- What is needed for soldering copper pipes

- Methods for soldering copper parts

- Features of high temperature compounds

- Brazing

- Safety precautions when soldering copper pipes

- Insulation of branch pipes in the heating network

- Copper plumbing system

- Copper pipe for air conditioners

- Dremel soldering irons

- Other soldering options: work with copper pipes and various metals

- The nuances of soldering copper pipes: how to do it right

- How to solder copper wire to aluminum

- How to solder copper and stainless steel

- Soldering copper with iron - is it possible

- Necessary tools and materials

- Devices (soldering irons)

- Solders and other consumables

- Installation of water supply from copper pipes

- How to choose the right solder?

- Preparation for soldering

- Equipment

- materials

- Examples of finished water pipes made of copper pipes

- Soft soldering technology

- Avoiding Mistakes

- Rules for soldering copper

- Soldering large parts

- Soldering wires or wire

- Soldering dishes or soldering holes in copper

What is needed for soldering copper pipes

Soldering copper pipes, which is not difficult to do with your own hands, does not require expensive equipment and any special materials. In order to properly implement it, you will need the following devices.

A burner, due to which the solder and the pipe section where they will be connected will be heated.As a rule, propane gas is supplied to such a burner, the pressure of which is regulated by a welding reducer.

Special tool for cutting copper pipes. Since products made of this metal are very soft, they should be cut gently enough so as not to wrinkle the walls. Pipe cutters of various models are offered on the modern market, differing both in their functionality and technical capabilities.

The design of individual models of such devices, which is important, allows them to be used even for work in hard-to-reach places.

A pipe expander is a device that allows you to expand the diameter of a copper pipe, which is necessary in order to better solder. In various systems mounted from copper pipes, elements of the same section are used, and in order to connect them qualitatively, it is necessary to slightly increase the diameter of one of the connected elements. It is this problem that such a device as a pipe expander solves.

It is this problem that such a device as a pipe expander solves.

Copper pipe flaring kit

Device for chamfering the ends of copper pipes. After trimming, burrs remain on the ends of the parts, which can interfere with obtaining a high-quality and reliable connection. To remove them and give the ends of the pipes the required configuration, a beveler is used before soldering. There are two main types of chamfering devices on the market today: placed in a round body and made in the form of a pencil. More convenient to use, but also more expensive, are round devices that can process soft copper pipes with a diameter of not more than 36 mm.

To properly prepare copper pipes for soldering, it is necessary to remove all impurities and oxides from their surface. For these purposes, brushes and brushes are used, the bristles of which are made of steel wire.

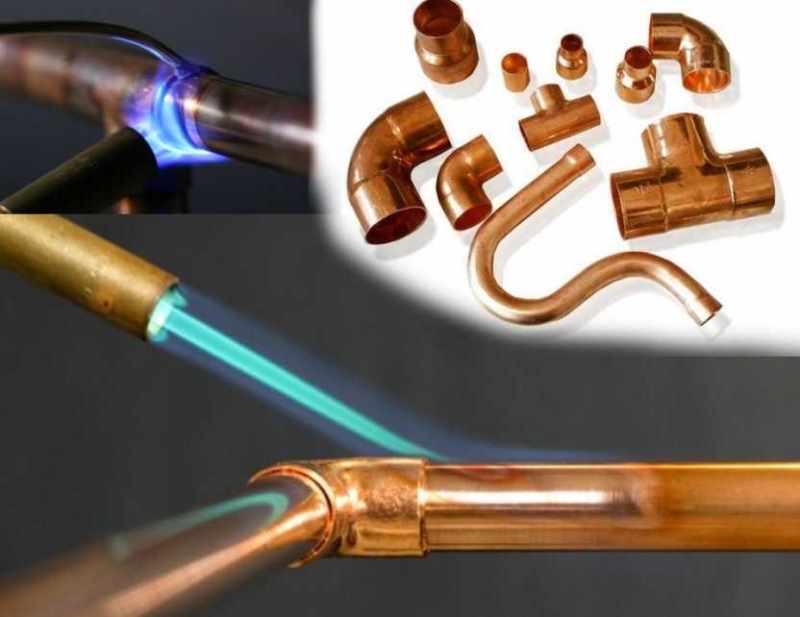

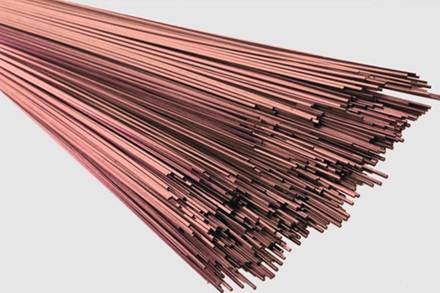

Brazing of copper pipes is usually performed with hard solder, which can be high and low temperature. High-temperature solder is a copper wire containing about 6% phosphorus in its composition. Such a wire melts at a temperature of 700 degrees, while for its low-temperature type (tin wire), 350 degrees is enough.

The technology of soldering copper pipes involves the use of special fluxes and pastes that perform a protective function. Such fluxes not only protect the formed seam from the formation of air bubbles in it, but also significantly improve the adhesion of the solder to the pipe material.

In addition to flux, solder and other basic elements, additional tools will be needed to solder copper pipes, which can be found in every workshop or garage. To solder or weld copper products, additionally prepare:

- regular marker;

- roulette;

- building level;

- a small brush with stiff bristles;

- a hammer.

Before starting work, it is also important to decide how to solder copper pipes. There can be two main options: brazing copper (less commonly used) and using soft solder. When resolving this issue, it is important to proceed from the fact that there are requirements for the use of one or another type of solder

So, hard solders are used for soldering elements of refrigeration units and air conditioners. In all other cases (water supply systems, heating systems, etc.), tin wire can be used.But whatever technology is chosen, it should be remembered that the flux is necessary in any case.

When solving this issue, it is important to proceed from the fact that there are requirements for the use of one or another type of solder. So, hard solders are used for soldering elements of refrigeration units and air conditioners.

In all other cases (water supply systems, heating systems, etc.), tin wire can be used. But whatever technology is chosen, it should be remembered that the flux is necessary in any case.

Cleaning brushes the inner surface of the copper pipe before soldering

Methods for soldering copper parts

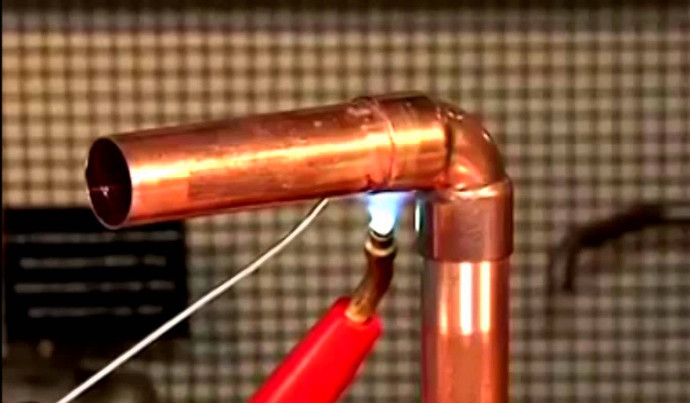

To connect copper pipes, only two soldering methods are used. Each one is used according to the part specification and characteristics. Do-it-yourself soldering of copper pipes is divided into:

- At high temperatures, it is otherwise called "solid". The temperature indicator in this mode reaches 900 °. Refractory solder allows you to produce a seam with high strength indicators, this method is used in the manufacture of pipelines subject to high loads.

- The soft soldering process is carried out at temperatures starting from 130 °, it is used in domestic applications when working with pipes with a diameter of up to 1 cm. The technology involves joining by docking, pre-treatment with flux paste.

During work, it is important not to forget that the power of the flame given out by the burner can reach 1000 degrees. Therefore, the processing of joints must be carried out no more than 20 seconds.

When heated, the soft solder begins to melt and fill the joint.

Features of high temperature compounds

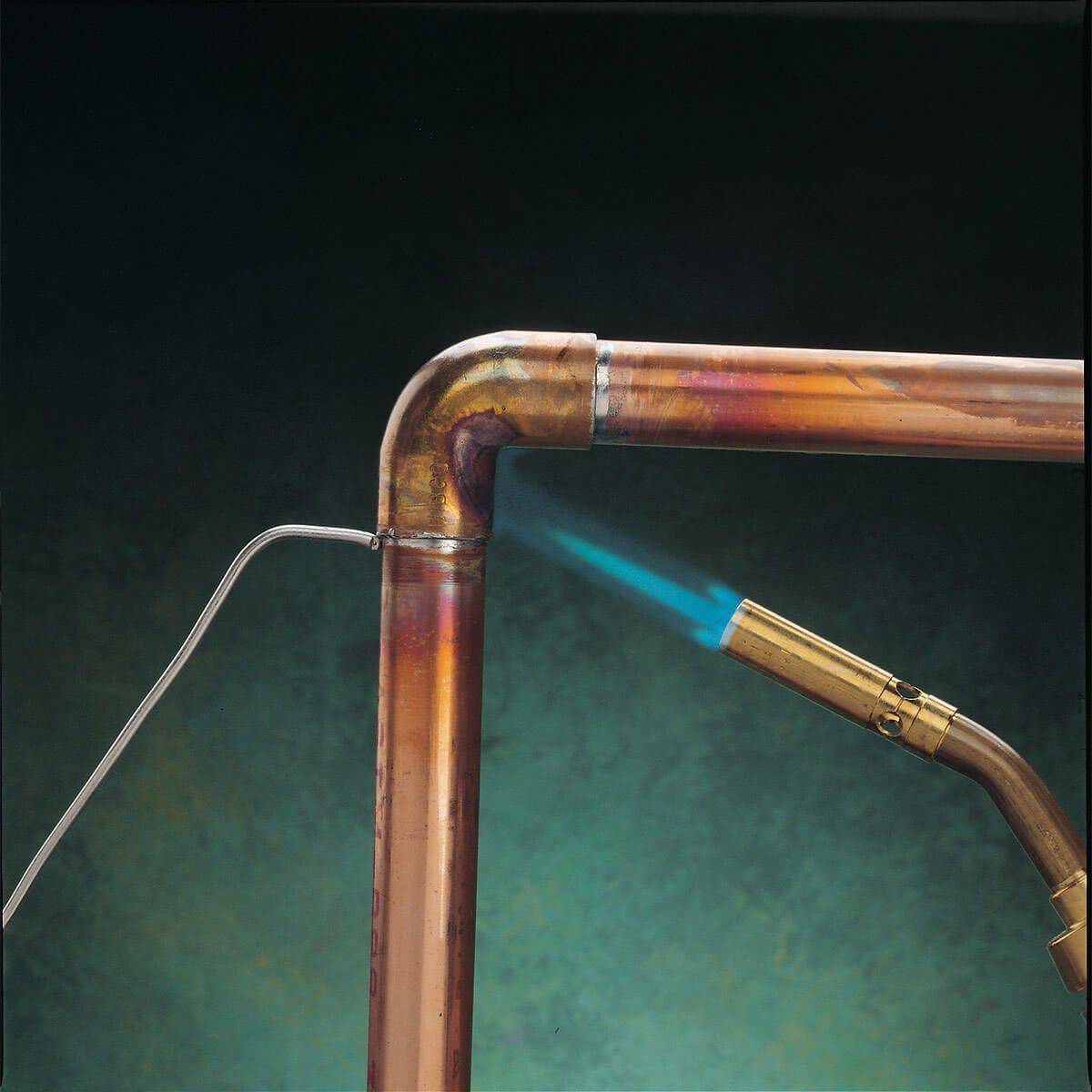

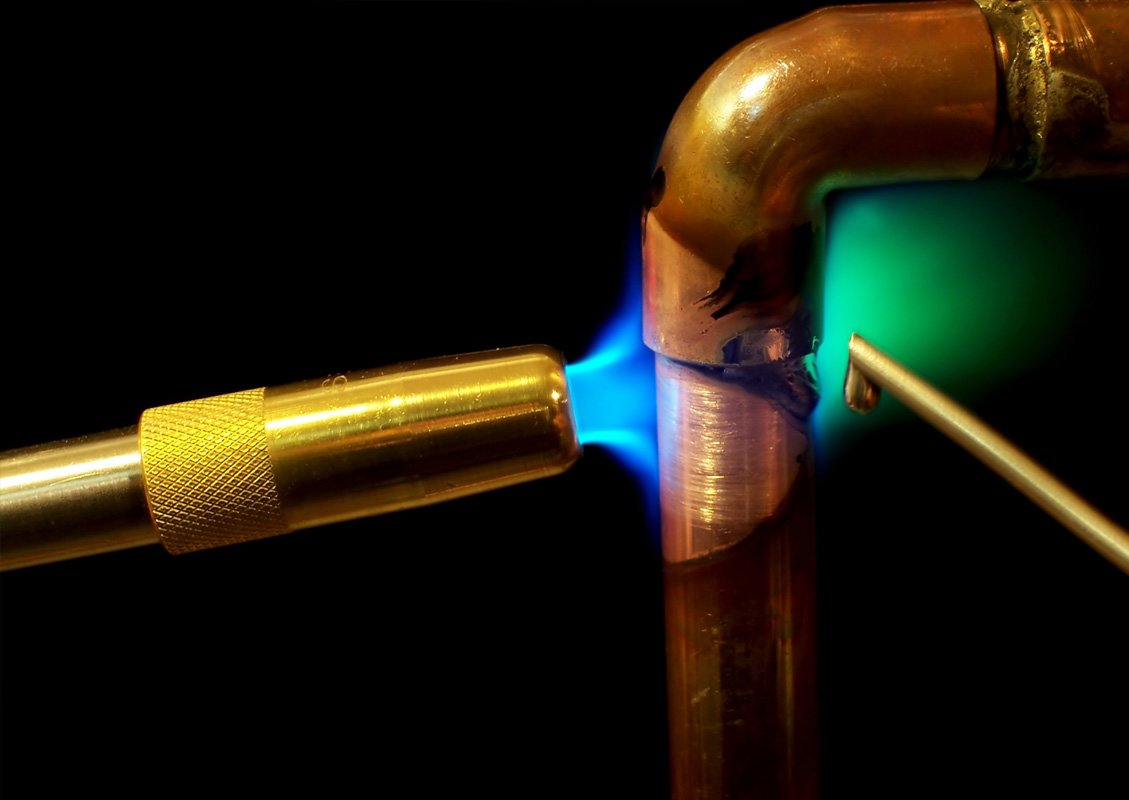

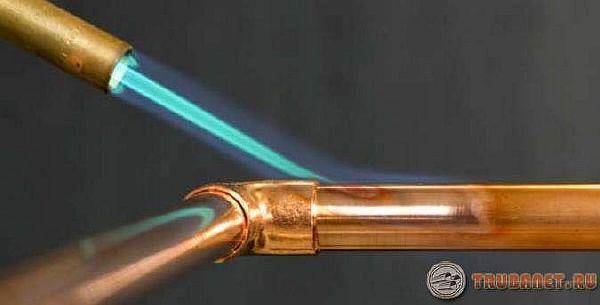

In the high-temperature soldering method, the metal is fired at 700 ° C and higher, which contributes to the softening of the metal. For soldering, flame equipment is used that is capable of melting hard solders. The solder consists of their copper-phosphorus composition, is produced in the form of rods. The process of soldering copper pipes does not imply the use of flux, following the sequence of actions, it is possible to correctly fill the joint.

High temperature copper pipe connection

The process starts when the solder rod melts, the work steps are:

- after assembly, the joining seam warms up;

- a solid-state solder is supplied to the junction, the softening of which is carried out by a gas burner;

- when it is visually confirmed that the solder is being applied to the metal, the pipe must be rotated, the docking must be checked along the entire perimeter.

The main advantages of this method is the high strength of the joint of copper pipes, if necessary, it is possible to change the diameter of the connection with a smaller side. High temperatures during operation cannot destroy the seam. Hard soldering requires certain skills; overheating is possible during operation, which leads to the destruction of the metal.

Brazing

Each process requires a responsible approach to the performance of work. For heating, a propane or gasoline burner is used when using soft solder by joining copper pipes

It is important to know that a burner with piezo ignition will significantly reduce the operating time; it is not advisable to purchase expensive models without this function.

Technological process

In the process, it is important to use high-quality accessories, flux paste plays an important role in the connection.Uniform coverage of copper pipe parts is achieved using a soft brush, after application, the excess is removed with a rag

The temperature of the burner can reach 900 degrees, when soldering it is important not to overexpose the product, otherwise overheating will occur.

Safety precautions when soldering copper pipes

Copper pipes are used as fluid conductors with good anti-corrosion properties. Installation of copper pipes cannot be performed to provide potable tap water. Copper comes into contact with chlorine, which is added to purify water, and can form substances harmful to the human body. For artesian sources, wells are not dangerous to use.

Soldering copper with gloves

It is important to use high-quality tools, work with gloves and monitor the condition of the equipment. The thermal conductivity of the metal is quite high, when one of the nodes is heated and safety precautions are not observed, it is possible to get burns

A high-quality seam can be obtained in the absence of external factors in the form of loads until the joint cools completely.

Insulation of branch pipes in the heating network

Video

Insulation of pipes in the heating network is carried out in order to reduce heat loss. Uninsulated copper fittings increase heat loss by five times, since this metal has a high thermal conductivity.

When asked how to insulate copper heating pipes hidden in a monolith (floor, walls), everything can be solved as follows. Corrugations will perfectly protect them from mechanical damage caused by temperature fluctuations of the heat carrier.

Copper plumbing system

Many people are trying to learn how to solder copper pipes for plumbing. Due to intensive use, the water pipe wears out quickly, which cannot be said about the copper pipe. This plumbing will last forever.

To connect a plumbing system made of copper pipes, a capillary soldering method (low-temperature and high-temperature) is used.

Video

Errors when soldering with these building materials for the water pipe lead to their corrosion. It appears in those places where the protective film is destroyed, which forms chlorine oxidation.

The reason for this is chlorine, which contains water. To avoid such corrosion, it is necessary:

- do not allow solder to get into the middle of the joint when soldering;

- purchase products from a trusted manufacturer;

- use water filters.

Copper pipe for air conditioners

This type of pipe assortment is used when installing an air conditioning network consisting of an indoor and outdoor unit.

Haldagen at the same time transports two copper pipes of different diameters. A workpiece of smaller diameter transports liquid freon, and the other - gaseous freon.

Such branch pipes from air conditioners lend themselves perfectly to soldering. For solder, phosphor-copper and silver types are recommended. And the aggregates themselves demonstrate high tensile strength.

Video

Briefly describe how to solder copper pipes for air conditioners, it will look like this:

- First get rid of the oxide film. Do it with sandpaper.

- After that, flux is applied to the cleaned areas.

- The fitting is connected to the pipe. In this case, we must not forget about the half-millimeter gap.

- The junction is heated at a temperature of almost three hundred degrees. Heating is carried out by a gas burner. Do this evenly, smoothly moving the flame along the structure.

- After you have finished soldering, it is imperative to flush the system, otherwise the flux residues will provoke metal corrosion, and this will lead to a breakdown of the air conditioner.

Dremel soldering irons

The problem of how to solder copper pipes is easily solved with a Dremel soldering iron. These small gas burners are able to burn, solder and cut. They easily remove old paint, defrost and heat up pipe materials for bending.

There is a soldering iron "Dremel" within 2000 rubles. With such a device, you can forget about a long warm-up and a large thermal gun.

The Dremel soldering iron comes with:

- soldering iron;

- burner nozzle;

- two knives of different sizes;

- reflex and crevice nozzle.

For ease of use, the device comes with several keys for changing nozzles, a protective cap for the mechanism and solder for soldering.

The hole is quite convenient to direct the heated air to the heat shrink tubes, and they can be installed without the participation of reflex nozzles.

Refuel the device with butane for gas lighters. One refill of the Dremel soldering iron is enough for an hour of work.

Video

This device is for home use. Professional analogues cost from 5 thousand rubles or more. Soldering with such a tool turns into a pleasure.

How to solder copper pipes, and the fact that this method is very effective is clear. After all, this does not require expensive special equipment.

It is important that the structure of the material itself remains unchanged.

The result is a strong and reliable joint that will last forever.The main thing when working is to follow the technology and act carefully.

Other soldering options: work with copper pipes and various metals

Soldering copper pipes requires some experience in this kind of work. Therefore, if a home master undertakes such work for the first time, it is worthwhile to practice beforehand so as not to redo the already finished water supply or heating line several times. Copper tubes can be soldered with both hard solder (using a gas burner) and soft alloys. In the second case, for copper pipes, it is appropriate to use a high-power hammer soldering iron.

Accurate and high-quality soldering is the key to the durability of the connection

The nuances of soldering copper pipes: how to do it right

As a flux for soldering copper pipes, it is best to use rosin. It is applied in an even layer on the outer surfaces of the pipe, after which the fitting is mounted on it. On its reverse side, the second part of the highway is mounted. Next, the fitting is heated with a gas burner and solder is “fitted” along the seams. Under the influence of high temperature, it melts, filling the seam and creating a high-quality tight connection.

Sometimes you have to do without fittings

Soldering copper pipes with your own hands is not too difficult, but this work requires care and accuracy. Of course, in words, not everything can be explained intelligibly, so we bring to the attention of the Dear Reader a video on how to solder copper with a gas burner, from which everything will become more clear.

Watch this video on YouTube

Having dealt with the question of how to solder copper pipes at home, you can move on to the next problem, namely the soldering of non-identical metals (copper with aluminum, iron or stainless steel).

How to solder copper wire to aluminum

Soldering aluminum with copper is a rather complicated process. It should be noted that the same solder is hardly suitable for aluminum as for copper, and vice versa. It is much easier to match these metals using a steel sleeve. Although today the manufacturer offers special solders and fluxes for such purposes, their cost is significant, which leads to the unprofitability of such work.

Soldering copper and aluminum is quite difficult

The whole problem lies in the conflict between copper and aluminum. They have different refractoriness, density. In addition, aluminum, when interacting with copper, begins to oxidize strongly. This process is especially accelerated when an electric current passes through the connection. Therefore, if necessary copper and aluminum connections wires, it is best to use WAGO self-clamping terminal blocks, inside which there is Alyu Plus contact paste. It is she who removes oxide from aluminum, prevents its subsequent appearance and promotes normal contact with copper conductors.

Having figured out how to solder copper to aluminum, you can move on to harder metals.

Sometimes such a connection is indispensable

How to solder copper and stainless steel

When soldering copper with stainless steel, not even the solder material itself plays an important role, but the tool used, although a lot depends on consumables. The most acceptable materials in this case are:

- copper-phosphorus solder;

- pewter silver (Castolin 157);

- radio engineering.

Some craftsmen claim that with the right approach to work, even the most common solder based on tin and lead will do.The main thing is the mandatory use of flux (borax, soldering acid), thorough heating and only after that soldering (soldering).

Complex soldering of copper and stainless steel

Such compounds are rare, and therefore specialized solders for such purposes are quite expensive.

Soldering copper with iron - is it possible

This option is possible, but subject to certain conditions. For example, a simple propane burner is no longer suitable as a heater. You must use propane with oxygen. Borax should be used as a flux, but brass will act as a solder. Only in this case can we hope for a normal result. It is not difficult to buy solder for soldering copper with iron or stainless steel. The main thing is to understand whether the extra costs will be justified.

Soldering copper and iron tubing is also possible

And now we offer to look at how carefully home craftsmen can perform work on soldering pipes of highways for various purposes.

1 of 5

Necessary tools and materials

Devices (soldering irons)

As you know, soldering irons can be gas and electric. A gas soldering iron will provide a faster heating rate, but this is almost always accompanied by overheating of the metal. The electric one is slower, but it has a controlled heating temperature. In addition, there is no open flame, which makes the soldering iron safer to handle, especially when there may be other materials, devices, or flammable substances in the soldering area.

The selection options are:

The selection options are:

- Power.The minimum will be the one that will ensure the heating of the metal in the soldering zone to a temperature not lower than 450C. More powerful devices are also available for sale: for example, the Rotenberger Rotherm 2000 soldering iron guarantees heating up to 800 ... 900C (however, it costs much more than budget models of domestic or Chinese production).

- Power supply - from a stationary power supply or battery through a step-down device. It is more reliable and easier to use a soldering iron with a direct connection.

- Weight. When performing complex manipulations with the device, it is better that the soldering iron is as light as possible, especially if you have to solder copper pipes in not very comfortable conditions.

- Cross-sectional area of the contact. The thicker the wall of the pipe, the more powerful the soldering iron should be.

Soldering iron for PVC pipes: an apparatus for welding plastic types, description PVC pipes are increasingly used in private and multi-storey construction instead of metal counterparts. They are light weight, high strength, corrosion resistant. To connect elements...

Solders and other consumables

The solder is injected into the gap between the pipe and the fitting, the area of which affects two important aspects of copper pipe soldering: joint strength and ease of soldering. From a strength point of view, it appears that the larger the overlap area, the better. In fact, this is not the case: it has been proven that an overlap that is twice the thickness of a thinner element no longer makes the connection stronger, but only makes it difficult to create a reliable connection.

The reasons are as follows. First, the brazed metal must flow evenly into the gap between the parts along the entire length and circumference of the joint.One obstacle is that the longer the overlap, the longer the brazed metal must flow, and the more it has the ability to trap the gases released when the pipes are soldered. This causes gaps in the joint. Sufficient flux supply and sufficiently high uniform heating of the joint promotes the flow of brazed metal into the joint, but as the overlap increases and the diameter increases, this process is more difficult to achieve.

Second, the solder begins to melt at a temperature lower than the temperature of the melt, called the solidus temperature. Just above this temperature, solder filler is a mixture of solid plus liquid. In such a highly viscous state, the metal cannot easily get into the tightly fitting joint.

As the solder warms up, it becomes more liquid, reaching liquidus temperature. Fluidity increases, so the filling of the gap occurs much faster. Therefore, the lower the liquidus temperature and its difference with the solidus temperature, the more optimal the solder.

During soldering, a small amount of copper dissolves into the solder, and a small amount of solder alloying elements, on the contrary, diffuses into the base metal. When this happens, the chemistry of the solder changes and this reduces fluidity.

Fortunately, the diffusion process is slower than the time it takes for the brazed metal to flow into a properly heated joint. The longer the weld is at the soldering temperature, the more the composition of the solder approaches that of copper.

Installation of water supply from copper pipes

Installing a plumbing or heating system made of copper is not much different than installing a plumbing or heating system made of other materials. At the first stage, a well-thought-out scheme of the entire route is needed, with well-adjusted corners and connections. Recall: the scheme should include a mandatory connection to the pipes of the main riser through ball valves, metering devices, additional outlets for future plumbing.

Plumbing from copper pipes

Plumbing from copper pipes

The choice of types and sizes of pipes: annealed and non-annealed, with 3/8 or 3/4 threads, with walls of various thicknesses: K, L, M. The weight of the copper pipe, and hence the entire water supply structure as a whole, may depend on such details, however, the essence of the installation as a whole will not change. The choice of technology for connecting copper pipes: soldering or push fittings. The choice is always up to the consumer, but we note briefly: the reliability of the connection of push fittings is not very high. It requires constant monitoring, and fittings require systematic tightening, while soldering copper water pipes means providing them with long-term and indispensable tightness. The main difference is the method of joining copper pipes with soft solder: it requires certain skills and equipment.

How to choose the right solder?

Correctly selected solder will help to organize a communication system of any complexity without much effort. When it comes to working at home, you should use a material that melts at low temperatures.

The use of high-temperature hard-melting elements in everyday life is problematic, since it requires heating the working alloy to 600-900 degrees. To achieve this without special equipment is quite difficult.

Soldering food copper can be carried out with special solders that do not contain toxic, poisonous and aggressive elements that can harm health

Soldering food copper can be carried out with special solders that do not contain toxic, poisonous and aggressive elements that can harm health

The use of metals and their derivatives that melt at high temperatures is associated with some risk. During processing, they can damage or even burn through a thin-walled copper pipe.

To prevent this from happening, it makes sense to take a strong, but low-melting soft solder, and leave the solid version for thick-walled copper communications.

When high loads are not expected on the system, it is not at all necessary to use high-melting solder, unless otherwise required. In the main household complexes, soft light-alloy solders are quite enough to create a reliable connection.

When high loads are not expected on the system, it is not at all necessary to use high-melting solder, unless otherwise required. In the main household complexes, soft light-alloy solders are quite enough to create a reliable connection.

To connect copper pipes in gas networks, it is worth choosing silver-containing solders. They provide maximum joint strength, vibration neutrality and high resistance to external and internal influences.

It will cost a little more to pay for silver, but the security, reliability and durability of the system will pay off all the financial costs over time.

Preparation for soldering

Before performing work on welding copper pipes, it is necessary to prepare:

- required equipment;

- Additional materials.

Equipment

For soldering, you will need the following equipment for copper pipes:

special device for cutting material. Copper is a fairly soft metal, so the pipe cutter must be of high quality. To determine the size of the pipes, you will also need a tape measure and a marker, and for the correct connection of the pipes to each other, the building level;

Pipe cutter

beveler - a device for processing the ends of pipes before soldering.Additional processing of pipes allows you to get a stronger connection. The beveler can be separate equipment or built into the pipe cutter;

Pipe end processing equipment

pipe expander. Pipelines are made of pipes of the same diameter. It is possible to connect individual sections of pipes into a single system using special devices - fittings - or directly to each other without additional devices. If fittings for soldering copper pipes are not used, then in order to obtain a strong connection, it is necessary to slightly increase the diameter of one of the pipes to be joined, for which a device such as a pipe expander is used;

Device for increasing the diameter at the end of the pipe

a soldering iron for copper pipes is the main device that heats the material for welding. Most often, a gas propane torch is used as a soldering iron, which can be equipped with a disposable or stationary cylinder. A device with a disposable cylinder is used for the construction of household pipelines with your own hands. Burners with stationary refillable cylinders are used by professional craftsmen who weld pipes quite often.

Tool for heating pipes during soldering process

metal brush (brush) for cleaning the surface of pipes from dirt and oxides. For better processing of the material, you can also use fine sandpaper.

Device for cleaning pipes before soldering

It is not advisable to purchase the necessary tool to perform a single job, for example, assembling a pipeline at home, since the financial costs of purchasing a device are quite high. Any tool can be rented in specialized stores.

materials

Welding of copper pipes is carried out using:

- solder;

- flux.

Solder is a special alloy designed to fill the space between pipes during the soldering process. The material increases the strength of the seam and allows you to increase the service life of the pipeline.

Depending on the melting temperature, the following types of solders are distinguished:

soft or low temperature. The melting temperature of the alloy does not exceed 300ºС. The alloy used is based on lead. Additionally, tin, zinc or silver are added. Soft soldering is suitable for pipelines with a temperature of the passing substance not more than 110ºС and with a pressure of not more than 16 atmospheres. The specified parameters correspond to domestic water pipes;

Low temperature alloy for brazing copper pipes

solid or high temperature. It is used for pipelines with increased pressure or temperature of the passing medium, for example, for a heating system. The basis of the alloy is copper. Silver, zinc, titanium are used as additional metals. The melting temperature of such solder is on average 700ºС.

High-temperature alloy for soldering pipelines with improved performance

Hard and soft soldering is carried out using an additional substance - flux, which performs the following functions:

- additionally cleans the soldering points from oxides that prevent the formation of a strong connection;

- degreases the connected sections of the pipeline;

- increases the spreadability of the solder used for soldering, thereby increasing the strength of the joint;

- protects the junction of pipes from oxidation during the use of the pipeline.

Flux can be:

- high temperature (more than 450ºС);

- low temperature (less than 450ºС).

The type of flux is selected for a certain type of soldering, respectively.

Flux can be produced:

- in liquid form;

- in solid form;

- in the form of a paste.

Varieties of fluxes for soldering

Examples of finished water pipes made of copper pipes

In the following photos, there are several examples in which the plumbing of copper pipes is already ready:

And here is a copper pipe in the underfloor heating system (although not quite on the topic of the section):

Do-it-yourself installation of copper pipes is relatively uncomplicated, but not everyone can afford plumbing from copper pipes - the price of copper pipes is very high. In addition, when the water quality is low, the pipes oxidize, turn green, and copper oxides that enter the (drinking) water, to put it mildly, do not bring health benefits. So it's up to you to decide whether to use copper pipes in your home's water supply system.

do-it-yourself copper pipe installation, copper pipe plumbing

Soft soldering technology

Before soldering copper pipes, a few words of theory are needed: if the soldering process is more conscious, then many subtleties will become clear as the work progresses. In everyday life and during the installation of plumbing systems in apartments, the so-called “low-temperature”, “soft” soldering is used: soldering points are heated up to 250-300 C, which allows soft solder (usually tin) to melt, however, these temperatures are also dangerous for copper pipes, so exposure should be directed and short-lived.

Soft solder copper water pipes

Soft solder copper water pipes

Cleaning pipes immediately before soldering is not a simple aesthetic manipulation, but a prerequisite that allows you to get rid of oxidation products on the metal and most effectively bond materials. When soft soldering, a capillary effect occurs, in which the molten solder soft for soldering copper pipes evenly spreads over the entire surface of the joint, regardless of whether the pipe is in a horizontal or vertical position. The recommended gap between the walls of the pipe and the fitting is strictly set - 0.1-0.15 mm: a larger distance requires more solder or will not give a capillary effect at all, a smaller one will create an unnecessary obstacle for the solder to spread.

Avoiding Mistakes

When soldering copper tubes, novice craftsmen often make a number of common mistakes. These are:

- Weak heating of the elements of the line, as a result of which the melting of the solder occurs incompletely. Such a connection will collapse under any load.

- Excessive overheating of the copper alloy, on the contrary, leads to the destruction of the flux layer. This, in turn, will lead to the formation of oxide and scale on the metal surface. Such an effect will also lead to the destruction of the connection.

- Ignoring security measures. Since work is carried out with chemical elements and at high temperatures, protective gloves and a mask should be worn.

- If you are going to check the connection, you should make sure that the tube at the soldering point has cooled down.

- When soldering, it is necessary to ensure good ventilation of the room. This is required by the technology of work, since soldering is performed using aggressive acidic substances.

- Protective clothing made of rough fabric will also not be superfluous, since there is a risk of flame sparks and solder particles falling on the body, which can lead to burns.

Video: technology for soldering copper tubes

Rules for soldering copper

When it is necessary to solder a copper product or a product containing copper components, it is impossible to give an unambiguous answer as to how and what is the best way to do this. The choice of method and tools depends on many factors, such as the size and weight of parts, their composition. The load to which already soldered products must be subjected is also taken into account. There are several soldering methods, and it is better to know them all in order to choose the most suitable one if necessary.

Soldering large parts

Scheme of capillary soldering of copper.

If you need to solder massive or large parts that cannot be heated to the desired temperature with a soldering iron, a torch and copper solder are used. The flux in this case is borax. The strength of copper-phosphorus solder is higher than that of standard tin solder.

A thin layer of flux is applied to the mechanically cleaned pipe or wire. After that, a fitting is put on the pipe, also mechanically cleaned. Using a gas burner, the junction is heated until the flux-coated copper changes color. The flux should become silvery in color, after which you can add solder. The solder melts instantly and penetrates into the gap between the pipe and the fitting. When drops of solder begin to remain on the surface of the pipes, the solder is removed.

Do not overheat the pipes, as this does not contribute to the appearance of a greater capillary effect. On the contrary, copper heated to blackness is less solderable. If the metal begins to blacken, the heating should be stopped.

Soldering wires or wire

Zinc chloride solder should not be used to solder thin copper wires, as this will destroy the copper. If no flux is available, in this case you can dissolve an aspirin tablet in 10-20 ml of water.

Scheme of copper welding in an inert gas environment.

Copper wire or parts made of wire of various sections can be easily heated to the desired temperature using a soldering iron. The temperature regime should be the one at which the solder melts, tin or lead-tin, and soldering is also performed by it. Fluxes must contain rosin or be made from rosin, soldering oil or even rosin itself can be used.

The surface of the wire is cleaned of dirt and oxide film, after which the parts are tinned. This process involves applying a thin layer of flux or rosin to the heated copper, and then solder, which is distributed over the surface as evenly as possible with a soldering iron. The parts that need to be connected are connected and heated again with a soldering iron until the already solidified solder begins to melt again. When this happens, the soldering iron is removed and the joint cools down.

Parts can be clamped in a vice so that the distance between them is 1-2 mm. Flux is applied to the parts and heated. Solder is brought to the gap between the hot parts, which will melt and fill the gap. The melting temperature of solder for soldering in this way must be lower than the melting temperature of copper so that the parts do not deform. The part cools down, then it is washed with water and finished, if necessary, with sandpaper until smooth and uniform.

Soldering dishes or soldering holes in copper

When soldering dishes, pure tin is used, the melting point of which is higher than that of tin or lead-containing solder. Sometimes, for soldering large parts, hammer soldering irons are used, heated on an open fire with a gas burner or blowtorch. In the future, everything happens according to the standard scheme: cleaning, fluxing and tinning, joining parts and heating with a soldering iron. It is for this soldering iron that pure tin solder is convenient.

From the inside, the fitting, as a rule, has a border that prevents it from being threaded through the pipe. It can be removed with a coarse file if the fitting needs to be pushed onto the pipe further than intended and the unnecessary hole must be soldered in this way.