- Furnace device

- Types of homemade stoves in development

- The device and disadvantages of an open-type potbelly stove

- Pros and cons of a dropper

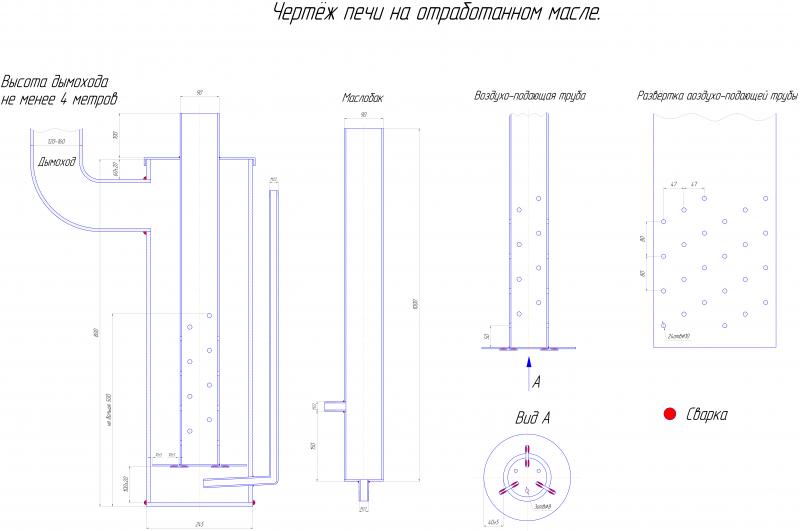

- How to make a waste oil boiler with your own hands

- Tools and materials

- Manufacturing process

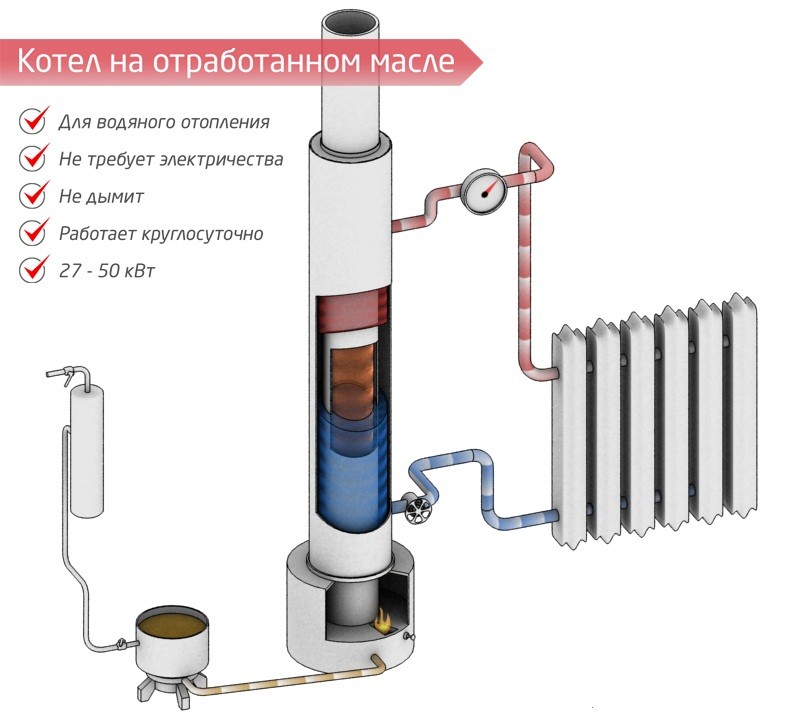

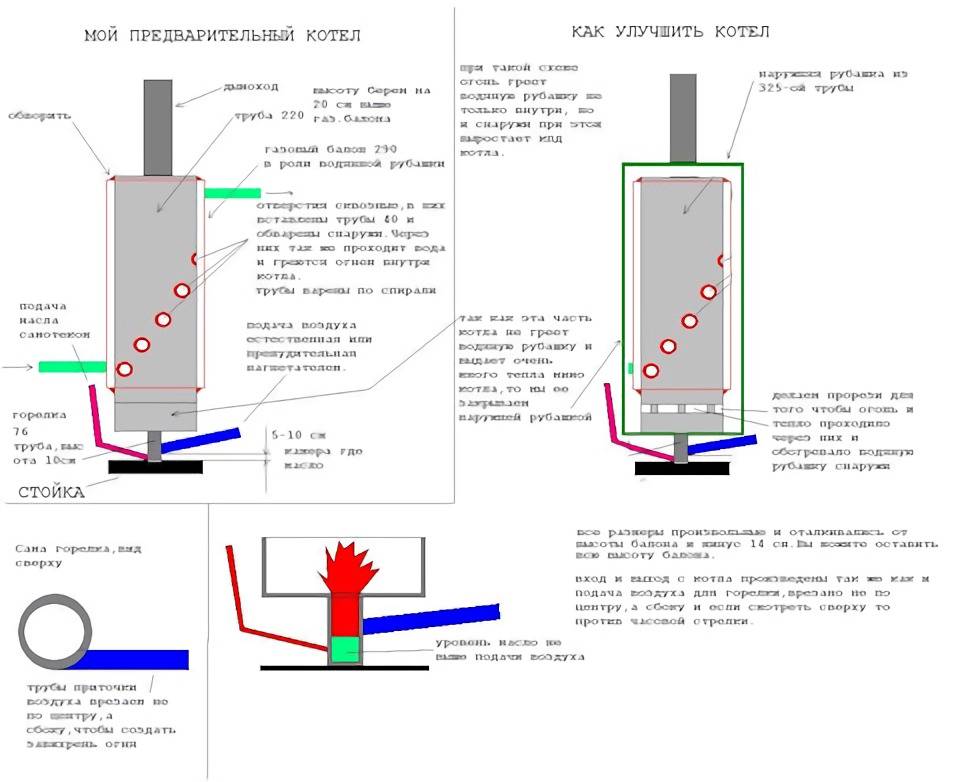

- Construction of a more powerful boiler

- 2 Technical characteristics of mining

- How to build a stove from a pipe?

- The pipe is an excellent "semi-finished product" for the construction of the furnace

- Part preparation

- Furnace manufacturing

- Production of a water heating tank

- Operation features

- Balance of advantages and disadvantages

- General principle of operation

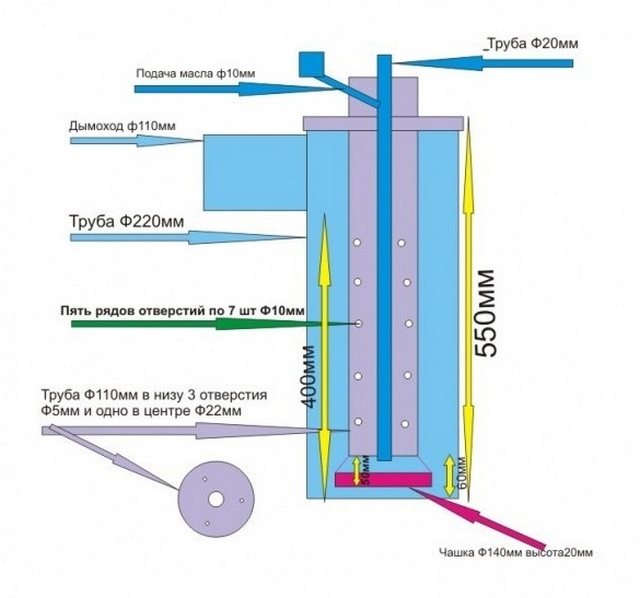

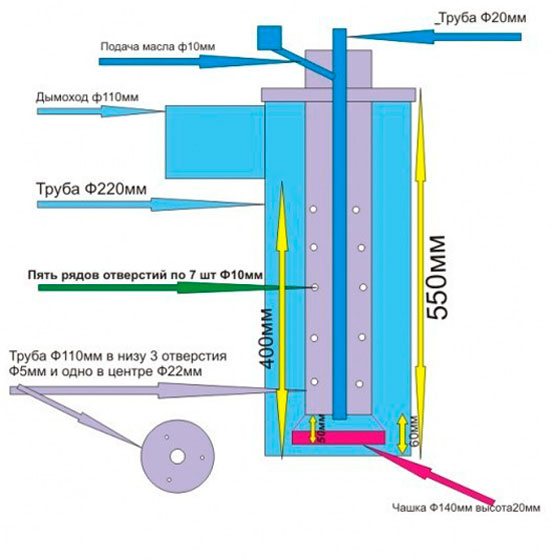

- Application of perforated tube

- Using the Plasma Bowl

- How does a heater work

- Who invented the stove

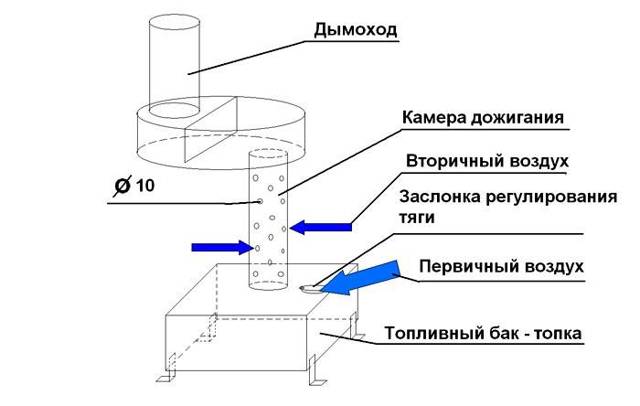

Furnace device

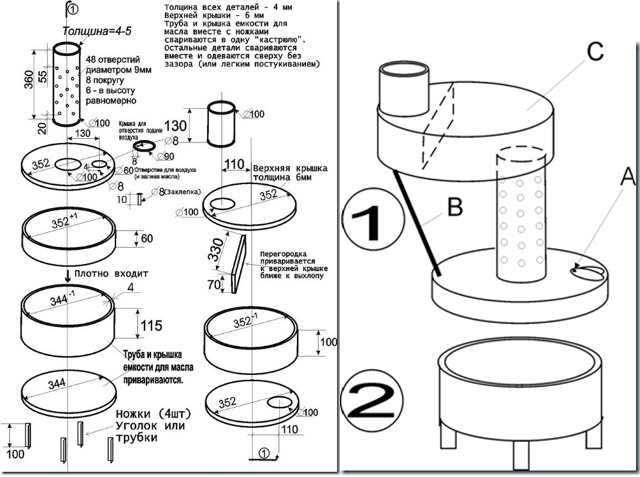

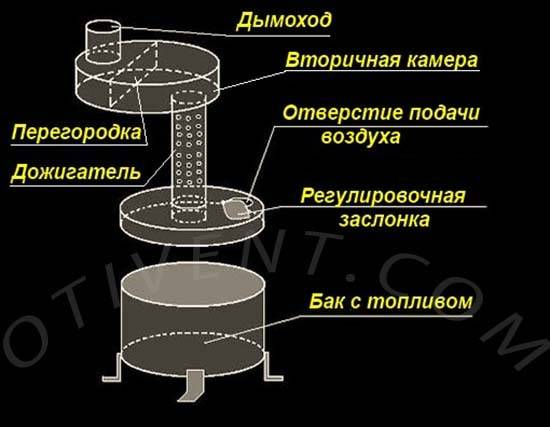

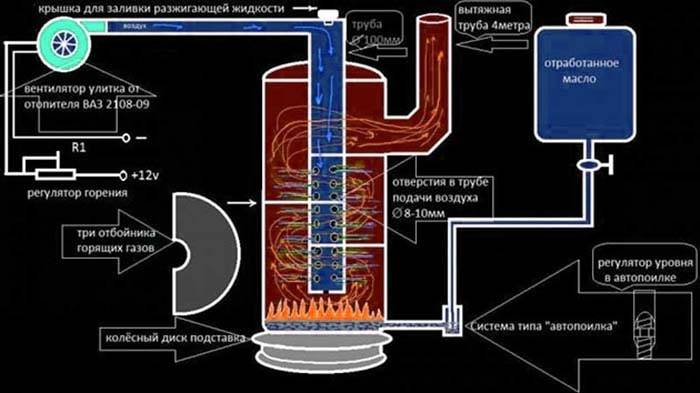

The principle of operation is as follows: fuel is poured into the lower metal container. There is also a damper to regulate the amount of air. A metal pipe with holes for air rises vertically from the lower tank, the length of which is at least 50 cm. It is connected to the second tank, where the oil vapors are burned. A long chimney departs from the second container (the longer, the better), and is discharged through a window or through a hole in the roof. This is the easiest option. There are more advanced devices:

- supercharged - a fan is provided to accelerate combustion;

- devices for testing with a water circuit;

- industrial ovens.

about no more than 4/5 volume.

Gasoline begins to burn intensely and heats up the oil. After 10 minutes, it begins to evaporate and the vapors ignite. From this moment on, the working furnace begins to perform its function. When the room warms up, the damper can be pushed a little and reduce combustion. Thus, the temperature will be maintained in the desired range.

Types of homemade stoves in development

Engine oil contaminated with impurities does not itself ignite. Therefore, the principle of operation of any oil potbelly stove is based on the thermal decomposition of fuel - pyrolysis. Simply put, to obtain heat, mining must be heated, evaporated and burned in the furnace furnace, supplying excess air. There are 3 types of devices where this principle is implemented in various ways:

- The simplest and most popular design of direct combustion with afterburning of oil vapors in an open-type perforated pipe (the so-called miracle stove).

- Waste oil drip furnace with closed afterburner;

- Babington burner. How it works and how to make it yourself is described in detail in our other publication.

The efficiency of heating stoves is low and amounts to a maximum of 70%. Note that the costs indicated at the beginning of the article designed for heating according to indicators of factory heat generators with an efficiency of 85% (for a complete picture and comparison of oil with firewood, you can go here). Accordingly, fuel consumption in home-made heaters is much higher - from 0.8 to 1.5 liters per hour versus 0.7 liters for diesel boilers per 100 m² of area. Consider this fact, taking up the manufacture of the furnace for testing.

The device and disadvantages of an open-type potbelly stove

Pictured a pyrolysis stove is a cylindrical or square container, a quarter filled with used oil or diesel fuel and equipped with an air damper. A pipe with holes is welded on top, through which secondary air is sucked in due to the chimney draft. Even higher is the afterburning chamber with a baffle to remove the heat of combustion products.

The principle of operation is as follows: the fuel must be ignited using a flammable liquid, after which the evaporation of mining and its primary combustion will begin, causing pyrolysis. Combustible gases, getting into a perforated pipe, flare up from contact with an oxygen stream and are completely burned. The intensity of the flame in the firebox is regulated by an air damper.

This oven in production has only two advantages: simplicity with low cost and independence from electricity. The rest are solid cons:

- stable natural draft is required for operation, without it the unit begins to smoke into the room and fade;

- water or antifreeze that gets into the oil causes mini-explosions in the firebox, which causes fire drops from the afterburner to splash in all directions and the owner has to put out the fire;

- high fuel consumption - up to 2 l / h with poor heat transfer (the lion's share of energy flies into the pipe);

- one-piece housing is difficult to clean from soot.

Although outwardly the potbelly stoves differ, but they operate according to the same principle, in the right photo, fuel vapors burn out inside a wood-burning stove

Some of these shortcomings can be leveled with the help of successful technical solutions, which will be discussed below.During operation, fire safety rules should be followed and used oil should be prepared - defended and filtered.

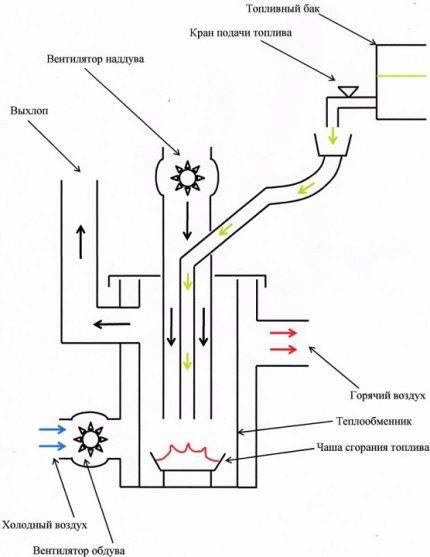

Pros and cons of a dropper

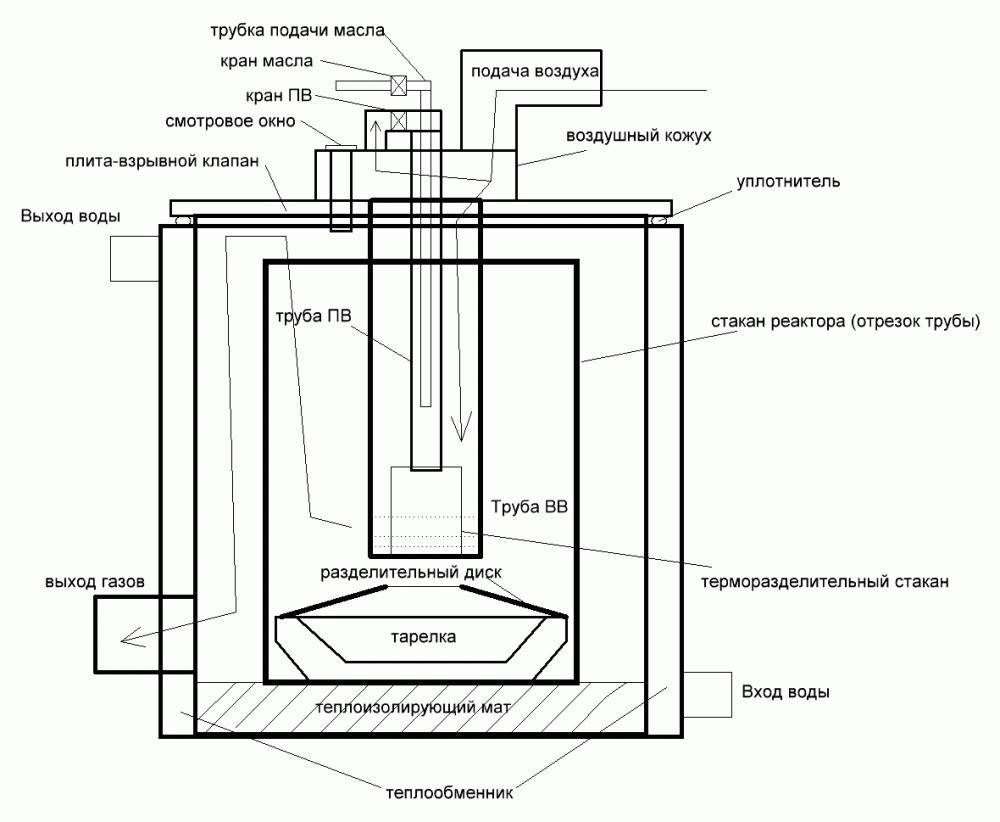

The cardinal difference of this furnace is as follows:

- the perforated pipe is placed inside a steel case from a gas cylinder or pipe;

- fuel enters the combustion zone in the form of droplets falling to the bottom of the bowl located under the afterburner;

- To increase efficiency, the unit is equipped with forced air by means of a fan, as shown in the diagram.

Scheme of a dropper with a bottom supply of fuel from a fuel tank by gravity

The real disadvantage of a drip stove is the difficulty for a beginner. The fact is that you cannot rely entirely on other people's drawings and calculations, the heater must be manufactured and adjusted to suit your operating conditions and properly organize the fuel supply. That is, it will require repeated improvements.

The flame heats up the body of the heating unit in one zone around the burner

The second negative point is typical for supercharged stoves. In them, a jet of flame constantly hits one place of the body, which is why the latter will burn out pretty quickly if it is not made of thick metal or stainless steel. But the listed disadvantages are more than offset by the advantages:

- The unit is safe in operation, since the combustion zone is completely covered with an iron case.

- Acceptable waste oil consumption. In practice, a well-tuned potbelly stove with a water circuit burns up to 1.5 liters in 1 hour to heat 100 m² of area.

- It is possible to wrap the body with a water jacket and remake the furnace for working out into a boiler.

- The fuel supply and power of the unit can be adjusted.

- Undemanding to the height of the chimney and ease of cleaning.

Pressurized air boiler burning used engine oil and diesel fuel

How to make a waste oil boiler with your own hands

The simplicity of the design of such heaters allows you to make them yourself. In this case, it is necessary to have locksmith and welding skills.

Tools and materials

To make a boiler with your own hands, the following devices are required:

- Bulgarian;

- welding machine;

- a hammer.

For the manufacture of the boiler in used oil do not forget the grinder with your own hands

For the manufacture of the boiler in used oil do not forget the grinder with your own hands

As a material for the heating structure, you must purchase:

- refractory asbestos cloth;

- heat-resistant sealant;

- steel sheet 4 mm thick;

- metal pipe with a cross section of 20 and 50 centimeters;

- compressor;

- ventilation pipe;

- drives;

- bolts;

- steel adapters;

- half-inch corners;

- tees;

- reinforcement with a cross section of 8 millimeters;

- pump;

- expansion tank.

The body of the boiler for heating small rooms can be made from a pipe; for a device with a higher power, it is best to use steel sheets.

Manufacturing process

The waste oil unit can be built in any shape. For garage heating or small agricultural buildings, it is best to make a small boiler out of pipes.

The manufacture of such a heating device consists of the following steps:

- A metal pipe with a large cross section is cut so that its size corresponds to one meter. Two circles corresponding to a diameter of 50 centimeters are prepared from steel.

- The second pipe with a smaller diameter is shortened to 20 centimeters.

- In the prepared round plate, which will serve as a cover, a hole is cut corresponding to the size of the chimney.

- In the second metal circle, intended for the bottom of the structure, an opening is made, to which the end of a pipe of a smaller diameter is joined by welding.

- We cut out a cover for a pipe with a cross section of 20 centimeters. All prepared circles are welded as intended.

- Legs are constructed from reinforcement, which are attached to the bottom of the case.

- Small holes are drilled in the pipe for ventilation. A small container is installed below.

- In the lower part of the case, with the help of a grinder, an opening for the door is cut out.

- A chimney is attached to the top of the structure.

For such a simple job boiler in operation all you need to do is pour oil into the tank from below and set it on fire with a wick. Before this, the new design should be checked for tightness and integrity of all seams.

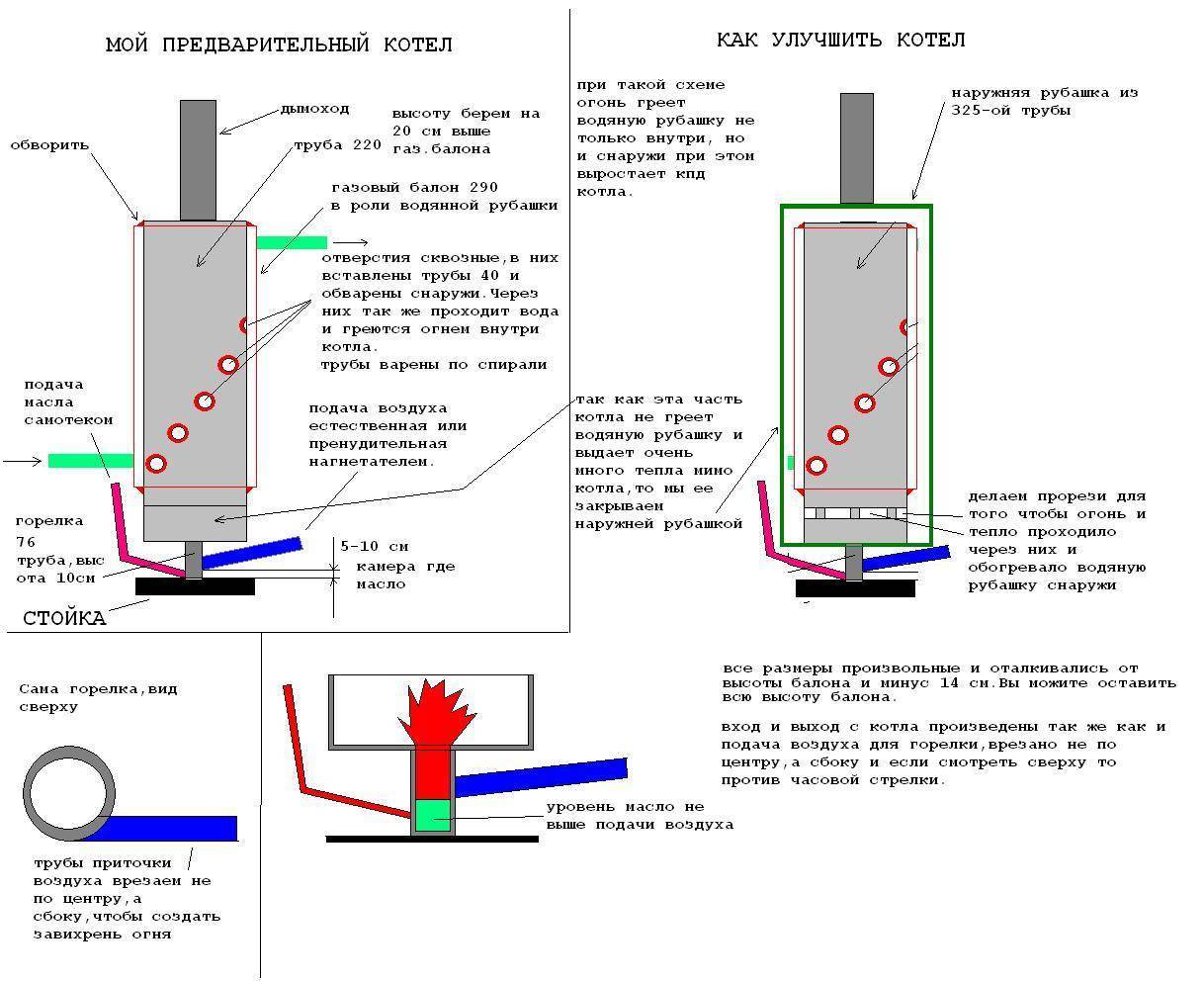

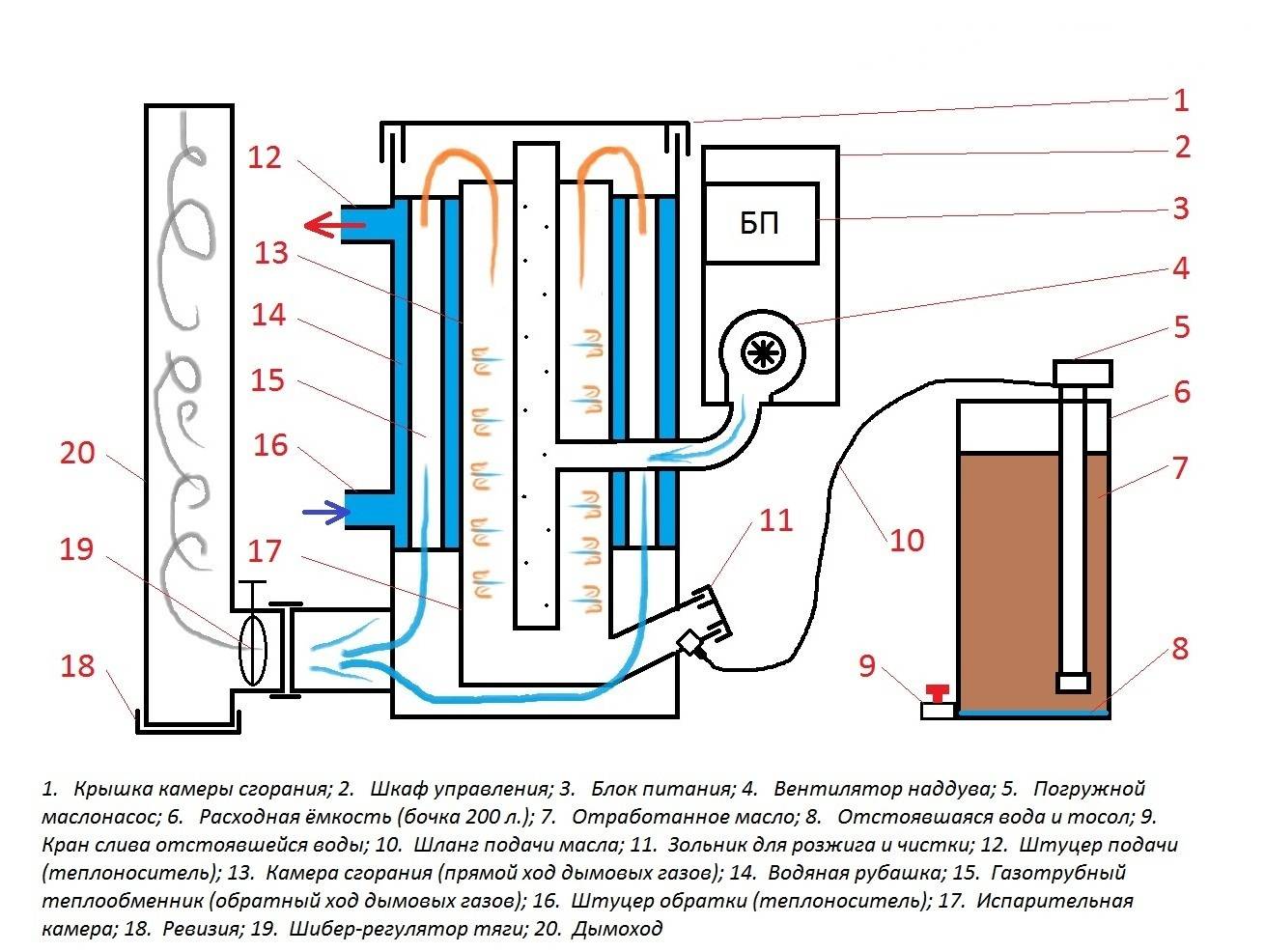

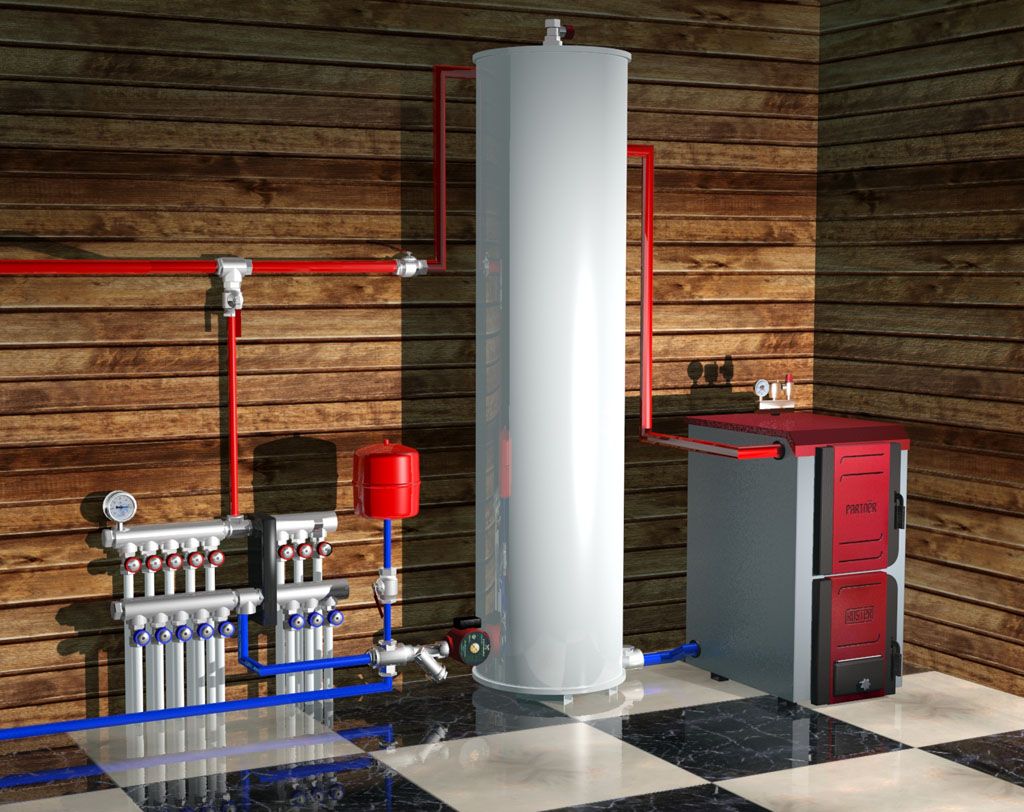

Construction of a more powerful boiler

Two boxes are made of strong sheet steel, which are connected using a perforated pipe. In the design, it is used as an air vent.

The subsequent manufacturing process of the heater has some features:

- A hole is made in the lower body of the boiler to supply oil to the evaporation tank. A damper is fixed opposite this container.

- The box located in the upper part is complemented by a special hole for the chimney pipe.

- The design is equipped with an air compressor, an oil supply pump and a container into which fuel is poured.

Do-it-yourself waste oil boiler

Do-it-yourself waste oil boiler

If water heating is required, then an additional circuit is connected, which requires the installation of a burner. You can build it yourself:

- half-inch corners are connected by spurs and tees;

- a fitting is fixed to the oil pipeline using adapters;

- all connections are pre-treated with a sealant;

- a burner cover is cut out of sheet steel, corresponding to the nests on the manufactured boiler;

- two different sizes of steel plates are used to install the burner;

- the inside of the tube adapter is tightly covered with an asbestos sheet, which is fastened with sealant and fixed with wire;

- the burner is inserted into the housing intended for it;

- after that, a smaller plate is fixed in the nest and covered with four layers of asbestos;

- a large plate is mounted as a mounting plate;

- holes are drilled in it for fastenings, and an asbestos sheet is applied on top;

- two prepared plates are connected with bolts.

To prevent the burner from disintegrating during the operation of the boiler, all parts should be carefully and tightly fastened. The device is ignited by a glow plug.

Waste oil boilers are considered economical and practical appliances. They can be purchased at a specialized store or built independently. When using such heating devices, it is necessary to remember the safety rules, which include the mandatory installation of a chimney, the presence of a ventilation system and the proper storage of liquid fuel.

2 Technical characteristics of mining

Oil is a hydrocarbon raw material from which free energy is extracted.Previously, it was forced to be disposed of, and these are additional costs for enterprises: transportation costs, environmental fines and fees. Sometimes the waste material was simply dumped onto the soil and into water bodies, which significantly harmed the environment.

First, engine oil was mixed with diesel fuel used to heat the room. The result was impressive. Then they began to use it as the main fuel.

The developers of the burners have achieved high efficiency of heating devices (up to 94%). By burning one liter of oil fuel, up to 11 kW per hour is obtained. This figure is about the same as that of diesel fuel. After cleaning, the energy efficiency of recycled materials increases by another 20-25%. In addition, the cost of secondary oil is much lower than diesel oil, and most people get it for nothing, and the enterprise solves the problem of mandatory disposal in a profitable way.

When heating with used oil, the efficiency is not always the same, but it directly depends on the composition and origin of the fuel. The efficiency is characterized by the following parameters:

- density, which determines the specific energy reserve;

- viscosity affecting efficiency;

- ignition and solidification temperatures at negative air temperatures;

- ash content (the content of solid non-combustible components remaining in the form of soot);

- the presence in its composition of water, as well as other substances (fuel, acids, antifreeze, additives, alkalis, etc.).

As mentioned above, heat can be extracted from any oil. More often than others, petroleum products are used:

- engine oil (used in internal combustion engines);

- industrial (various mechanisms are lubricated);

- compressor (in refrigeration units, compressors);

- energy (dielectric used in capacitors, transformers).

Appliance users, lacking enough of their own fuel, resort to purchasing fuel from suppliers who, in turn, buy and process it. Then the energy carriers are transported by oil trucks and pumped into special tanks provided free of charge for rent.

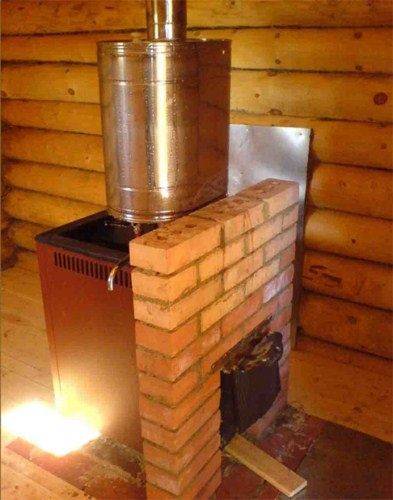

How to build a stove from a pipe?

Do-it-yourself sauna stove from a pipe

One of the most common homemade options is a pipe sauna stove. Consider how such construction is carried out.

The pipe is an excellent "semi-finished product" for the construction of the furnace

metal stoves can be made from steel sheet or, for example, from an old barrel. But if there is a piece of pipe of a suitable diameter on the farm, then you should use this "blank".

A home-made stove in a bath from a pipe can be made with a vertical or horizontal direction of the pipe section. The use of prefabricated furnace tubes reduces the amount of welding required when making sheet metal furnaces.

For making ovens suitable only high-quality pipes, without signs of corrosion.

If the pipe has lain on the street for a long time, then it should be preliminarily inspected and reinforced in problem areas by welding patches.

Part preparation

To make a good stove from a pipe, you need a piece of pipe rolled with a diameter of 50 cm and a length of 1.5 meters. The wall thickness of the pipe must be at least 10 mm.

The workpiece should be cut into two parts, 0.6 and 0.9 meters in size, respectively.A longer section is needed for the construction of a firebox and a heater, and the remaining piece will be used to make a tank.

Furnace manufacturing

An example of using a stove from a pipe in a bath

- First of all, you should do blower. A hole 5 cm high and 20 cm wide is cut out at the bottom of a long piece of pipe. A thick rounded steel plate is welded above the hole.

- Next, a niche for the firebox is formed and a door is made for it. The door is hung on hinges or hooks.

- A piece of pipe is welded over the firebox, which will be used as a heater. The height of the segment is 30-35 cm.

Rounded cobblestones should be used to fill the heater, in extreme cases, ceramic electrical insulators can be poured.

A steel sleeve is installed in the upper part of the future furnace, which will be required to fix the water heating boiler.

Production of a water heating tank

A range of stoves for a bath from pipes

During the construction of the kiln do-it-yourself baths a water-heating tank is also formed from the pipe.

- For its manufacture, a piece of pipe 0.6 m high is used.

- A steel circle is welded to the end part of the pipe section - the bottom.

Advice! The thickness of the metal for the manufacture of the bottom of the water tank is at least 8 mm

A hole is cut in the bottom of the tank, necessary for the chimney. It should be moved to the rear wall of the tank.

The chimney is fixed to the bottom of the tank by welding

It is important that the seam is of high quality in order to prevent water from leaking into the furnace.

The upper part of the tank is closed with a metal lid with holes made for passing the chimney and for filling water.The chimney is welded tightly to the lid, and a neck with a lid is installed in the hole for filling water.

Operation features

During the operation of such a furnace, one should be aware of its fire hazard. Do not place flammable substances and materials in the immediate vicinity of the oven.

Walls and floors are best insulated with metal sheets. This is to protect against ignition of accidentally spilled oil. And also the sheets on the walls will serve as an additional heat reflector inside the room.

Waste machine, transformer oil is used as fuel in such a stove. It is unsafe to add fuel to the tank during combustion, it is better to do this when the previous refueling is completely burned.

Ignite the fuel with a wick. You can also use rolled up newspaper.

In the process of combustion, the damper regulates the air supply to the tank, thereby regulating the intensity of combustion.

Balance of advantages and disadvantages

It would seem that the idea is practically devoid of flaws, but it is not. To make an informed decision about the use of such heating in your home, you need to see not only the pros of its use, but also the cons.

Let's start with the advantages of the method. So, if you have regular access to junk fuel, which is essentially mining, then you can efficiently use and dispose of this material at the same time. Proper use of technology allows you to get heat with complete combustion of the material without the emission of harmful substances into the atmosphere.

Other pluses include:

- uncomplicated design of the heating unit;

- low fuel and equipment costs;

- the possibility of using any oil that is on the farm: vegetable, organic, synthetic;

- combustible material can be used even if the pollution is a tenth of its volume;

- high efficiency.

The shortcomings of the method should be taken seriously. If the process technology is not observed, incomplete combustion of the fuel may occur. Its fumes are dangerous to others.

If there were more disadvantages to heating during mining than advantages, such factory-made products would not appear on sale, which are sold out like hot cakes, despite the rather high prices

It is not for nothing that the main requirement for arranging heating at mining is the presence of ventilation in the room where the boiler will be operated.

Here are some other cons:

- since good draft requires a high-quality chimney, it must be straight, and its length must be from five meters;

- the chimney and the plasma bowl must be cleaned regularly and thoroughly;

- the complexity of the drip technology lies in the problematic ignition: at the time of fuel supply, the bowl should already be red-hot;

- operation of the boiler causes drying of the air and burnout of oxygen;

- self-creation and use of water-heating structures can contribute to lowering the temperature in the combustion zone, which jeopardizes the efficiency of the process as a whole.

To solve the last of the above problems, you can mount a water jacket where it cannot affect the quality of combustion - on the chimney.These shortcomings have led to the fact that the product without significant modifications is practically not used for heating residential premises.

If there is no desire or time to build the unit with your own hands, you can take advantage of the numerous offers from workshops involved in the production and installation of metal structures of various sizes:

General principle of operation

If we want to get high-quality heating based on mining, the oil cannot simply be taken and set on fire, because it will smoke and stink. In order not to experience these unpleasant and dangerous side effects, you need to heat the fuel so that it begins to evaporate.

The volatiles obtained as a result of heating will burn. This is the main principle of operation of the heating unit on processing.

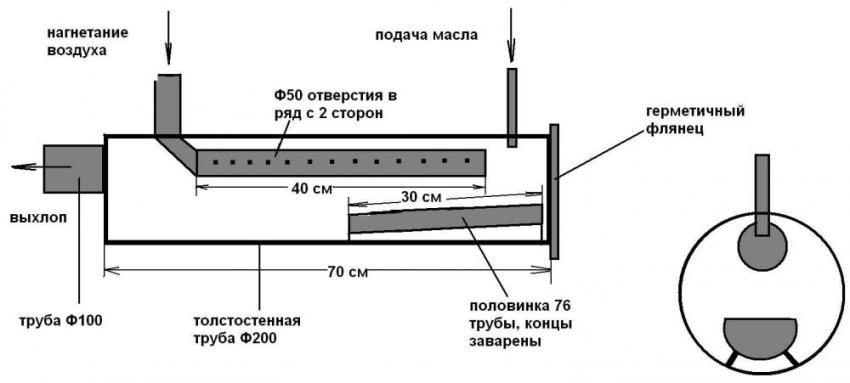

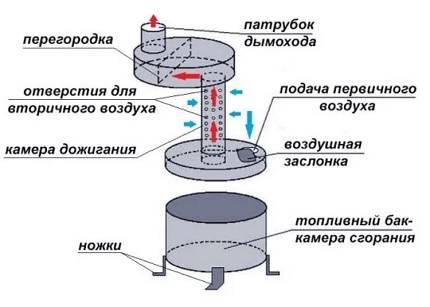

Application of perforated tube

To implement this principle in the design of the stove, two chambers are provided, which are interconnected by a pipe with holes. Fuel enters the lower chamber through the filler hole, which is heated here. The resulting volatile substances rise up the pipe, being saturated with atmospheric oxygen through the perforation.

The schematic diagram of a two-chamber stove with a connecting perforated pipe allows you to understand exactly how a simple unit works at mining

The resulting combustible mixture ignites already in the pipe, and its full combustion takes place in the upper chamber afterburning, separated from the chimney by a special partition. If the process technology is properly observed, soot and smoke are practically not formed during combustion. But the heat will be enough to heat the room.

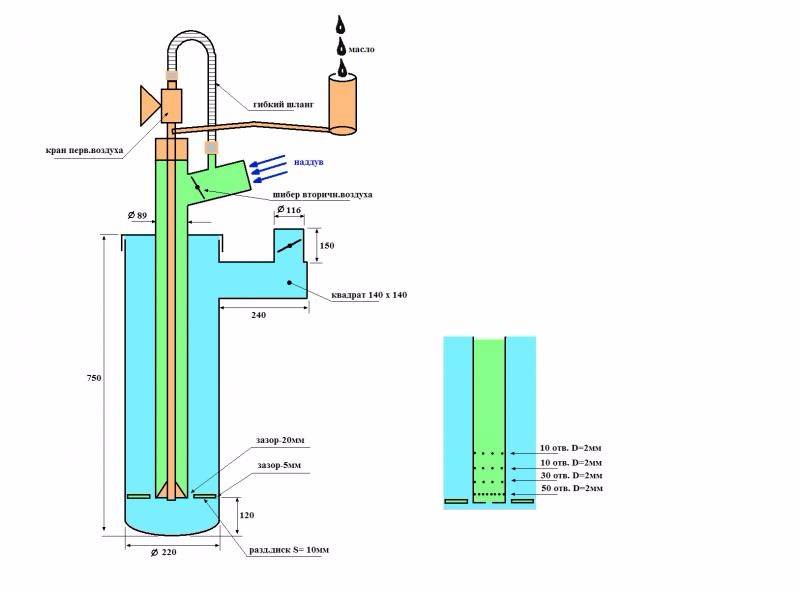

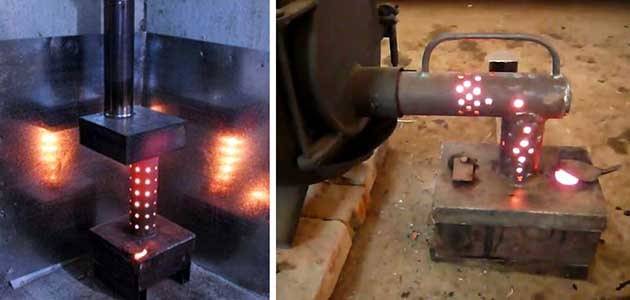

Using the Plasma Bowl

In order to achieve maximum efficiency of the process, you can go a more complicated way. Recall that our goal is to release volatile components from the fuel by heating it. To do this, a metal bowl should be placed in the only chamber of the unit, which must not only be heated, but heated.

Through a special dispenser from the fuel tank, mining will come into the chamber in a thin stream or drops. Getting on the surface of the bowl, the liquid will instantly evaporate, and the resulting gas will burn.

The efficiency of such a model is higher, since the fuel supplied by the drip burns better, and the problem of topping it up during the operation of the furnace disappears by itself.

If everything is done correctly, the combustion of gases should be accompanied by a bluish-white flame. A similar flame can be observed when a plasma burns, so a red-hot bowl is often called a plasma bowl. And the technology itself is called drip supply: after all, fuel with it must be supplied in exceptionally small doses.

With all the variety of designs, the operation of all waste fuel heating units is based on the principle described above.

How does a heater work

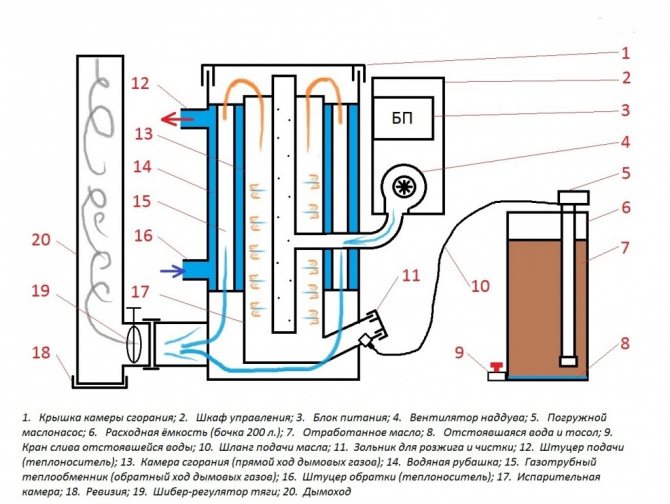

The design of the boiler is extremely simple. It includes two compartments: evaporation and combustion. In the first, the process of preparing the oil for combustion takes place, in the second, it burns out.

Everything happens as follows. From the recovery tank, the pump supplies the waste oil to the evaporation chamber, which is located at the bottom of the device. It maintains a temperature sufficient for the mining to heat up and begin to evaporate.

This is how a boiler works with oil evaporation and forced air supply (+)

This is how a boiler works with oil evaporation and forced air supply (+)

Oil vapor rises to the top of the housing where the combustion chamber is located. It is equipped with an air duct, which is a pipe with holes. With the help of a fan, air is supplied through the duct and mixed with oil vapor.

The oil-air mixture burns almost without residue - the resulting heat heats up the heat exchanger, the combustion products are sent to the chimney.

Oil preheating is an essential part of the process. It must be understood that mining contains a large amount of impurities and toxic substances. All this is decomposed into simple carbohydrates, which are subsequently burned.

After that, water vapor, carbon dioxide and nitrogen are formed - completely harmless elements. However, this result is only possible under certain temperature conditions.

Complete oxidation or combustion of hydrocarbons occurs only at a temperature of +600°C. If it is lower or higher by 150-200°C, then a large amount of various toxic substances is formed during the combustion process. They are not safe for humans, so the combustion temperature must be exactly observed.

Who invented the stove

a simple sailor

Then one member of the expedition came up with a stove on seal fat and bones. In the process of combustion, the fat melted, evaporated and burned. There was no smell or soot. People were able to keep warm and cook hot meals for themselves.

This allowed them to return to the camp with the onset of spring, where they were all considered dead.

In the days of the USSR, such structures were transferred to oil sludge and oil. Such stoves were called - a potbelly stove at work. They were widely used for heating homes, since firewood was in short supply, laws forbade deforestation.On such a device, it was possible to cook food, heat water, and not be afraid of the cold in winter.