- Price policy

- Soldering iron features

- How much power is consumed

- Types of nozzles

- Which firm is better?

- The first acquaintance with a soldering iron for pipes

- Do-it-yourself soldering iron for pipes

- Popular models

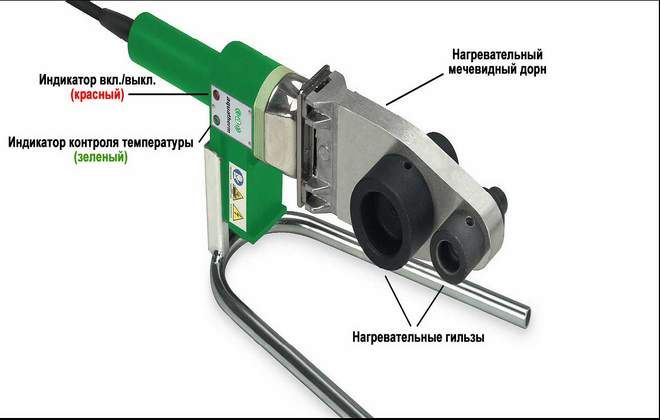

- Types of soldering irons for polypropylene and their device

- Features of the operation of the soldering iron

- The best machines for socket welding of polypropylene pipes

- Caliber SVA-2000T

- Sturm TW7219

- Gigant GPW-1000

- Soldering iron device for polypropylene pipes

- Choosing the right tool

- Conclusion on the topic

- Conclusion

Price policy

How much money you have to pay for the purchase of a soldering iron - the market itself will better answer.

Several important factors play into the pricing policy. The first of them is the reliability of the equipment and its durability. This can only be provided by a manufacturer with a reliable reputation.

The next factor is the purpose:

- professional equipment;

- home use tool.

A professional tool costs about $500. Household appliances are less durable and cost an order of magnitude lower, around $100. Of course, you can find cheaper, but the quality will remain in question.

A professional tool costs about $500. Household appliances are less durable and cost an order of magnitude lower, around $100. Of course, you can find cheaper, but the quality will remain in question.

Different configurations can make the tool much more expensive.

It is worth paying attention to the quality of the additional tool.As a rule, in an inexpensive device, nozzles are also of poor quality to reduce cost.

As a result of their use, it is easy to ruin the highway.

Soldering irons of an imported manufacturer are equipped with better nozzles, which is why their cost is higher, but they last much longer. In any case, the nozzles last less than the welding machine. We have to change them after two years of operation, but this is not scary - the market is saturated with such consumables.

Professional pipeline assemblers change nozzles several times a year. The operation of the water supply system, its durability and functionality depend on high-quality soldering.

Soldering iron features

Before choosing the required device, it is important to familiarize yourself with the contents and main technical characteristics of a particular device. It is worth remembering that factors such as:

It is worth remembering that factors such as:

- Heating element power;

- Nozzle quality;

- Where was the equipment manufactured?

- What price range is it in.

How much power is consumed

Some Internet users and amateurs claim that this parameter should be no less than ten times the size of the product. That is, if the product has a diameter of more than 63 mm, then the recommended power is not less than 650 watts. But this approach is inappropriate, so there is no point in paying attention to it. Since 79% of soldering irons consume more than 1 kW and at the same time show high efficiency

It is also important to remember that most products offered in stores have a power of 800 watts (minimum) to 2 kW (maximum).For this reason, regardless of the model chosen, the user will have enough power to install a home plumbing system.

Soldering irons that are equipped with a perfect heating element and have a power 1.5-2 times higher than the previous value, only reach the set temperature faster. Otherwise, they are almost similar to less powerful counterparts.

It is also important to remember that the power of the equipment does not really affect the final cost of the product. Therefore, when considering this parameter, a person, first of all, takes into account electrical safety

Since not every wiring is designed for 4 kW. Therefore, experts recommend buying a two-kilowatt soldering iron, it will last for a long time. However, if a person is afraid to purchase equipment of such power, but he does not want to buy with a minimum value, then the best option is a device with an electrical energy consumption of 1.2 kW or more.

Types of nozzles

This element is always present in the device kit. Due to the shape of the heater, they can be made in two versions. For flat electric heaters, products are used that are closed from a certain place on the cylinder. Fastening takes place on both sides.

Fixing is carried out by means of bolts. This design is more efficient due to the fact that the surface of the element has more contact, due to which heating occurs in a couple of minutes and evenly. Also, the speed is affected by the number of nozzles located on the rod of the heating element.

Mandrels and sleeves are made of metal and coated with Teflon, which prevents plastic from sticking.

It is also important to remember that, regardless of the simplicity of the design of the nozzles, this element is fragile and requires careful maintenance. In addition, in cheap devices coated with a thin layer of Teflon, rapid erasure occurs, which makes the device useless.

Therefore, it is important to buy products only from trusted companies that have proven themselves. Because a visual inspection of the thickness will not give the desired results.

Several nozzles of standard diameter are included as standard. Also, some equipment is sold with a mandrel and a sleeve with a larger diameter up to 60 mm.

It is important to consider that good nozzles are expensive. Therefore, when a person sees a dozen elements in a set, but at the same time the cost is record low, you should know that most likely there is a small thickness of the protective layer

It is better to purchase a minimum number of devices, and in the future to buy them if necessary.

Which firm is better?

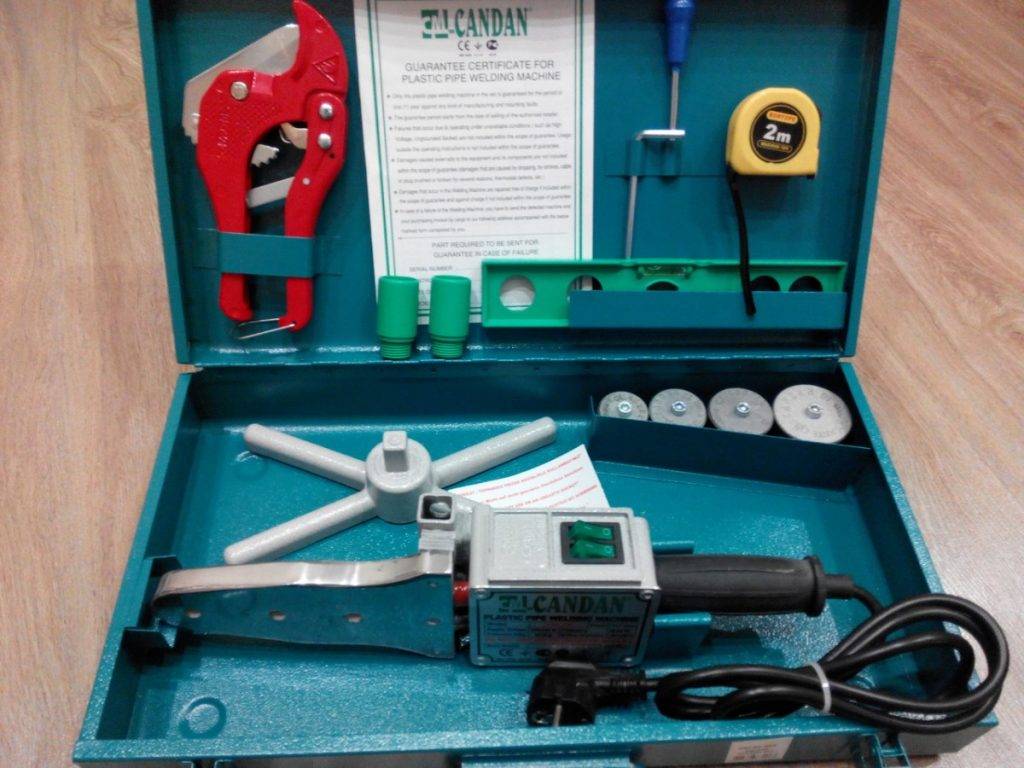

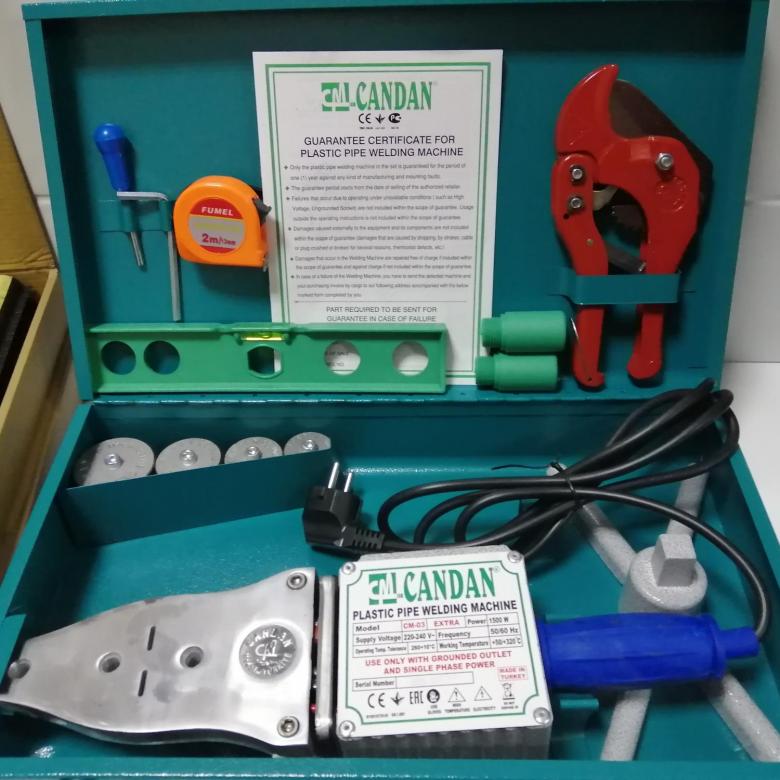

Due to the fact that no user is able to assess the external condition by the type of soldering iron, it is important to know the best manufacturers that have been in demand by professionals for decades and have excellent equipment. One of the best representatives in this area is Candan, which produces devices with an acceptable price-quality ratio, MEGEON, Enkor, Rothenberger, etc.

Most experts recommend buying products from German manufacturers. Their devices will last longer, however, the price is ten times higher.

One of the best representatives in this area is Candan, which produces devices with an acceptable price-quality ratio, MEGEON, Enkor, Rothenberger, etc. Most experts recommend buying products from German manufacturers. Their devices will last longer, however, the price is ten times higher.

The first acquaintance with a soldering iron for pipes

All soldering irons, regardless of purpose, have a similar design. They consist of a heating element and a heat-insulating handle that prevents burns. The function of the heater, as you might guess, is to melt the working medium when the desired temperature is reached.

An electric soldering iron for polypropylene pipes has a handle shape common to all soldering irons, however, instead of the heater used in conventional products of this kind, a heating tire is installed in the soldering iron for pipes, on which nozzles are fixed for heating the connected pipe and fitting.

Another distinctive feature of the soldering iron for propylene pipes is the presence of a heating process control device. Its necessity is due to the fact that polypropylene is a thermally unstable material that begins to “flow” already at 260 ° C.

As a result, without proper monitoring of the heating process of the material, there is not only damage to consumables, but also an unreasonable waste of time, own effort and money. The unit regulates the temperature and duration of heating of products, depending on the pipe section and the thickness of the coupling.

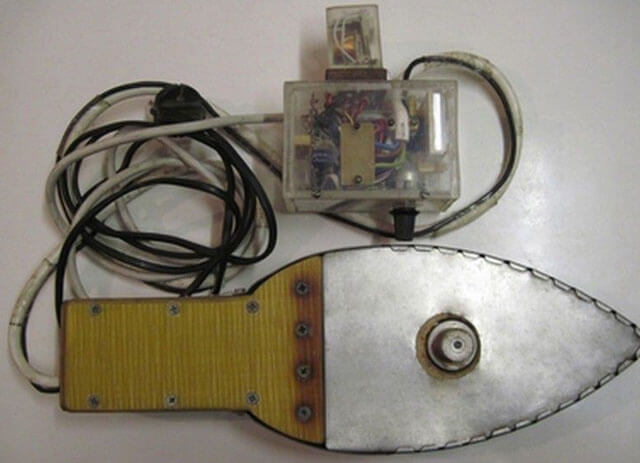

Do-it-yourself soldering iron for pipes

It should be noted that such soldering irons are unreliable and require constant monitoring during operation, because there is no heating control unit in them, which means that there is always a risk of overheating and ruining the pipe.As a result, not only the time of the work will increase, but also its cost.

To make a homemade soldering iron for polypropylene pipes, you need:

- Cut out two plates from a sheet of copper or aluminum.

- Make holes for nozzles in blanks.

- Attach wire contacts with an electrical plug to the plates.

- It is best to add a layer of non-conductive material between the plates, this will increase the heat transfer of the nozzle.

- Attach a handle (made of non-conductive material) to the assembled structure, insulate the contacts.

Whatever soldering iron is used to connect pipes, it should work according to one general principle.

Popular models

Below is a ranking of the three best-selling models in 2017 from various brands. Descriptions of soldering irons for polypropylene pipes are given taking into account average prices. Models are listed in order from “worst” to “best”, taking into account user opinion and value for money.

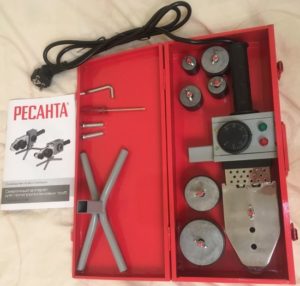

RESANTA ASPT-1000

This model has the lowest price among the presented non-professional sets. Country of brand and manufacturer - China. The average price in stores is 1430 rubles.

With this kit, you can work with polypropylene pipes with a diameter of 20 mm to 63 mm. Heads of appropriate sizes are coated to prolong their service life. The maximum power of the soldering iron is 1 kW.

The temperature is adjustable from 50 to 300℃. Visual control of the working state of the soldering iron by light indicators is allowed.

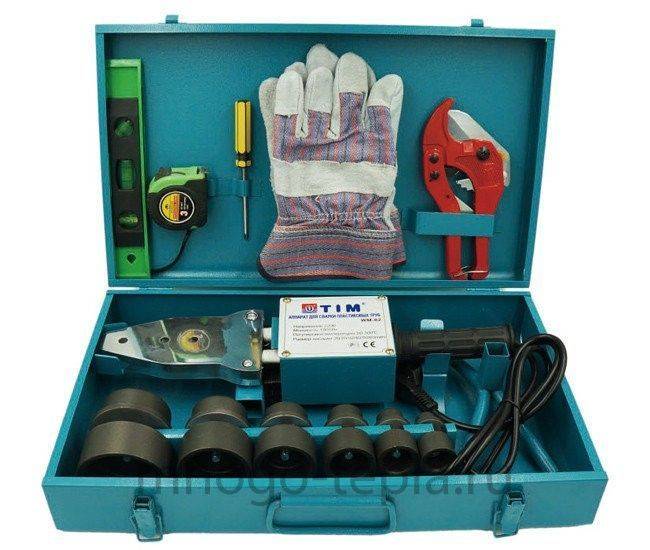

The set is completed with a stand with a wrench for installing nozzles and a screwdriver, supplied in a case.

According to user reviews, the device for polypropylene pipes is in demand due to its low price, light weight, and the presence of a long power cord.

Of the shortcomings, the poor quality of the nozzles is most often indicated (there are bumps and burrs), a not very functional temperature switch.

ENKOR ASP-1500/20-63

This is perhaps the easiest kit to use for beginners. The country of the brand is Russia, the soldering iron is produced in China. The average price is 2600 rubles.

The temperature controller allows you to set two values. The set includes three nozzles - 16, 25, 32 mm. Heater power 1.5 kW. In user reviews, the unreliability of the thermostat is noted. But at the same time, the service network is well developed.

BRIMA TG-171

The country of the brand is Germany. Produced in China. Average price: 4055 rubles.

The tool is very compact and reliable. For soldering polypropylene pipes there are nozzles from 20 mm to 63 mm. The power is only 750 W, but this is quite enough to quickly warm up the nozzles and melt the material. The temperature controller works very accurately.

The tool is very compact and reliable. For soldering polypropylene pipes there are nozzles from 20 mm to 63 mm. The power is only 750 W, but this is quite enough to quickly warm up the nozzles and melt the material. The temperature controller works very accurately.

The set comes in a metal case, which also contains scissors for cutting polypropylene pipes, a marker and a tape measure.

According to user reviews, the disadvantage is not a very stable stand.

Types of soldering irons for polypropylene and their device

Devices that solve similar problems work according to the same scheme. They are essentially a simple heater, which is equipped with certain microcircuits for temperature control.

The main purpose of the heated part is to maintain a certain temperature, which will be sufficient for the thermal connection of polypropylene pipes.This temperature is set at 250-260 degrees Celsius.

There are various types of soldering irons for polypropylene pipes. All of them have approximately the same design, like the principle of operation. There is always a body on top of which the handle goes. All electronics are mounted just in it.

Regardless of the design, soldering irons first heat the front part to the desired temperature, which is set by the user using the thermostat, then turns off the heating.

Further, the device turns on only after the temperature of the heating element drops below the set value. There is a window of 5 degrees Celsius for this. After passing it, the thermostat, or the microcircuit that is responsible for this, again applies voltage to the heated surface.

Devices whose configuration cannot be changed performed very poorly in the market. Awfully low versatility has led to the fact that this can be seen very rarely

The attention and hearts of buyers were kept by devices that require nozzles for a soldering iron for polypropylene pipes.

They are of two kinds. It depends on the shape of the heating element. It can be in the form of a cylinder, on which you need to put on the nozzle and tighten its fasteners.

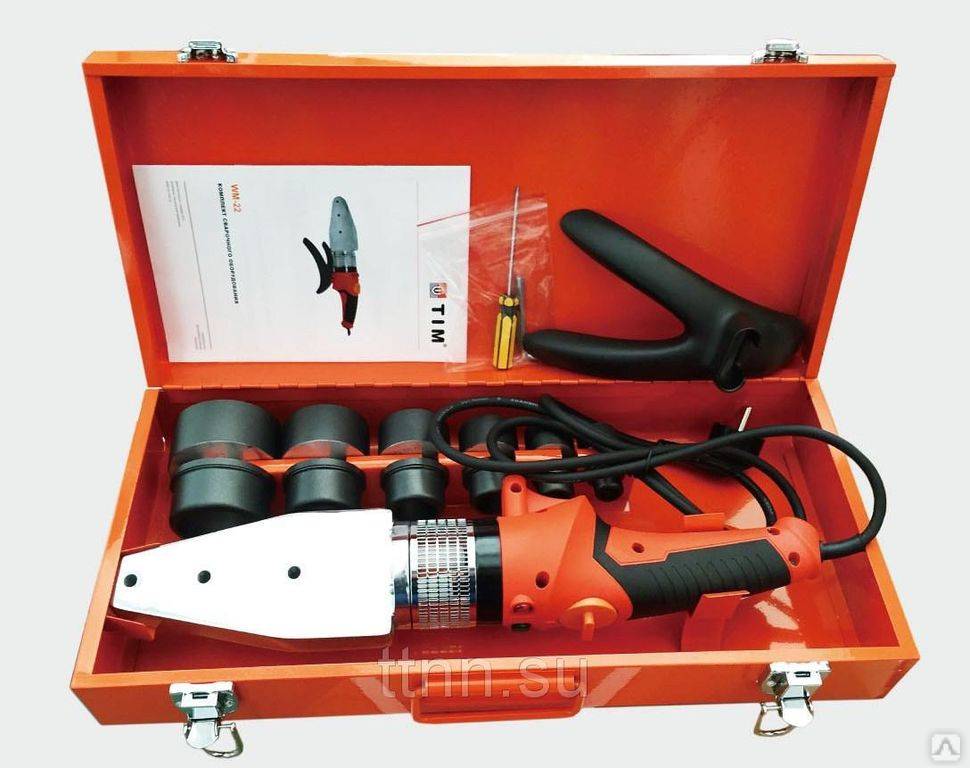

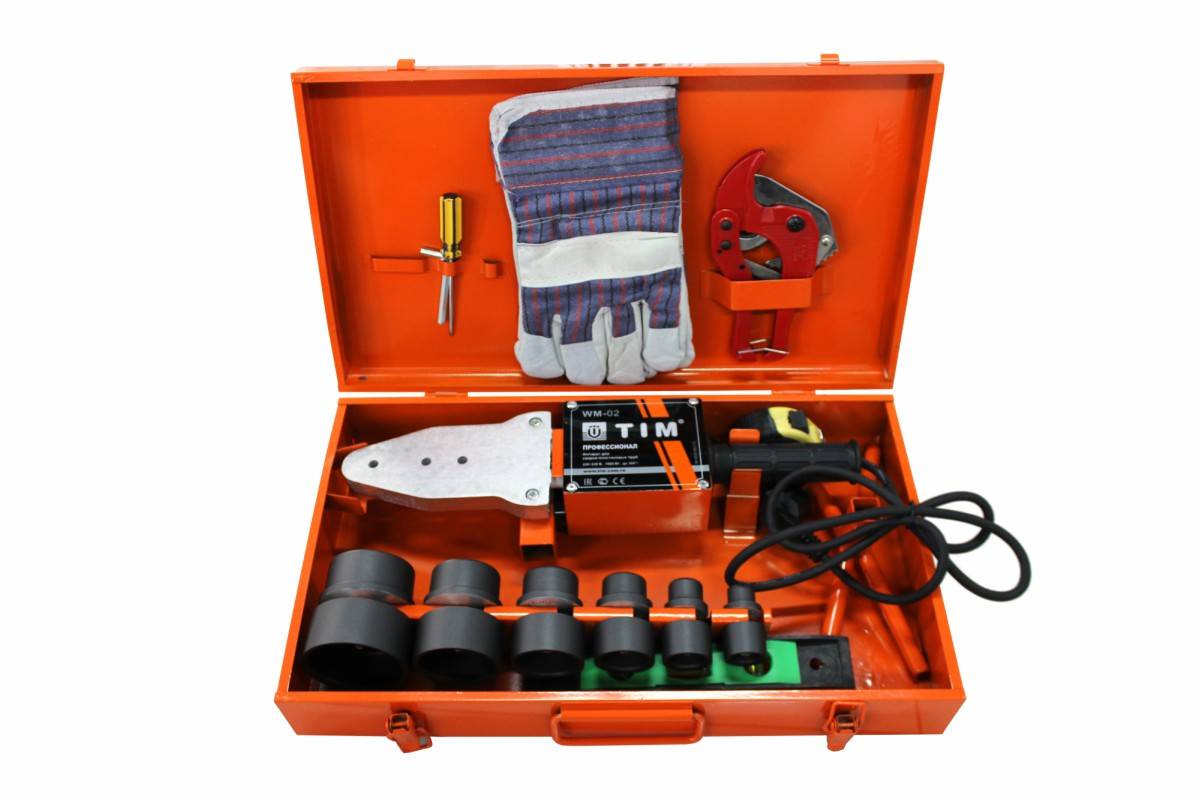

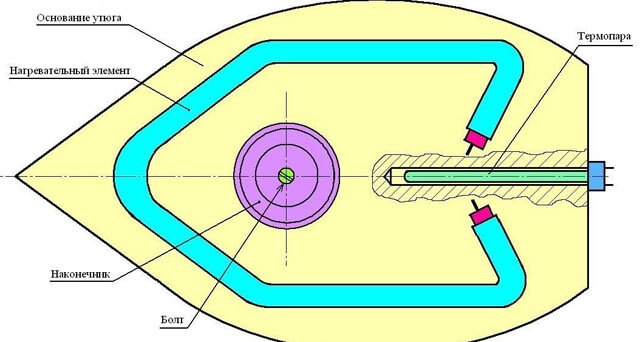

The second type is characterized by a heating plate made in the form of a flat plate of thick metal. To such a heating element, it is necessary to fasten the nozzles with through fasteners. Often this modification is called an iron.

Features of the operation of the soldering iron

The official name of the equipment is a welding machine.However, among the people it is called a soldering iron by analogy with the mode of operation or an iron because of its specific shape. The working part heats up to 300 °C, heats the nozzle-matrices located on both sides.

One matrix is responsible for heating the outer part of the pipe, the second for heating the inside of the fitting. Both elements are held on the soldering iron at the same time, then quickly joined. Polypropylene cools, forming a strong one-piece connection. This is how all sections of the pipeline are connected. Most models are equipped with a stand, so the soldering iron can be installed, soldering on the desktop. This reduces the load on the masters, provides comfort during work.

On weight, it remains only to connect only those pipe joints that are located in hard-to-reach places. Then the device is removed from the stand, soldering is carried out at the place where the pipeline is laid. To prevent burns, the master holds the device by the handle. However, the equipment is quite bulky, it is not always convenient to hold it on weight. That is why it is more often used for stationary work, and the finished sections of the pipeline are laid in accordance with the scheme.

Another type of welding machine is a cylinder on which matrices are fixed. The undoubted advantage of such models is the ability to fix nozzles in any position: at the ends or in the middle of the cylinder. Due to the design features, it is possible to work with the most difficult areas, including places with difficult access, close to the wall, the presence of various obstacles, and complex geometry of the room. The tool itself is compact, so it is easy to get it anywhere.Such models are equipped with a cord of at least two meters, which makes it possible for the master to move freely around the working area. When stationary use is required, the soldering iron can be mounted on a folding bracket.

Subject to the soldering technology, the presence of a good welding machine, reliable ones are obtained, and the life of the pipeline can exceed 100 years. However, before you begin to understand the process itself, you should choose the right soldering iron.

The best machines for socket welding of polypropylene pipes

This type of welding is based on the connection of tubular elements using special fittings. The tool consists of a heating element, a set of nozzles and a stand for fixing the device.

The connection of pipes using socket welding devices provides high sealing and reliability of the joint, however, in order to avoid rapid cooling of heated parts, the operator must work quickly and accurately.

Caliber SVA-2000T

5.0

★★★★★

editorial score

98%

buyers recommend this product

The model is equipped with a 2000 W motor and a comfortable rubberized handle. The device sits firmly in the hand and is able to process polypropylene pipes with a diameter of 20, 25, 32, 40, 50 and 63 millimeters.

The device heats up to 300 degrees, has a temperature controller and a stable stand, which allows you to use it in a stationary mode.

High speed of work is provided by the scissors included in the package for cutting of plastic pipes and to the adjusting tool.

Advantages:

- powerful engine;

- Teflon coating of heating elements;

- extended equipment;

- rapid heating.

Flaws:

high price.

Caliber SVA-2000T is used to connect pipes made of polymeric materials of various diameters. The device will be an excellent assistant if you need a quick and efficient installation of the pipeline.

Sturm TW7219

4.9

★★★★★

editorial score

95%

buyers recommend this product

See review

The distinctive characteristics of the model include high engine power and comfort in use.

Special indicators located on the case indicate the current state and temperature mode of the device. Two heating elements are turned on separately, which improves the stability and performance.

In addition to the welding machine, the package includes a metal case for transportation, six nozzles with a diameter of 20 to 63 mm, mounting bolts, an Allen wrench, a screwdriver and other tools. This allows you to start welding work immediately after purchasing the device.

Advantages:

- high power (1900 W);

- rapid heating;

- wear resistance;

- rich equipment;

- stable work.

Flaws:

heavy.

Sturm TW7219 is suitable for professional use in the plumbing industry. Powerful motor and high heating temperature of the elements allow fast and efficient connection of small diameter pipes.

Gigant GPW-1000

4.8

★★★★★

editorial score

90%

buyers recommend this product

A feature of the model is a convenient temperature setting. The rotary regulator is equipped with a special scale that allows setting with an accuracy of 10 degrees.

The power of the device is 1000 watts. It heats up quickly and can process pipes up to 63 mm in diameter.

The compactness and light weight of the instrument guarantee easy transportation and contribute to long-term work without fatigue for the operator.

Advantages:

- Ease of use;

- light weight;

- temperature setting;

- heating time - up to 2.5 minutes.

Flaws:

unstable stand.

Gigant GPW-1000 is used for installation of plumbing or heating systems. An excellent solution at an affordable price for both domestic and professional work.

Soldering iron device for polypropylene pipes

It is a heating device powered by a 220 V electrical network. A soldering iron for pipe welding has a characteristic working part, shaped like the sole of a household appliance that housewives use to iron clothes, which is why professionals call it a pipe soldering iron. Inside, the device has one or more heating elements that create the temperature needed to melt the plastic. On both sides, the unit is equipped with matrices - nozzles of different diameters.

Ease of use is ensured by a plastic case and a rubber-covered handle, which excludes contact of unprotected parts of the body with heating elements. In order not to put the unit on the floor during operation, which it can also spoil, a special metal stand is used. Such devices are equipped with a heating temperature controller.

Choosing the right tool

Let's see what are the main and important characteristics of soldering irons for polypropylene:

Power rating

This characteristic is extremely important, it is worth focusing on it. High power will allow heating pipes of larger diameter and significantly reduce the warm-up time of the device, and, accordingly, the welding speed

This is extremely important if you have a lot of work to do. But do not think that the best device is the one that consumes a lot of energy.

Most consumers will do just that - they will purchase a product with a power of one and a half to two kW, but this is not right.

For example, to solder fifty-millimeter tubes, a device with a power of five hundred watts will be required. When repairing a house, where, for example, the main diameters are from sixteen to sixty-three millimeters, a power of seven hundred watts is enough. And for professionals and diameters of one hundred millimeters, a device of one and a half to two kW is suitable.

nozzles

It immediately becomes clear that with a large number of nozzles, the functionality of the device increases. Basically, nozzles are included in the kit for the most popular diameters. For example, the twentieth nozzle corresponds to a metal pipe of zero point five tenths of an inch, and the twenty-fifth and fortieth nozzles correspond to a diameter of seventy-five hundredths and one point twenty-five inches.

If welding of large diameter pipes is required, then nozzles will have to be purchased separately. A hand soldering iron is capable of welding plastic pipes with a maximum diameter of not more than sixty-three millimeters.

Manufacturer

Please inspect the product carefully before purchasing. Both the price and quality depend on the country of origin. According to consumer reviews, you can make an unofficial top manufacturer. At the moment it looks like this:

- Germany;

- Czech;

- Turkey;

- Russia;

- China.

Very reliable and durable equipment is created by Germany. The German apparatus will function for a long time and will help in the work. Consumers love devices from the Czech Republic for their excellent functionality and impeccable quality.Yes, the price of such a device is quite high, but such equipment will last a long time and they can perform a large amount of action.

The cheapest and most numerous in the construction market are products from China. The low quality is offset by the low price tag. With careful work, they are quite capable of working the entire warranty period.

Conclusion on the topic

In order to choose a quality tool, you need to take into account all the nuances and little things, because the quality of the water supply most often depends on them. Remember to follow safety precautions to avoid possible injury or damage.

Conclusion

The choice of a soldering iron should begin with a study of the configuration, characteristics and parameters. The advantage will be the country of origin and the popularity of the model. But for home one-time use, you can consider an inexpensive Chinese tool for soldering polypropylene pipes.

When choosing, professional installers take into account: power, number of nozzles, tripod, coating and quality of the heating element. Because the market is oversaturated with Chinese fakes. When buying, be sure to ask for a certificate and check on the spot how the surface heats up. Skillful installation of polypropylene pipes.

HelpfulUseless