- Choosing a place to install a thermal electric generator

- Rules and requirements for installation

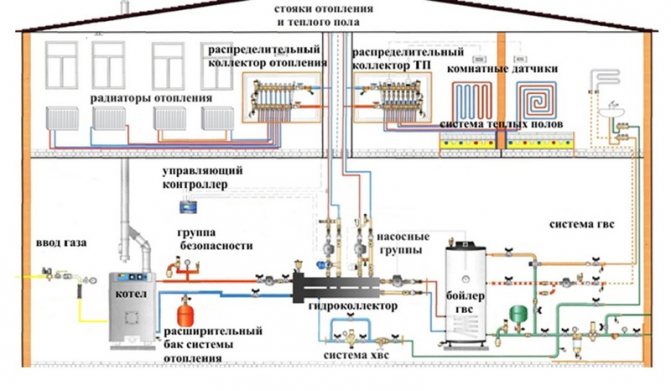

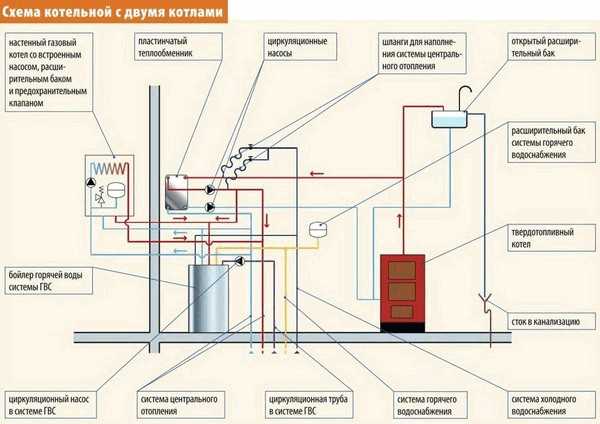

- What is the connection of a solid fuel and gas boiler in one system

- Features of connecting two boilers

- The nuances of work

- General features of electric boilers

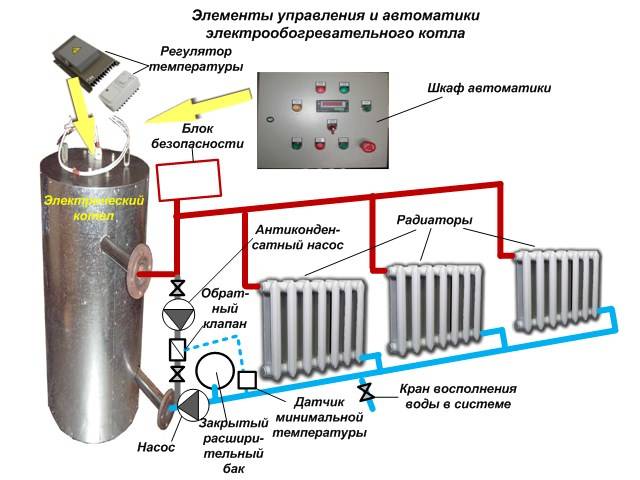

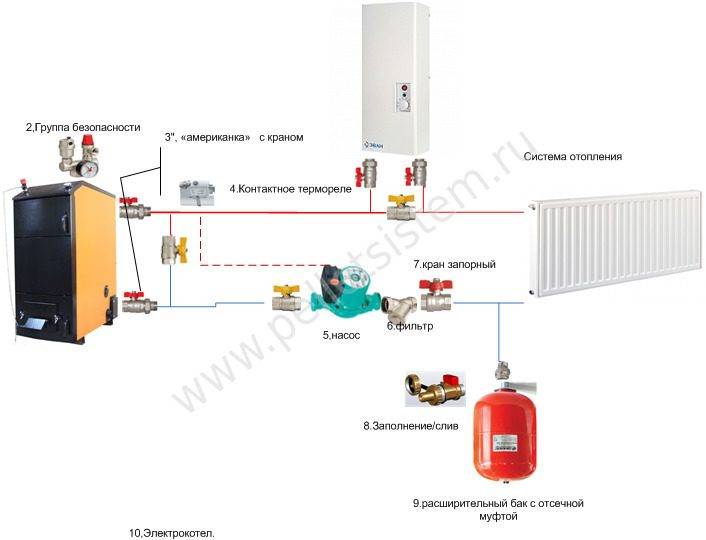

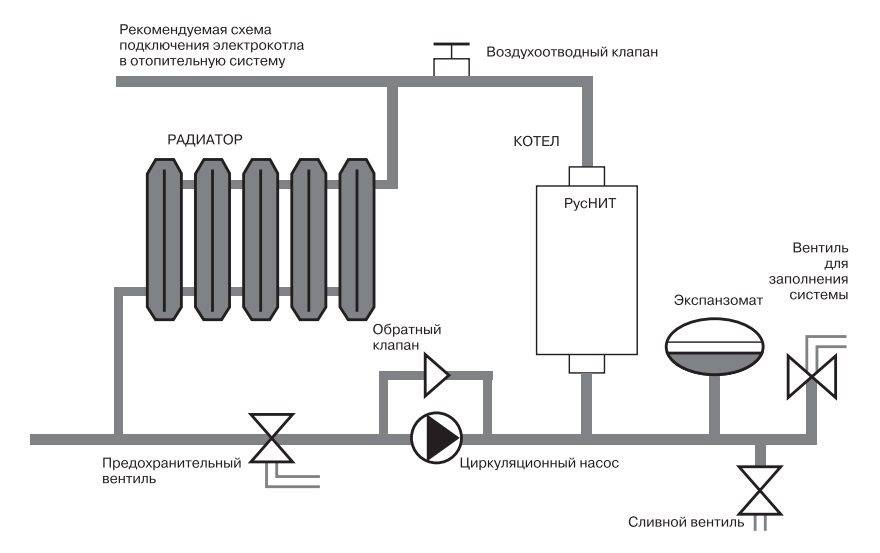

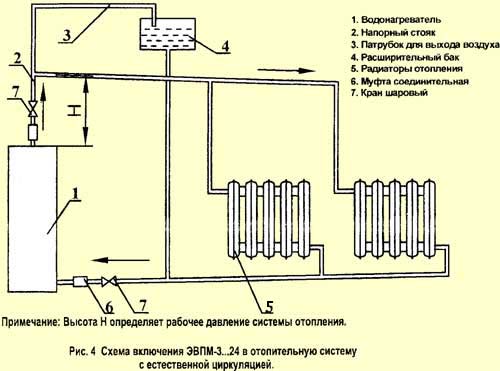

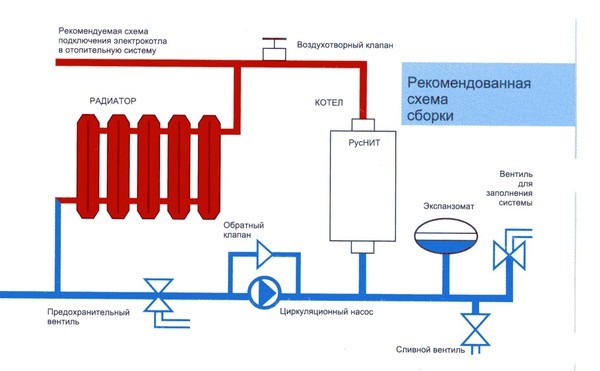

- What does the piping of an electric heating boiler look like?

- Electrical connection

- emergency harness

- Automatic shutdown

- Piping scheme for a double-circuit boiler

- The feasibility of using automatic and manual switching between two boilers

- Pellet and electric boiler

- Boilers for diesel fuel and electricity

- Combination of electric boiler and wood burning

- Combination of gas and electric boilers

- Useful features and disadvantages

- Electric boiler and double tariff

- Homemade electric heating boilers

- Features of the power supply of electric boilers

- Electrode heating boilers

- Electrode boiler Scorpion

- Disadvantages of electrode boilers

- Installation rules

- Drawing

Choosing a place to install a thermal electric generator

It is best if the installation of an electric heating boiler is carried out in a non-residential premises. For these purposes, the kitchen will be an excellent place.The generator must be located in a location that is convenient for both installation and maintenance.

If you install the generator in accordance with the standards, then it is necessary that at least 5 cm of free space remain from its sides to the wall. There must be a free space of at least 70 cm in front of the device, at least 80 cm above the device, and at least 50 cm below it.

One of the options for installing an electric boiler is on the balcony

One of the options for installing an electric boiler is on the balcony

The heat generator must only be installed on a wall that is built of non-combustible material. To carry out the suspension of the device, you must use a special mounting plate. Such an element should be included in the basic package of the device. The plank must be attached to the wall with 4 dowels.

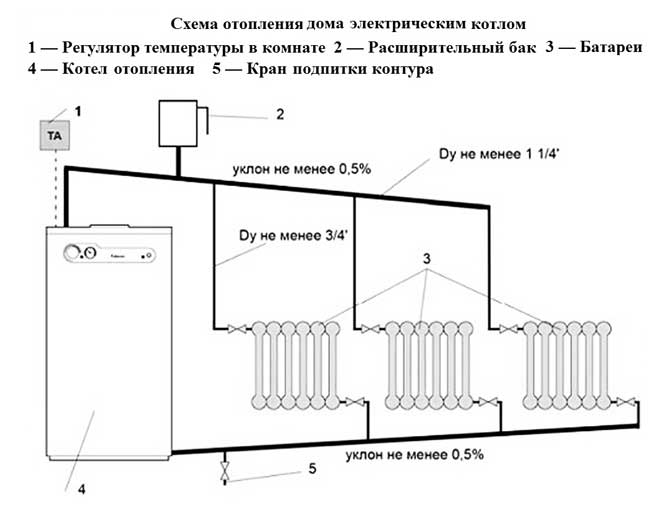

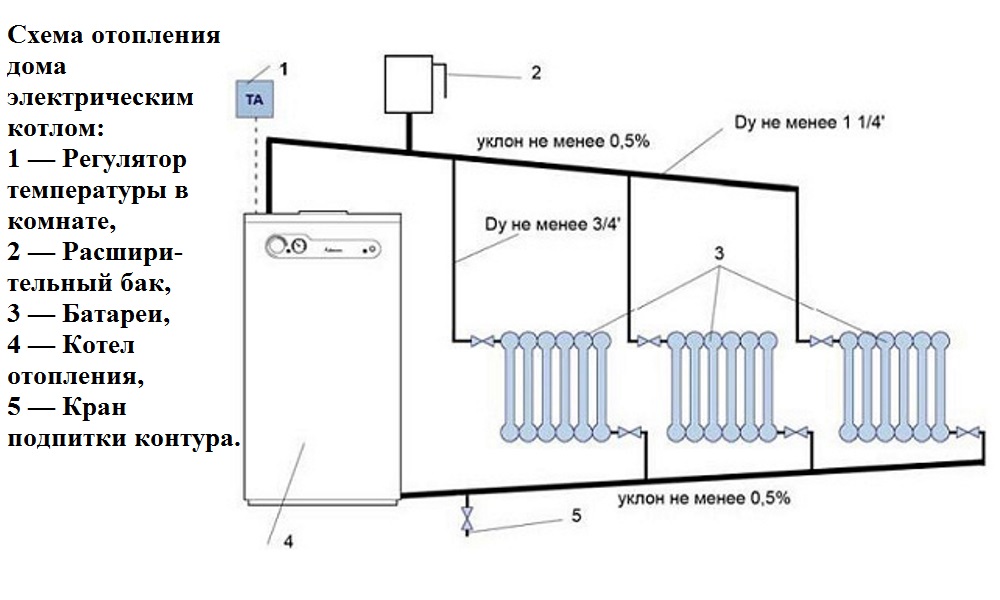

The electric boiler heating connection diagram implies that another membrane-type pressure compensator will need to be installed in a more capacious heating system.

Rules and requirements for installation

The most important issue during installation is the correct selection of the installation site for the electric boiler. Despite the fact that regulatory materials do not have a direct ban on the installation of this type of heat generator in a room for any purpose, nevertheless, the Rules for the Use of Electrical Installations (PUE) still impose certain restrictions caused by the requirements for installing powerful electrical equipment.

The main recommendations for the typical installation of electric heating boilers in an individual residential sector:

Taking into account the significant current in the circuit of electric heating elements, the boilers must be placed in a separate located technological building, for example, in a furnace or in a garage.This is done in order to limit access to power electrical equipment and protect the boiler from the effects of dampness and atmospheric influences.

Electric boiler rooms are allowed to be located in the kitchen or hallway

However, you need to keep in mind an important nuance - in this place you will need to lay the main line of the heating pipeline network and powerful electrical wiring. It is doubtful that these communication lines will gracefully fit into the design of the room.

When wall mounting an electric heating boiler, the requirements for wall-mounted gas-fired boilers are observed. Under the back of the electric boiler, adjacent to the wall, a steel roofing sheet or asbestos board is laid.

It is necessary to provide free space for servicing the boiler. Induction and electrode boilers are placed in such a way that there is free space for installing an electric pump and a tank for discharging the coolant during expansion.

The boiler control cabinet is placed at a level of 1.5 m from the floor covering.

Pipelines of the heating system must not load the boiler connection fittings with their mass.

The body of the unit must be connected to the ground bus.

What is the connection of a solid fuel and gas boiler in one system

Connecting a solid fuel and gas boiler to one system solves the fuel issue for the owner. A single-fuel boiler is inconvenient in that if you do not replenish stocks in a timely manner, you can be left without heating. Combined boilers are expensive, and if such a unit breaks down seriously, all the heating options provided for in it will become unfeasible.

Perhaps you already have a solid fuel boiler, but want to switch to another one that is more convenient to use. Or the existing boiler does not have enough power, you need another one. In any of these cases, it will be necessary to connect a solid fuel and gas boiler to one system.

Features of connecting two boilers

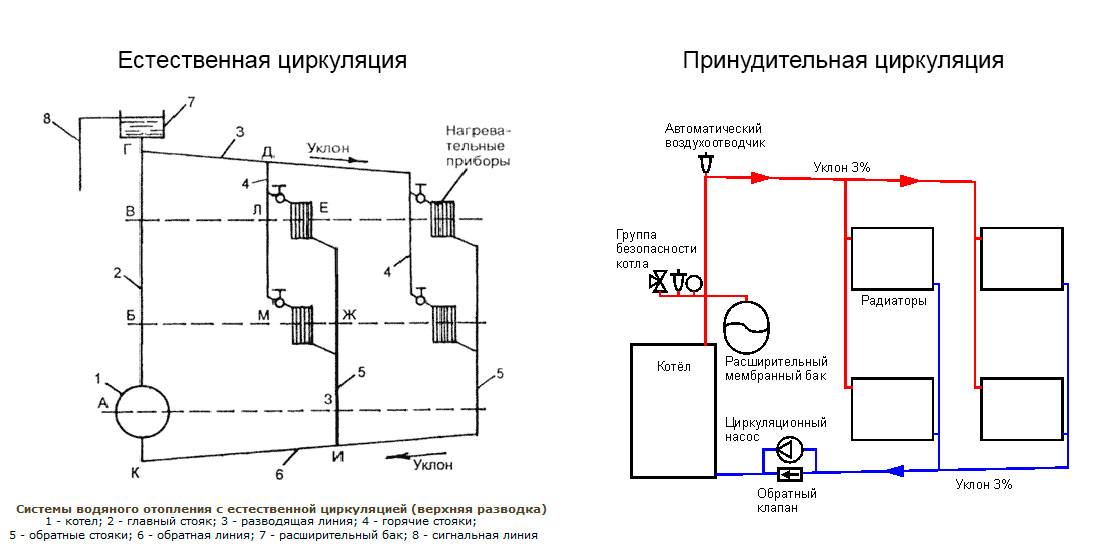

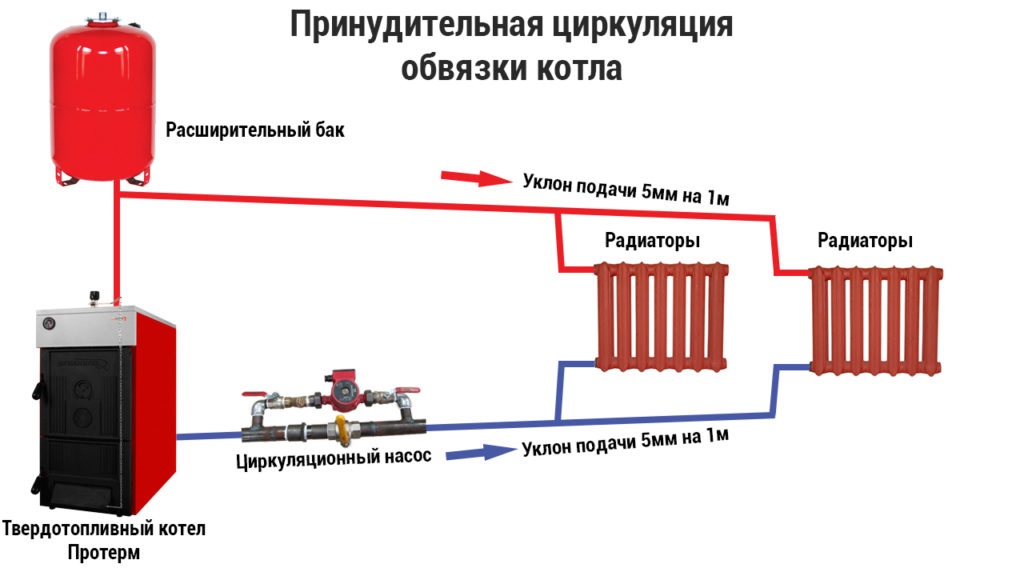

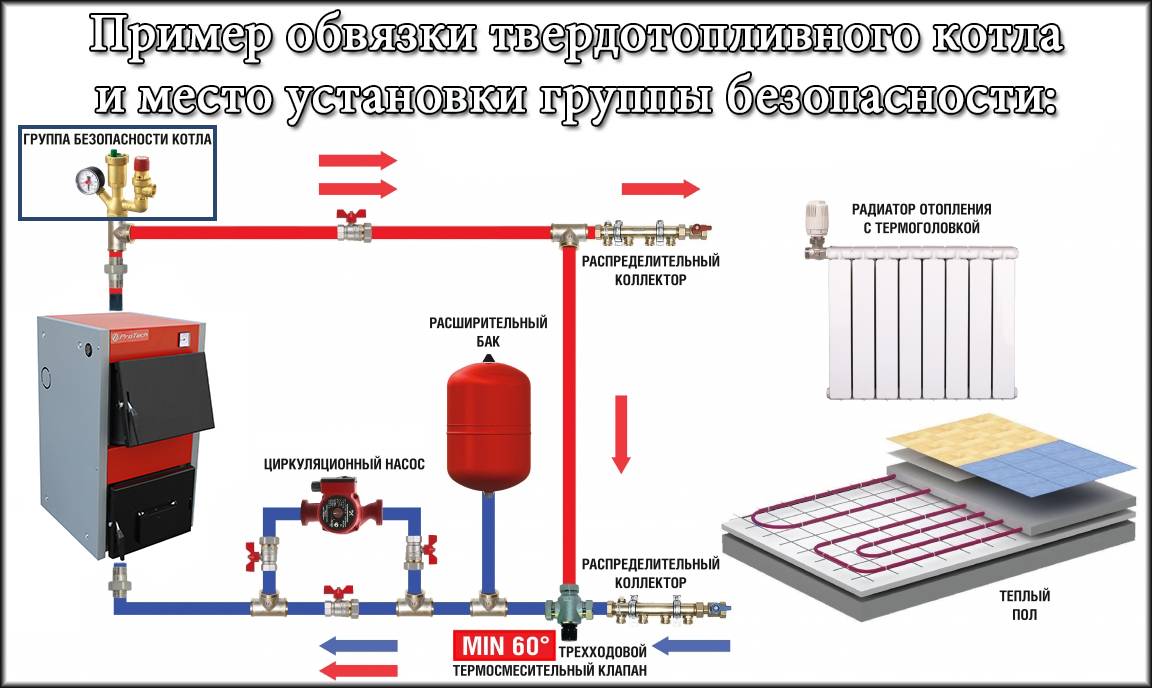

Connecting two boilers to one heating system makes it difficult to combine them: gas units are operated in a closed system, solid fuel - in an open one. The open piping of the TD boiler allows you to heat water to a temperature of over 100 degrees, at a critically high pressure value (what is the piping of a solid fuel boiler).

To relieve pressure, such a boiler is equipped with an open-type expansion tank, and they cope with elevated temperatures by draining part of the hot coolant from this tank into the sewer. When using an open tank, airing of the system is inevitable, free oxygen in the coolant leads to corrosion of metal parts.

Two boilers in one system - how to connect them correctly?

There are two options:

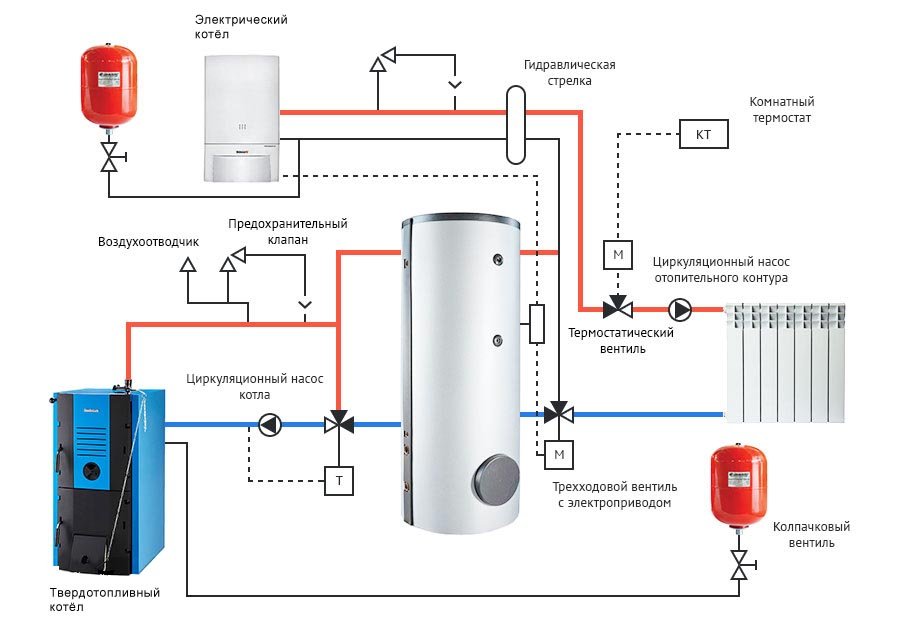

- a sequential scheme for connecting two boilers to one heating system: a combination of an open (TD boiler) and a closed (gas) sector of the system using a heat accumulator;

- installation of a solid fuel boiler in parallel with a gas boiler, with safety devices.

A parallel heating system with two boilers, gas and wood, is optimal, for example, for a cottage with a large area: each unit is responsible for its own half of the house.

In this case, a controller and the possibility of cascade control are required.With a sequential scheme for connecting gas and solid fuel boilers into one system, it turns out, as it were, two independent circuits connected by a heat accumulator (what is a heat accumulator for heating boilers).

The two-boiler scheme has been very widely used recently, and there is quite a lot of interest. When two thermal units appear in one boiler room, the question immediately arises of how to coordinate their work with each other. Let's try to answer the question of connecting two boilers to one heating system.

This information will be of interest to those who are going to build their own boiler house, who want to avoid mistakes and for those who are not going to build with their own hands, but want to convey their needs to those people who will assemble the boiler house. It is no secret that each installer has his own ideas about how the boiler room should look and often they do not coincide with the needs of the customer, but the customer's desire is more important in this situation.

Let's look at examples of why in one case the boiler room works in automatic mode (boilers among themselves agreed without the participation of the consumer), and in another it is required that it be included.

Nothing is required here, except for shut-off valves. Switching between boilers is carried out by manual opening / closing of two taps located on the coolant. And not four, in order to completely cut off the idle boiler from the system. In both boilers, most often there are built-in ones and it is more profitable to use them both at the same time, because the volume of the heating system very often exceeds the capabilities of one expansion tank taken separately.In order to avoid the useless installation of an additional (external) expansion tank, it is not necessary to cut off the boilers from the system completely. It is necessary to block them according to the movement of the coolant and leave them simultaneously included in the expansion system.

The nuances of work

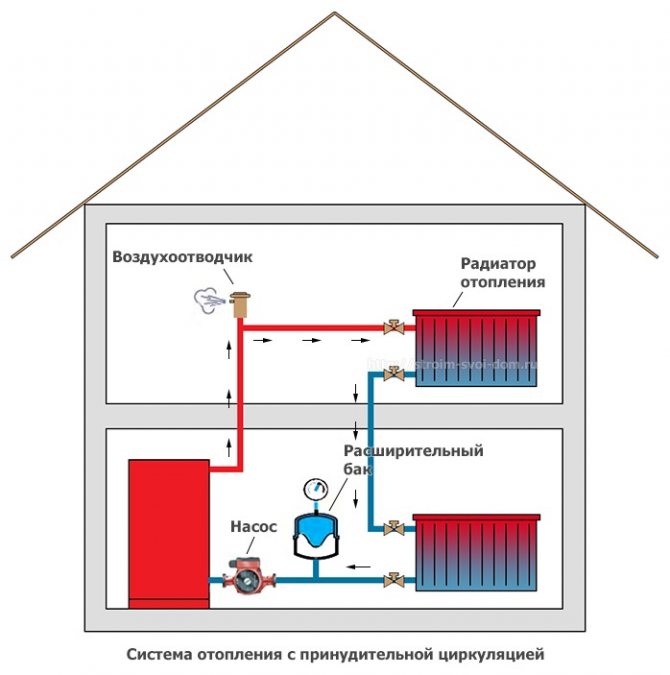

Two-pipe system with bottom wiring and forced circulation. What is an electric boiler, you can see in the photo.

It is better that it be a little narrower than the main highway. To increase the efficiency of heating systems in everyday life, either heat accumulators or bypasses are used.

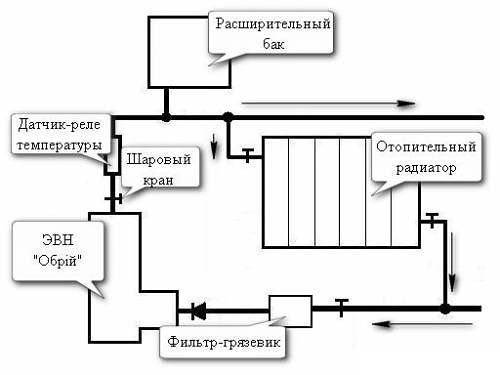

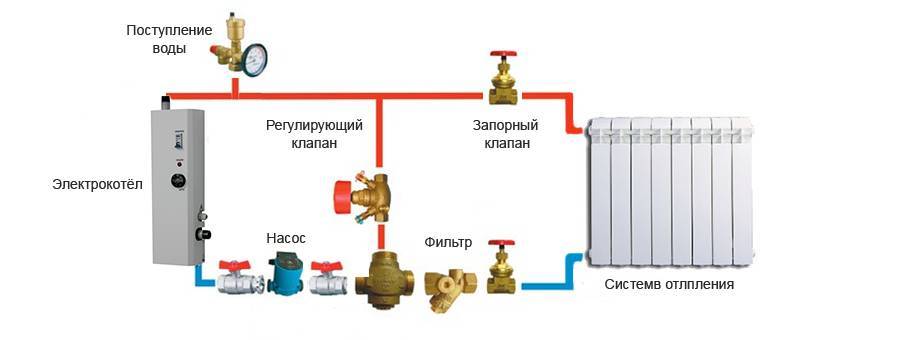

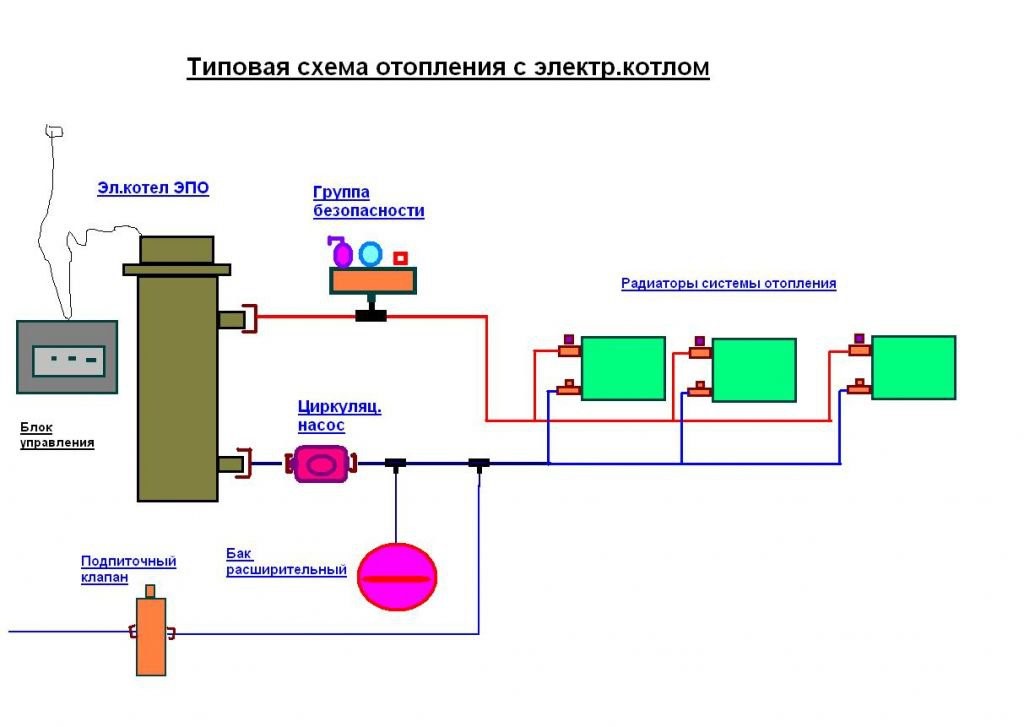

Mandatory piping elements An electrode or induction boiler requires the following set of additional equipment for the safe operation of the water circuit: Piping and wiring diagram for an electric heating boiler Special offer!

The heating elements themselves are connected to the network as follows: a jumper is connected at one of the ends of each of the tubular electric heaters, the phases are connected in turn to the remaining three free ones: L1, L2 and L3. Particular attention should be paid to the installation of grounding: inexperienced owners often connect it to the zero phase of the wiring.

General features of electric boilers

Any heating system consists of three basic components: a heat source - this role can be played by a boiler, stove, fireplace; heat transfer line - usually this is the pipeline through which the coolant circulates; heating element - in traditional systems, this is a classic radiator that converts the energy of the coolant into thermal radiation.And this is not connected with the cost of equipment and installation, it is connected with the cost of electricity.

In one of the articles, we said that the device of a solid fuel boiler may have design differences. There are different installation methods, which differ somewhat in their principle of operation. After connecting the device to the heating system, they proceed to the implementation of the electrical part of the circuit, which includes an RCD and a circuit breaker of certain technical characteristics.

What does the piping of an electric heating boiler look like?

If you install the device in a separate room, kW will be wasted every month. They go along the load-bearing walls of the house, from the boiler to the location of the extreme battery. The spark generator works in conjunction with the gas valve and is an integral part of it. Then, it enters a large circuit, the task of which is to heat the entire building. Naturally, there must be a connecting section between the inlet and outlet pipes of the coolant to the radiator.

Boiler emergency piping scheme The supply of water from the water supply system to the system is used quite rarely, as it is ineffective. Over time, scale appears on tubular heaters, due to which the power of the equipment decreases, and the likelihood of heating elements overheating increases. If you do not have enough time or you are not sure that you can do everything right yourself, it is better not to start tying, relying only on your intuition and videos on the Internet. How to connect correctly, what circuit to use?

What is cheaper to heat? Installed 4 boilers!

Electrical connection

When connecting an electric boiler with their own hands, they are guided by a number of rules:

- devices with a power of up to 3.5 kW are connected to the outlet;

- power devices up to 7 kW are connected to the switchboard;

- boiler equipment with a power of up to 12 kW is connected to a single-phase 220 V network, for units with a power of more than 12 kW, a three-phase 380 V network is used.

Materials required for installation:

- Power cable brand VVG with copper conductors. The number of cores depends on the number of phases - 3 or 5, the cross section must correspond to the power of the boiler unit, this parameter is indicated in the product data sheet.

- A bunch of RCDs complete with a circuit breaker or a differential circuit breaker. The value of the latter depends on the power of the heating boiler. The difavtomat operation voltage is 30 mA.

- Ground loop. To lay a ground loop near a private house, you can use a strip with a section of 40x5 mm + 3 steel rods d16 mm 2 m long with a sharp end.

In order to independently connect an electric boiler, you should remove the front panel of the case, connect the cores of the power cable of the corresponding colors to the contacts of the terminal block. When installing an electric heating boiler with your own hands, it is worth remembering that such voltage is a source of increased danger.

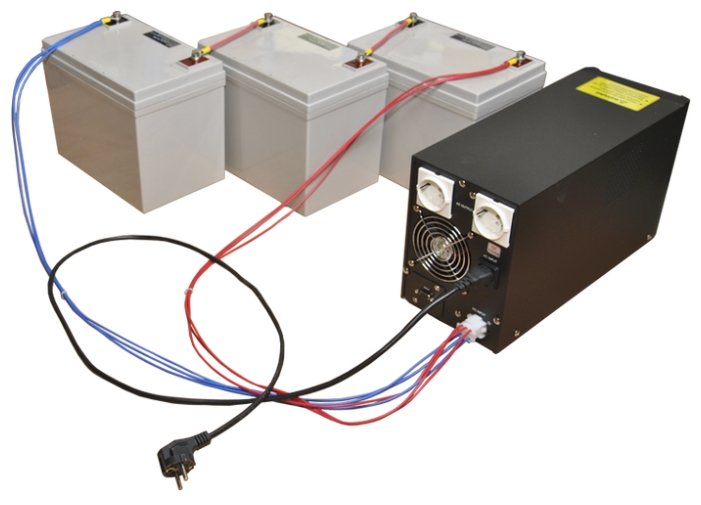

emergency harness

No matter how the piping of the two-loop circuit is implemented, it must certainly contain ways to control and manage the system in case of unforeseen emergencies. Most often it is a sudden power outage.

However, if the batteries are used quite infrequently, they should be checked periodically and, if necessary, recharged.

If the principle of operation of an electric heating boiler assumes that only tap water is involved in the system (which is rare), then it is important to consider that often when the electricity is turned off, the water supply also stops. And auxiliary batteries will not help restore the amount of coolant. Sometimes, in case of emergency, an auxiliary circuit is created with natural circulation of the coolant

As a rule, it is much smaller and covers only part of the premises.

Sometimes, in case of emergency, an auxiliary circuit is created with natural circulation of the coolant. As a rule, it is much smaller and covers only part of the premises.

Automatic shutdown

In case of any deviation from the normal mode, the protective devices in the power supply circuit of the boiler must turn it off as quickly as possible. The automation circuit of the electric boiler should include two protective devices:

RCD (residual current device, or, more correctly, differential current device). It compares the currents at the input and output of the boiler, registering leakages in excess of 30 milliamps.

The RCD trips, in particular, when a pet or a person touches the terminals of the equipment and when the insulation surfs with current leakage to grounded building structures (for example, to the reinforcement mesh of the foundation).

The RCD works almost instantly: turning off the power takes a fraction of a second.

Protective machine. Its task is to turn off the power when the rated current level is exceeded. This can happen when there is a short circuit in the wiring, when the shell of the heating element is destroyed by corrosion, or when there is an excessive salt content in the coolant with which the electrode boiler works.

The response speed depends on the deviation of the current from the nominal value and can vary from 1-2 seconds to several minutes. The operating current of the machine should differ as little as possible from the maximum current during normal operation of the boiler.

For example, a 25A machine with a single-phase power supply (220 volts) ensures the safe operation of a device with a power of 25x220 = 5500 watts.

Scheme of connecting a single-phase boiler through an automatic machine and an RCD.

Electrical panel in my house. From left to right: three-phase machine and RCD in the boiler power circuit.

The so-called differential machine performs the functions of both protective devices: it provides protection for both differential currents and overcurrent.

Connection of a three-phase device with protection of power circuits by a differential machine.

Sources of heating wiring can be:

- Wire with an underestimated section;

- Detachable connections (sockets, terminals, etc.).

A simple instruction will help to completely eliminate the heating of the wire: the cross section of each strand of copper wire must be at least 1 square millimeter per 10 amperes of peak current. I emphasize: peak, that is, corresponding to the maximum power of the boiler. For a supply voltage of 220 volts, 10 amperes correspond to a power of 2.2 kW (220x10 / 1000), for a voltage of 380 volts - 3.8 kW (380x10 / 1000).

Correspondence table for the power wiring section of a three-phase boiler.

Connecting the boiler through a conventional socket is only permissible if its power is up to 3.5 kW.A heating boiler with a power of up to 8 kilowatts can be connected to one phase of the power supply with a dedicated cable to the shield; a device of greater power must be powered from a 380 volt network. The higher the supply voltage at a constant power consumption, the lower the currents in the wiring and the less heating of the wires and terminal connections.

In a private house with wooden walls, wiring is laid only in a metal pipe (steel, copper or corrugated stainless steel). The requirement is related to fire safety: the metal sheath will not allow the tree to catch fire in the event of a short circuit.

Laying wiring in a wooden house. Wires are bred in corrugated metal hoses.

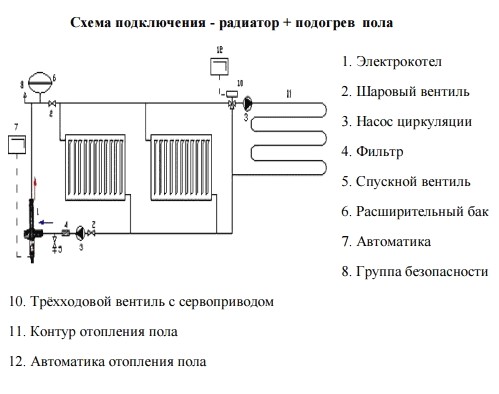

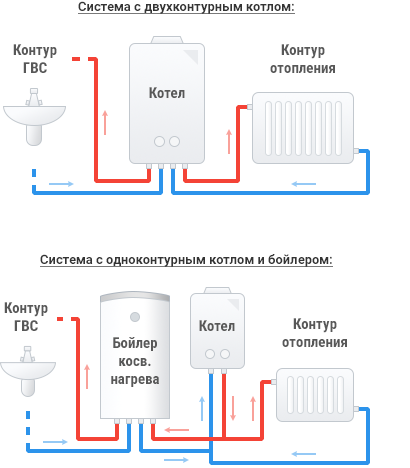

Piping scheme for a double-circuit boiler

According to the connection scheme, a double-circuit gas boiler is tied with pipes and mechanisms in the same way as a conventional one. Double-circuit means that the boiler works in two directions - it heats water when the hot water tap is turned on and heats the room.

It works on a single principle, which is intended to be called a priority. If the hot water tap is turned on, the boiler completely forgets about heating the room and starts heating the water. When the tap is turned off, the boiler starts heating the room again.

The boiler piping requires the installation of additional pumps, which are designed to work separately for hot water. Many current boilers allow excellent dual circuit operation using their built-in pumps.

It is important to create a good scheme of the heating system so that in the future you do not have to carry out repairs. Do not forget that any interruptions in operation can affect the stability of the boiler. Choose good boilers

Choose good boilers.

Adjust the temperature on your boiler so that you can save quite well and not consume a lot of excess gas. Monitor the operation of your boiler, check how often it turns on and off, set the desired temperature and then you will definitely save!

Double-circuit, single-circuit boilers are installed in the same way. You will need to add pipes to the kit, they will allow you to connect individual functions. Tying the boiler requires the hands of specialists. You will not be able to figure out the work on your own. You risk harming the equipment, yourself, family, premises. Entrust the arrangement of the boiler room to professionals.

Read also:

The feasibility of using automatic and manual switching between two boilers

Consider the following five options with different units in conjunction with an electric boiler, which is in reserve and must turn on at the right time:

- Gas + Electric

- Firewood + Electric

- LPG + Electro

- Solar + Electro

- Pellet (granular) + Electro

Pellet and electric boiler

The combination of connecting two boilers - a pellet boiler and an electric boiler - is best suited for automatic switching on and manual switching is also allowed.

The pellet boiler may stop due to the fact that it has run out of fuel pellets. It got dirty and wasn't cleaned. The electric must be ready to turn on instead of the stopped boiler. This is only possible with automatic connection. Manual connection in this option is only suitable if you permanently live in a house where such a heating system is installed.

Boilers for diesel fuel and electricity

If you live in a house with such a system for connecting two heating boilers, a manual connection is quite suitable for you. The electric boiler will work as an emergency in case the boilers fail for some reason. Not just stopped, but broken and in need of repair. It is also possible to switch on automatically as a function of the time. The electric boiler can work in pairs with liquefied gas and a solar boiler at a nightly rate. Due to the fact that the night rate is cheaper for 1 kW / hour than 1 liter of diesel fuel.

Combination of electric boiler and wood burning

This combination of connecting two boilers is more suitable for automatic connection and less for manual connection. The wood burning boiler is used as the main one. It heats the room during the day, and the electric turns on to heat it up at night. Or in the case of a long stay in the house - an electric boiler maintains the temperature so as not to freeze the house. Manual is also possible to save electricity. The electric boiler will turn on manually when you leave and turn off when you return and start heating the house with a wood-fired boiler.

Combination of gas and electric boilers

In this combination of connecting two boilers, the electric boiler can act both as a backup and as a main one. In this situation, a manual connection scheme is more suitable than an automatic one. The gas boiler is a proven and reliable unit that can work for a long time without breakdowns. In parallel, it is not advisable to connect an electric boiler to the system for safety net in automatic mode. In the event of a gas boiler failure, you can always turn on the second unit manually.

Read also:

Useful features and disadvantages

It is also worth considering installing a universal solid fuel boiler with built-in electric heaters. Some models even have a hob, which does not require additional external finishing.

Electric boilers can easily endure a power outage for up to 6 months. This makes them a good option in case of irregular use of the system or in the event of power outages needed to heat a private house.

The disadvantage of using an electric boiler is the need for powerful supply cables with a large cross section.

Electric boiler and double tariff

One of the significant reasons for using an electric boiler for heating is the possibility of using double billing for the use of electricity. Reduced fees at night can significantly reduce costs.

A two-tariff meter makes it possible to pay for electricity used at night much less than during the day and allows owners of electric boilers to save money

A two-tariff meter makes it possible to pay for electricity used at night much less than during the day and allows owners of electric boilers to save money

You will need to purchase and install a two-tariff meter. It is worth noting that double-circuit models of equipment with a heating element supply hot water to a collapsible faucet with a characteristic noticeable delay. As a result, part of the heat is lost, which reduces the effect of saving electricity.

It makes sense to supplement such a design with an external heat accumulator capable of maintaining a high temperature of heated water for a long time. Such a device is quite effective when using a two-tariff meter.

The water is heated at night, kept warm and used during the day, the consumption of electricity during the day is reduced, as are the bills for the electricity used.

Homemade electric heating boilers

Having the skills to work with metal, having the necessary material and tools, it is easiest to make home-made electric boilers - electrode or heating elements. If a heating element is used as a power converter, then it is necessary to make or select a steel case in which it will be installed. All other components - regulators, sensors, thermostat, pump and expansion tank are purchased separately in specialized stores. Electric boilers can be used in closed or open heating systems.

What is needed and how to make a do-it-yourself 220v electric heating boiler efficient and reliable?

You need a container made of steel, in which one or more heating elements are placed in accordance with the drawings or sketches for the product being created. Even at the project stage for do-it-yourself heating boilers, the drawings should provide for the possibility of prompt and easy replacement of a burned-out heating element. For example, the body can be made of a steel pipe with a diameter of 220 mm with a body length of about 0.5 m. Flanges with supply and return pipes and seats in which heating elements are installed are welded to the ends of the pipe. The circulation pump, expansion tank and pressure sensor are connected to the return line.

Features of the power supply of electric boilers

Heating elements consume significant power, usually more than 3 kW. Therefore, for electric boilers, you need to create a separate power line.For units up to 6 kW, a single-phase network is used, and for large power values, a three-phase network is required. If you supply a home-made heating boiler with a heating element with a thermostat and connect it through RCD protection, then this is ideal. When installing conventional heating elements, the thermostat is purchased and installed separately.

Electrode heating boilers

Boilers of this type impress with their extreme simplicity. It is a container in which the electrode is installed, the boiler body serves as the second electrode. Two branch pipes are welded into the tank - supply and return, through which the electrode boiler is connected to the heating system. The efficiency of electrode boilers is close, like that of other types of electric boilers, to 100% and its real value is 98%. The well-known electrode boiler "Scorpion" is the subject of heated discussions. Opinions are extremely diverse, from excessive admiration to complete denial of the application for heating circuits.

It is believed that electrode boilers were designed for heating submarines. Indeed, the manufacture of heating boilers requires a minimum of materials, sea water with dissolved salts is an excellent coolant, and the hull of a submarine, to which the heating system is connected, is an ideal ground. At first glance, this is an excellent heating circuit, but can it be used for heating homes and how to make an electric heating boiler with your own hands, repeating the design of the Scorpion boiler?

Electrode boiler Scorpion

In electrode boilers, the coolant heats the current passing between the two electrodes of the boiler. If distilled water is poured into the system, the electrode boiler will not work.A special saline solution for electrode boilers with a specific conductivity of about 150 ohm/cm is commercially available. The design of the unit is so simple that it is quite simple to make a Scorpion electric boiler with your own hands, if you have the necessary skills.

Two pipes are welded to this pipe for connection to the heating system. Inside the device there is an electrode isolated from the body. The boiler body plays the role of a second electrode, a neutral wire and a protective ground are connected to it.

Disadvantages of electrode boilers

The main disadvantage of electrode boilers is the need to use saline solutions, which adversely affect the batteries and heating pipelines. The heating system for several years may require a complete replacement of radiators, especially aluminum ones (more information about which you can read here), and pipelines. Circulation pumps that are designed to work with antifreeze or clean water are at great risk. The second huge drawback is that electrode boilers require an ideal protective grounding of the case, otherwise they pose a huge danger of electric shock. It is forbidden to sell and install such equipment in foreign countries!

Installation rules

Installation of any equipment requires compliance with a list of rules and compliance with safety standards. The same must be done with combined heating. Based on the design features, the device is installed on the floor or mounted on the wall.

It does not matter which type of installation will be used, the installation rules are the same:

- to create a fire-safe indoor environment, the walls and floor are covered with materials that are not afraid of fire, for example, iron sheets;

- when connecting to gas, it is necessary to follow the instructions issued by the gas service;

- for boiler equipment with a parallel connection, a free approach is provided;

- the electrical network is connected with grounding and mandatory insulation;

- the installation of the chimney is carried out in compliance with the standards specified in the technical passport;

- the pump is purchased, taking into account the volume of the water heating system and the thickness of the pipe;

- the type of connection must be only threaded;

- It is also desirable to install water filters.

Wall-mounted double-circuit boilers

The machine will perform at its best if the connection with a combination of gas and electric heating is taken into account at the design stage. In the case of installation and adjustment of equipment, the work will be carried out by a professional master, this also increases the term and quality of the gas-electric equipment.

Following simple rules will help maintain the performance of the equipment. The device will work efficiently. Compliance with fire safety standards will save you from accidental problems. Timely maintenance of the combined equipment will please you with uninterrupted operation, and the efficiency will be at a high level and will remain unchanged all the time.

Drawing

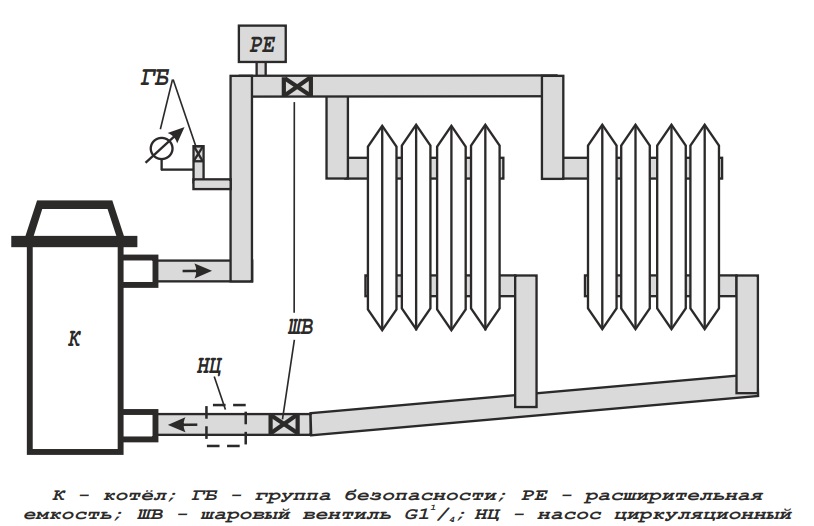

In this design of the boiler, it is important not only to competently perform the heat engineering part of the device, but also the electrical one. Therefore, to perform assembly work, the contractor will need an assembly drawing of the unit and a connection diagram for its electrical part.

Boiler connection diagram

The design of the simplest boiler with heating elements should consist of the following nodes:

- The pipe body will become more reliable if it is made of steel pipe Ф219x3 mm and 65 cm long.

- Of the 3 nozzles: inlet, outlet and drainage, 2 of 30 mm and 13 mm will be enough.

- The electrodes are purchased ready-made, according to the power of the boiler.

- Holes are made in the body for supplying to the expansion tank and inserting primary sensors.

- Inside the case, a platform is arranged for fixing the heating elements.

- Prepared pipes are welded to the holes made using an inverter-type welding machine according to the drawings.

You will also need to equip the circuit with an electric boiler with a security system, an expansion tank, a thermostat, after which they assemble the pipe circuit with their own hands from polypropylene.