- Popular manufacturers

- Kyiv Novaslav

- NMK

- Eurosib

- Conclusion

- Expert evaluation of the furnace "Buleryan Classic" (type 00)

- The principle of operation of the furnace

- Do-it-yourself buleryan oven: sequence of actions

- Models with water circuit

- Kinds

- For heating

- with hob

- The opinion of experts about the furnace "Buleryan Classic" (type 01)

- Buleryan efficiency in comparison with gas heating

- Positive characteristics

- Cons of buleryan

- Design and principle of operation

Popular manufacturers

Buleryan furnaces are produced by various factories in many countries, Russia and neighboring countries are no exception. The most popular are 3 manufacturers:

Kyiv Novaslav

A company from Ukraine, which specializes in the production of stove accessories for saunas, baths, and heating various premises. Novaslav equipment works according to the concept of original models, but is better adapted for heating, compared to standard stoves of this type. Produced in a number of series:

- Vancouver 01 type up to 200 m3, power limit 11 kW. Weight 97 kg. Upon request, it can be completed with a thermoglass door. Scope of use - rooms with a volume of up to 200 m3. The cost ranges from 16,000 to 20,000 rubles.

- Montreal, 02 type up to 400 m3 - this model range is distinguished by increased power up to 18 kW, in comparison with Vancouver, with a slight weight of 127 kg and small dimensions, it is able to heat a room up to 400 m3. The cost ranges from 26,000 to 30,000 rubles.

- Quebec, 03 type up to 600 m3 - this type is best suited for production needs. On request, the door can be equipped with a thermal insert made of glass. The maximum heating area is 260 m2. The cost ranges from 30,000 to 40,000 rubles.

- Toronto, 04 type up to 1000 m3 - high power heat generator. The power is sufficient for heating an area up to 350 m2. The cost starts from 43,000 rubles.

- Ontario, 05 type up to 1300 m3 is the highest capacity convection type oven sold by the company. The power of the equipment reaches 45 kW, it is easy for them to heat a volume of up to 1300 m³. The cost starts from 44,000 rubles.

The lineup

Furnaces look aesthetically pleasing and can serve as an element of a design solution. The company also produces a variety of stoves and fireplaces Buleryan.

NMK

A metalworking company from Novosibirsk produces furnace equipment and accessories. NMK manufactures ovens using convection, Sibir BV Buleryan. The equipment of this company is perfect for heating any premises. You can purchase the following equipment:

- Siberia BV 120 is best suited for industrial premises: greenhouses, dryers, etc. The highest temperature of heated air is 80 ° C. On a single load, in the gas generating mode, it will work up to 10 hours. The largest heating volume is 120 m³. The cost is 11500–13000 rubles.

- Siberia BV 180 - works on any solid fuel mass: wood logs, coal, cardboard packaging or briquettes.A thermometer is installed to control the temperature of the outgoing gases. The furnace is undemanding to the quality of the fuel mass. The cost is 14,000–15,000 rubles.

- Siberia BV 480 - differs by modifying the design scheme of convection pipes, the standard circle section has been replaced with a rectangular one. Differs in optimum dimensions of a fire chamber door, and the lock of eccentric type which provides impenetrable contact with the case. Heats up to 480 m³. The cost is 17,000–19,000 rubles.

- Siberia BV 720 - with a mass of 157 kg, this equipment is a powerful heat generator that produces energy of 49 kW. Suitable for heating large storage areas and premises with a large number of living rooms. The cost is 23500–26000 rubles.

Models "Siberia BV"

Eurosib

A company from Russia that specializes in the manufacture of structures entirely from metal. A distinctive feature is the presence of a cooking surface in some models. The company sells a few modifications:

-

Furnace Klondike NV Buleryan - their capacity ranges from 100 to 1200 m3. They were developed for efficient heating with buleryan in harsh winter conditions. On a single load, the operating mode is about 10 hours; they are not too demanding on the quality of the fuel mass. The cost is from 12,000 to 46,000 rubles.

Buleryan Klondike-NV

- Furnaces on wood fuel of convection type of long burning buleryan with hob Tulinka NVU. A distinctive feature is that convection pipes that stick out on other models are absent. Instead, a cooking panel with holes for convection is mounted on top. Suitable for heating individual houses and this configuration of the Buleryan stove is ideal for giving.The limiting volume of heating is 150 m3. The cost of the Buleryan furnace ranges from 7500 to 12500 rubles.

Conclusion

The owners of individual buildings or houses should pay close attention to the Buleryan stove. Use the Buleryan stove for giving - the best solution

After all, it has a high efficiency, is able to operate on a single load up to 12 hours (this eliminates the need to add fuel late at night), does not require conservation, is easy to operate and maintain.

Expert evaluation of the furnace "Buleryan Classic" (type 00)

This Buleryan furnace with a water circuit received good reviews from most experts. According to experts, its dimensions are quite acceptable for such a high power device. The height of the model is 700 m, the width is 480 mm, and the depth is 685 mm. The total weight of the oven with water circuit is 65 kg. In this case, the diameter of the chimney is 120 mm.

In addition, experts assessed the quality of the loading chamber. The handles are quite tight and the door is easy to open. Also, many positively described the mechanism for adjusting the power of the furnace. During heating, everything can be easily adjusted and at the same time monitor the internal camera. All pipes have the correct ovalization and at the same time are made without microdefects on special equipment.

The seams along the edges of the joints are well smoothed, which indicates the high quality of welding. Additionally, experts noted the convenience of loading fuel. The diameter of the entrance chamber is quite large, and this allows you to quickly make a clutch.

The principle of operation of the furnace

Next, we will consider the principle of operation of Buleryan.Traditional stoves burn wood in a direct way - a flame rages inside the firebox, giving off thermal energy through the body to the surrounding space. Moreover, a wild amount of heat simply flies into the atmosphere - their chimneys are red-hot. As for Buleryan, it works differently, using the gas generation process.

A very interesting experiment was published in school physics textbooks - sawdust was placed in a glass flask, and a discharge tube was made on the other side of the flask. The flask was installed above the burner, inside it the pyrolysis process began - the wood, being exposed to heat, began to emit combustible gases. These gases escaped through the outlet tube, and when a match was brought up, a steady flame appeared here.

Firewood has a good calorific value, especially if it is dry enough - every extra percentage of moisture will make it difficult to burn and lead to the formation of condensate. But their calorific value can be raised using the pyrolysis reaction - it is this principle of operation that is implemented in the Buleryan furnace. It has a large combustion chamber, provides the generation of pyrolysis products and effectively heats up the premises.

A Canadian potbelly stove called Buleryan works as follows:

- Logs are loaded into its firebox and kindled in the traditional way;

- After engulfing the flame of all loaded fuel, the supply of oxygen to the Buleryan furnace is limited;

- The pyrolysis process begins - its products enter the afterburner, mix with secondary air and ignite;

- The heat generated from the smoldering and combustion of wood, as well as from the combustion of pyrolysis products, is sent to the air heat exchanger.

This is where things get interesting.The heat exchanger of the Buleryan furnace is an assembly of large diameter pipes. They start at the floor, cover the combustion chamber in a semicircle and end at the top. Moreover, they cross from below and from above, forming a firebox of a symmetrical teardrop shape. In fact, the air heat exchanger of the Buleryan furnace is its body.

To ensure the tightness of the combustion chamber, the heat exchanger pipes are welded together with small pieces of sheet iron.

The heat dissipation of the stove is so great that, with a properly built chimney, Buleryan will be able to heat not only the room in which he is located, but also the room through which only the chimney pipe passes.

The resulting heat exchanger is the heart of the Buleryan furnace. Thanks to him, she got her high efficiency. Hot gases give off thermal energy into curved pipes, which play the role of the most common convector. Due to the rounded shape and the maximum area of contact with the heat source, they create powerful convection - each pipe passes a huge amount of air through itself, quickly warming up residential and non-residential buildings.

Do-it-yourself buleryan oven: sequence of actions

-

Equal segments of a metal pipe with a diameter of 45-50 mm are taken in the amount of 8 pieces and bent in the middle part with a pipe bender at an angle of approximately 80 degrees. For a medium-sized oven, pipes 1-1.5 m long are sufficient. Then, by welding, curved convection pipes are connected into a single structure. They need to be welded symmetrically, with the outlet part outward.

-

The resulting heat-removing structure will simultaneously play the role of a frame.Accordingly, strips of metal 1.5-2 mm thick are welded onto the pipes, which will become the furnace body.

-

A metal plate located horizontally should be welded inside the housing. This plate will become the floor (tray) of the furnace compartment and firewood will burn on it. Therefore, it is better to choose metal for this plate with a thickness of at least 2.5 mm. To facilitate the cleaning of the oven, it is best to weld the pallet from two halves located at a large angle to each other. To make it easier to fit the pallet of parts into place, first you need to make patterns from cardboard, and only then just start working with metal.

-

Production of the front and rear walls of the furnace. Start this stage with the preparation of a cardboard pattern based on the actual dimensions of the oven. The easiest way is to attach a sheet of cardboard to the sidewall of the oven and circle around the perimeter with a pencil. The walls of the heating device are cut directly from the sheet metal template. For the front wall, you will need to cut a window for loading fuel. The diameter of this window should be approximately half the diameter of the furnace, the center of the hole should be shifted slightly below the axis of the structure itself. Along the perimeter of the window, we weld a ring from a strip of sheet metal 40 mm wide from the outside.

- The rear wall is made in the same way, only the hole should be located in the upper part of the wall, and its diameter should correspond to the diameter of the outlet pipes. Both walls are welded to their seats.

-

Furnace door. It is made of sheet metal cut to the diameter of the window in the front wall of the stove. A narrow strip of metal is welded onto the metal circle around the perimeter, which improves the tightness of the door.In addition, it is necessary to cut a hole to the door cover and weld a blower with a valve into it.

- On the inside of the door, you will need to install a heat-reflecting screen, for which a semicircle of the appropriate diameter is cut out of metal and welded into the inside of the door on metal spacers.

-

The door is suspended on metal hinges welded to the outer wall of the furnace. You can use either industrial-made hinges, or construct them yourself from scraps of metal. The same applies to the bottom door lock.

-

Chimney. The T-shaped outlet-chimney is mounted on a hole in the rear wall of the furnace. To create it, a piece of metal pipe with a diameter of 110 mm is taken of the required length. At the height of the outlet in the rear of the furnace, a cut is made in the pipe to install a tap with a valve.

The valve itself can also be made by hand. To do this, a metal circle is cut out along the inner diameter of the branch, and a hole is drilled in the branch itself so that the valve axis can be inserted horizontally into it. After that, the whole structure is assembled and welded. Another rod is welded onto the outer part of the axis, which becomes a handle. This handle will need to be equipped with either wooden or heat-resistant plastic lining.

Now it is enough to make metal pipes from the remains of pipes oven feet.

Feet for oven

At the same time, it is important that the body of the buleryan furnace is located at a height of at least 30 cm from the floor level. This will increase the draft in the convection pipes, which will ensure greater efficiency of the entire heater.

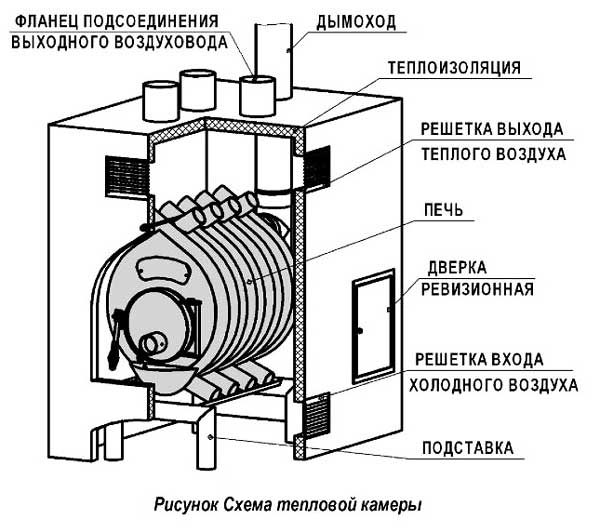

Models with water circuit

Traditional Buleryan stoves, which are not equipped with water circuits, can be adapted for heating several rooms. To do this, heat chambers are created around them with grilles for cold air intake and air pipes for distributing heat to other rooms. Such a scheme is characterized by exceptional simplicity and allows you to easily organize full-fledged heating of a multi-room building.

The disadvantage of the presented scheme is that the air in the air pipes cools quickly, so their length is limited. It is also necessary to consider the installation location of the stove in order to minimize heat loss in the air ducts.

A water circuit is a more efficient solution for heating multi-room buildings and other buildings. Water cools much more slowly than air due to its high heat capacity. A large number of radiators can be connected to the water circuit, and using circulation pumps, it is easy to implement a scheme with long pipelines. Let's see how Buleryan works with a water circuit and how it works.

Aqua Buleryan is a slightly modified version of the traditional air oven. We have already said that its combustion chamber is surrounded by curved pipes that form a productive convector. Through a short work with the welding machine, these pipes turn into a giant heat exchanger. To do this, all the lower tubes are welded together, forming a collector, to which the inlet (return) pipe is welded. The same is done with the upper pipes, from which the outlet pipe departs - here is the heat exchange system for you.

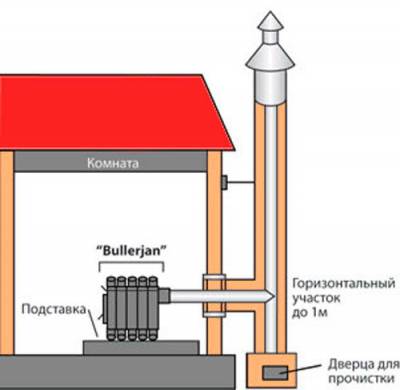

Such a scheme provides the best smoke removal.In addition, to improve the traction characteristics, a deflector is installed on the chimney head.

- Efficient heating of several rooms - these are suburban households and multi-room cottages;

- High heating rate - an efficient water circuit with a large heat exchanger is responsible for this;

- You don't need to add firewood often - the long-burning system eliminates many tedious approaches.

Thus, Buleryan furnaces with water circuits have good technical characteristics.

Kinds

For heating

According to the method of work, there are two types:

-

with water line. Perfect for private homes. The specificity of the operation of furnaces lies in the heating of the liquid (more often it is water, less often antifreeze), plying through the heating system, and it warms up the house. 90% of the combustion energy is spent on heating the liquid and only 10% on air.

Water buleryan

-

convection type, they heat the air, evenly diverging through the air ducts throughout the premises.

standard model

Advantages of the heating furnace Buleryan:

- heating of a large volume;

- uniformity of heating;

- soot and smoke do not enter the room;

- compact size;

- rapid heating;

- economy.

with hob

For residential premises, stoves are produced with a convenient modification - a cooking surface. The Buleryan stove with a hob is used for the following purposes:

- area heating up to 150 m2;

- cooking and heating food, a pot with a capacity of 6 liters boils for 30 minutes.

To achieve the effectiveness of heating, it is recommended to mount them in rooms without partitions. The installation point must provide air convection. Such Buleryan is suitable for giving just perfect.

Model with hob (VESUVI)

Furnace Breneran AOT-6 type 00

Structurally, they have a number of features:

- 2-chamber structure - in one, gas generation processes are performed, in the other, afterburning of the gaseous mixture is performed.

- Injectors - afterburners are mounted in the channels of convection flows to increase the efficiency of the equipment.

- 2 operating modes. They function in the form of generation of combustible gas and as a conventional furnace. In the second type, food can be cooked on the hob.

- Productivity - the equipment is able to heat the area up to 150 m2. On one load, the oven will work up to 6 hours.

- The working principle is the use of gas generation processes. As a result of combustion, the fuel mass is oxidized - this generates CO. It enters the afterburner, which increases the amount of thermal energy received.

- Heating occurs due to convection - air comes from the room due to pipes located 2/3 in the furnace - this gives rapid heating. Heated air comes in almost instantly.

Buleryan wood-fired cooking and heating stoves are suitable for individual houses, especially when natural gas or electricity is not available.

The opinion of experts about the furnace "Buleryan Classic" (type 01)

In general, experts consider this model comfortable and powerful. At the same time, it has all the advantages that are displayed in previous models. The secondary camera of the device is quite solid. The thickness of the metal in this place reaches 4 mm. Also, experts noted the convenience of the boot compartment. Its door fits snugly and provides good sealing.

The front wall is quite strong and protects the injector well. All power controls are easily adjustable. The chimney handle, in turn, is securely fastened.Additionally, many experts on the positive side noted the work of the blower, which is hidden behind the rear panel. In general, this model can be described as a practical and powerful device for heating large houses.

Buleryan efficiency in comparison with gas heating

Before buying any heating equipment, you need to make sure that it will be beneficial for the potential owner. The stores now offer a large number of boilers that have excellent designs. but they are quite expensive to operate. Therefore, it is necessary to find such an installation model that has an aesthetic appearance, is inexpensive, and does not require large financial costs from the owner during operation.

Positive characteristics

- The use of Buleryan stoves provides fast and uniform heating of a large area. If the installation is equipped with a water circuit, then the generated thermal energy is easily transported even to rooms located on the second and third floors.

- This model is small.

- After installation, the owner is provided with ease of use. The installation process is not very difficult. However, a chimney device is necessary, for which it is better to invite a professional stove-maker.

- Compared to traditional ovens, this oven consumes less fuel during operation. One full load will be enough for 12 hours of plant operation.

Cons of buleryan

When using this stove, only firewood with a low percentage of moisture can be loaded into the combustion chamber.It is advisable to use those tree species that do not form resins during combustion.

During operation, the resulting generator gases in such models are not fully used. In the combustion chamber, their combustion occurs in a volume of less than 70%, so such a furnace cannot be called perfect.

Performing work on the construction of the chimney, special attention must be paid to the insulation of the pipe. If this is not done, then during the operation of the equipment condensate will occur, which will reduce the efficiency of the buleryan. In most cases, these stoves are made of metal.

Therefore, a suitable protection should be placed a meter from the installation. If the location of the boiler is the corner at the junction of two walls, then you need to think about protecting them. They cannot be placed close to the walls. This is a big problem for small spaces. 20 cm is the maximum allowable distance from these units to the wall

In most cases, these stoves are made of metal. Therefore, a suitable protection should be placed a meter from the installation. If the location of the boiler is the corner at the junction of two walls, then you need to think about protecting them. They cannot be placed close to the walls. This is a big problem for small spaces. 20 cm is the maximum allowable distance from these units to the wall.

If you want to save space and place the stove as close to the wall as possible, you will have to sheathe them with long metal sheets that exceed the height of the stove. It is advisable to install basalt insulation between the wall and the sheet.When this is done, the metal screen will perform two functions at once - to protect the system from heating and act as an additional source of heat.

There is one more thing to be aware of. It concerns the design features of the furnace. During operation of the unit, dust will enter the openings of the pipes. During the operation of the furnace, a high temperature arises, which burns out everything in its path. When using buleryan, an unpleasant odor may occur. In addition, positively charged ions appear in the air near the furnace. They well attract particles of dirt that are inside the human body. If cold viruses predominate in the room, then the risk of illness for healthy people is high. Therefore, in order to avoid this, it is necessary to regularly ventilate the room, as well as perform wet cleaning 2 times a day.

Design and principle of operation

Cold air is sucked in through the lower part of the pipes, heated air comes out through the upper part.

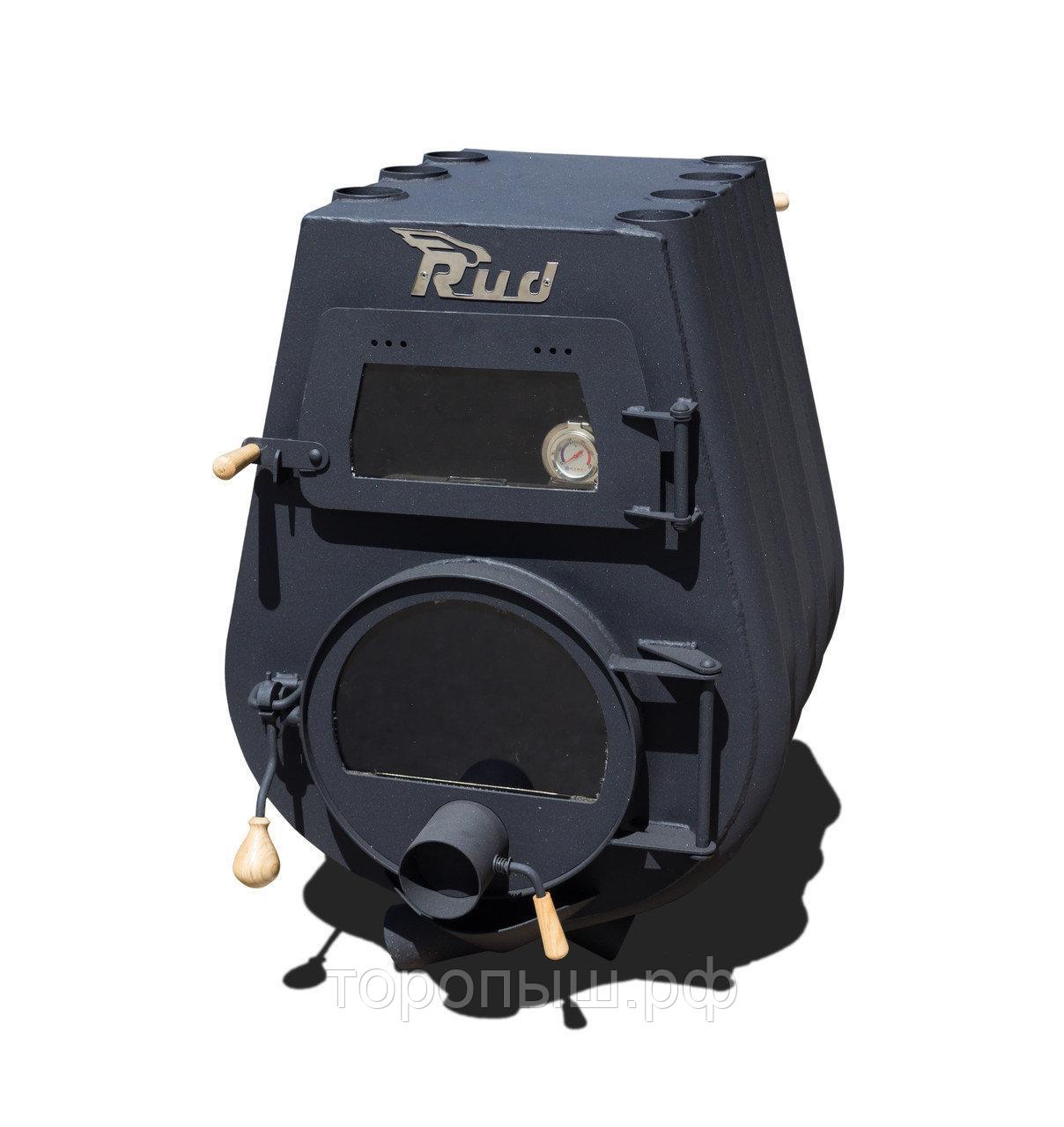

Buleryan long-burning heating furnace (Buleryan) is a powerful air heater, which is a metal case with tubes built into it, through which heated air rises and is distributed throughout the heated room.

Cold air is taken from the floor through the lower part of the tubes, after which, passing along the body, it heats up to a temperature of +60°C to +150°C, while rising upwards it goes outside, thereby heating the room. This process is possible thanks to a simple physical phenomenon that everyone knows from school: warm air always rises.

The first ignition of the stove (as well as the next 2-3 fireboxes) is accompanied by a characteristic smell, which is formed due to the fact that the body is covered with heat-resistant paint, which finally polymerizes during the first firebox. Therefore, manufacturers recommend heating the unit several times outdoors.

The Buleryan stove is able to heat several rooms at once, for this, special metal sleeves are put on the pipes from which the heated air comes out, which are brought into the right rooms.

Replica of the Bullerjan stove.

Advice! When loading fuel and not only, it should be remembered that the glass on the door can be broken, because. it is only heat-resistant, but not impact-resistant. The glass must “walk” freely in the mounting frame.

The design of the furnace does not provide for the presence of a grate. Ash must be in the furnace on the lower pipes, this prolongs their service life (prevents burnout) and ensures normal fuel gasification. In addition, there is no need to often clean the firebox from ash, because the fuel burns out almost completely. Ash does not form as quickly as, for example, in a potbelly stove. If, nevertheless, too much ash has accumulated and it spills out of the firebox, it is enough to remove only the top layer, leaving the lower pipes closed.

In addition to firewood, briquettes, brown coal, cardboard, as well as waste from the woodworking industry can be used as fuel. The best fuel for Buleryan is round logs, preferably the same length as the stove itself.

Advice! Coking coal should not be used as a fuel, as this may affect the performance of the unit. It is also forbidden to use liquid fuel.

Bullerjan

The fuel burns out almost completely, this is possible due to the design of the Buleryan long-burning furnace. In the lower chamber, during combustion (smoldering), the fuel emits gases that enter the upper chamber, where they are completely burned. At the same time, the main source of thermal energy is not the burning wood or briquettes themselves, but the gas released during combustion, which completely burns out in the upper chamber. Due to the fact that the fuel does not burn (as, for example, in a potbelly stove), but smolders, there is no need for frequent filling of fuel. On one tab, the oven can work 8-12 hours.