- The principle of operation of closed-type heating

- Options for a two-pipe system

- Vertical system with bottom wiring

- Vertical system with top wiring

- Horizontal heating system - three main types

- Differences between open and closed heating systems

- Benefits of an open heating system

- Disadvantages of an open heating system

- Advantages of a closed heating system

- Disadvantages of a closed heating system

- Dependent and independent heating systems

- Breakdowns and malfunctions

- 2 Components of a closed heating circuit

- Principle of operation

- Filling methods built-in mechanism and pumps

- Filling the heating with antifreeze

- Automatic filling system

- District heating

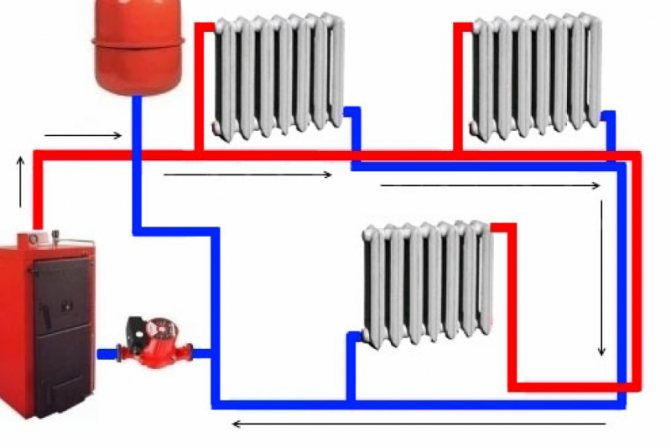

The principle of operation of closed-type heating

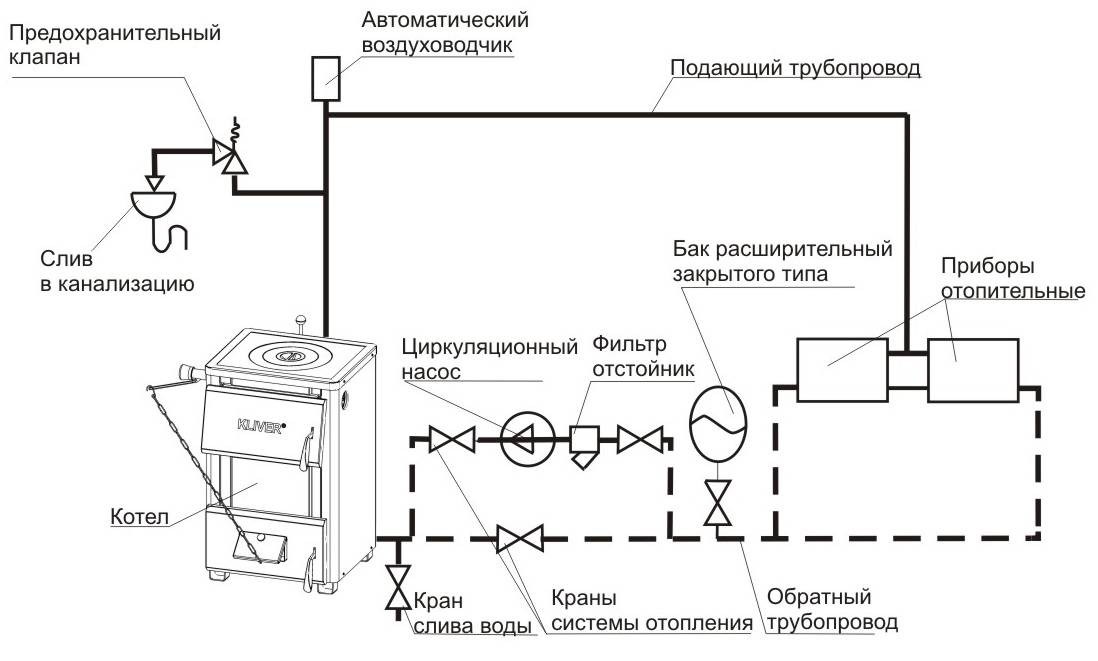

What does a closed-type heating scheme look like? The main design feature that determines the name of such a system is its tightness.

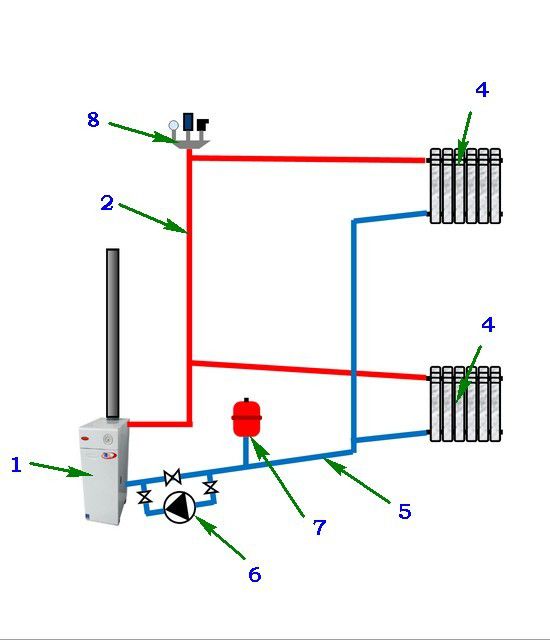

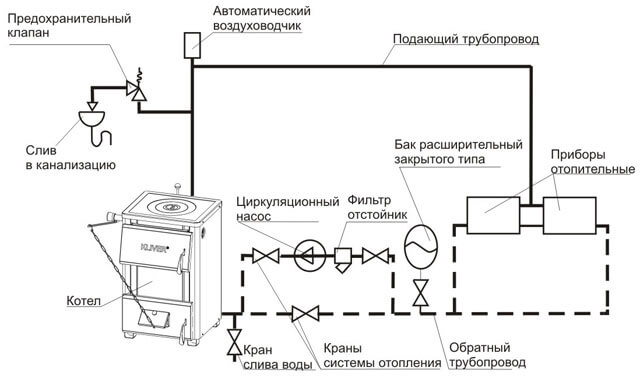

A closed-type heating system, the scheme of which includes elements, some of which are used in other types of heating, looks like this:

- boiler;

- air valve;

- thermostat;

- heating devices;

- expansion tank;

- balancing valve;

- ball valve;

- pump and filter;

- manometer;

- safety valve.

But if there are no constant interruptions in electricity, the closed heating systems of a private house will work correctly (read: "How to make heating in a private house - expert advice"). In addition, such a system can be supplemented, for example, with “warm floors”, which will increase heat transfer and heat retention, which, in turn, will increase the efficiency of such a design.

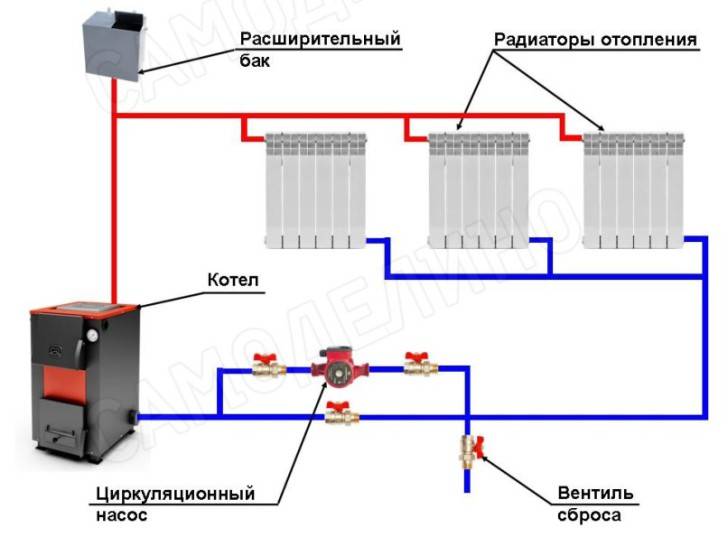

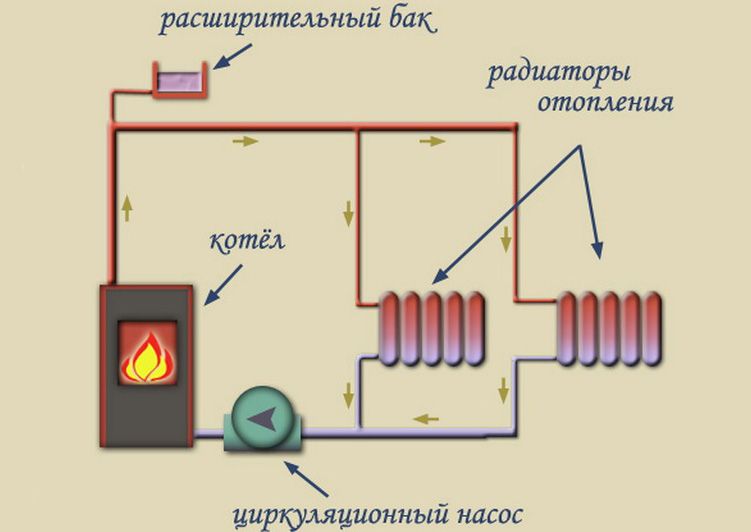

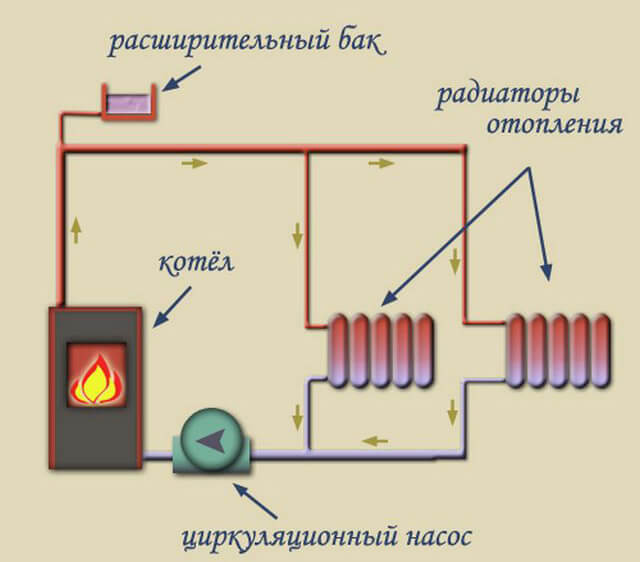

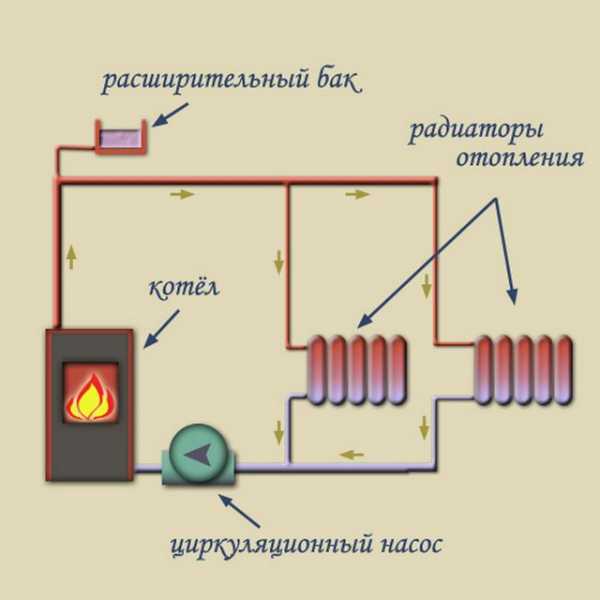

The circulation pump is installed on the return line directly in front of the heating boiler. An expansion tank can also be placed here. With such an arrangement of elements important for the system, you can forget about the need to create a constant slope of the pipeline and not pay much attention to the diameter of the pipes.

The closed-type heating system is protected from air ingress, but this process cannot be eliminated. For example, when adding liquid to the system, some air can still seep into the pipeline. Air trapped in the pipes will accumulate at the top of the system and form air pockets that will impair system performance and increase the risk of failure.

To save heat, the closed-type heating system uses a thermostat that automatically turns the pump on and off when the room temperature changes.

Options for a two-pipe system

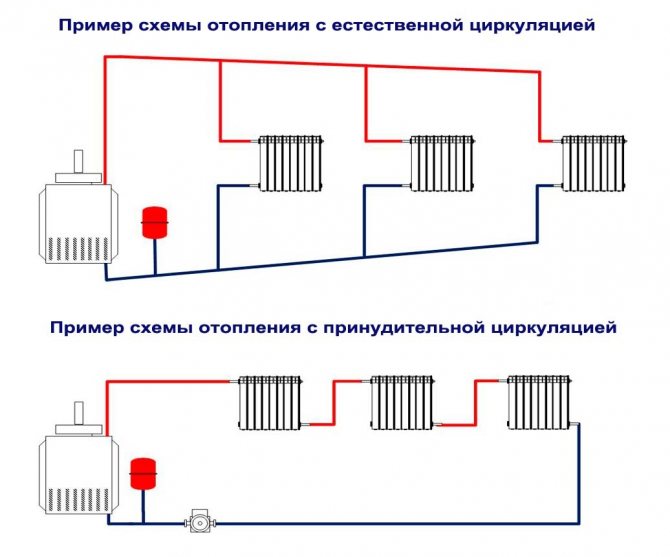

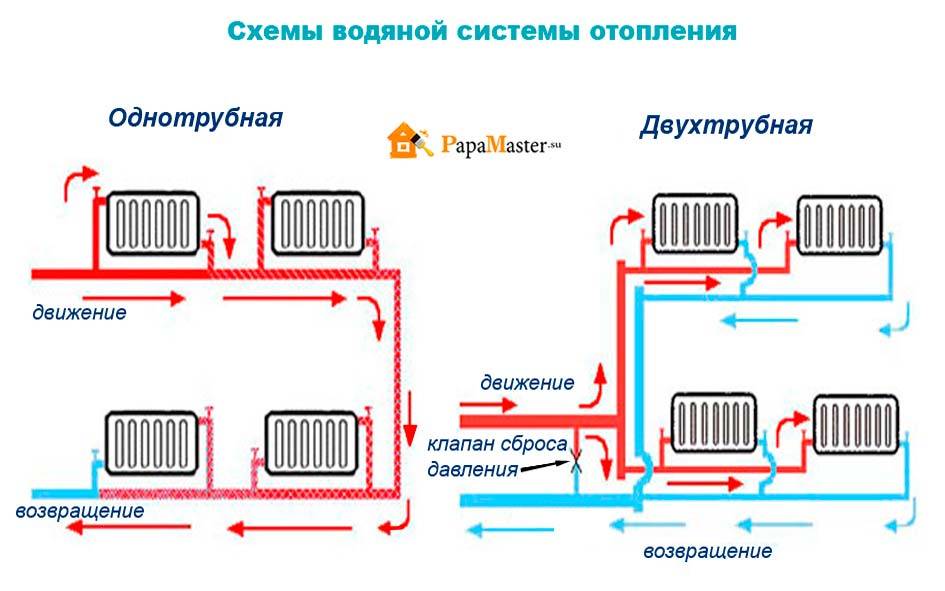

The main difference between a two-pipe heating scheme for a private house is the connection of each battery to the mains of both direct and reverse current, which doubles the consumption of pipes. But the owner of the house has the opportunity to regulate the level of heat transfer of each individual heater. As a result, it is possible to provide a different temperature microclimate in the rooms.

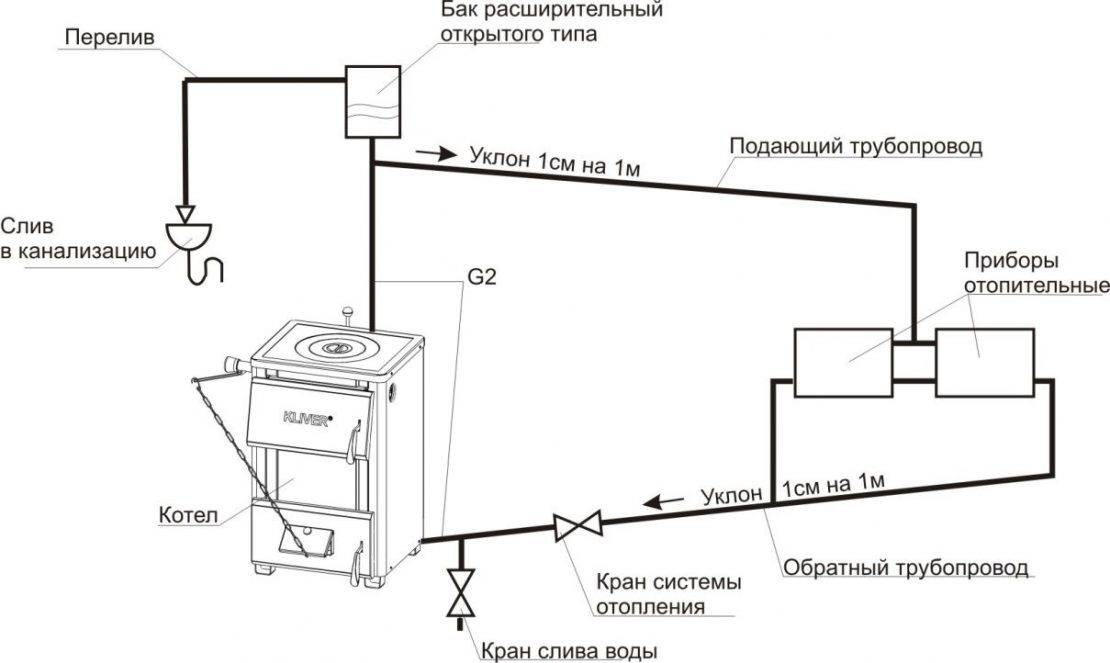

When mounted vertically two-pipe heating system, the lower one is applicable, as well as the top, heating wiring diagram from the boiler. Now in more detail about each of them.

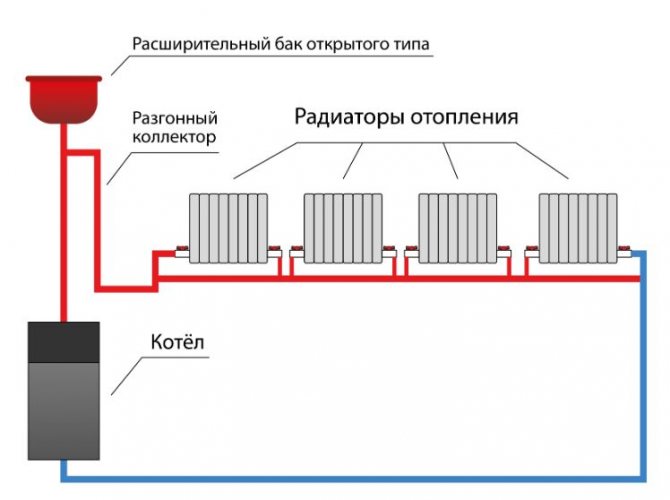

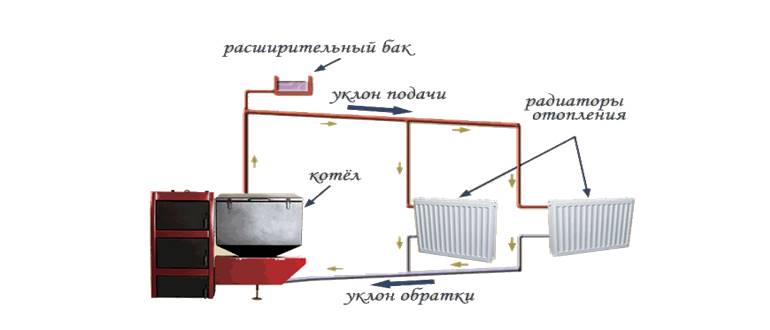

Vertical system with bottom wiring

Set it up like this:

- From the heating boiler, a supply main pipeline is launched along the floor of the lower floor of the house or through the basement.

- Further from the main pipe, risers are launched upwards, which ensure that the coolant enters the batteries.

- A return current pipe departs from each battery, which takes the cooled coolant back to the boiler.

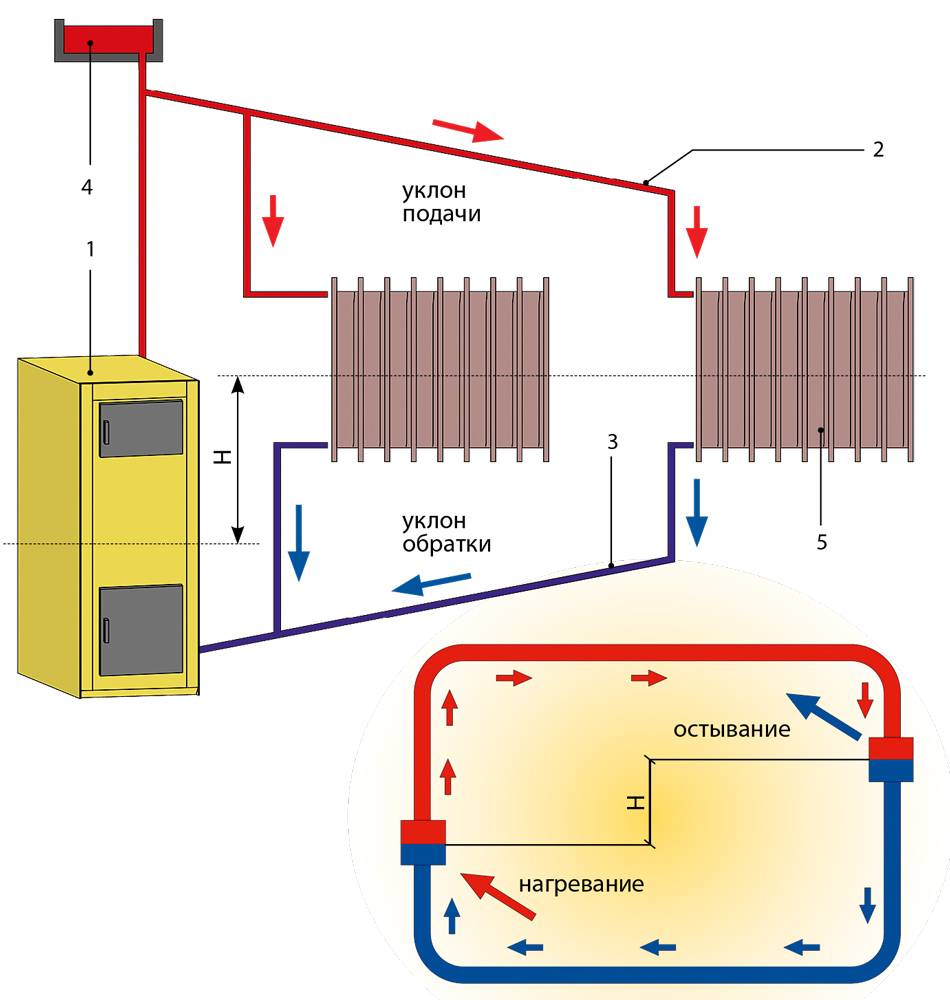

When designing lower wiring of an autonomous heating system take into account the need for constant removal of air from the pipeline. This requirement is met by installing an air pipe, as well as installing an expansion tank, using Mayevsky taps on all radiators located on the top floor of the house.

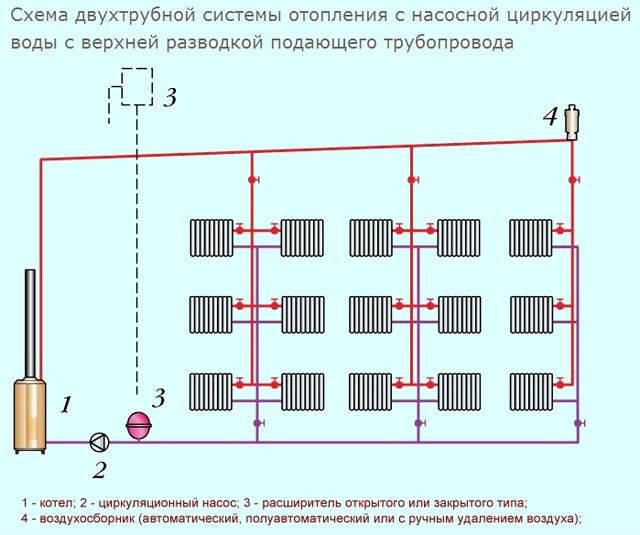

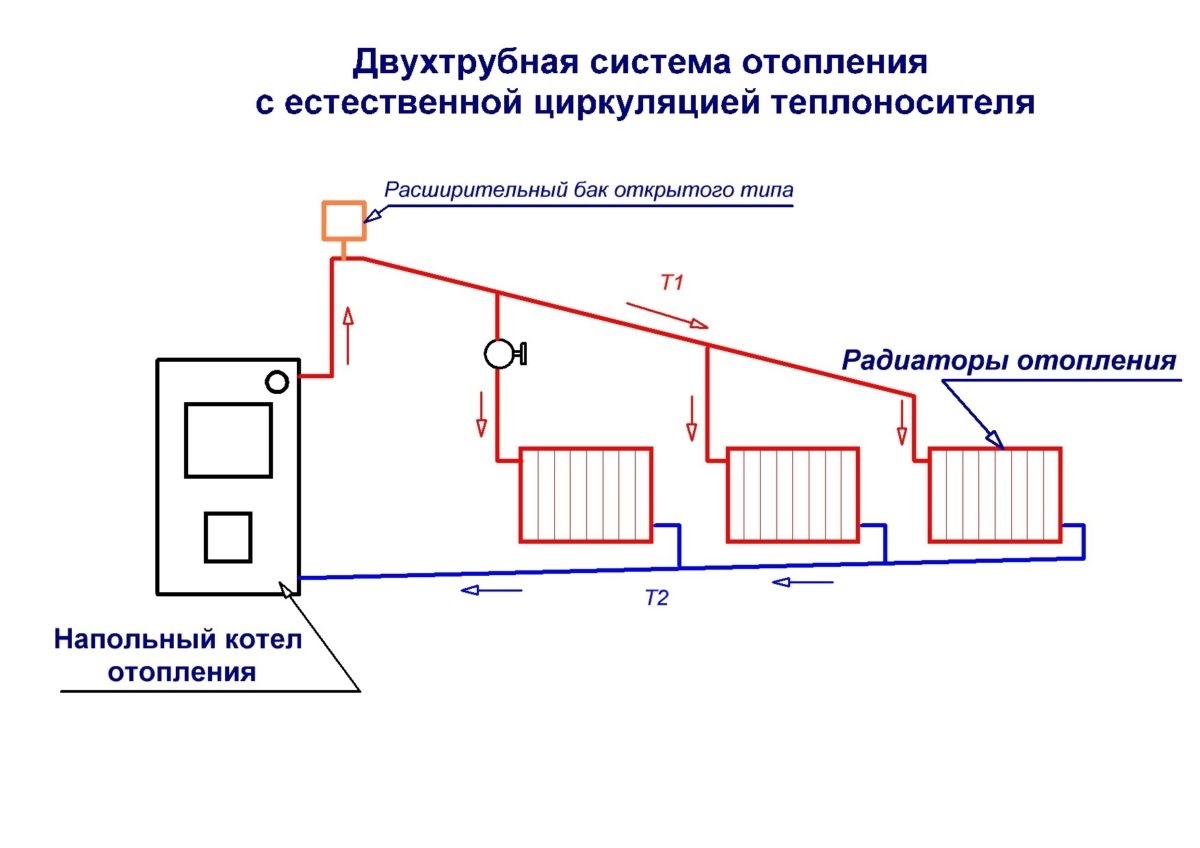

Vertical system with top wiring

In this scheme, the coolant from the boiler is supplied to the attic through the main pipeline or under the very ceiling of the upper floor. Then the water (coolant) goes down through several risers, passes through all the batteries, and returns back to the heating boiler through the main pipeline.

An expansion tank is installed in this system to periodically remove air bubbles. This version of the heating device is much more effective than the previous method with lower piping, since higher pressure is created in the risers and in the radiators.

Horizontal heating system - three main types

The device of a horizontal two-pipe autonomous heating system with forced circulation is the most common option for heating a private house.In this case, one of three schemes is used:

- Dead end circuit (A). The advantage is the low consumption of pipes. The disadvantage lies in the large length of the circulation circuit of the radiator farthest from the boiler. This greatly complicates the adjustment of the system.

- Scheme with the associated advancement of water (B). Due to the equal length of all circulation circuits, it is easier to adjust the system. During implementation, a large number of pipes will be required, which increase the cost of work, and also spoil the interior of the house with their appearance.

- Scheme with a collector (beam) distribution (B). Since each radiator is connected separately to the central manifold, it is very easy to ensure uniform distribution of all rooms. In practice, the installation of heating according to this scheme is the most expensive due to the high consumption of materials. Pipes are hidden in a concrete screed, which at times increases the attractiveness of the interior. The beam (collector) scheme for distributing heating on the floor is becoming increasingly popular among individual developers.

This is how it looks like:

When choosing typical wiring diagram it is necessary to take into account many factors, ranging from the area of \u200b\u200bthe house, and ending with the materials used in its construction. It is better to resolve such issues with specialists in order to eliminate the possibility of error. After all, we are talking about heating the house, the main condition for comfortable living in private housing.

Differences between open and closed heating systems

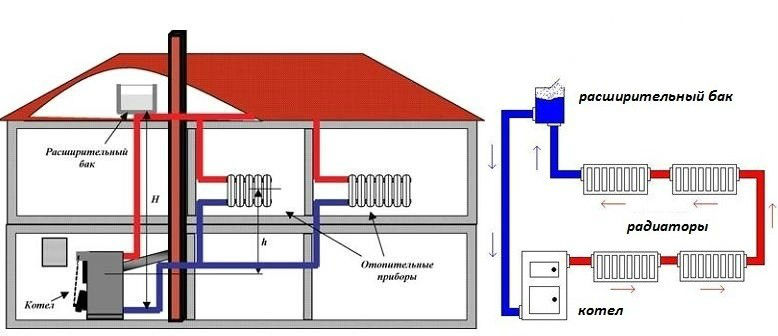

There are the following distinctive features of open and closed heating systems:

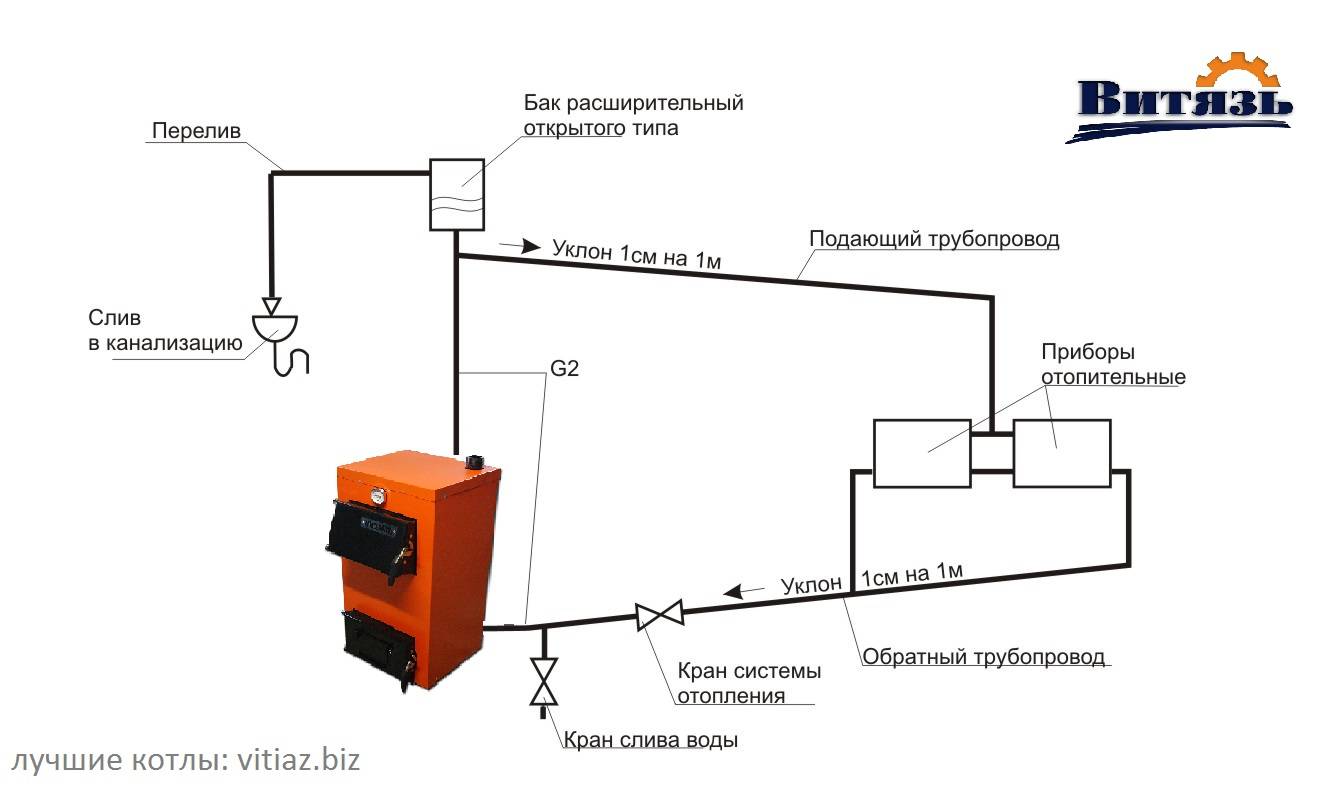

The location of the expansion tank.

In an open heating system, the tank is located at the highest point in the system, and in a closed system, the expansion tank can be installed anywhere, even next to the boiler.

The closed heating system is isolated from atmospheric flows, which prevents air from entering. This increases the service life.

Due to the creation of additional pressure in the upper nodes of the system, the possibility of air locks is reduced

in radiators located on top.

In an open heating system, pipes with a large diameter are used,

which creates inconvenience, also the installation of pipes is carried out at an angle to ensure circulation. It is not always possible to hide thick-walled pipes

To ensure all the rules of hydraulics

it is necessary to take into account the slopes of the distribution of flows, the height of the lift, turns, narrowing, connection to radiators.

In a closed heating system, pipes of a smaller diameter are used, which reduces the cost of construction.

Also, in a closed heating system, it is important to install the pump correctly,

to avoid noise.

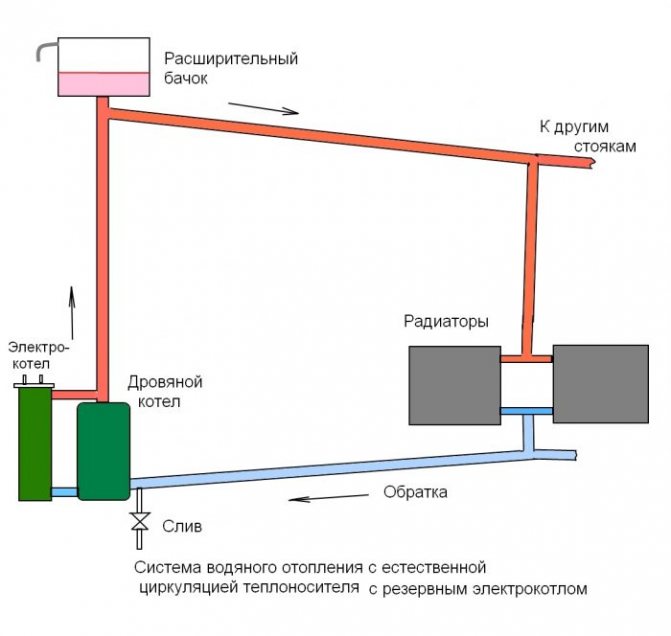

Benefits of an open heating system

- simple maintenance of the system;

- lack of a pump ensures silent operation;

- uniform heating of the heated room;

- quick start and stop of the system;

- independence from power supply, if there is no electricity in the house, the system will be operational;

- high reliability;

- no special skills are required to install the system, first of all, a boiler is installed, the power of the boiler will depend on the heated area.

Disadvantages of an open heating system

- the possibility of reducing the life of the system when air enters, since heat transfer decreases, resulting in corrosion, water circulation is disturbed, and air plugs are formed;

- the air contained in an open heating system can cause cavitation, which destroys the elements of the system located in the cavitation zone, such as fittings, pipe surfaces;

- possibility of freezing coolant in the expansion tank;

- slow heating systems after switching on;

- needed constant level control coolant in the expansion tank to prevent evaporation;

- the impossibility of using antifreeze as a coolant;

- cumbersome enough;

- low efficiency.

Advantages of a closed heating system

- simple installation;

- there is no need to constantly monitor the level of the coolant;

- possibility antifreeze applicationswithout fear of defrosting the heating system;

- by increasing or decreasing the amount of coolant supplied to the system, it is possible to regulate the temperature in room;

- due to the lack of evaporation of water, the need to feed it from external sources is reduced;

- independent pressure regulation;

- the system is economical and technologically advanced, has a longer service life;

- possibility of connection to the closed heating system of additional sources of heating.

Disadvantages of a closed heating system

- the main drawback is the dependence of the system on the availability permanent power supply;

- the pump requires electricity;

- for emergency power supply, it is recommended to purchase a small generator;

- in case of violation of the tightness of the joints, air may enter the system;

- dimensions of expansion membrane tanks in enclosed spaces of a large area;

- the tank is filled with liquid by 60–30%, the smallest percentage of filling falls on large tanks, at large facilities tanks with an estimated volume of several thousand liters are used.

- there is a problem with the placement of such tanks, special installations are used to maintain a certain pressure.

Open heating system thanks to ease of use, high reliability, used for optimal heating small spaces. It can be small one-story country houses, as well as country houses.

The closed heating system is more modern and more sophisticated. It is used in multi-storey buildings and cottages.

Dependent and independent heating systems

Both open and closed heating systems can be connected in two ways - dependent and independent.

Dependent way of connecting an open system means connecting through elevators and pumps. In the independent type, hot water enters through a heat exchanger.

An example of an open heating system on video:

For space heating, a closed and open heat supply system is used. The latter option additionally provides the consumer with hot water. At the same time, it is necessary to control the constant replenishment of the system.

A closed system uses water only as a heat transfer medium. It constantly circulates in a closed cycle, where losses are minimal.

Any system consists of three main parts:

- heat source: boiler room, thermal power plant, etc.;

- heating networks through which the coolant is transported;

- heat consumers: heaters, radiators.

Breakdowns and malfunctions

Typical DHW malfunctions include:

-

equipment failure;

- noise in the system;

- the temperature of the heating devices is below normal;

- weak pressure of hot water;

- temperature spread of the coolant on the floors of the house;

- leaks in connections;

- corrosion of pipelines and valves.

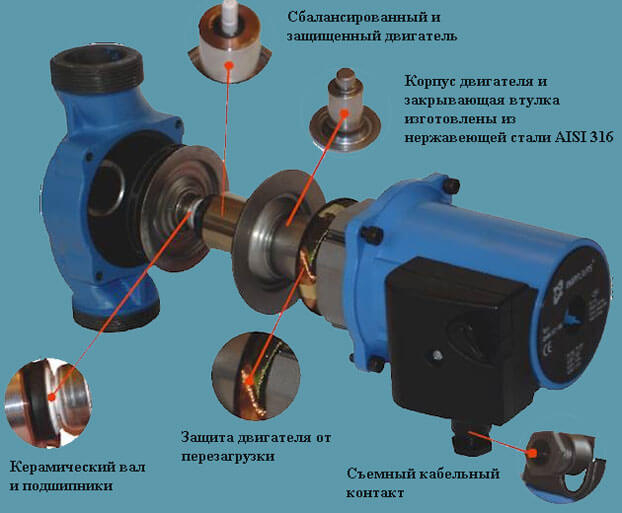

Noises are usually caused by vibration of improperly installed pumps, worn motor bearings, loose pipe fittings, failure of control valves.

Air locks in the devices themselves, misalignment of the elevator assembly, blockages and violation of thermal insulation in the heating risers lead to a decrease in the temperature of the heating devices.

Weak water pressure in the absence of blockages is most often caused by malfunctions of booster pumps. Timely maintenance increases the reliability of the heating system.

2 Components of a closed heating circuit

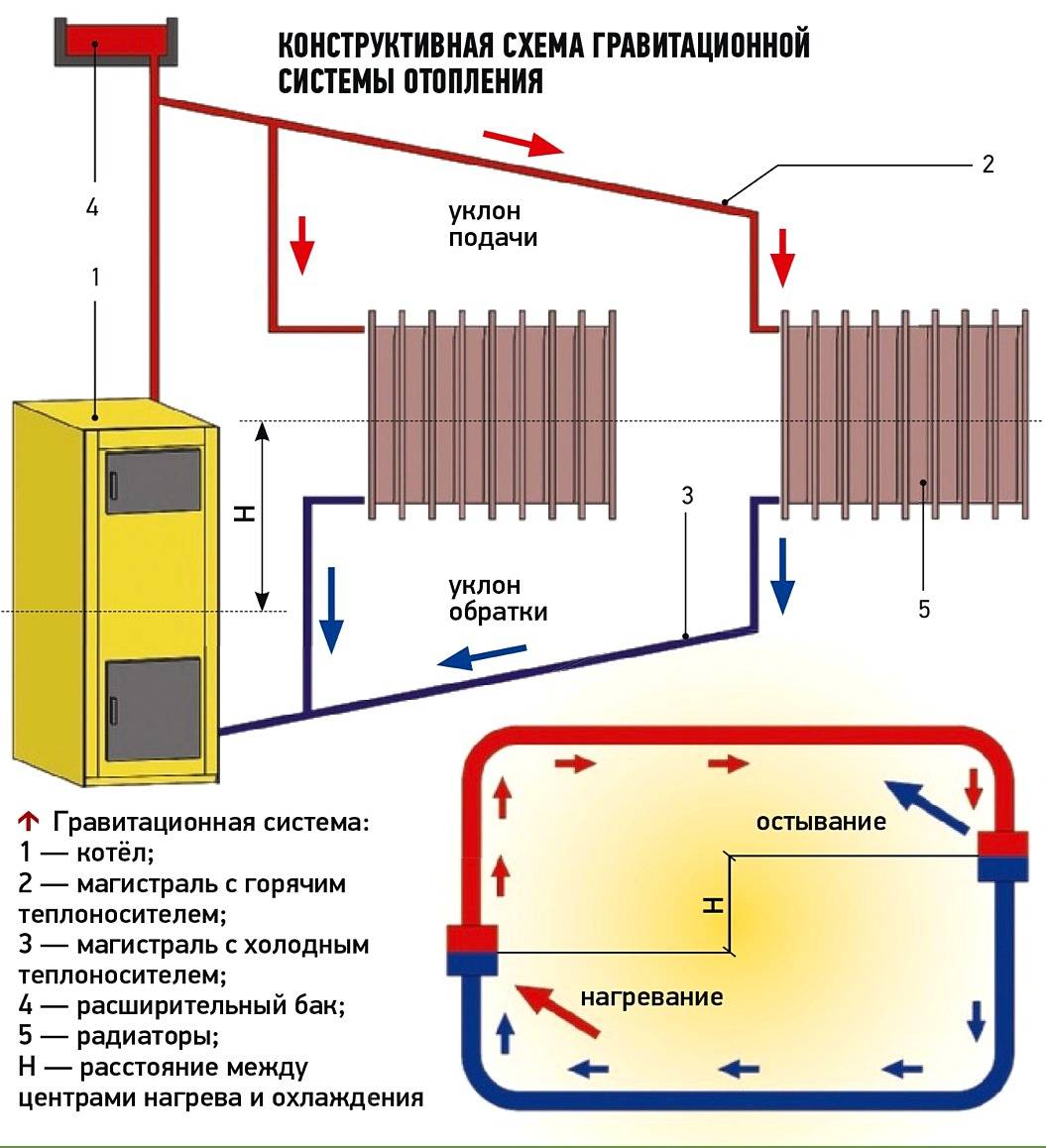

The difference from the gravity system lies in the need to install specific nodes. Some of them are necessarily used in a closed system, but sometimes they are also used in natural circulation. The source of thermal energy is boilers. Some of the models of wall-mounted gas and pellet, solid fuel are immediately equipped with the necessary safety group. If it is not available, it is purchased separately, installed on a pipe with hot water.

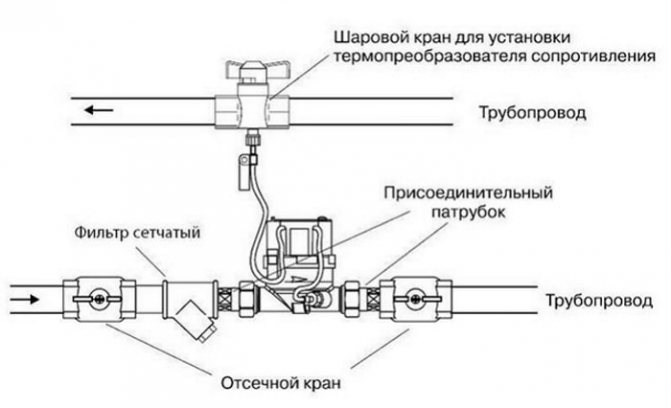

A sealed tank maintains pressure, compensates for the volume of coolant. Its effective movement is provided by a circulation pump, which is recommended to be installed on the return line near the boiler itself.This arrangement is dictated by the fact that the water in this place is quite cool, the device is less prone to overheating. The remaining elements are the same as in the gravitational system: pipelines, radiators or registers.

Principle of operation

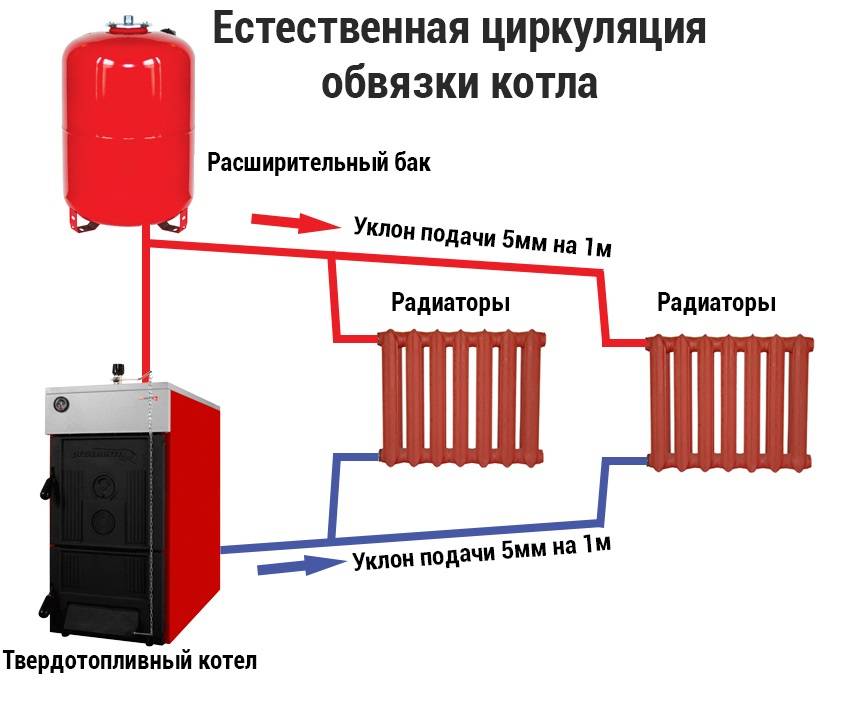

The water-type heating scheme implies both natural and forced movement of the heat carrier. The role of the heating device is floor or wall models of boilers: one or two circuits, heat carrier in the form of steam, water or antifreeze. An open-type heating system most often has plain water as a coolant.

At the same time, its movement is carried out in a natural way due to the different density of cold and hot water and the slope under which the pipeline is laid. The fact is that heated water has a much lower density than cold water. As a result, a hydrostatic head is created, due to which hot water moves to the radiators.

Filling methods built-in mechanism and pumps

Heating filling pump

How to fill the heating system in a private house - using the built-in connection to the water supply using a pump? This directly depends on the composition of the coolant - water or antifreeze. For the first option, it is enough to pre-flush the pipes. Instructions for filling the heating system consists of the following items:

- It is necessary to make sure that all shut-off valves are in the right position - the drain valve is closed in the same way as the safety valves;

- The Mayevsky crane at the top of the system must be open. This is necessary to remove air;

- Water is filled until water flows from the Mayevsky tap, which was opened earlier. After that, it overlaps;

- Then it is necessary to remove excess air from all heating devices. They must have an air valve installed. To do this, you need to leave the system filling valve open, make sure that air comes out of a particular device. As soon as water flows out of the valve, it must be closed. This procedure must be done for all heating devices.

After filling the water in a closed heating system, you need to check the pressure parameters. It should be 1.5 bar. In the future, to prevent leakage, pressing is performed. It will be discussed separately.

Filling the heating with antifreeze

Before proceeding with the procedure for adding antifreeze to the system, you need to prepare it. Usually 35% or 40% solutions are used, but to save money, it is recommended to purchase a concentrate. It should be diluted strictly according to the instructions, and only using distilled water. In addition, it is necessary to prepare a hand pump to fill the heating system. It is connected to the lowest point of the system and, using a manual piston, the coolant is injected into the pipes. During this, the following parameters must be observed.

- Air outlet from the system (Mayevsky crane);

- Pressure in pipes. It must not exceed 2 bar.

The whole further procedure is completely similar to the one described above. However, you should take into account the features of the operation of antifreeze - its density is much higher than that of water.

Therefore, special attention should be paid to the calculation of the pump power. Some formulations based on glycerin may increase the viscosity index with increasing temperature.Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite

This will greatly reduce the chance of leaks.

Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite ones. This will greatly reduce the chance of leaks.

Automatic filling system

For double-circuit boilers, it is recommended to use an automatic filling device for the heating system. It is an electronic control unit for adding water to pipes. It is installed on the inlet pipe and operates fully automatically.

The main advantage of this device is the automatic maintenance of pressure by the timely addition of water to the system. The principle of operation of the device is as follows: a pressure gauge connected to the control unit signals a critical pressure drop. The automatic water supply valve opens and remains in this state until the pressure stabilizes. However, almost all devices automatic water filling system heating costs are high.

A budget option is to install a check valve. Its functions are completely similar to the device for automatic filling of the heating system. It is also installed on the inlet pipe. However, the principle of its operation is to stabilize the pressure in pipes with a water make-up system. When the pressure drops in the line, the pressure of tap water will act on the valve. Due to the difference, it will automatically open until the pressure stabilizes.

In this way, it is possible not only to feed the heating, but also to fully fill the system.Despite the apparent reliability, it is recommended to visually control the coolant supply. When filling the heating with water, the valves on the devices must be opened to release excess air.

District heating

Water with central heating is heated in the central boiler house or CHP. This is where the compensation for the expansion of water with a change in temperature takes place. Further, hot water is pumped by a circulation pump into the heating network. Houses are connected to the heating network by two pipelines - direct and reverse. Entering the house through a direct pipeline, the water is divided along two directions - heating and hot water supply.

- Open system. The water goes directly to the hot water taps and is discharged into the sewer after use. An “open system” is simpler than a closed one, but in central boiler houses and CHPs, additional water treatment has to be performed - air purification and removal. For residents, this water is more expensive than tap water, and its quality is lower.

- closed system. Water passes through the boiler, giving off heat to heat tap water, is combined with heating return water and returned to the heating network. The heated tap water enters the hot water taps. A closed system due to the use of heat exchangers is more complicated than an open one, but tap water does not undergo additional processing, but only heats up.

Closed heating system

The terms "open system" or "closed system" do not apply to all city central heating system or village, but to each house separately. In one central heating system, it is possible to connect houses with both an “open system” and a “closed system”.Gradually, open systems should be supplemented with heat exchangers and turn into closed systems.