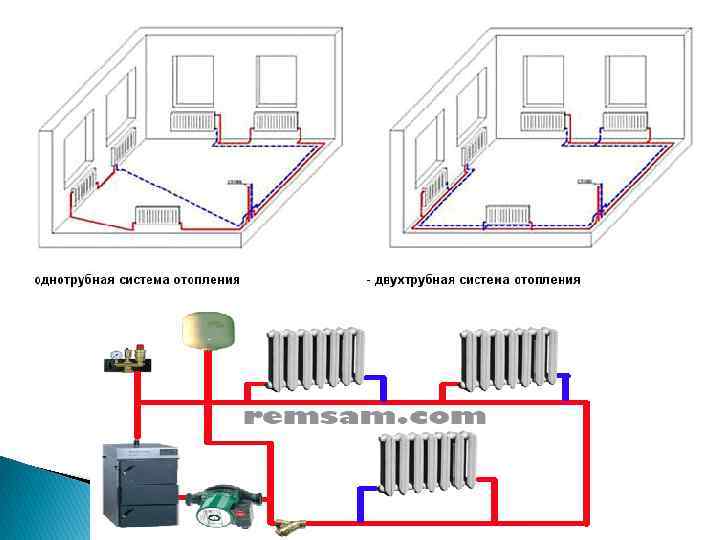

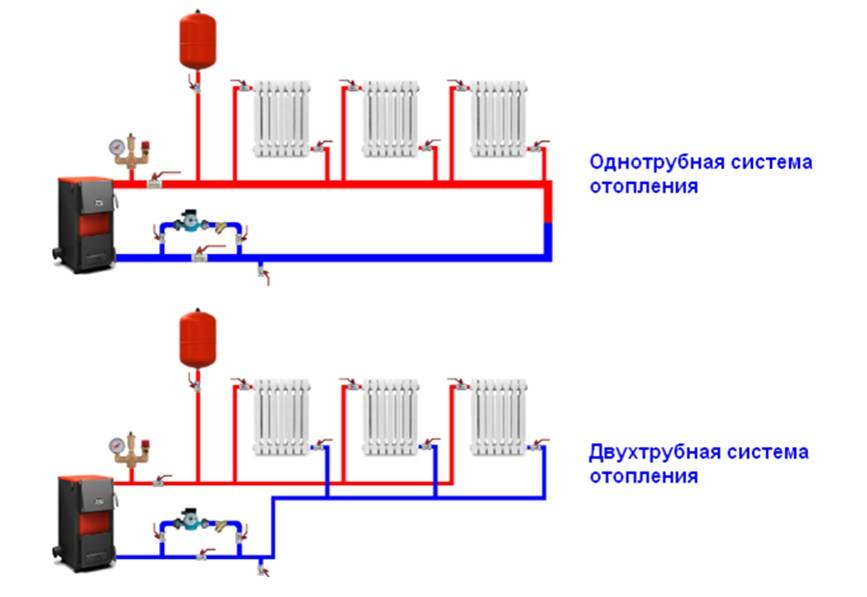

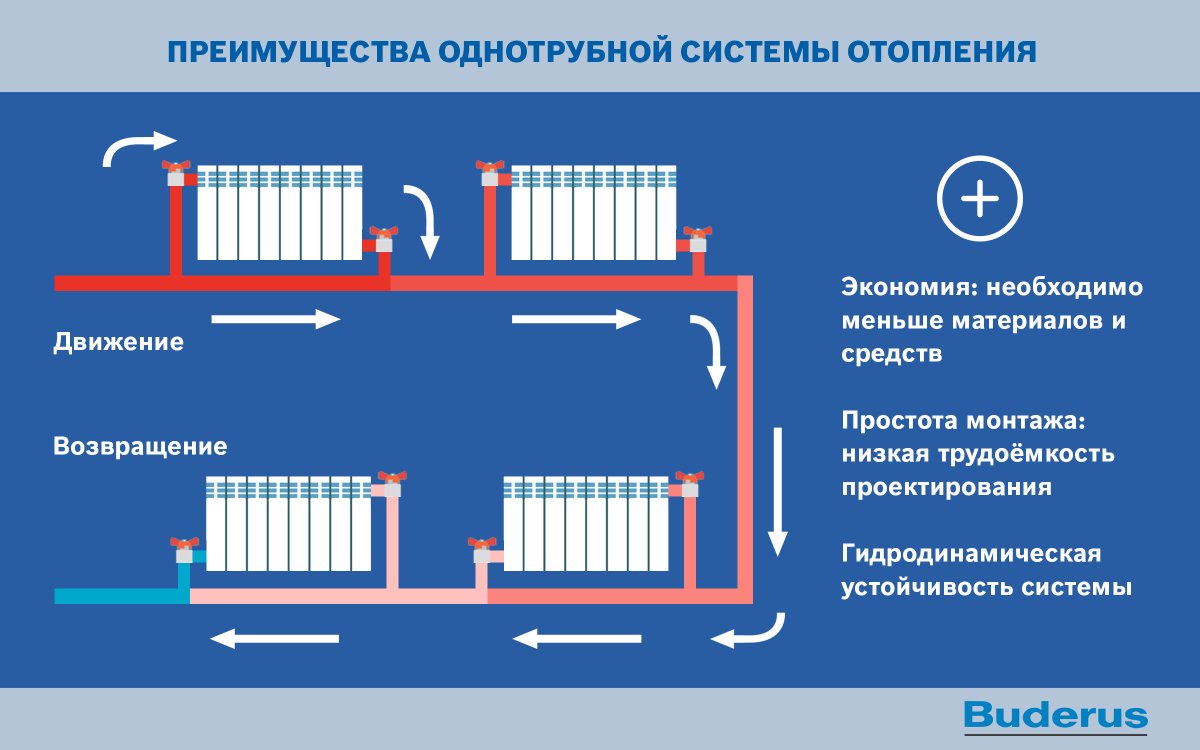

- One-pipe heating scheme

- Radiation system

- Heating floor and plinth

- Norms and requirements for autonomous heating

- Varieties of heating systems

- Installation of the cottage heating system

- Internal wiring

- Tips for installing a house heating system

- Installation and connection of equipment - how to install the boiler

- Calculation of the heating system at home

- How to calculate the heating of a private house?

- How to calculate pipe diameter

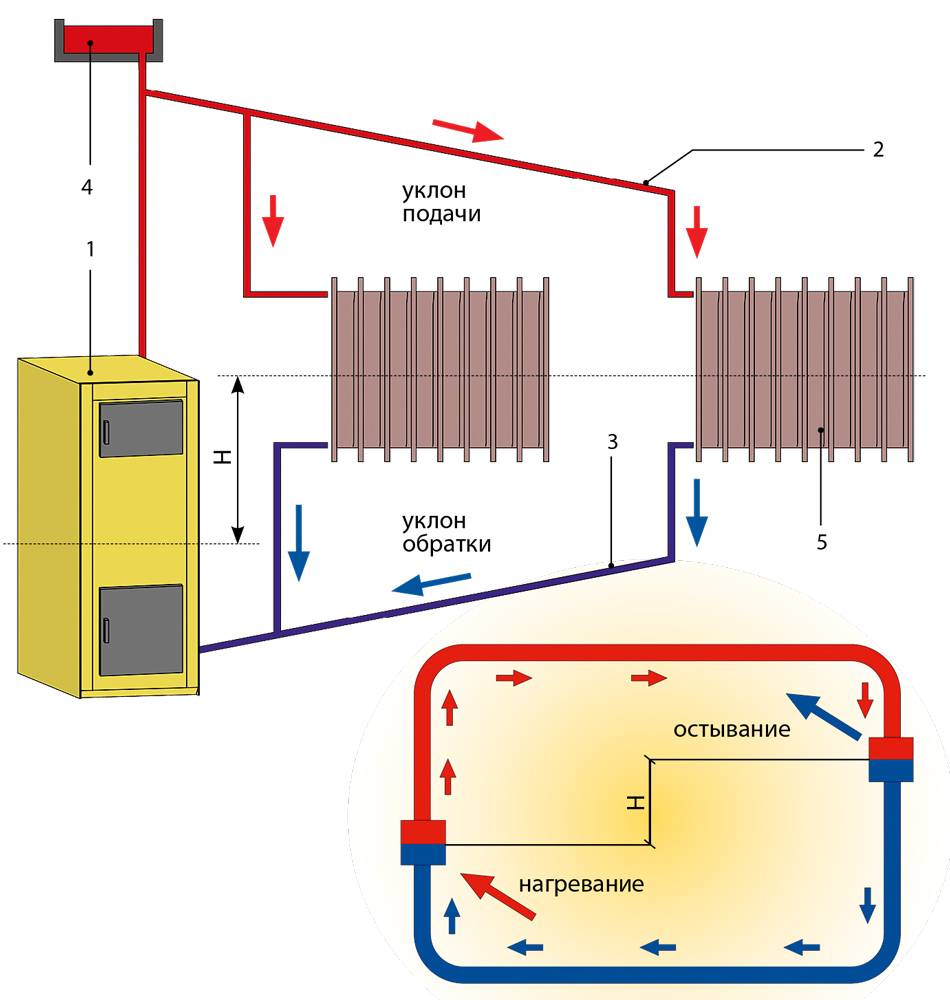

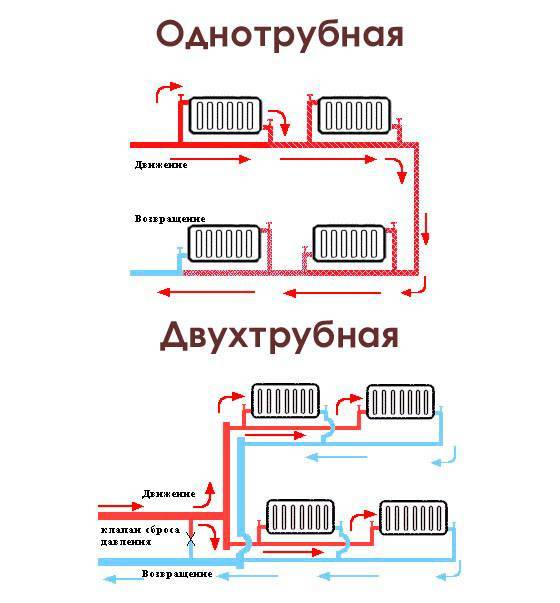

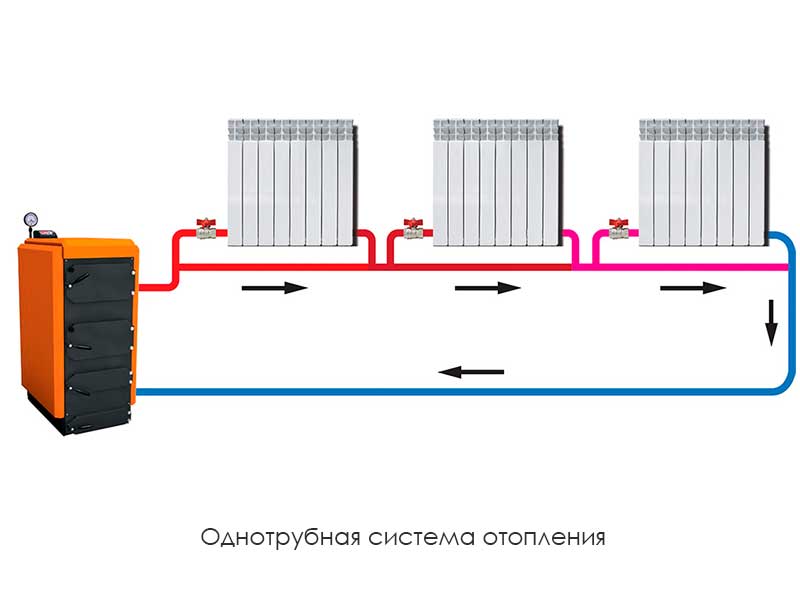

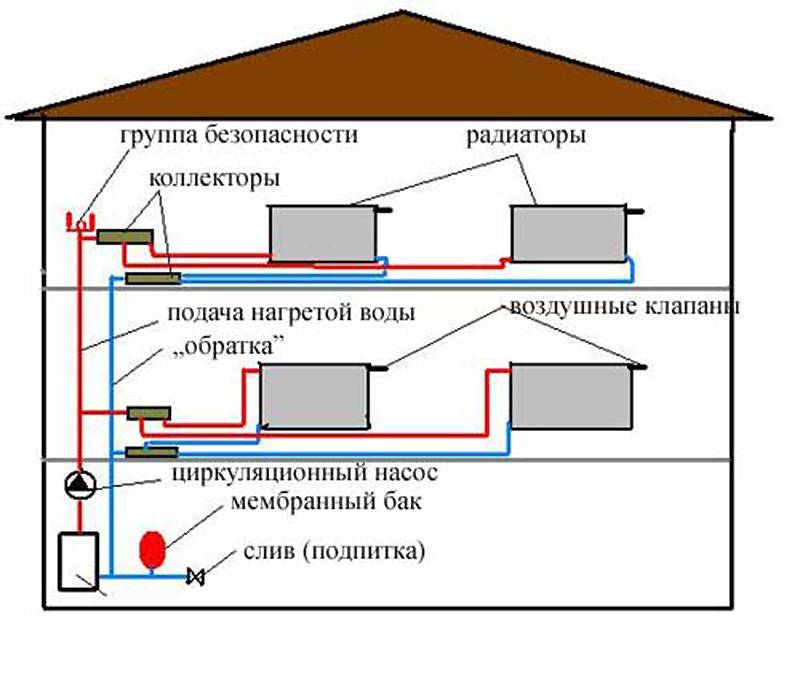

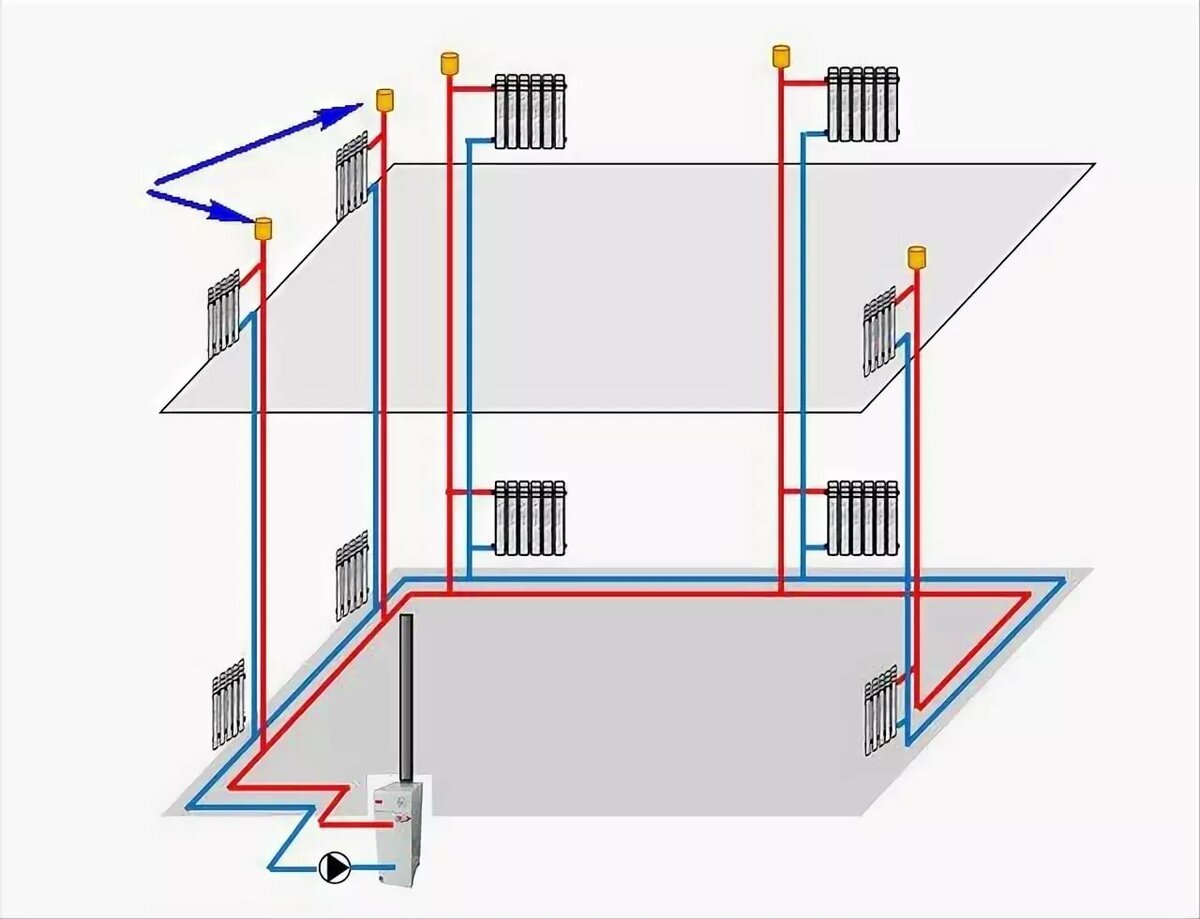

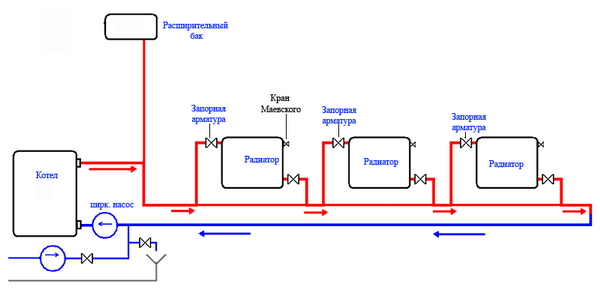

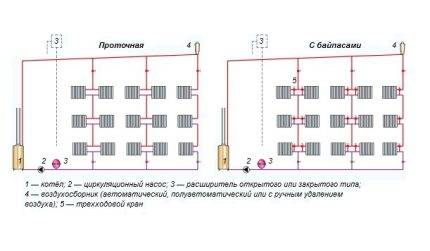

One-pipe heating scheme

From the heating boiler, you need to draw the main line representing the branching. After this action, it contains the required number of radiators or batteries. The line, drawn according to the design of the building, is connected to the boiler. The method forms the circulation of the coolant inside the pipe, heating the building completely. The circulation of warm water is adjusted individually.

A closed heating scheme is planned for Leningradka. In this process, a single-pipe complex is mounted according to the current design of private houses. At the request of the owner, elements are added to:

- Radiator controllers.

- Temperature controllers.

- balancing valves.

- Ball valves.

Leningradka regulates the heating of certain radiators.

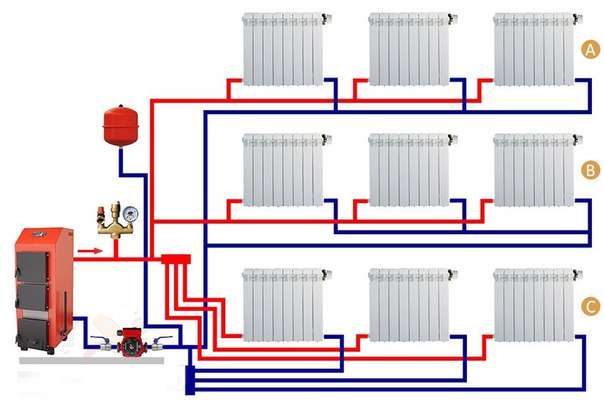

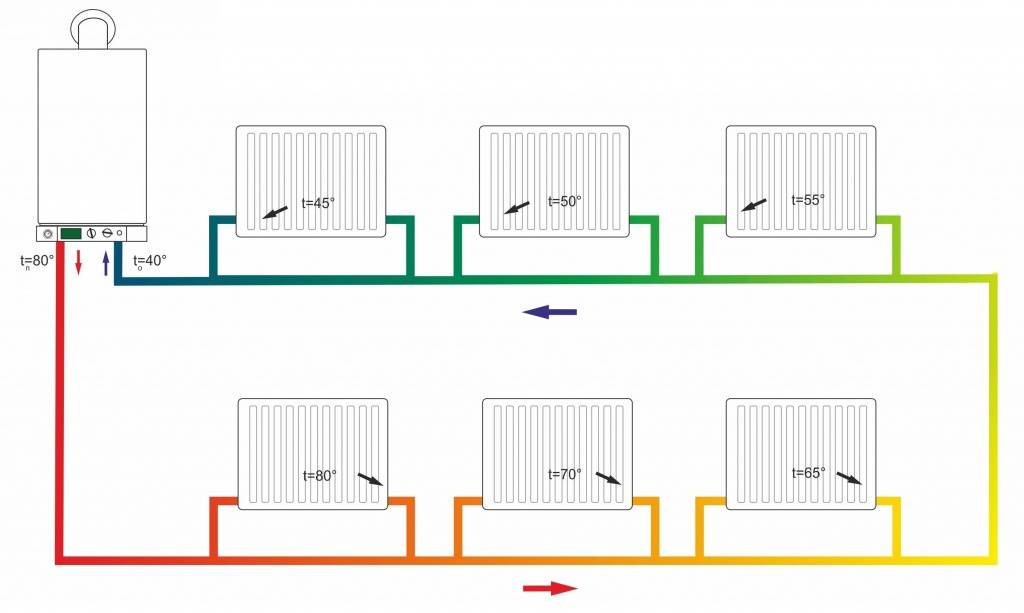

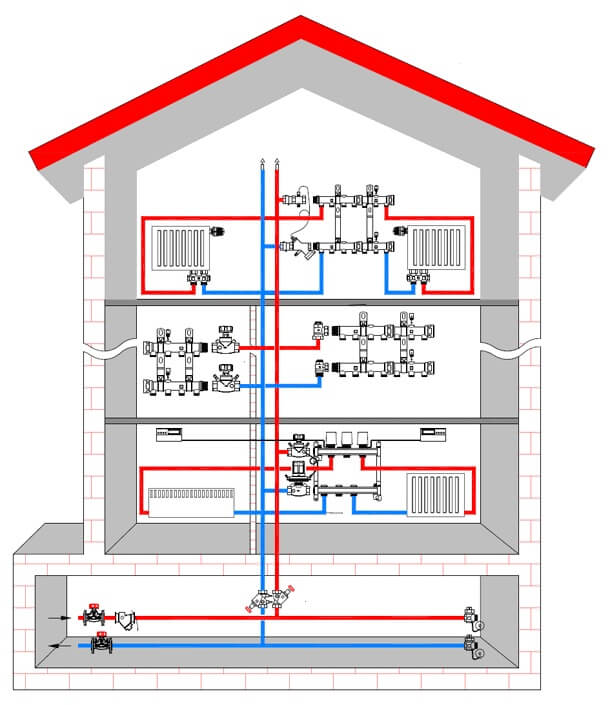

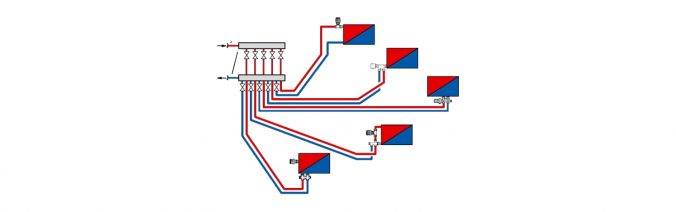

Radiation system

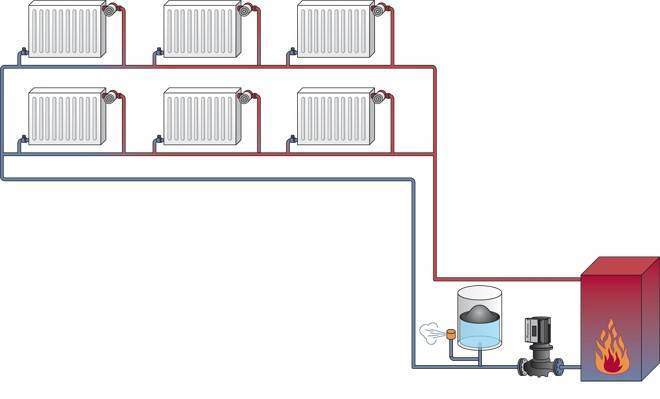

The collector (radiant) heating scheme is the most advanced and modern in terms of thermal efficiency.In it, a pair of pipes from two common collectors for the floor, which are themselves connected to the boiler equipment, are connected to each of the radiators. Temperature control with this wiring is more flexible. Plus, it is permissible to connect to the collectors not only batteries, but also a “warm floor”.

Pipelines in this case can be laid in any way. Often they are simply laid under the filler floor. The main disadvantage of the beam scheme is the high cost of the system as a whole and the long length of the pipes. Plus, it will be difficult to lay the latter in an already finished cottage in large quantities. Their device should be planned in advance at the design stage of the dwelling.

Beam pattern - ideal heat distribution

This slate, if necessary, can be relatively easily replaced with other roofing material. The scheme for laying heating pipes is more sophisticated; it is not so easy to change it later. Even the rigid dimensions of the ondulin sheet are not so terrible, there are a lot of trimmings, but this is just a slight increase in the roof estimate. With heating pipelines, especially for beam wiring, everything is much more complicated.

Heating floor and plinth

Hot water pipes laid in the floor with a calculated step allow you to evenly heat the premises with the entire surface of the floor covering. From each heating circuit, whose length does not exceed 100 m, the connections converge to a collector with a mixing unit that provides the required heat carrier flow and its temperature within + 35 ° ... + 45 ° С (maximum + 55 ° С). The collector is powered directly from the boiler by one branch and controls the heating on 2 floors at the same time. The positive side of the warm floor:

- uniform heating of the space of rooms;

- heating is comfortable for people, since heating comes from below;

- low water temperature saves up to 15% on energy;

- any level of system automation is possible - operation from temperature controllers, weather sensors or according to a program embedded in the controller;

- the system with the controller can be controlled from a distance - via GSM-connection or the Internet.

Similar automatic control systems are also being introduced into the collector circuit of a two-story cottage. The disadvantage of underfloor heating is the high cost of materials and installation work, which are difficult to perform on your own.

Heating skirting boards are a suitable option for any private house, not just a two-story one. These heaters in the form of large plinths are copper or aluminum convectors connected in a two-pipe scheme. They encircle the premises along the perimeter, heating the air from all sides. Skirting board heating is easy to install and meets all interior design requirements.

Norms and requirements for autonomous heating

Before designing a heating structure, it is necessary to look into SNiP 2.04.05-91, which sets out the basic requirements for pipes, heaters and valves.

General norms boil down to ensuring that the house has a comfortable microclimate for the people living in it, to properly equip the heating system, having previously drawn up and approved the project.

Many requirements are formulated in the form of recommendations in SNiP 31-02, which regulates the rules for the construction of single-family houses and their provision with communications.

Separately, provisions related to temperature are stipulated:

- the parameters of the coolant in the pipes should not exceed + 90ºС;

- optimal indicators are within + 60-80ºС;

- the temperature of the outer surface of heating devices located in the direct access zone should not exceed 70ºС.

Pipelines of heating systems are recommended to be made of brass, copper, steel pipes. The private sector mainly uses polymer and metal-plastic tubular products approved for use in construction.

Pipelines of water heating circuits are most often laid in an open way. Hidden laying is allowed when installing "warm floors"

The method of laying the heating pipeline can be:

- open. It involves laying on building structures with fastening with clips and clamps. It is allowed when constructing circuits from metal pipes. The use of polymer analogs is permitted if their damage from thermal or mechanical impact is excluded.

- Hidden. It involves laying pipelines in strobes or channels selected in building structures, in skirting boards or behind protective and decorative screens. Monolithic contour is allowed in buildings designed for at least 20 years of operation and with a service life of pipes of at least 40 years.

The priority is the open method of laying, because the design of the pipeline route should provide for free access to any element of the system for repair or replacement.

Pipes are hidden in rare cases, only when such a solution is dictated by technological, hygienic or constructive necessity, for example, when installing “warm floors” in a concrete screed.

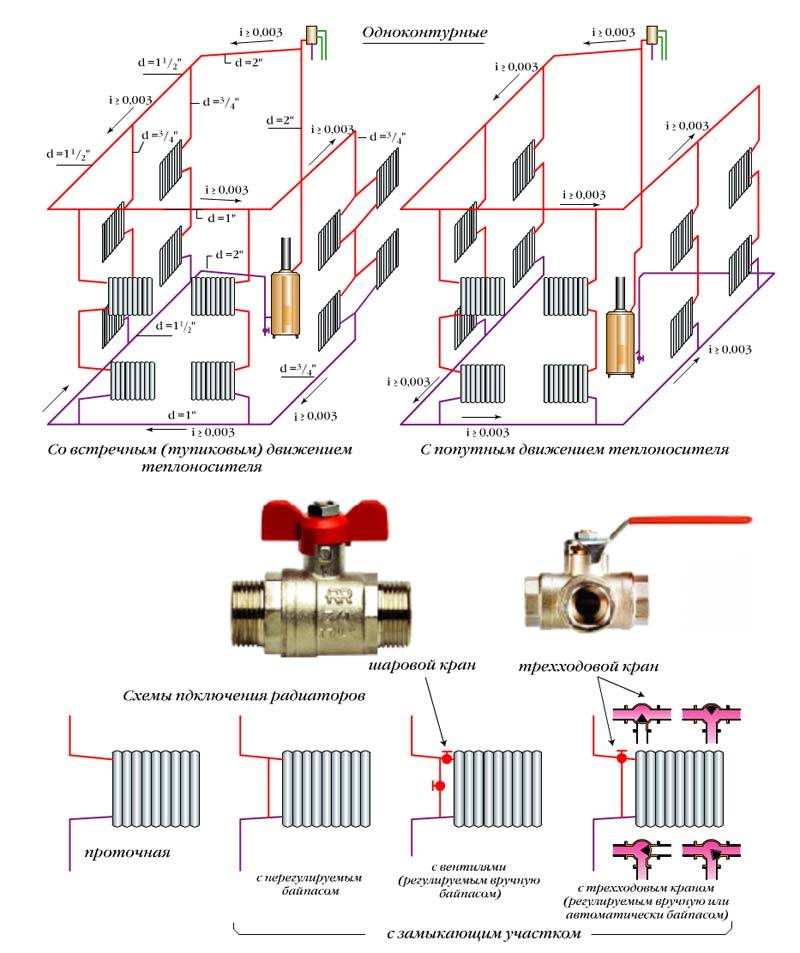

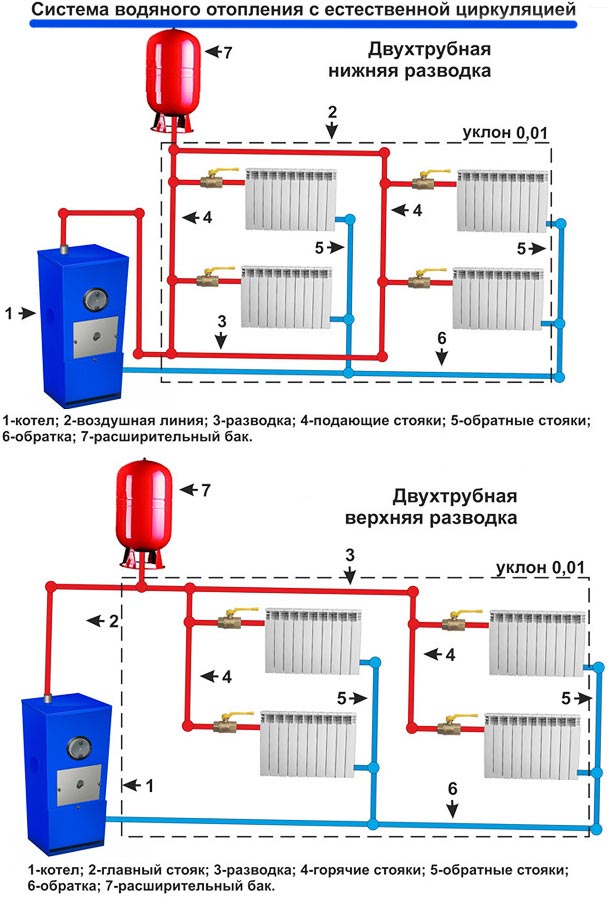

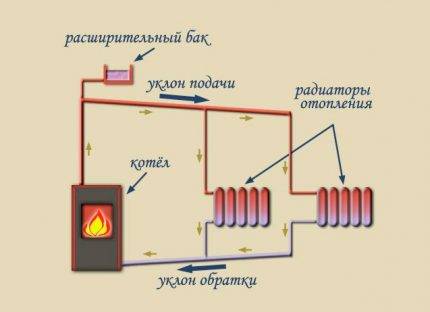

When laying the pipeline of systems with natural movement of the coolant, it is necessary to observe a slope of 0.002 - 0.003. Pipelines of pumping systems, inside which the coolant moves at a speed of at least 0.25 m/s, do not need to provide slopes

In case of open laying of the main, the sections crossing unheated premises must be provided with thermal insulation corresponding to the climatic data of the construction region.

Autonomous heating pipelines with a natural circulation type must be installed in the direction of the coolant movement, so that the heated water reaches the batteries by gravity, and after cooling, moves along the return line to the boiler in the same way. The mains of pumping systems are built without a slope, because. it is not necessary.

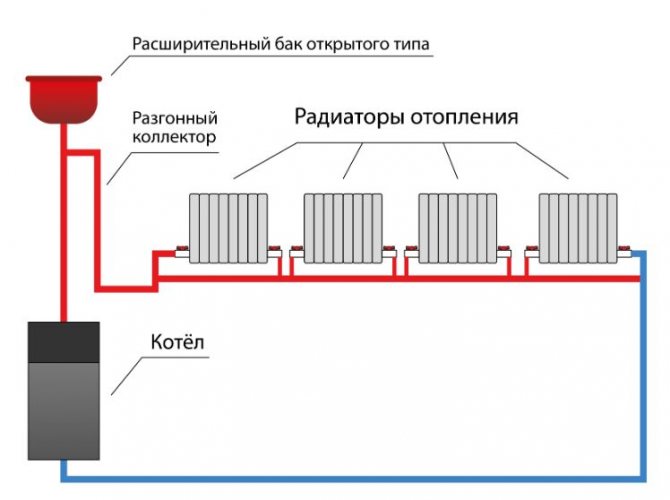

The use of various types of expansion tanks is stipulated:

- open, used for systems with both pumping and natural forcing, should be installed above the main riser;

- closed membrane devices, used exclusively in forced systems, are installed on the return line in front of the boiler.

Expansion tanks are designed to compensate for the thermal expansion of the liquid when heated. They are needed to dump excess into the sewer or corny into the street, as is the case with the simplest open options. Closed capsules are more practical, because they do not require human intervention in adjusting the pressure of the system, but more expensive.

bottle open type is installed at the highest point of the system. In addition to providing a reserve for expanding the liquid, it is also entrusted with the task of removing air. Closed tanks are placed in front of the boiler, air vents and separators are used to remove air

bottle open type is installed at the highest point of the system. In addition to providing a reserve for expanding the liquid, it is also entrusted with the task of removing air. Closed tanks are placed in front of the boiler, air vents and separators are used to remove air

When choosing shut-off valves, preference is given to ball valves, when choosing a pumping unit - equipment with a pressure of up to 30 kPa and a capacity of up to 3.0 m3 / h.

Budget opening varieties need to be replenished periodically due to the standard weathering of the fluid. Under their installation, it is necessary to significantly strengthen the attic floor and insulate the attic.

Radiators and convectors are recommended to be mounted under windows, in places convenient for maintenance. The role of heating elements in bathrooms or bathrooms can be played by heated towel rails connected to heating communications

Varieties of heating systems

There are several ways to organize electric heating in your home. Each of them has its own advantages and disadvantages. Some are cheaper at the purchase stage, and some save significantly during operation. Let's look at what features each method has:

Installation of an electric boiler designed to heat water flowing through the pipes of the heating system. Perhaps the most well-known method, but it is far from the most effective today. Manufacturers claim that current models have become much more productive and now consume 80% less energy, but this is a moot point. Manual switching on and off of the boiler, of course, is impractical, and automatic at a given interval does not take into account the temperature regime of day and night. A more or less economical option is to install thermostats and appropriate automation to turn on depending on the temperature in the rooms, but this is difficult in terms of installation and very costly.Reduced power models with equal performance are also nothing more than advertisements. Such a boiler, most likely, will not have enough “strength” to heat a large private house.

infrared panels. This is not just a way to heat rooms, but a fundamentally different technology. The point is not to warm up the air (which has a very low efficiency), but to influence the objects located in the room. Under the light of IR lamps, floors and furniture heat up and begin to emit heat themselves. The fundamental difference is that the traditional "radiator" method of space heating actually heats the ceiling (warm air from the battery rises), and the floors remain cold. With infrared heating, the opposite is true. The light is directed downwards, which means that the warmest place is the floor. Supplement the system with thermostats - and economical heating of a country house, private house or garage is ready. And the opinion about the dangers of infrared radiation on a person is nothing more than a myth. The main thing is not to be under the lamp for a long time, and nothing dangerous will happen.

The use of convectors. According to manufacturers, this is the most efficient way of space heating, which combines high performance and economical energy consumption. Both of these statements are the subject of a long dispute, since the technology is based on the same "radiator" principle, and many individual characteristics should be taken into account in heating a house. The main difference lies in the significant ease of installation and operation and lower price.

An important advantage of convectors is fire safety, which is very important when heating a country or private house from wood.Convectors allow you to install them sequentially from room to room, they are compact and pleasant to look at, and they are also protected from power surges.

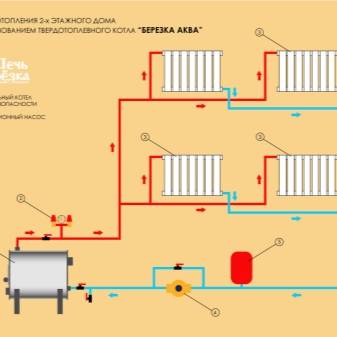

Installation of the cottage heating system

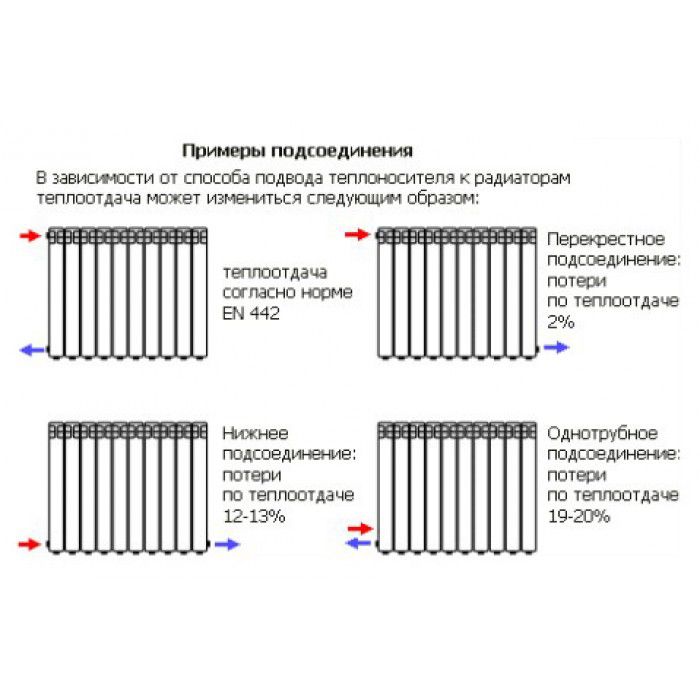

After the arrangement of the boiler room, according to the heating scheme of the cottage, radiators are mounted. The main parameters by which consumers choose radiators are dimensions, power and the material from which they are made.

Internal wiring

During installation cottage heating systems special attention should be paid to the pipe material. To date, there are several types of pipes that are traditionally used in heating systems.

Let's take a closer look at these types.

- Steel pipes. Durable, resistant to pressure drops, but difficult to install and subject to corrosion. Over the years, a layer of rust settles on the inner walls, which can impede the flow of water.

- Metal pipes. Strong, flexible and easy to install. It is convenient to use with complex geometry of the heating system. But they also have a number of weak points: they are destroyed by mechanical impact and ultraviolet radiation, as well as flammable.

- Propylene pipes. The most popular material, which is undoubtedly related to the price of such pipes. They are the most economical compared to pipes of their other materials. They have only one drawback - good flammability. Otherwise, it is an ideal material for heating pipes. They do not rust, do not crack, are easily welded with the help of special “irons”, and are durable in use.

- Stainless steel pipes. They are usually used in non-residential premises: basements, laundries, billiard rooms. They have good heat dissipation, and so high that they can heat the room without installing radiators.Variety - corrugated stainless steel pipes. In addition to those listed, they have another advantage: they easily “bypass” corners and turns without additional joints.

Tips for installing a house heating system

The heating device begins with the installation of batteries in pre-prepared places under the windows or on the corner outer walls. Devices are hung on special hooks attached to the structure itself or plasterboard finish. The unused lower outlet of the radiator is closed with a cork, a Mayevsky tap is screwed in from above.

The pipeline network is mounted according to the assembly technology of certain plastic pipes. To save you from mistakes, we will give some general recommendations:

- When installing polypropylene, consider the thermal elongation of the pipes. When turning, the knee should not rest against the wall, otherwise, after starting the heating, the line will bend like a saber.

- It is better to lay the wiring in an open way (excluding collector circuits). Try not to hide the joints behind the sheathing or embed them in the screed, use the factory "clips" to fasten the pipes.

- Lines and connections inside the cement screed must be protected with a layer of thermal insulation.

- If for any reason an upward loop has formed on the piping, install an automatic air vent on it.

- It is desirable to mount horizontal sections with a slight slope (1-2 mm per linear meter) for better emptying and removal of air bubbles. Gravity schemes provide slopes from 3 to 10 mm per 1 meter.

- Place the diaphragm expansion tank on the return line near the boiler.Provide a valve to cut off the tank in case of malfunction.

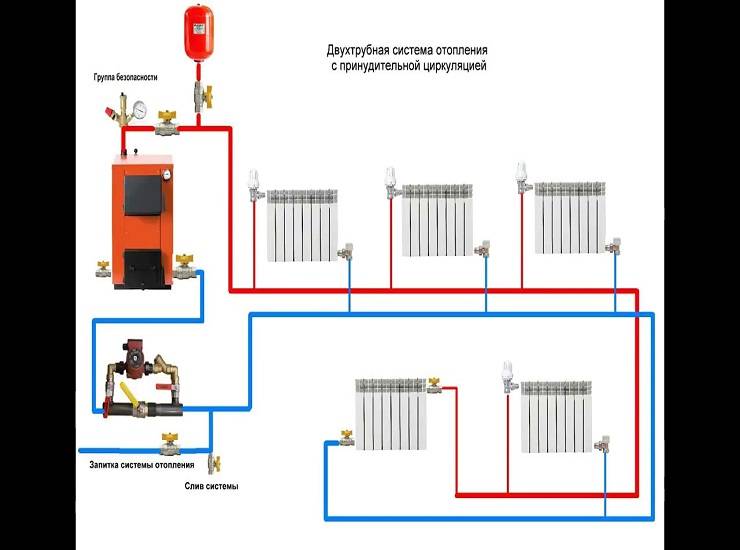

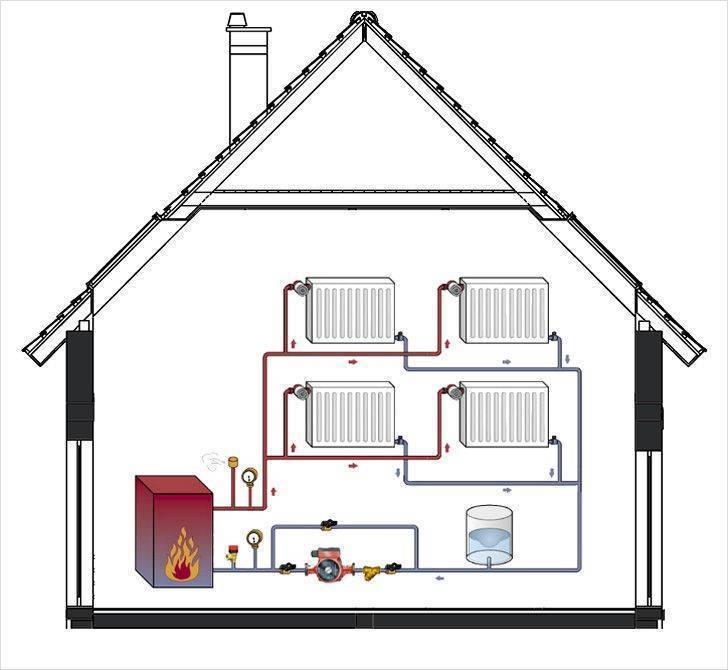

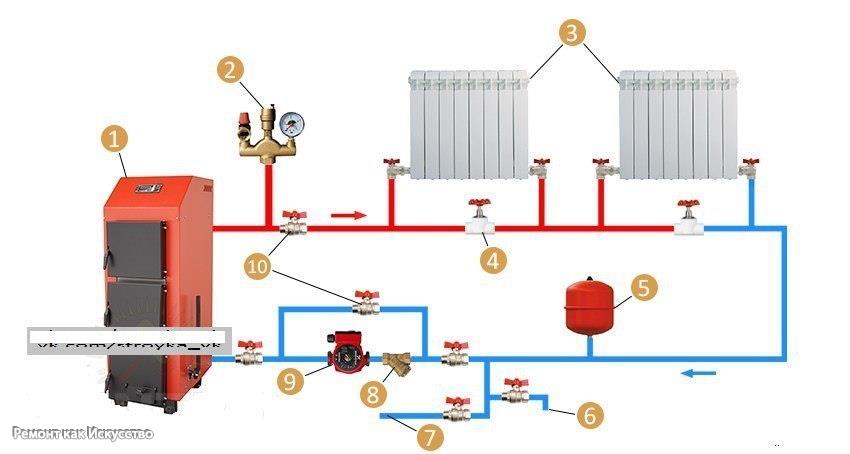

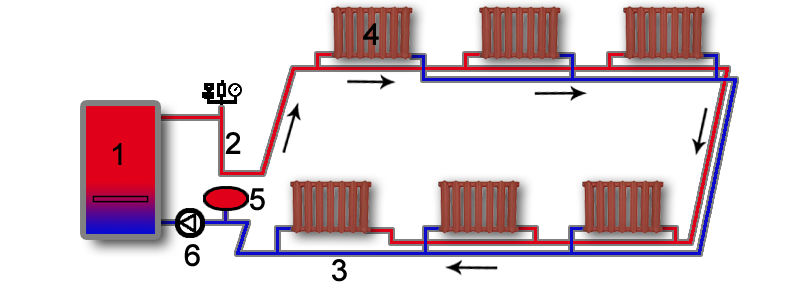

Installation and connection of equipment - how to install the boiler

Gas, diesel and electric boilers are obliged in almost the same way. The fact is that almost all wall-mounted models have built-in circulation pumps and expansion tanks. The simplest and most common piping scheme provides for the location of the pump with a bypass line and a sump on the return line. An expansion tank is also mounted there. For pressure control a pressure gauge is used, and air is vented from the boiler circuit through an automatic air vent. An electric boiler that is not equipped with a pump is tied in the same way.

If the heat generator has its own pump, and its resource is also used to heat water for hot water, pipes and elements are bred in a slightly different way. The removal of flue gases is carried out using a double-walled coaxial chimney, which goes out through the wall in a horizontal direction. If the appliance uses an open type firebox, then a conventional chimney duct with good natural draft will be required.

Extensive country houses quite often provide for the docking of a boiler and several heating circuits - a radiator, underfloor heating and an indirect hot water heater. In this case, the best option would be to use a hydraulic separator. With its help, you can achieve high-quality organization of autonomous circulation of the coolant in the system. At the same time, it acts as a distribution comb for other circuits.

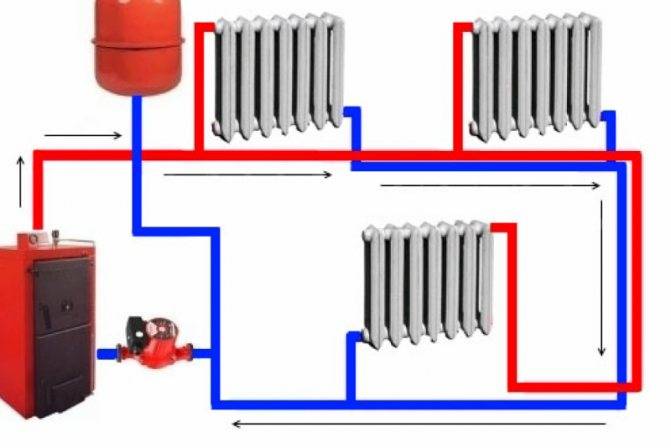

The great complexity of tying solid fuel boilers is explained by the following points:

- The risk of overheating due to the inertness of the appliances, as the heating system in a private house works on wood, which does not go out quickly.

- When cold water enters the tank of the unit, condensation usually appears.

So that the coolant does not overheat and does not boil, a circulation pump is placed on the return line, and a safety group is placed on the supply immediately after the heat generator. It consists of three elements - a pressure gauge, an automatic air vent and a safety valve. The presence of a valve is of particular importance, since it is used to relieve excess pressure in case of overheating of the coolant. When firewood is used as a heating material, the firebox is protected from liquid condensation by a bypass and a three-way valve: it retains water from the network until it heats up above +55 degrees. In heat generating boilers, it is desirable to use special buffer tanks that act as heat accumulators.

Often, furnace rooms are equipped with two different heat sources, which provides for a special approach to their piping and connection. Usually, in this case, in the first scheme, a solid fuel and electric boiler are combined, synchronously supplying the heating system. The second option involves a combination of a gas and wood-burning heat generator that feeds home heating systems and DHW.

Calculation of the heating system at home

| Calculation private heating systems at home - the very first thing with which the design of such a system begins. We will talk with you about the air heating system - these are the systems that our company designs and installs both in private homes and in commercial buildings and industrial premises.Air heating has many advantages over traditional water heating systems – you can read more about it here. |

System calculation - online calculator

Why is a preliminary calculation of heating in a private house necessary? This is required to select the correct power of the necessary heating equipment, which allows you to implement a heating system that provides heat in a balanced way to the corresponding rooms of a private house. A competent choice of equipment and the correct calculation of the power of the heating system of a private house will rationally compensate for heat loss from building envelopes and the flow of street air for ventilation needs. The formulas themselves for such a calculation are quite complex - therefore, we suggest you use the online calculation (above), or by filling out the questionnaire (below) - in this case, our chief engineer will calculate, and this service is completely free.

How to calculate the heating of a private house?

Where does such a calculation begin? Firstly, it is required to determine the maximum heat loss of the object (in our case, this is a private country house) under the worst weather conditions (such a calculation is carried out taking into account the coldest five-day period for this region). It will not work to calculate the heating system of a private house on the knee - for this they use specialized calculation formulas and programs that allow you to build a calculation based on the initial data on the construction of the house (walls, windows, roofs, etc.). As a result of the data obtained, equipment is selected whose net power must be greater than or equal to the calculated value.During the calculation of the heating system, the desired model of the duct air heater is selected (usually it is a gas air heater, although we can use other types of heaters - water, electric). Then the maximum air performance of the heater is calculated - in other words, how much air is pumped by the fan of this equipment per unit of time. It should be remembered that the performance of the equipment differs depending on the intended mode of use: for example, when air conditioning, the performance is greater than when heating. Therefore, if in the future it is planned to use an air conditioner, then it is necessary to take the air flow in this mode as the initial value of the desired performance - if not, then only the value in the heating mode is sufficient.

At the next stage, the calculation of air heating systems for a private house is reduced to the correct determination of the configuration of the air distribution system and the calculation of the cross sections of the air ducts. For our systems, we use flangeless rectangular air ducts with a rectangular section - they are easy to assemble, reliable and conveniently located in the space between the structural elements of the house. Since air heating is a low-pressure system, certain requirements must be taken into account when building it, for example, to minimize the number of turns of the air duct - both the main and the terminal branches leading to the grates. The static resistance of the route should not exceed 100 Pa. Based on the performance of the equipment and the configuration of the air distribution system, the required section of the main air duct is calculated.The number of terminal branches is determined based on the number of feed grates required for each specific room of the house. In the air heating system of a house, standard supply grilles with a size of 250x100 mm with a fixed throughput are usually used - it is calculated taking into account the minimum air velocity at the outlet. Thanks to this speed, air movement is not felt in the premises of the house, there are no drafts and extraneous noise.

| The final cost of heating a private house is calculated after the end of the design stage based on the specification with a list of installed equipment and elements of the air distribution system, as well as additional control and automation devices. To make an initial calculation of the cost of heating, you can use the questionnaire for calculating the cost of the heating system below: |

online calculator

How to calculate pipe diameter

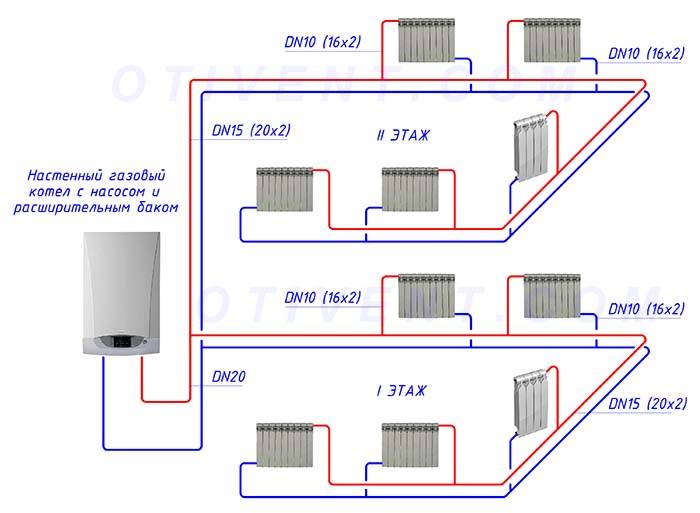

When arranging dead-end and collector wiring in a country house with an area of up to 200 m², you can do without scrupulous calculations. Take the cross section of highways and piping according to the recommendations:

- to supply the coolant to radiators in a building of 100 square meters or less, a Du15 pipeline (outer dimension 20 mm) is sufficient;

- battery connections are made with a section of Du10 (outer diameter 15-16 mm);

- in a two-story house of 200 squares, the distributing riser is made with a diameter of Du20-25;

- if the number of radiators on the floor exceeds 5, divide the system into several branches extending from the Ø32 mm riser.

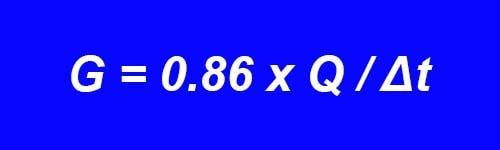

Gravity and ring system is developed according to engineering calculations.If you want to determine the cross-section of pipes yourself, first of all, calculate the heating load of each room, taking into account ventilation, then find out the required coolant flow rate using the formula:

- G is the mass flow rate of heated water in the section of the pipe supplying the radiators of a particular room (or group of rooms), kg/h;

- Q is the amount of heat required to heat a given room, W;

- Δt is the calculated temperature difference in the supply and return, take 20 °С.

Example. To warm up the second floor to a temperature of +21 °C, 6000 W of thermal energy is needed. The heating riser passing through the ceiling must bring 0.86 x 6000 / 20 = 258 kg / h of hot water from the boiler room.

Knowing the hourly consumption of the coolant, it is easy to calculate the cross section of the supply pipeline using the formula:

- S is the area of the desired pipe section, m²;

- V - hot water consumption by volume, m³ / h;

- ʋ – coolant flow rate, m/s.

Continuation of the example. The calculated flow rate of 258 kg / h is provided by the pump, we take the water velocity of 0.4 m / s. Cross-sectional area supply pipeline is 0.258 / (3600 x 0.4) = 0.00018 m². We recalculate the section into diameter according to the circle area formula, we get 0.02 m - DN20 pipe (outer - Ø25 mm).

Note that we neglected the difference in water densities at different temperatures and substituted the mass flow rate into the formula. The error is small, with a handicraft calculation it is quite acceptable.