water pressure is turned on in the pipeline, but if the soldering went well, the reliability of the connection does not decrease in any way from the water temperature, possible pressure drops or from time to time.

Fastening copper pipes with other materials

There are several important nuances associated with the possibilities of connecting copper structures with products from other metals:

- Fastening copper and galvanized steel can adversely affect the condition of the galvanized steel pipeline: chemical reactions between zinc and copper lead to the destruction of the former.

- Copper fasteners with steel, plastic and brass are safe and do not corrode metals.

Therefore, if there is a need to fasten copper and galvanized pipes, then it can be done only with the help of a brass fitting and only in one direction: through the circulation of water from the galvanized pipe to the copper pipe.

Copper pipes are attached to plastic or steel pipes only with brass push fittings.The main fastening of the system takes place using the clamping ring and the clamping nut of the fitting: they are screwed on by the standard number of turns indicated in the technical support of the fitting, and they must be periodically checked during operation for possible leaks or loosening.

Myths about copper piping

Due to the lack of habit of copper as a material for gas, water supply and heating systems, the modern domestic consumer has a certain distrust of this metal. There are two myths:

- Copper pipes are dangerous when in contact with chlorinated water. Of course, copper, starting a reaction with chlorine elements, oxidizes, but the film that appears inside the pipeline, on the contrary, protects the pipes from various chemical actions and is absolutely safe for the human body.

- Copper piping is expensive and impractical, despite the high cost. The impracticality is explained by the probable oxidation of the outer side of the pipes, while inside the copper pipes are also oxidized, but they are completely immune to corrosion. The more expensive price of copper pipes is more than covered by the durability of the materials and the ease of do-it-yourself installation.

But such myths can only be destroyed by years of practice. It is not for nothing that this metal was used in plumbing systems several centuries ago, and copper still has well-deserved recognition in European countries. Due to the ease of installation and the quality of materials, copper pipes for domestic plumbing are more preferable, and will certainly find new admirers in our country.

How to choose the right solder?

Correctly selected solder will help to organize a communication system of any complexity without much effort. When it comes to working at home, you should use a material that melts at low temperatures.

The use of high-temperature hard-melting elements in everyday life is problematic, since it requires heating the working alloy to 600-900 degrees. To achieve this without special equipment is quite difficult.

Soldering food copper can be carried out with special solders that do not contain toxic, poisonous and aggressive elements that can harm health

The use of metals and their derivatives that melt at high temperatures is associated with some risk. During processing, they can damage or even burn through a thin-walled copper pipe.

To prevent this from happening, it makes sense to take a strong, but low-melting soft solder, and leave the solid version for thick-walled copper communications.

When high loads are not expected on the system, it is not at all necessary to use high-melting solder, unless otherwise required. In the main household complexes, soft light-alloy solders are quite enough to create a reliable connection.

To connect copper pipes in gas networks, it is worth choosing silver-containing solders. They provide maximum joint strength, vibration neutrality and high resistance to external and internal influences.

It will cost a little more to pay for silver, but the security, reliability and durability of the system will pay off all the financial costs over time.

High pressure binding crimp connections

Advances in bonding crimp technology and in the development of o-ring materials have made it possible to apply bonding crimps to high pressure systems. However, high pressure systems require slightly different press jaw configurations.

The result of the production of the connecting node using the 360º double crimp technique

Bonding crimp connections for low-pressure, process, and non-medical compressed gas lines use a single standard hexagonal crimp shape.

Higher pressure bonding requires the use of specially designed press fittings and clamping jaws to provide a 360° double crimp on the fitting.

Method #4: Push-connect connection

A distinctive feature of the push-in assembly method is that no additional tools, burners, special fuel gases or electricity are required for installation. Push-in assembly is ensured by an integrated elastomer seal and a stainless steel grip ring.

Convenient in all respects and quite practical for operation, the method of assembling the assembly by inserting by pressing (push-connect)

Typical pressure and temperature ranges for push-in assemblies are shown in the table:

| Assembly type | Pressure range, kPa | Temperature range, ºC |

| Push-in insertion, D = 12.7 – 50.8 mm | 0 – 1375 | minus 18 / plus 120 |

There are two common types of fittings for this type of assembly. Both options create strong, reliable knot assemblies.However, while one type of push-in fitting allows the assembly to be easily removed after installation, such as for system maintenance, the other does not support this configuration. This moment fittings differ from one another.

Types of fittings for push-in connections: on the left - a collapsible design; right - non-separable design

Before assembling the assembly, it is required to perform all the preparatory procedures with the copper pipe, as already described above

Here, special attention should be paid to cleaning the beveled end of the copper pipe with sandpaper, nylon abrasive cloth or sanitary cloth. These actions ensure the integrity of the sealing gasket at the time of insertion of the copper pipe into the body of the fitting.

The assembly involves the execution of a rigid pushing, simultaneously twisting movement directed into the body of the fitting. The movement of the copper pipe inside the fitting is performed until the copper pipe rests against the back of the fitting cup. This moment is usually indicated by a previously made mark of the insertion depth on the copper surface.

With the help of information: Cooper

![Do-it-yourself soldering of copper pipes [selection of a torch, video, tips]](https://fix.housecope.com/wp-content/uploads/8/0/1/801490b7bbbfe2c416281ada3dc007be.jpeg)