- Varieties of furnaces in development

- Furnace for mining from an old gas cylinder

- Furnace for working out with pressurization

- Working furnace with water circuit

- Drip Furnace

- Advantages and disadvantages of the unit

- Furnace for mining from a gas cylinder

- Materials and tools for the manufacture of the furnace

- Manufacturing technology

- Furnace operation

- Varieties of oil boilers for waste oil

- Characteristics of the waste oil heating boiler

- 1 How the system works

- Types of aggregates

- Heating structures

- Water heaters

- Appliances

- Instructions for assembling the oven

- How exactly does oil evaporate?

- We make a heat generator from a cylinder

Varieties of furnaces in development

It has already been said above that the simplest potbelly stove is not very convenient and effective. Therefore, various modification options have appeared, which we will consider below.

Furnace for mining from an old gas cylinder

Here, too, a sheet metal of 4 mm (approximately 50 sq. cm) is required, but another basic element is more important - a spent gas cylinder with a capacity of 50 liters, better than the old Soviet model, propane. Oxygen is heavier and more massive, it is difficult to work with it. In addition, you need:

- steel pipe with a diameter of 100 m, length 2000 mm;

- valve with ½ inch thread;

- steel corner with a shelf of 50 mm, a meter or a little more;

- clamps;

- loops;

- a piece of fuel supply hose;

- car brake disc. We select the diameter so that it freely enters the balloon;

- another cylinder (freon) to create a fuel tank.

Work sequence:

- we release the remaining gas from the cylinder, drill a hole in the bottom and rinse the cylinder with water;

-

cut out two openings in the side wall - a large lower and a smaller upper one. The fuel chamber will be located in the lower one, the afterburning chamber will be located in the upper one. By the way, if the dimensions of the lower opening allow, in addition to mining, it will be possible to use firewood as fuel;

-

from a steel sheet we make the bottom of the afterburner chamber;

-

we make a burner from a pipe - a place where volatile gases mix with air and ignite. Holes are drilled in the burner (according to the principle described above), the pipe is GRINDED inside, this is necessary for greater product efficiency;

-

the finished burner is welded into the bottom of the afterburner chamber;

-

from a brake disc and a piece of steel sheet we make a pallet for testing. We weld a cover in its upper part;

-

to connect the burner and the pan cover, it is better to use a coupling - this facilitates the maintenance of the furnace;

-

we carry out a supply for fuel. To do this, a hole is made in the wall of the cylinder, into which a pipe with a threaded edge is welded;

-

a valve is placed at the outer end of the pipe, a hose is connected to it. The hose, in turn, is connected to a fuel tank;

-

the chimney pipe is welded into the upper part of the cylinder, then “taken away” with a smooth transition upwards, to the exit from the room.

In fact, this completes the work with the furnace itself, but it is better to additionally build a heat exchanger - this will increase efficiency.

One of the heat exchanger options - plates welded onto the body - is shown in the photo below.

The finished oven with open doors (the hinges were needed specifically for them, the pieces of the cylinder cut out in paragraph 2 are attached to the hinges).

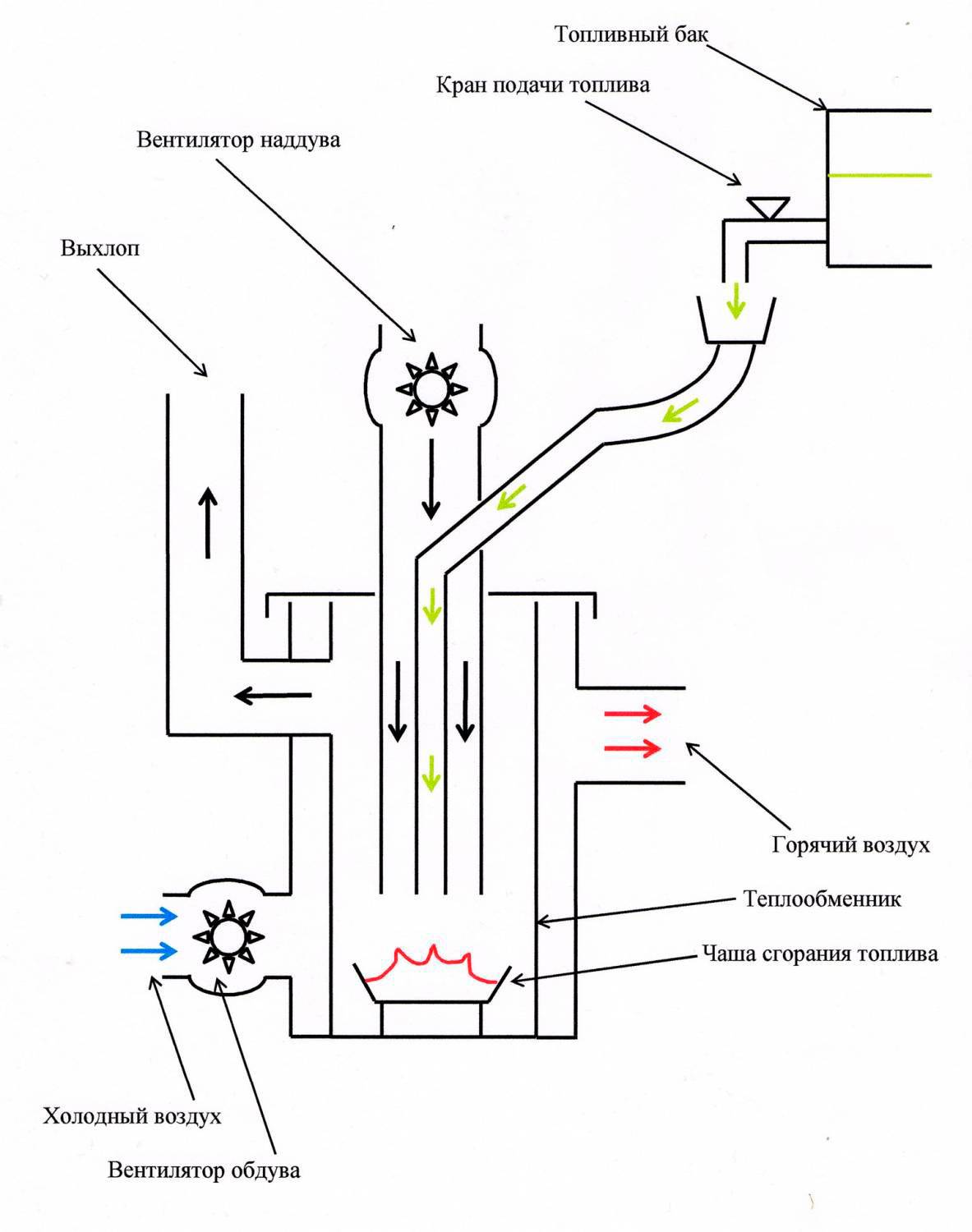

Furnace for working out with pressurization

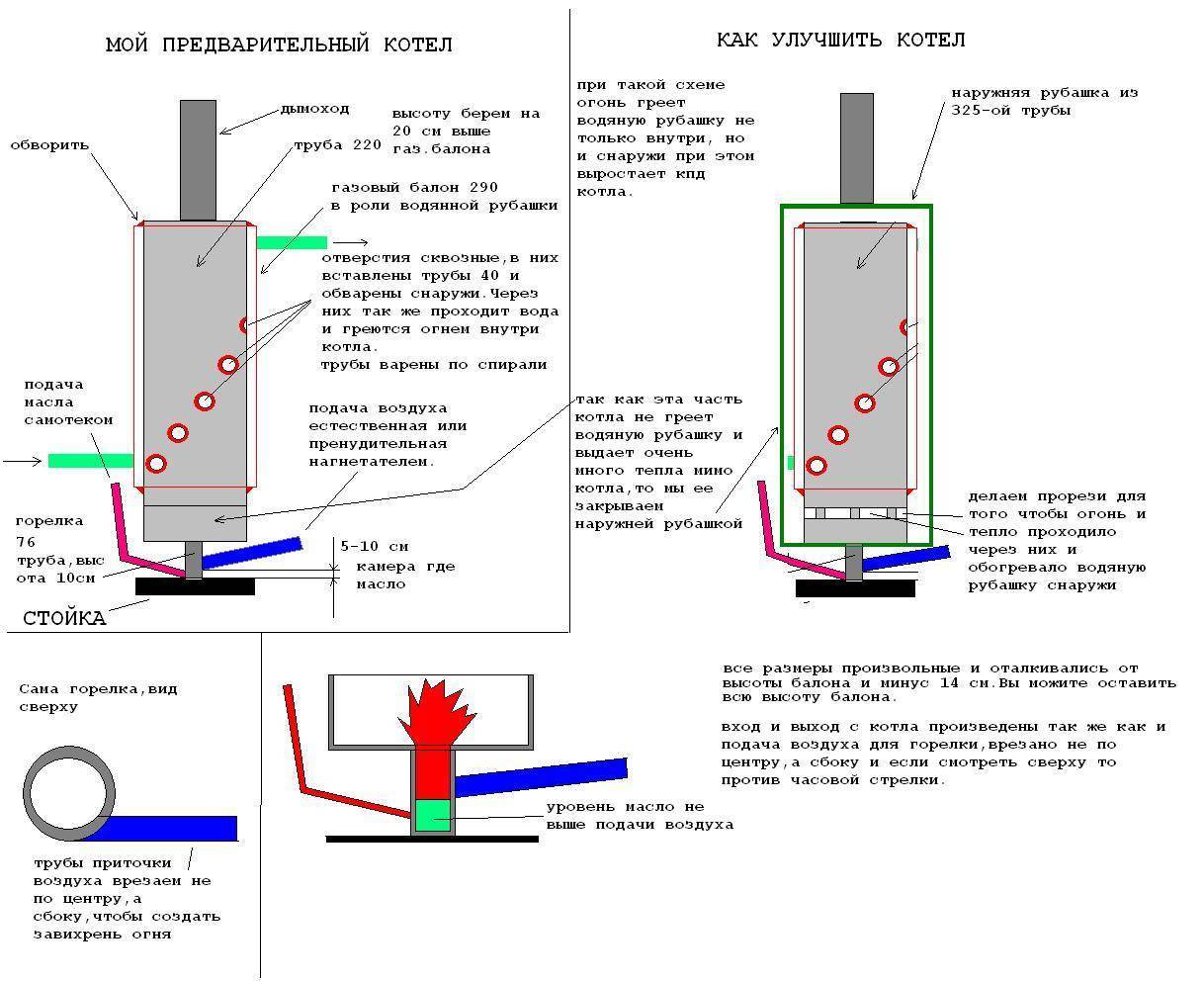

This design is also assembled on the basis of a 50-liter cylinder.

The air supply here comes from a fan (for example, from the stove of a VAZ 2108 car), which allows you to increase the thrust in the afterburner and at the same time make the entire surface of the cylinder actually a heat exchanger.

The process of work and ignition are shown in the video.

Working furnace with water circuit

The manufacture of a furnace with a water circuit can be almost the same as in the simplest version. The main difference is the organization of heat extraction into the water coolant. In the photo below, this possibility is realized by winding the pipe around the furnace body. At the same time, cold water is supplied from below, heated water comes out from above.

A more "advanced" option is a stove with a "water jacket". In fact, the body is enclosed in a second, hollow, inside which water circulates. The heated liquid is supplied to the heating radiators.

True, the phrase “does not smoke” from the manufacturer is some exaggeration - this is real only with regular cleaning of the chimney and the use of sufficiently high-quality, filtered fuel.

In the drawing, the device looks something like this.

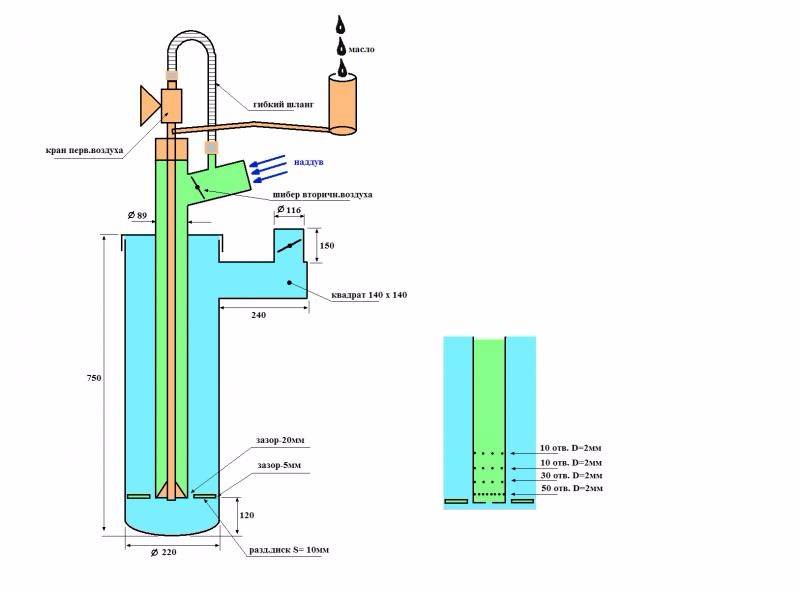

Drip Furnace

This type of furnace is safer than those designs into which fuel is poured at once. In addition, in the case of gradual feeding, the burning time can be freely adjusted.

A mandatory element of the system is a separate fuel tank, from which mining is supplied in small portions - almost drops - using a special device.

The photo below shows a design where there is a separate tank with an oil line located above the fuel chamber. The base of the furnace is a gas cylinder, a valve is used to adjust the intensity of the mining supply. The device of the furnace is discussed in more detail above.

Another type of product is with a retractable fuel compartment and a double afterburner.

She, realized in metal.

Please note: due to pressurization and the absence of fuel losses during filling, the mining consumption is reduced by 20 ... 30%

Advantages and disadvantages of the unit

A device that runs on engine oil is especially popular at car services, where this raw material is always in excess.

Advantages of the heating device in development:

- as a result of burning engine oil, soot and fumes are not formed;

- the device is fireproof, since it is not the oil itself that burns, but its vapors;

- the raw materials for the operation of the furnace cost nothing, it can be obtained at any service station.

Oil heater device

Cons of using mining:

- before use, mining must be cleaned of impurities of water and alcohol, otherwise the nozzles of the unit may become clogged;

- mining cannot be stored in the cold, so it will have to be kept in a warm garage or in a specially prepared bunker.

Waste after draining should be stored in closed containers

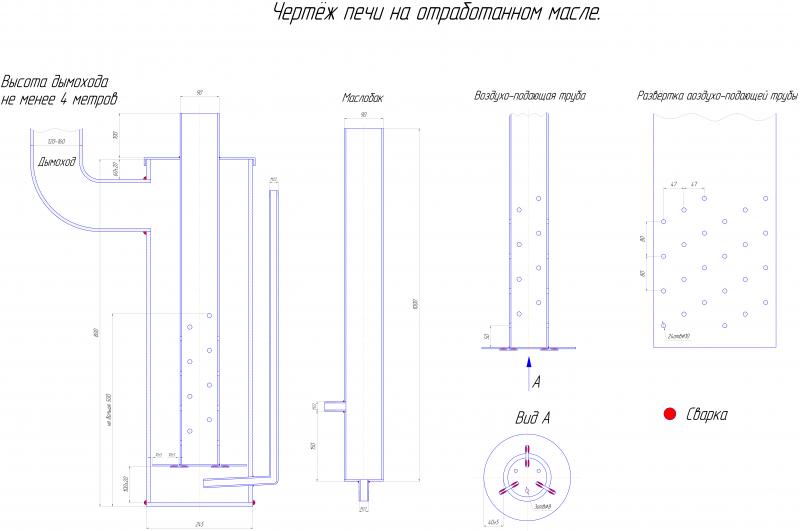

Furnace for mining from a gas cylinder

Materials and tools for the manufacture of the furnace

The easiest way is to make a furnace from a used gas, oxygen or carbon cylinder.The cylinders have a good wall thickness, so that such a furnace will last more than one year. A heating unit from one cylinder can heat a room up to 90 m 2. Also, this design can be converted for water heating. The stove from the cylinder will not require forced air supply, and the oil will flow by gravity. To prevent the cylinder from heating up to fire hazardous temperatures, it is necessary to set the height of the unit circuit in accordance with the height of the combustion source inside the device. To make a furnace from a used cylinder, you must purchase:

- chimney pipes with an inner diameter of at least 10 cm, a wall thickness of not more than 2 mm and a length of at least 4 m;

- fuel tank with a volume of 8-15 liters;

- burner pipes;

- welding machine and electrodes;

- Bulgarian;

- file;

- steel corners;

- drill and a set of drills;

- level and tape measure.

Manufacturing technology

up to 1.5 cm thick, filled to the top with water

The top of the balloon is cut off with a grinder. After the first cut, water begins to drain into the pan or onto the ground. When it drains the water, you can continue to cut the top. Most of the bottom will serve as a chamber, and the cut off top with a valve will become the stove cover.

Using a welding machine, we weld 20 cm “legs” for the stove from steel corners to the bottom of the cylinder. Then the balloon is placed on the "legs". In the upper part of the sawn-off lower half of the cylinder, we retreat from above 10-15 cm and, using welding, cut a hole for the main exhaust pipe along the diameter of the pipe.

As a hood, you must choose a thin-walled chimney pipe with a diameter of at least 10 cm and a length of at least 4 m.We insert it into the hole made, hold it strictly vertically and weld it. In the chimney, you also need to make a small hole, covered with a plate. With it, you can regulate the air supply.

In the same pipe, at a height of one meter from the floor, a hole is made for a new pipe with a diameter of 5–8 cm and a length of 2–4 m. The pipe is inserted parallel to the floor and welded by welding.

A hole with a diameter of 5-8 cm is cut in the cut off upper part of the cylinder. Recycled oil will be poured there.

In the upper removable part of the cylinder, you can connect a “tray” on which you can warm up a mug of water or porridge. To do this, a small square or rectangle is cut out of a steel sheet and welded to the lid. Or it can be installed on a pipe that is parallel to the floor.

Furnace operation

Waste oil is poured into 2/3 of the cylinder. Then you need to light a sheet of paper, put it on top of the oil and close the stove lid.

After a certain time, the temperature inside the furnace will begin to rise, the oil will evaporate and the oil vapor will ignite spontaneously.

After the end of work and cooling of the furnace, it is necessary to clean it of the contents. Remove accumulated soot from the upper removable part by tapping the lid on the cylinder.

Varieties of oil boilers for waste oil

There are three options for waste oil boilers: water heating, heating and domestic. The first option is an alternative to a modern boiler. Having a platform design, the device warms up a flat surface where the water tank is located. A small pump is installed at the outlet of the tank, which regulates the pressure in the system.

For waste oil hot water boilers, a water tank with a volume of not more than 140 liters is used. It heats up for 2 hours, which is several times faster than the speed of a modern electric boiler. The oil water heater can operate in two modes: fast and wick. The first option is used to heat completely cold water. The wick mode allows the water in the tank to be in a heated state. However, this will require a large amount of fuel resource.

There are three options for waste oil boilers: water heating, heating and domestic

Household boilers are considered the ideal solution for country houses. They have a built-in gas cleaning mechanism, which contributes to the operation of the device without smoke. Such devices are mobile structures, which will allow them to be transferred to any place without compromising the performance of the product. This multifunctional device allows not only to heat the room, but also to heat food. The unit can be used outdoors or while traveling.

Waste oil boiler automation can perform various functions. Here you can configure the control over the heating of the coolant, the air temperature in the room. Such devices are installed on the floor. Their cost depends on the functional features of the device.

Due to the compact dimensions of the boiler, it is convenient to install it in the boiler room

Characteristics of the waste oil heating boiler

Waste oil heating boiler must be located in non-residential premises. As a rule, for heating the house it is installed in a special extension.Despite the fact that modern devices are equipped with an improved filtration unit, during operation they emit an unpleasant smell of engine oil.

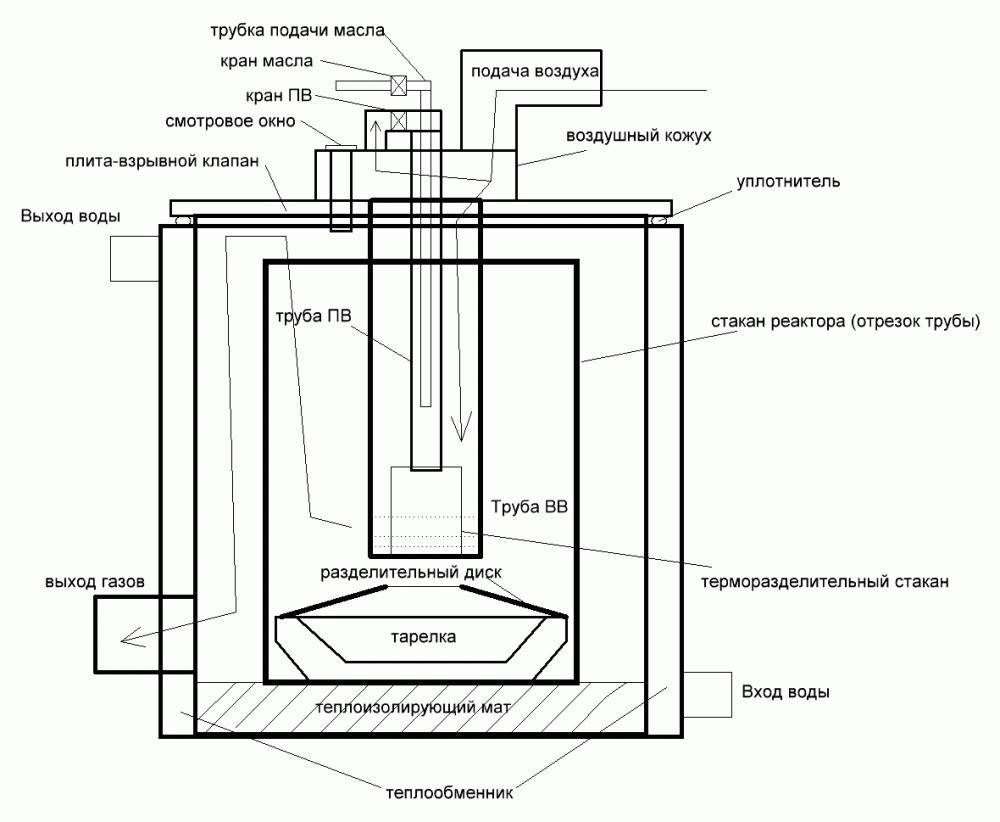

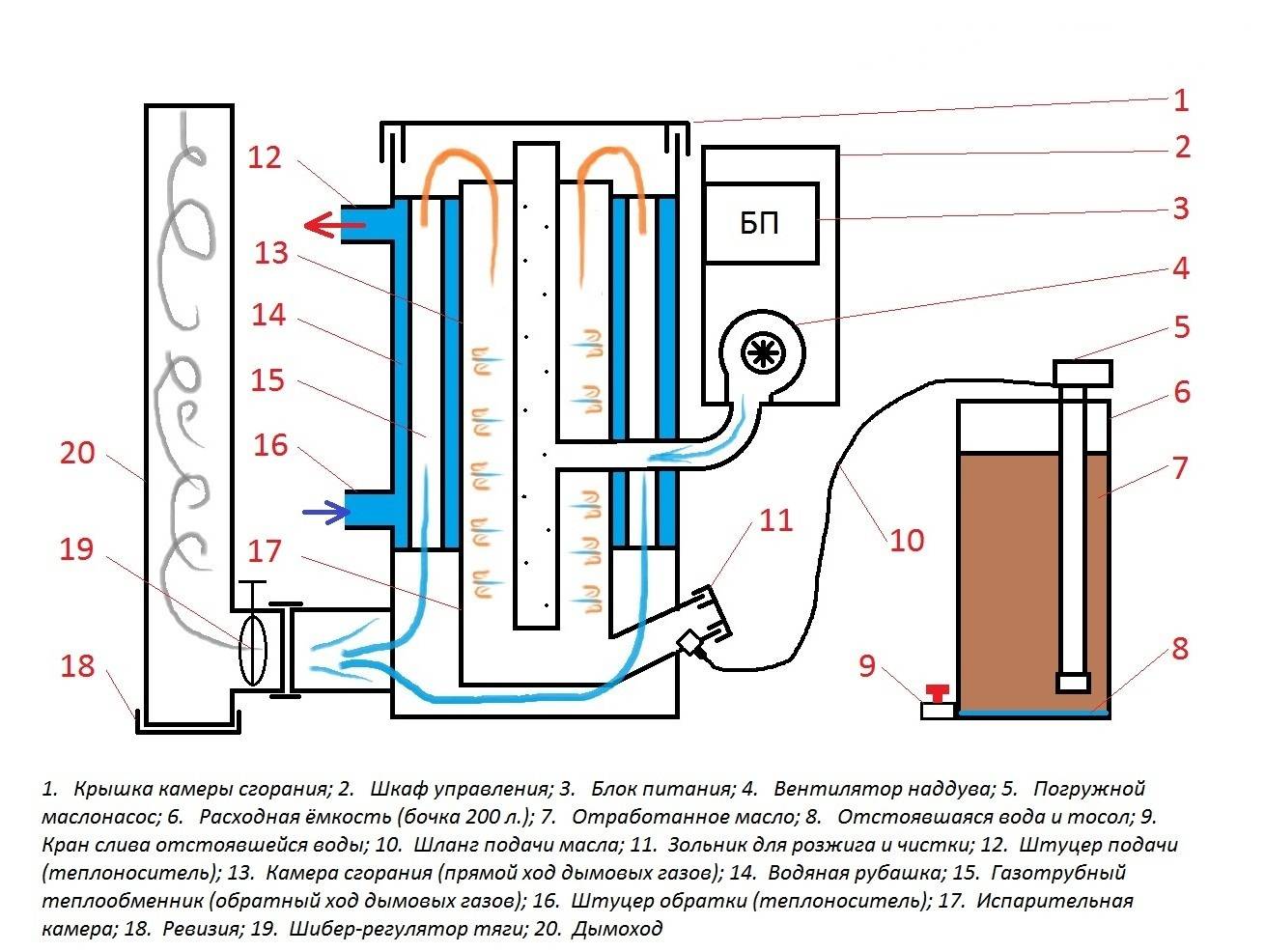

The inside of the block is equipped with a heating unit with a water tube and a hydropump. The last element can work from the electrical network or from the energy generated by the device itself. With the help of a hydropump, the coolant is circulated in the circuit in the form of ordinary water.

The principle of operation of the device is as follows. In the combustion chamber, oil vapors and air masses are oxidized, which come under the influence of a ventilated compressor. The level of fire is regulated by a hose with a valve. The ventilating device is the only movable element, as a result of which it may fail.

Such boilers are characterized by high performance and the ability to maintain the air temperature in the room for a long time. The fuel tank is located on the floor, and the air heater can be mounted on the wall or ceiling.

The inner part of the boiler block is equipped with a heating unit with a water tube and a hydropump.

1 How the system works

The oil potbelly stove works on the principle of long burning. First, mining is burned in a special container (tank), as a result of which gases are formed that mix with oxygen. Then it is this substance that burns, in connection with which the device is divided into two circuits.

The first circuit (separation) is a tank into which used oil is poured. Combustion occurs here at a low temperature. Above the first compartment is the second, in which the mixture of gases and air burns.The combustion temperature here is much higher, it can reach 700-750 °C. When designing a potbelly stove, it is necessary to ensure uninterrupted access of oxygen to it

It is important that air enters both chambers, otherwise the unit simply will not work. It follows from this that the drawings play a very important role in the manufacture and installation of a potbelly stove. A hole is made in the lower tank for air access, which also serves to fill fuel into the system.

It must be closed with a special damper. Air usually enters the upper chamber through holes made in the pipe connecting both circuits. Their diameter is small - about 10 mm

A hole is made in the lower tank for air access, which also serves to fill fuel into the system. It must be closed with a special damper. Air usually enters the upper chamber through holes made in the pipe connecting both circuits. Their diameter is small - about 10 mm.

But if you approach this situation from the other side, then there are still some risks. An unsafe design may be when using a flammable fuel, such as gasoline. In addition, some types of oil can release substances that are harmful to humans when heated.

As a rule, preparations for the heating season take place during the summer period. To do this, the owners of technical premises stock up on mining, draining it into a separate container. At the beginning of December, a decent amount of oil accumulates. You can get it for free or at a very low price at auto repair shops, service stations, etc.

Types of aggregates

If you need to organize heating in the house, it is better to purchase a boiler in a standard version. Such designs currently have sufficient autonomy and safety. Comfort and ease of use is also due to the fact that there are no specific odors emitted by the fuel.

The boiler works in automatic mode. This makes it possible to use it without special knowledge and experience. The process of burning oil is arranged in such a way that it burns completely without being accompanied by fumes and smell of gas.

Heating structures

Such units should not be installed in residential premises. Usually, special extensions are used for this. Although the boilers are equipped with modern filters, the smell of machine oil can be smelled during operation.

A heating unit is built into the design of the device, consisting of a water pipe and a pump, which operates not only from the mains voltage, but also from the energy of the device itself. Thanks to it, water circulates evenly in the system.

The principle of operation of such devices is based on the combustion of a mixture of fuel and air supplied by a compressor fan. The strength of the fire is regulated using a conventional hose, at the end of which a valve is installed.

Water heaters

The function of these devices is to heat water. They can be called ordinary boilers. They have a platform principle of operation: a tank with water is installed on a heated plane. A pump built into the outlet serves to correct and equalize the pressure inside the system.

This is interesting: the principle of operation of the boiler.

It should be noted that it will be quite difficult to adjust the constant temperature of the liquid. Inside the tank it can reach +80…100°С.Often, in such heating systems, containers for a coolant with a volume of 60–140 liters are used. The process during which the water is heated lasts about 2 hours, which is almost half as much as in the boiler.

The hot water boiler has two modes of operation. When fast, cold water is heated in the shortest possible time (the automatic switch is in the “wick” mode). In this case, a lot of fuel is consumed, and if the tank is small, carbon monoxide emissions are likely.

Appliances

Another subspecies of devices of this kind are household boilers. These are multifunctional devices. More often, such designs are used in houses that do not have a water heating circuit. They are endowed with a fairly good gas cleaning system that eliminates soot and smoke during operation of the device.

Fuel consumption is very low compared to previous types. Mobility is the main advantage of such a device. It can be transported even in the trunk of a car and used on trips, for example, to nature. In this case, it performs the functions of a stove for cooking, as well as a heater. The main thing is to provide a fireproof platform necessary for installation or a recess in the ground by 30–40 cm.

Instructions for assembling the oven

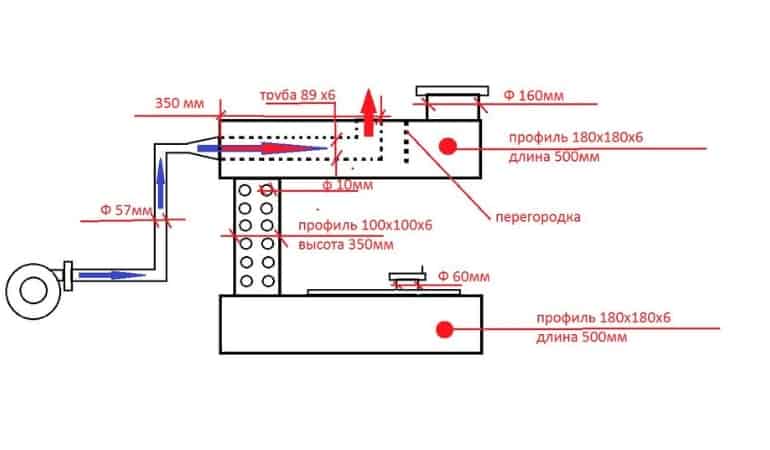

In order to correctly solve the problem of how to make a boiler for working out with your own hands, you must strictly follow the instructions:

- First, cut blanks for the upper container. To do this, on a sheet of steel, the top and bottom plates are marked with a size of 35 * 62 cm, two end walls with a size of 35 * 12 cm, two longitudinal walls with a size of 62 * 12 cm and a partition of 35 * 10 cm.

- Then cut the details of the lower container.You will need a top and bottom plate measuring 35 * 35 cm and 4 side walls measuring 35 * 15 cm.

- Next, proceed to the manufacture of the burner. For this, a steel pipe is used, a piece 36 cm long is cut off from it. Marks are made on this segment for 48 holes, the distance between which should be the same. With the help of a hammer and a punch, the drilling points are punched. The result should be 6 rows of 8 points.

- Through the treated points, a drill makes through holes.

- Now a small hatch is made in the upper panel of the lower tank according to the scheme of the waste oil boiler. To do this, they retreat from the edge by 3 cm and draw a rectangle measuring 10 * 15 cm. A plate is cut along the drawn lines.

- Next, you need to cut a plate that will close the hatch. A rectangle measuring 11 * 16 cm is cut out of a sheet of steel and a hole with a diameter of 4 cm is drilled in the center. The resulting rectangle is applied to the hatch on the panel and through holes are made for fasteners.

- Using bolts and nuts, connect the plate and the top panel of the lower tank.

- Proceed to the assembly of the lower container. In the top panel, make a hole for the burner and grab the pipe. Next, the top and bottom plates are spot welded to the side parts.

- After assembling the container, all joints are welded to make the structure completely sealed. For complete safety and efficient operation of the boiler during mining, the seam must be continuous and neat.

- Now it's time to assemble the top of the boiler. Using the do-it-yourself drawings of a waste oil boiler, a hole is cut in the bottom panel for the burner pipe, and in the top panel for the chimney.Then the side elements, the partition and the bottom panel are successively welded to the top panel.

- To connect both containers, they must be welded to the burner pipe. Due to the displacement of the upper part of the boiler, the structure is not stable. This problem can be solved by using a diagonal strut welded to both parts. It is necessary to give the structure additional rigidity.

- The entire product must be carefully inspected and identified places of poor-quality connections. Such areas need to be welded with a continuous seam.

- You can start making legs for the boiler at work. To do this, 4 identical pieces 7 cm long are cut off from the steel corner with a grinder. 4 squares with a side of 5 cm are cut out of the steel sheet, then the corners are welded to them.

- Finished legs must be welded to the lower tank of the boiler. This stage requires careful work, since for the stability of the structure on the floor, all legs must have the same length.

- The boiler is ready and can be installed at the place of permanent residence. Here, the design is checked for stability, and with the help of the level, existing distortions are revealed.

- To remove combustion products from the boiler, you need to assemble a chimney. First, the inner part is assembled, which is a section of a straight pipe and an elbow for leading out through the wall to the street.

- Before making a hole in the wall, you need to correctly determine its location and size. To do this, the assembled chimney is tried on against the wall and its contour is outlined. To get smooth edges of the hole, it is necessary to make several through holes along the drawn line after 2-3 cm. After that, the central part should be removed without much difficulty.

- A straight section of the inner chimney pipe is fixed on the boiler, and the knee is led out into the street through a hole in the wall.

- For the safe operation of the boiler during mining, you need to take care of the arrangement of the outer part of the chimney. Therefore, an additional section of the pipe with the elbow is attached to the outside of the outgoing part of the elbow. The outer part must be securely fixed under the roof overhang using a bracket.

- After the structure is fully assembled, a traction check is required. You need to bring a lit match to one of the holes in the burner pipe, if the draft is good, then the flame will deviate towards the pipe. With good traction, mining will burn well. To increase traction, you can slightly open the hatch.

How exactly does oil evaporate?

There are 2 main ways of burning fuel and evaporating oil:

- Ignition of a liquid substance. This releases steam. For its afterburning, a special chamber is used.

- Pouring over a hot surface. A white-hot "white-hot" bowl made of metal is used. Mining is dripping onto its surface. When the fuel comes into contact with hot metal, it evaporates. The "cooperation" of air and steam is called "diffusion". When air enters the tank, the steam flares up and ignites. The result of this is the generation of heat.

Fuel consumption is quite economical. From ½ to 1 liter is used per hour.

European boilers, despite the excellent efficiency, do not allow such a principle of operation to be possible. This is true only in the case of boilers of a domestic manufacturer.

The easiest way is to soak the wick with gasoline, set fire to it and throw it into the tank.When the bowl warms up well, you can start serving oil.

It is important that the oil is supplied evenly. It is recommended to use a drip approach. To ensure the desired level of extraction filtration, an automotive filter should be used.

It is put on a tube, one of the ends of which must be lowered into a container with working out

An automotive filter should be used to provide the desired level of extraction filtration. It is put on a tube, one of the ends of which must be lowered into a container with mining.

The filter should be replaced at least once every 30 days. If the fuel cannot be called clean, then it is recommended to do this 1 time / 15 days.

The amount of oil dripping onto the bowl should be optimal. The most important thing is to ensure that it burns evenly. It shouldn't choke.

If the owner of the boiler has decided to change the fuel, the frequency of drops must be adjusted each time.

The installation should also be given maximum protection. Do not allow the oil to boil - this can lead to unpredictable consequences. The same applies to fuel overflow.

If the level of fuel in the tank is higher than in the stove itself, a fire may occur. The only way to deal with it is with a fire extinguisher.

Do not pour oil into the boiler when the unit is running - this can be very dangerous. It is best to mount an additional container. It will be possible to place the main supply of fuel in it.

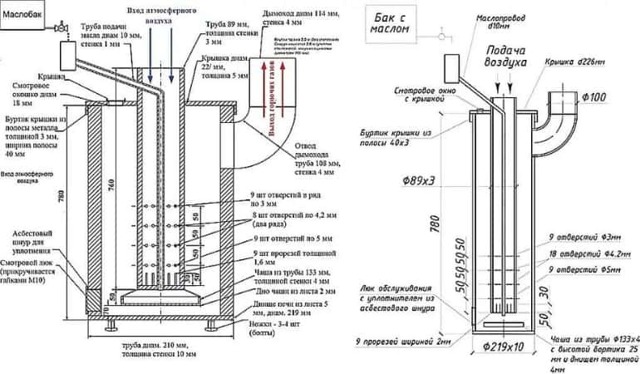

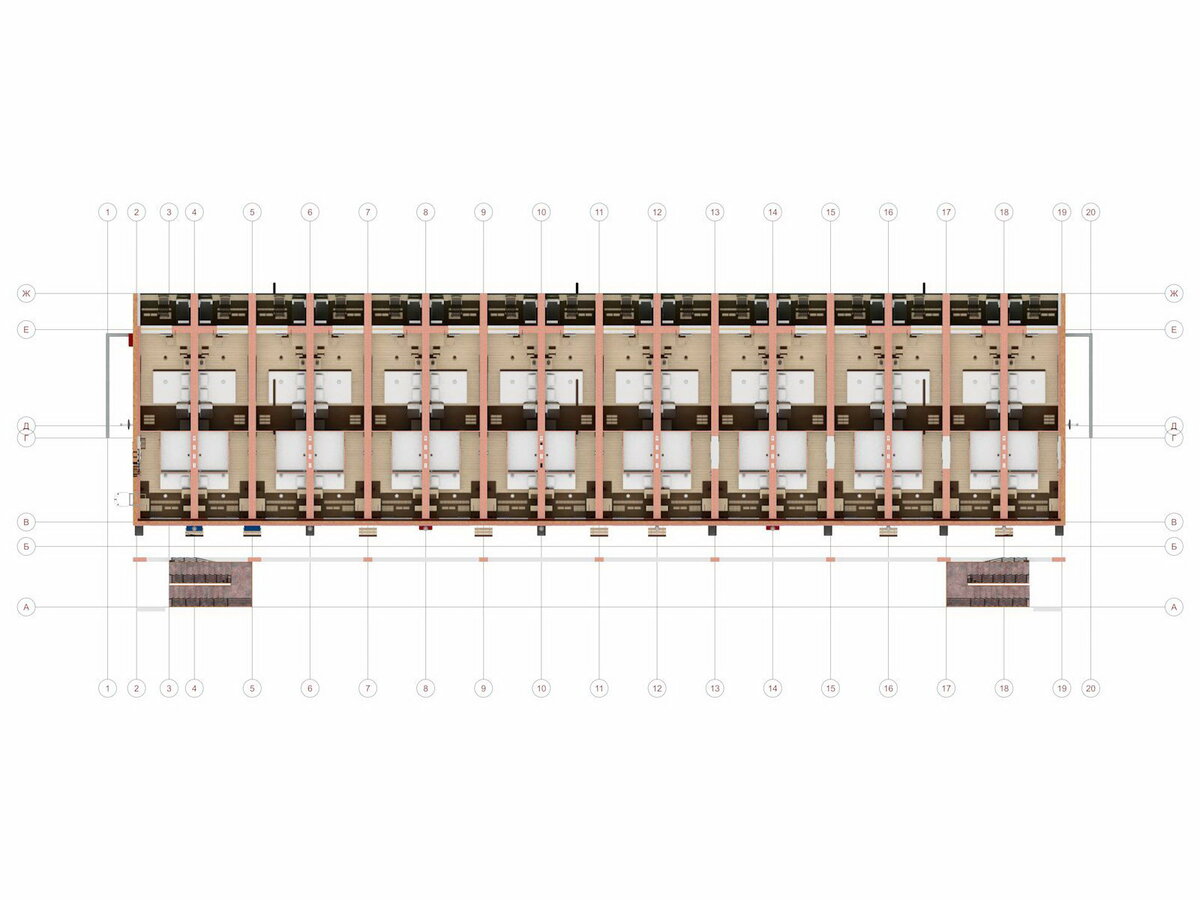

We make a heat generator from a cylinder

First of all, prepare gas cylinders for welding - remove the spherical parts (do not forget to fill it with water beforehand!) And cut one vessel to size so that together they make up a body of the required height (1 m).

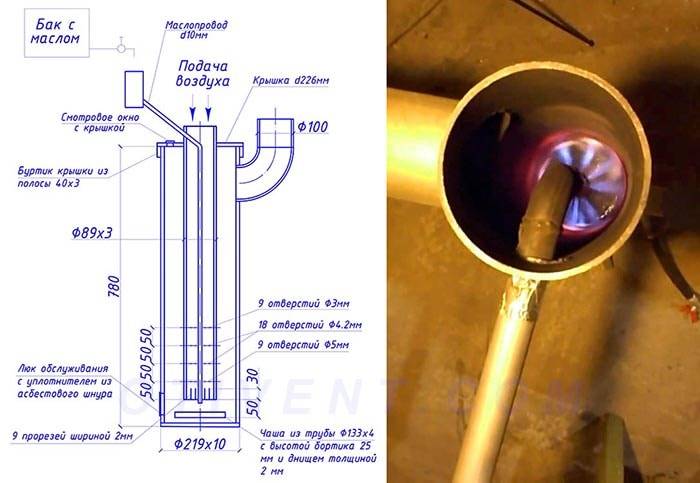

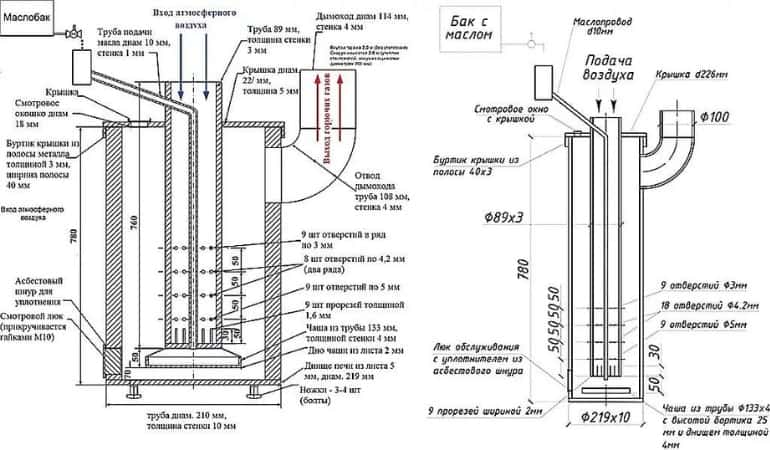

Prepare the rest of the materials, considering the following recommendations:

- the combustion chamber and the flame bowl are best made of stainless steel 1.5–3 mm thick (for example, grade 12X18H12T);

- if it was not possible to find a stainless steel, use black steel grade St3 - St20 from 4 mm thick;

- pick up a stainless steel waste oil supply pipe;

- the thickness of the walls of the flame tubes is not less than 3.5 mm;

- to seal the top cover, select a steel strip 40 x 4 mm (rim) and an asbestos cord;

- prepare sheet metal 3 mm for the manufacture of an inspection hatch;

- on the heat exchanger, take pipes with a wall thickness of at least 4 mm.

The manufacturing process of a two-way boiler for mining looks like this:

- Cut the Ø32mm flame tubes to size and weld the heat exchanger using one cylinder as the outer casing and the Ø150mm tube as the combustion chamber walls.

- Attach the inlet pipes of the water heating system to the heat exchanger.

- In the second cylinder, cut holes for the inspection hatch and the chimney. Weld on a Ø114 mm fitting and make a neck with a cover from sheet steel.

- Weld both tanks into one body. From above, make a shell from an iron strip - it will serve as a seal for the lid. Fill the gap between the edges with asbestos cord.

- Make an afterburner according to the drawing. Make holes in the hemispherical cover (in the past - the end of the cylinder) for the viewing window and the installation of the afterburner (in the center).

- Equip the lid with handles and a shutter on the window. The afterburner pipe can be welded to it tightly or screwed with bolts sealed with an asbestos cord.

From the lower end, the perforated pipe is closed with a plug, where 4 holes are made - one in the middle, the remaining three - radially. An oil pipe is led into the central hole and scalded. The last step is the manufacture of a fiery bowl of the boiler, where the waste oil will burn.

Upon completion of the assembly, weld an elbow with a flange to the afterburner pipe and install the “snail”. To ensure that the outer metal wall of the water jacket does not lose heat in vain and does not heat the boiler room, insulate the body from non-combustible basalt wool. The simplest way is to wind the insulation with twine, and then wrap it with thin-sheet painted metal.

More clearly, the manufacturing process of a liquid fuel boiler is demonstrated in the following video: