- Types of copper pipes and their use

- Methods for soldering copper parts

- Features of high temperature compounds

- Brazing

- Safety precautions when soldering copper pipes

- Other soldering options: work with copper pipes and various metals

- The nuances of soldering copper pipes: how to do it right

- How to solder copper wire to aluminum

- How to solder copper and stainless steel

- Soldering copper with iron - is it possible

- Consumables and tools

- Solder and flux

- Burner

- Related materials

- The essence of the process

- Methods for soldering copper parts

- Features of high temperature compounds

- Brazing in detail

- How else can you connect copper elements

- Types of Brazed Copper Fittings

- Features of copper soldering

- Cons of copper pipes

- Communications from copper pipes and fittings

Types of copper pipes and their use

Two types of copper pipes are most commonly found on sale - unannealed and annealed. During molding in production, there is a loss of elasticity, which is necessary in some industries, home structures. Elasticity is returned to materials by firing at temperatures up to 700 °. Annealed copper pipes are more expensive, but more flexible and can withstand high temperature changes.However, there is a certain drawback - the loss of strength of the product, which is lost during heating to temperatures close to melting.

Unannealed pipes do not bend, but are much stronger. When connecting copper joints, fittings are used, the connection process takes place by soldering. Different wall thickness allows you to choose the product according to the parameters of strength and heat transfer. Annealed materials are sold in bottles from 25 to 50 meters, respectively, as a rule, such copper pipes are supplied with a smaller diameter. Rigid materials are sold in runs of various lengths.

Methods for soldering copper parts

To connect copper pipes, only two soldering methods are used. Each one is used according to the part specification and characteristics. Do-it-yourself soldering of copper pipes is divided into:

- At high temperatures, it is otherwise called "solid". The temperature indicator in this mode reaches 900 °. Refractory solder allows you to produce a seam with high strength indicators, this method is used in the manufacture of pipelines subject to high loads.

- The soft soldering process is carried out at temperatures starting from 130 °, it is used in domestic applications when working with pipes with a diameter of up to 1 cm. The technology involves joining by docking, pre-treatment with flux paste.

During work, it is important not to forget that the power of the flame given out by the burner can reach 1000 degrees. Therefore, the processing of joints must be carried out no more than 20 seconds. When heated, soft solder begins to melt and fill the joint

When heated, the soft solder begins to melt and fill the joint.

Features of high temperature compounds

In the high-temperature soldering method, the metal is fired at 700 ° C and higher, which contributes to the softening of the metal. For soldering, flame equipment is used that is capable of melting hard solders. The solder consists of their copper-phosphorus composition, is produced in the form of rods. The process of soldering copper pipes does not imply the use of flux, following the sequence of actions, it is possible to correctly fill the joint.

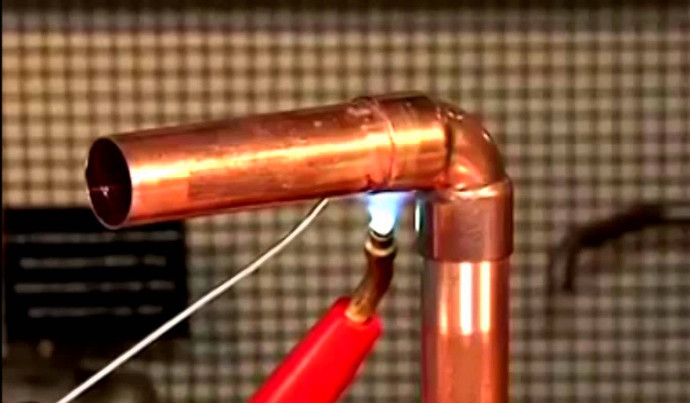

High temperature copper pipe connection

The process starts when the solder rod melts, the work steps are:

- after assembly, the joining seam warms up;

- a solid-state solder is supplied to the junction, the softening of which is carried out by a gas burner;

- when it is visually confirmed that the solder is being applied to the metal, the pipe must be rotated, the docking must be checked along the entire perimeter.

The main advantages of this method is the high strength of the joint of copper pipes, if necessary, it is possible to change the diameter of the connection with a smaller side. High temperatures during operation cannot destroy the seam. Hard soldering requires certain skills; overheating is possible during operation, which leads to the destruction of the metal.

Brazing

Each process requires a responsible approach to the performance of work. For heating, a propane or gasoline burner is used when using soft solder by joining copper pipes

It is important to know that a burner with piezo ignition will significantly reduce the operating time; it is not advisable to purchase expensive models without this function.

Technological process

In the process, it is important to use high-quality accessories, flux paste plays an important role in the connection.Uniform coverage of copper pipe parts is achieved using a soft brush, after application, the excess is removed with a rag. The temperature of the burner can reach 900 degrees, when soldering it is important not to overexpose the product, otherwise overheating will occur

The temperature of the burner can reach 900 degrees, when soldering it is important not to overexpose the product, otherwise overheating will occur

Safety precautions when soldering copper pipes

Copper pipes are used as fluid conductors with good anti-corrosion properties. Installation of copper pipes cannot be performed to provide potable tap water. Copper comes into contact with chlorine, which is added to purify water, and can form substances harmful to the human body. For artesian sources, wells are not dangerous to use.

Soldering copper with gloves

It is important to use high-quality tools, work with gloves and monitor the condition of the equipment. The thermal conductivity of the metal is quite high, when one of the nodes is heated and safety precautions are not observed, it is possible to get burned. A high-quality seam can be obtained in the absence of external factors in the form of loads until the joint cools completely

A high-quality seam can be obtained in the absence of external factors in the form of loads until the joint cools completely.

Other soldering options: work with copper pipes and various metals

Soldering copper pipes requires some experience in this kind of work. Therefore, if a home master undertakes such work for the first time, it is worthwhile to practice beforehand so as not to redo the already finished water supply or heating line several times.Copper tubes can be soldered with both hard solder (using a gas burner) and soft alloys. In the second case, for copper pipes, it is appropriate to use a high-power hammer soldering iron.

Accurate and high-quality soldering is the key to the durability of the connection

The nuances of soldering copper pipes: how to do it right

As a flux for soldering copper pipes, it is best to use rosin. It is applied in an even layer on the outer surfaces of the pipe, after which the fitting is mounted on it. On its reverse side, the second part of the highway is mounted. Next, the fitting is heated with a gas burner and solder is “fitted” along the seams. Under the influence of high temperature, it melts, filling the seam and creating a high-quality tight connection.

Sometimes you have to do without fittings

Soldering copper pipes with your own hands is not too difficult, but this work requires care and accuracy. Of course, in words, not everything can be explained intelligibly, so we bring to the attention of the Dear Reader a video on how to solder copper with a gas burner, from which everything will become more clear.

Watch this video on YouTube

Having dealt with the question of how to solder copper pipes at home, you can move on to the next problem, namely the soldering of non-identical metals (copper with aluminum, iron or stainless steel).

How to solder copper wire to aluminum

Soldering aluminum with copper is a rather complicated process. It should be noted that the same solder is hardly suitable for aluminum as for copper, and vice versa. It is much easier to match these metals using a steel sleeve.Although today the manufacturer offers special solders and fluxes for such purposes, their cost is significant, which leads to the unprofitability of such work.

Soldering copper and aluminum is quite difficult

The whole problem lies in the conflict between copper and aluminum. They have different refractoriness, density. In addition, aluminum, when interacting with copper, begins to oxidize strongly. This process is especially accelerated when an electric current passes through the connection. Therefore, if it is necessary to connect copper and aluminum wires, it is best to use WAGO self-clamping terminal blocks, inside which there is Alyu Plus contact paste. It is she who removes oxide from aluminum, prevents its subsequent appearance and promotes normal contact with copper conductors.

Having figured out how to solder copper to aluminum, you can move on to harder metals.

Sometimes such a connection is indispensable

How to solder copper and stainless steel

When soldering copper with stainless steel, not even the solder material itself plays an important role, but the tool used, although a lot depends on consumables. The most acceptable materials in this case are:

- copper-phosphorus solder;

- pewter silver (Castolin 157);

- radio engineering.

Some craftsmen claim that with the right approach to work, even the most common solder based on tin and lead will do. The main thing is the mandatory use of flux (borax, soldering acid), thorough heating and only after that soldering (soldering).

Complex soldering of copper and stainless steel

Such compounds are rare, and therefore specialized solders for such purposes are quite expensive.

Soldering copper with iron - is it possible

This option is possible, but subject to certain conditions. For example, a simple propane burner is no longer suitable as a heater. You must use propane with oxygen. Borax should be used as a flux, but brass will act as a solder. Only in this case can we hope for a normal result. Buy solder for soldering copper with iron or stainless steel is easy. The main thing is to understand whether the extra costs will be justified.

Soldering copper and iron tubing is also possible

And now we offer to look at how carefully home craftsmen can perform work on soldering pipes of highways for various purposes.

1 of 5

Consumables and tools

In addition to pipes and fittings, you will also need a torch, solder and flux - for the soldering itself. And also a pipe bender and a few related little things for processing before starting work.

Brush for stripping fittings from the inside

Solder and flux

Soldering copper pipes of any type occurs with the help of flux and solder. Solder is an alloy usually based on tin with a certain melting point, but necessarily lower than that of copper. It is fed into the soldering zone, heated to a liquid state and flows into the joint. After cooling, it provides a tight and durable connection.

For amateur soldering of copper pipes with your own hands, tin-based solders with the addition of silver, bismuth, antimony, and copper are suitable. Compounds with the addition of silver are considered the best, but they are the most expensive, optimal ones with a copper additive. There is also with the addition of lead, but they should not be used in plumbing. All these types of solder provide good seam quality and easy soldering.

Flux and solder are essential consumables

Before soldering, the joint is treated with flux. A flux is a liquid or pasty agent that causes molten solder to flow into a joint. There is nothing special to choose here: any flux for copper will do. Also, you will need a small brush to apply the flux. Better - with natural bristles.

Burner

To work with soft solder, you can buy a small hand torch with a disposable gas bottle. These cylinders are attached to the handle, have a volume of 200 ml. Despite its small size, the flame temperature is from 1100 °C and higher, which is more than enough to melt soft solder.

What you should pay attention to is the presence of piezo ignition. This function is not superfluous in any way - it will be easier to work. A valve is located on the handle of a manual gas burner.

It regulates the length of the flame (the intensity of the gas supply). The same valve shuts off the gas if the burner needs to be extinguished. Safety is ensured by a non-return valve, which, in the absence of a flame, will shut off the gas supply

A valve is located on the handle of a manual gas burner. It regulates the length of the flame (the intensity of the gas supply). The same valve shuts off the gas if the burner needs to be extinguished. Safety is provided by a non-return valve, which, in the absence of a flame, will shut off the gas supply.

Hand torch for soldering copper pipes

Some models have a flame deflector. It does not allow the flame to dissipate, creating a higher temperature in the soldering zone. Thanks to this, the burner with a reflector allows you to work in the most inconvenient places.

When working in household and semi-professional models, you must be careful not to overheat the unit so that the plastic does not melt. Therefore, it is not worth doing a lot of soldering at a time - it is better to let the equipment cool down and prepare the next connection at this time.

Related materials

To cut copper pipes, you need a pipe cutter or a hacksaw with a metal blade. The cut must be strictly vertical, which provides a pipe cutter. And to guarantee an even cut with a hacksaw, you can use an ordinary carpentry miter box.

pipe cutter

When preparing pipes, they must be cleaned. To do this, there are special metal brushes and brushes (for cleaning the inner surface), but you can get by with sandpaper with medium and fine grains.

To remove burrs from cuts, there are bevelers. The pipe they have worked out fits better into the fitting - its socket is only a fraction of a millimeter larger than the outer diameter. So the slightest deviation leads to difficulties. But, in principle, everything can be eliminated with sandpaper. It will only take more time.

It is also advisable to have protective goggles and gloves. Most home crafters neglect these safety measures, but burns are very unpleasant. These are all the materials and tools needed for soldering copper pipes.

The essence of the process

The pipeline created in this way, due to the use of copper pipes during its installation, is highly reliable and exceptionally durable. Of course, such a system has a rather high cost, but it is fully justified by the unique characteristics that

What is important, copper pipes can be used both in plumbing and heating systems.In both cases, they demonstrate the highest reliability and durability.

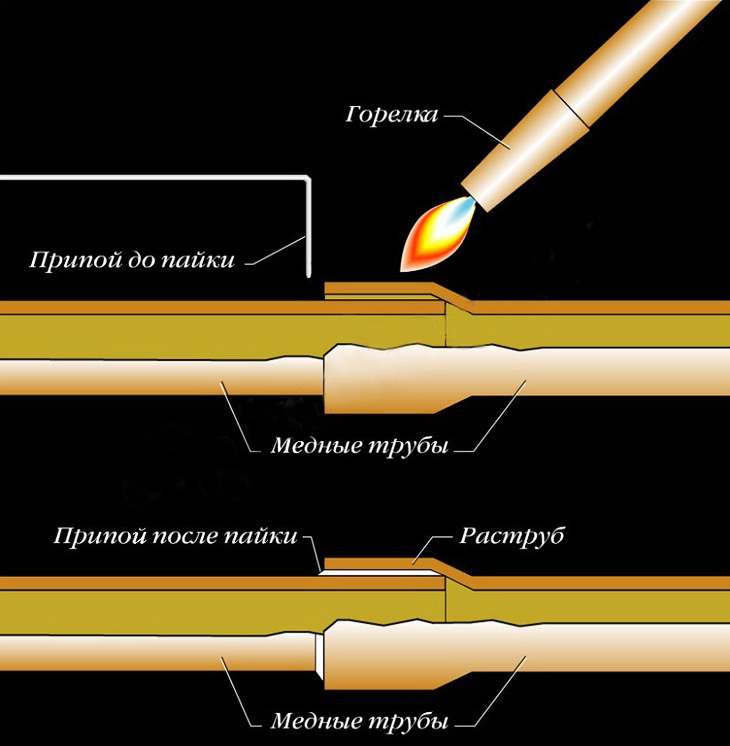

The simplest and most reliable way to install such systems is to solder copper pipes. This connection technology has been used for a long time, it is well studied and does not cause any problems in practical implementation. The essence of this method lies in the fact that the joint between the parts to be joined is filled with a special compound called solder. In order for the solder for soldering copper pipes to get in and fill the joint between the parts, it is melted under the influence of high temperature. After the heating of the solder stops, and it has already completely filled the future seam, it solidifies, forming a reliable, tight and durable joint.

Copper soldering is also convenient because, if necessary, the connected elements of the pipeline can always be easily separated. To do this, it is enough to heat the junction to make the solder soft and pliable.

Copper pipe soldering process

Methods for soldering copper parts

Soldering is considered the best method for joining copper parts. During operation, molten solder fills a small gap between the elements, thus forming a reliable connection. There are two most common ways to obtain such compounds. This is a high-temperature and low-temperature capillary soldering. Let's see how they differ from each other.

Features of high temperature compounds

In this case, the process of connecting copper elements takes place at a temperature exceeding +450 degrees. As a solder, compositions are selected, the basis of which is quite refractory metals: silver or copper.They give a strong seam, resistant to mechanical damage and high temperatures. Such a connection is called solid.

In the high-temperature capillary soldering process, the temperature exceeds 450C, BAg or BCuP refractory solder is used to form a joint.

A feature of the so-called hard soldering is the annealing of the metal, which leads to its softening. Therefore, in order to minimize the loss of strength characteristics of copper, the finished seam should be cooled only naturally, without using artificial blowing or lowering the part into cold water.

A solid connection is used for pipes with a diameter of 12 to 159 mm. Brazing is used to connect gas pipes. In plumbing, it is used in the process of assembling water pipes for monolithic joining of parts whose diameter exceeds 28 mm. In addition, such a connection is used in cases where the temperature of the liquid circulating in the pipes can exceed +120 degrees.

High-temperature soldering is also used for the assembly of heating systems. Its advantage is the possibility of arranging a drain from a previously installed system without its preliminary dismantling.

Brazing in detail

Soft or low-temperature soldering is the connection of copper parts, during which a temperature below + 450C is used. In this case, soft low-melting metals, such as tin or lead, are selected as solder. The width of the seam formed by such soldering can vary from 7 to 50 mm. The resulting joint is called soft. It is less durable than solid, but has a number of significant advantages.

During low-temperature soldering, a so-called soft joint is formed. It is less durable than solid, therefore it cannot be used when connecting gas pipes.

The main difference is that there is no annealing of the metal during the soldering process. Accordingly, its strength remains the same. In addition, the temperature during low-temperature soldering is not as high as during high-temperature soldering. Therefore, it is considered safer. The so-called soft joints are used to assemble small diameter pipes: from 6 to 108 mm.

In plumbing, low-temperature connections are used for the installation of water mains and heating networks, but on condition that the temperature of the liquid circulating in them is less than +130 degrees. For gas pipelines, the use of connections of this type is strictly prohibited.

How else can you connect copper elements

Long service life, corrosion resistance, light weight and antibacterial properties have made the copper connection quite popular in certain circles. High heat transfer allows the material to be used in cooling systems. Before soldering copper pipes, it is necessary to determine the method of soldering, in addition to temperature effects, there are various fittings, the use of which depends on the degree of damage or the design of the joint.

Fittings for copper pipe

Types of Brazed Copper Fittings

An alternative way to soldering is to use fittings to join copper pipes. There are two main types:

- Crimps have a ring inside the design, which makes it possible to create a tight connection. The structure is made of brass.

- Capillary fittings differing in diameter from the external indicator. The process involves soldering, by varying the diameters and compression, thereby making the connection.

The above docking methods are used in places where there is a frequent change of elements. The reasons for the replacement may be interaction with aggressive metals, docking with materials of different composition.

Features of copper soldering

Docking of segments is carried out from the processing of the edges of the metal. The size of the fitting must correspond to the given configuration, it is not allowed to stretch the metal to the desired size, in this case, strength and elasticity are lost. Cleaning occurs in order, the expanded element is cleaned inside, and the docked one is outside. When working with a soldering iron, solder is heated from the tip. For the implementation of a high-quality connection of copper pipes, experience is required, since irreparable errors can be made.

Copper products are used in almost all refrigeration equipment of various types. The material has proven itself in the industry, it is used for electromechanical purposes, when pumping combustible materials.

Cons of copper pipes

One of the main disadvantages is the high price of copper products. Alternative materials such as plastic or steel can be significantly cheaper. The metal material is soft, with the slightest external impact, deformation occurs, failure of a certain area.

The transfer of hot water in heating systems can be traumatic, since copper has a high heat transfer. Heat loss is excluded by the use of insulating materials; for safe operation, it is necessary to drown the pipes inside the finishing materials of the room.

Communications from copper pipes and fittings

High-quality copper pipes and fittings, the technical and operational characteristics of which comply with the international standards ISO 9002, BS2 and DIN, are now produced by both foreign and domestic companies. Such pipes, as well as connecting elements for them, successfully withstand the high pressure of the media transported through them, high and low temperatures, and mechanical stresses to which they may be subjected during operation, transportation and storage.

Unlike polymer pipes popular in our time, copper pipe products do not deteriorate from exposure to sunlight, they are not afraid of corrosion, which is a real scourge for products made from ferrous metals. In terms of the service life that copper pipes and fittings differ in, no similar product made from another material can be compared with them. It is noteworthy that copper products are practically eternal, the service life of communications from them is at least 100 years.

Heating and water supply system from copper pipes in a private house

Pipe products, as well as fittings made of copper, are used for arranging engineering networks for various purposes:

- heating systems;

- air conditioning;

- cold and hot water supply;

- gas communications.

Those consumers who decide to use copper pipe products and copper fittings mainly use them to equip reliable and durable water supply networks. Fittings made from copper are more compact and look much cleaner than those made from ferrous metals.This is explained by the fact that when designing and manufacturing copper fittings, there is no need to make their walls thicker, taking into account their further corrosion, since they are simply not subject to it.

Do-it-yourself installation of copper pipes in the heating system

There are several reasons explaining the high popularity of pipes and fittings for them made of copper:

- copper, as you know, has antiseptic properties, therefore, pathogens do not develop in water pipes made from this metal, and the quality of the water transported through them even improves;

- installation of pipelines for which pipes and fittings made of copper are used is much easier than communications from black pipes;

- due to the high plasticity of copper, pipes made of this metal, when water freezes in them, do not burst, but simply deform; to destroy a copper pipe, it is necessary to apply an internal pressure of 200 atm to it, and such pressures simply do not exist in household communications.