- Advantages and disadvantages

- pyrolysis option

- Safety regulations

- Instructions for using the oven

- Varieties of furnaces in development

- Furnace for mining from an old gas cylinder

- Furnace for working out with pressurization

- Working furnace with water circuit

- Drip Furnace

- Installation and trial ignition

- How to make a homemade waste oil stove

- Furnace for working out from steel sheets

- Materials and tools

- Stages of manufacturing a furnace from steel sheets

- 1 General information

- Diesel heating

- What does it represent?

- Advantages and disadvantages

- Safety Requirements

Advantages and disadvantages

It would seem that the idea is practically devoid of flaws, but it is not. To make an informed decision about the use of such heating in your home, you need to see not only the pros of its use, but also the cons.

Let's start with the advantages of the method. So, if you have regular access to junk fuel, which is essentially mining, then you can efficiently use and dispose of this material at the same time. Proper use of technology allows you to get heat with complete combustion of the material without the emission of harmful substances into the atmosphere.

Other pluses include:

- uncomplicated design of the heating unit;

- low fuel and equipment costs;

- the possibility of using any oil that is on the farm: vegetable, organic, synthetic;

- combustible material can be used even if the pollution is a tenth of its volume;

- high efficiency.

The shortcomings of the method should be taken seriously. If the process technology is not observed, incomplete combustion of the fuel may occur. Its fumes are dangerous to others.

If there were more disadvantages to heating during mining than advantages, such factory-made products would not appear on sale, which are sold out like hot cakes, despite the rather high prices

It is not for nothing that the main requirement for arranging heating at mining is the presence of ventilation in the room where the boiler will be operated.

Here are some other cons:

- since good draft requires a high-quality chimney, it must be straight, and its length must be from five meters;

- the chimney and the plasma bowl must be cleaned regularly and thoroughly;

- the complexity of the drip technology lies in the problematic ignition: at the time of fuel supply, the bowl should already be red-hot;

- operation of the boiler causes drying of the air and burnout of oxygen;

- self-creation and use of water-heating structures can contribute to lowering the temperature in the combustion zone, which jeopardizes the efficiency of the process as a whole.

To solve the last of the above problems, you can mount a water jacket where it cannot affect the quality of combustion - on the chimney.

These shortcomings have led to the fact that the product without significant modifications is practically not used for heating residential premises.

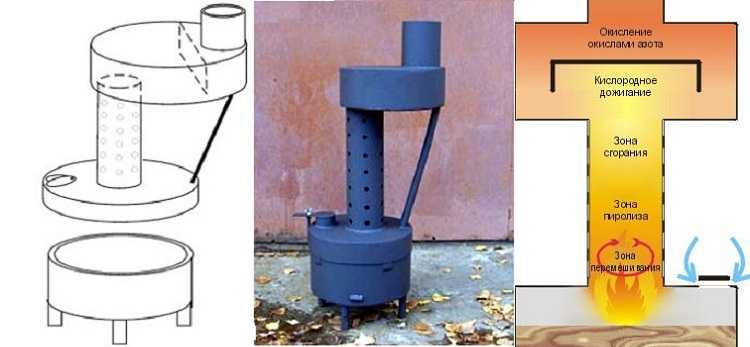

pyrolysis option

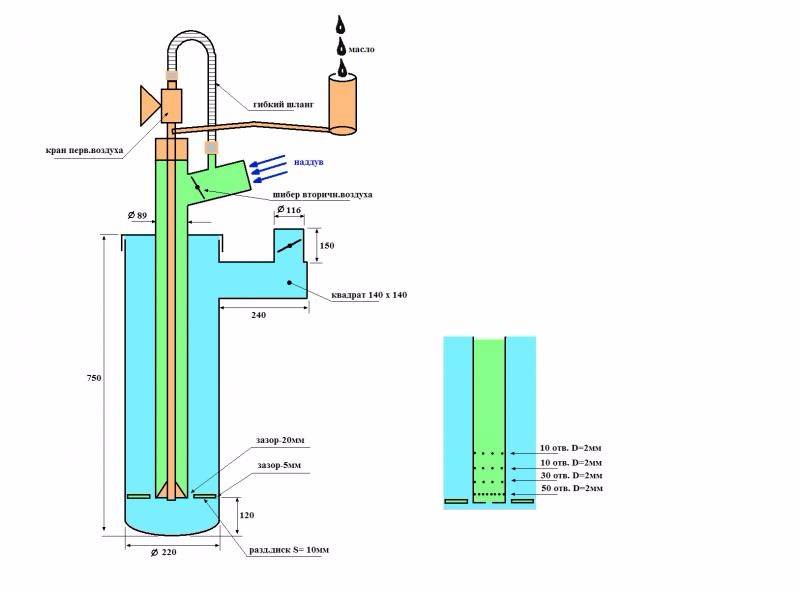

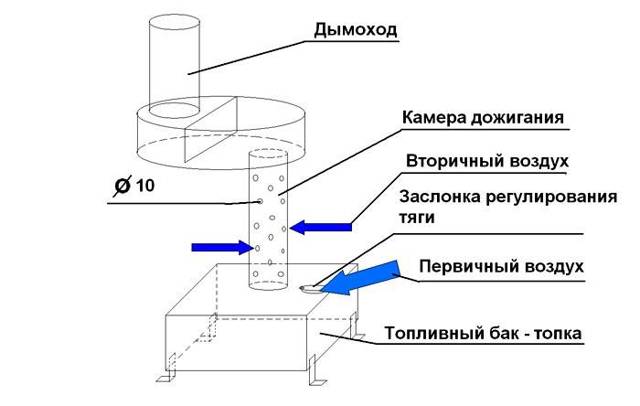

This design is so popular that it is also produced in industrial enterprises. In this case, the oil in the reservoir is ignited. When heated, it evaporates, the vapors rise up into the combustion chamber (pipe with holes), where, mixing with oxygen, they continue to burn. In the afterburner chamber (expansion on the pipe) there is a complete and final oxidation (combustion) of all fuel components.

You can read about pyrolysis boilers here.

Do-it-yourself boiler for working out: pyrolysis method

For normal operation of the furnace, air is supplied to the container where the oil is located and primary combustion takes place through a special hole with a damper. The position of this damper regulates the intensity of combustion and the temperature in the room. Air must flow freely into the upper combustion chamber. Therefore, a vertical pipe with two tanks is made with a large number of holes.

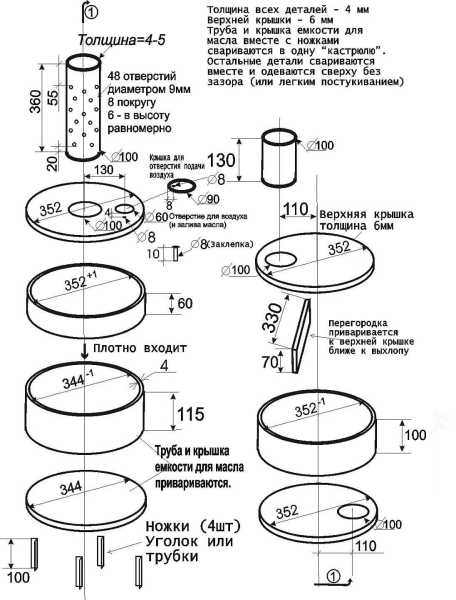

Waste gas boiler oil. Dimensional drawing

Such an oven requires strict adherence to the recommended dimensions, compliance with the indicated proportions. If you require a larger unit, increase all parts proportionately.

Installation requires a straight chimney. Its height to the “crown” is at least 4 meters. Since the stove is not very heavy, either a metal chimney or a sandwich would be ideal.

Why can't the proportions be broken? The thing is that the optimum temperature at which all hydrocarbons are burned, and only carbon dioxide, nitrogen and water vapor remain at the outlet is 600oC. If the oven produces temperatures above 900oC or below 400oC, heavy organic matter will be present in the exhaust. They have a very bad effect on the human body.Therefore, it is advisable to strictly adhere to the given proportions: this way you guarantee the safety of both yourself and those around you.

Everyone loves this oven. There is only one drawback: a small tank. Adding fuel while the stove is running is dangerous, and waiting until it burns out is not always possible. Simply increasing the size of the tank will not work: a large amount of oil will not warm up to the desired temperature and will not evaporate. There is one refinement that will allow you to extend the burning without any problems. All that is needed is to make an additional reservoir nearby, which is connected to the main one according to the principle of communicating vessels.

Stove tank - a way to extend the burning at one gas station

Another refinement allows you to remove heat from the upper circuit to heat water. Having welded metal pipes into the upper part of the furnace, you get a working furnace with heated water. The photo shows one of the options for such a heat exchanger.

The top of this boiler can be used to heat water

The disadvantage of such a boiler is that it burns out the oxygen in the room very quickly, so a good ventilation system is needed. In addition, the furnace body is heated to a red glow, the temperature is very high, which requires careful compliance with fire safety standards.

Be sure to take care of the fireproof base on which the stove is installed and protect the nearby walls from excessive heating with a metal screen, under which lay a layer of heat insulator. So that no one accidentally touches the stove, it is also desirable to have a protective fence.

Safety regulations

A potbelly stove at work with additional devices requires careful attention.

In order not to damage the equipment and not harm the room, you need to remember a few rules:

- Do not leave the device unattended for a long time, such as overnight.

- Before use, it is better to concrete the place under the furnace.

- Cover the walls with non-combustible materials.

- Do not place the device in a draft so that the fire does not spread to combustible materials. At the moment of ignition, the flame burns strongly and breaks through the holes in the pipe.

- Until the oil vapors begin to burn, it is impossible to add it.

Instructions for using the oven

Before the first test, you need to make sure that the unit is stable. Sequencing:

- fill the lower container with fuel to 2/3 of the volume;

- pour a little gasoline on top;

- open the damper;

- light a match and light a wick, a newspaper;

- wait until the gasoline heats up the oil and the vapors begin to burn;

- close the damper when the room warms up.

Oil consumption with low combustion will be about 0.5 liters per hour. With strong burning - 1.5 liters per hour.

Varieties of furnaces in development

It has already been said above that the simplest potbelly stove is not very convenient and effective. Therefore, various modification options have appeared, which we will consider below.

Furnace for mining from an old gas cylinder

Here, too, a sheet metal of 4 mm (approximately 50 sq. cm) is required, but another basic element is more important - a spent gas cylinder with a capacity of 50 liters, better than the old Soviet model, propane. Oxygen is heavier and more massive, it is difficult to work with it. In addition, you need:

- steel pipe with a diameter of 100 m, length 2000 mm;

- valve with ½ inch thread;

- steel corner with a shelf of 50 mm, a meter or a little more;

- clamps;

- loops;

- a piece of fuel supply hose;

- car brake disc. We select the diameter so that it freely enters the balloon;

- another cylinder (freon) to create a fuel tank.

Work sequence:

- we release the remaining gas from the cylinder, drill a hole in the bottom and rinse the cylinder with water;

-

cut out two openings in the side wall - a large lower and a smaller upper one. The fuel chamber will be located in the lower one, the afterburning chamber will be located in the upper one. By the way, if the dimensions of the lower opening allow, in addition to mining, it will be possible to use firewood as fuel;

-

from a steel sheet we make the bottom of the afterburner chamber;

-

we make a burner from a pipe - a place where volatile gases mix with air and ignite. Holes are drilled in the burner (according to the principle described above), the pipe is GRINDED inside, this is necessary for greater product efficiency;

-

the finished burner is welded into the bottom of the afterburner chamber;

-

from a brake disc and a piece of steel sheet we make a pallet for testing. We weld a cover in its upper part;

-

to connect the burner and the pan cover, it is better to use a coupling - this facilitates the maintenance of the furnace;

-

we carry out a supply for fuel. To do this, a hole is made in the wall of the cylinder, into which a pipe with a threaded edge is welded;

-

a valve is placed at the outer end of the pipe, a hose is connected to it. The hose, in turn, is connected to a fuel tank;

-

the chimney pipe is welded into the upper part of the cylinder, then “taken away” with a smooth transition upwards, to the exit from the room.

In fact, this completes the work with the furnace itself, but it is better to additionally build a heat exchanger - this will increase efficiency.

One of the heat exchanger options - plates welded onto the body - is shown in the photo below.

The finished oven with open doors (the hinges were needed specifically for them, the pieces of the cylinder cut out in paragraph 2 are attached to the hinges).

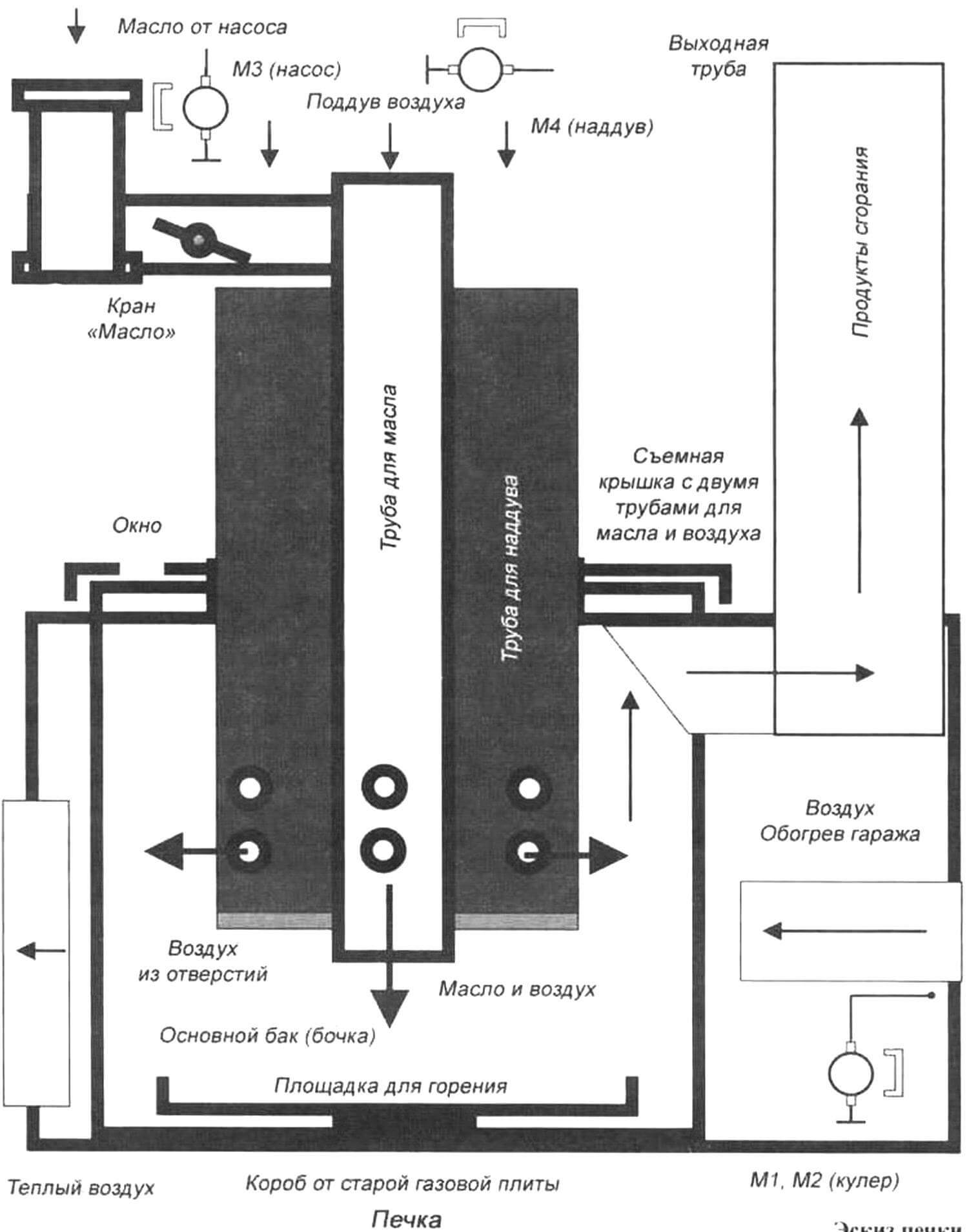

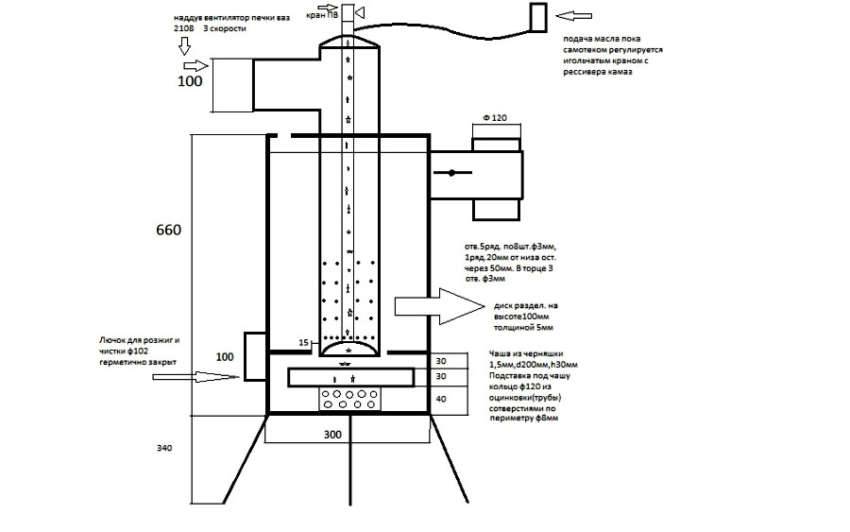

Furnace for working out with pressurization

This design is also assembled on the basis of a 50-liter cylinder.

The air supply here comes from a fan (for example, from the stove of a VAZ 2108 car), which allows you to increase the thrust in the afterburner and at the same time make the entire surface of the cylinder actually a heat exchanger.

The process of work and ignition are shown in the video.

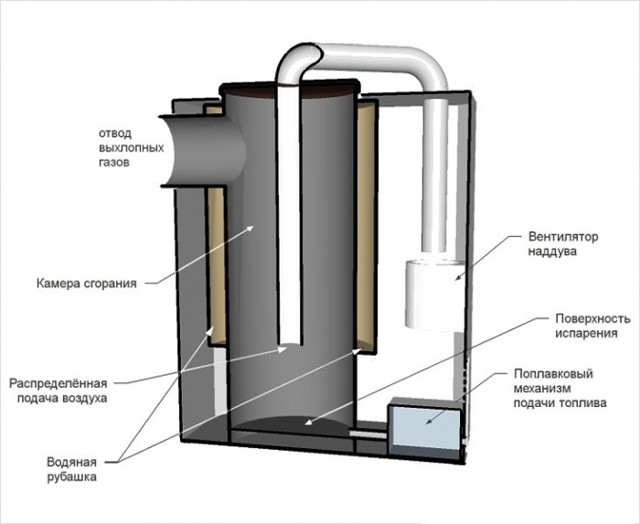

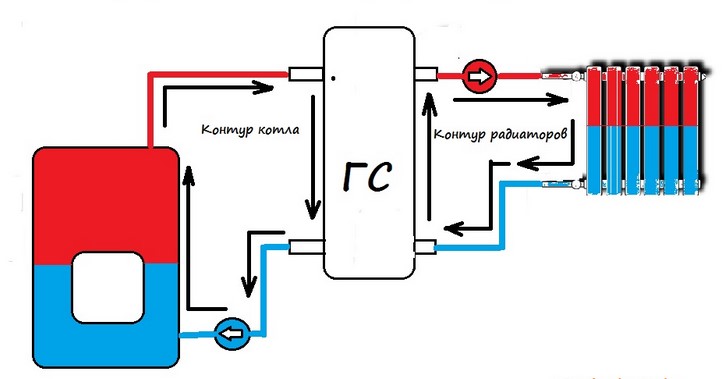

Working furnace with water circuit

The manufacture of a furnace with a water circuit can be almost the same as in the simplest version. The main difference is the organization of heat extraction into the water coolant. In the photo below, this possibility is realized by winding the pipe around the furnace body. At the same time, cold water is supplied from below, heated water comes out from above.

A more "advanced" option is a stove with a "water jacket". In fact, the body is enclosed in a second, hollow, inside which water circulates. The heated liquid is supplied to the heating radiators.

True, the phrase “does not smoke” from the manufacturer is some exaggeration - this is real only with regular cleaning of the chimney and the use of sufficiently high-quality, filtered fuel.

In the drawing, the device looks something like this.

Drip Furnace

This type of furnace is safer than those designs into which fuel is poured at once. In addition, in the case of gradual feeding, the burning time can be freely adjusted.

A mandatory element of the system is a separate fuel tank, from which mining is supplied in small portions - almost drops - using a special device.

The photo below shows a design where there is a separate tank with an oil line located above the fuel chamber. The base of the furnace is a gas cylinder, a valve is used to adjust the intensity of the mining supply. The device of the furnace is discussed in more detail above.

Another type of product is with a retractable fuel compartment and a double afterburner.

She, realized in metal.

Please note: due to pressurization and the absence of fuel losses during filling, the mining consumption is reduced by 20 ... 30%

Installation and trial ignition

The place for installing the stove should be chosen as far as possible from objects and materials that are sensitive to heat. The device gets really hot. If handled carelessly, it can damage property and even cause a serious fire.

There must be a non-flammable base under the device. Do not place such a device in places of active movement of air currents. Under the influence of a draft, the flame can be knocked out, and this is dangerous. Ready and installed in a suitable place, the furnace is connected to a vertical chimney.

Then a test firing is performed. To do this, oil is poured into the fuel tank, and about 100 ml of liquid for fireplaces or another similar composition is added on top. At first, this liquid will burn, but soon the oil will boil, the device will begin to make noise. This means that the oven is made correctly, it can be used for its intended purpose.

All welding work must be done carefully, a tight and even seam is required so that the device is safe and easy to clean

Oil before pouring into the tank must be defended for some time so that unnecessary impurities settle down and do not get inside.Only two-thirds of the capacity should be filled, then the primary combustion process will be more efficient and safer.

From time to time it is necessary to clean the inside of the fuel tank from accumulated contaminants. The cover is removed and the remaining oil is simply drained, deposits are removed, etc. From time to time, you need to tap the perforated pipe and chimney to remove the collected soot and soot.

How to make a homemade waste oil stove

The waste oil stove model presented below is perhaps the simplest and at the same time effective and environmentally friendly design option for heating a small workshop or garage in cold autumn or winter. This liquid fuel stove is quite suitable as a basic element of a boiler or electric generator with the necessary additions and improvements.

Furnace in production

Furnaces and boilers running on cheap used oil have been created in large numbers by craftsmen in recent years, and are now being produced at factories in Russia and abroad. Their price is not so high, and the savings are significant. It is even cheaper and more interesting for many to make a stove for working out with their own hands. The stove, which will be discussed in this message, according to the experience of various craftsmen, can be assembled and welded in one or two days. The reviews of those who gathered their strength and made this thermal unit are often the most flattering.

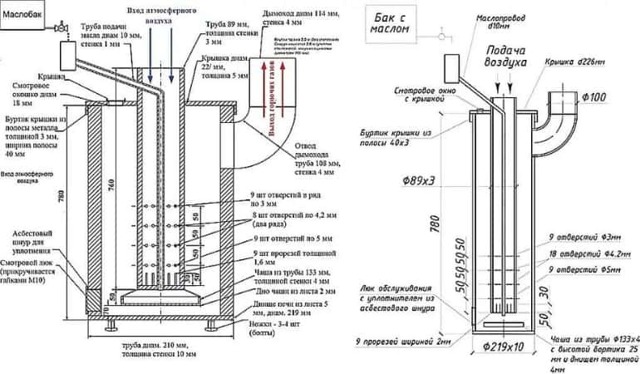

Operational and technical characteristics of a home-made furnace for testing.

The furnace is intended for heating of air in the fireproof room.It is allowed to use motor oil or substances similar in composition to it as fuel (industrial oil, transmission oil, transformer oil, petroleum oil, solar oil, heating oil, fuel oil, kerosene, diesel fuel).

#8211 minimum chimney height 4 m (distance from the top edge of the chimney to ground level). With a shorter chimney pipe, according to the experience of those who have already experimented, complete combustion of the fuel does not occur and smoke is released.

#8211 flue diameter 102 mm

#8211 oven overall dimensions: height 700 mm, width 300 mm, depth 500 mm

#8211 oven weight 28 kg.

When using used motor oil type MG-10, the furnace demonstrates quite high characteristics: fuel consumption from 0.5 to 2.0 liters / hour efficiency 75% furnace temperature #8211 800-900 degrees, and at the outlet of the furnace #8211 90 degrees , this allows, at an outdoor air temperature of minus 35 degrees, to maintain heat in an unheated small standard garage from plus 15 degrees to plus 20, depending on the set operating mode of the stove. You can adjust the burning power from a barely warm stove to red-hot (800-900 degrees C).

Advantages of the oven

1. The most important advantage of this #8211 oil furnace is the possibility of huge savings, since the price of used oil is very low or even zero. Sometimes you can find the opportunity to take this oil for free as waste, which is thrown away by some enterprises. This is how people do #8211 in the summer they accumulate oil in the auto repair shop, and in the winter they heat garages with it.

2. There are benefits from such a waste-free stove for nature. After all, firstly, it is unlikely that all car owners or workshops, enterprises always properly dispose of mining.Secondly, the oil in such a home-made furnace on used oil burns out almost completely without residue, without harming nature and human health.

Furnace for working out from steel sheets

Materials and tools

Waste oil stove designs made of steel sheets are very popular among craftsmen from the people. Such an oven has compact dimensions (70/50/35 cm without a chimney), weighs 27 kg, it can be connected to heating, it can be used in the cold, and the top of the oven can be used for cooking. To make such an oven, we need:

- steel sheet 4 mm thick

- steel sheet 6 mm thick

- Bulgarian

- file

- welding machine and electrodes

- a pipe with an inner diameter of 10 cm, a length of at least 4 m and a wall thickness of 4-5 mm for a chimney

- steel corners 20 cm high 4 pieces as legs for the oven

- drawing

- level and tape measure

- a hammer

- burner pipes made of steel, copper or painted sheet

Stages of manufacturing a furnace from steel sheets

To begin with, we print out a drawing of the future furnace with the details drawn on it.

Next, we make the details according to the drawing. Parts for the tank are made of steel sheet 4 mm thick, and for the bottom of the firebox and the cover of the tank from sheet 6 mm thick. The sheets are laid out on a flat surface, markings are made on them and details are cut out with the help of a grinder. All welding seams are checked for tightness and cleaned with a file.

A strip 115 mm wide is cut out of a sheet 4 mm thick, and we fold the strip into a ring with a diameter of 34–34.5 cm on a bending machine. We weld the strip by electric welding. We got an oil tank pipe.

From the same steel sheet we cut out a circle with a diameter of 34.5 cm.This will be the lid of the oil container. Weld the cap to the pipe for the oil container. We also weld corners to the lid from 4 sides. The oil container is ready!

We cut a strip 6 cm wide from a 6 mm thick steel sheet and roll a ring out of it to make a diameter of 35.2 cm.

From the same sheet of 6 mm we cut a circle with a diameter of 35.2 cm. We make it exactly in the middle circle hole diameter 10cm. The chimney pipe will be inserted into it. To the right of the hole, we retreat 4 cm and make another hole 5-6 cm, where the oil will pour. We weld a ring with a diameter of 35.2 cm with a circle with a diameter of 35.2 cm. The oil tank is ready!

We make the lower part of the tank. We cut a circle with a diameter of 35.2 cm from a 6 mm thick steel sheet. We step back a few centimeters from the edge of the circle and cut a hole with a diameter of 10 cm. From the center of the hole to the center of the circle itself, there should be about 11 cm. This will be a hole for the pipe into which the chimney is inserted pipe.

We cut off a part 13 cm high from a pipe with a diameter of 10 cm. This will be a branch pipe.

From a sheet 6 mm thick, cut out a rectangle 7 cm wide and 33 cm long. This will be the partition. It must be placed in a circle with a diameter of 35.2 cm closer to a hole with a diameter of 10 cm and welded. We insert an exhaust pipe 13 cm high into a 10 cm hole.

We prepare the pipe for the burner. On it from below, at a distance of 36 cm, we make evenly 48 holes of 9 mm, 6 circles of 8 holes 6 cm apart.

We insert a pipe with holes into the cover of the oil container, made of a sheet 4 mm thick. Using a level, make sure that the pipe is inserted evenly. If there are any deviations, then they are eliminated with a file and a grinder.Parts should fit snugly into each other, but not welded.

We insert an exhaust pipe 16 cm high into the opening of the oil filling tank.

We connect the bottom and top of the tank

ATTENTION! We don't weld! Parts must fit into each other. To strengthen, we make an o-ring with a diameter of 35.4 cm and put it on top of the tank structure

We check the accuracy of the fit of the parts with a level.

We weld the oil tank to the pipe with 48 holes by electric welding. On the other side of the pipe with holes, we weld a structure fastened with a sealing ring. Before welding, we carefully check the accuracy of the installation of parts with a level! We equip the oil filling hole with a round plate, which can be easily moved and moved away according to the principle of a peephole.

Now we mount a chimney from a pipe 4 m long. If it can be tilted indoors, then it is strictly vertical on the street so that the wind does not blow. ATTENTION! Under no circumstances should the chimney be laid horizontally! If the inclined pipes are long, then they can be strengthened with special bends made of steel bars.

1 General information

Currently, more and more users are gaining interest in oil-based heating. The cost of commercially manufactured heating appliances is approximately the same as that of gas units, however, they differ in much cheaper operation.

A wide range of devices is presented by any outlet of building materials, and enterprises also carry out individual orders.Wanting to save money, you can independently make a device for testing, which will be simple and will not require special knowledge and special efforts for execution. In addition, the materials necessary for the manufacture and installation of additional boiler equipment will be inexpensive. Due to the versatility, the devices can be used for water and air heating. There are other positive features:

- 1. Homemade devices are autonomous and absolutely safe, as they are made according to the latest technical projects.

- 2. Comfortable in operation, do not have burning smells typical for this type of construction.

- 3. When functioning, they do not cause any inconvenience.

- 4. Easy to use due to the high degree of automation.

- 5. With self-assembly, no special effort or significant time is required.

With almost 100% fuel combustion, there is no fumes and gases. By actually using waste (used oil) for heating, the boiler pays off pretty quickly. Units of domestic production, which are distinguished by reliability, or Finnish (considered the most economical) are very popular.

Diesel heating

This method of heating is used to heat suburban real estate and garages.

What does it represent?

Such heating has a similar principle of operation with a water circuit, but there are some nuances. The boiler that heats the coolant is powered by diesel fuel.

The liquid is carried through the system and returned back using a circulation pump. After heating the coolant, the source stops its work, and after cooling it resumes.

Advantages and disadvantages

Advantages of diesel heating:

- automated operation of the boiler;

- independence from central heating, thanks to which the heating is turned on and off by the user at his own discretion, based on the temperature outside;

- the prevalence of fuel that can be purchased at any gas station.

Flaws:

- high cost of diesel fuel;

- high price of equipment and components.

Safety Requirements

Flammable liquids must not be used as the main fuel. Gasolines or thinner are intended only to start the combustion process and are used in small quantities. In order to efficiently use the heating system, only clean used oil should be taken as fuel. Even a small admixture of water leads to a sharp foaming of the oil, its release to the surface, after which a fire can occur.

Therefore, you need to carefully monitor the quality of the fuel and have a fire extinguisher nearby. The oil stove should not be used in rooms with strong drafts - this leads to the damping of the flame in the stove. In order to re-ignite it, you will need to wait for the device to cool completely.

The stoves during mining should not be left unattended, since in the optimal mode of operation its surface heats up to 800 ° C - this can ignite nearby objects. After finishing work, you need to wait for the furnace to cool down to an acceptable temperature.