- Types of stoves for different operating conditions

- Fuel used

- 4 Getting started - what you need

- Advantages and disadvantages

- Criteria for the selection of long-burning furnaces

- Advantages and disadvantages of pyrolysis ovens

- The design of the furnace, its features and principle of operation

- Design features of long-burning furnaces

- Differences between conventional and pyrolysis oven

- What's better?

- Factory or homemade?

- Distinctive features

- The best long burning fireplace stoves with a water circuit

- MBS Thermo Vesta plus

- MBS VULKAN

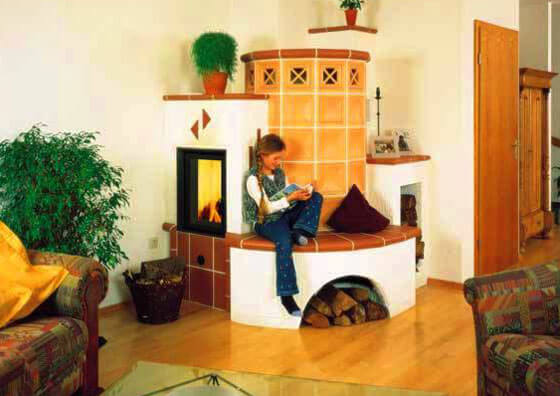

- Romotop GRANADA

- META Pechora Aqua

- EdilKamin Warm CS

- The device and dimensions of wood stoves

Types of stoves for different operating conditions

A rocket stove with a water circuit, brick or metal, can replace the boiler. The heat exchanger here is arranged in the upper part of the flame tube in the form of a surrounding water jacket. Jumpers are located inside the jacket for more efficient heat removal to the coolant. The design is extremely simple, it can heat households up to several tens of square meters.

A rocket stove for a garage can be made from an old pot-bellied gas bottle or barrel. To do this, two holes are made in the selected container - one in the top cover, and the other on the side surface. An L-shaped pipe is inserted inside.With little experience with a welding machine, all work will take you a maximum of half an hour.

You can also make an oven of the above-described rocket type from pieces of a square and metal pipe according to the drawing.

Also, for heating the garage, the heating rocket stove "Ognivo - Boss" is suitable. This is a shop model made of corrugated aluminum pipe and ordinary sheet iron. It works in much the same way and allows you to warm a garage up to 30 square meters. m.

There are no drawings of her in the public domain yet, so you can try to assemble the Flint stove with your own hands based on her photograph. It can also be purchased from the manufacturer's website.

We have already said that a long-burning rocket stove with a water circuit will be required to heat large households. A small household from one room can be heated with a simpler stove with a stove bench - this way you save space on furniture. It consists of the following nodes:

- Firebox with vertical loading - logs are placed in it;

- Afterburner - a horizontal section in front of the riser (flame tube), pyrolysis combustion takes place here;

- Riser with a hob - a vertical section with a metal case that gives off heat to the room;

- Horizontal channels - they heat the stove bench, after which the combustion products are sent to the chimney.

A rocket stove for heating a house from one room is coated with clay to make a flat and comfortable bed - here you can lay a mattress or a small blanket.

For field use, the simplest rocket-type furnaces made of metal pipes are used.They are compact, easy to kindle and extinguish, cool quickly and allow you to quickly cook dinner in the open air. The main thing is not to overdo it with the amount of fuel loaded, so as not to burn the food with a high-temperature flame.

Fuel used

It's no secret that firewood is the most environmentally friendly fuel. The same category is supplemented by dry logs and pellets, since they are obtained by pressing small dried chips and sawdust.

For stoves with long burning, fuel pellets can be used as fuel, which are obtained from such materials:

- cones;

- husks of seeds;

- nut shells;

- dried peel of citrus fruits;

- tree bark.

Charcoal can also be used, but only on condition that when creating the furnace, the walls of the unit are deliberately thickened. If the walls are not thickened, then the furnace can be damaged, since during operation it will undergo strong heat.

4 Getting started - what you need

To make a homemade oven, you need to choose a convenient place. It should be a room with connected electricity, sufficient area. Now about the materials. It is easier for a stove with a long burning time to use a 200 l steel barrel. However, the volume is not of fundamental importance, the heat transfer of the device will simply depend on it. Use gas cylinders and even fire extinguishers.

The stove can be made from an old gas cylinder

But, again, the volume of the workpiece: from a 27-liter cylinder you can make a stove for heating a bath, from a smaller one or a fire extinguisher - for a tiny room. The thickness of the metal matters: the thicker, the longer the furnace will last.If there is nothing suitable, we use a thick-walled pipe, steel sheets. The metal must be free of damage and rust. From other materials you will need:

- material for the legs, if the oven is round (pipes, square, fittings);

- sheet steel 5 mm thick according to the dimensions of the end side of the product;

- sealed door or material for it;

- 100 mm pipe is 15 cm longer than the device;

- 5 m pipe 150 mm for smoke removal.

Measuring devices are needed: tape measure, plumb line, level, as well as a hammer, mallet, trowel.

Advantages and disadvantages

Let's look at the main pros and cons of homemade long-burning heating stoves. Let's start, as usual, with the positive features:

Compactness and relative mobility are the main advantages of stoves.

- Cheapness - most often they are assembled from cheap sheet metal, capacious gas cylinders, barrels and much more. All this can be found at the ruins and at old enterprises. Some people can rummage in their garage or barn - for sure there will be unnecessary metal for a home-made long-burning stove;

- Easy to assemble - no one requires ultra-precise following of the chosen scheme. For example, all the same pyrolysis stove-potbelly stove can have a variety of sizes;

- High Efficiency - A properly assembled long-burning stove can provide heat to large rooms without requiring frequent refills.

There are also certain disadvantages:

- Not the most attractive appearance - homemade products really cannot please users with good external data;

- Some types of stoves cannot be used in residential premises - the same “bubafonya” will smoke and smell great before it enters the operating mode;

- A long-burning stove with a water circuit will be difficult to implement - you need to somehow ensure the intake of heat into the heating circuit.

Despite some obvious shortcomings, home-made long-burning wood-burning stoves are in some demand.

A long-burning stove is an excellent unit for heating greenhouses. Heat them up with electricity or gas is expensive or impossible at all, and by buying cheap firewood, you can provide greenhouses with life-giving heat for the whole winter.

Criteria for the selection of long-burning furnaces

When choosing a long-burning stove, you should give preference only to trusted manufacturers from various European brands, as their products are always marked with quality and safety certificates.

It is worth noting that today there are a large number of different types and styles, which are expanded with additional functions, have a special lining and are installed in different ways. There are various options that are equipped with fans, oven, solid fuel compartments, etc.

The main criterion when choosing a heating device with a long combustion cycle on solid (wood) fuel is its power.

It must correspond to the volume of the heated room. It makes no sense to install a high-power stove in a small room, since part of the heating material will burn out irrationally. In addition, a large appliance will take up a lot of space, and the room temperature will be too high.

Conversely, a low-power stove in large rooms will work to the limit, which will quickly disable it.

When choosing, you should decide on the type of fuel that is supposed to be used - firewood, pellets, coal, fuel briquettes, etc.

You should be aware that the moisture content of wood fuel is of great importance, since water vapor diluting gases interferes with combustion, reduces the power of the device and contributes to the formation of condensate.

In some cases, excessive moisture content of the combusted material can lead to spontaneous combustion of the furnace. Firewood for long-burning fireboxes, for example, should have a moisture content of no higher than 20-35%.

The metal or alloy from which the long-burning furnace is made is also an important selection criteria. The thicker the body material of the device, the slower the device cools down and the longer its service life.

Some models of long-burning stoves made of cast iron last up to 50 years and, moreover, are not subject to corrosion.

The elements of many modern stoves - a firebox, a hob, a finish, a door - are made from different materials (cast iron, vermiculite, steel, stainless steel, heat-resistant glass, etc.), which allows you to increase the service life, improve design, increase ease of use and long time to keep the look.

The appearance of the heater often plays no less important role than other factors. A stove for a living space should have a modern design and harmoniously fit into the interior.

There are many imported models on the market, among which you can choose a ready-made stove for any home.

All long-burning stoves are supplied with instructions, but they often do not mention some of the nuances that must be taken into account:

- around the furnace it is necessary to provide free space and protection against fire;

- for convenient maintenance (cleaning), the chimney should, if possible, have a collapsible design;

- pipes must be installed in the direction of gas flow;

- due to the small draft, the chimney should not have a curved shape;

- Condensation may form in the chimney during operation.

It should also be noted that liquid fuel cannot be used in long-burning furnaces, some models are quite difficult to set up and require constant supervision.

Advantages and disadvantages of pyrolysis ovens

Nothing in this world is perfect, so even long-burning wood stoves are not without flaws. The main ones are the following:

- The price of modern high-tech long-burning pyrolysis furnaces with good performance in terms of efficiency will be quite high. However, you can significantly save money by constructing a heater with your own hands.

- Pyrolysis boilers of industrial production often require the provision of additional uninterrupted power supply to their auxiliary units: air injection systems (combustion chamber pressurization), water heating circuit pumps, sensors, etc.

- Long burning stoves are more finicky in terms of wood log moisture requirements. Insufficiently dried firewood placed in the furnace of a pyrolysis boiler can easily go out, stopping the operation of the entire heating system.

- Compared to gas (electric) boilers, boilers or columns, long-burning stoves are much larger and also require additional free space for storing firewood.

- You will have to manually throw up fuel for the pyrolysis boiler; this operation cannot be fully automated by 100%.

- A more complex water circuit device compared to other types of heating installations. The fact is that too supercooled coolant, returning from the batteries to the boiler heat exchanger, can interrupt the smoldering of firewood and extinguish the furnace. To avoid this situation, you have to install an additional pipe (the so-called "bypass"), which allows you to mix already heated water with cold water. Naturally, with the increasing complexity of the design of the heating circuit, the total cost of the entire device also increases.

At first glance, the list of shortcomings of long-burning wood-burning stoves seems quite impressive. And many people have a natural question: why is this type of stove so popular and in such good demand? The answer is simple and obvious: all the shortcomings of the pyrolysis plant are more than offset by the advantages that the owner of such a device receives:

Fuel energy is used almost 100%. All loaded firewood will burn to the ground, completely transferring its heat to the heated room. High-quality commercially manufactured long-burning stoves have fantastic efficiencies, up to 90 percent. For greater clarity, we present a table below that compares the efficiency of various types of boilers.

Comparison of fuel efficiency indicators in boilers of different types

- Long burning wood stoves are convenient and easy to maintain, they produce almost no waste. Nothing remains of the firewood but a handful of ash.

- Environmental friendliness of the heating system. With full-fledged pyrolysis combustion, only water vapor and carbon dioxide are released into the atmosphere. During the operation of a high-quality pyrolysis oven, you will not feel any extraneous unpleasant odors, compared to a conventional oven. This is due to the fact that the source of such aromas are unburned complex organic compounds. In a long-burning furnace, fuel oxidation occurs by 100%, therefore it can be safely heated even with industrial waste.

- One "refueling" with logs is enough for 10-15 (and sometimes more) hours of continuous operation. No ordinary wood-burning stove can burn for such a long time.

- The heating system based on the pyrolysis boiler warms up the house very quickly and enters the operating mode.

- The power of a heater using the pyrolysis effect can be easily and smoothly adjusted, just like a gas or electric one. Unlike conventional solid fuel installations, in a long-burning furnace, the main heat is generated by the gas burned in a separate chamber. Accordingly, by controlling the level of oxygen supply to the furnace, we can easily change the heat release of the entire system.

The design of the furnace, its features and principle of operation

Before proceeding with the independent manufacture of the furnace, it is necessary to carefully study all the characteristics of the device.

If it is planned to make a unit for heating a large room, then the furnace must have a high heat output.For example, for a house or room with an area of 150 m², you should choose a stove designed for heating up to 200 m². This "reserve" of power is necessary for complete confidence that every corner of the house will be warm.

If it is designed to heat a room with an area of 30–50 m², then the stove can be made without the specified “reserve”. In such a small room, heat leakage will be minimal, so a unit with a small capacity is enough. Automatic refueling will greatly simplify its maintenance. In the manufacture of such an oven, hobs for cooking can be provided on its body. If the stove is not only a source of heat, but also an interior item, then windows can be made of refractory glass in its body.

Design features of long-burning furnaces

Long-burning heaters have design features that distinguish them from other stoves:

- the combustion chamber has a volume for loading a large amount of combustible material;

- the body of long-burning furnaces is equipped with a large door;

- the furnace compartment in the furnace body is divided into two chambers; one chamber is designed for smoldering combustible material, the second - for gas combustion;

- the design of such a furnace provides for the presence of a special chipper, which prevents the flame from entering the chimney;

- this element of the furnace frame is made of a metal plate, which is welded in the upper part of the furnace compartment.

Differences between conventional and pyrolysis oven

To understand the principle of operation of a long-burning furnace, you need to compare it with the operation of a conventional furnace.

The work of a conventional stove is to heat its surface and release heat into the room.The combustion material is ignited from below, which causes the flame to spread to the sides, heading up. This is due to the access of a large amount of air into the combustion chamber. The fuel in such a furnace burns out quickly, which is why the air temperature in the room is unstable - it either drops or rises.

The principle of operation of a long-burning furnace is different. Firewood is ignited from above, and the fire spreads down, while air is supplied only to the place of combustion. As a result, the material smolders, evenly releasing heat over a long period of time. In addition to the combustion material, pyrolysis gas is released, which also serves as a fuel, additionally creating heat.

In a conventional furnace, fuel burns quickly, in a pyrolysis furnace it slowly smolders.

What's better?

Let's compare a few positions that, in our opinion, are important:

- The principle of operation. Metal furnaces belong to the category of permanent operation. In order for them to continuously give off heat, they must be “fed” with fuel. Brick units are temporary heating devices. That is, they can be heated and a little fuel is thrown into them to maintain the required temperature. Sometimes they are not heated at all for a certain period, but due to the heat capacity of the brickwork, the temperature inside the room remains stable.

- heating speed. Unfortunately, a brick oven in this category loses to a metal one. In order for it to begin to give off heat to the room, it is necessary to burn fuel for 2-3 hours. It all depends on the design. A metal oven is much better in this regard. After half an hour of operation, it heats up and begins to emit sufficient temperature. True, with the same speed it cools down.

- Safety.In this regard, a metal stove is clearly worse. Its walls are so hot that a fire can occur from a slight contact. That is why these models are necessarily reinforced in terms of fire safety with special screens made of non-combustible materials.

- Equipment price. It is clear here without words that the brick version will cost much more. In addition, experts do not advise building it with your own hands. It is very difficult for an inexperienced person to achieve that the design is 100% tight. And the probability of improperly folded brickwork is too high. What can not be said about the metal counterpart.

- heating area. In this position, both the brick structure and the metal structure are defined in the same way. The larger the room for heating, the larger the oven should be in size. But you need to do some calculations first. Although large metal stoves used in summer cottages do not justify themselves in terms of fuel consumption. They "eat" too much.

Factory or homemade?

Since we started talking about metal stoves for summer cottages, I would like to draw another parallel - to compare factory products and home-made ones. Although such a comparison would probably be wrong. It's all about the quality of workmanship and the price of equipment.

The price of factory devices is several times higher, the appearance of these units is better, and they differ in quality. But homemade stoves are characterized by a low price. If they are made by a highly qualified master, then the quality will be at a high level. Of course, in appearance they are inferior to the factory ones. But installing a protective screen can solve the problem if you treat it with imagination and creativity.

And one moment.If we have already begun to compare models, then to the end. Currently, the market offers stoves for the home made of cast iron and steel. It is impossible to make cast-iron units with your own hands. This requires a casting process, which cannot be organized in a suburban area. This requires special equipment, in which the cast iron casting process is carried out.

Distinctive features

The operation of any of the systems based on long-term combustion of fuel occurs by ensuring the combustion of pyrolysis gases. Their release is made when fossil fuel burns slowly.

Air ducts in such structures have their own characteristics, due to which the wood smolders and releases hydrocarbons in the form of gas.

The principle of operation of fireplace stoves is as follows:

- Pyrolysis gases, which were formed during the slow oxidation of organic fuels, come into contact with air and then enter the combustion chamber. As a result of the process, a significant amount of thermal energy is released.

- The resulting heat can be used to transfer the temperature to a heat carrier or a boiler with an indirect type of heating.

IMPORTANT! An important advantage of the fireplace stove can be considered the minimum level of soot formation during the combustion of pyrolysis compounds. But it is worth considering that when arranging such a device, you need to properly mount the chimney

It will allow you to efficiently remove exhaust gases, ensuring the safety of residents and the efficiency of the furnace.

But it is worth considering that when arranging such a device, you need to properly mount the chimney.It will allow you to efficiently remove exhaust gases, ensuring the safety of residents and the efficiency of the furnace.

The best long burning fireplace stoves with a water circuit

MBS Thermo Vesta plus

Designed for heat supply of premises equipped with water heating systems. The oven can be connected  to the system in tandem with a solid fuel boiler or in stand-alone mode.

to the system in tandem with a solid fuel boiler or in stand-alone mode.

The maximum possible water temperature inside the heat exchanger is 90°C.

The furnace is made of cast iron and high quality steel. The outer enamel coating is distinguished by its special aesthetics and retains its attractive appearance for a long time.

There is a solid cooking surface made of cast iron.

Rapid heating of the room is provided by convection. The ash drawer can be pulled out directly during kindling, which makes maintenance easier.

Characteristics:

- power: 11 kW;

- Efficiency - 83%;

- hob - yes;

- location: wall;

- heating area - up to 110m2;

- chimney: 150mm, ;

- material: steel, cast iron, ceramic tiles, fireclay;

- glass type: straight;

- dimensions: 90*46*44cm;

- weight: 91.5kg.

Advantages:

- design;

- build quality;

- high efficiency and long heat retention.

Flaws:

The inner surface of the firebox may require replacement after a couple of years of use.

MBS VULKAN

A wood-burning stove can heat large rooms while being compact in size. Great for  use in a country house outside the city.

use in a country house outside the city.

It will help organize autonomous heating or supplement the existing one.

The furnace is voluminous, while fuel is consumed in economy mode.

With the MBS Vulkan Thermo stove, your home will become not only unique in terms of atmosphere, but also more comfortable. There are modes of intense heating or smoldering.

Characteristics:

- power: 24 kW;

- Efficiency - 83%;

- hob - yes;

- location: wall;

- heating area - up to 140m2;

- chimney: 120mm, ;

- material: steel, cast iron;

- glass type: straight;

- dimensions: 65*78*64.5cm;

- weight: 151kg.

Advantages:

- ease of kindling and care;

- high reliability;

- room heating rate;

- fuel economy.

Flaws:

missing.

Romotop GRANADA

The stove has a modern appearance, workmanship and uses an innovative method of burning wood.

The body is made of steel with a decorative tile cladding. Steel stoves warm up the air faster - already 15 minutes after kindling.

Fireclay is installed in the combustion chamber, which can withstand up to 1300 degrees. The furnace chamber is separated from the body to reduce the risk of fire and extend the life of the furnace itself.

Characteristics:

- power: 13 kW;

- location: wall;

- heating area - up to 130m2;

- chimney: 150mm, ;

- material: steel, ceramics;

- glass type: straight;

- dimensions: 125*50*56cm;

- weight: 254kg.

Advantages:

- modern design;

- a wide choice of body colors;

- heating efficiency.

Flaws:

high price.

META Pechora Aqua

Pechora is one of the most efficient fireplace stoves that can effectively heat a large house. Installation  connected to radiators.

connected to radiators.

The stove warms up in a matter of minutes, and the hearth itself is made of non-combustible materials, the main one being stainless steel. If you need to heat a small room, this model is suitable for this.

Then it can not be connected to the water heating circuit, the air heating power will be enough. Do not connect the stove to heating radiators if there is no water in the batteries.

Characteristics:

- power: 9 kW;

- location: wall;

- heating area - up to 90m2;

- chimney: 150mm, ;

- material: steel, ceramics;

- glass type: straight;

- dimensions: 104*75*49cm;

- weight:155kg.

Advantages:

- does not take up much space;

- economical consumption of firewood;

- smoldering mode.

Flaws:

cools down quickly.

EdilKamin Warm CS

The stove belongs to a new generation. Depending on the area of the room, you can choose the Warm Base or Warm package.  Scaldavivande.

Scaldavivande.

This stove can not only heat the home, but also provide hot water.

Designed in a classic rustic style, but will also fit into a modern interior. The ends, the facade and the base are cast iron, the hearth is made of steel, the cladding is made of ceramics.

Characteristics:

- power: 14 kW;

- location: wall;

- heating area - up to 140m2;

- chimney: 150mm, ;

- material: cast iron, steel, ceramics;

- glass type: straight;

- dimensions: 108*56*51.5cm;

- weight: 253kg.

Advantages:

- efficiency;

- heating and hot water;

- reliable components;

- perfect build.

Flaws:

high price.

The device and dimensions of wood stoves

The size of the oven is directly related to the area to be heated. So, one square meter of stove masonry is able to heat 35 "squares" of the room. The advantage of such heat sources lies in its preservation throughout the day after the end of the firebox.

One of the main stages when a brick heating wood-burning stove is being built is the foundation, since its design is of considerable weight. True, if it is a stove exclusively for cooking, and its weight does not exceed 750 kilograms, then about 200 bricks will need to be laid out for the base. In the case of building a furnace for heating, the foundation must be more solid.It is laid out separately from the foundation of the house from clay mortar, asbestos sheets and roofing iron.

Therefore, as a general information, you can familiarize yourself with the basic rules for the construction of the furnace, which will help to avoid heat loss:

- the foundation for a wood-burning stove with a pipe is made at least 1 meter deep;

- dig a pit 10 centimeters wider than the base;

- masonry seams should not exceed 5 millimeters in width;

- rows and angles relative to the horizontal should be perfectly even;

- the maximum deviation from the vertical is allowed in the amount of 10 millimeters;

- between the masonry and the grate, the minimum gap can be 5 millimeters;

- the grate of the grate is placed no higher than the first row of brickwork, counting from the opening of the furnace.

To ensure good traction and unhindered passage of gases, flawless interior masonry is required. At the same time, the inner surfaces should not have even the slightest distortions, and the turns should be made smooth.