- High pressure binding crimp connections

- Method #4: Push-connect connection

- Other soldering options: work with copper pipes and various metals

- The nuances of soldering copper pipes: how to do it right

- How to solder copper wire to aluminum

- How to solder copper and stainless steel

- Soldering copper with iron - is it possible

- Technology of soldering copper products

- Cut the item to the required length

- Apply flux to the surface of the pipe

- Connecting parts before soldering

- Joint formation during low temperature soldering

- Seam formation in high temperature soldering

- Types of copper pipes

- What is needed for soldering copper pipes

- Consumables and tools

- Solder and flux

- Burner

- Related materials

- Where apply

- 3 How to solder copper pipes?

- Installation of copper pipes

- Assembling the pipeline with fittings

- Tools and materials

- Assembly instructions

High pressure binding crimp connections

Advances in bonding crimp technology and in the development of o-ring materials have made it possible to apply bonding crimps to high pressure systems. However, high pressure systems require slightly different press jaw configurations.

The result of the production of the connecting node using the 360º double crimp technique

Bonding crimp connections for low-pressure, process, and non-medical compressed gas lines use a single standard hexagonal crimp shape.

Higher pressure bonding requires the use of specially designed press fittings and clamping jaws to provide a 360° double crimp on the fitting.

Method #4: Push-connect connection

A distinctive feature of the push-in assembly method is that no additional tools, burners, special fuel gases or electricity are required for installation. Push-in assembly is ensured by an integrated elastomer seal and a stainless steel grip ring.

Convenient in all respects and quite practical for operation, the method of assembling the assembly by inserting by pressing (push-connect)

Typical pressure and temperature ranges for push-in assemblies are shown in the table:

| Assembly type | Pressure range, kPa | Temperature range, ºC |

| Push-in insertion, D = 12.7 – 50.8 mm | 0 – 1375 | minus 18 / plus 120 |

There are two common types of fittings for this type of assembly. Both options create strong, reliable knot assemblies. However, while one type of push-in fitting allows the assembly to be easily removed after installation, such as for system maintenance, the other does not support this configuration. This moment fittings differ from one another.

Types of fittings for push-in connections: on the left - a collapsible design; right - non-separable design

Before assembling the assembly, it is required to perform all the preparatory procedures with the copper pipe, as already described above

Here, special attention should be paid to cleaning the beveled end of the copper pipe with sandpaper, nylon abrasive cloth or sanitary cloth. These actions ensure the integrity of the sealing gasket at the time of insertion. copper pipe in fitting body

The assembly involves the execution of a rigid pushing, simultaneously twisting movement directed into the body of the fitting. The movement of the copper pipe inside the fitting is performed until the copper pipe rests against the back of the fitting cup. This moment is usually indicated by a previously made mark of the insertion depth on the copper surface.

With the help of information: Cooper

Other soldering options: work with copper pipes and various metals

Soldering copper pipes requires some experience in this kind of work. Therefore, if a home master undertakes such work for the first time, it is worthwhile to practice beforehand so as not to redo the already finished water supply or heating line several times. Copper tubes can be soldered with both hard solder (using a gas burner) and soft alloys. In the second case, for copper pipes, it is appropriate to use a high-power hammer soldering iron.

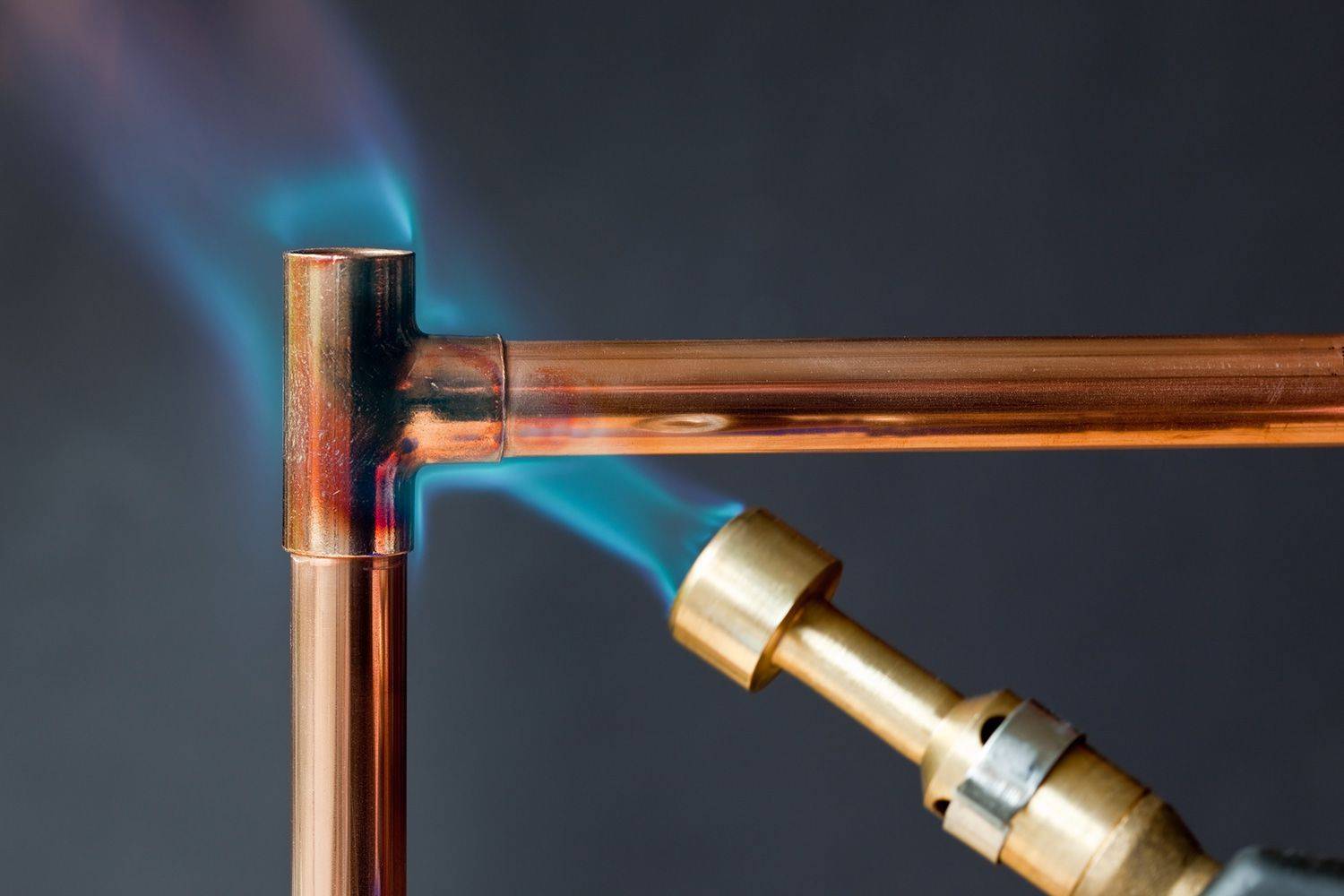

Accurate and high-quality soldering is the key to the durability of the connection

Accurate and high-quality soldering is the key to the durability of the connection

The nuances of soldering copper pipes: how to do it right

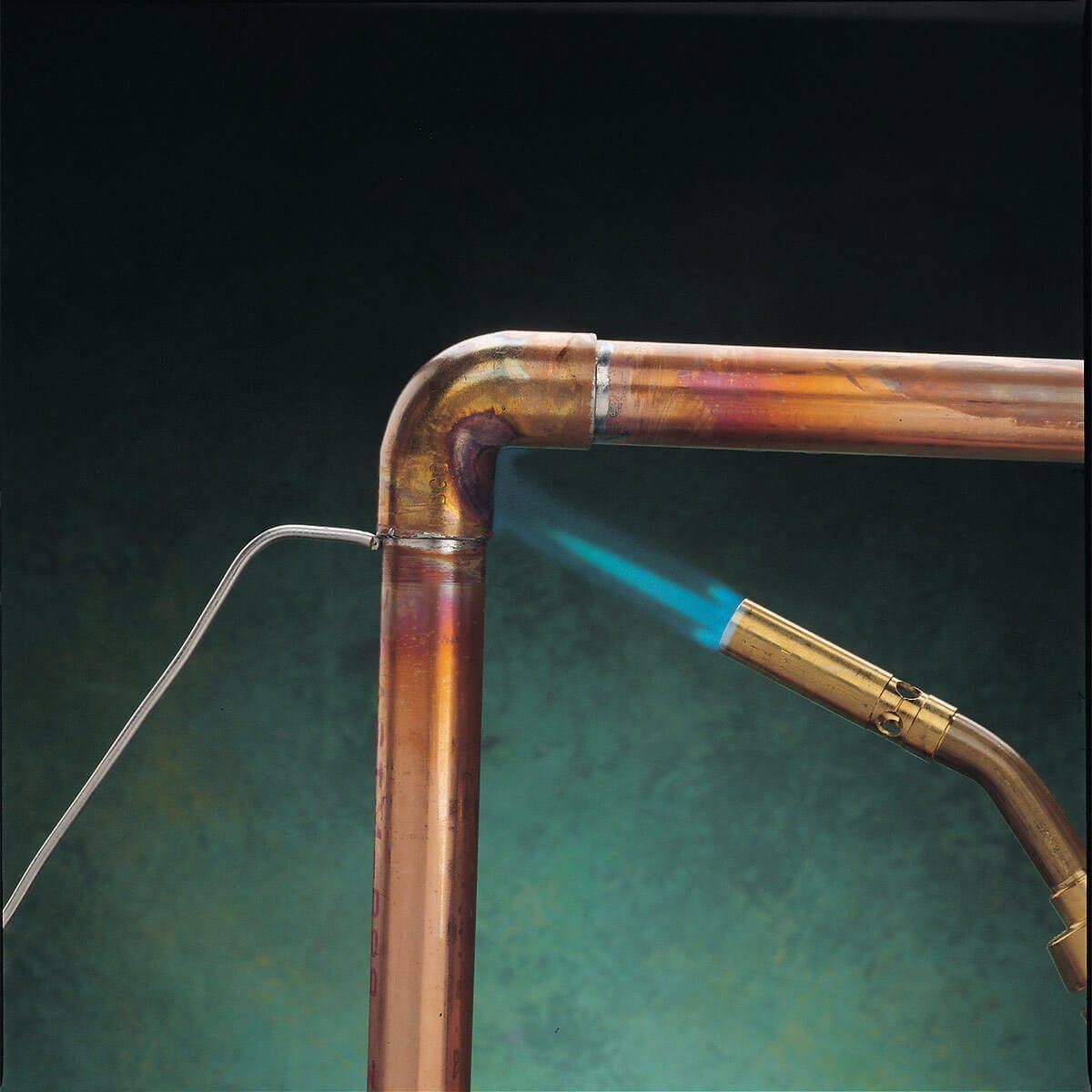

As a flux for soldering copper pipes, it is best to use rosin. It is applied in an even layer on the outer surfaces of the pipe, after which the fitting is mounted on it. On its reverse side, the second part of the highway is mounted. Next, the fitting is heated with a gas burner and solder is “fitted” along the seams.Under the influence of high temperature, it melts, filling the seam and creating a high-quality tight connection.

Sometimes you have to do without fittings

Sometimes you have to do without fittings

Soldering copper pipes with your own hands is not too difficult, but this work requires care and accuracy. Of course, in words, not everything can be explained intelligibly, so we bring to the attention of the Dear Reader a video on how to solder copper with a gas burner, from which everything will become more clear.

Watch this video on YouTube

Watch this video on YouTube

Having dealt with the question of how to solder copper pipes at home, you can move on to the next problem, namely the soldering of non-identical metals (copper with aluminum, iron or stainless steel).

How to solder copper wire to aluminum

Soldering aluminum with copper is a rather complicated process. It should be noted that the same solder is hardly suitable for aluminum as for copper, and vice versa. It is much easier to match these metals using a steel sleeve. Although today the manufacturer offers special solders and fluxes for such purposes, their cost is significant, which leads to the unprofitability of such work.

The whole problem lies in the conflict between copper and aluminum. They have different refractoriness, density. In addition, aluminum, when interacting with copper, begins to oxidize strongly. This process is especially accelerated when an electric current passes through the connection. Therefore, if necessary copper and aluminum wire connections it is best to use WAGO self-clamping terminal blocks, inside of which there is Alyu Plus contact paste. It is she who removes oxide from aluminum, prevents its subsequent appearance and promotes normal contact with copper conductors.

Having figured out how to solder copper to aluminum, you can move on to harder metals.

Sometimes such a connection is indispensable

Sometimes such a connection is indispensable

How to solder copper and stainless steel

When soldering copper with stainless steel, not even the solder material itself plays an important role, but the tool used, although a lot depends on consumables. The most acceptable materials in this case are:

- copper-phosphorus solder;

- pewter silver (Castolin 157);

- radio engineering.

Some craftsmen claim that with the right approach to work, even the most common solder based on tin and lead will do. The main thing is the mandatory use of flux (borax, soldering acid), thorough heating and only after that soldering (soldering).

Complex soldering of copper and stainless steel

Complex soldering of copper and stainless steel

Such compounds are rare, and therefore specialized solders for such purposes are quite expensive.

Soldering copper with iron - is it possible

This option is possible, but subject to certain conditions. For example, a simple propane burner is no longer suitable as a heater. You must use propane with oxygen. Borax should be used as a flux, but brass will act as a solder. Only in this case can we hope for a normal result. It is not difficult to buy solder for soldering copper with iron or stainless steel. The main thing is to understand whether the extra costs will be justified.

Soldering copper and iron tubing is also possible

Soldering copper and iron tubing is also possible

And now we offer to look at how carefully home craftsmen can perform work on soldering pipes of highways for various purposes.

1 of 5

Technology of soldering copper products

After preparing tools and materials, pipes are soldered, consisting of the following steps:

- cutting blanks into segments;

- degreasing and removal of oxides;

- docking of elements;

- applying solder to the joint line.

Cut the item to the required length

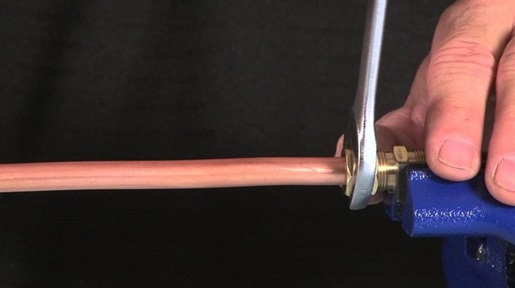

Welding of copper pipes begins with the marking of the pipeline, which is then cut into elements of the desired length. When marking, it is necessary to take into account the length margin required to connect the tubes after expanding the end. A hand-held cutting tool allows the pipe to be clamped, and then a carbide roller is rolled around the outer surface of the workpiece. As the pipe body is cut, the roller is pressed with an adjusting bolt, which allows you to get an even cut.

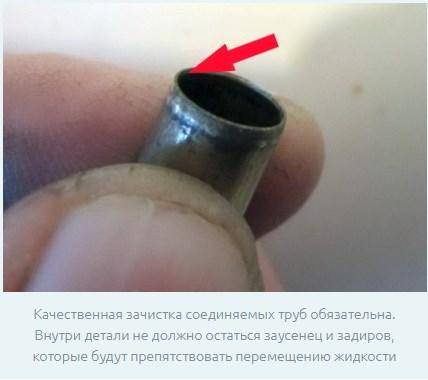

It is allowed to cut blanks with a hacksaw and a special template that ensures the perpendicularity of the cut. When cutting, compression of the pipe is not allowed, since the ovality of the outer surface worsens the tightness of the joint (due to a change in the gap that will not be filled with solder). The resulting flash is removed with sandpaper and a metal brush. Then one of the edges is treated with an expander, which will create a sealed joint with increased strength.

Apply flux to the surface of the pipe

Do-it-yourself welding of copper pipes requires the removal of oxides from the surface of the parts to be joined. The blanks are wiped with a degreasing agent (for example, acetone), and then a reagent is applied to the joined edges. It is not recommended to use an increased dose of flux, the active substance evenly applied in a thin layer to the connection area. To apply the reagent, a paint brush is used, which does not leave fibers on the surface.

Connecting parts before soldering

After applying the flux, the tubes are connected, it is recommended to join the elements immediately after lubricating the surface (to reduce the risk of dust settling). The parts rotate relative to each other when connected, which allows the flux to be distributed and provides a tight fit. The reagent squeezed out of the joint is removed with a dry cloth; it is forbidden to keep the flux on elements made of non-ferrous metals, since the destruction of the material begins.

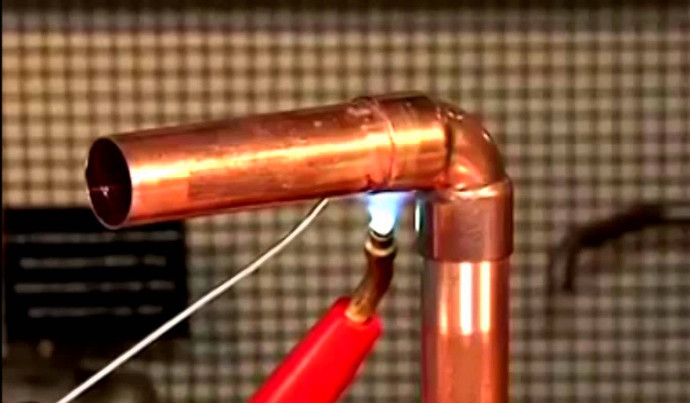

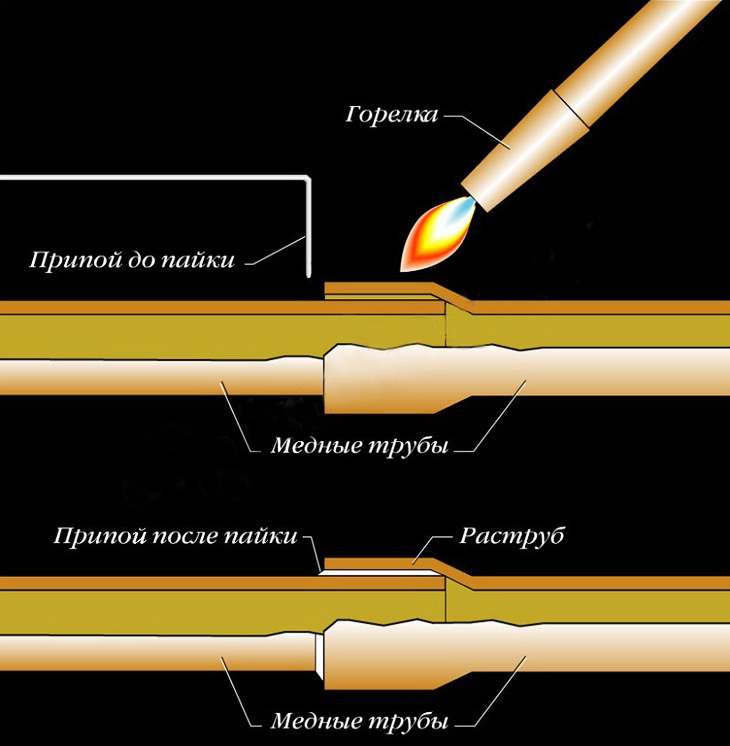

Joint formation during low temperature soldering

The low-temperature technology uses a flux designed for reduced heating of the structure during connection. Soldering copper tubes with a gas burner provides for the supply of a torch to the connection zone, the burner moves along the joint, ensuring uniform heating of the parts. Then a bar of solder is taken into the hand, which is fed into the gap between the pipes. The molten metal begins to spread over the surfaces, the burner is removed to the side, the solder fills the joint due to the temperature of the heated pipe.

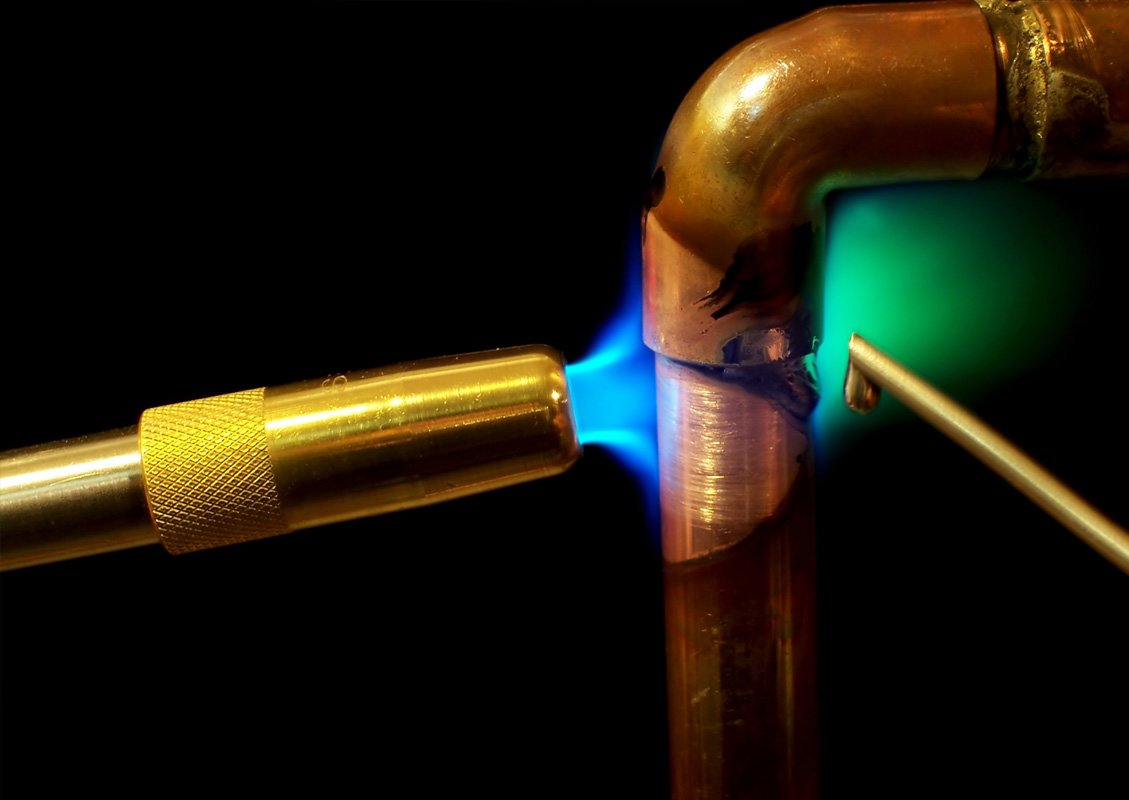

Seam formation in high temperature soldering

When using refractory solders, the pipes are heated by a burner to an elevated temperature. The burner moves along the joint zone until the pipe is heated to a cherry-red hue (corresponding to a temperature of 750°C). Then, solder, preheated by a burner flame, is fed into the junction.

The solder melts from contact with heated pipes, evenly filling the mounting gap. Applying excess solder is not required as the material will remain on the outside of the piping. After the end of the procedure, it is necessary to wait 2-3 minutes, after the temperature of the joint decreases and the solder crystallizes, the flux residues are removed.Additional machining of the connection is not required.

Types of copper pipes

Before manufacturing the pipeline, you need to select the parts. Among the purchased parts, there are two types:

- Unannealed - high-strength elements with a low ductility index. They do not undergo additional heat treatment after manufacture.

- Annealed - elements that undergo additional heat treatment. They are kept at a temperature of about 700 degrees Celsius. The material acquires a high plasticity index. Thanks to additional heat treatment, they become more resistant to critical temperatures.

Copper pipes vary in wall thickness and the size of the coils in which they are sold. According to GOST, they must be made of pure copper.

What is needed for soldering copper pipes

Soldering copper pipes, which is not difficult to do with your own hands, does not require expensive equipment and any special materials. In order to properly implement it, you will need the following devices.

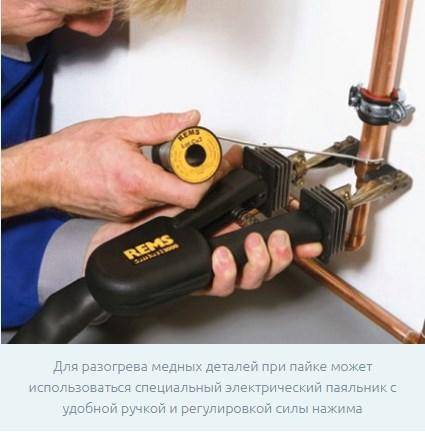

A burner, due to which the solder and the pipe section where they will be connected will be heated. As a rule, propane gas is supplied to such a burner, the pressure of which is regulated by a welding reducer.

Special tool for cutting copper pipes. Since products made of this metal are very soft, they should be cut gently enough so as not to wrinkle the walls. Pipe cutters of various models are offered on the modern market, differing both in their functionality and technical capabilities.

The design of individual models of such devices, which is important, allows them to be used even for work in hard-to-reach places.

A pipe expander is a device that allows you to expand the diameter of a copper pipe, which is necessary in order to better solder. In various systems mounted from copper pipes, elements of the same section are used, and in order to connect them qualitatively, it is necessary to slightly increase the diameter of one of the connected elements. It is this problem that such a device as a pipe expander solves.

It is this problem that such a device as a pipe expander solves.

Copper pipe flaring kit

Device for chamfering the ends of copper pipes. After trimming, burrs remain on the ends of the parts, which can interfere with obtaining a high-quality and reliable connection. To remove them and give the ends of the pipes the required configuration, a beveler is used before soldering. There are two main types of chamfering devices on the market today: placed in a round body and made in the form of a pencil. More convenient to use, but also more expensive, are round devices that can process soft copper pipes with a diameter of not more than 36 mm.

To properly prepare copper pipes for soldering, it is necessary to remove all impurities and oxides from their surface. For these purposes, brushes and brushes are used, the bristles of which are made of steel wire.

Brazing of copper pipes is usually performed with hard solder, which can be high and low temperature. High-temperature solder is a copper wire containing about 6% phosphorus in its composition. Such a wire melts at a temperature of 700 degrees, while for its low-temperature type (tin wire), 350 degrees is enough.

The technology of soldering copper pipes involves the use of special fluxes and pastes that perform a protective function. Such fluxes not only protect the formed seam from the formation of air bubbles in it, but also significantly improve the adhesion of the solder to the pipe material.

In addition to flux, solder and other basic elements, additional tools will be needed to solder copper pipes, which can be found in every workshop or garage. To solder or weld copper products, additionally prepare:

- regular marker;

- roulette;

- building level;

- a small brush with stiff bristles;

- a hammer.

Before starting work, it is also important to decide how to solder copper pipes. There can be two main options: brazing copper (less commonly used) and using soft solder. When resolving this issue, it is important to proceed from the fact that there are requirements for the use of one or another type of solder

So, hard solders are used for soldering elements of refrigeration units and air conditioners. In all other cases (water supply systems, heating systems, etc.), tin wire can be used. But whatever technology is chosen, it should be remembered that the flux is necessary in any case.

When solving this issue, it is important to proceed from the fact that there are requirements for the use of one or another type of solder. So, hard solders are used for soldering elements of refrigeration units and air conditioners.

In all other cases (water supply systems, heating systems, etc.), tin wire can be used. But whatever technology is chosen, it should be remembered that the flux is necessary in any case.

Brushes for stripping the inner surface of a copper pipe before soldering

Consumables and tools

In addition to pipes and fittings, you will also need a torch, solder and flux - for the soldering itself. And also a pipe bender and a few related little things for processing before starting work.

Brush for stripping fittings from the inside

Solder and flux

Soldering copper pipes of any type occurs with the help of flux and solder. Solder is an alloy usually based on tin with a certain melting point, but necessarily lower than that of copper. It is fed into the soldering zone, heated to a liquid state and flows into the joint. After cooling, it provides a tight and durable connection.

For amateur soldering of copper pipes with your own hands, tin-based solders with the addition of silver, bismuth, antimony, and copper are suitable. Compounds with the addition of silver are considered the best, but they are the most expensive, optimal ones with a copper additive. There is also with the addition of lead, but they should not be used in plumbing. All these types of solder provide good seam quality and easy soldering.

Flux and solder are essential consumables

Soft solder is sold in small reels, hard solder is sold in packs, cut into pieces.

Before soldering, the joint is treated with flux. A flux is a liquid or pasty agent that causes molten solder to flow into a joint. There is nothing special to choose here: any flux for copper will do. Also, you will need a small brush to apply the flux. Better - with natural bristles.

Burner

To work with soft solder, you can buy a small hand torch with a disposable gas bottle. These cylinders are attached to the handle, have a volume of 200 ml.Despite the small size, the flame temperature is from 1100°C and higher, which is more than enough to melt soft solder.

What you should pay attention to is the presence of piezo ignition. This function is not superfluous - it will be easier to work

A valve is located on the handle of a manual gas burner. It regulates the length of the flame (the intensity of the gas supply). The same valve shuts off the gas if the burner needs to be extinguished. Safety is provided by a non-return valve, which, in the absence of a flame, will shut off the gas supply.

Hand torch for soldering copper pipes

Some models have a flame deflector. It does not allow the flame to dissipate, creating a higher temperature in the soldering zone. Thanks to this, the burner with a reflector allows you to work in the most inconvenient places.

When working in household and semi-professional models, you must be careful not to overheat the unit so that the plastic does not melt. Therefore, it is not worth doing a lot of soldering at a time - it is better to let the equipment cool down and prepare the next connection at this time.

Related materials

To cut copper pipes, you need a pipe cutter or a hacksaw with a metal blade. The cut must be strictly vertical, which provides a pipe cutter. And to guarantee an even cut with a hacksaw, you can use an ordinary carpentry miter box.

pipe cutter

When preparing pipes, they must be cleaned. To do this, there are special metal brushes and brushes (for cleaning the inner surface), but you can get by with sandpaper with medium and fine grains.

To remove burrs from cuts, there are bevelers. The pipe they have worked out fits better into the fitting - its socket is only a fraction of a millimeter larger than the outer diameter.So the slightest deviation leads to difficulties. But, in principle, everything can be eliminated with sandpaper. It will only take more time.

It is also advisable to have protective goggles and gloves. Most home crafters neglect these safety measures, but burns are very unpleasant. These are all the materials and tools needed for soldering copper pipes.

Where apply

Soldering with hard solders is notable for the fact that when it is carried out, the joint area of \u200b\u200bproducts must be heated to temperatures of the order of 450 degrees or more.

Such solders are called refractory, and the connection obtained with their help retains its strength characteristics even with strong thermal heating.

Unlike hard soldering, soft soldering involves the use of low-temperature consumables that provide reliable adhesion at much lower heat (about 200-300 ℃).

Unlike hard soldering, soft soldering involves the use of low-temperature consumables that provide reliable adhesion at much lower heat (about 200-300 ℃).

They, as a rule, are used when soldering products operated under normal temperature conditions, and do not guarantee the preservation of contact with strong heating.

The possibilities of hard solders are widely used in those areas where it is required to obtain a seam that, in terms of its strength properties, occupies an intermediate position between welding and low-temperature soldering.

At the same time, special attention is paid to maintaining the structure of materials in the contact zone, which, after processing, should not lose their original characteristics. Carbide joints are most often in demand in the following situations:

Carbide joints are most often in demand in the following situations:

- production of metal-cutting tools, cutters with hard-alloy working inserts;

- in the manufacture of containers and vessels made on the basis of non-ferrous metals and stainless steel;

- in car repair shops (when repairing radiators and individual transmission elements), as well as in those places where the use of welding is highly undesirable;

- when installing and repairing pipes made of hard copper alloys installed in refrigeration and heat exchange equipment and operating under “critical” temperatures or high pressure;

- for reliable and durable connection of thin-walled objects and parts that experience increased loads and elastic deformations during operation.

The use of hard soldering technology ensures the necessary strength of the resulting joint and its resistance to overheating. In addition, carbide methods are used in the repair of copper or brass products that are exposed to high temperatures during operation.

Unlike the brazing materials described above, soft soldering applications are limited to normal operating conditions. This method is most often used when it is necessary to obtain a reliable connection of products and parts made of fusible materials that are not subject to excessive heat and deformation.

Tin-lead soldering compositions, which have become widespread, are especially popular with the “soft” articulation of parts.

3 How to solder copper pipes?

The scheme for the installation of a pipeline made of copper products is very simple:

Using a pipe cutter, we cut off the pipe (it should be placed perpendicular to the cutting device in order to obtain the most even edge) of the length we need.

With a brush with steel bristles, we remove burrs from the pipe, and with a brush we clean its surfaces

Please note - it is strictly forbidden to perform these works using fine-grained sandpaper, as small particles of it will remain on the copper surface and reduce the level of adhesion.

We expand the second piece of the tubular product to the required section in such a way that both segments freely enter into each other (in this case, a small gap should also remain).

We clean (all the same devices) from dirt and burrs the edge of the expanded product.

We apply a flux to a pipe of a smaller section and distribute it with a brush over the surface. It is impossible to apply too much flux (or distribute it unevenly), since when heated, the solder can get inside the pipeline through it and form frozen drops there, which during the operation of the system will cause noise when moving water.

After that, you can connect the pipes (insert them one into one). At the same time, in order to avoid sticking of the solder to the pipe, it is necessary to remove excess flux with a damp cloth. The next step in the procedure is to warm up the resulting compound. The joint heating operation is terminated at the moment when the flux turns silver.

Next, solder is brought to the joint, which melts from the heated pipe material (everyone knows the high thermal conductivity of copper) without heat from the burner. Solder due to the capillary phenomenon penetrates between the connected elements. Soldering is completed when solder droplets appear on the surface of the tubular product.

After that, the junction of the pipes should cool down. During cooling, you can not exert a mechanical effect on the system, as well as try to speed up the process cold air supply. The cooled joint at the last stage of soldering is wiped with a cloth dipped in water. This will ensure a neat appearance of the pipeline, which will be free of solder and flux residues.

Installation of copper pipes

In the process of installing plumbing systems with your own hands, it often becomes necessary to connect copper pipes with products made from other materials. In heating systems, cold and hot water supply, copper compounds with steel, plastic and brass are safe from the point of view of the occurrence of corrosion processes. But the contact of copper with galvanized steel is dangerous for galvanized pipes and leads to their destruction due to electrolytic processes. In order to avoid failure of the pipeline, it is necessary to make the connection with the help of, and ensure that the water flow is directed from steel to copper.

Before starting work, it is necessary to prepare a tool for installing copper pipes in a heating system or supplying hot or cold water. To do this, you will need: a pipe cutter or a hacksaw for metal, a file or a scraper, in the presence of sections of complex configuration - a pipe bender, gas burner or hot air gun.

Copper piping do-it-yourself begins with sections of a pre-calculated length. Then it is necessary to deburr the outer and inner parts of the pipe, if necessary, align the cut. The use of a pipe bender will prevent flattening of the pipe and the formation of creases, which can cause a decrease in the performance of the pipeline in these places.

If the pipe diameters do not exceed 15 mm, then their bending radius must be at least 3.5 diameters, and if more than 15 mm, then four diameters.When bending by hand, a high-quality bend can only be obtained with a radius equal to 8 diameters.

Despite their resistance to corrosion, copper pipes, due to violations of manufacturing technology, improper soldering and severe water contamination with abrasive inclusions, can undergo very dangerous pitting corrosion. The pipe corrodes in places where the oxide film is destroyed. One way to avoid this process is to install filters on water supply and heating pipelines.

In the modern construction market, copper pipes, due to their unique performance, quite successfully compete with steel, plastic and metal-plastic products, despite their high cost.

Even with the fact that polymer pipes are used more and more often, metal products are still a great success. As a rule, copper, brass and steel are used as the metal. For the better in terms of resistance to corrosion and high temperatures, copper is distinguished. Actually, the connection of copper pipes will be discussed in this article.

Even despite the fact that copper pipes are distinguished by their high cost, given all the characteristics of the material, their use is quite justified.

First of all, before connecting copper pipes, it is worth deciding how to connect them, by soldering or otherwise.

Assembling the pipeline with fittings

The connection of copper pipes with fittings is carried out exclusively in places accessible for inspection. This rule is due to the fact that the connection is not completely sealed and leaks may form over time.

The advantage of a threaded connection is that, if necessary, repairs can be made without additional effort, since the resulting connection is detachable.

Tools and materials

To assemble the pipeline, you will need the following materials and tools:

- copper pipes of suitable diameter;

- connecting crimp or press fittings;

Special Devices for Piping Assembly

The types and number of fittings are selected in accordance with the pipeline scheme.

- pipe cutter or hacksaw;

- pipe bender for copper pipes. The device is used to organize a pipeline with fewer connections, which increases the strength of the system;

- file for processing pipes after cutting (before joining). Additionally, you can use fine sandpaper;

- FUM-tape for sealing threads. In addition to the FUM tape, you can also use linen thread, Tangit Unilok thread or any other sealing material;

- wrench.

Assembly instructions

Do-it-yourself assembly of a copper pipeline using fittings is carried out in the following way:

- cutting pipes for the pipeline. The length of each pipe must fully comply with the scheme drawn up during the development of the system;

- removal of the insulating layer. If pipes with insulation are used for an equipped pipeline system for any purpose, then the insulation layer is removed for a strong connection. To do this, the desired section is cut with a knife and the pipe is cleaned;

- the cut edge is processed with a file, sandpaper until a smooth surface is obtained. If burrs, potholes or other irregularities remain at the end of the pipe, the connection will turn out to be less airtight;

Stripping the pipe before connecting to the fitting

- if necessary, pipes are bent;

- a union nut and a compression ring are put on the prepared pipe;

Installation of fitting elements for connection

- the pipe is connected to the fitting. Initially, the tightening is done by hand, and then with a wrench. During tightening, the ferrule completely seals the connection, eliminating the need for additional sealants. However, when connecting a copper pipe to a pipe or fitting made of a different material, additional sealing with FUM tape is required.

Fitting fixation

It is important not to overtighten the threads, as soft copper is easily deformed.